Primer coating for single-component room-temperature vulcanized silicone rubber and preparation method thereof

A technology of room temperature vulcanization and silicone rubber, which is applied in the direction of coating to achieve the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

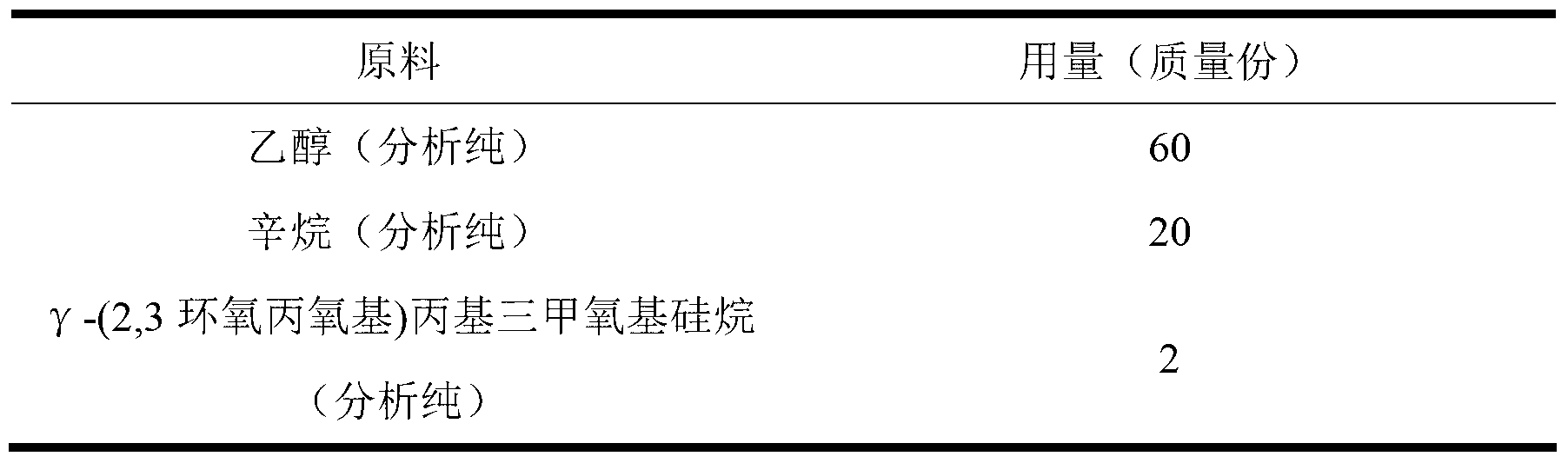

[0020] A primer for one-component room temperature vulcanized silicone rubber, the formulation of which is as follows:

[0021] Table 1: Formula composition of primer

[0022]

[0023]

[0024] The corresponding preparation method is:

[0025] Step 1: Put all the raw materials except essence into the stirring tank, and stir at room temperature for 30-60 minutes to disperse them evenly;

[0026] Step 2: Add essence and stir at room temperature for 10-20 minutes to disperse evenly;

[0027] The third step: filter the solution to obtain the finished product.

Embodiment 2

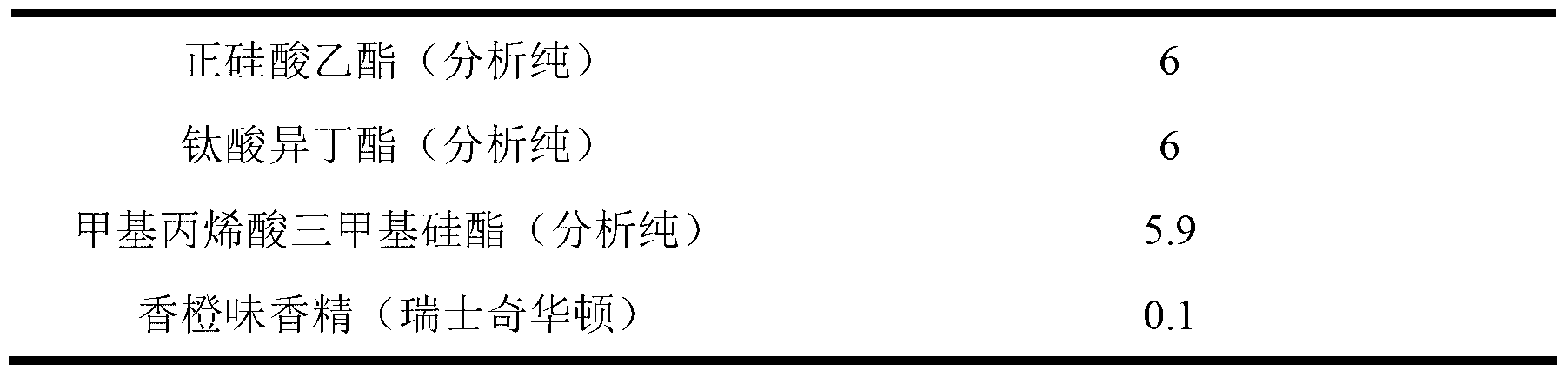

[0029] A primer for one-component room temperature vulcanized silicone rubber, the formulation of which is as follows:

[0030] Table 2: Formula composition of primer

[0031]

[0032] The corresponding preparation method is:

[0033] Step 1: Put all the raw materials except essence into the stirring tank, and stir at room temperature for 30-60 minutes to disperse them evenly;

[0034] Step 2: Add essence and stir at room temperature for 10-20 minutes to disperse evenly;

[0035] The third step: filter the solution to obtain the finished product.

