Patents

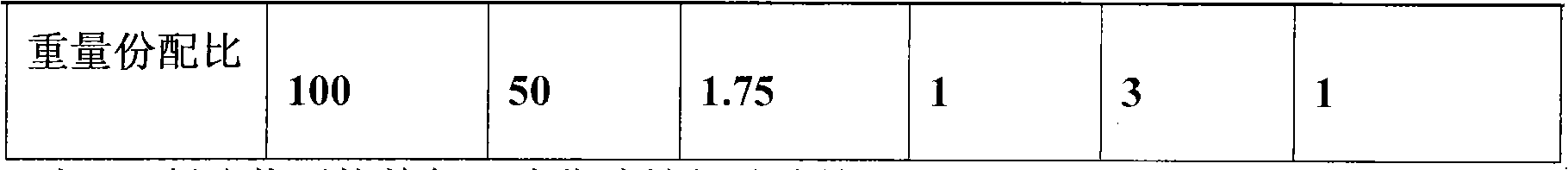

Literature

127 results about "Rubber nanocomposites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functional graphene-rubber nanocomposites

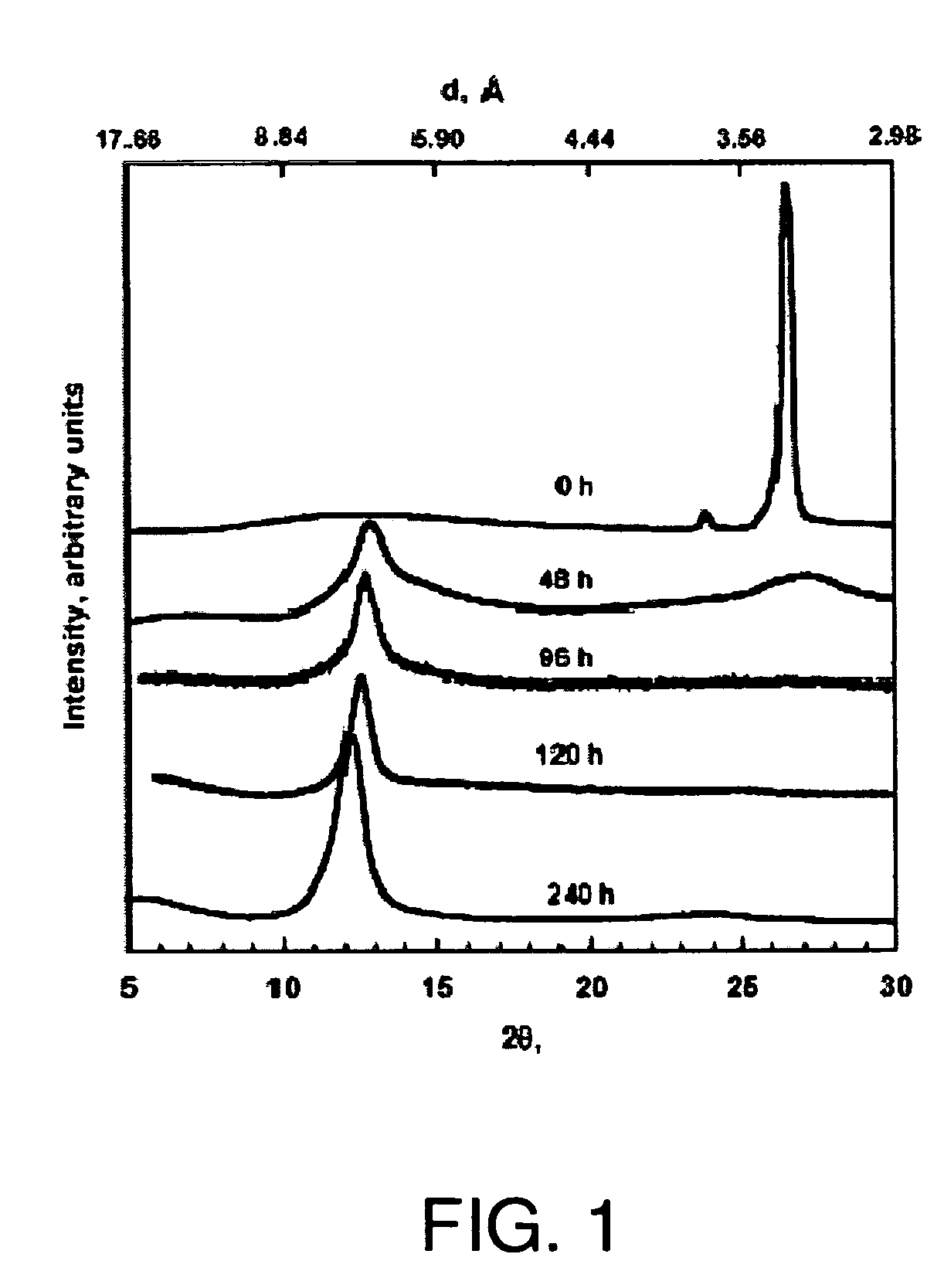

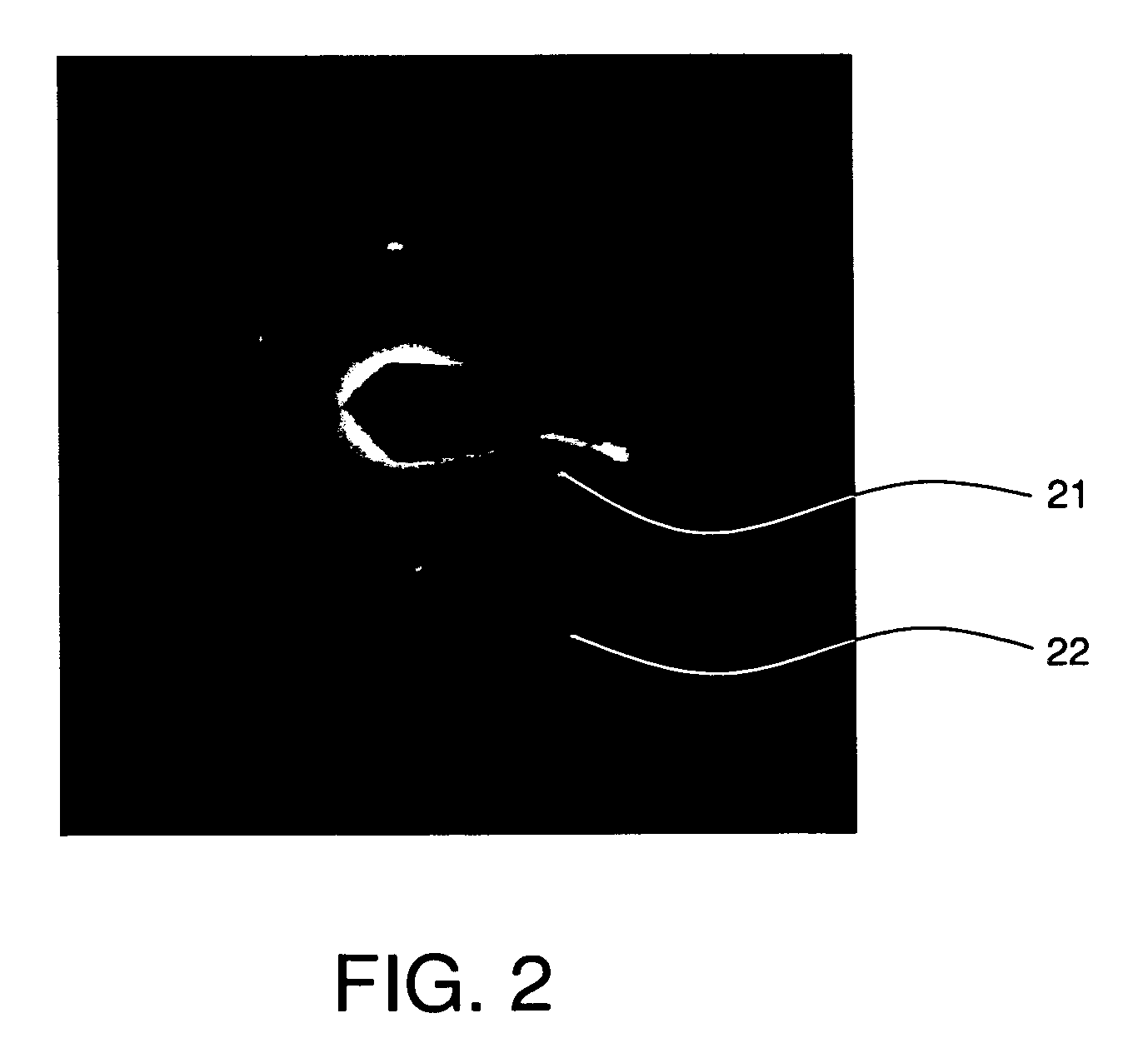

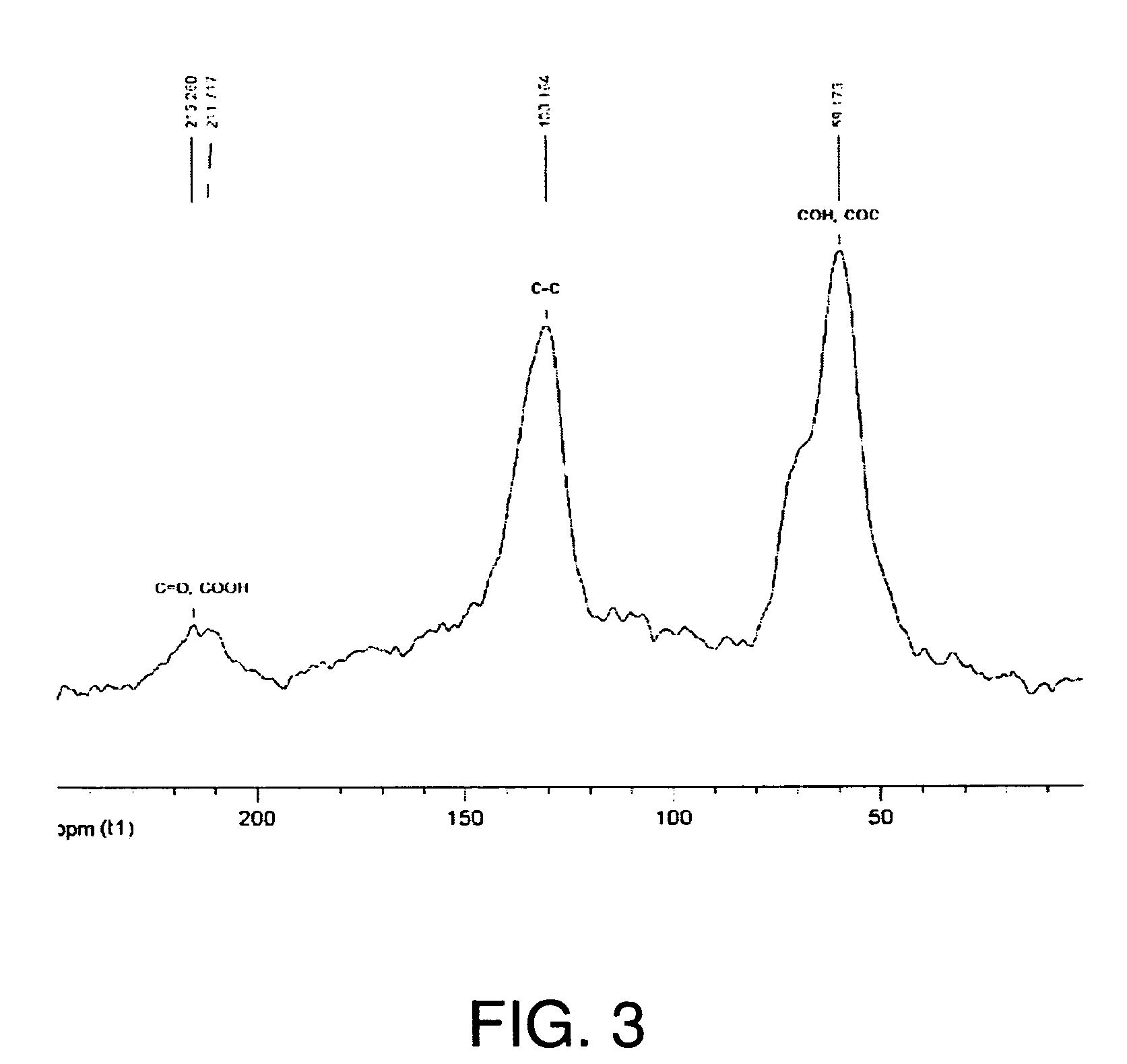

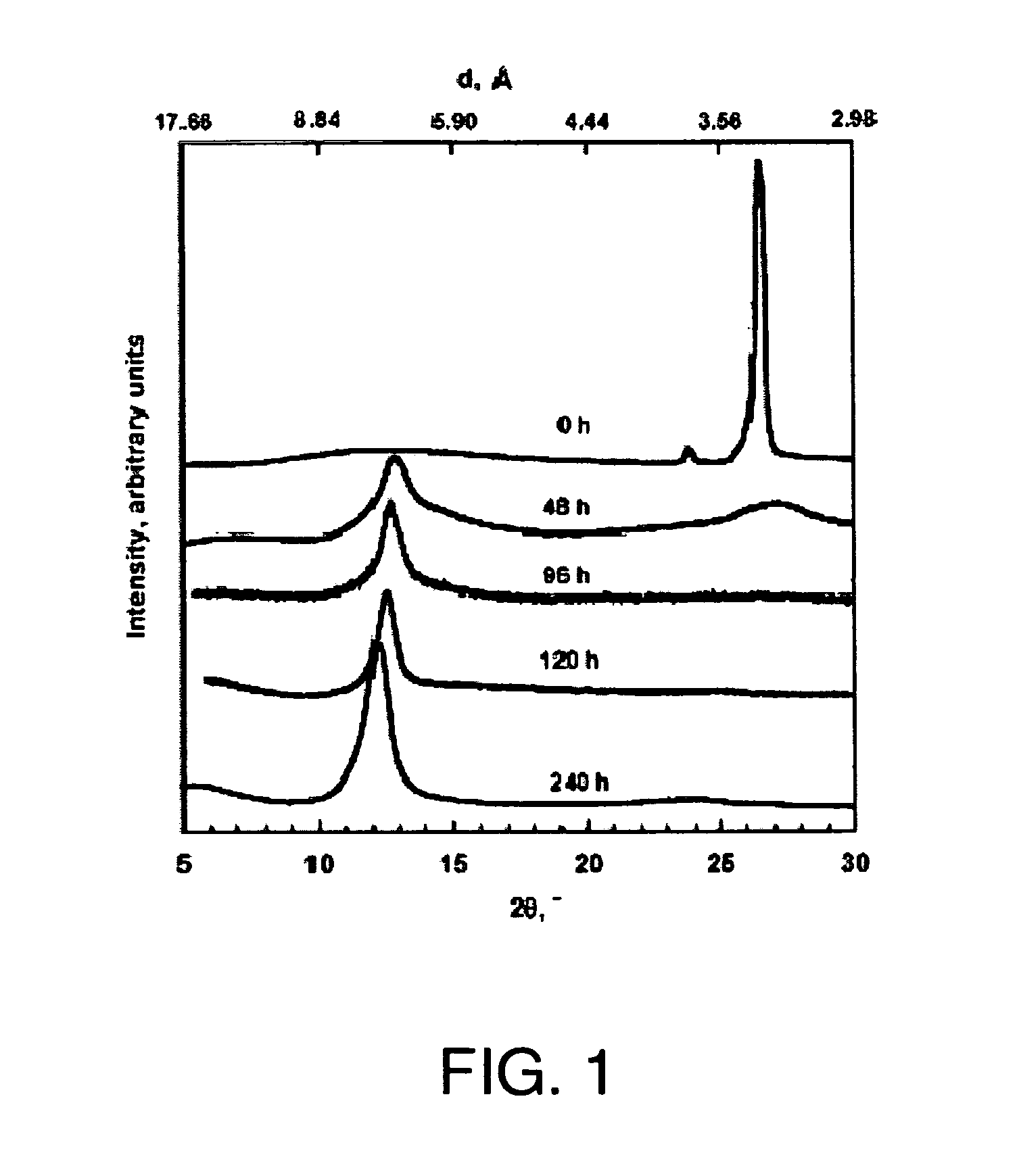

