High temperature resistant silicon rubber and preparation method thereof

A silicone rubber and high temperature resistant technology, applied in the field of polymer materials, can solve the problems of softening, the decline of rubber mechanical properties, affecting the normal operation of the workpiece, etc., and achieve the effect of good high temperature resistance and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

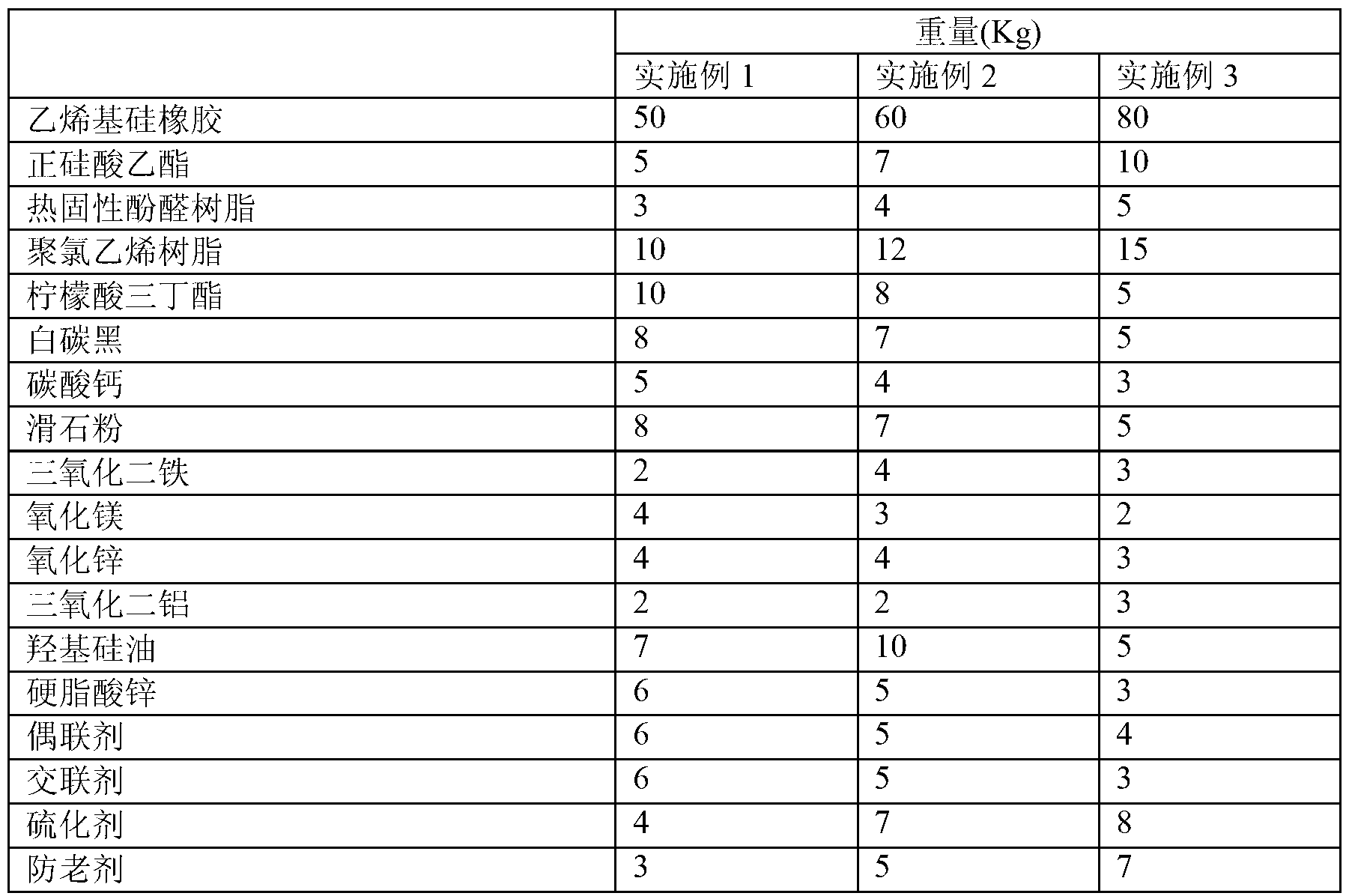

[0020] Prepare the raw materials of each embodiment according to the weight shown in Table 1.

[0021] The weight proportion of table 1 embodiment 1~embodiment 3

[0022]

[0023] In the above examples, the cross-linking agent is methyl triacetone oximino silane, the vulcanizing agent is vulcanizing agent BP, the anti-aging agent is anti-aging agent MB, and the coupling agent is titanate coupling agent TMC-201.

[0024] The preparation method is:

[0025] S1: Knead vinyl silicone rubber, thermosetting phenolic resin, polyvinyl chloride resin, and tributyl citrate in a vacuum kneader for 5 to 10 minutes, then add white carbon black, calcium carbonate, talcum powder, ferric oxide, Stir magnesium oxide, zinc oxide, and aluminum oxide evenly;

[0026] S2: Add hydroxyl silicone oil, zinc stearate, coupling agent, and crosslinking agent to the mixture obtained in step S1, heat up to 180°C, heat for 1 hour; turn on the vacuum, the vacuum degree is -0.05MPa, and vacuum for 60 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com