Low cost room temperature silicon sulfide rubber composition

A technology of silicone rubber composition and room temperature vulcanization, which is applied in the field of room temperature vulcanization silicone rubber composition, and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

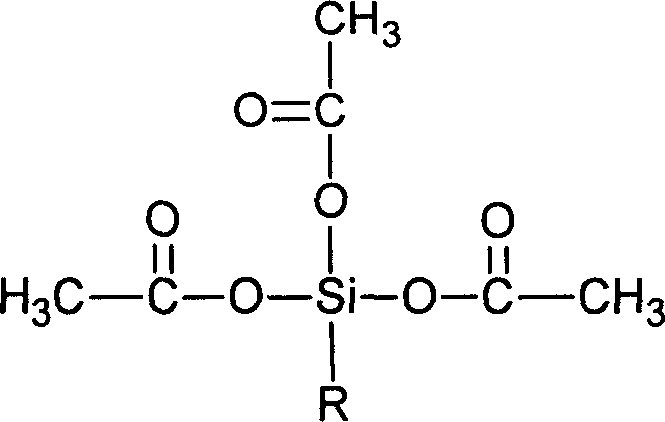

Method used

Image

Examples

Embodiment 1

[0021] Mix 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 50 Pa·s, 6 parts of methyltriacetoxysilane, and 10 parts with a specific surface area of 150m 2 / g of hydrophilic fumed silica, 20 parts of 0.35Pa s methyl silicone oil and 20 parts of industrial white oil with a viscosity of 0.004Pa s, and 0.02 parts of dibutyltin dilaurate were successively added to the high-speed mixer in vacuum After stirring and mixing for 60 minutes, release the vacuum with nitrogen and put it into a sealed packaging container. The prepared sample was made into an H-type test piece according to GB / T13477.8 "Determination of Tensile Adhesion", and the tensile bond strength was measured to be 0.70MPa, the maximum elongation rate was 186%, and the glue was cured for one month No yellowing afterwards. The storage period is tested according to the empirical method. The packaged samples are placed at 70°C and 50% humidity for two weeks. After being placed at room temperatur...

Embodiment 2

[0023] Stir 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 30 Pa·s, 5 parts of methyltriacetoxysilane, and 1 part of ethyltriacetoxysilane in a high-speed mixer under vacuum for 20 minutes, and then sequentially add The specific surface area of 12 parts that has been stirred evenly is 200m 2 / g of hydrophilic fumed silica and 60 parts of industrial white oil paste with a viscosity of 0.004 Pa s, 0.02 parts of dibutyltin dilaurate and vacuum stirring for 30 minutes, then use nitrogen to remove the vacuum and put it into a sealed container inside the packaging container. The prepared samples were made into H-type test pieces according to GB / T13477.8 "Determination of Tensile Adhesion", and the tensile bond strength was measured to be 0.66MPa, the maximum elongation of force was 175%, and the storage period was based on empirical methods For the test, the packaged sample was placed at 70°C and 50% humidity for two weeks, and it cured normally after b...

Embodiment 3

[0025] Stir 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 30 Pa·s, 5 parts of methyltriacetoxysilane, and 1 part of ethyltriacetoxysilane in a high-speed mixer under vacuum for 20 minutes, and then sequentially add The specific surface area of the 3 parts that have been stirred evenly is 150m 2 / g of hydrophilic fumed silica, 20 parts specific surface area is 150m 2 / g precipitation method and 50 parts of industrial white oil paste with a viscosity of 0.004Pa·s, 0.02 parts of dibutyltin dilaurate were stirred in vacuum for 30 minutes, and the vacuum was released with nitrogen and packed into a sealed packaging container. The prepared samples were made into H-type test pieces according to GB / T13477.8 "Determination of Tensile Adhesion", and the tensile bond strength was measured to be 0.66MPa, the maximum elongation rate was 181%, and the glue was cured for one month No yellowing afterwards. The storage period is tested according to the empirical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com