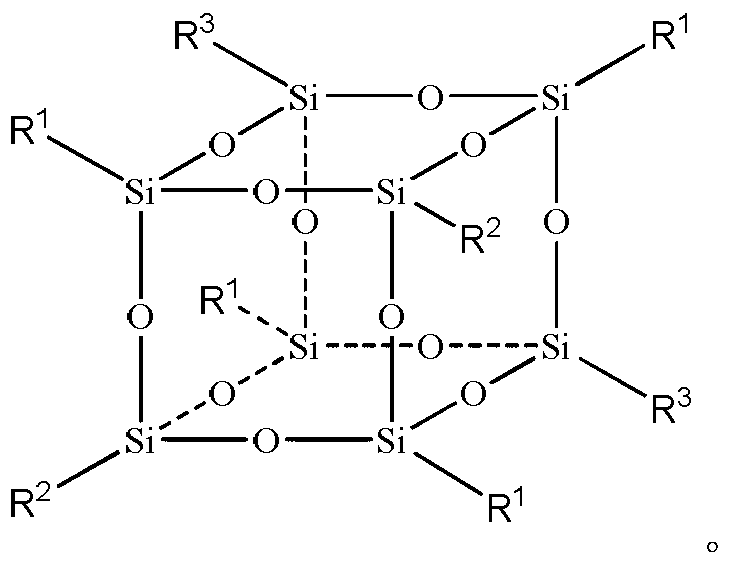

Novel alkoxy silane based POSS (polyhedral oligomeric silsesquioxanes) as well as preparation method and application thereof

An alkoxysilyl group, a new type of technology, applied in the direction of silicon organic compounds, can solve the problems of enhancing mechanical properties and thermal properties, and achieve the effect of improving mechanical properties and thermal properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