ActiveUS7745528B2Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerX-ray

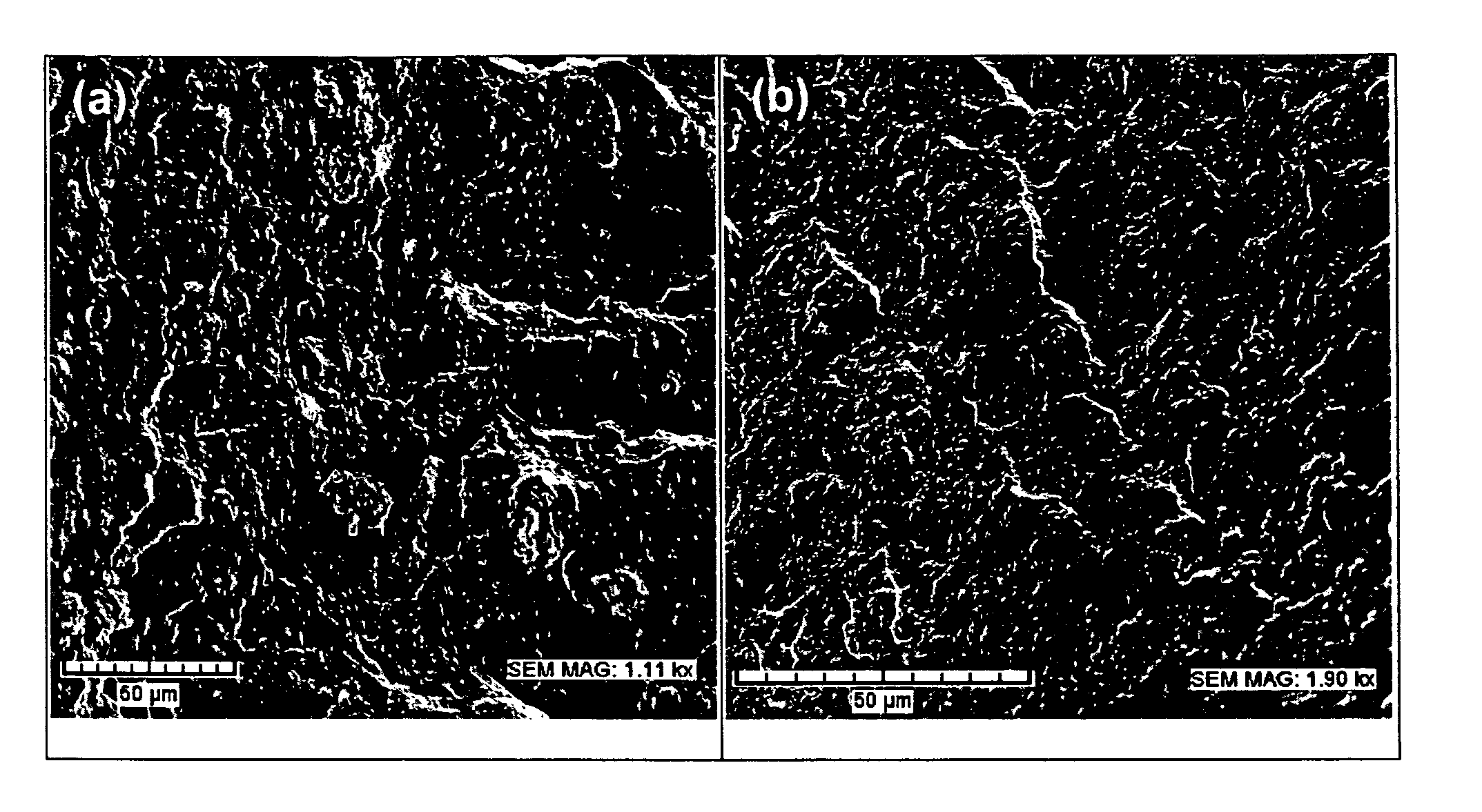

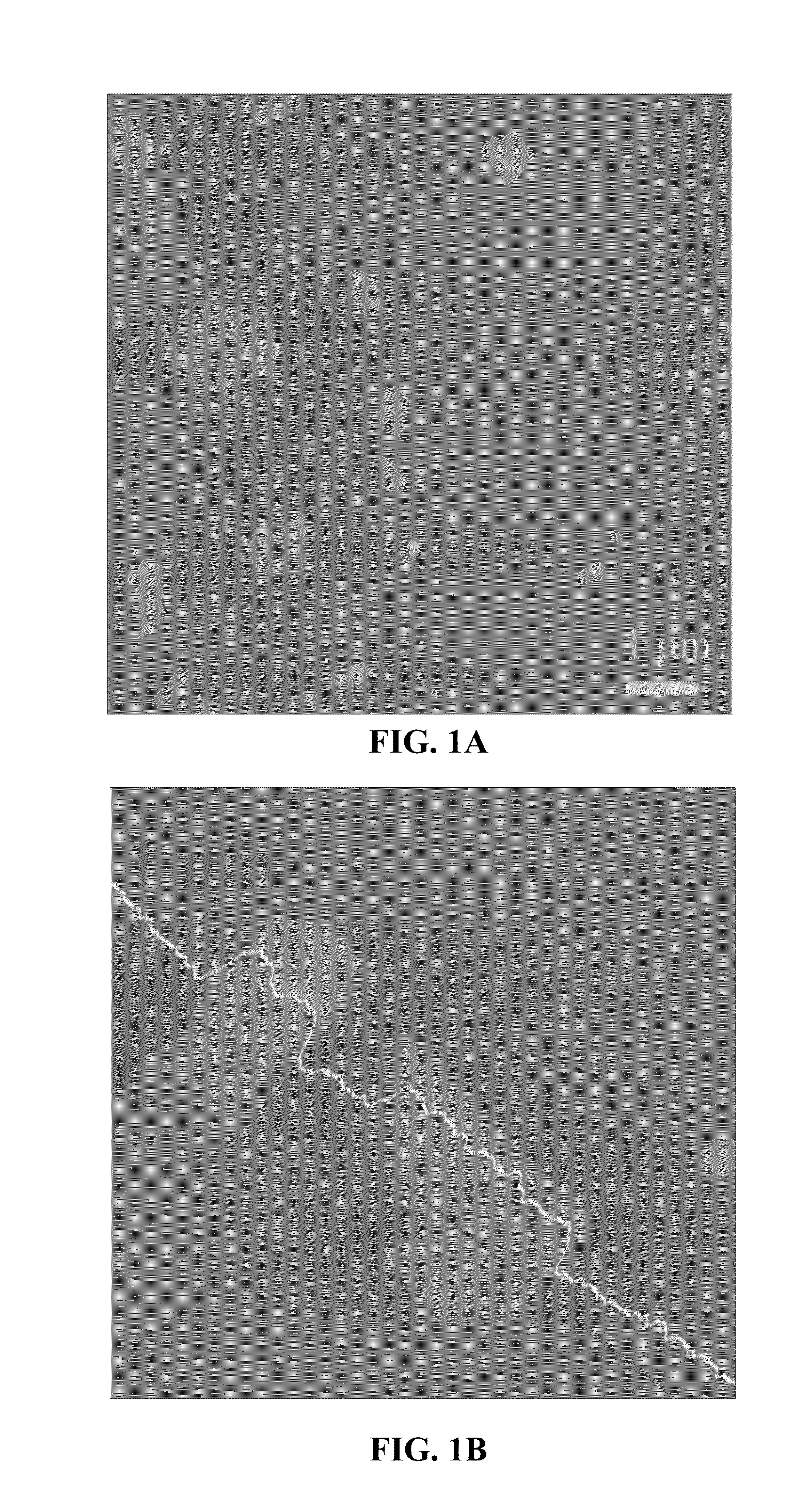

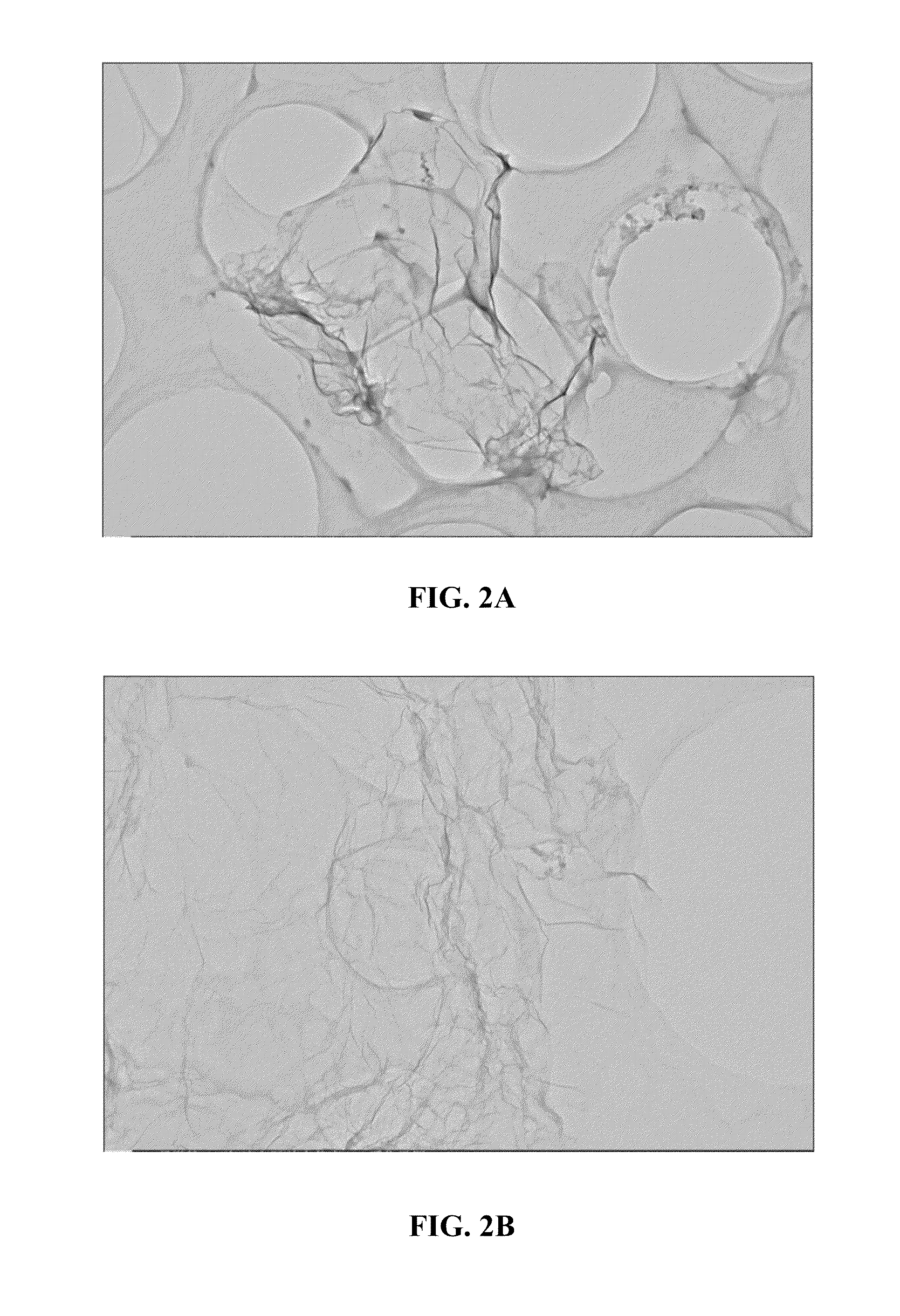

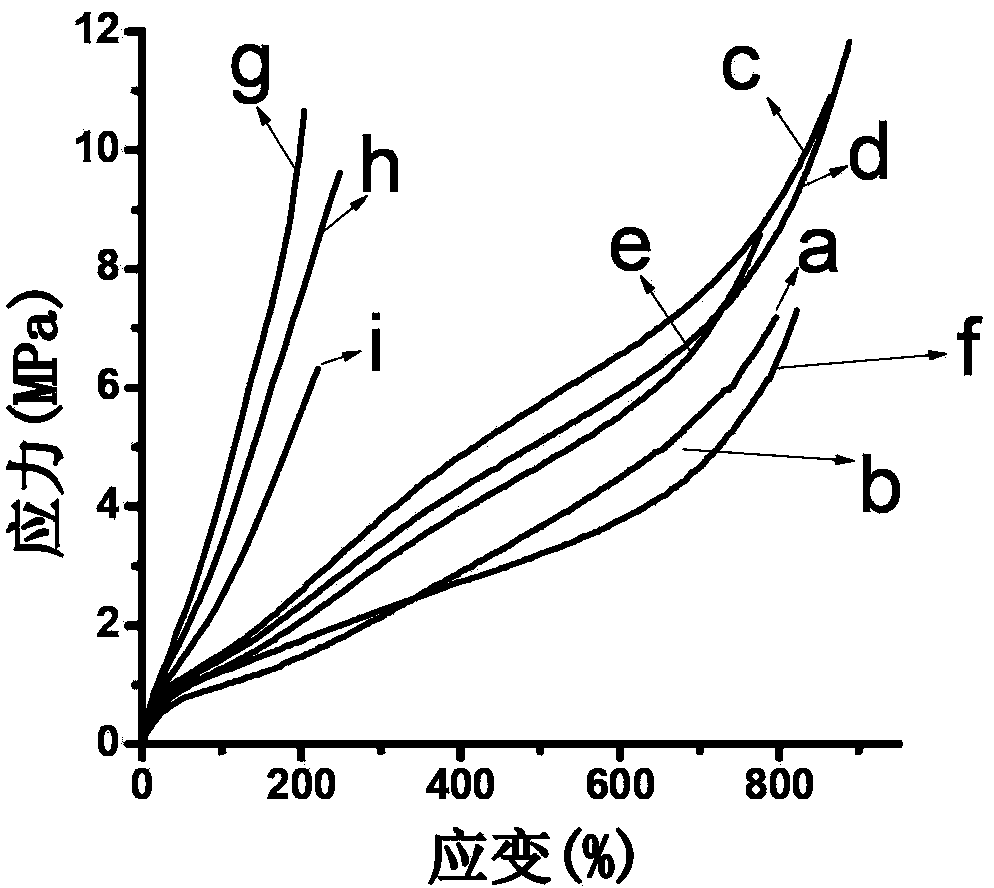

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Functional graphene-rubber nanocomposites

ActiveUS20100096597A1Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerPolymer science

