Patents

Literature

55results about How to "Excellent high strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its prepn

InactiveCN1887996AImprove physicsGood chemical propertiesInorganic pigment treatmentAnti-corrosive paintsEpoxyHigh intensity

The present invention discloses one kind of heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its preparation process. The anticorrosive paint consists of primer, finishing paint and intercoat paint. The primer consists of polyphenylene sulfide, epoxy resin, glass scale and cyanamide dimmer. The finishing paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, 4, 4'-diamino diphenyl sulphone and cyanamide dimmer. The intercoat paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, glass scale, dihydrazide sebacate and 4, 4'-diamino diphenyl sulphone. The anticorrosive paint produces no sag, and can form homogeneous and smooth coating with excellent physical and chemical performance, high heat resistance, high corrosion resistance, high impact strength, and high insulating performance.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Easily workable high-performance polyimide material and its preparation method

InactiveCN1428361AEasy to processEasy to withstand high temperatureDiphenyl etherDiaminodiphenyl ether

The present invention uses 4,4-diphenyl ether tetrahydric dianhydride and 4,4'-diaminodiphyl ether as polymerization monomer, and adopts the solution polycondensation method combining chemical imidation process and thermal imidation process to synthesize the high-temp.-resistant and solvent-resistant polyimide resin. Said invented polyimide resin possesses good working property, the polyimide plate material die-moulded by using said polyimide resin possesses high strength and fire resistance, its glas-stransition temperature is 267.7 deg.C, 5% thermal weight loss temperature is 543.1 deg.c, tensile strength is 145 MPa, impact strength is 192 KJ / sq.m, compressive strength is 1635 MP and oxygen index is 46.2.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Steel wire rod having excellent cold heading quality and hydrogen delayed fracture resistance, method of manufacturing the same, and mehod of manufacturing bolt using the same

InactiveUS20120128524A1Excellent hydrogen delayed fracture resistanceExcellent cold heading qualityFurnace typesHeat treatment furnacesWire rodHydrogen