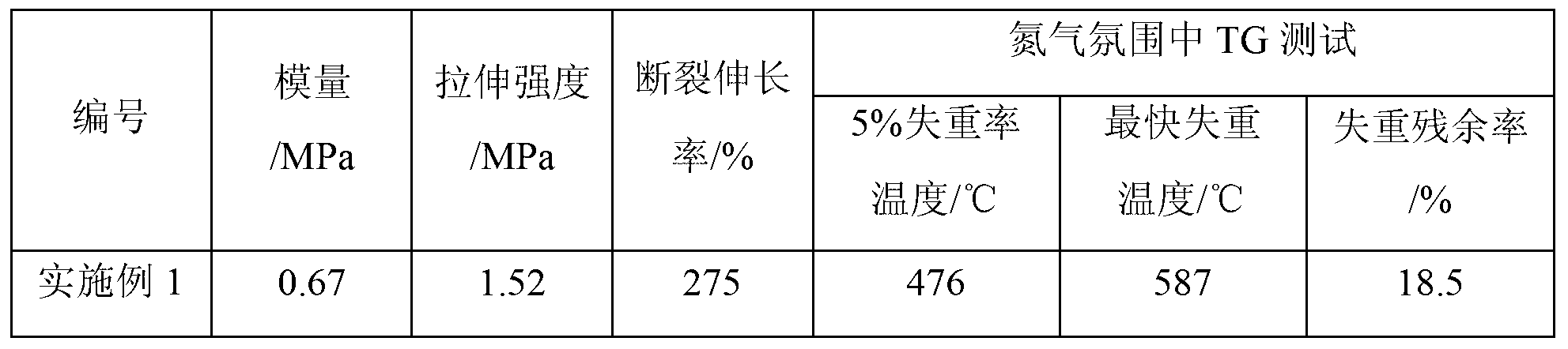

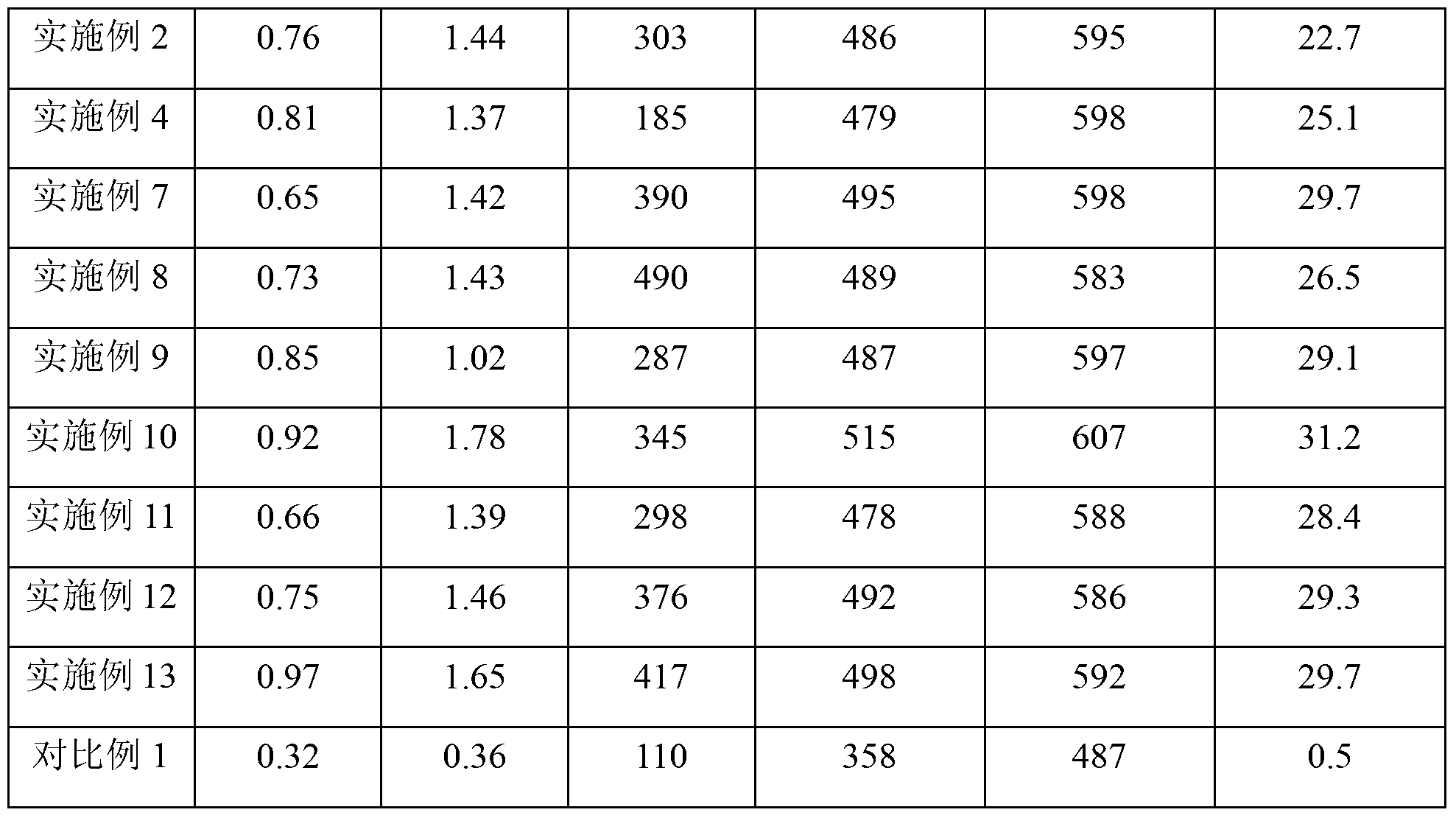

Examples

Embodiment 1

[0028] Anhydrous ether 500g, trimethoxysilane 4.88g (39.5mmol) and H 2 [PtCl 6] (dissolved in isopropanol, concentration 4wt%, take 0.5g) and octavinyl T8-POSS (Vinyl-POSS) 5.00g (7.90mmol, the number of moles of double bonds is 63.20mmol) into a 1000mL three-necked flask , reacted at 35°C for 8h, cooled to 20°C and continued to stir for 15h. After the reaction, add activated carbon, stir at 35°C for 0.5h, filter the obtained black ether solution through silica gel and diatomaceous earth to obtain a clear liquid, concentrate the obtained clear liquid, and obtain 9.78 g of a colorless oily liquid as the obtained product Si 8 o 12 R 1 3 R 3 5 (R 1 = Vinyl, R 3 = trimethoxysilylethyl), yield 98.9%. The NMR characterization results of the product are: 1 HNMR (CDCl 3 ,ppm):δ5.78-6.15(m,H 2 C=CH-,9H),3.55(s,-OCH 3 ,45H),0.66(m,Si-CH 2 ,20H).

[0029] Add commercially available 107# hydroxyl-terminated silicone oil (60.00g) with a viscosity of 80,000 cP into the knead...

Embodiment 2

[0031] Anhydrous tetrahydrofuran (THF) 13g, triethoxysilane 3.90g (32.0mmol) and H 2 [PtCl 6 ] (dissolved in isopropanol, concentration 4wt%, take 0.5g) and tetravinyl tetracyclopentyl T8-POSS (CAS Registry Number: 1228876-88-7) 6.4g (8.00mmol, the number of moles of double bonds 32mmol) into a 100mL three-necked flask, reacted at 65°C for 4h, cooled to 65°C, added activated carbon, stirred at 65°C for 0.5h, filtered the obtained black ether solution through silica gel and diatomaceous earth to obtain a clear liquid, and the obtained clear The solution was concentrated to obtain 10.07 g of a colorless oily liquid, which is the product Si 8 o 12 R 2 4 R 3 4 (R 2 = Cyclopentyl, R 3 = triethoxysilylethyl), yield 97.8%. The NMR characterization results of the product are: 1 HNMR (CDCl 3 ,ppm):δ3.75(m,-OCH 2 CH 3 ,24H),1.4~1.72(m,-C 5 h 9 ,36H),1.36(t,-OCH 2 CH 3 36H),0.61(q,Si-CH 2 ,16H).

[0032] Condensation-type RTV silicone rubber was prepared according to t...

Embodiment 3

[0034] Add 50 g of dichloromethane and 9.50 g of deca(3-(3-methacryloyloxy)propyl)T10-POSS (prepared according to the literature: Dalton Trans., 2010, 39, 3239–32440) into a 250 mL three-necked flask ( 5.0mmol, the mole number of double bonds is 50mmol) and triphenylrhodium chloride catalyst 1.9g (dissolved in THF, concentration 10wt%), after stirring at 40°C for 0.5h, dichloromethane 100mL and dimethyl chloride were added dropwise Add the mixed solution of 0.47g (5.0mmol) silane within 2h, continue to react at 40°C for 4h, add activated carbon after cooling down, stir at 40°C for 0.5h, filter the obtained ether solution through silica gel and diatomaceous earth, Concentrate the resulting clear liquid to obtain 9.86 g of white solid, which is the product Si 10 o 15 R 1 R 3 9 (R 1 =3-(3-methacryloyloxy)propyl, R 3 =(CH 3 ) 2 ClSiCH 2 CH 2 COOC 3 h 6 -), yield 98.9%. The NMR characterization results of the product are: 1 HNMR (CDCl 3 ,ppm): δ6.3~6.4(d,-OCOC(CH 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com