Dealcoholization type room-temperature silicon sulfide rubber composite

A technology of silicone rubber composition and room temperature vulcanization, which is applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of thickening reaction, long surface drying time, and inconvenient production, and achieve high stability, Effect of short dry time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039]The compositions can be prepared by conventional methods in the art. In some embodiments, the preparation method of the composition may comprise: under vacuum conditions, the components (A), components (B), components (C) and components (D) which are preferably dried Homogeneous mixing at preferably 10-40°C, more preferably 15-35°C, most preferably 20-30°C for 1-4 hours, preferably 1.5-3.5 hours, more preferably 2-3 hours. In other embodiments, the preparation method of the composition may include: first uniformly mixing component (A), optional component (F) and optional component (G), and , dehydration at a temperature of preferably 60-160°C, more preferably 80-140°C, most preferably 100-120°C for 0.5-2, preferably 0.8-1.5 hours, after cooling in a vacuum and preferably at 10-40°C, more preferably 15 Add the dried component (C), component (D), optional component (E) and optional component (H) at a temperature of -35°C, most preferably 20-30°C, and mix Uniformly 0.5-2 ...

Embodiment

[0045] The mixer used in the test is a DLH-5 planetary power mixer produced by Foshan Jinyinhe Machinery Equipment Co., Ltd.; the vacuum pump used is a ZWLW23B oil-free vertical vacuum pump produced by Tianfeng Vacuum Pump Co., Ltd.

[0046] Synthesis of Silazanes

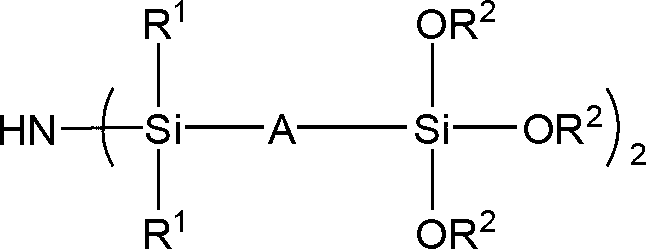

[0047] 1 mol of silazane of the following formula

[0048]

[0049] where R 1 = n-propyl and B = vinyl

[0050] With 2mol alkoxysilane of the following formula

[0051]

[0052] where R 2 = n-propyl

[0053] Mix in the flask, then add 5g chloroplatinic acid-isopropanol solution (the concentration of platinum in this chloroplatinic acid-isopropanol solution is 1000 μg / g, based on the total mass of silazane and siloxane, platinum element The concentration is about 12μg / g), gently shake the flask for 2 minutes to mix the reactants evenly, the reaction exotherm is violent, after 15-30 minutes, the exotherm stops, the reaction is over, and the component (B) silicon The structure of azane is:

[0054]

[...

Embodiment 1

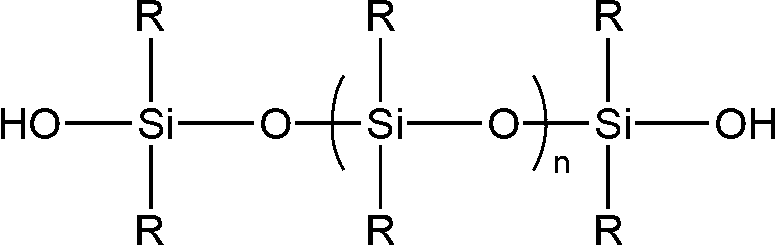

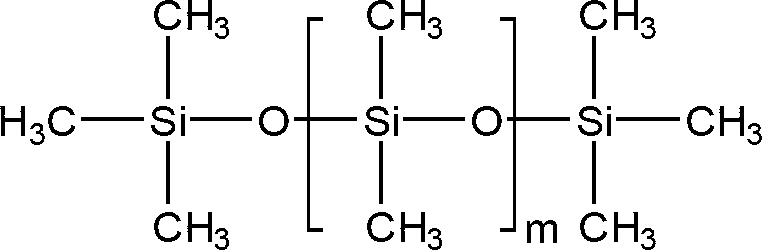

[0062] 100 parts by mass of a viscosity of 5,000 mPa·s hydroxyl-terminated polydimethylsiloxane (structural formula: Wherein n=600) (A), the specific surface area of 6 mass parts is 150m 2 / g, hydrophilic fumed silica (F) with an average particle size of 12nm, mixed uniformly at 23°C, dehydrated at 120°C for 2 hours under vacuum conditions, and cooled to room temperature; under moisture-proof conditions, add 1.3 The silazane (B) of the present invention (wherein, R 1 = n-propyl; R 2 = n-propyl; A = -C 2 h 4 -)( 1 H-NMR (CDCl 3 , δppm): 0.96 (30H, t), 1.52 (12H, m), 3.79 (12H, t), 1.4 (8H, m), 1.3 (8H, t), 0.6 (4H, t), 1.4 (4H, t), 2.0(1H, s)), 0.15 parts by mass of formic acid (E), mixed in vacuum at 25°C for 2.2 hours; then added 6 parts by mass of dimethyldimethoxysilane (D), 3 parts by mass of Dimethoxybis(methylacetoacetate)titanium (C), mixed under vacuum at 25°C for 1.45 hours; 2 Subpackage under protection and keep in airtight condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com