Modified clay and rubber composite material preparation method

A composite material and clay technology, which is used in the field of preparing clay and rubber nanocomposite materials, can solve the problems of limiting the wide application of the melt method, hidden dangers of environmental pollution, and increasing the cost of waste liquid, and achieves a simple method, easy industrialization, and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

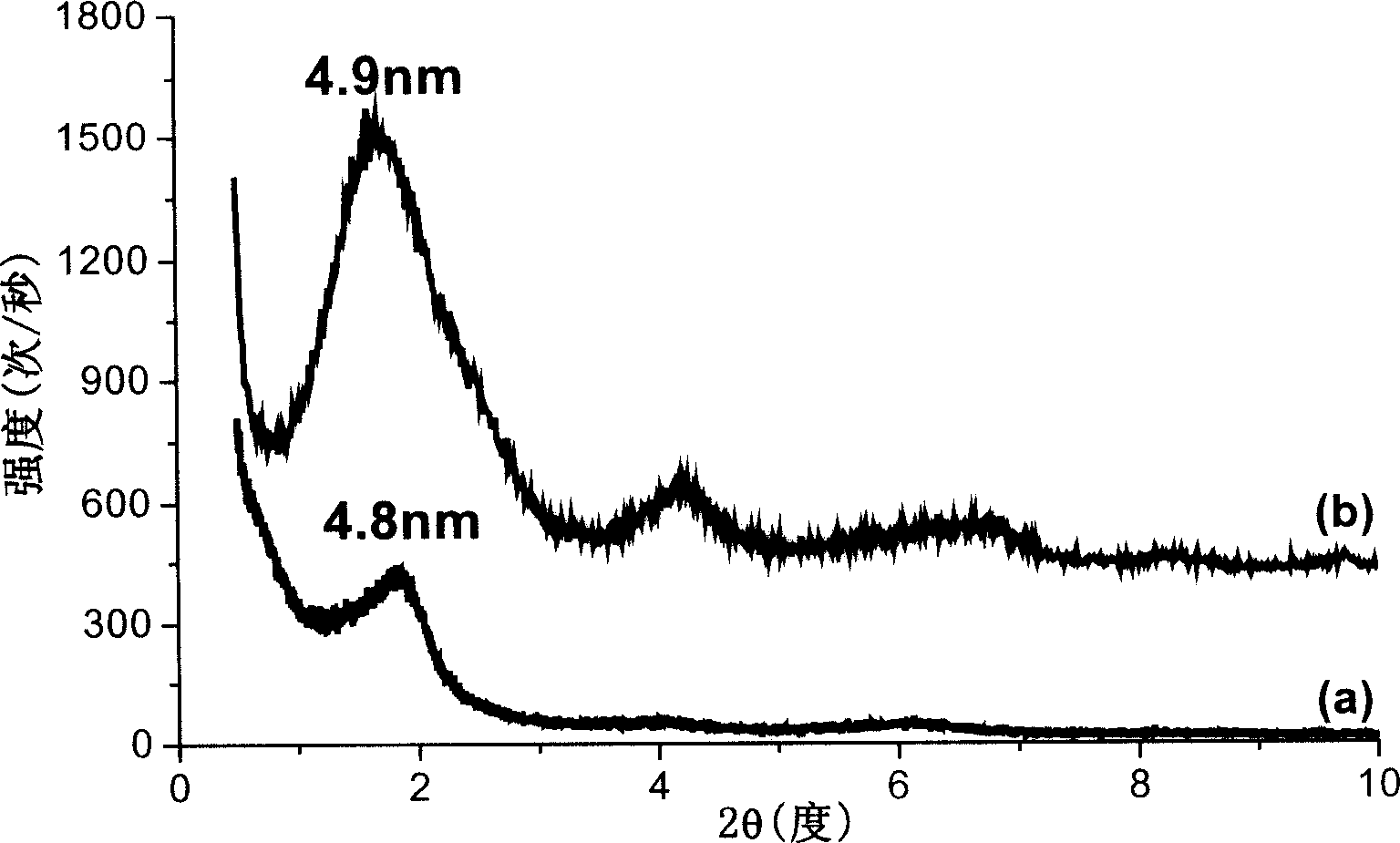

[0032] Put 4 parts of hexadecyltrimethylammonium bromide (amount of 0.11*M, M is organic modifier molecular weight 363.5), and 10 parts of water (by mass ratio, water: clay=1:1) in a magnetic Stir and heat on a mixer to obtain an aqueous solution of quaternary ammonium salt, add 10 parts of clay, further stir, and mix evenly to obtain a mixed system of an organic modifier and clay. On a double-roller mill, after mixing the organic modifier and clay mixing system with 100 parts of styrene-butadiene rubber evenly, add the vulcanization system according to the conventional process, and the proportion is 5 parts of ZnO, 2 parts of SA, 2 parts of S, TT 0.2 parts, 0.5 parts of DM, 0.5 parts of D, 1.0 parts of 4010NA to obtain the compound of modified clay and styrene-butadiene rubber, and then press the normal vulcanization time T at 150°C 90 vulcanized to obtain vulcanized rubber. The X-ray diffraction curve of the sample is shown in figure 1 Middle curve (a); transmission electr...

