Preparation method of high-performance hydrotalcite/silicon dioxide/rubber nano composite material

A silica and rubber nanotechnology, which is applied in the field of preparation of high-performance hydrotalcite/silica/rubber nanocomposite materials, can solve the problem of destabilizing latex, inability to add hydrotalcite in higher dosage, poor compatibility, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare the high-performance hydrotalcite / silicon dioxide / rubber nanocomposite material of the present invention according to the following raw material formula and steps, including the following raw material components by mass:

[0035]

[0036] The preparation process is as follows:

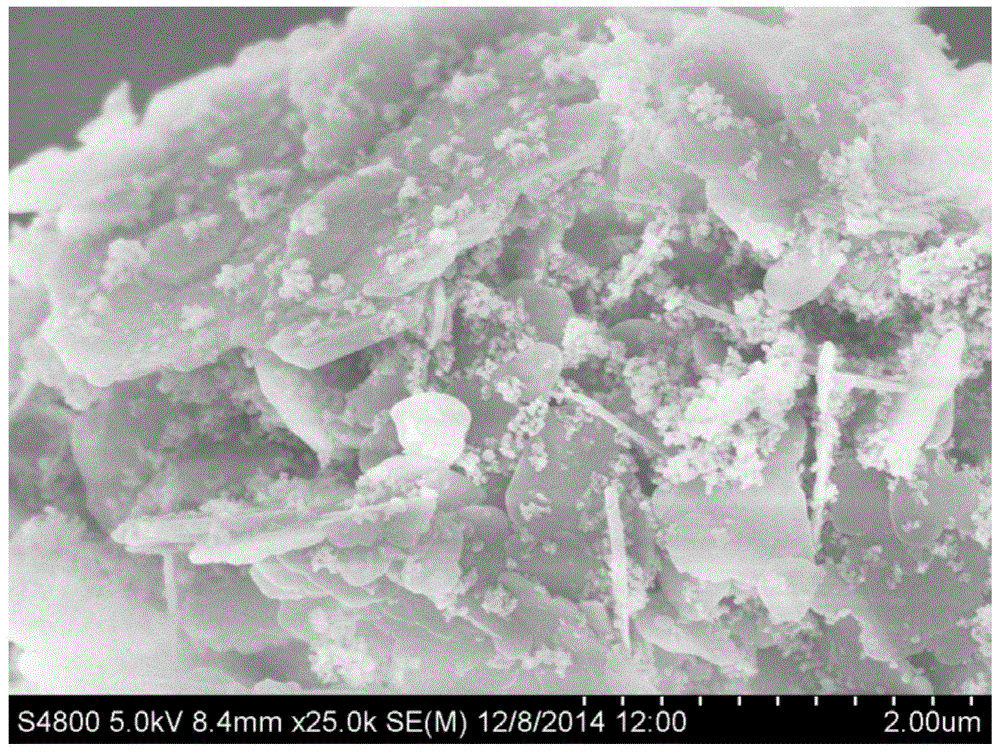

[0037] a. Hydrotalcite suspension, SiO 2 Preparation of suspensions and flocs

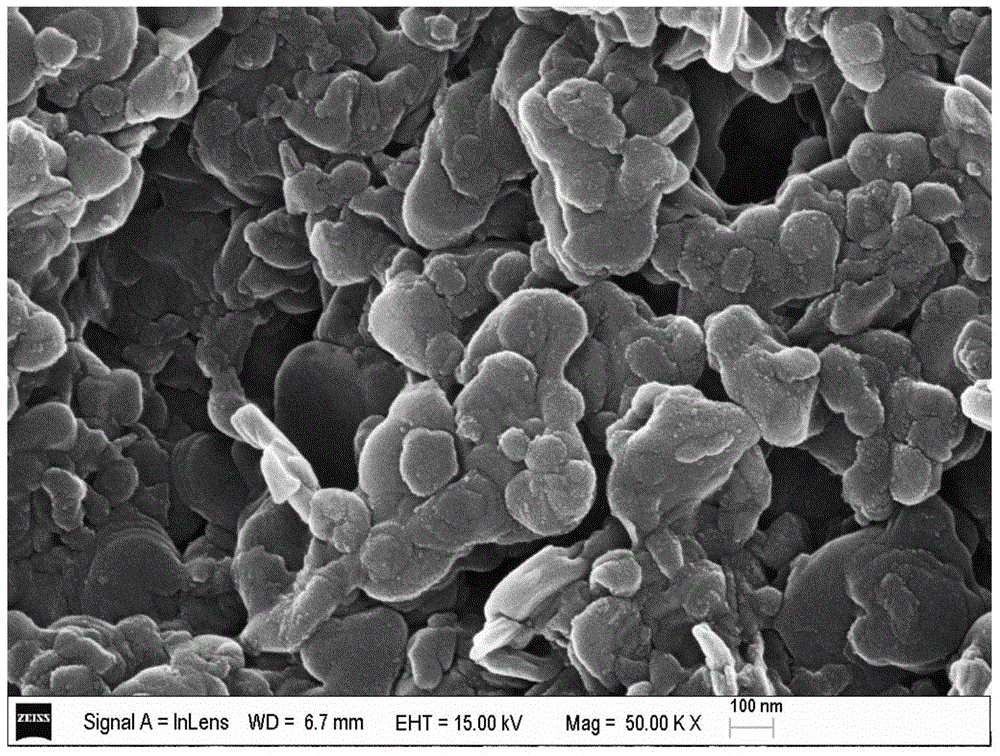

[0038] (1) Preparation of hydrotalcite suspension

[0039] First, take 0.5 g of magnesium aluminum hydrotalcite (LDHs) to prepare a hydrotalcite suspension for use, and the solid content of the suspension is 1%.