Embodiment 3

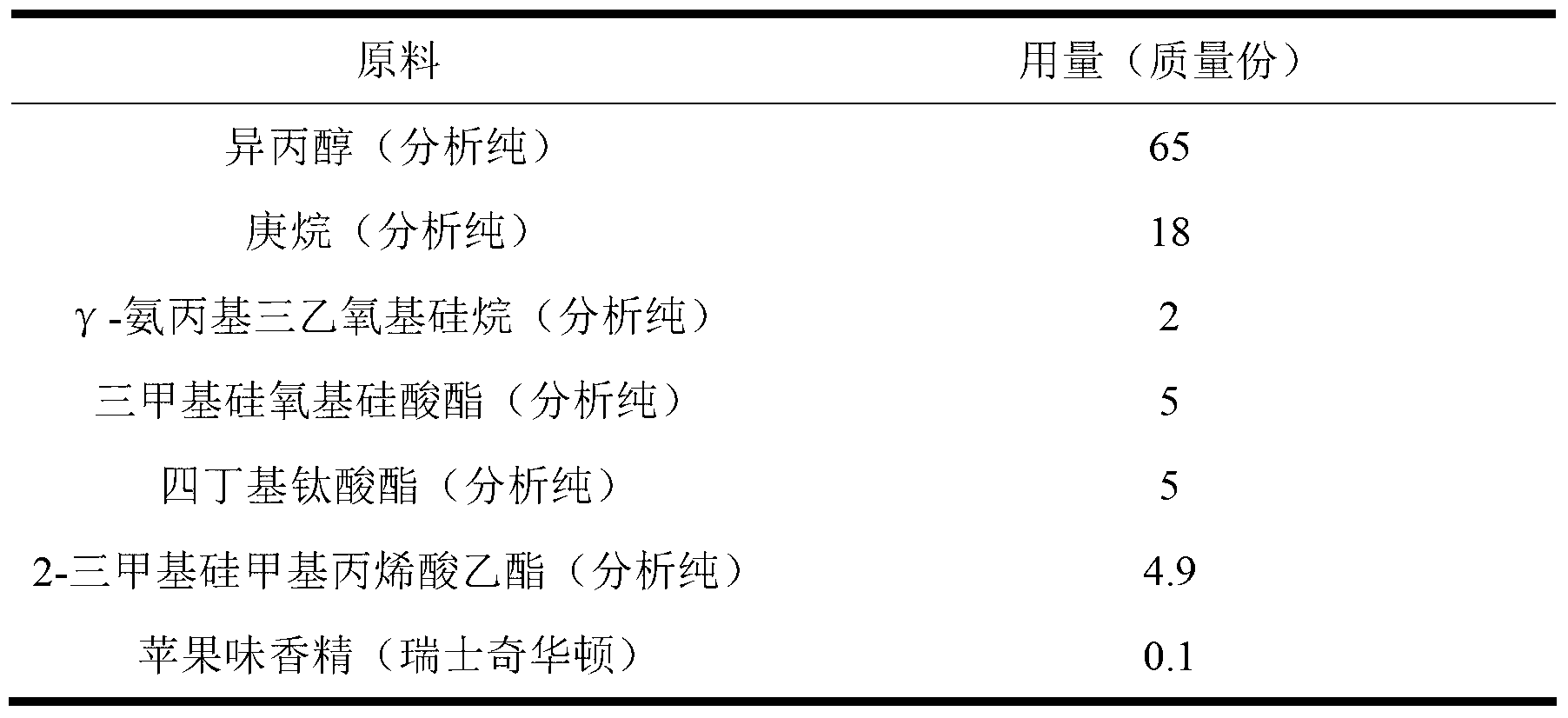

[0037] A primer for one-component room temperature vulcanized silicone rubber, the formulation of which is as follows:

[0038] Table 3: Formula composition of primer

[0039]

[0040] The corresponding preparation method is:

[0041] Step 1: Put all the raw materials except essence into the stirring tank, and stir at room temperature for 30-60 minutes to disperse them evenly;

[0042] Step 2: Add essence and stir at room temperature for 10-20 minutes to disperse evenly;

[0043] The third step: filter the solution to obtain the finished product.

[0044] For the primer prepared in the embodiment of the present invention, the primer is directly coated on the substrate to be bonded, and the sizing process can be performed after 20 seconds to 45 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com