High-strength single-component room temperature vulcanized silicone rubber

A room temperature vulcanization, one-component technology, used in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problem of tensile strength, adhesion and chemical resistance, tensile strength Low cost, limited application range and other issues, to achieve the effects of improved mechanical strength, low cost, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

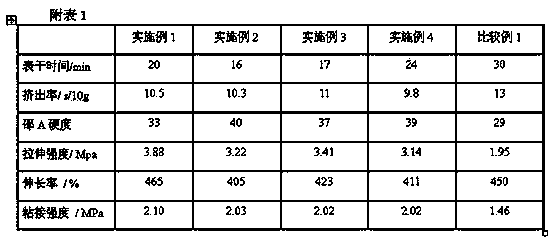

Examples

Embodiment 1

[0031] Example 1 Select a hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000mPa·s and a dimethicone oil with a viscosity of 1000mPa·s, and its components are as follows:

[0032] 100 parts of hydroxyl-terminated polydimethylsiloxane polymer;

[0033] 60 parts of nano calcium carbonate;

[0034] Kaolin (2000 mesh) 37 parts;

[0035] Talc powder (600 mesh) 12 parts;

[0036] Fumed white carbon black 4 parts;

[0037] 33 parts of silicone oil plasticizers;

[0038] 3 parts of pigment;

[0039] 3 parts of vinyl tributylketoxime silane;

[0040] 7 parts of tetramethylketoxime silane;

[0041] 1 part of γ-(2,3-epoxypropoxy)propyltrimethoxysilane.

Embodiment 2

[0042] Example 2 Select a hydroxyl-terminated polydimethylsiloxane with a viscosity of 5000mPa·s and a dimethicone oil with a viscosity of 1000mPa·s, and its components are as follows:

[0043] 100 parts of hydroxyl-terminated polydimethylsiloxane polymer;

[0044] Kaolin (2000 mesh) 40 parts;

[0045] Talcum powder (400 mesh) 59 parts;

[0046] Fumed white carbon black 6 parts;

[0047] 33 parts of silicone oil plasticizers;

[0048] 3 parts of pigment;

[0049] 3 parts of vinyl tributylketoxime silane;

[0050] 3 parts of methyl tributylketoxime silane;

[0051] 1.7 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane;

[0052]0.4 parts of dibutyltin dilaurate.

Embodiment 3

[0053] Example 3 selects 20000mPa·s and 50000mPa·s hydroxyl-terminated polydimethylsiloxane with a viscosity of 100mPa·s dimethicone, and its components are as follows:

[0054] 50 parts of 20000mPa·s hydroxyl-terminated polydimethylsiloxane polymer;

[0055] 50 parts of 50000mPa·s hydroxyl-terminated polydimethylsiloxane polymer;

[0056] 45 parts of nano calcium carbonate;

[0057] Kaolin (1250 mesh) 55 parts;

[0058] Fumed white carbon black 5 parts;

[0059] 33 parts of silicone oil plasticizers;

[0060] 3 parts of pigment;

[0061] 6 parts of methyl tributylketoxime silane;

[0062] 1.7 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane;

[0063] 0.5 parts of dibutyltin dilaurate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com