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

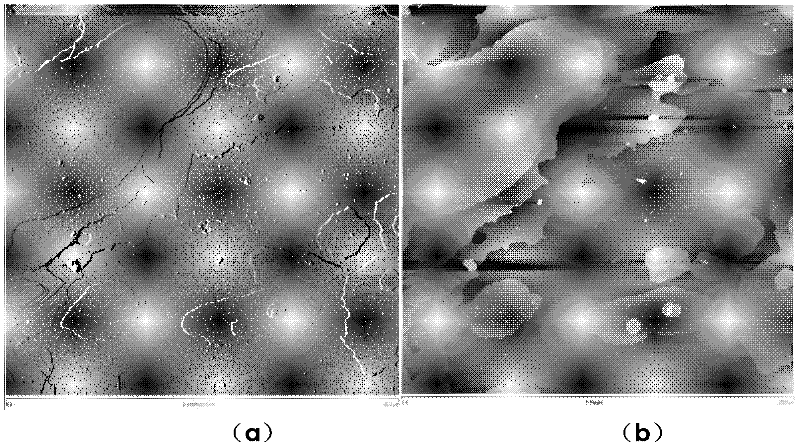

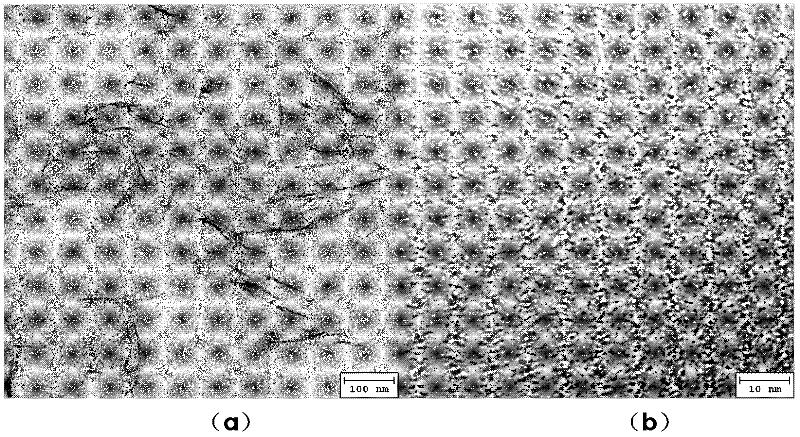

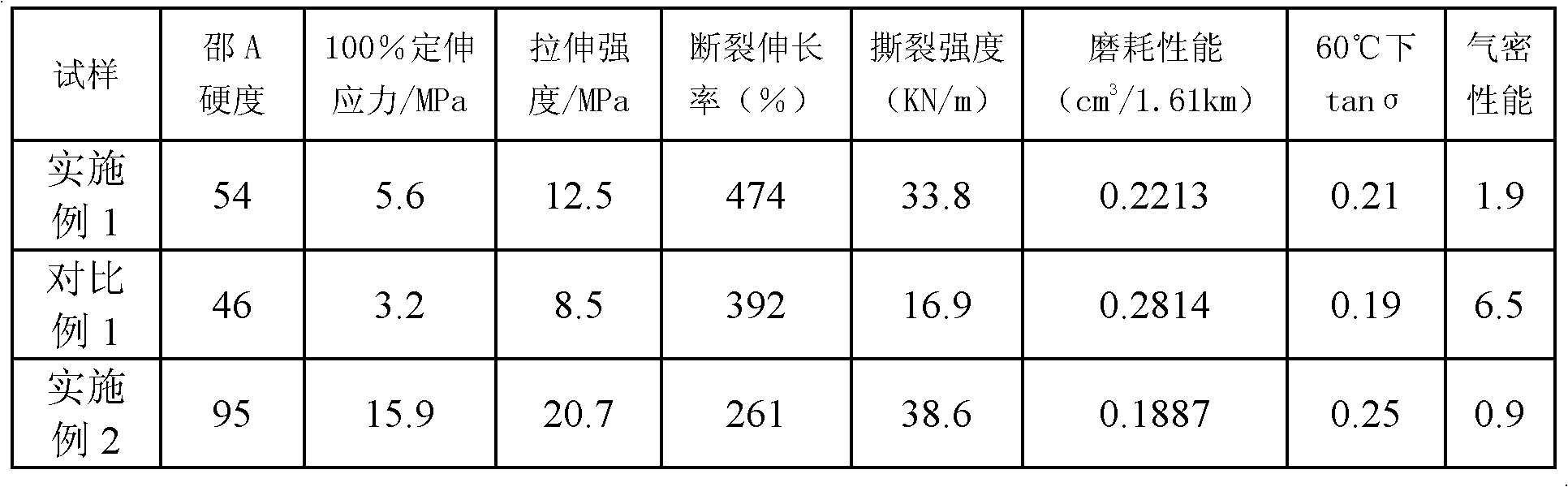

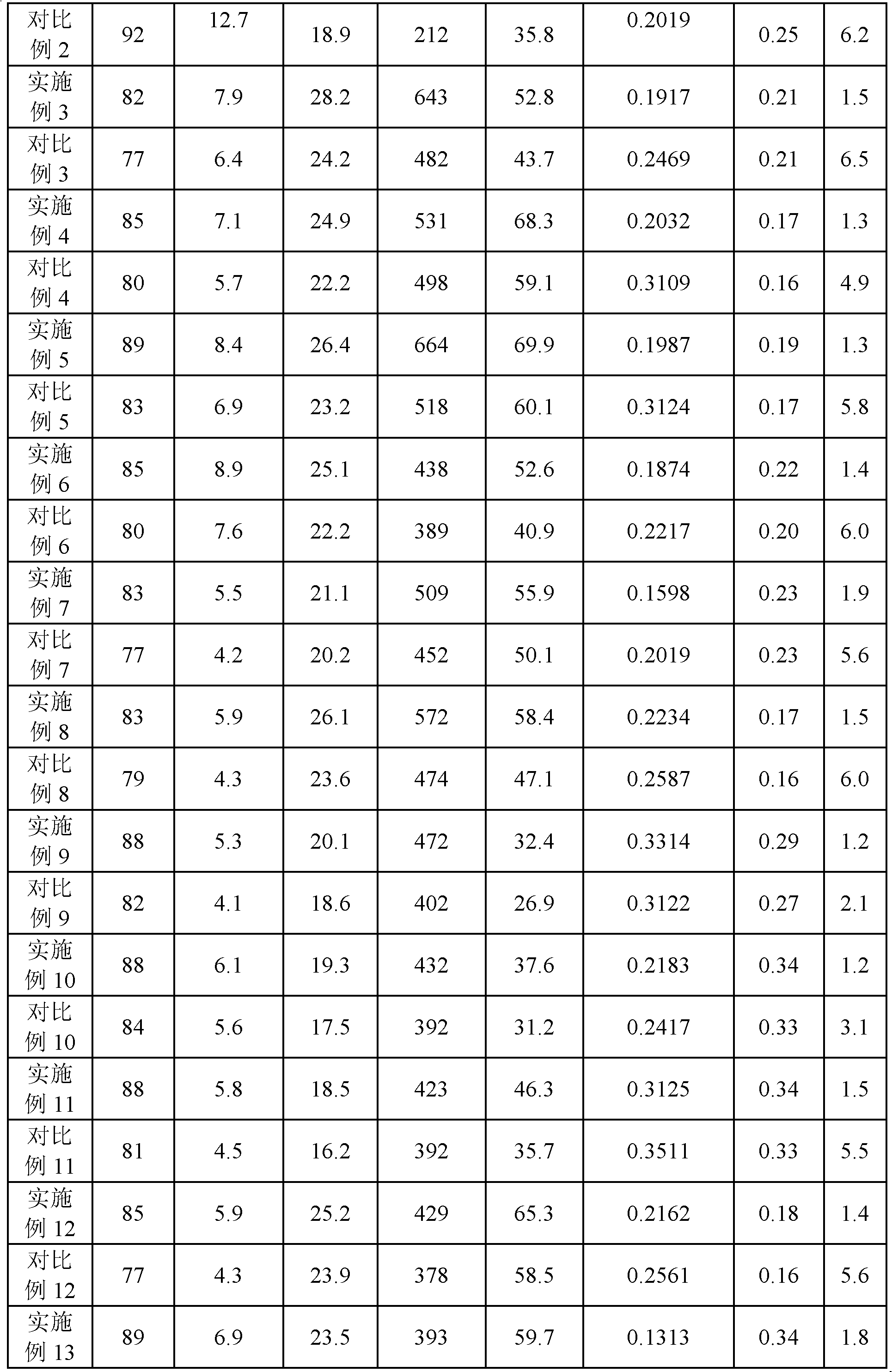

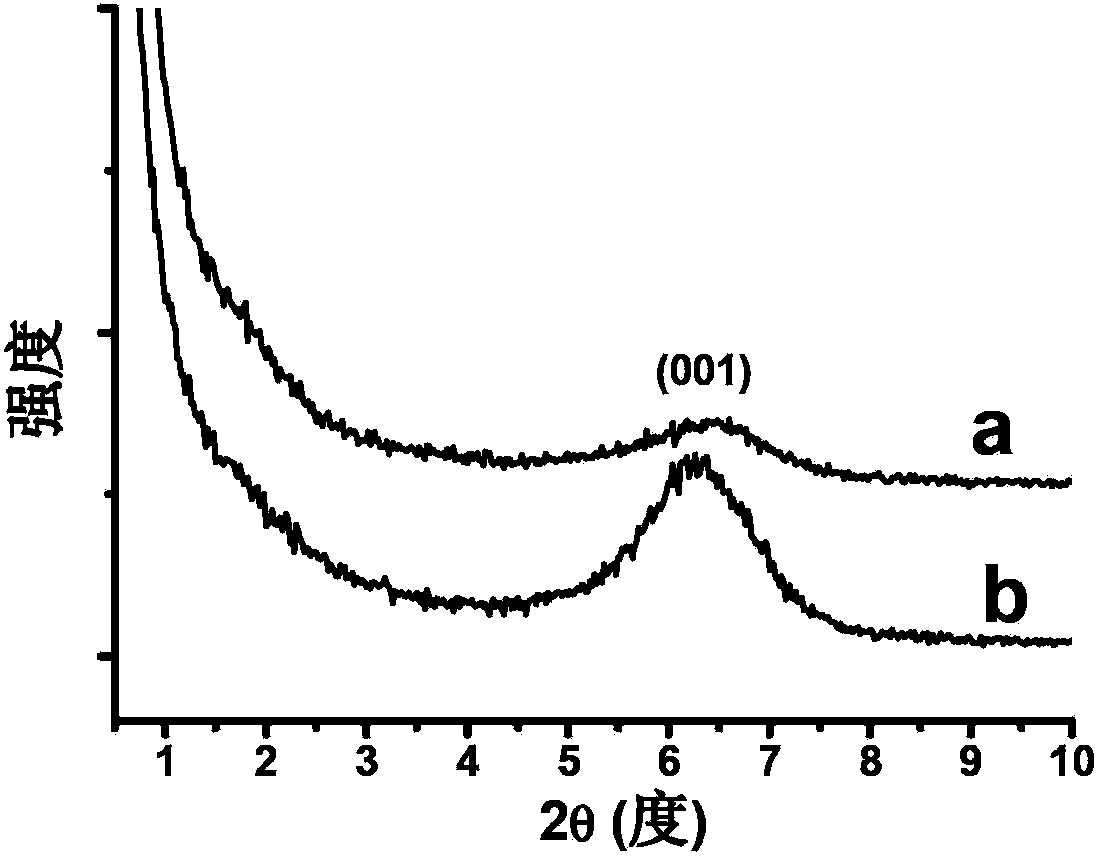

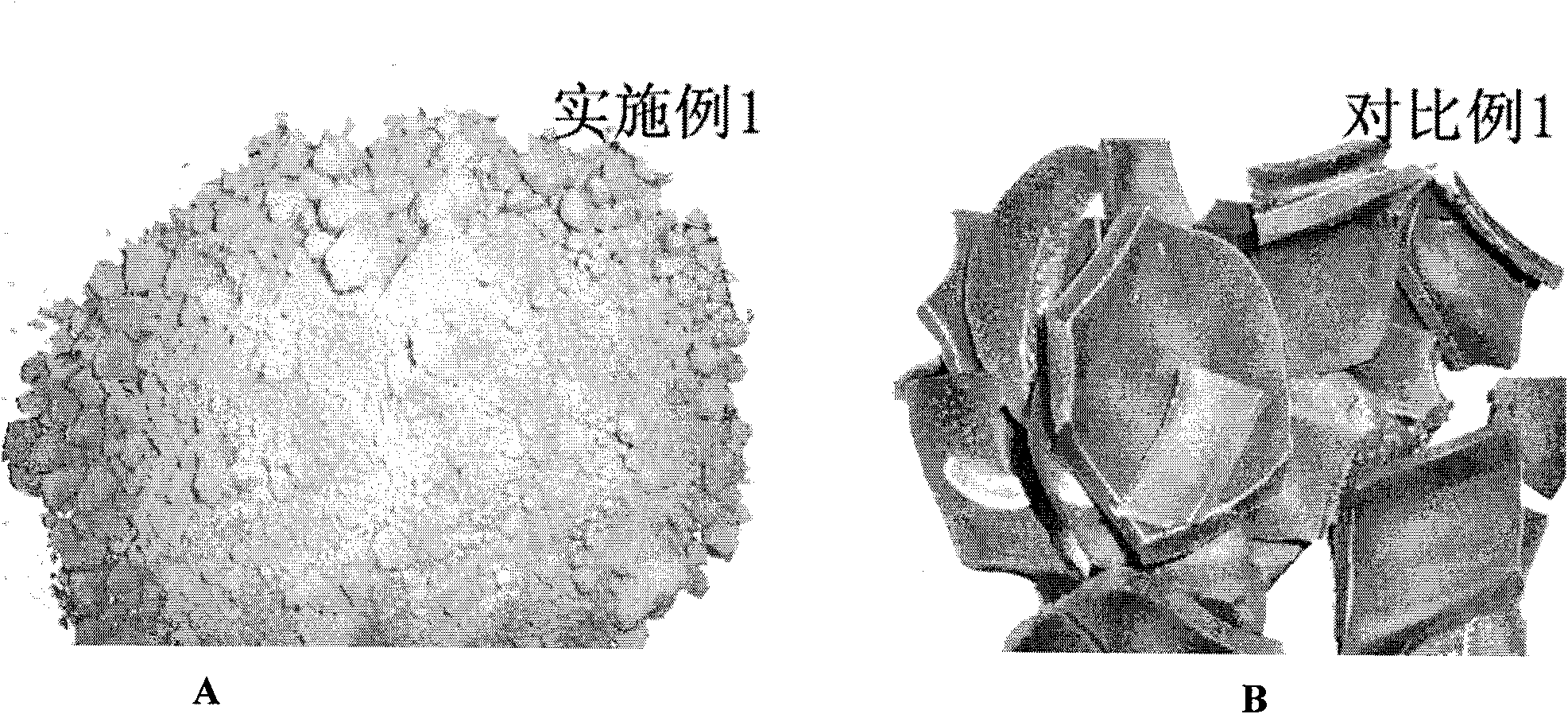

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

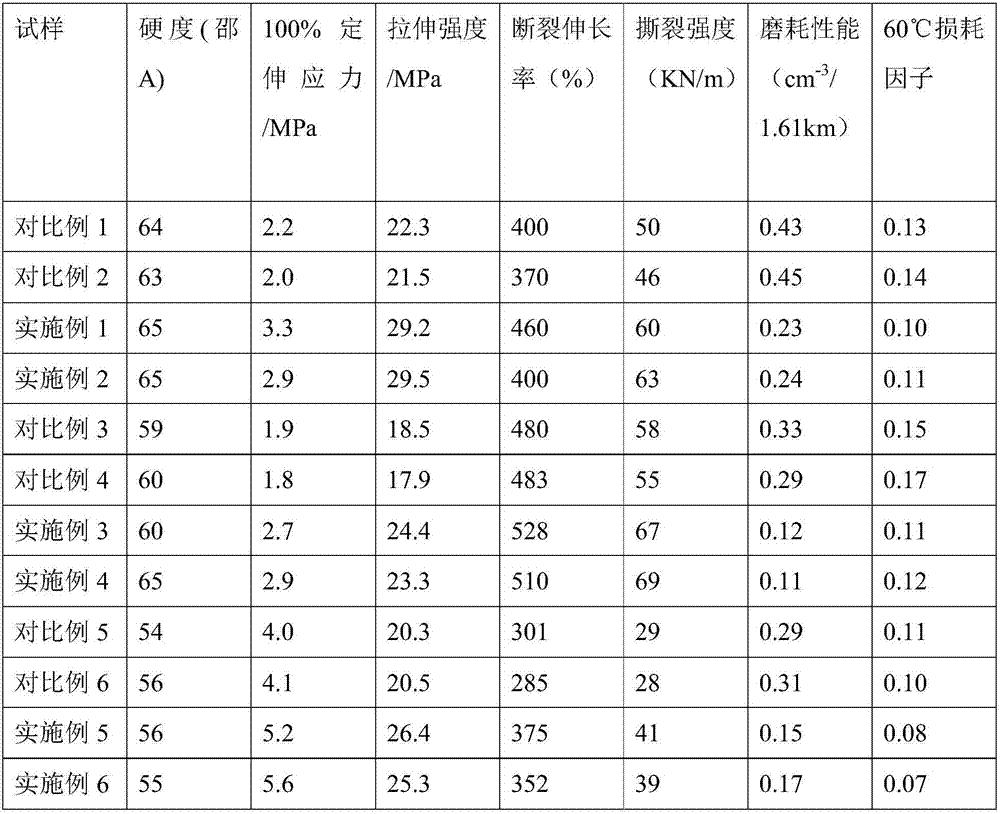

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

Oxidized grapheme/carbon black rubber nanocomposite and preparation method thereof

The invention provides an oxidized grapheme / carbon black rubber nanocomposite and preparation method thereof, which belongs to the field of rubber nanocomposite technology. The nanocomposite comprises the following basic compositions by mass: 100 parts of diene series rubber matrix, 0.5-5 parts of oxidized grapheme, 30-70 parts of hard carbon black of average particle size 11-30nm, 1-10 parts of plasticizer, 6-10 parts of activator, 0.5-4 parts of anti-aging agent, 1-4 parts of sulfuration promoter and 1-6 parts of insoluble sulphur; oxidized grapheme modifier. The oxidized grapheme powder is dispersed in deionized water for ultrasound, and a natural rubber emulsion is added, and masterbatch after flocculation, washing and drying is mixed uniformly with other additives, after sulfuration, the product is obtained. The oxidized grapheme / carbon black rubber nanocomposite has the advantages of excellent processing performance and obviously reduced dynamic themogenesis, thereby improving the usage life of tyre.

Owner:BEIJING UNIV OF CHEM TECH

Preparation of wear resistant rubber composite material

InactiveCN101463149AImprove mechanical propertiesImprove recycling efficiencyOrganic solventPolymer science

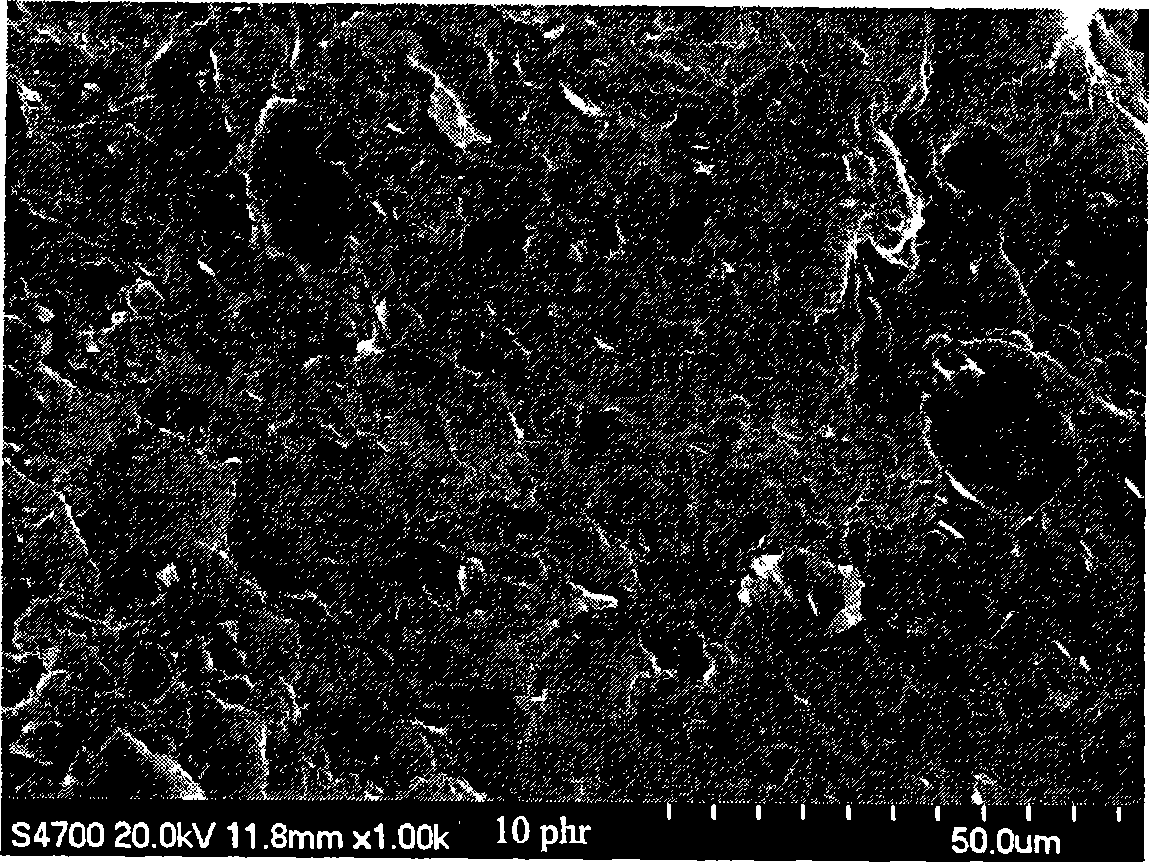

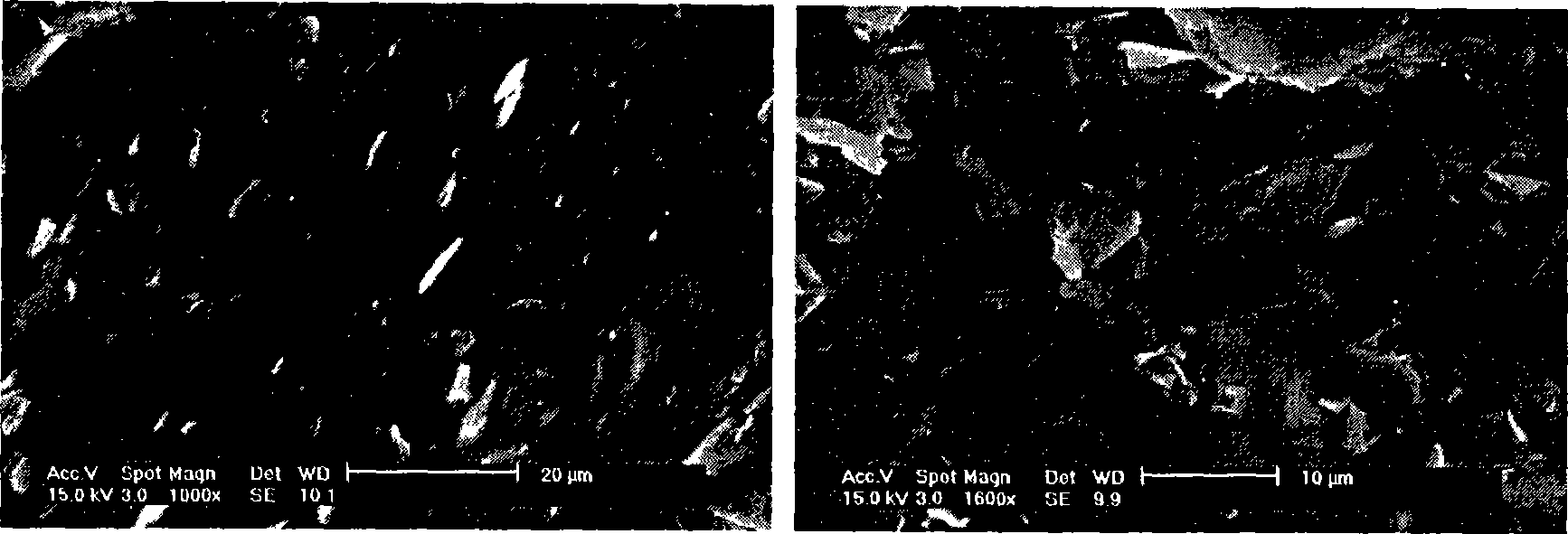

The invention relates to a preparation method of a graphite-modified abrasive resistant rubber composite material. The method comprises the following steps: soaking expandable graphite with laminar crystal layer structure in water or an organic solvent containing a surfactant; preparing a suspension system of nano flaky graphite by stirring and ultrasonic treatment; mixing the suspension system with rubber latex or rubber solution, and then adding a flocculant for breaking latex and flocculating or adding a poor solvent for precipitation; and drying flocculate or precipitate, mixing and vulcanizing to obtain the graphite / rubber composite material. The latex (solution) blending process is introduced into preparation of the graphite / rubber nano-composite material to realize homogeneous dispersion of the graphite in a rubber matrix compound system by a nanoscale size, to cause good strengthening effect and prepare the rubber composite material with excellent mechanical property, low frictional coefficient and high abrasive resistance.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing graphene oxide/white carbon black/rubber nanocomposite material