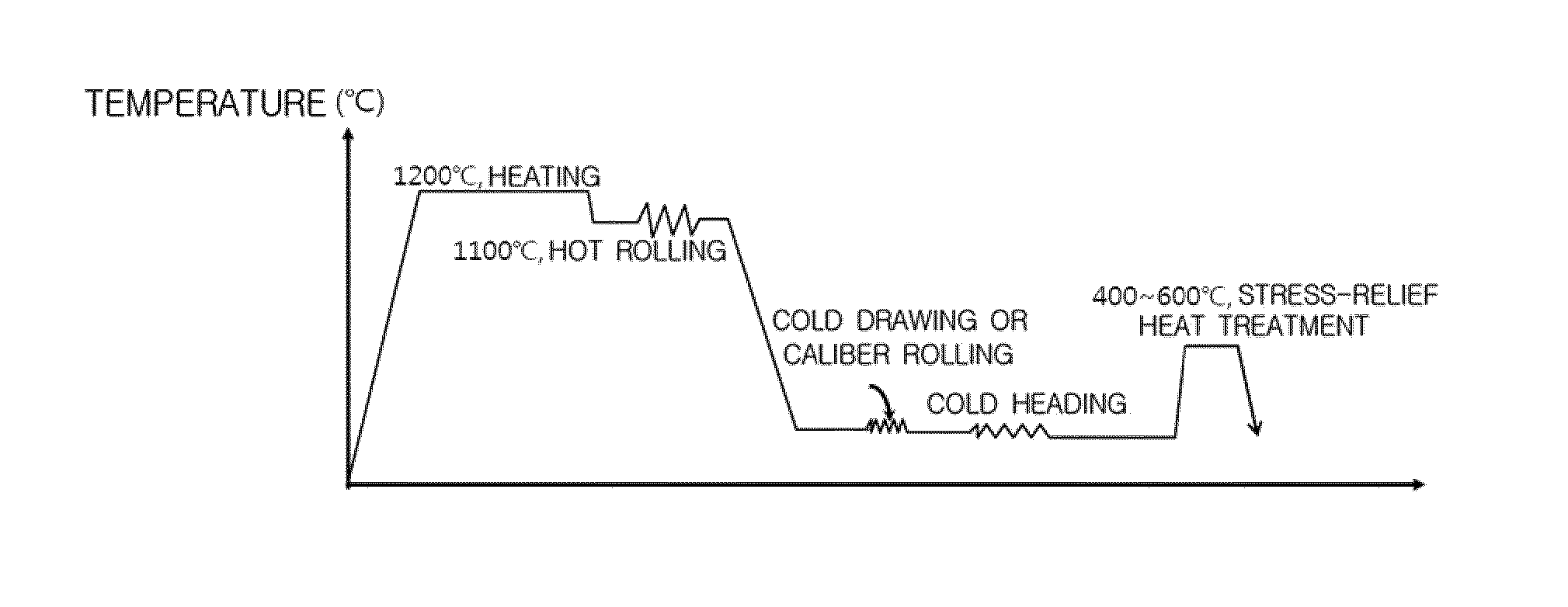

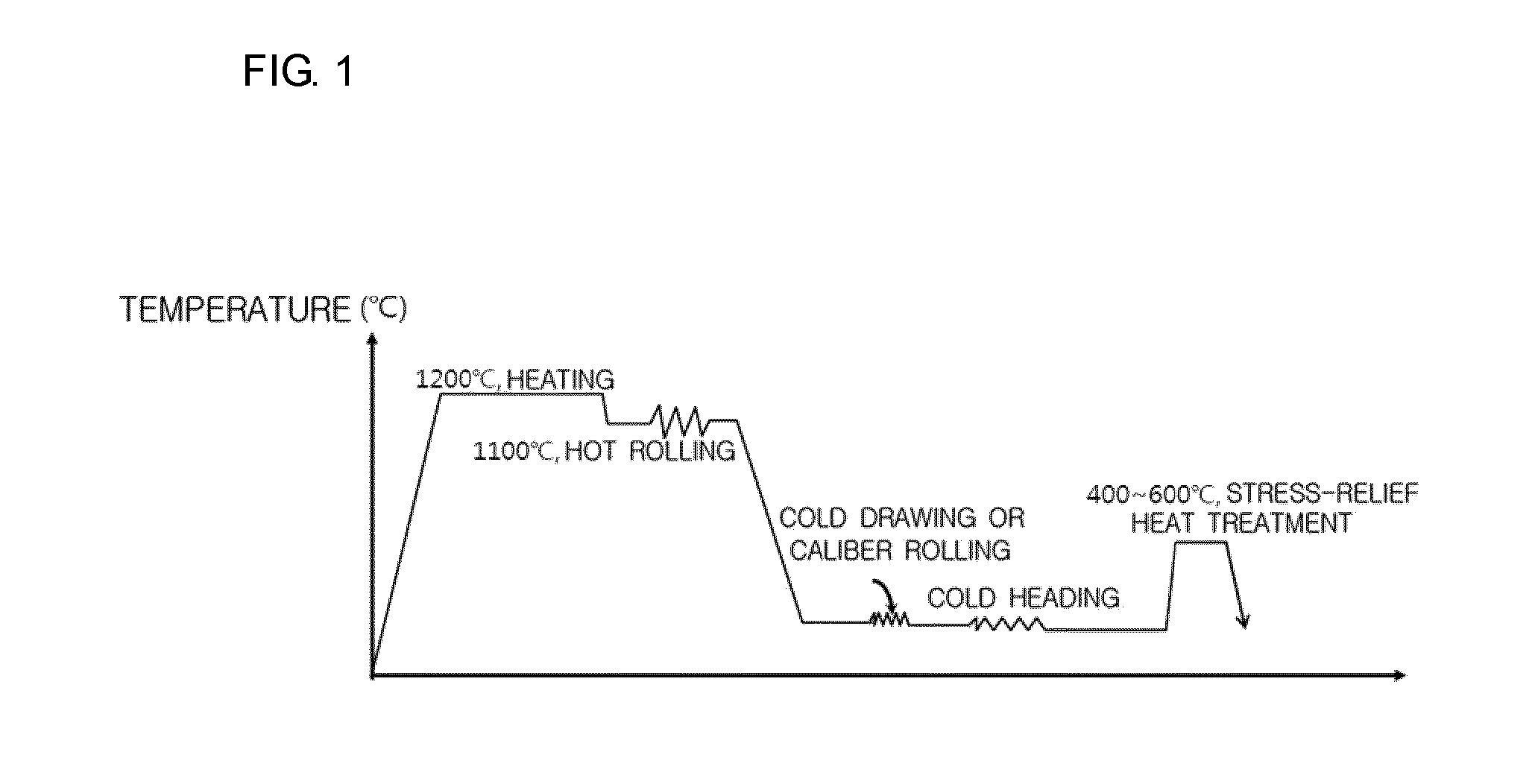

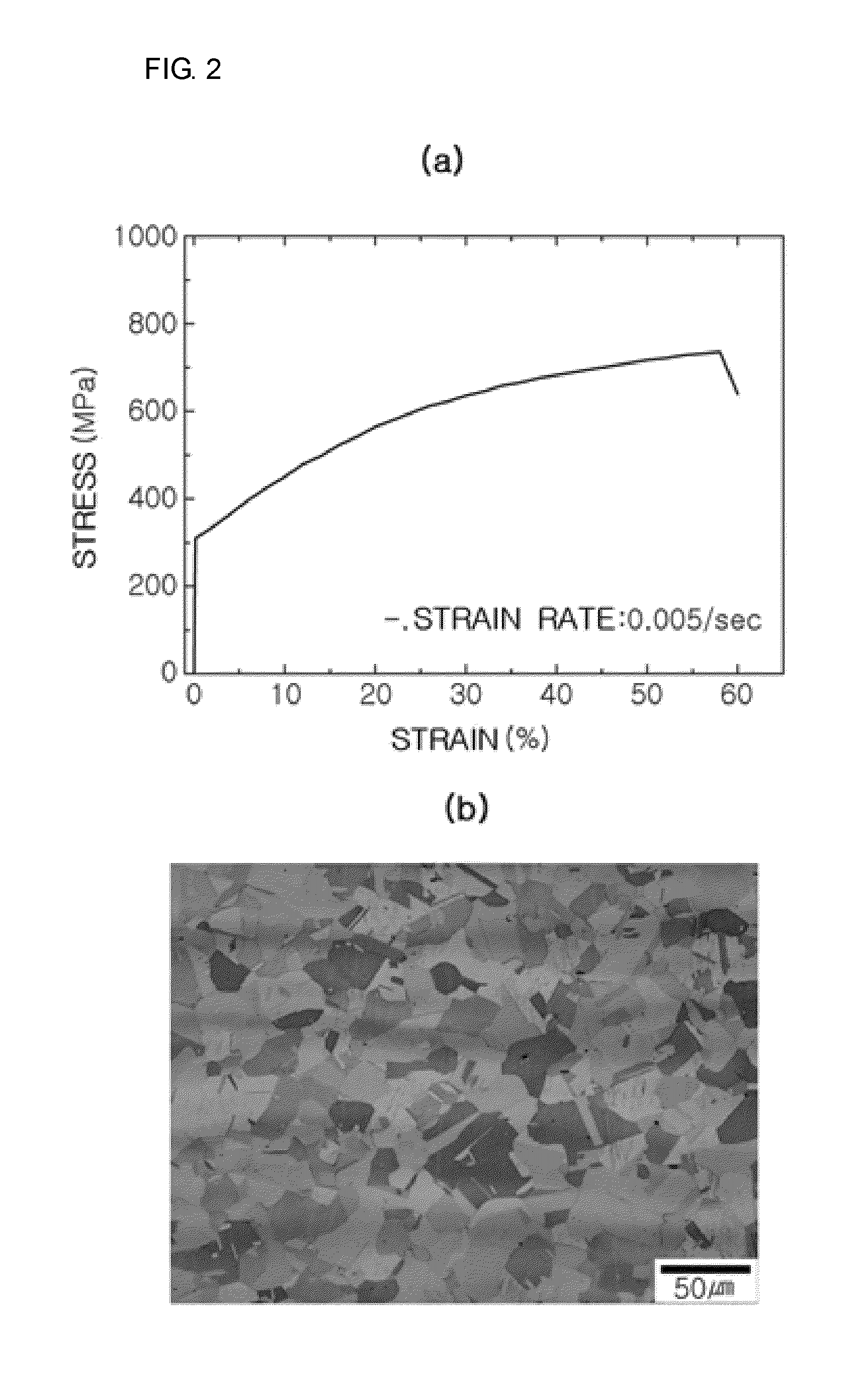

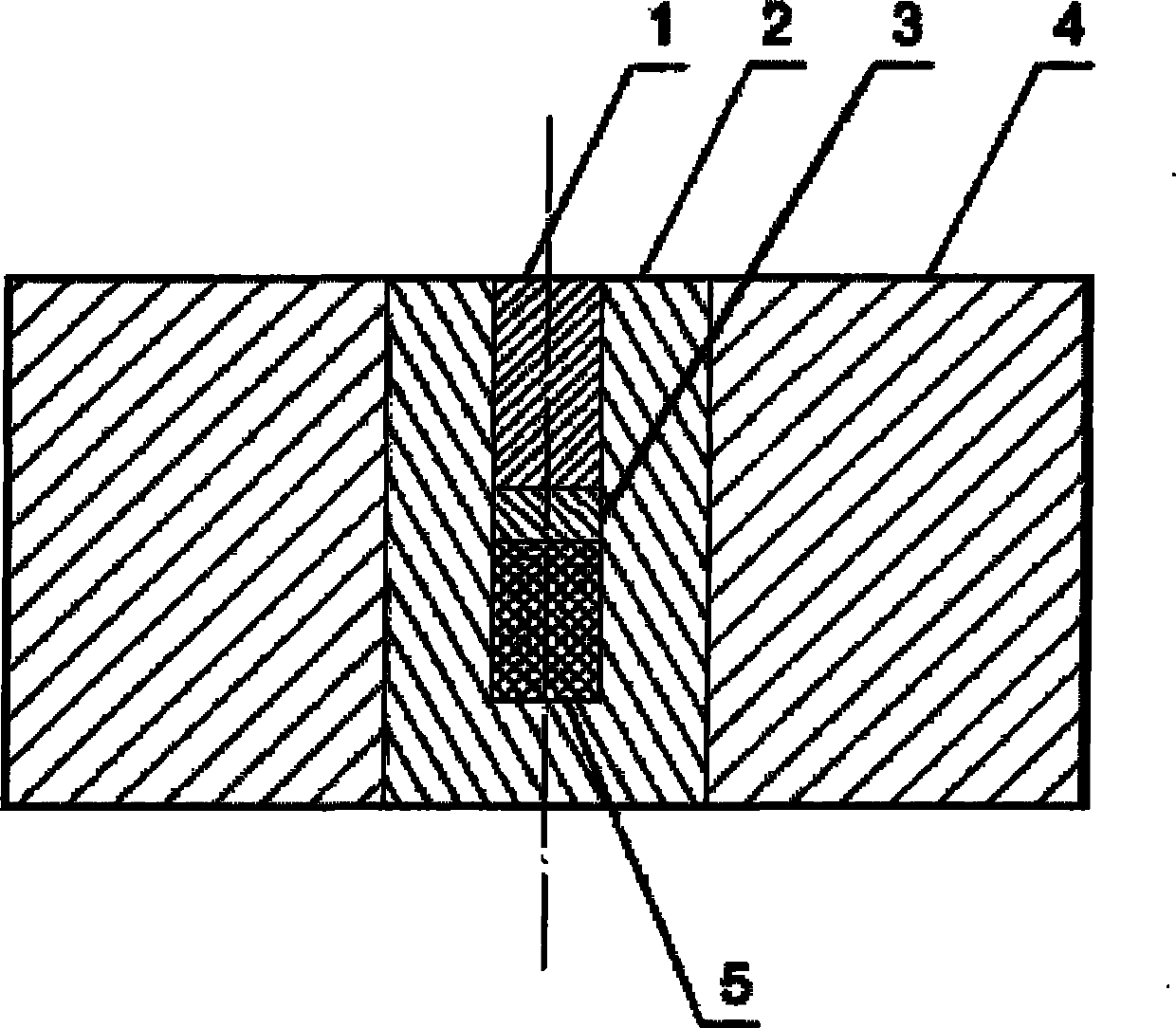

Provided are a high-strength, high-manganese steel wire rod having excellent cold heading quality and not requiring spheroidizing and quenching-tempering treatments during manufacturing a bolt and a method of manufacturing a bolt using the steel wire rod. The method of manufacturing a steel wire rod includes heating a steel containing 12 to 25 wt % of Mn within a temperature range of 1100° C. to 1250° C., hot rolling the heated steel within a temperature range of 700° C. to 1100° C., and cooling the hot rolled steel to a temperature of 200° C. or less and cold caliber rolling or drawing to manufacture a steel wire rod.

