Method for preparing natural rubber exhaust gasket for forming rubber shoes

A technology of natural rubber and exhaust pads, which is applied in the field of preparation of natural rubber exhaust pads, can solve the problems of affecting product qualification rate, poor bonding of rubber parts, and short service life of gaskets, etc., and achieves low production cost and improved Long service life and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

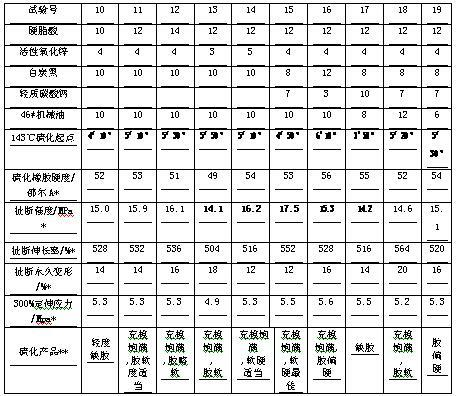

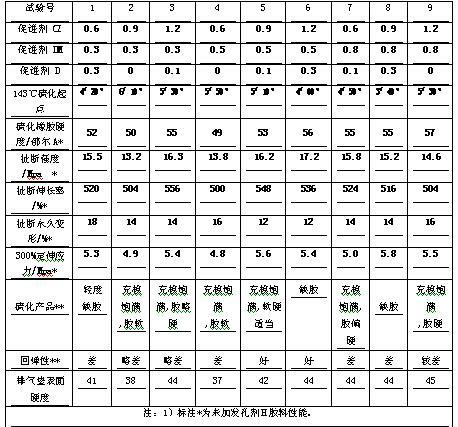

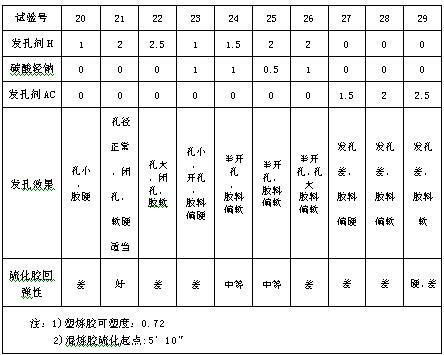

[0060] Embodiment 1 of the present invention: the preparation method of the natural rubber exhaust pad that is used for rubber shoe molding, first prepares the rubber main body of exhaust pad, calculates by weight, 100 parts of 2# standard rubbers are carried out three times on the open rubber mixing machine Duan Botong, prepared a plastic rubber A with a Vickers plasticity of 0.70 to 0.75; it was obtained by mixing a reinforcing filler consisting of 7 parts of light calcium carbonate and 8 parts of precipitated white carbon black with 10 parts of 46# mechanical oil B product; The vulcanization accelerator that is made up of 0.9 part of accelerator CZ, 0.5 part of accelerator DM and 0.1 part of accelerator D and the vulcanization activator that is made up of 12.5 parts of stearic acid and 4 parts of active zinc oxide are mixed to obtain C product; Mix 2 parts of pore-forming agent H and 2 parts of sulfur to obtain product D; roll the plasticized rubber A in an open rubber mixer...

Embodiment 2

[0061] Embodiment 2 of the present invention: the preparation method of the natural rubber exhaust pad that is used for rubber shoe molding, first prepares the rubber main body of exhaust pad, calculates by weight parts, 90 parts of 2# standard rubbers are carried out three times on the open rubber mixing machine Duan Botong, prepared a plastic rubber A with a Vickers plasticity of 0.70 to 0.75; mixed a reinforcing filler consisting of 7 parts of light calcium carbonate and 7 parts of precipitated white carbon black with 8.5 parts of 46# mechanical oil to obtain B product; The vulcanization accelerator that is made up of 0.8 part of accelerator CZ, 0.4 part of accelerator DM and 0.1 part of accelerator D and the vulcanization active agent that is made up of 8.5 parts of stearic acid and 3.5 parts of active zinc oxide are mixed to obtain C product; Mix 1.9 parts of pore-forming agent H and 1.8 parts of sulfur to obtain product D; roll the plasticized rubber A in an open rubber m...

Embodiment 3

[0062] Embodiment 3 of the present invention: the preparation method of the natural rubber exhaust pad that is used for rubber shoes molding, first prepares the rubber main body of exhaust pad, calculates by weight, 110 parts of 2# standard rubbers are carried out three times on the open rubber mixing machine Duan Botong, prepared a plastic rubber A with a Vickers plasticity of 0.70-0.75; mixed a reinforcing filler consisting of 8 parts of light calcium carbonate and 10 parts of precipitated white carbon black with 12 parts of 46# mechanical oil to obtain Product B; the vulcanization accelerator made up of 1 part of accelerator CZ, 0.6 part of accelerator DM and 0.2 part of accelerator D and the vulcanization activator composed of 12 parts of stearic acid and 6 parts of active zinc oxide are mixed to obtain product C; 2.1 parts of pore forming agent H and 12.3 parts of sulfur are mixed to obtain product D; the plasticized rubber A is rolled in an open rubber mixer at a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com