A method for preparing a graphene oxide / white carbon black / rubber nanocomposite material is described. The prepared graphene oxide / white carbon black / rubber nanocomposite material contains nanoscale graphene oxide and white carbon black that are highly dispersed. The nanocomposite material has a relatively high modulus, excellent wear resistance and tear resistance, a relatively low rolling resistance, and at the same time has a low air-permeability and excellent self-healing capability.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing high-dispersion white carbon black/rubber nano composite material

The invention relates to a method for preparing a high-dispersion white carbon black / rubber nano composite material. According to the invention, by means of mixing rubber latex and white carbon black water slurry to obtain a uniform mixed solution and forming a great amount of micro droplets of the mixed solution by utilizing a spray drying atomization process, the specific surface area of the mixed solution is obviously increased, so that the moisture in the mixed solution is rapidly removed in a drying medium of a spray drying device; and by means of introducing a gasified flocculating agent into spray drying carrier gas and combining the spray drying process with a flocculation process, the processes of ion flocculation, rapid dehydration and the like are carried out at the same time and the speed and the efficiency of the conversion process of the white carbon black / rubber mixed solution from a liquid phase to a solid phase are improved, so that the high-dispersion white carbon black / rubber nano composite material is prepared. The method is simple to operate, is energy-saving, has low cost and wide application range and is easy for industrialization. The white carbon black / rubber nano composite material product prepared with the method has excellent comprehensive performances.

Owner:BEIJING UNIV OF CHEM TECH

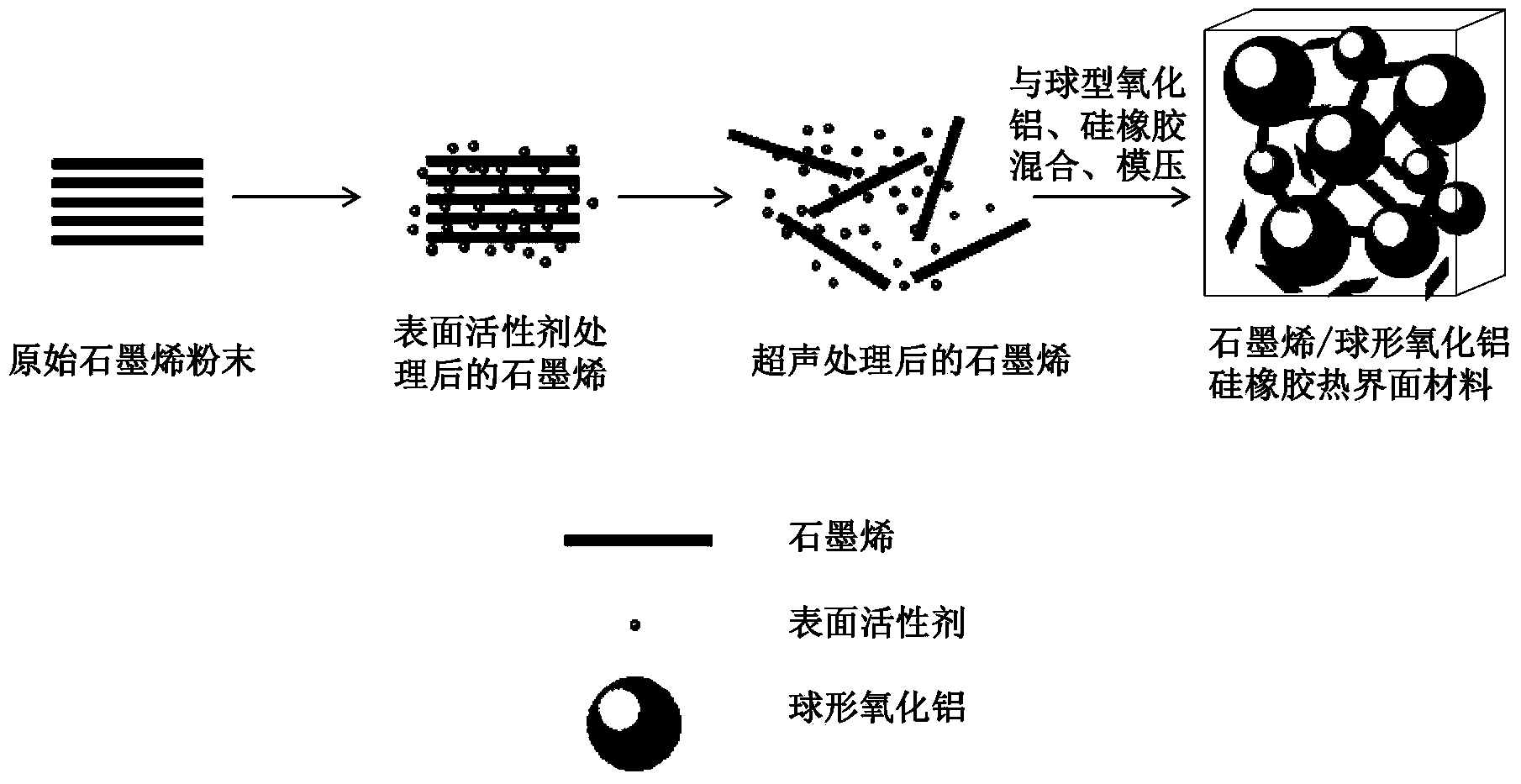

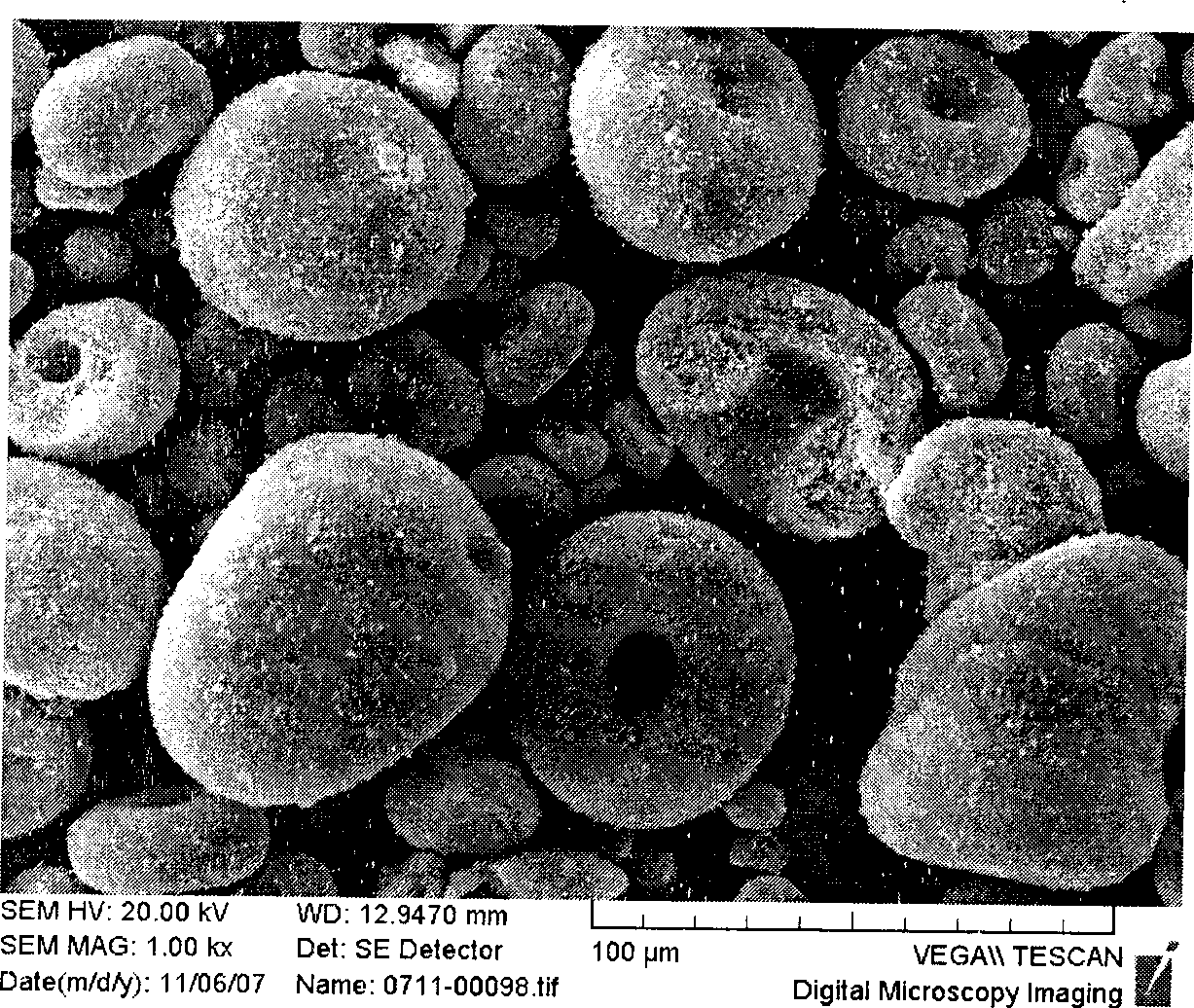

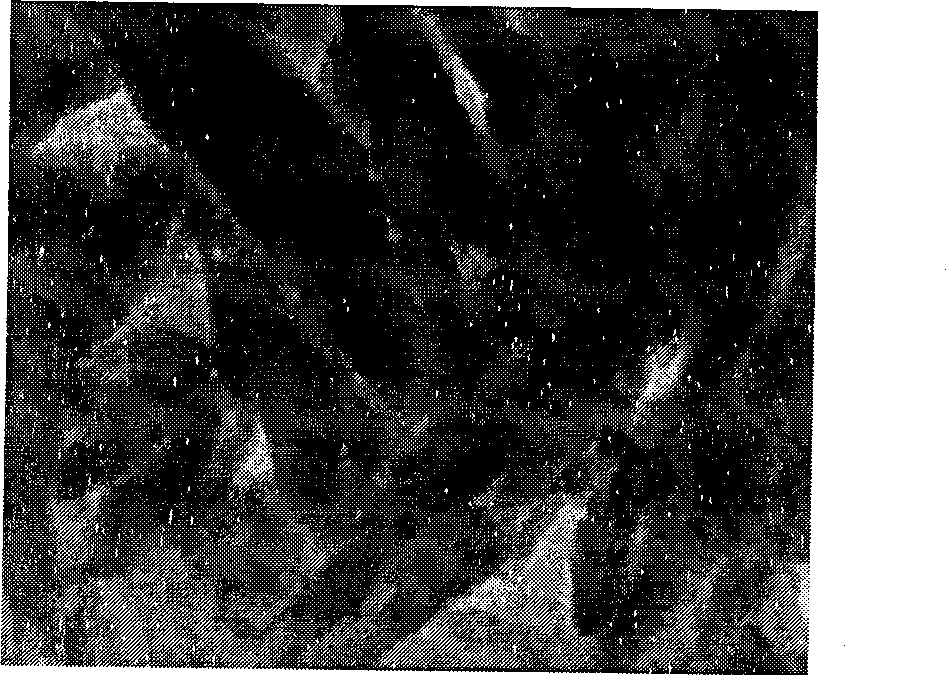

Heat-conducting electric insulation silicon rubber thermal interface material and preparation method thereof

The invention discloses a heat-conducting electric insulation silicon rubber thermal interface material and a preparation method thereof and belongs to the technical field of rubber nanocomposite materials. The preparation method comprises the following steps: treating graphene by employing a surfactant, ultrasonically dispersing the graphene into a relatively thin and uniform nano sheet structure, compounding the graphene with spherical aluminum oxide, adding compounded packing into raw silicon rubber dissolved by normal hexane for uniformly mixing, drying, adding a cross-linking agent, a catalyst and a polymerization inhibitor, vulcanizing and performing compression molding to obtain the heat-conducting electric insulation silicon rubber thermal interface material. The graphene is subjected to the surface treatment and is ultrasonically dispersed into a relatively thin sheet structure, and the formation of a heat-conducting network is promoted; moreover, due to the addition of a small amount of treated graphene, the heat-conducting performance can be greatly improved, the influence on the hardness of a composite material is small, and the composite material can reach an insulating level by controlling the amount of the graphene, so that the heat-conducting electric insulation silicon rubber thermal interface material can be applied to electronic products.

Owner:BEIJING UNIV OF CHEM TECH +1

Kaolin/rubber nano compound material with strengthening and obstructing dual property

InactiveCN101381488AEasy to processShorten vulcanization timeUltimate tensile strengthRubber nanocomposites

The invention relates to preparation of kaolin / rubber nano composite materials which simultaneously have strengthened property and gas barrier property by mixing nano kaolin powdery body and rubber and adding various matching accessory ingredients in the prior art of rubber production without changing manufacturing equipment. The diameter of a sheet layer of the nano kaolin is between 100 and 800 nanometers, and the thickness of the sheet layer is between 10 and 100 nanometers; the nano kaolin is kaolin with out-of-order crystallization; and the nano kaolin powdery body is processed by an organic modifier and granulated. The composite materials have good tensile strength, stretching strength, elasticity and elongation; and the air permeability of the composite materials is reduced by 30 to 80 percent compared with pure rubber.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

