Protective eyeshade with cleaning-resistant, high-temperature-resistant, damp-heat-resistant and sterilizing composition

A technology of moist heat sterilization and composition, applied in goggles, ophthalmic surgery, etc., can solve the problems of inability to perform high-temperature cleaning and sterilization, waste of resources and manpower and material resources, increase environmental pollution, etc., and achieve a wide range of use and excellent environmental performance. , good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The protective goggles with cleaning-resistant, high-temperature, damp-heat-resistant sterilization composition of the present embodiment include protective lenses, goggle frames and fixing pieces, the protective lenses are embedded in the goggle frame, and the fixing pieces fix the goggle frame and the webbing together.

[0034] Among them, the protective lens is composed of modified polycarbonate composition.

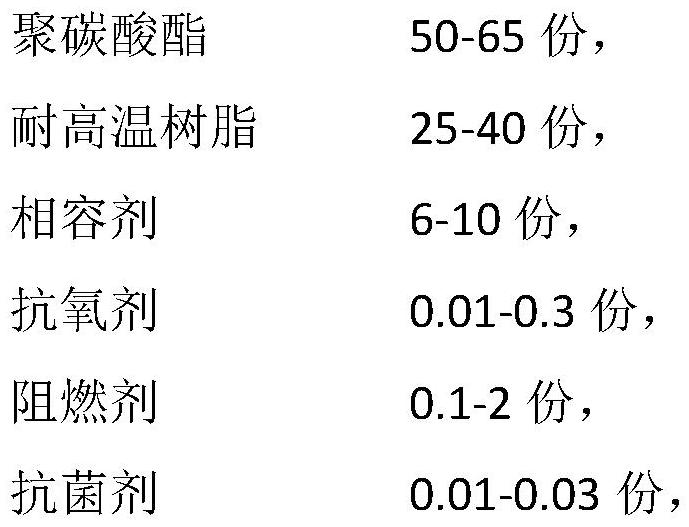

[0035] The modified polycarbonate composition comprises the following components:

[0036]

[0037] Modified polycarbonate composition preparation method comprises the steps:

[0038] (1) Add polycarbonate, high temperature resistant resin, compatibilizer, antioxidant, flame retardant and antibacterial agent to the mixer in turn and mix them. The mixing temperature is 50°C and the mixing time is 6 minutes to obtain a premixed thing;

[0039] (2) Then put the premix into a twin-screw extruder for melt mixing and extruding to obtain a modified polycarbonate ...

Embodiment 2

[0057] The protective goggles with cleaning-resistant, high-temperature, damp-heat-resistant sterilization composition of the present embodiment include protective lenses, goggle frames and fixing pieces, the protective lenses are embedded in the goggle frame, and the fixing pieces fix the goggle frame and the webbing together.

[0058] Among them, the protective lens is composed of modified polycarbonate composition.

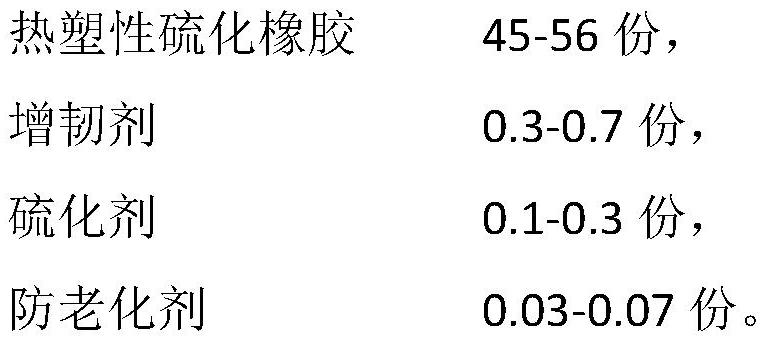

[0059] The modified polycarbonate composition comprises the following components:

[0060]

[0061] Modified polycarbonate composition preparation method comprises the steps:

[0062] (1) Add polycarbonate, high temperature resistant resin, compatibilizer, antioxidant, flame retardant and antibacterial agent to the mixer in turn and mix them. The mixing temperature is 40°C and the mixing time is 6 minutes to obtain a premixed thing;

[0063] (2) Then put the premix into a twin-screw extruder for melt mixing and extruding to obtain a modified polycarbonate ...

Embodiment 3

[0081] The protective goggles with cleaning-resistant, high-temperature, damp-heat-resistant sterilization composition of the present embodiment include protective lenses, goggle frames and fixing pieces, the protective lenses are embedded in the goggle frame, and the fixing pieces fix the goggle frame and the webbing together.

[0082] Among them, the protective lens is composed of modified polycarbonate composition.

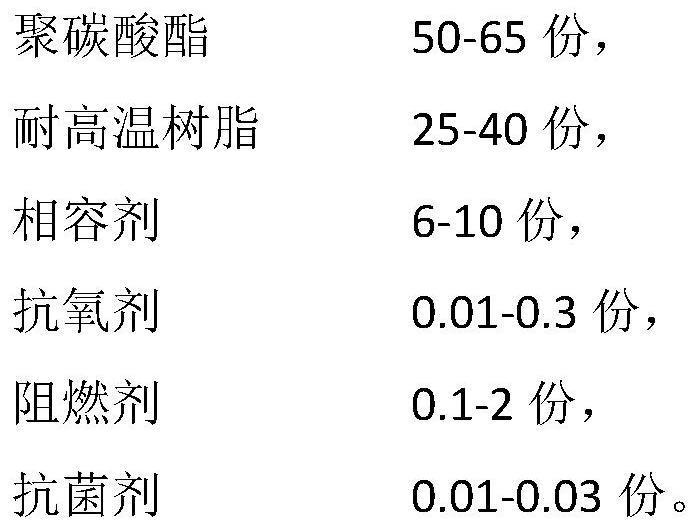

[0083] The modified polycarbonate composition comprises the following components:

[0084]

[0085] Modified polycarbonate composition preparation method comprises the steps:

[0086] (1) Add polycarbonate, high temperature resistant resin, compatibilizer, antioxidant, flame retardant and antibacterial agent to the mixer in turn and mix them. The mixing temperature is 40°C and the mixing time is 6 minutes to obtain a premixed thing;

[0087] (2) Then put the premix into a twin-screw extruder for melt mixing and extruding to obtain a modified polycarbonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com