Kaolin/rubber nano compound material with strengthening and obstructing dual property

A technology of rubber nano-composite materials, applied in the field of kaolin/rubber nano-composite materials, to achieve the effects of energy saving, easy popularization and application, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

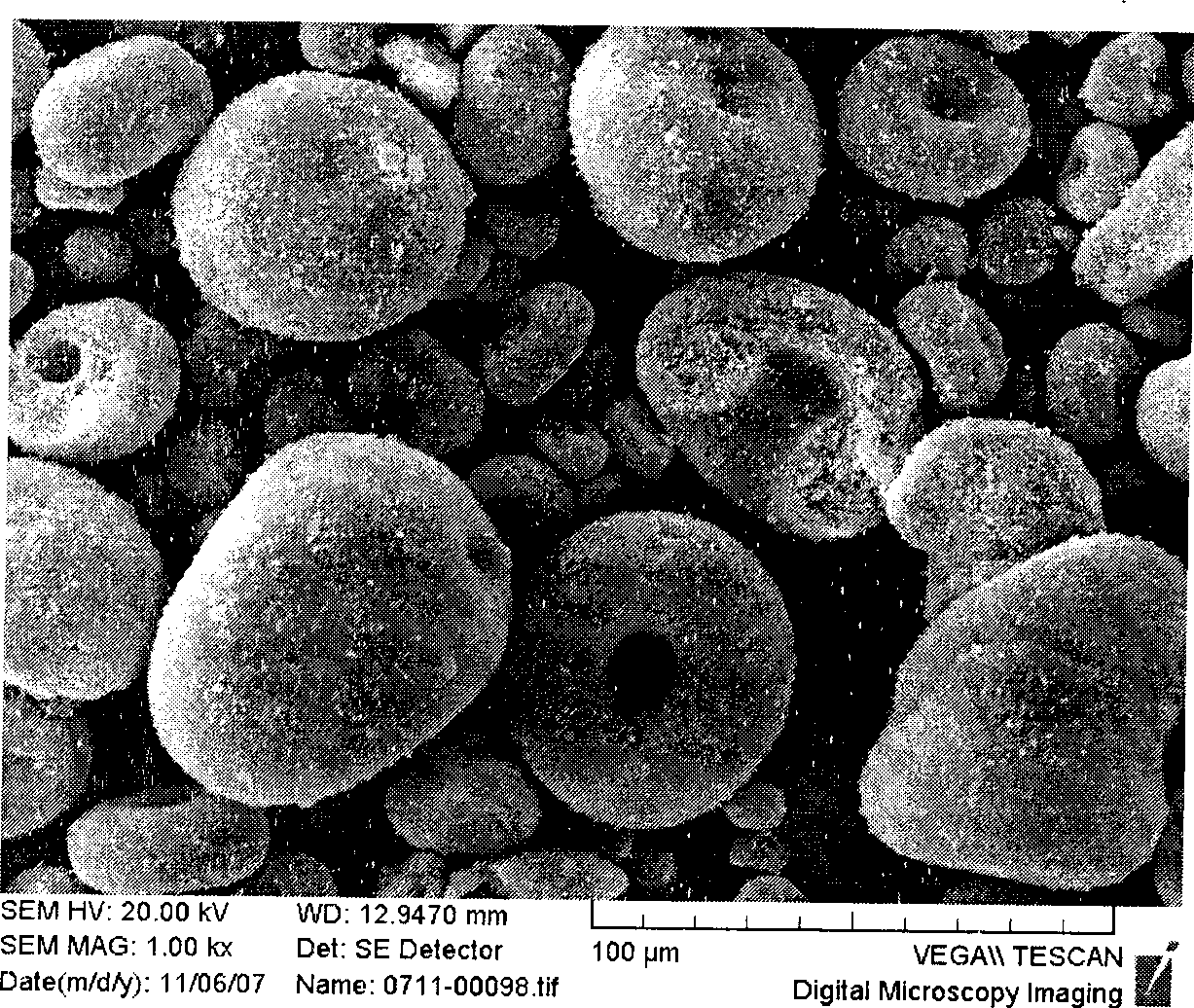

Image

Examples

Embodiment 1

[0043] Using 3% of the total amount of vinyl trimethoxysilane coupling agent and 2% of isopropyl triisostearyl titanate coupling agent to modify the mixture of nano kaolin accounting for 95% of the total amount to prepare organic modified Sexual nano-kaolin.

[0044] 50 parts of nano-kaolin, 1500 parts of styrene-butadiene rubber, 3 parts of zinc oxide, 1 part of stearic acid, 1 part of accelerator NS, 1.75 parts of sulfur, and 1.75 parts of organically modified nano-kaolin obtained by blending, in order to make the powder in To achieve uniform dispersion in the rubber matrix, the rubber is firstly mixed in an open mill (φ160mm×320mm, Shanghai Rubber Machinery Factory). The mixing process is: raw rubber → small materials (accelerators, active agents) → silane-modified Nano-kaolin→softener→sulfur→thin pass several times and then evenly slice down. The mixing time is 12~15min. The positive vulcanization point is measured with a vulcanization meter, the vulcanization condition i...

Embodiment 2

[0054] Using 4% isopropyl trimethacryloyl titanate coupling agent to modify the nano-kaolin which accounts for 96% of the total amount to prepare titanate-modified nano-kaolin.

