Dopamine modified carbon nanotube/rubber composite material and preparation method thereof

A carbon nanotube and composite material technology, which is applied in the direction of fibrous fillers, dyed low molecular organic compounds, etc. To achieve uniform dispersion of carbon nanotubes and other issues, to achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

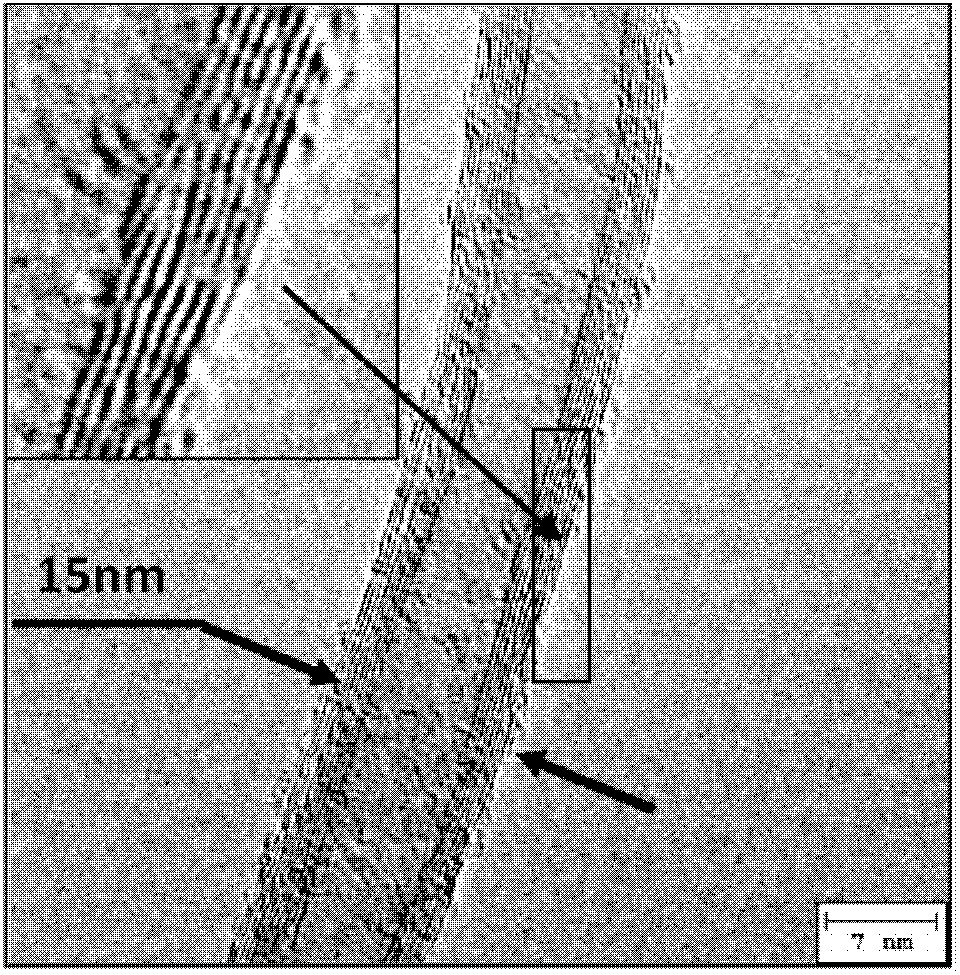

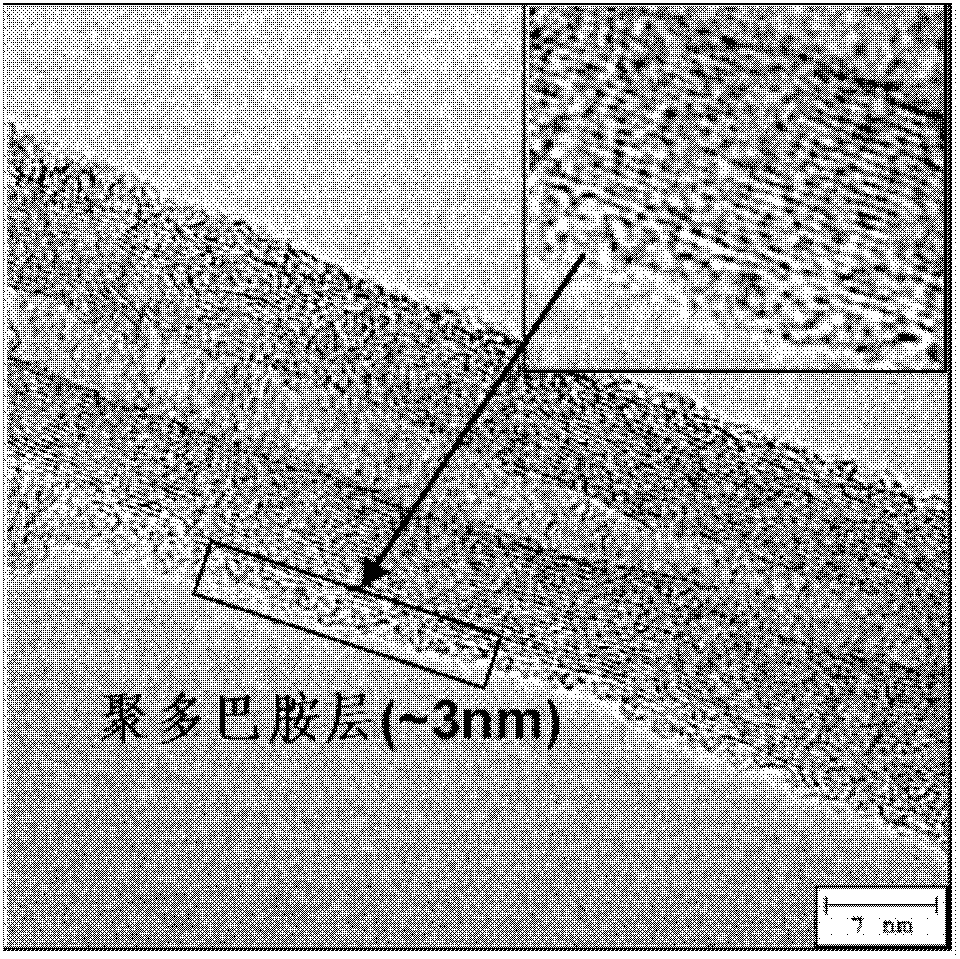

[0026] Take 1 part of original carbon nanotubes (CNTs) and preliminarily disperse them in 250 parts of deionized water by means of ultrasonic vibration, add 0.121 parts of trishydroxymethylaminomethane, and use a mass fraction of 10% dilute hydrochloric acid solution to adjust the pH of the carbon nanotube suspension to Adjust the value to 7, add 1 part of dopamine, deposit and react at room temperature for 8 hours, then wash, filter, and dry to obtain dopamine-modified carbon nanotubes (CNTs-PDA);

