Montmorillonite-styrene butadiene rubber nanocomposite material

A nano-composite material, styrene-butadiene rubber technology, applied in the field of styrene-butadiene rubber composition, montmorillonite and styrene-butadiene rubber nano-composite materials and their preparation, can solve difficult industrial production, poor particle cohesion, small rubber particles, etc. problems, to achieve the effect of improved wear resistance, large particle size, and significant reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

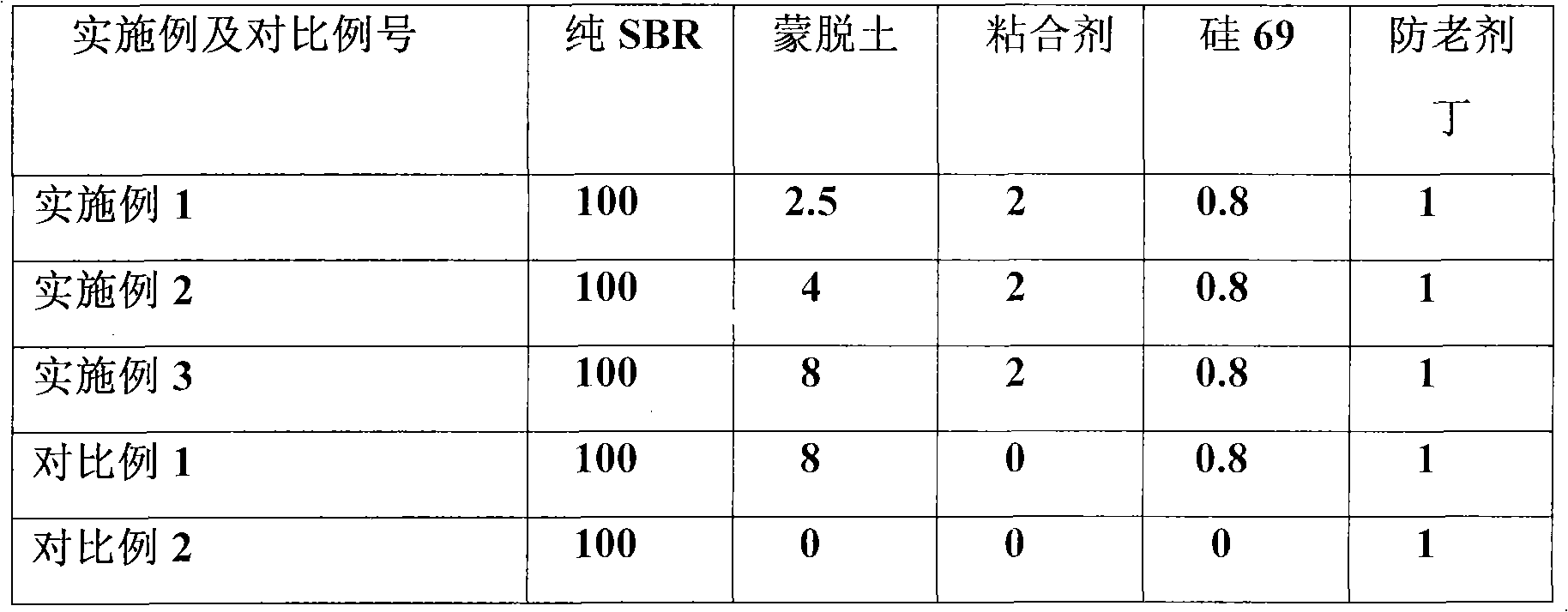

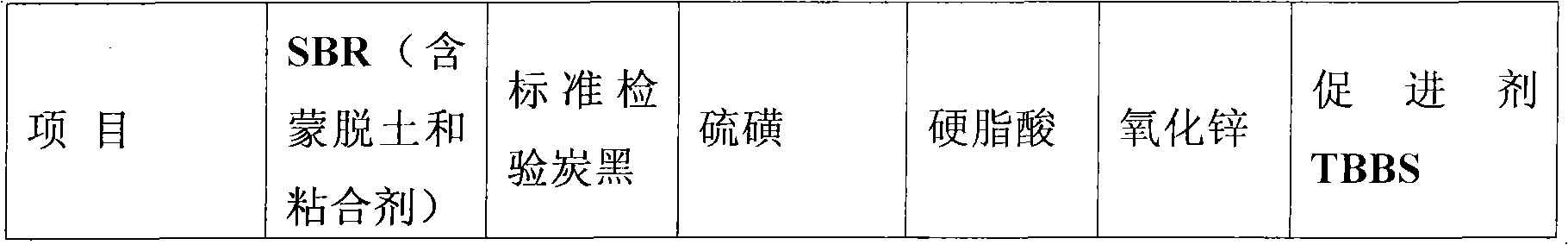

Embodiment 1

[0063] Prepare montmorillonite and styrene-butadiene rubber nanocomposite of the present invention according to the following raw material formula and steps

[0064] a. Preprocessing of some raw materials

[0065] (1) Preparation of organically modified montmorillonite suspension

[0066] ① Preparation of montmorillonite aqueous suspension

[0067] Add water and stir the montmorillonite ore, pass through a 100-mesh sieve to remove impurities, settle again to remove sand, and pass through a 325-mesh sieve to obtain a montmorillonite water suspension. The ion exchange capacity of the montmorillonite is 96.4meq / 100g for subsequent use;

[0068] ②. Preparation of intercalation agent solution

[0069] Add 0.18 parts by weight of dodecylamine to 100 parts by weight of hydrochloric acid solution with a concentration of 0.01 mol, dissolve and disperse completely at a temperature of 60°C, and set aside;

[0070] ③. Preparation of organically modified montmorillonite suspension

[0...

Embodiment 2

[0083] According to the method and steps of Example 1, the only difference is that the organically modified montmorillonite suspension prepared in step a (1) added in step b and step e is 20 parts by weight. The montmorillonite and styrene-butadiene rubber nanocomposite material of the present invention is prepared.

Embodiment 3

[0085] According to the method and steps of Example 1, the only difference is that the organically modified montmorillonite suspension prepared in step a (1) added in step b and step e is 40 parts by weight. The montmorillonite and styrene-butadiene rubber nanocomposite material of the present invention is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com