Preparation method of high-performance graphene oxide/carbon black rubber nanocomposite material

A nano-composite material and carbon black rubber technology, which is applied in the field of preparation of high-performance graphene oxide/carbon black rubber nano-composite materials, can solve the problems of high energy consumption, serious processing pollution, long mixing time, etc. Excellent thermal and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

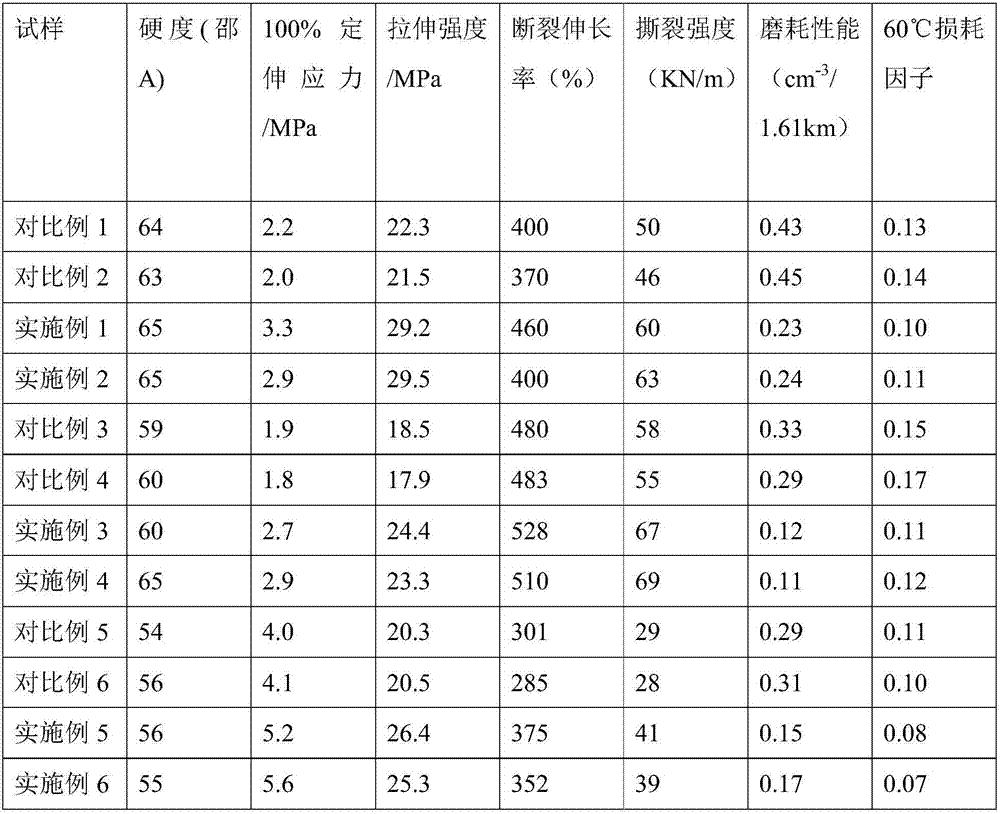

Examples

Embodiment 1

[0034] Natural rubber latex (dry rubber) 100 parts

[0035] Graphene oxide 1 part

[0036] Carbon black N220 20 parts

[0037] 2 parts stearic acid

[0038] Zinc oxide 5 parts

[0039] Antiaging agent 4010NA 1 part

[0040] Accelerator DM 2 parts

[0041] Sulfur 1.5 parts

[0042] Take 1g of graphite oxide and disperse it in the aqueous solution, ultrasonicate for 1min in the ultrasonic equipment, the ultrasonic power is 5000W, and the ultrasonic frequency is 50KHZ, to prepare an aqueous solution with a width of 5nm and a thickness of 5nm graphene oxide sheet. Weigh 20g of N220 carbon black with a particle size of 19nm, add 20g of sodium polystyrene sulfonate into 1kg of water, and ultrasonicate for 10 minutes in an ultrasonic device with an ultrasonic power of 5000W and an ultrasonic frequency of 50KHZ to prepare a well-dispersed carbon black aqueous solution. Take the graphene oxide aqueous solution and the carbon black aqueous solution prepared above and pre-mix them ...

Embodiment 2

[0044] Natural rubber latex (dry rubber) 100 parts

[0045] Graphene oxide 1 part

[0046] Carbon black N110 20 parts

[0047] 2 parts stearic acid

[0048] Zinc oxide 5 parts

[0049] Anti-aging agent RD 2 parts

[0050] Accelerator NS 1 part

[0051] Sulfur 2.5 parts

[0052]Take 1g of graphite oxide and disperse it in the aqueous solution, ultrasonicate in the ultrasonic equipment for 180min, the ultrasonic power is 50W, and the ultrasonic frequency is 1HZ, to prepare an aqueous solution with a width of 500um and a thickness of 0.335nm graphene oxide sheet. Weigh 20g of N110 carbon black with a particle size of 5nm, add 0.005g of sodium methylene dinaphthalene sulfonate NNO to 1kg of water, and ultrasonicate for 180min in an ultrasonic device with ultrasonic power of 50W and ultrasonic frequency of 1HZ to prepare well-dispersed carbon black aqueous solution. Take the graphene oxide aqueous solution and carbon black aqueous solution prepared above and pre-mix them in ...

Embodiment 3

[0054] 100 parts of styrene-butadiene rubber latex (dry rubber)

[0055] Graphene oxide 1 part

[0056] Carbon black N990 30 parts

[0057] 2 parts stearic acid

[0058] Zinc oxide 5 parts

[0059] Anti-aging agent RD 2 parts

[0060] Accelerator TMTD 0.8 part

[0061] 3 parts sulfur

[0062] Take 1g of graphite oxide and disperse it in the aqueous solution, ultrasonicate for 60min in the ultrasonic equipment, the ultrasonic power is 1KW, and the ultrasonic frequency is 1KHZ, to prepare an aqueous solution with a width of 100um and a thickness of 2nm graphene oxide sheet. Weigh 30g of N990 carbon black with a particle size of 500nm, add 10g of dispersant sodium dodecyl sulfate SDS to 1kg of water, and ultrasonicate for 120min in an ultrasonic device with an ultrasonic power of 2000W and an ultrasonic frequency of 3KHZ to prepare a well-dispersed aqueous solution of carbon black . Take the prepared graphene oxide aqueous solution and carbon black aqueous solution and pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com