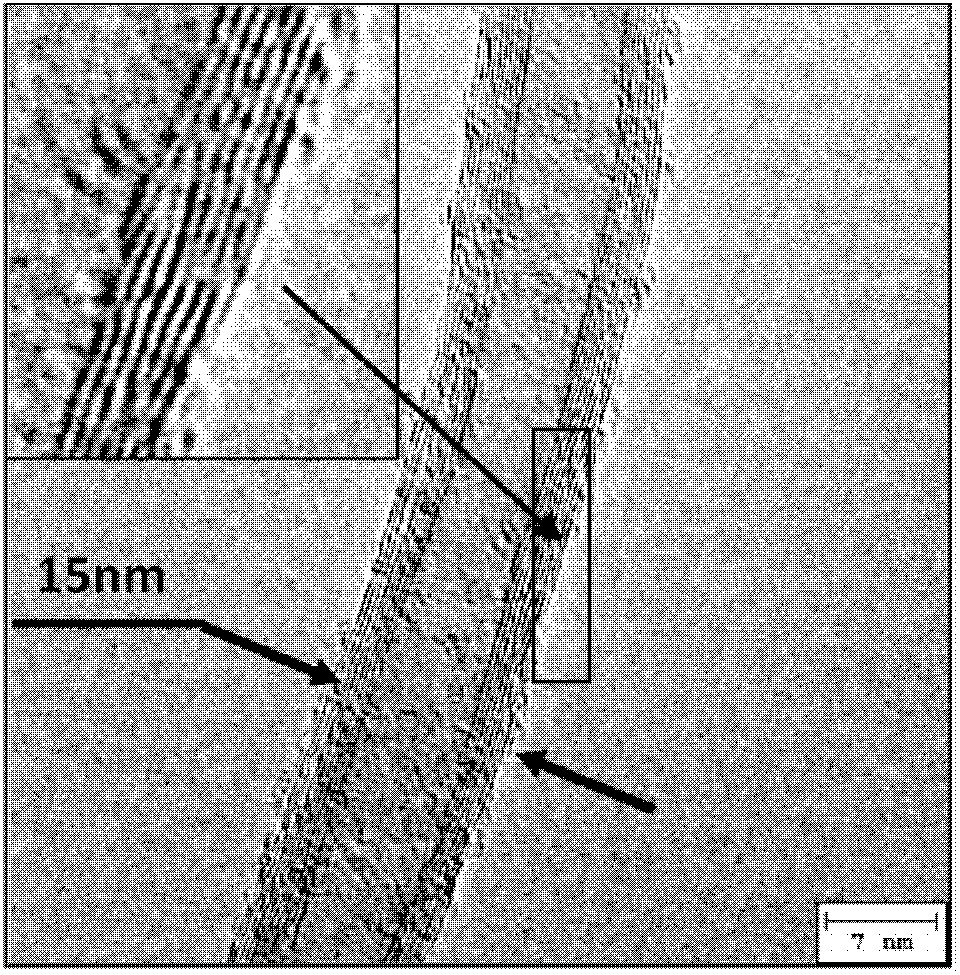

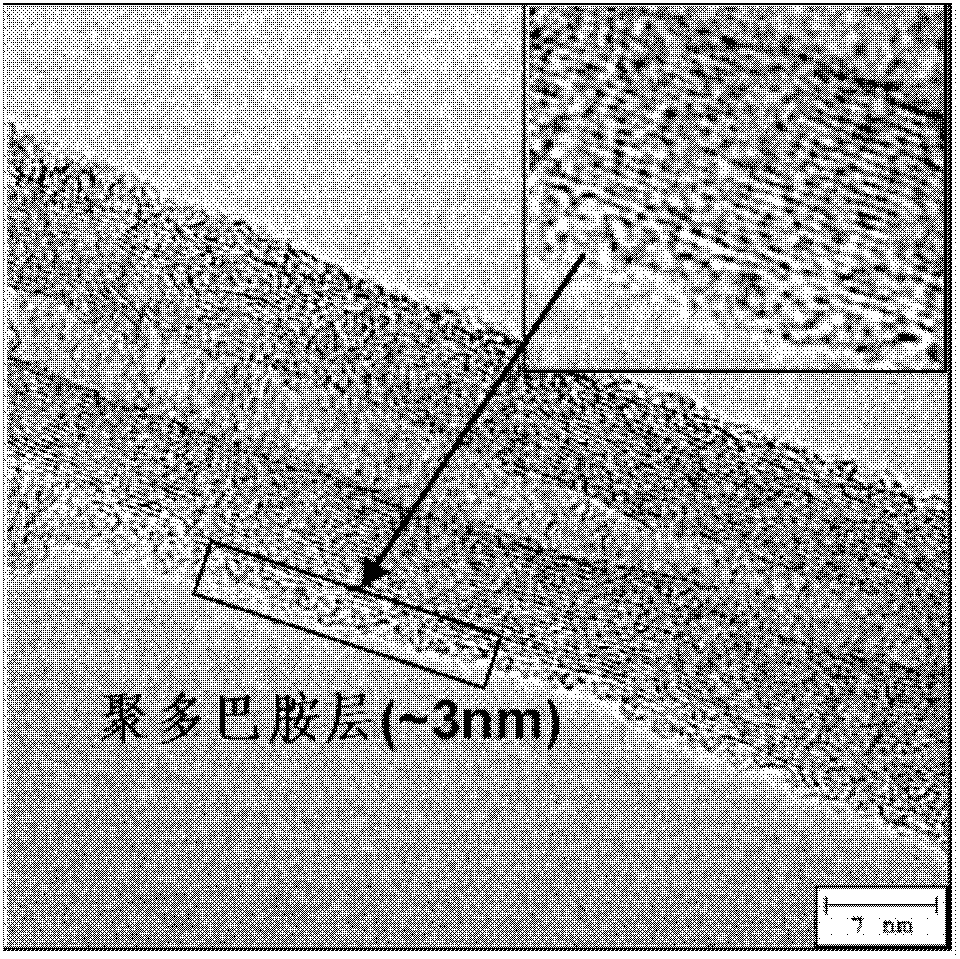

Dopamine modified carbon nanotube/rubber composite material and preparation method thereof

ActiveCN102321279AEvenly dispersedGive full play to reinforcementPigment treatment with non-polymer organic compoundsRubber materialMasterbatch

The invention discloses a dopamine modified carbon nanotube / rubber composite material and a preparation method thereof, and belongs to the technical field of rubber nano composite materials. The carbon nanotubes of which surfaces are modified by dopamine are uniformly dispersed into a rubber material. The preparation method comprises the following steps of: dispersing original carbon nanotubes into deionized water to keep pH value stably within a range of 5-8; adding the dopamine to sediment and polymerize at room temperature so as to obtain the carbon nanotubes with dopamine modified surfaces; adding modified carbon nanotubes into the deionized water to form carbon nanotube-deionized water suspension; and dropwise adding the suspension into latex, continuously mechanically stirring to obtain carbon nanotube-latex mixed solution, and dropwise adding into a demulsifier to perform flocculation, breaking and drying so as to obtain the carbon nanotube / rubber composite material in a masterbatch state. By adopting the conventional mechanical blending method, an auxiliary agent is added into the master batch. The tensile strength, the stress at definite elongation and the thermal conductivity of the composite material are correspondingly improved.

Owner:BEIJING UNIV OF CHEM TECH

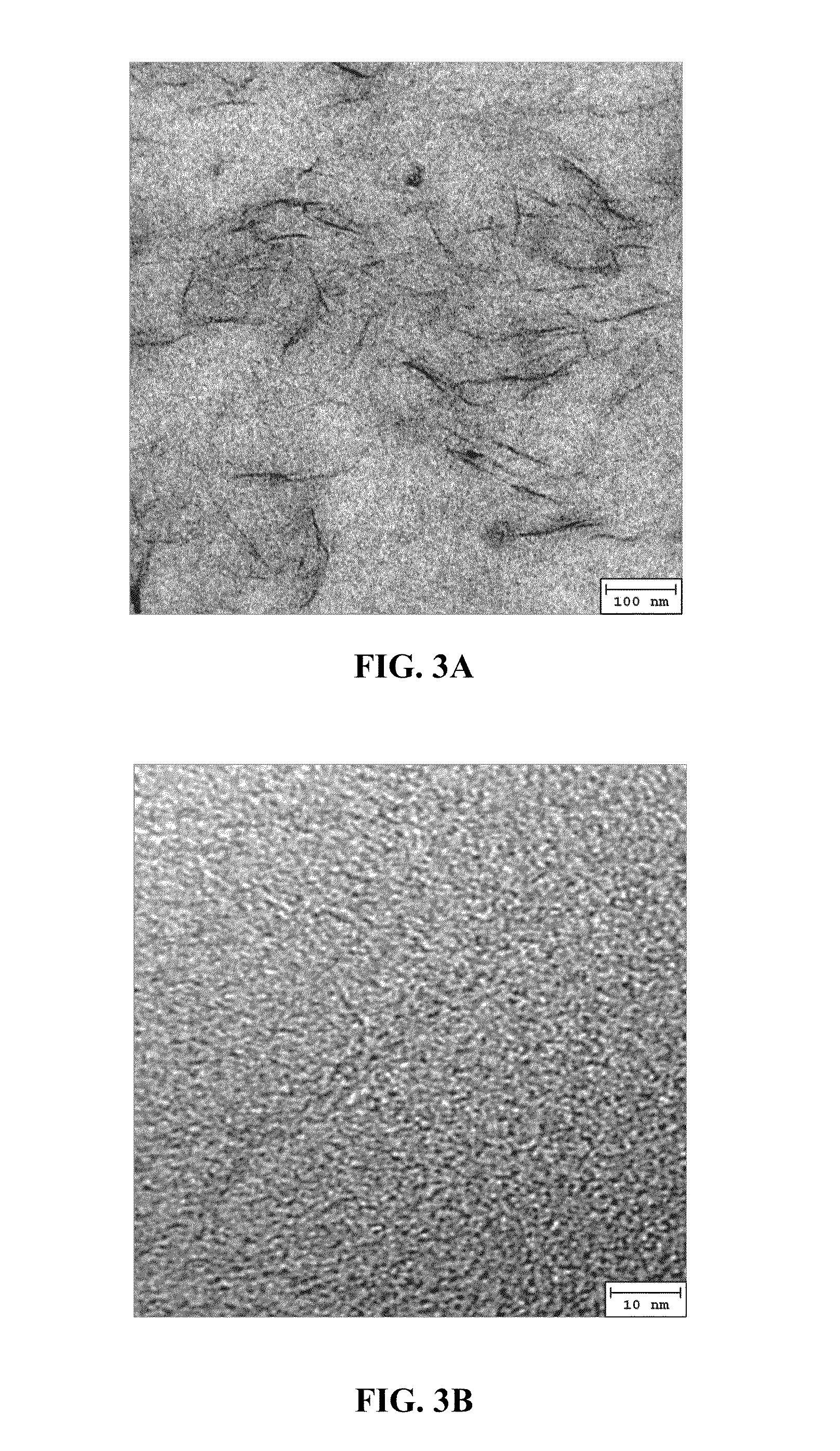

Process for preparing completely delaminated graphene oxide/rubber nanocomposite

A process for preparing a completely delaminated graphene oxide / rubber nanocomposite. The process combines emulsion compounding with flocculation or spray drying, retains the morphology of graphene oxide / rubber composite in a liquid state, and achieves highly dispersed and highly delaminated morphology dispersed on nano scale. Furthermore, a substance able to produce ionic bonding or chemical bonding with the surface functional groups of graphene oxide is added to graphene oxide / hydrosol, as a surfactant, thus the interfacial bonding between graphene oxide and the rubber is increased. The composite is subjected to subsequent compounding and vulcanization to prepare a vulcanizate with dynamic performance, such as a high tensile strength, stress at a definite elongation, tearing strength, etc.

Owner:BEIJING UNIV OF CHEM TECH

Clay rubber nano-composite material used for cover layer of conveyor belt and preparation method thereof

The invention relates to a clay rubber nano-composite material used for the cover layer of a conveyor belt and a preparation method thereof. The material can be used to support the use of various large carrying capacity and long distance conveyors, and is widely used in metallurgy, mining, ports and other heavy industries. The preparation method of the clay rubber nano-composite material used forthe cover layer of a conveyor belt comprises: taking nano-clay and natural rubber to prepare nano-clay / natural rubber nano-composite masterbatch through an emulsion flocculation method, then adding synthetic rubber for plasticating, and then adding zinc oxide, stearic acid, an age resister, a coupling agent, and a reinforcing agent in order for first mixing, and adding sulphur as well as an accelerator for second mixing so as to obtain the product. The cover rubber of a conveyor belt manufactured with the clay rubber nano-composite material, and can have improved tensile strength, tearing resistance and shearing resistance, so that the service life of the conveyor belt can be prolonged. In the preparation process, the employment of a small amount of nano-clay and a lot of carbon black together to serve as a filling system can have an enhancing effect, and besides, the lamellar structure of the nano-clay can effectively inhibit gas and heat transfer, thus improving the thermo-oxidativeaging resistance, and making the conveyor belt difficult to age when used in an open-air environment for a long time.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

Composites comprising elastomer, layered filler and tackifier

The invention relates to rubber nanocomposites particularly suitable for innerliners and other tire applications. The uncured nanocomposite comprises an elastomer, tackifier and nanoclay.