[0055] Blend 45 parts of the obtained titanate-modified nano kaolin, 100 parts of natural rubber, 5 parts of zinc oxide, 4 parts of stearic acid, 1 part of accelerator M, 3 parts of sulfur, and 1.5 parts of antioxidant D. The mixing process and the sequence of feeding are the same as in Example 1. After testing, the mechanical properties of natural rubber / kaolin nanocomposites are as follows:

[0056] Elongation at break, 670%;

[0057] Tensile strength, 24.7Mpa;

[0058] 300% constant stretch, 4.68Mpa;

[0059] 500% constant stretch, 12.6Mpa;

[0060] Air permeability 53.80×10 -18 m 2 / Pa.s.

[0061] Compared with Comparative Example 2, the modulus of elongation is improved, and the air permeability is reduced by 35.0%.

[0062] Figure 4 The transmission electron micrograph of the ion slice...

Embodiment 3

[0064] 3% of the total amount of stearic acid is used to modify the mixed nano-kaolin which accounts for 97% of the total amount to prepare organic carboxylic acid-modified nano-kaolin.

[0065] 60 parts of the obtained organic carboxylic acid modified nano kaolin, 100 parts of butyl rubber, 3 parts of zinc oxide, 1 part of stearic acid, 1 part of accelerator TMTD and 1.75 parts of sulfur are blended. The mixing process and the sequence of feeding are the same as in Example 1. After testing, the mechanical properties of butyl rubber / kaolin nanocomposites are as follows:

[0066] Elongation at break, 750%;

[0067] Tensile strength, 13.7Mpa;

[0068] 300% constant stretch, 1.78Mpa;

[0069] 500% constant stretch, 3.6Mpa;

[0070] Tear strength, 21kN / m;

[0071] Air permeability 1.19×10 -18 m 2 / Pa.s.

[0072] Compared with Comparative Example 3, various mechanical properties are significantly improved, and the air permeability is reduced by 82.6%.

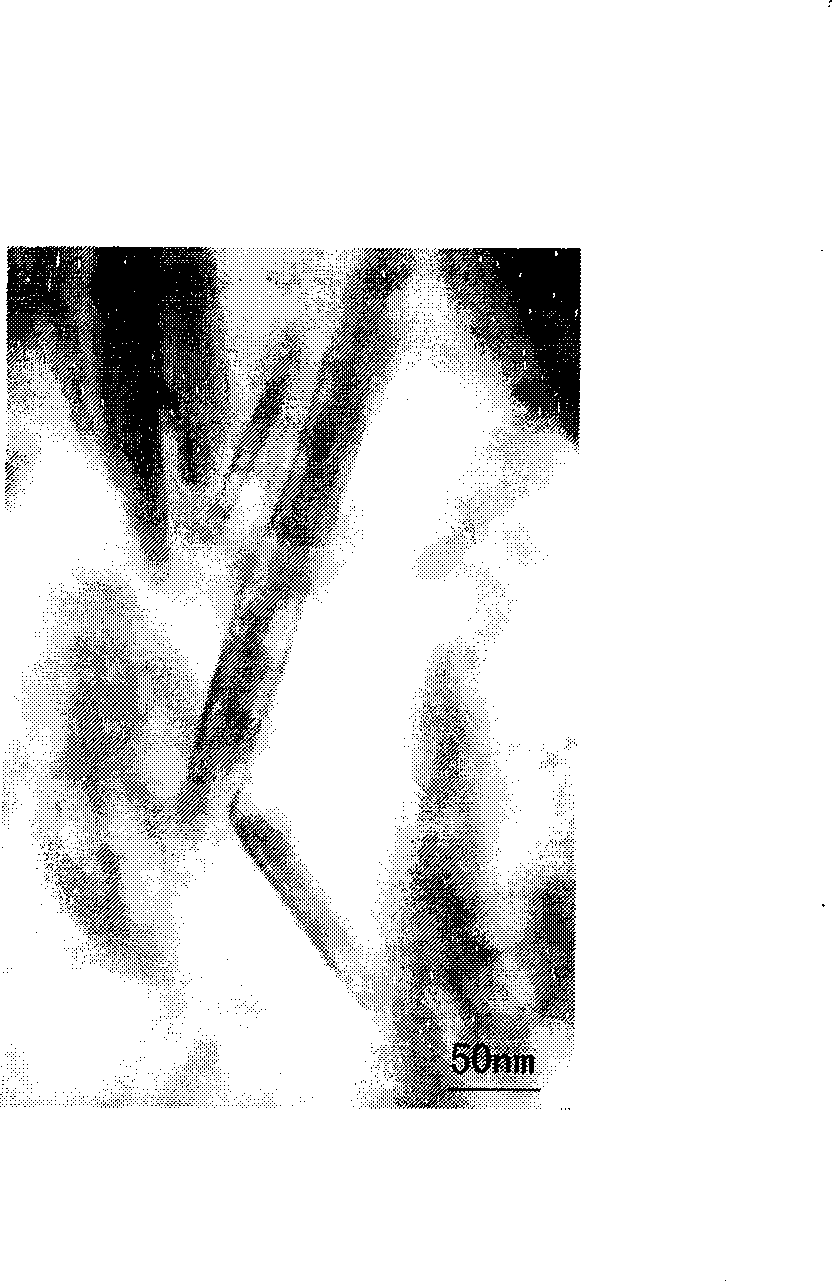

[0073] Figure 5 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com