Oxidized grapheme/carbon black rubber nanocomposite and preparation method thereof

A nanocomposite material and composite material technology are applied in the field of graphene oxide/carbon black rubber nanocomposite materials and their preparation, which can solve the problems of poor dispersion interface adhesion, limited improvement in modulus and hardness of composite materials, and degree of exfoliation of expanded graphite. not enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

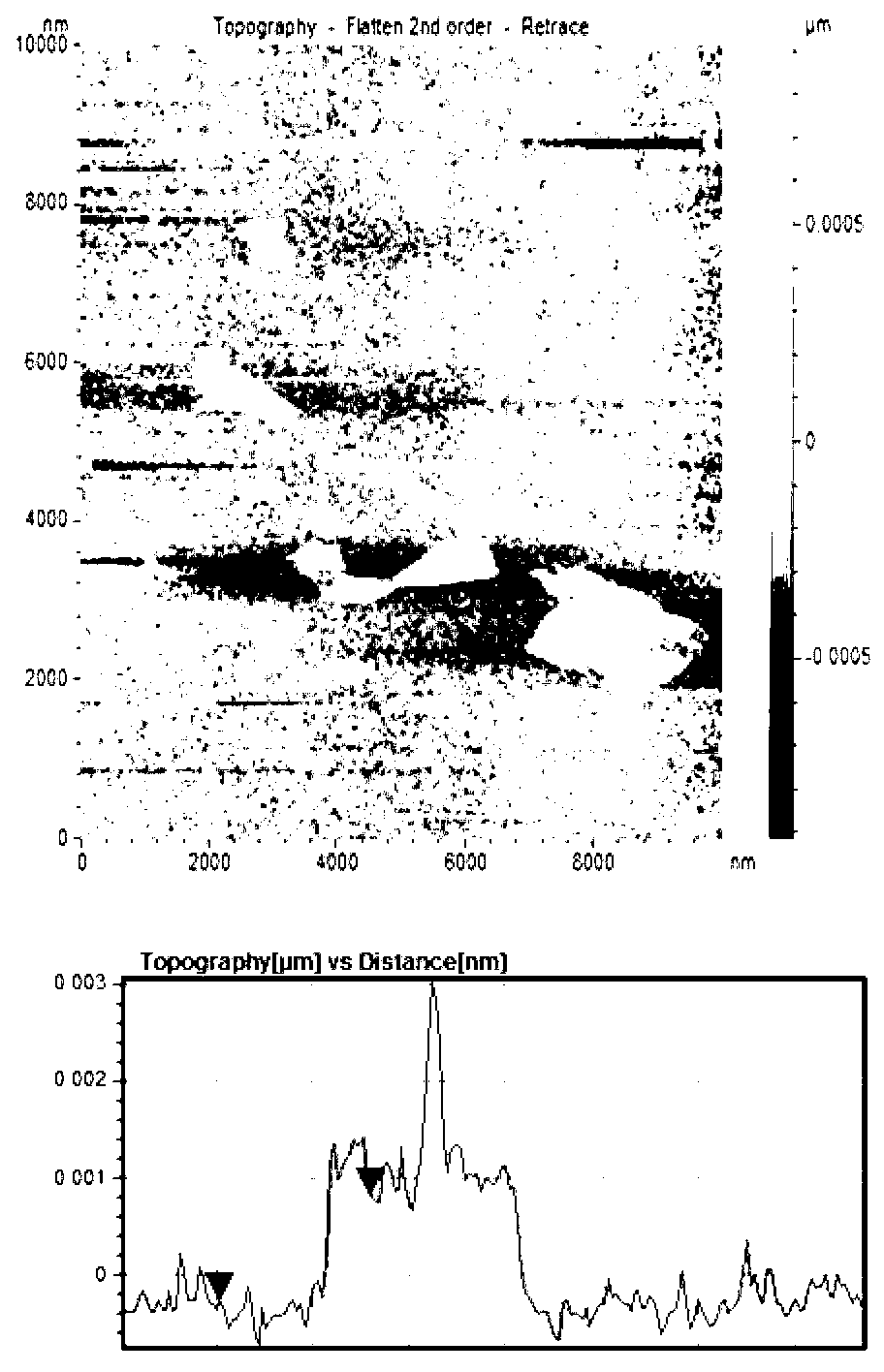

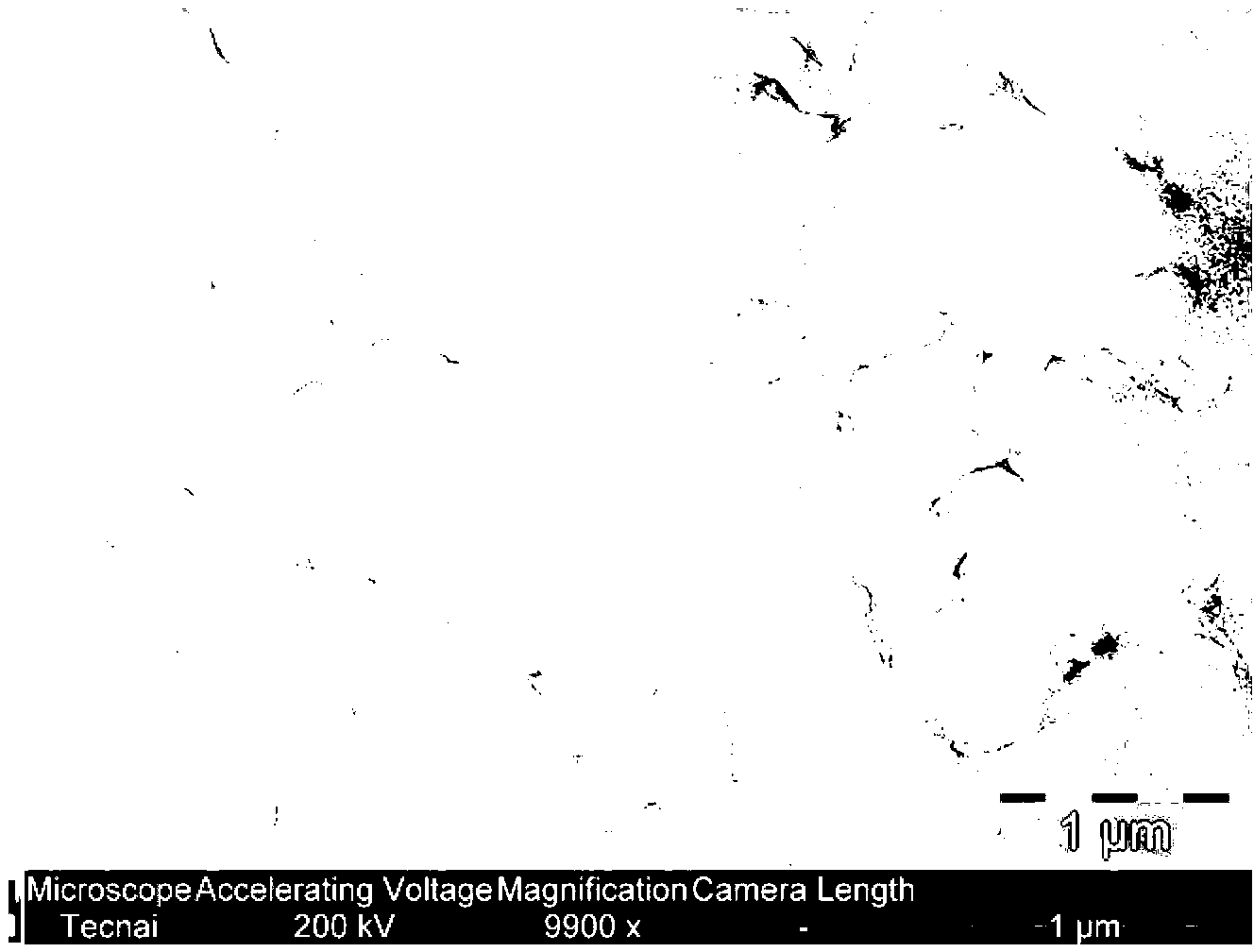

Image

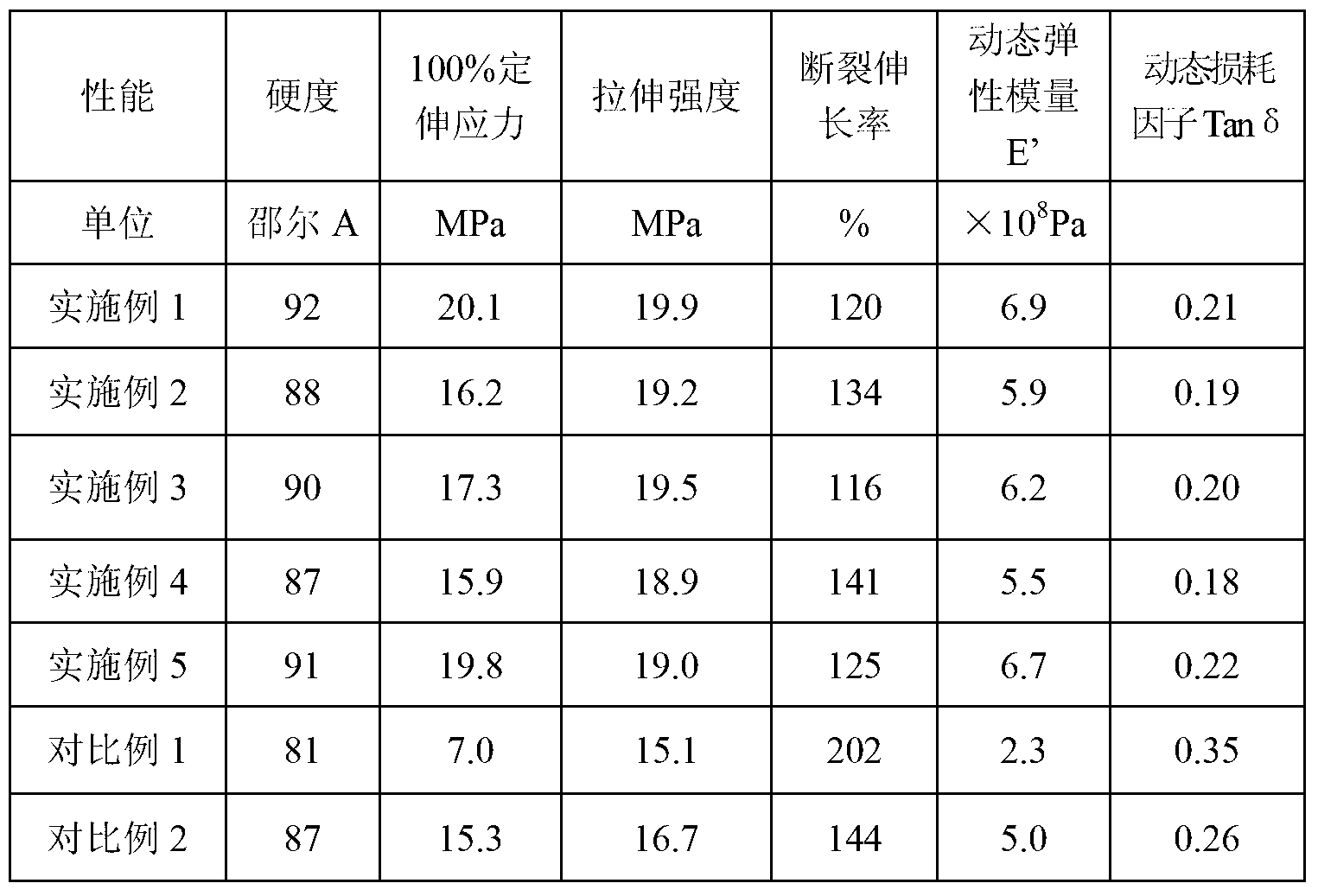

Examples

Embodiment 1

[0037] A graphene oxide / carbon black rubber nanocomposite material for automobile tires and a preparation method thereof, the mass parts of each component are:

[0038] 100 parts of natural rubber matrix;

[0039] 2 parts of graphene oxide;

[0040] Hard carbon black N33060 parts;

[0041] 3 parts paraffin oil;

[0042] 2 parts stearic acid;

[0043] 5 parts of zinc oxide;

[0044] 5 parts of insoluble sulfur;

[0045]Anti-aging agent: 40203 parts;

[0046] Vulcanization accelerator: 3 parts of DM;