Owner:EXXONMOBIL CHEM PAT INC

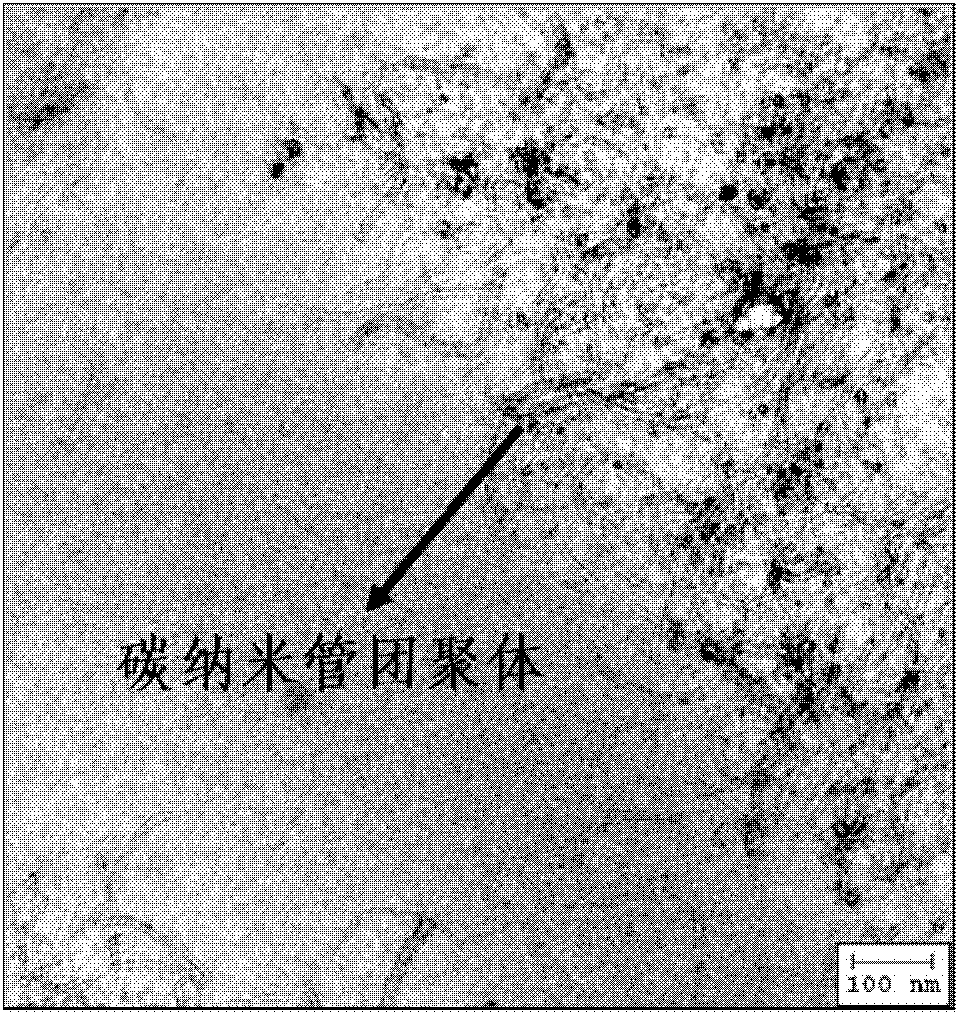

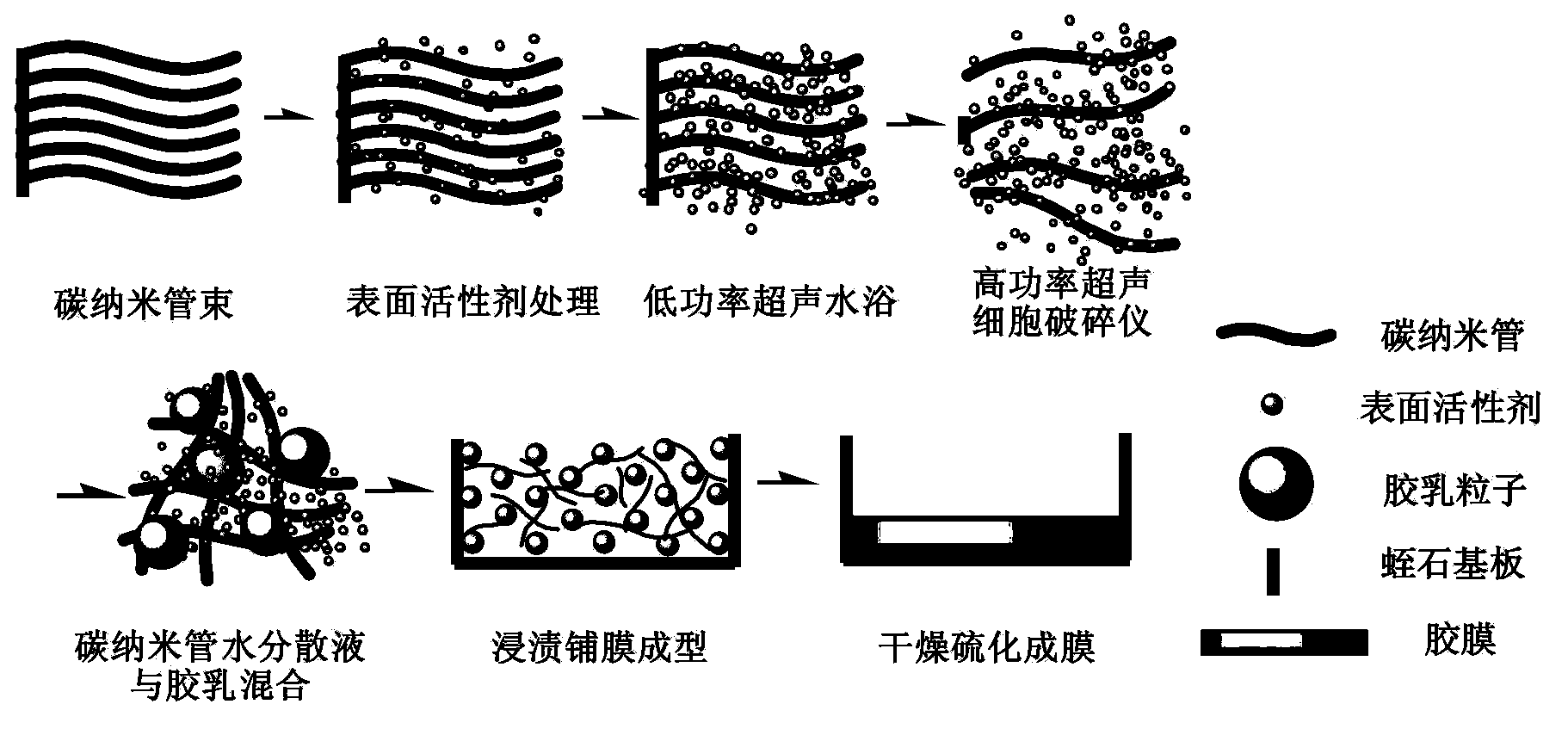

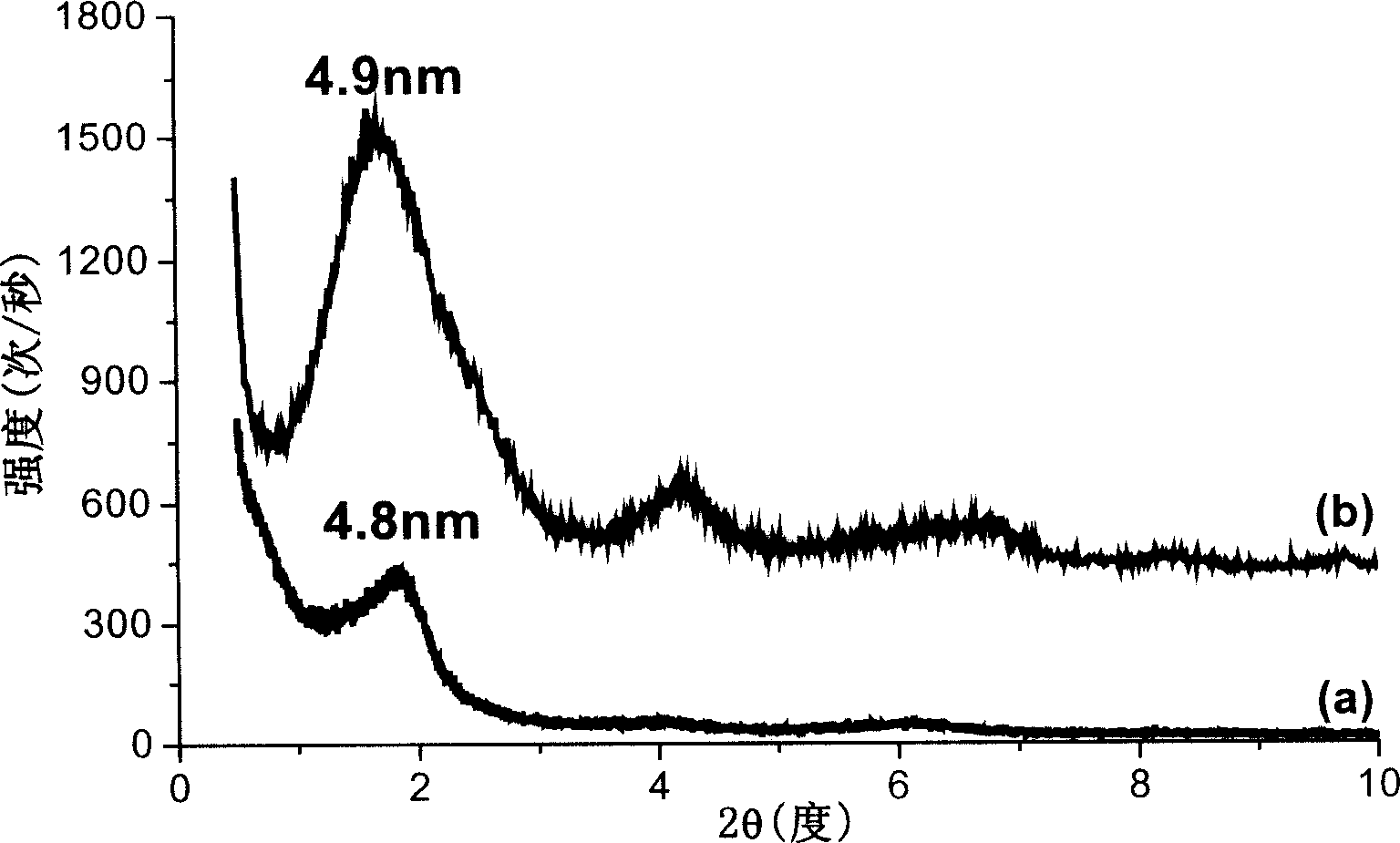

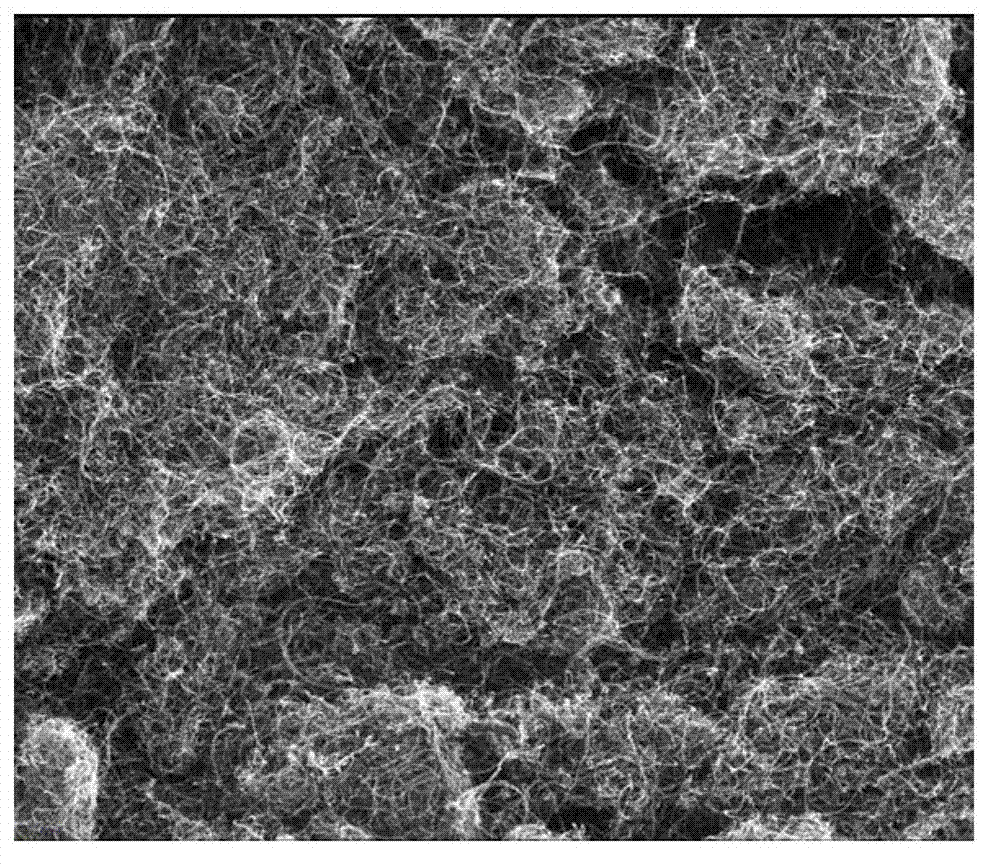

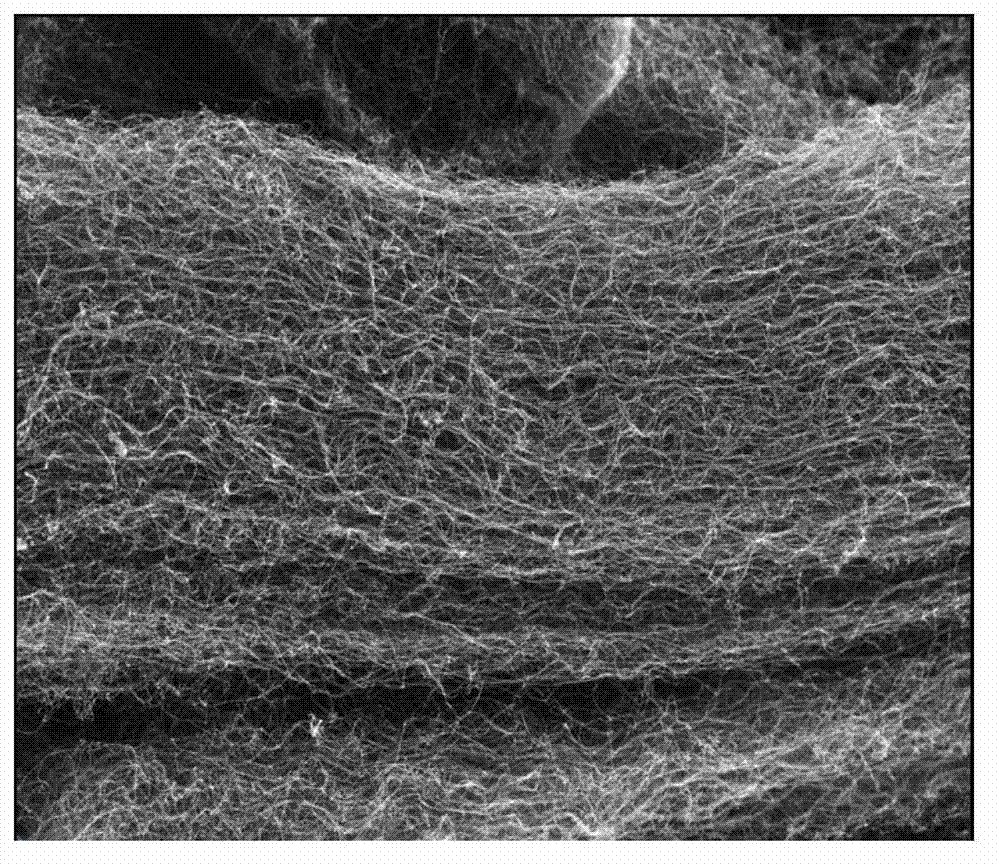

High-conductivity carbon nanotube/rubber nanocomposite and preparation method thereof

The invention provides a high-conductivity carbon nanotube / rubber nanocomposite and preparation method thereof, and belongs to the field of nanocomposite technology. The invention employs an oriented growth carbon nanotube bundle, and the oriented growth carbon nanotube bundle is added into a surfactant aqueous solution, and is subjected to ultrasonic treatment with different powers in sequence, thereby ensuring the carbon nanotubes are uniformly dispersed in water. The carbon nanotube dispersion liquid and the pre-vulcanized latex are mixed, after mechanical stirring and uniformly mixing, the carbon nanotube / latex mixing liquid is poured into an organic glass mould by using a dipping and film spreading process, and the liquid is dried at room temperature for vulcanizing moulding. The carbon nanotube in the obtained carbon nanotube / rubber composite material prepared by the method has the advantages of higher length-diameter ratio and better dispersibility, good compatibility with rubber matrix, and substantially increased conductivity of vulcanizate.

Owner:BEIJING UNIV OF CHEM TECH

Modified clay and rubber composite material preparation method

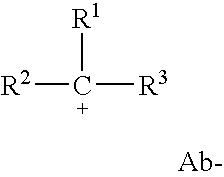

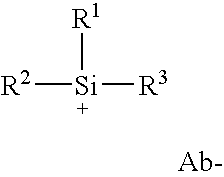

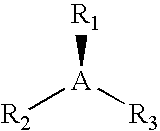

The preparation process of composite material of modified clay and rubber includes mixing organic modifier aqua and clay via stirring to obtain mixed system of organic modifier and clay, and preparing composite material of clay and rubber with the mixed system of organic modifier and clay to replace organic modified clay and rubber. The mixed system of organic modifier and clay has average clay grain size smaller than 80 microns, montmorillonite content in clay not lower than 90 %, mass ratio between water and clay of 1-2, and mass ratio between clay and organic modifier of 100 to 0.11*M, where M is molecular weight of the organic modifier. The rubber matrix may be natural rubber, styrene-butadiene rubber, chloroprene rubber, or other rubber. The present invention is one simple, feasible and low cost process of preparing nanometer composite material of clay and rubber.

