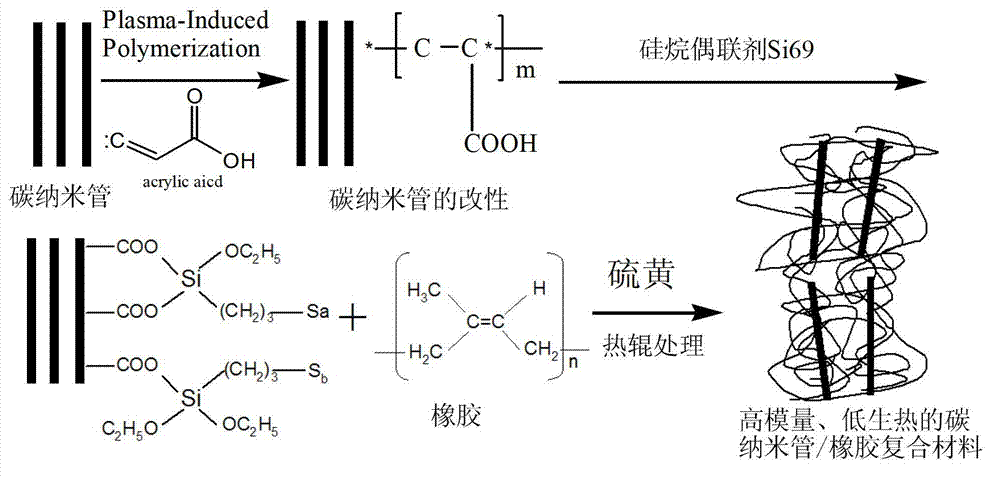

Preparation method of high-modulus low-heat carbon nano tube/ rubber composite material

A technology of carbon nanotubes and composite materials, which is applied in the preparation of carbon nanotubes/rubber composite materials with low heat generation and high modulus. The effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