[0047] Composite material preparation method: disperse graphene oxide powder in deionized water with a mass concentration of 0.4mg / mL, and use an ultrasonic wave with a power of 750W for 45min to obtain a water suspension system of graphene oxide; The corresponding amount of natural rubber latex (solid content 60%) was added to the suspension system for ultrasonic treatment for 15 minutes, and then added to 2wt% CaCl 2 In the aqueous solution, after flocculation, washing, ...

Embodiment 2

[0049] A graphene oxide / carbon black rubber nanocomposite material for automobile tires and a preparation method thereof, the mass parts of each component are:

[0050] 90 parts of natural rubber matrix;

[0051] 10 parts of butadiene rubber matrix;

[0052] 0.5 part of graphene oxide;

[0053] Hard carbon black N23470 parts;

[0054] 4 parts aromatic oil;

[0055] 3 parts of stearic acid;

[0056] 6 parts of zinc oxide;

[0057] 2 parts of insoluble sulfur;

[0058] Antiaging agent: 4 parts of RD;

[0059] Vulcanization accelerator: 4 parts of CZ;

[0060] Composite material preparation method: disperse graphene oxide powder in deionized water with a mass concentration of 0.1mg / mL, and use an ultrasonic wave with a power of 500W for 60 minutes to obtain a water suspension system of graphene oxide; mix with graphite according to the distribution ratio of each component The corresponding amount of natural rubber latex (solid content 60%) was added to the suspension syst...

Embodiment 3

[0062] A graphene oxide / carbon black rubber nanocomposite material for automobile tires and a preparation method thereof, the mass parts of each component are:

[0063] 80 parts of natural rubber matrix;

[0064] 20 parts of styrene-butadiene rubber matrix;

[0065] 5 parts of graphene oxide;

[0066] Hard carbon black N22030 parts;

[0067] 5 parts paraffin oil;

[0068] 2 parts stearic acid;

[0069] 8 parts of zinc oxide;

[0070] 6 parts of insoluble sulfur;

[0071] Antiaging agent: 2 parts of 4010NA;

[0072] Vulcanization accelerator: NS2 parts;

[0073] Composite material preparation method: disperse graphene oxide powder in deionized water with a mass concentration of 0.25mg / mL, and use an ultrasonic wave with a power of 1000W for 45min to obtain a water suspension system of graphene oxide; The corresponding amount of natural rubber latex (solid content 60%) was added to the suspension system for ultrasonic treatment for 10 minutes, and 0.5wt% CaCl 2 In the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com