Owner:BEIJING UNIV OF CHEM TECH

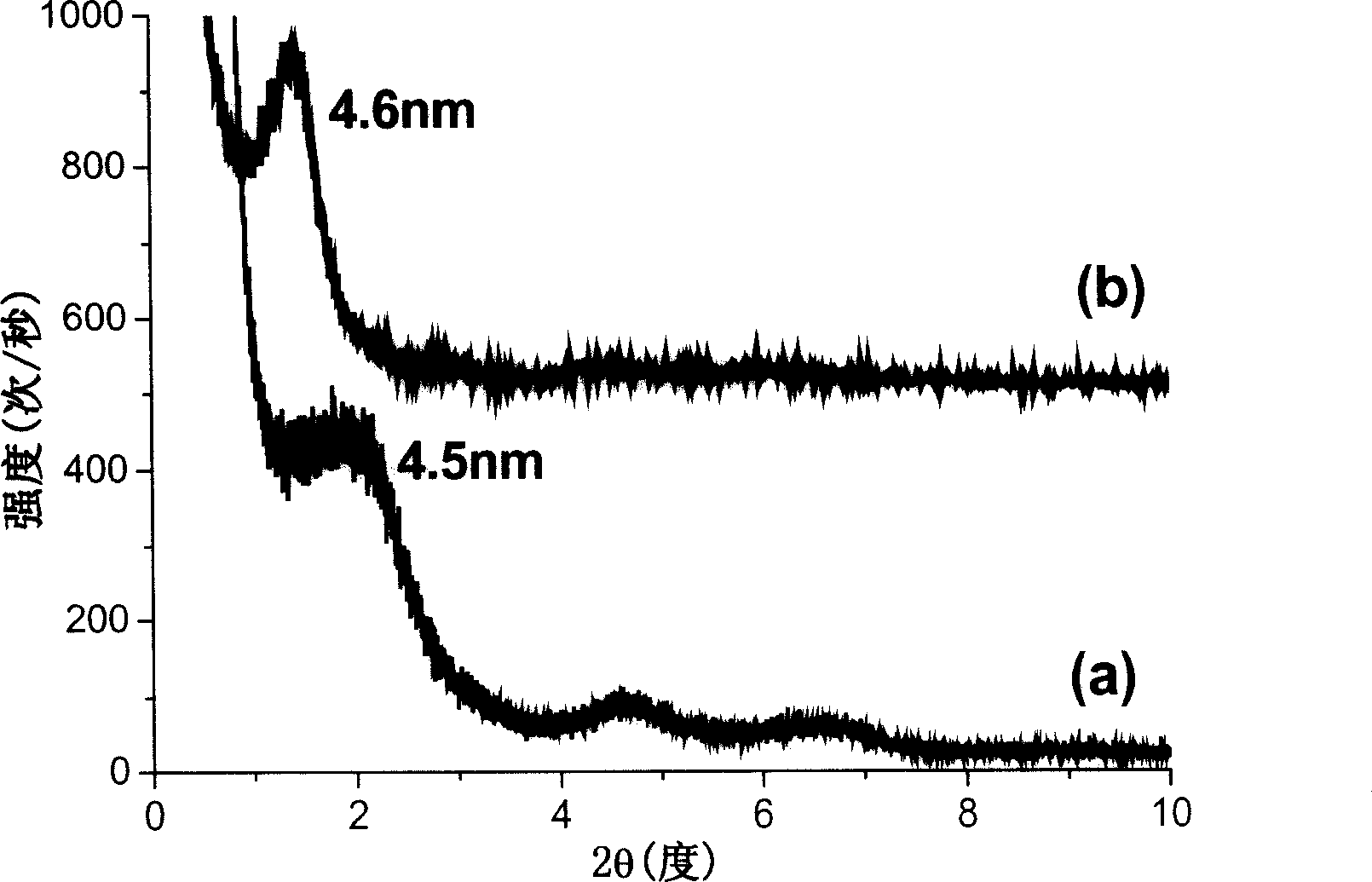

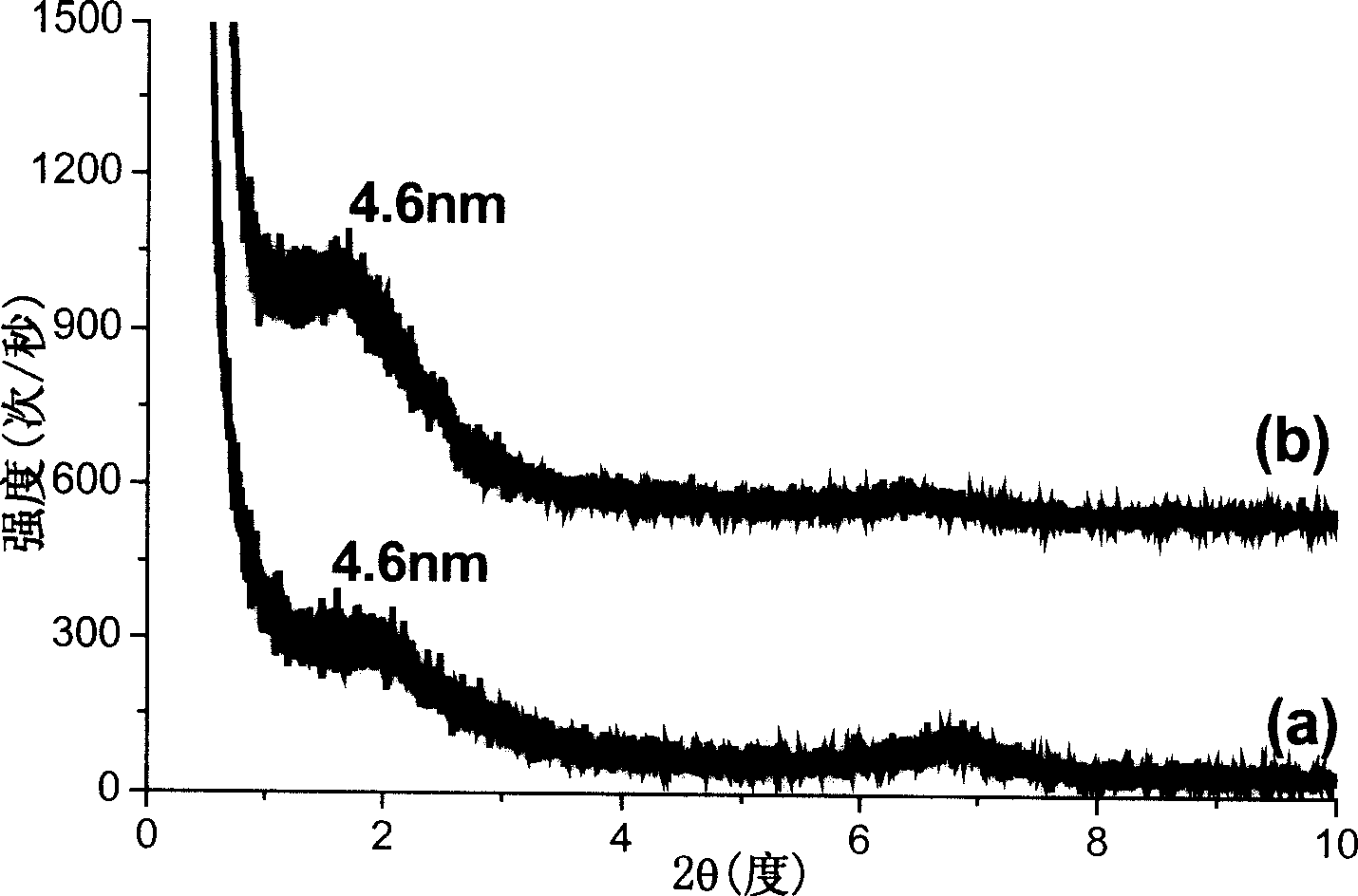

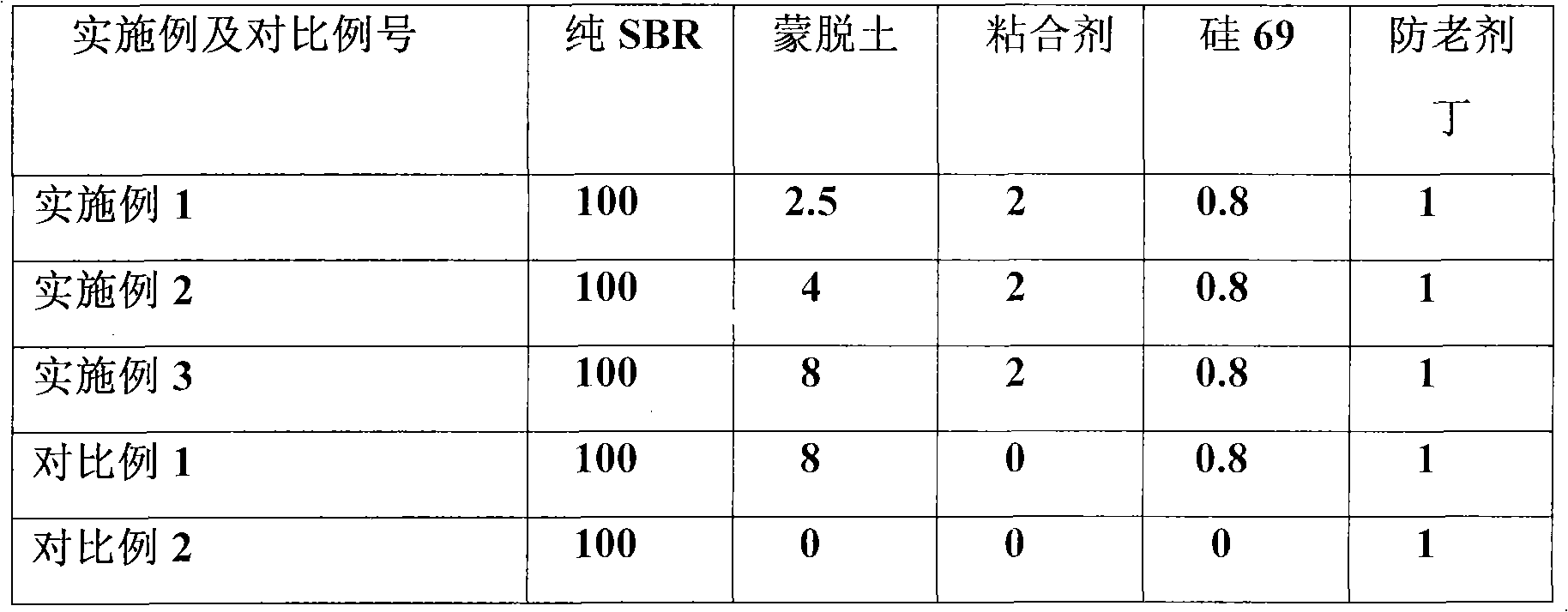

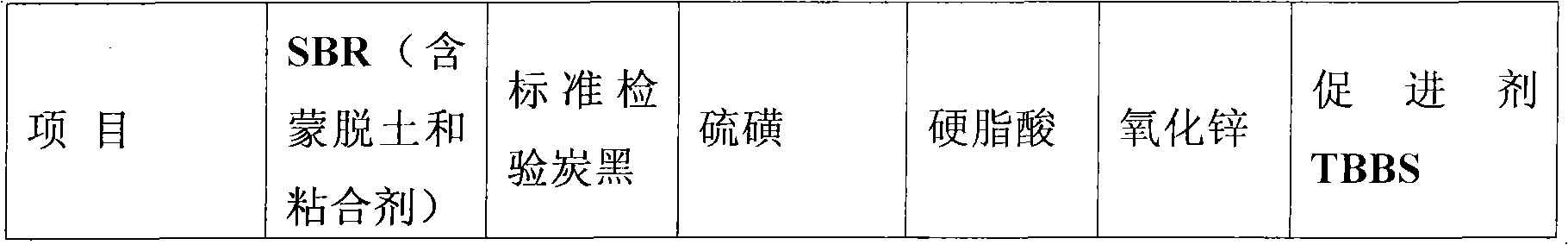

Montmorillonite-styrene butadiene rubber nanocomposite material

The invention discloses a montmorillonite-styrene butadiene rubber nanocomposite material. The montmorillonite-styrene butadiene rubber nanocomposite material is a composition of macromolecular compounds. The montmorillonite-styrene butadiene rubber nanocomposite material comprises: by weight, 416 parts of butadiene-styrene emulsion having solid content of 24%, 10 to 120 parts of organic modifiedmontmorillonite fluid suspension, 1 to 8 parts of adhesive emulsion, 0.2 to 20 parts of a coupling agent, 0.2 to 2 parts of an antioxidant, 1.5 to 8 parts of a flocculating agent, 2000 to 5000 parts of an inorganic salt-flocculating agent aqueous solution, an appropriate amount of an inorganic acid and an appropriate amount of an inorganic base. A preparation method of the montmorillonite-styrenebutadiene rubber nanocomposite material comprises thr following steps of 1, carrying out preprocessing of a part of the raw materials, 2, carrying out premixing of a part of the raw materials, 3, carrying out preliminary flocculation, 4, adding adhesive emulsion into flocculates obtained by the step 3, and 5, carrying out secondary flocculation. The montmorillonite-styrene butadiene rubber nanocomposite material and the preparation method thereof have the advantages that flocculated styrene butadiene rubber particle sizes are large; a montmorillonite reinforcement effect is improved obviously; vulcanizate wear resistance is improved several times; an original styrene butadiene rubber polymerization technology is not changed but processes and a formula are improved simply; and continuous industrialized production is realized.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing pretreated white carbon black/natural rubber composite material

The invention relates to a method for preparing a pretreated white carbon black / natural rubber composite material, relates to the technical field of property improvement on natural rubber composite materials, and is used for solving the problem that natural latex is easy to be cured at an early stage in an experiment process. Firstly, the white carbon black is treated by using a coupling agent to organize the surface of the white carbon black, so that the mutual action between the white carbon black and the rubber is improved; secondly, a white carbon black / rubber nano composite material is obtained through flocculation, washing and drying processes. The method comprises the following steps: firstly, normally stirring and premixing the white carbon black with water, subsequently dropping the coupling agent to modify, further mixing with the natural latex, and finally flocculating, washing and drying so as to obtain the white carbon black / rubber nano composite material. As the white carbon black is uniformly dispersed in natural rubber liquid slurry added with the white carbon black, the white carbon black / rubber nano composite material can be directly used for machining and preparing rubber products such as vulcanized natural rubber which is modified by the white carbon black.

Owner:BEIJING UNIV OF CHEM TECH

Peroxide curable rubber compound containing high multiolefin halobutyl ionomers

InactiveUS20100010140A1Optimize level of residualEasy curingMaterial nanotechnologyIonomerPolymer science

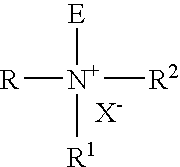

The present invention relates to a peroxide curable rubber nanocomposite compound comprising a peroxide curative, a nanoclay and a high multiolefin halobutyl ionomer prepared by reacting a halogenated butyl polymer having a high mol percent of multiolefin with at least one nitrogen and / or phosphorus based nucleophile. The resulting high multiolefin halobutyl ionomer comprises from about 2 to 10 mol % multiolefin. The present invention is also directed to a shaped article comprising the rubber compound.

Owner:LANXESS LTD

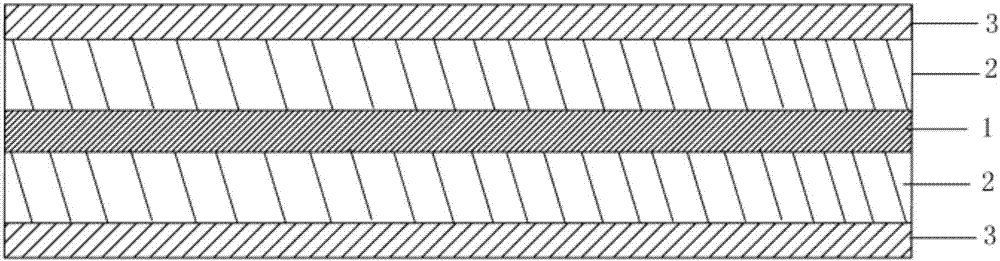

High-tenacity waterproof coiled material and preparation method

InactiveCN106881927AImprove toughnessImprove waterproof performanceSynthetic resin layered productsLaminationGlass fiberPolymer modified

The invention discloses a high-toughness waterproof coiled material and a preparation method thereof, belonging to the field of waterproof coiled materials. The waterproof coiled material includes: a substrate layer, the upper and lower surfaces of the substrate layer are respectively provided with self-adhesive waterproof layers, and the surfaces of the self-adhesive waterproof layers are respectively provided with isolation protection layers. Wherein, the base material layer is an alkaline glass fiber felt layer, the self-adhesive waterproof layer is a polymer modified asphalt, and the isolation protection layer is a PE film. The preparation steps include: (1) preparation of graphene / natural rubber nanocomposite material; (2) preparation of polymer modified asphalt; (3) preparation of waterproof coiled material. The waterproof coiled material of the present invention not only has good waterproof and anti-corrosion effects, but also greatly improves the toughness of the waterproof coiled material, and the existence of graphene makes the waterproof coiled material have better environmental stability, greatly extending the waterproof coiled material. service life and has a good application prospect.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

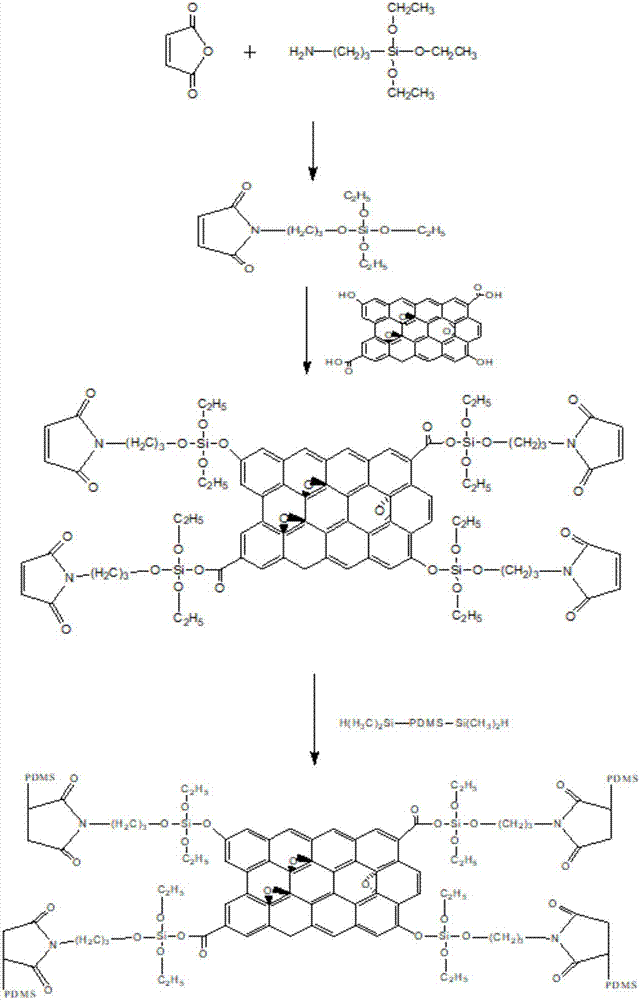

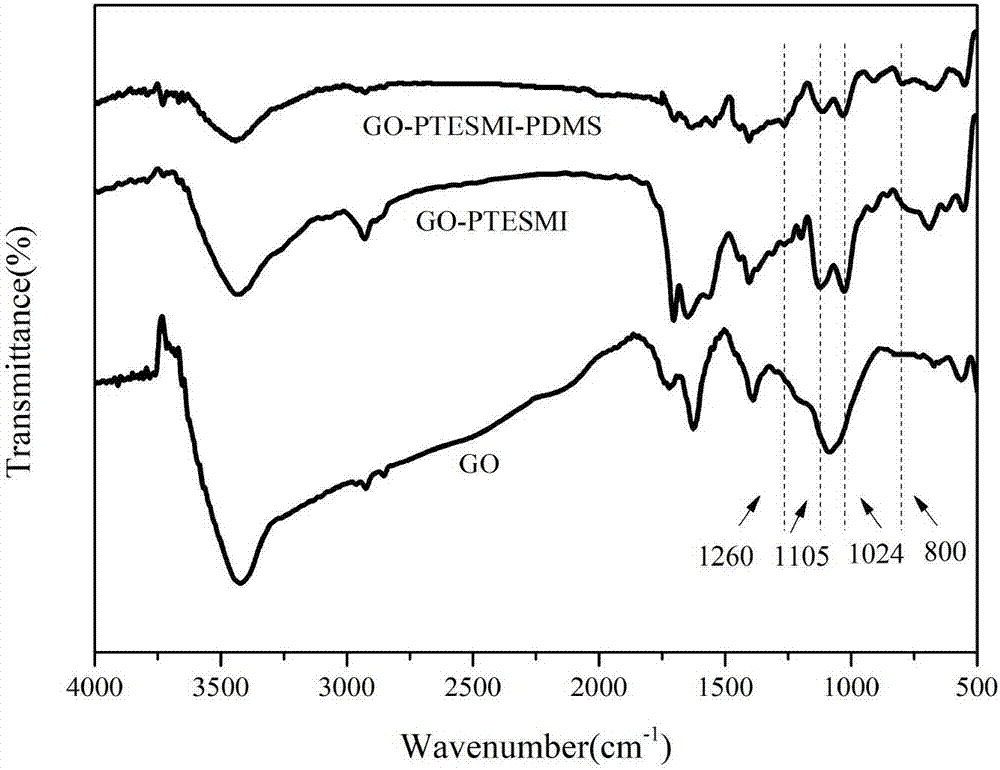

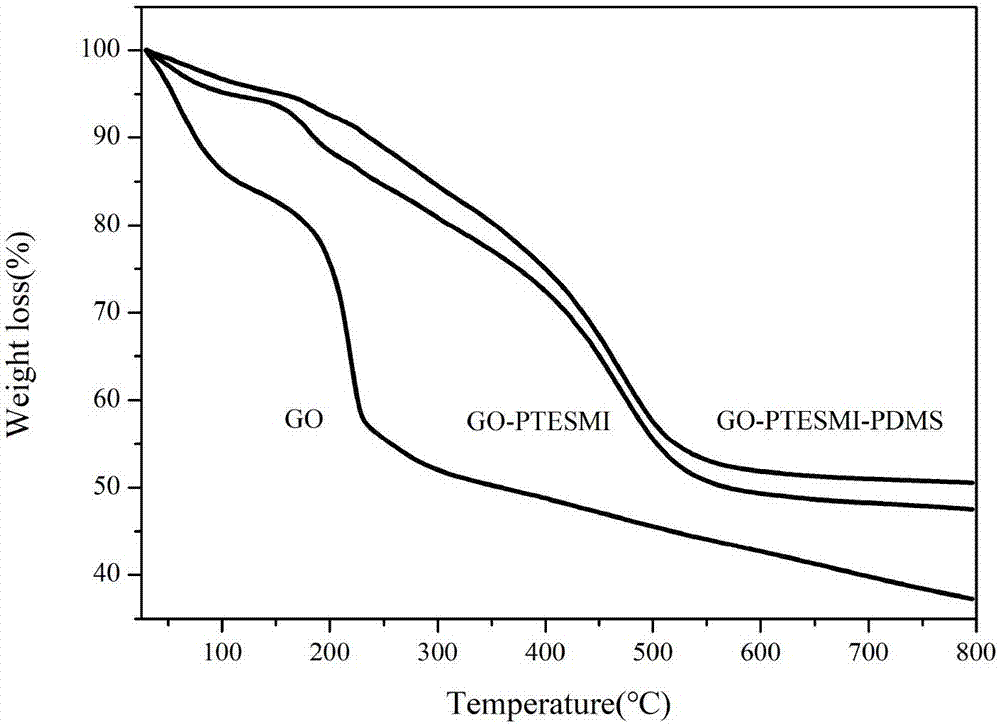

Functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and preparation method thereof

The invention discloses a functionalized GO (graphene oxide) and RTV (room temperature vulcanization) silicone rubber nanocomposite and a preparation method thereof. The method comprises steps as follows: firstly, the surface of GO is grafted with maleimide siloxane, GO-PTESMI is obtained, then double bonds of maleimide on grafting chains in GO-PTESMI are subjected to a hydrosilation reaction with Si-H group terminated PDMS (polydimethylsiloxane) in a solution, and GO (functionalized GO) with surface linked with PDMS grafting chains containing imide groups is prepared; then the functionalized GO is dispersed in a dispersing agent uniformly, and the silicone rubber nanocomposite with different content of functionalized GO is prepared through solution blending. According to the invention, imide bonds and polysiloxane long chains are introduced to the surface of GO, so that interface interaction force and mechanical properties of the nanocompoiste can be improved simultaneously, and the RTV silicone rubber material with capacity of playing excellent performance of GO better is prepared.