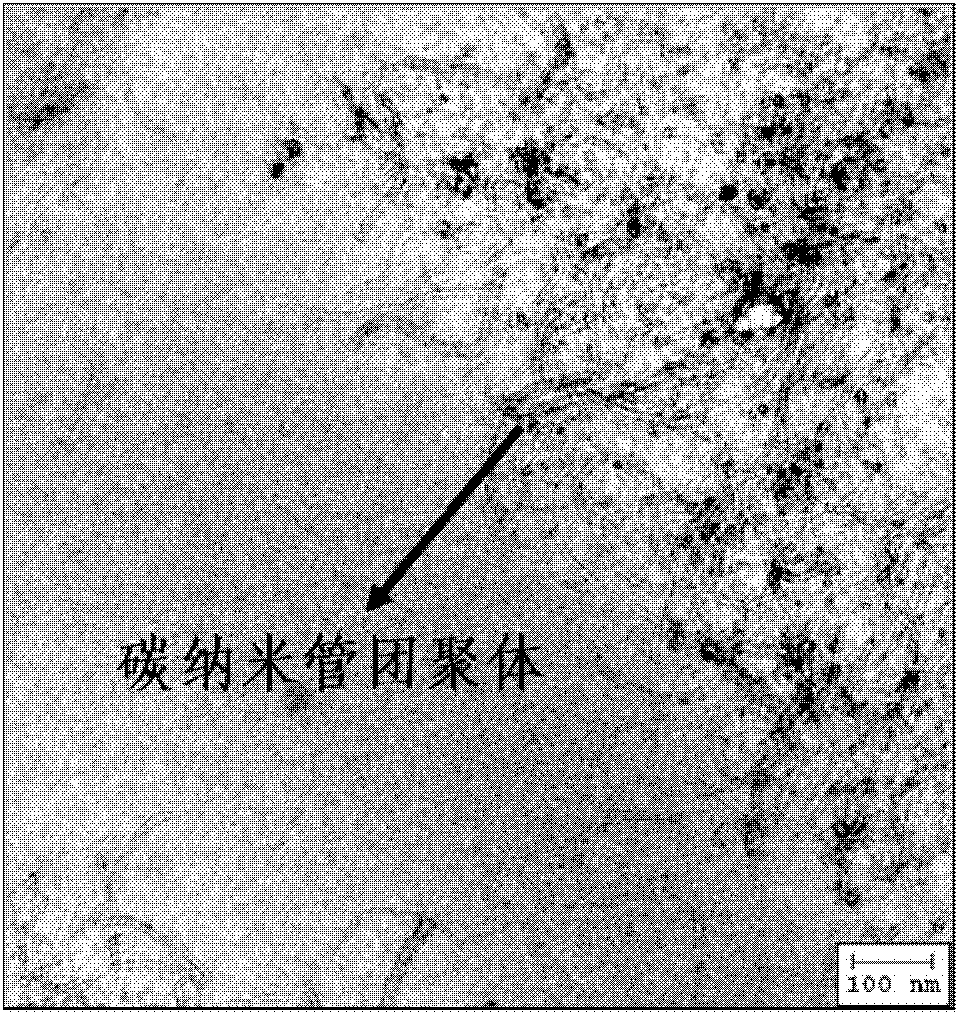

[0027] The modified carbon nanotubes were dispersed in 250 parts of deionized water, and oscillated for 1 hour using an ultrasonic cell pulverizer (GA 98-III type) to form a uniform and stable carbon nanotube-deionized water suspension. Then the suspension was added dropwise into 170 parts of natural rubber latex, mechanically stirred for 2 hours, and deionized water was added to determine the solid content of the mixed solution to be 8%. The carbon nanotube-natural rubber latex m...

Embodiment 2

[0031] Take 2 parts of original carbon nanotubes (CNTs) and preliminarily disperse them in 500 parts of deionized water by means of ultrasonic vibration, add 0.121 parts of tris-hydroxymethylaminomethane, and adjust the pH of the suspension of carbon nanotubes with 10% dilute hydrochloric acid solution Adjust the value to 7.5, add 2 parts of dopamine, deposit and react at room temperature for 12 hours, then wash, filter, and dry to obtain carbon nanotubes (CNTs-PDA) after dopamine modification;

[0032] The modified carbon nanotubes were dispersed in 500 parts of deionized water, and oscillated for 1 hour using an ultrasonic cell pulverizer (GA 98-III type) to form a uniform and stable carbon nanotube-deionized water suspension. Then the suspension was added dropwise into 170 parts of natural rubber latex, mechanically stirred for 0.5 hour, and deionized water was added to determine the solid content of the mixed solution as 10%. Add the carbon nanotube-natural rubber latex mi...

Embodiment 3

[0036] Take 5 parts of original carbon nanotubes and disperse them in 1500 parts of deionized water by ultrasonic vibration, add 1.21 parts of trishydroxymethylaminomethane, and adjust the pH value of the carbon nanotube suspension to 8.5 with a mass fraction of 10% dilute hydrochloric acid solution , add 2.5 parts of dopamine powder, deposit and react at room temperature for 24 hours, then wash and filter until the filtrate is colorless and transparent, and dry at 60°C to obtain dopamine-modified carbon nanotubes;

[0037] The modified carbon nanotubes were dispersed in 900 parts of deionized water, and ultrasonically oscillated for 0.5 hours to form a uniform and stable suspension of carbon nanotubes. Then the suspension was added dropwise into 170 g of natural rubber latex, mechanically stirred for 2 hours, and deionized water was added to determine the solid content of the mixed solution as 20%. Add the carbon nanotube-natural rubber latex mixture dropwise to a high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com