Functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and preparation method thereof

A silicon rubber nano-composite material technology, applied in the field of nano-composite materials, can solve the problems of few examples and achieve high yield, easy industrialization, and simple reaction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 35g of component A and 3.5g of component B of Dow Corning Sylgard 184, stir rapidly at a speed of 1800 r / min for 15 minutes, mix well, pour into a mold, vacuum defoam, and cure at 125 °C for 55 minutes. The performance test results of the obtained pure silicone rubber are shown in Table 1.

Embodiment 2

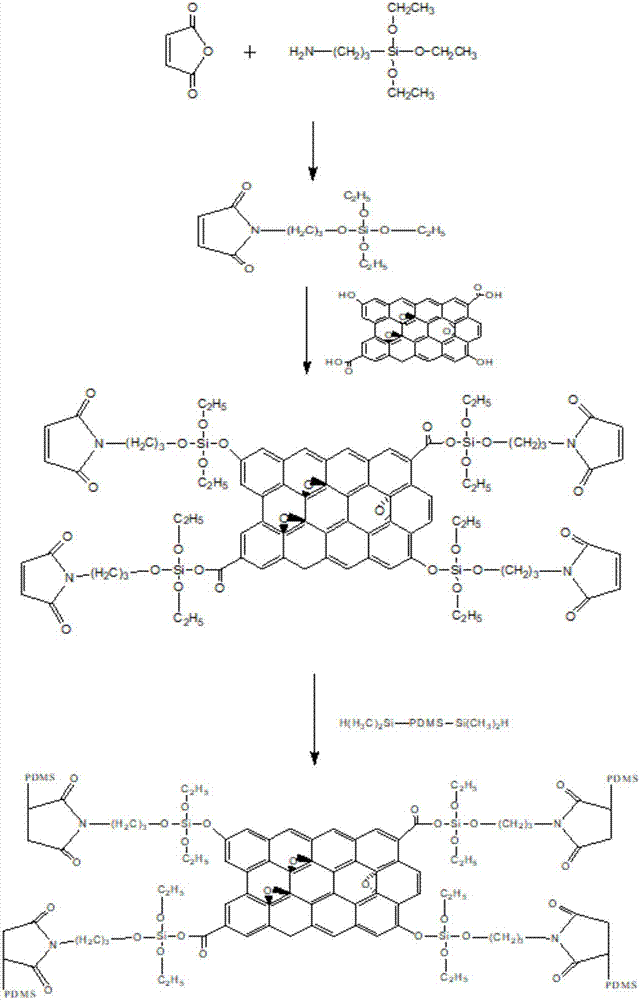

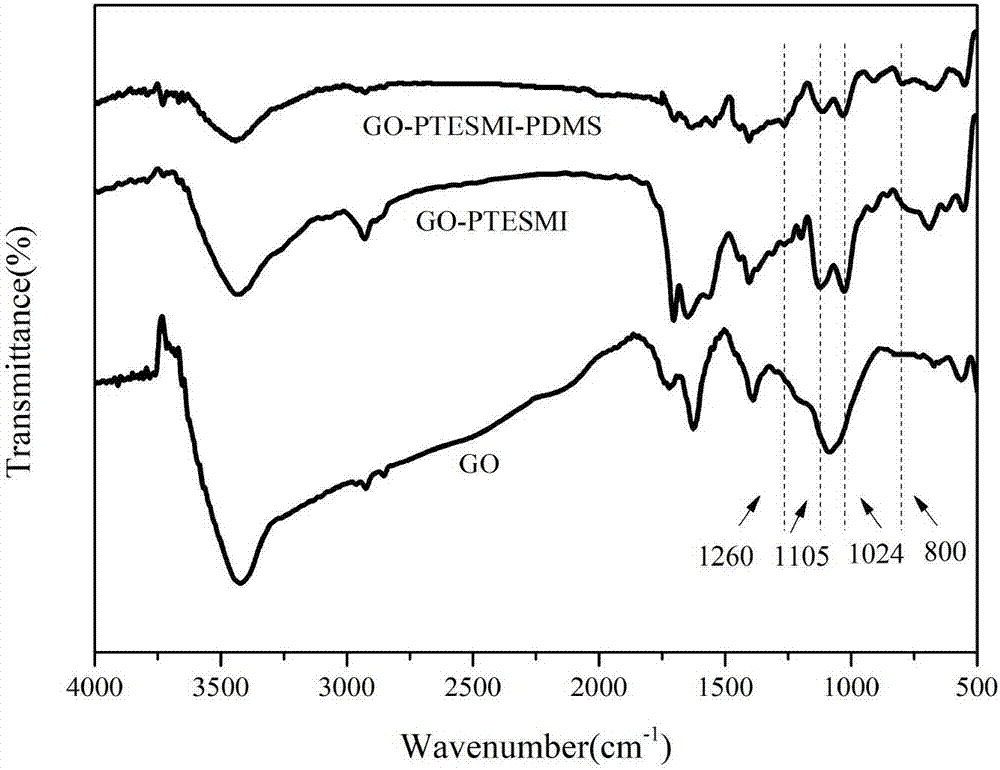

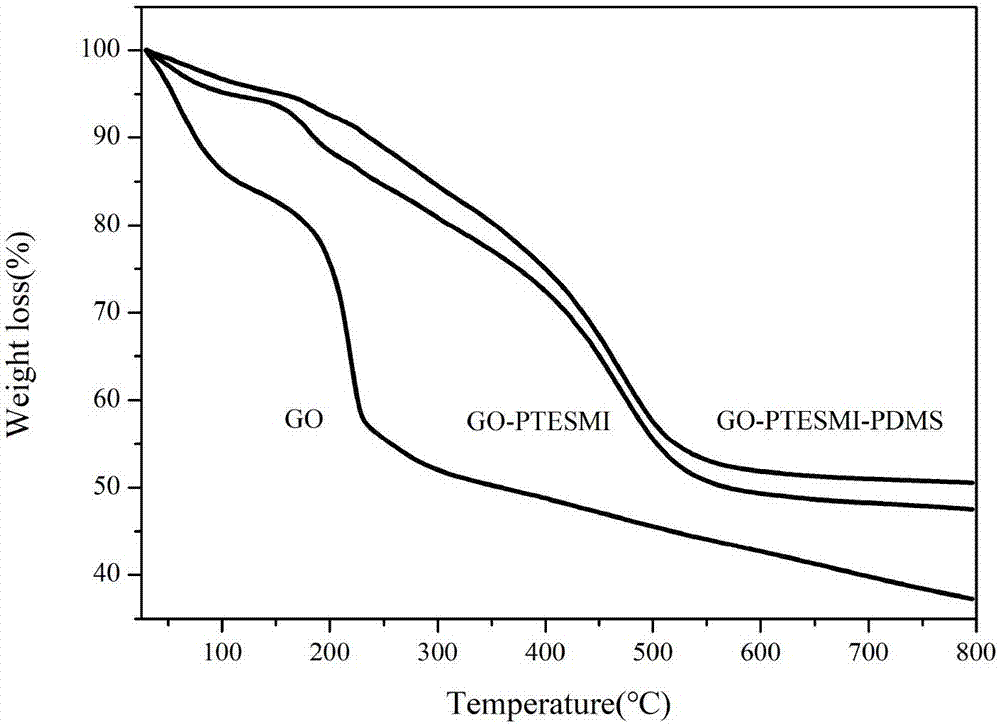

[0043] (1) Surface modification of graphene oxide

[0044] In a 250 mL round bottom flask, 9.855 g of maleic anhydride, 100 mL of acetone and 23.43 mL of γ-aminopropyltriethoxysilane were added sequentially, and reacted at room temperature for 8 h under nitrogen protection, followed by adding 8.203 g of sodium acetate, 10.364 g acetic anhydride, refluxed for 10 h. After the reaction, the solid-liquid two phases were separated by suction filtration, and the brown-yellow liquid was rotary evaporated for 1 h to obtain a brown-yellow viscous liquid, namely PTESMI.

