High-damping high-temperature silicon sulfide rubber and preparation method and application thereof

A high-temperature vulcanization and high damping technology, which is applied in the field of polymer materials, can solve problems such as unsatisfactory, low glass transition temperature, and low damping coefficient, and achieve the effect of improving quality, simple method, and stable damping and vibration reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

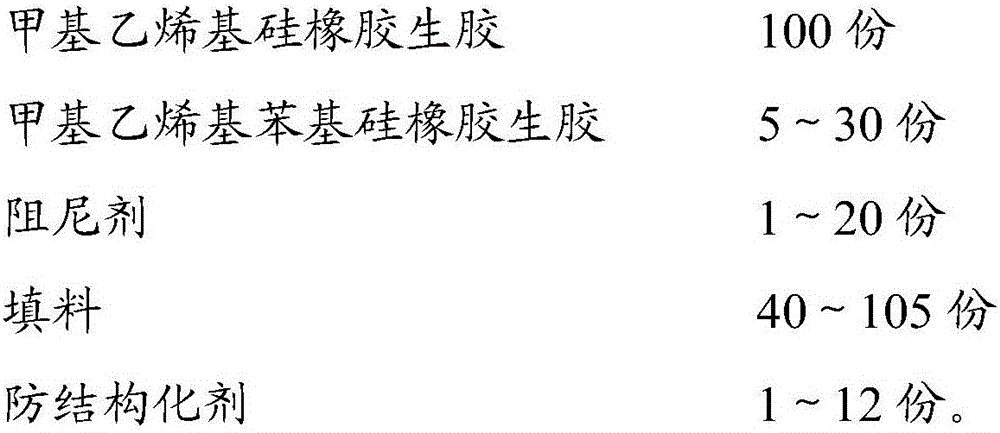

Method used

Image

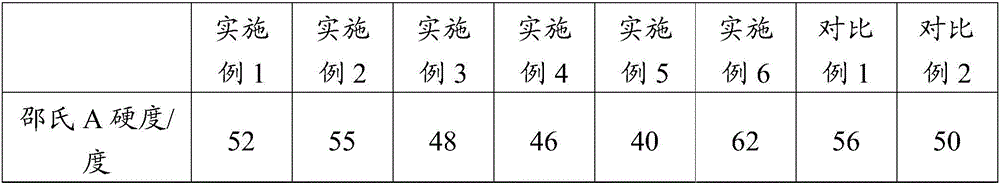

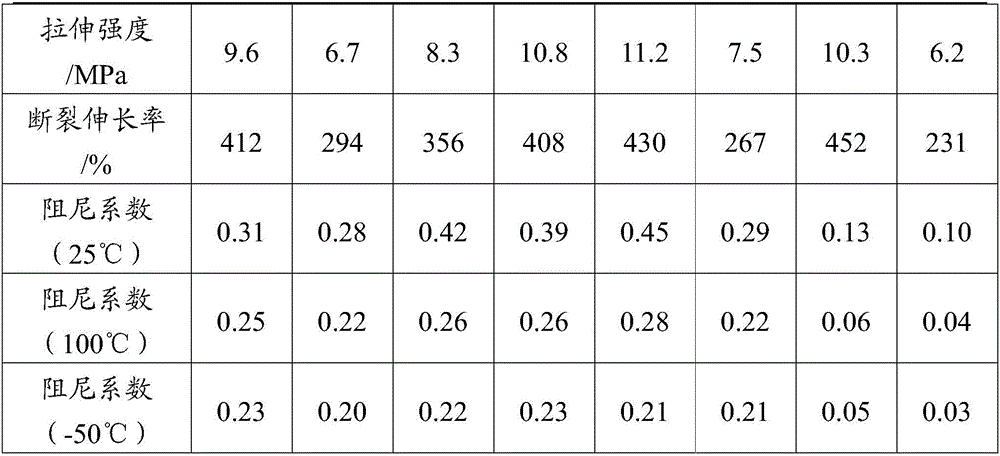

Examples

Embodiment 1

[0031] Add 5 parts of methyl vinyl phenyl silicone rubber raw rubber (vinyl molar content: 0.21%, Phenyl molar content: 20%, average molecular weight: about 590,000), 5 parts of acrylic damping agent (ethylene-acrylic acid copolymer with a molar ratio of 80:20, average molecular weight: about 6000), 2 parts of mica, 40 parts of gas phase French silica (specific surface area: 300m 2 / g), 10 parts of α, ω-dihydroxy polydimethylsiloxane (average degree of polymerization: 6), fully kneaded in a kneader for 2 hours, and then kneaded at 170°C for 4 hours under normal pressure , and finally mixed at 170°C for 2 hours under the condition that the absolute pressure was not higher than 20KPa, and the compound rubber I without vulcanizing agent was obtained;

[0032] Cool the rubber compound Ⅰ to room temperature, add 0.5 parts of vulcanizing agent 2,4-dichlorobenzoyl peroxide to 100 parts of the Agent compound II;

[0033] Feed the mixed rubber II containing vulcanizing agent into th...

Embodiment 2

[0036] Add 30 parts of methyl vinyl phenyl silicone rubber raw rubber (vinyl molar content: 0.30%, Phenyl molar content: 5%, average molecular weight: 460,000), 0.5 parts of 4,4'-bis(α,α-dimethylbenzyl) diphenylamine, 1 part of wollastonite, 50 parts of precipitated silica (Specific surface area: 200m2 / g), 6 parts of diphenylsilanediol, mixed in a kneader for 4 hours (temperature: 180°C, pressure: normal pressure), and finally mixed at 180°C, absolute pressure not higher than 20KPa for 0.5 hours , to prepare compound III without vulcanizing agent.

[0037] Cool the rubber compound III to room temperature, add 2 parts of benzoyl peroxide to 100 parts of the rubber compound, and mix it on a two-roll mill for 5 times to obtain the rubber compound IV containing a vulcanizing agent;

[0038] Feed the mixed rubber IV containing vulcanizing agent into the filter machine to make a rubber compound strip with a diameter of 4 cm, then feed the mixed rubber strip containing vulcanizing ...

Embodiment 3

[0041] Add 20 parts of methyl vinyl phenyl silicone rubber raw rubber (vinyl molar content: 0.1%, Phenyl molar content: 30%, average molecular weight: 460,000), 1 part of 2,6-di-tert-butyl-4-methylphenol, 3 parts of graphite, 20 parts of fumed silica (specific surface area: 380m 2 / g), 25 parts of precipitated silica (specific surface area: 260m 2 / g), 12 parts of hexamethyldisilazane, fully kneaded in a kneader for 2 hours, then kneaded at 100°C for 4 hours under normal pressure, and finally at 100°C, the absolute pressure was not higher than 20KPa Down mixing for 2 hours, the mixed rubber V without vulcanizing agent was obtained;

[0042] Cool the rubber compound V to room temperature, add 1 part of 2,4-dichlorobenzoyl peroxide and 1 part of 2,5-dimethyl-2,5-di-tert-butyl peroxide to 100 parts of the rubber compound Hexane was oxidized, and Botong was mixed 5 times on a two-roll mill to obtain vulcanizing agent-containing rubber compound VI;

[0043] Feed the mixed rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com