Embodiment 2

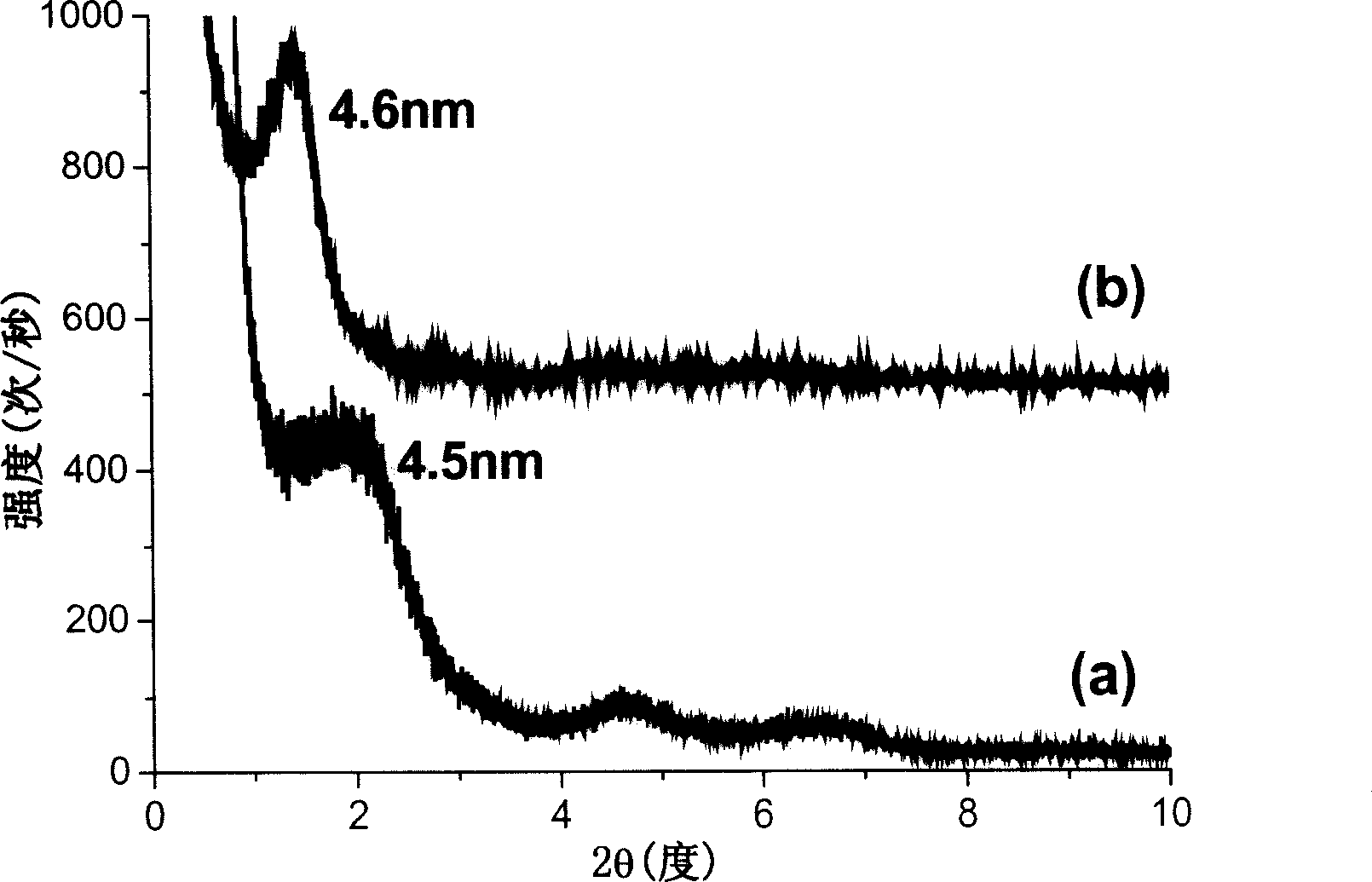

[0034] The matrix was changed to natural rubber, and the rest of the operating conditions were the same as in Example 1 to obtain a composite of modified clay and natural rubber. Under vulcanization condition 143℃×T 90 , to obtain vulcanized rubber. The X-ray diffraction curve of the vulcanized rubber sample is shown in figure 2 Curve (a) in; transmission electron microscope photo see Figure 8 .