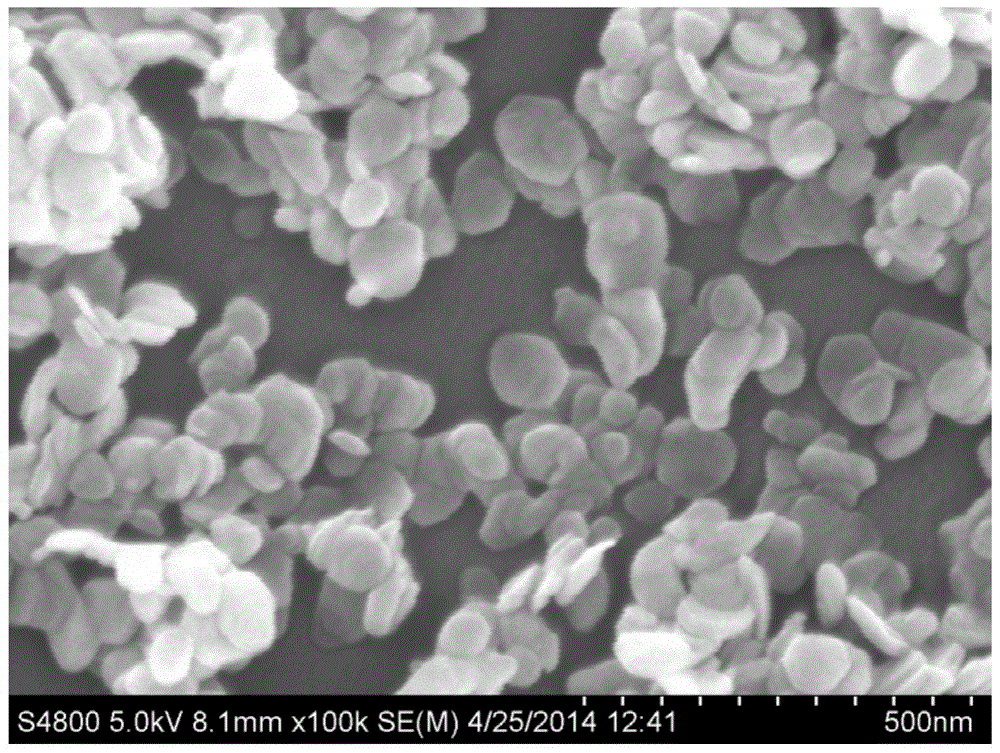

[0040] (2) SiO 2 Preparation of the suspension

[0041] Take 1gSiO 2 , suspended in deionized water, ultrasonicated in a cell disruptor for 10min, with a power of 100W, to prepare SiO with a solid content of 1% 2 The suspension is ready for use.

[0042] (3) Preparation of flocculant

[0043] Add 30g of analytically pure CaCl to 3000g of water 2 Prepare flocculation water for use.

[00...

Embodiment 2

[0053] Prepare the high-performance hydrotalcite / silicon dioxide / rubber nanocomposite material of the present invention according to the following raw material formula and steps, including the following raw material components by mass:

[0054]

[0055]

[0056] The preparation process is as follows:

[0057] a. Hydrotalcite suspension, SiO 2 Preparation of suspensions and flocs

[0058] (1) Preparation of hydrotalcite suspension

[0059]First, take 5 g of magnesium aluminum hydrotalcite (LDHs) to prepare a hydrotalcite suspension for use, and the solid content of the suspension is 5%.

[0060] (2) SiO 2 Preparation of the suspension

[0061] Take 10gSiO 2 , suspended in deionized water, and ultrasonicated for 20 minutes in a cell disruptor with a power of 400W to prepare SiO with a solid content of 5%. 2 The suspension is ready for use.

[0062] (3) Preparation of flocculant

[0063] Add 30g of analytically pure CaCl to 3000g of water 2 Prepare flocculation wat...

Embodiment 3

[0073] Prepare the high-performance hydrotalcite / silicon dioxide / rubber nanocomposite material of the present invention according to the following raw material formula and steps, including the following raw material components by mass:

[0074]

[0075] The preparation process is as follows:

[0076] a. Hydrotalcite suspension, SiO 2 Preparation of suspensions and flocs

[0077] (1) Preparation of hydrotalcite suspension

[0078] Firstly, 10 g of magnesium aluminum hydrotalcite (LDHs) was taken to prepare a hydrotalcite suspension for use, and the solid content of the suspension was 10%.

[0079] (2) SiO 2 Preparation of the suspension

[0080] Take 20gSiO 2 , suspended in deionized water, ultrasonicated for 30 minutes in a cell disruptor, with a power of 700W to prepare SiO with a solid content of 10% 2 The suspension is ready for use.

[0081] (3) Preparation of flocculant

[0082] Add 30g of analytically pure CaCl to 3000g of water 2 Prepare flocculation water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com