[0045] Graphene oxide was prepared by the improved Hummers method, then 1.0 g of graphene oxide was weighed and dispersed into 200 mL of absolute ethanol, and a uniform dispersion was obtained by ultrasonic treatment, then 5 mL of ammonia water with a mass fraction of 27% and 6.027 g of PTESMI, quickly transfer the reaction system to an oil bath at 65 °C, stir vigorously, and reflux for 48 h. After the reaction, GO-P...

Embodiment 3

[0051] Graphene oxide surface modification process is the same as example 2. Weigh 57.75 mg of GO-PTESMI-PDMS prepared in step (1) of Example 2 and disperse it in tetrahydrofuran. After ultrasonic treatment for 1 h, a stable graphene dispersion with a content of 1 mg / mL is obtained, and then weigh 35 g of Dow Corning Mix component A of 184 with tetrahydrofuran evenly to obtain a silicone rubber dispersion with a content of 0.5 g / mL, mix the two dispersions, and stir for 40 min at a speed of 23000 r / min in a digital display high-speed dispersing homogenizer, Rotary evaporation under reduced pressure for 1 h to remove the dispersant. Add 3.5 g of component B of Dow Corning 184, stir rapidly at a speed of 1800 r / min for 15 minutes, mix well, pour into a mold, vacuum defoam, and cure at 125 °C for 55 minutes to obtain functionalized graphene oxide Functionalized graphene oxide and room temperature vulcanized silicone rubber nanocomposites with a mass fraction of 0.15%.

[0052] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com