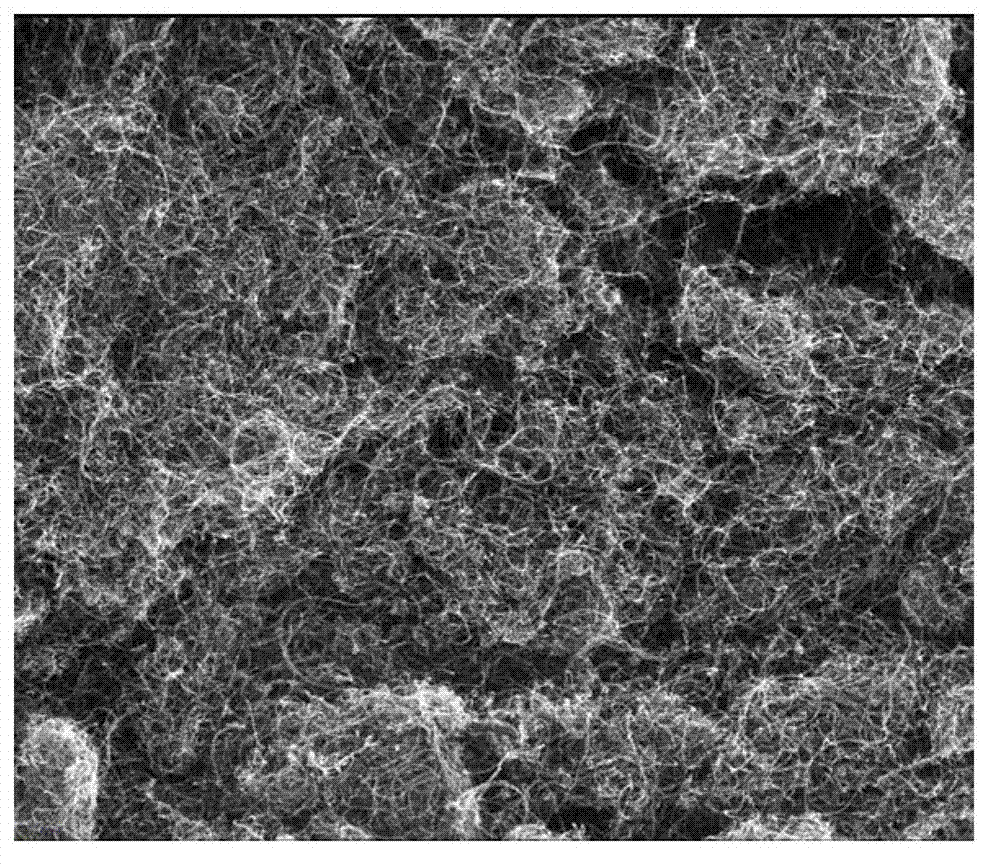

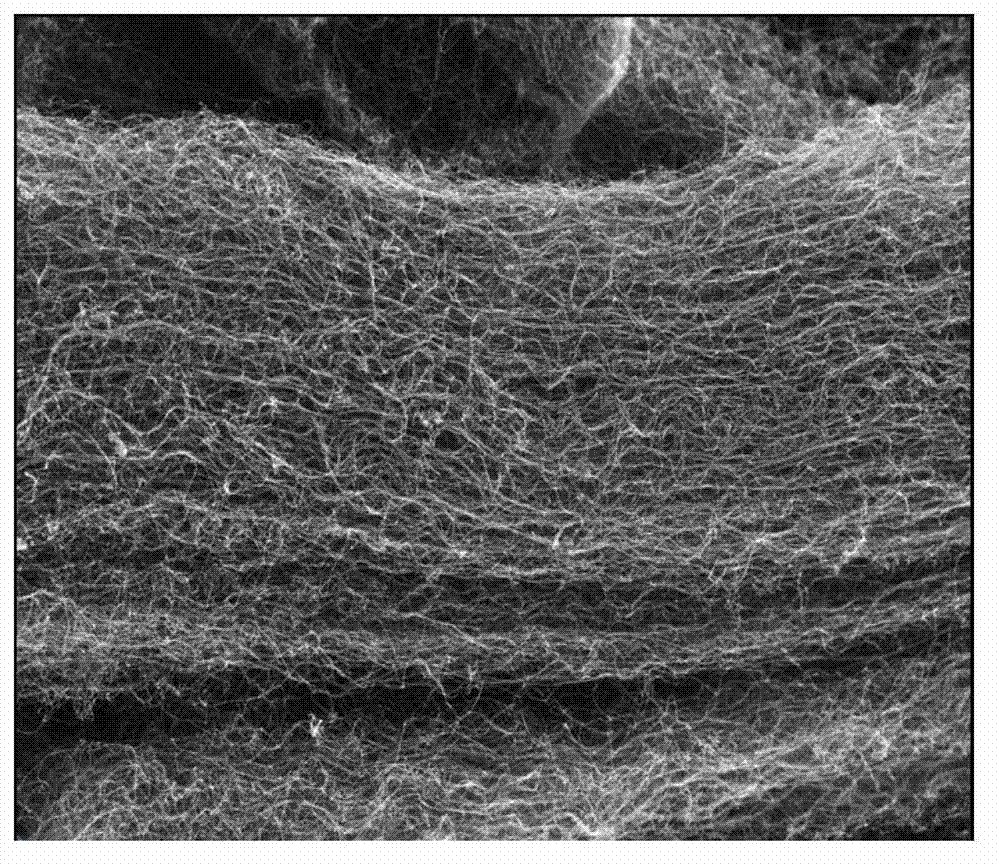

Image

Examples

Embodiment 1

[0023] 5.5 g of carbon nanotubes were placed in a plasma reaction vessel, vacuumed to 20 Pa, argon was introduced, and the chamber pressure was adjusted to 40 Pa; the preheating time was 5 minutes. Afterwards, treat with glow discharge for 7 minutes at a power of 50W, stop the glow discharge reaction, take out the carbon nanotubes, and park them in the air for 5 minutes; in a 4000ml beaker, add 2500ml of deionized water, 120ml of acrylic acid, 1g of ammonium persulfate, and modify The final carbon nanotubes were stirred at 80°C for 24 hours; the obtained product was centrifuged, the lower layer of solid was removed, washed 4 times with acetone until pure, and then vacuum-dried at 80°C for 24 hours to complete the modification of carbon nanotubes.

[0024] Using the mechanical blending method, 2phr of silane coupling agent Si69 and 10phr of modified carbon nanotubes were added to 100phr of natural rubber NR. On-machine heat roller treatment with a treatment time of 4 minutes. ...

Embodiment 2

[0031] 5.5 g of carbon nanotubes were placed in a plasma reaction vessel, vacuumed to 20 Pa, argon was introduced, and the chamber pressure was adjusted to 40 Pa; the preheating time was 5 minutes. Afterwards, treat with glow discharge for 7 minutes at a power of 50W, stop the glow discharge reaction, take out the carbon nanotubes, and park them in the air for 5 minutes; in a 4000ml beaker, add 2500ml of deionized water, 120ml of acrylic acid, 1g of ammonium persulfate, and modify The final carbon nanotubes were stirred at 80°C for 24 hours; the obtained product was centrifuged, the lower layer of solid was removed, washed 4 times with acetone until pure, and then vacuum-dried at 80°C for 24 hours to complete the modification of carbon nanotubes.

[0032] Adopt mechanical blending method, the carbon nanotube after the silane coupling agent Si75 of 2phr and 10phr modification is added in the polyisoprene rubber IR of 100phr, park after 2 hours, mix the above-mentioned obtained rub...

Embodiment 3

[0037] 5.5 g of carbon nanotubes were placed in a plasma reaction vessel, vacuumed to 20 Pa, and oxygen was introduced to adjust the chamber pressure to 40 Pa; the preheating time was 5 minutes. Afterwards, treat with glow discharge for 7 minutes at a power of 50W, stop the glow discharge reaction, take out the carbon nanotubes, and park them in the air for 5 minutes; in a 4000ml beaker, add 2500ml of toluene solvent, 120ml of acrylic acid, 1g of ammonium persulfate, after modification The carbon nanotubes were stirred at 80°C for 24 hours; the obtained product was centrifuged, the lower layer of solid was removed, washed 4 times with acetone until pure, and then vacuum-dried at 80°C for 24 hours to complete the modification of carbon nanotubes.

[0038] Using the mechanical blending method, 3 phr of silane coupling agent Si69 and 10 phr of modified carbon nanotubes were added to 100 phr of styrene-butadiene rubber SBR. Carry out hot roll treatment on the mill, and the treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com