Owner:FUJIAN NORMAL UNIV

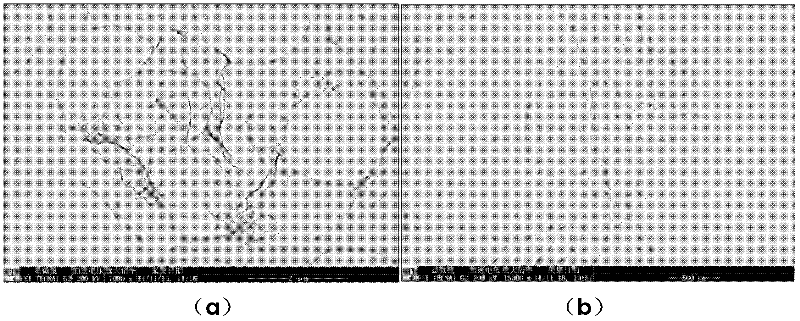

Preparation method of preprocessed clay/rubber nano composite material

The invention relates to a preparation method of a preprocessed clay / rubber nano composite material. The preparation method comprises the following steps: first subjecting the clay to an acid process to increase the reactive hydroxyl groups on the clay surface; subjecting the acid-processed clay to carry out grafting reactions with a silane coupling agent in a water phase, wherein the grafting amount is 0.1-1.1*10<-3> mole for each gram of clay; stirring and mixing the water suspension containing the clay grafted with a silane coupling agent with rubber emulsion, then subjecting the mixture to processes of flocculating, washing, drying, mixing, and vulcanizing so as to obtain the clay / rubber nano composite material. The reactive hydroxyl group number on the clay surface is increased through the acid process, thus the grafting amount of the silane coupling agent is increased, so that the interaction between the clay and the rubber is strengthened. The preparation method provided by the invention strengthens the interfacial strength between the clay and the rubber, solves the severe clay aggregation problem caused by high-temperature and high pressure during the sulfuration process at the same time, and obtains a high surface strength, high performance, and high dispersant clay / rubber nano composite material.

Owner:BEIJING UNIV OF CHEM TECH

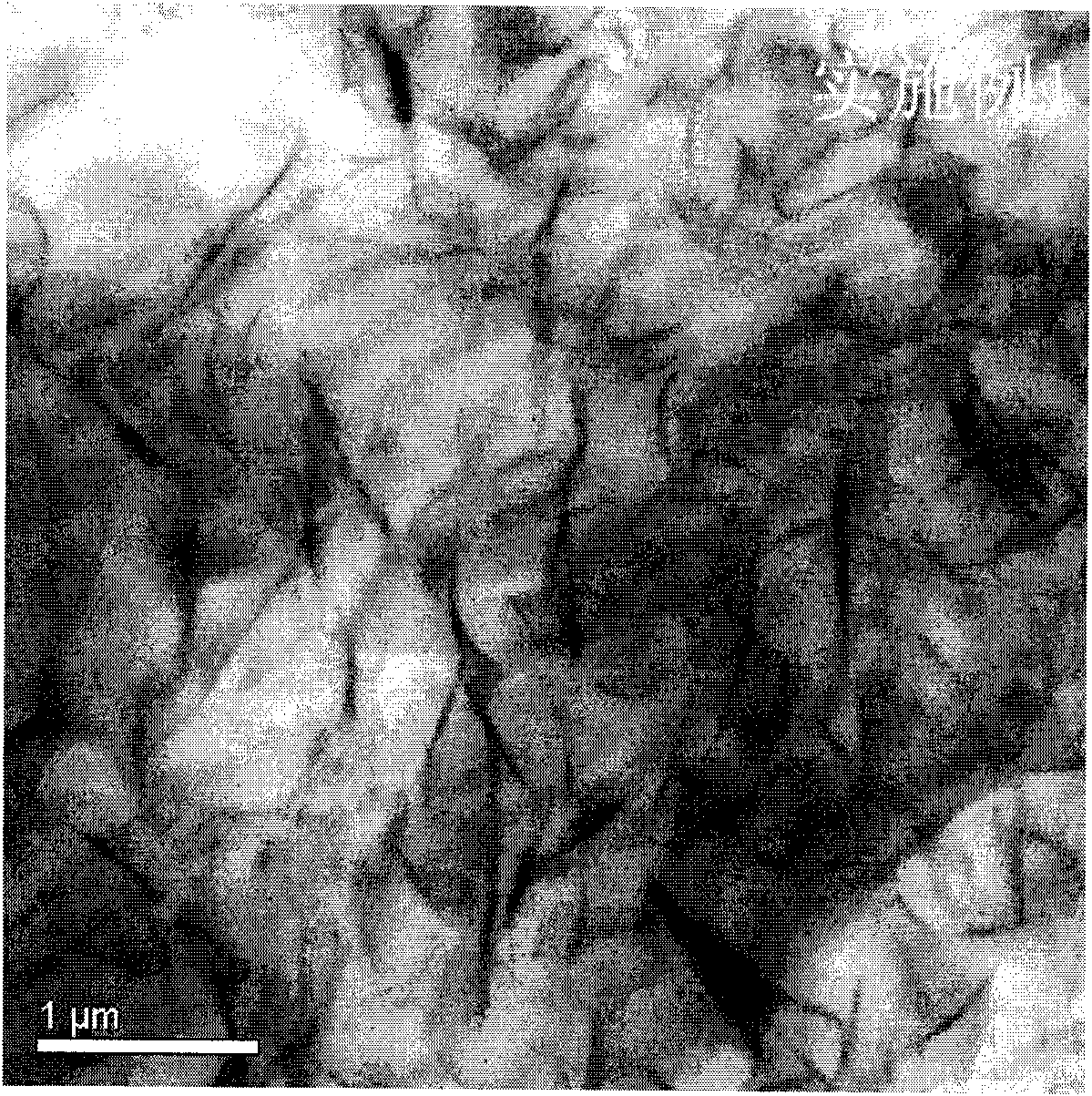

Preparation method of high-performance graphene oxide/carbon black rubber nanocomposite material

A preparation method of a high-performance graphene oxide / carbon black rubber nanocomposite material belongs to the field of rubber composite material. By combining technologies of compounding of graphene oxide and carbon black and rubber latex, composite emulsion co-flocculation and mechanical blending, the graphene oxide / carbon black rubber nanocomposite material is prepared. By emulsion compounding, graphene oxide and carbon black are intercrossing so as to effectively inhibit aggregation of the two fillers. Then, the highly-dispersed, highly-stripped and nanoscale-dispersed composite material is obtained. The rubber composite material prepared by the method can fully perform traditional advantages of a spherical filler and can perform effects of graphene oxide to the maximum. By the preparation method, mechanical strength, wear resistance and wet-skid resistance of the rubber composite material are enhanced, and thermogenesis is reduced. The preparation method is simple and feasible, is low-cost, is easy for industrialization, has a wide application range, and has good economic benefit and social effect.

Owner:BEIJING UNIV OF CHEM TECH

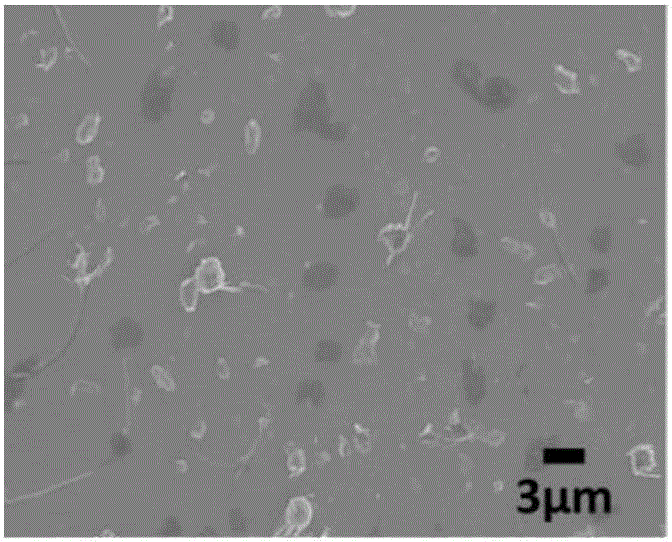

Method for preparing easily mixed high filling clay/rubber nano composite material

The invention discloses a method for preparing an easily mixed high filling clay / rubber nano composite material, which comprises the following steps of: blending rubber emulsion and clay / water suspension; breaking the emulsion by using electrolyte solution; forming flocculation granules of 1 to 100 microns; performing separation by using a hydraulic cyclone, washing and concentration; performing atomization and drying by using a spray drying process; and preparing powdery clay / rubber nano composite material with high clay filling quantity and high dispersion. The spray drying process solves the difficulty that the flocculated composite material with high clay filling part has fine colloidal particles and is not easy to filter and dry and the problem of difficult subsequent mixing and processing process and dispersion caused by hardening of the colloidal particles after the composite glue with high clay filling part is dried. Meanwhile, because the drying time of the product is shortened to dozens of seconds from several hours, the product has the advantages of low ageing, good dispersion and high performance.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing rubber nanocomposite by peeling expanded graphite through in-situ reaction

ActiveCN106496712AReduce van der Waals forcesImprove mechanical propertiesAcrylonitrileMaterials science

The invention relates to a method for preparing a rubber nanocomposite by peeling expanded graphite through an in-situ reaction. In an internal mixer, hydrogenated butadiene-acrylonitrile rubber, expanded graphite and diene or dienophile undergo a Diels-Alder reaction, and strong shearing force transmitted by rubber is employed, so chemically-modified expanded graphite is peeled in situ to prepare graphene, and the graphene / rubber nanocomposite is prepared in situ. The method has the advantages of mild reaction conditions, simple process and low energy consumption; almost no organic solvent is used in reaction process, so small pollution is posed to the environment; and the prepared graphene has good electrical conductivity and thermal conductivity, and the prepared rubber nanocomposite has excellent electrical conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing carbon nano tube/rubber nano composite matcrial by non-acidation treatment

The invention relates to a method to manufature carbon nm tube / rubber nm compounding material. The carbon nm tube directly reacts with polysulfide under the condition of the existing of nitroso compounding. The polysulfide covalence is grafted on the surface of the nm tube, the carbon nm tube and rubber molecules are covalence combined by sulphur atoms, the polymer molecules is covalence grafts on the tube surface of the carbon nm tube. The nm compounding material is manufactured by covalence grafting the carbon nm tube and the rubber. The invention could improve the dispersibility of carbon nm tube in rubber.

Owner:SHANGHAI JIAO TONG UNIV

Preparation process for improving bonding capacity of carbon nanotube with rubber molecule

InactiveCN1803939AGood dispersionHigh tensile strengthPigment treatment with non-polymer organic compoundsCarbon nanotubePolysulfide

The disclosed preparation method for carbon nano tube / rubber nano composite material to improve bonding capacity among molecule comprises: covalent binding polysulfide on carbon nano tube surface treated by acid; then blending the decorative tube and rubber to prepare the target; wherein, the said carbon nano tube is obtained by any one of following methods: 1) treating the tube with acid; then reacting with acylating agent and the polysulfide; 2) taking the acidized tube to react with polysulfide directly; 3) using functionalized tube to react with polysulfide. This invention introduces strong mutual action between the carbon nano tube and polymer to improve property of the composite material.

Owner:SHANGHAI JIAO TONG UNIV

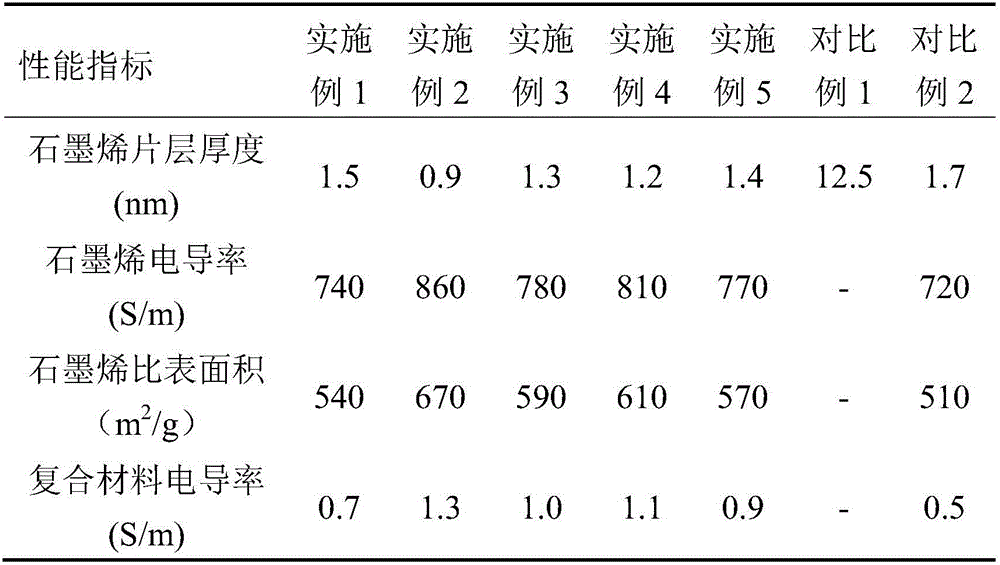

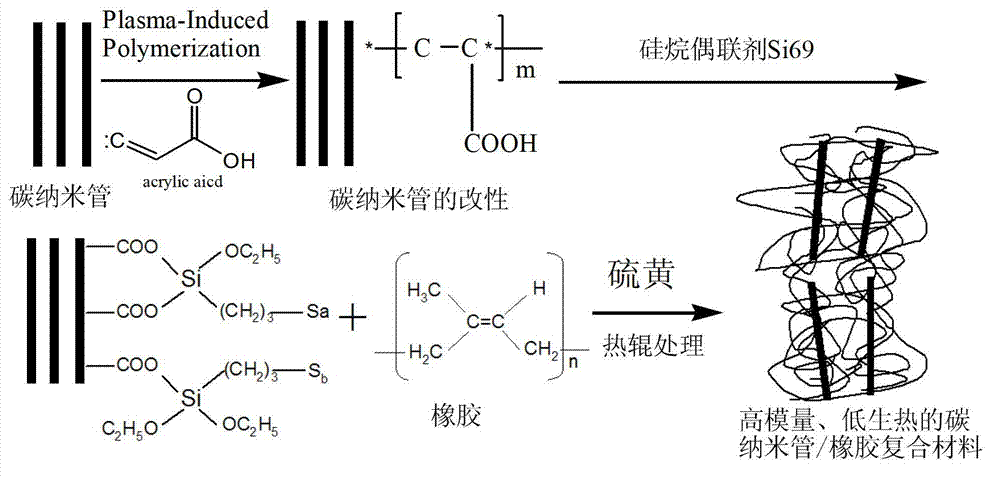

Preparation method of high-modulus low-heat carbon nano tube/ rubber composite material

A preparation method of a high-modulus low-heat carbon nano tube / rubber composite material belongs to the technical field of rubber nano composite materials and is characterized in that a method of plasma modification is utilized to precipitate a polyacrylic acid amorphous layer of 1-2nm on the surface of the carbon nano tube, the modified carbon nano tube and a silane coupling agent are added into rubber through a mechanical blending method, heating roller processing technology under high temperature state is adopted to further strengthen the interface combination effect and improve dispersion, and the modified carbon nano tube / rubber composite material is obtained by vulcanization under high temperature high pressure state. The carbon nano tube is a common carbon nano tube or a carbon nano tube with a one-dimension orientation arrangement structure, and the rubber is natural rubber, polyisoprene rubber, butadiene styrene rubber or butadiene rubber. The composite material prepared by the method greatly improves tensile strength, remarkably improves modulus, and simultaneously greatly compresses heating quantity.

Owner:BEIJING UNIV OF CHEM TECH

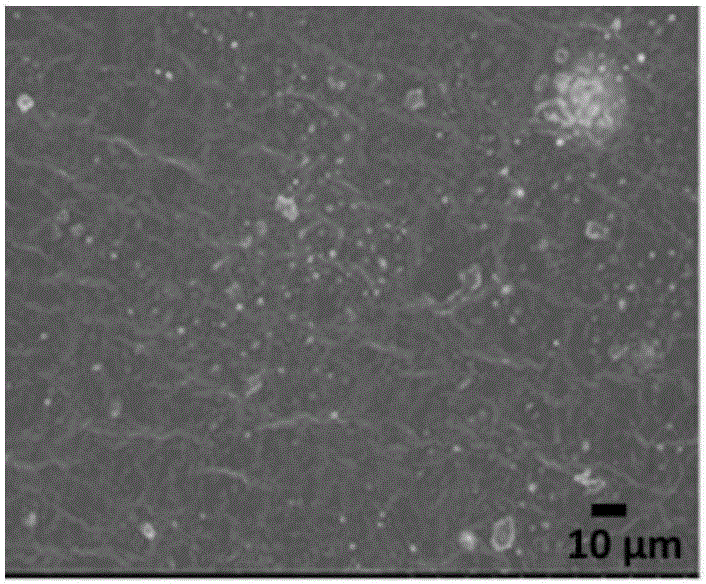

Preparation method of high-performance hydrotalcite/silicon dioxide/rubber nano composite material

ActiveCN104558724ASolve the problem of high filling and easy demulsificationTroubleshoot difficult process issuesHigh concentrationCrazing

The invention relates to a preparation method of a high-performance hydrotalcite / silicon dioxide / rubber nano composite material. The stability of a rubber latex system is dependent on the zeta potential value of the system and hydrotalcite is filled to easily destroy the stability of the rubber. The preparation method comprises the following steps: by adopting an emulsion grafting method, firstly adhering silicon dioxide on a hydrotalcite laminate in an emulsion system by using a silane coupling agent to reduce the zeta potential value of the filler system; and furthermore, adjusting according to increase of the use level of SiO2 with electronegativity and obtaining a hydrotalcite / silicon dioxide / rubber emulsion composite system with high concentration so as to prepare the highly filled hydrotalcite / rubber composite material. The material is endowed with preferable air impermeability due to the laminate effect of hydrotalcite. SiO2 is adhered on the hydrotalcite laminate by means of chemical reaction of the silane coupling agent, so that the organic compatibility is improved, and the material is endowed with good crack propagation resistance and mechanical property. The material is expected to be importantly applied in the field of a tire inner liner material, space flight and aviation seal, medical seal and the like.

Owner:BEIJING UNIV OF CHEM TECH

NANO composite material of rubber/layer silicate and preparation method

A rubber / layered silicate nanocomposite is prepared from rubber, organic modified-layered silicate monomer or mixed monomer and initiator. Its preparing process includes adding organic modified-layered silicate and reactable monomer in rubber mixing procedure or adding proper amount of initiator is necessary, realizing layer-insertion for layered silicate by home polymerization of monomer in course of rubber heating-valcanizing and simultaneously generating graft between rubber and mnonomer or same other chemical combination.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com