Method for preparing rubber nanocomposite by peeling expanded graphite through in-situ reaction

A technology of expanded graphite and composite materials, which is applied in the field of rubber products, can solve problems such as the difficulty of uniform dispersion of graphene, and achieve the effects of reducing van der Waals force, easy industrialization, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

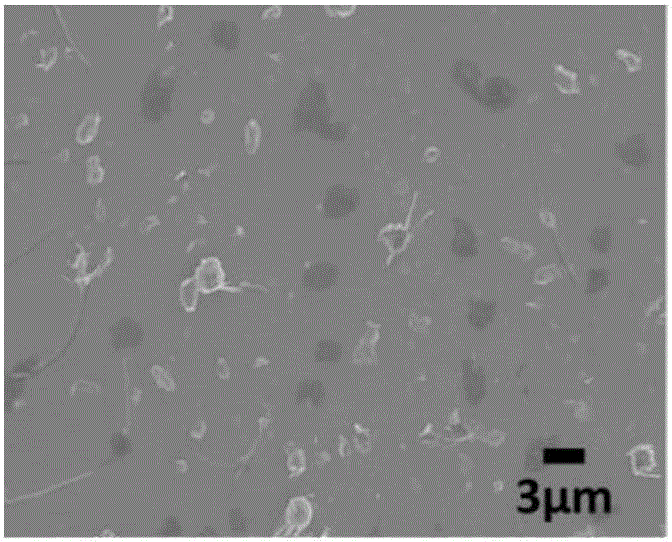

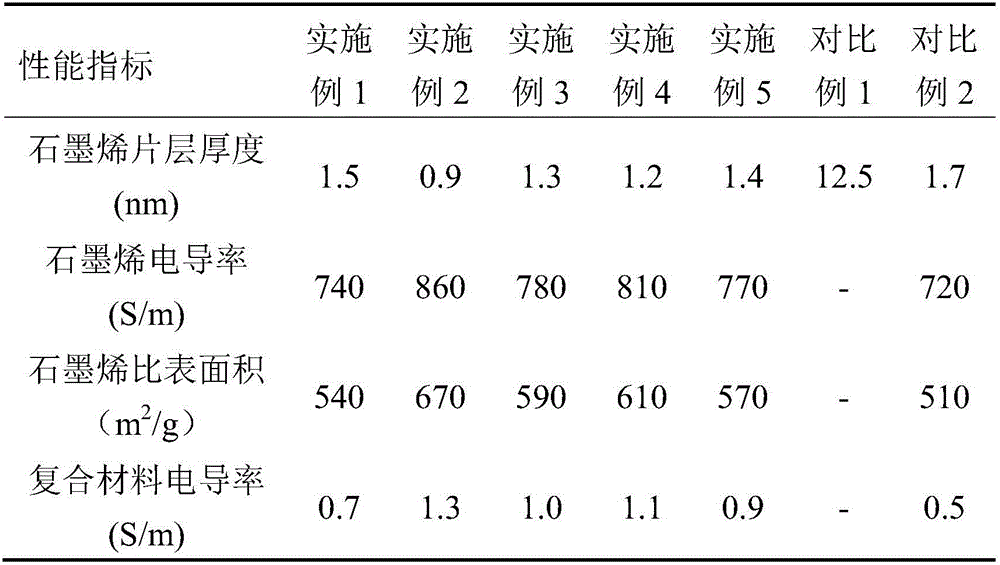

[0026] First, 1 part (refer to parts by mass, the same below) of expanded graphite and 10 parts of 2-methoxythiophene are added to tetrahydrofuran, ultrasonically (400W ultrasonic cleaner, the same below) and stirred for 20min, then heated to remove tetrahydrofuran and dried to obtain A mixture of expanded graphite and methoxythiophene; masticate 100 parts of hydrogenated nitrile rubber in a Haake internal mixer for 3 minutes, set the speed at 130 rpm, and set the temperature at 100 ° C. When the torque becomes stable, add 0.2 Parts of ferric chloride, the temperature rises to 130°C, then add the mixture of graphite and thiophene which removes tetrahydrofuran, and react at 130°C for 40min. After the reaction is finished, cool down to room temperature and take out the product from the internal mixer to obtain the product. Finally, the product was hot-pressed by a flat vulcanizer at 160°C to obtain a composite material, and the dispersion test was carried out with a scanning ele...

Embodiment 2

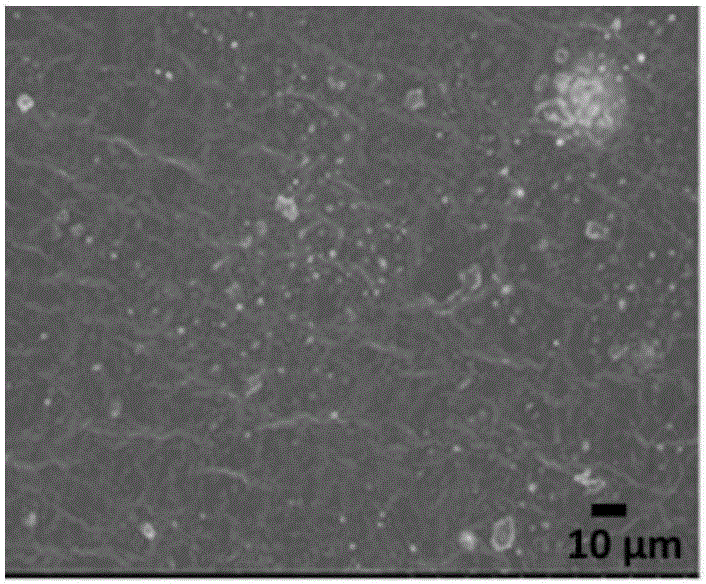

[0032] First, 3 parts of expanded graphite and 30 parts of maleic anhydride are added to tetrahydrofuran, ultrasonicated and stirred for 50 minutes, then heated to remove tetrahydrofuran and dried to obtain a mixture of expanded graphite and maleic anhydride; 100 parts by mass of hydrogenated nitrile rubber in banburying Masticate in the machine for 3 minutes, set the speed at 130 rpm, and set the temperature at 120°C. When the torque becomes stable, add 0.8 parts of zinc tetrafluoroborate, raise the temperature to 160°C, and then add graphite and maleic acid that remove tetrahydrofuran. A mixture of acid anhydrides was reacted at 160°C for 48 minutes. After the reaction is finished, cool down to room temperature and take out the product from the internal mixer to obtain the product. Finally, the product is hot-pressed at 160°C through a flat vulcanizer to obtain a composite material; the leftovers are dissolved in a solvent, and the solution is diluted with tetrahydrofuran, a...

Embodiment 3

[0034] First, 5 parts of expanded graphite and 50 parts of itaconic anhydride are added to tetrahydrofuran, ultrasonically stirred for 60 minutes, then heated to remove tetrahydrofuran and dried to obtain a mixture of expanded graphite and itaconic anhydride; 100 parts of hydrogenated nitrile rubber in a mixer Medium masticating for 3 minutes, the speed is set at 130 rpm, the temperature is set at 125°C, when the torque becomes stable, add 1 part of aluminum chloride, the temperature rises to 170°C, and then add the mixture of graphite and itaconic anhydride that removes tetrahydrofuran , 170°C for 52min. After the reaction is finished, cool down to room temperature and take out the product from the internal mixer to obtain the product. Finally, the product is hot-pressed at 160°C through a flat vulcanizer to obtain a composite material; the leftovers are dissolved in a solvent, and the solution is diluted with tetrahydrofuran, and centrifuged on a high-speed centrifuge to pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com