Nano preservative film for preventing edible fungus from deterioration and application thereof

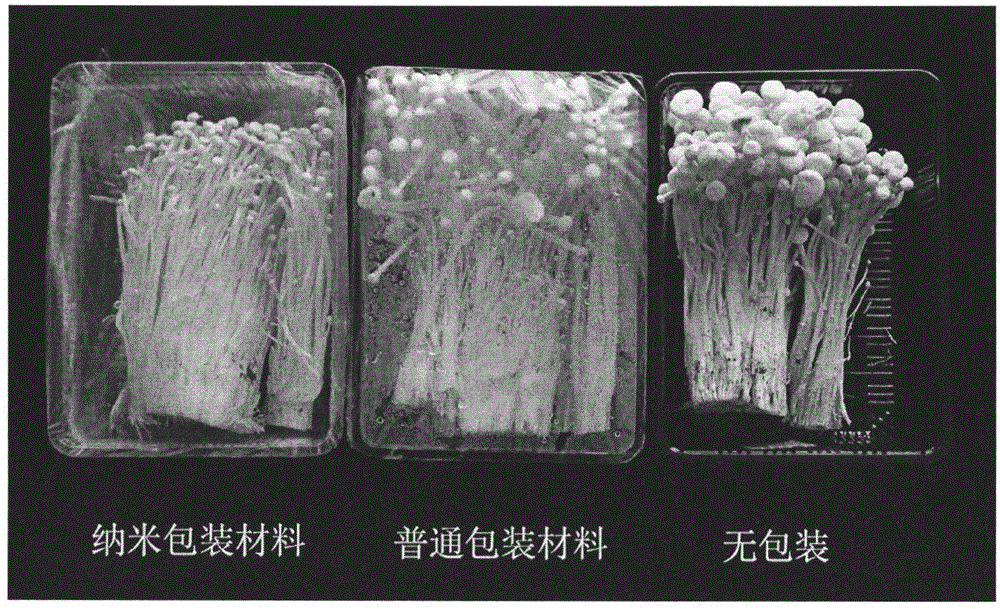

A technology of nano-preservation film and edible fungi is applied in the field of storage and processing of agricultural products, which can solve the problems of low material transparency, high content of silver ions, large nanoparticles, etc., and achieve the effects of improving fresh-keeping quality, high retention rate and beneficial to preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of nano-preservative film

[0045] 1) Raw material

[0046] Nanocomposite powder mass ratio composition: nano-silver (HTB-032, Nanjing Haitai Nano Company) 30%, nano-titanium dioxide (HTTi-01, HTTi-03, Nanjing Haitai Nano Company) 35%, nano-attapulgite (HTDK , Nanjing Haitai Nano Company) 25%, nano silicon dioxide (HTSi-11, Nanjing Haitai Nano Company) 10%;

[0047] The coupling agent is silane reagent KH-570.

[0048] 2) Processing of masterbatch

[0049] Get above-mentioned nanocomposite powder 15%, low-density polyethylene (TN-26, Sinopec Qilu Petrochemical Company) 46% according to mass ratio, linear low-density polyethylene (7042, Sinopec Yangzi Petrochemical Co., Ltd.) 22%, 10% dispersant, 5% lubricant, 2% coupling agent, knead and extrude in a plasticizer (TN-26, Nanjing Keya Company, Jiangsu, China) after high-speed mixing for 0.5 hours, and cut after cooling in a cold water tank Obtain nano-masterbatch (3mm*3mm*1.5mm);

[0050] 3) Processing of...

Embodiment 2

[0057] Microstructure and physical properties of nano-preservative film

[0058] 1) Structural characterization

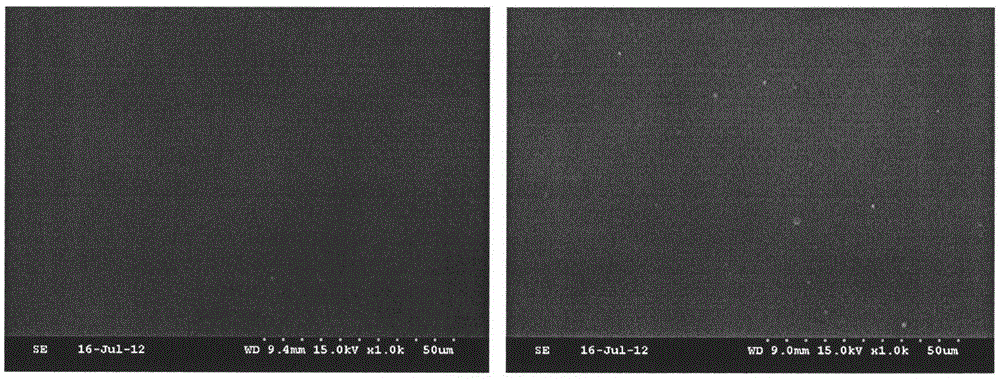

[0059] The complete and traceless nano-preservative film was selected to make a disc with a diameter of 1 cm. After spraying gold, the prepared sample was observed with a scanning electron microscope at an accelerating voltage of 15kV. The results show that the nano-particles of the new nano-preservation film material have a uniform particle size, between 10-50nm, and are evenly distributed, and there is no undesirable phenomenon of particle agglomeration ( figure 2 ).

[0060] 2) Determination of physical properties

[0061] According to the test method in GB 10457-2009 "Plastic self-adhesive plastic wrap for food", the physical properties of the nano-preservation film are tested. The test indicators include tensile strength, nominal strain at break, light transmittance, right-angle tear strength, and oxygen permeability. Rate, carbon dioxide permeability, moi...

Embodiment 3

[0066] Determination of Mobility of Nano-silver in Nano Preservative Film

[0067] Flammulina velutipes were packaged with nano-film and stored at 4°C and 25°C respectively. After 15 days, the silver content in mushroom body and nano-film was measured, and then the migration of nano-silver was analyzed. The results are shown in Table 2. After 15 days of storage, there was no obvious migration of silver particles in the mushroom body, and the silver content of the dry powder of the mushroom body was very low, within the safe range specified by the national standard (GB 9685-2008).

[0068] Table 2 The content of metal Ag in mushroom body (dry weight) and nanobags under different storage temperature conditions (unit: mg / kg)

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Brown coloration index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com