Embodiment 3

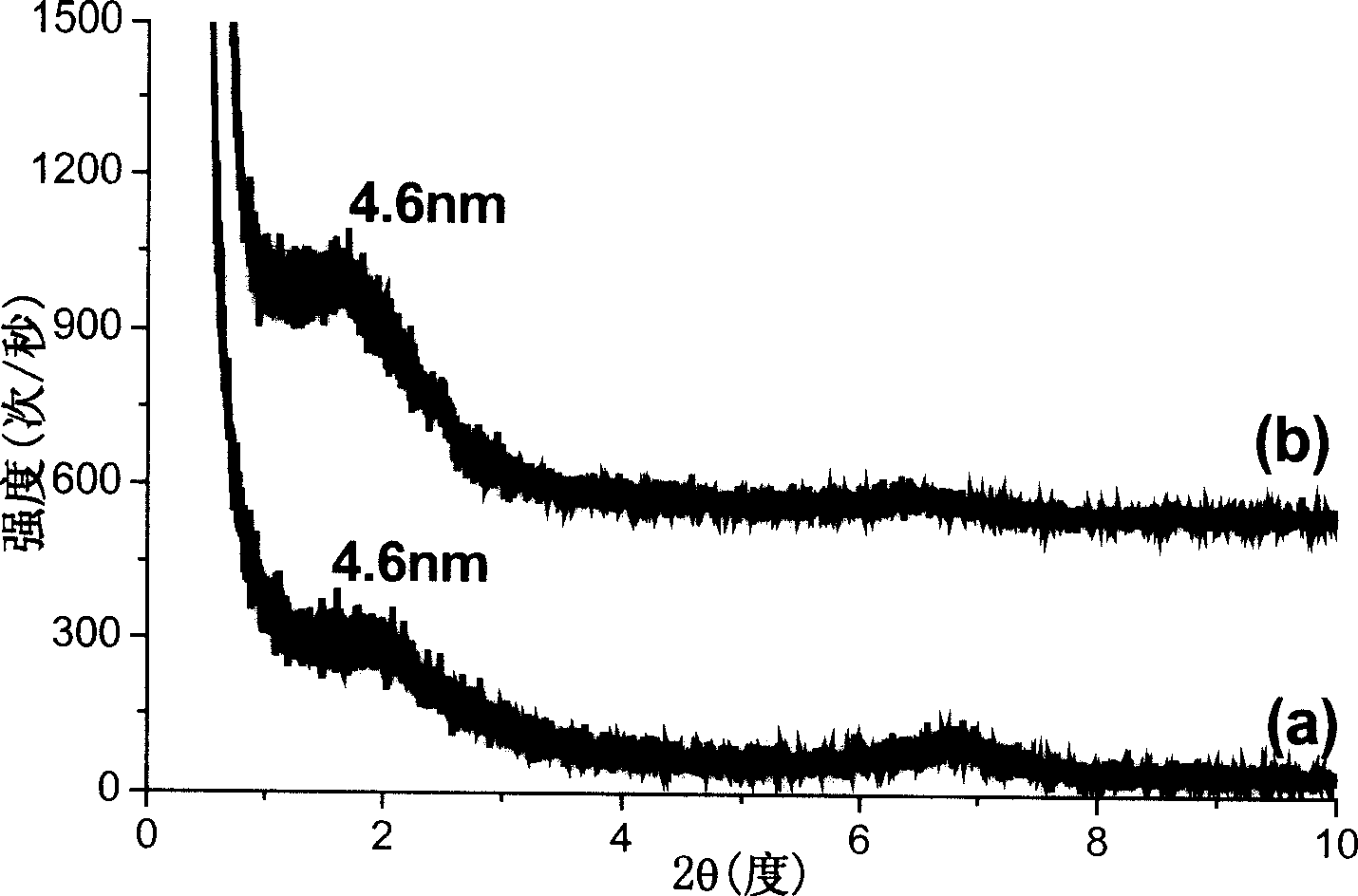

[0036] Change the matrix into EPDM rubber, the vulcanization system ratio is 5 parts of ZnO, 1 part of SA, 1.5 parts of S, 1 part of TT, and 0.5 part of M. The remaining operating conditions are the same as in Example 1 to obtain modified clay and three Ethylene Propylene Rubber Compound. Under vulcanization condition 160℃×T 90 , to obtain vulcanized rubber. The X-ray diffraction curve of the vulcanized rubber sample is shown in image 3 Curve (a) in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com