Evaluation method of aging degree of operational composite insulator

A composite insulator, aging degree technology, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of poor accuracy, not involving the volume resistivity characteristics of high-temperature vulcanized silicone rubber, etc., to achieve simple operation, improve accuracy, and ensure reliability. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention provides a method with simple operation, accurate detection and the ability to quantitatively judge the aging degree of composite insulators.

[0031] Concrete steps of the present invention are:

[0032] a. Sample collection: Use a special slicer to cut a disc-shaped sample on the surface of the composite insulator removed by hanging the net. The sample is a disc-shaped sample with a diameter of 20mm and a thickness of 1.3mm.

[0033] b. Clean the sample: Use absolute ethanol to clean the surface of the sample, and then use deionized water to clean the surface of the sample, and then put it in a drying oven and dry it at 303K for 24 hours.

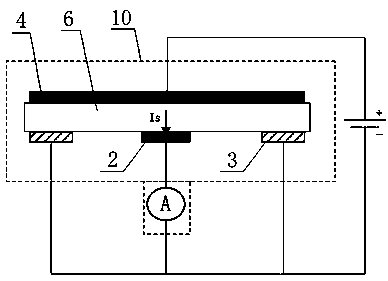

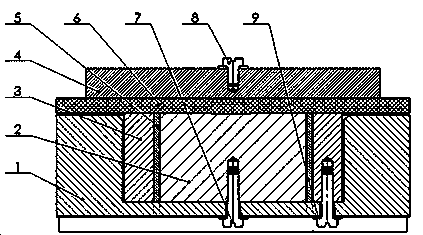

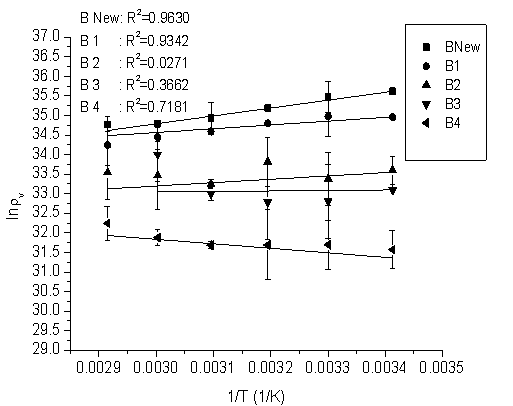

[0034] c. Test sample: Aging test is carried out by using a self-made three-electrode volume resistivity test device. The volume resistivity device is specially designed for small samples after hanging net operation. The measuring element is placed in a temperature-adjusted shielding box as a whole. This shielding me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com