Owner:POSTECH ACAD IND FOUND

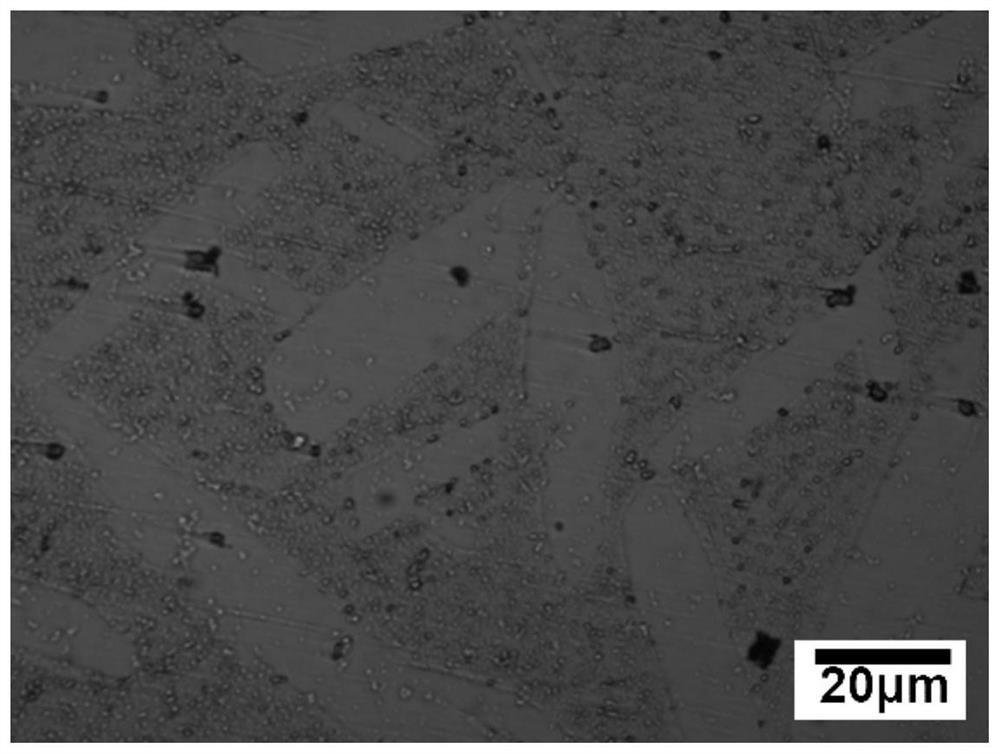

Preparation method of high wear-resistant eutectic ceramic

The invention provides a preparation method of high wear-resistant eutectic ceramic, belonging to the technical field of new material preparation, wherein the eutectic ceramic comprises Al2O3-ZrO2(3Y). The preparation method of the eutectic ceramic comprises the following steps: firstly acquiring a ceramic sintered body with a certain shape as a blank for preparing the eutectic ceramic, and finally obtaining the high wear-resistant eutectic ceramic by a high-temperature melting method under the condition of vacuum. In the method, mol content of Al2O3 in the eutectic ceramic is 40%-49%, mol content of ZrO2(3Y) is 51%-60%, and average particle size of the original powder is less than 100 nanometers; and sintering temperature of the eutectic ceramic is 1400-1550 DEG C, melting temperature is 1850-1950 DEG C, and melting holding time is 30-60min. The effect and benefit of the invention is that the preparation method of the eutectic ceramic is simple. The preparation method of the invention has the advantages of low price of main equipment, easy implementation, simplicity and capability of producing large-sized materials; and the obtained eutectic ceramic has high-temperature resistance and high wear resistance.

Owner:DALIAN UNIV OF TECH

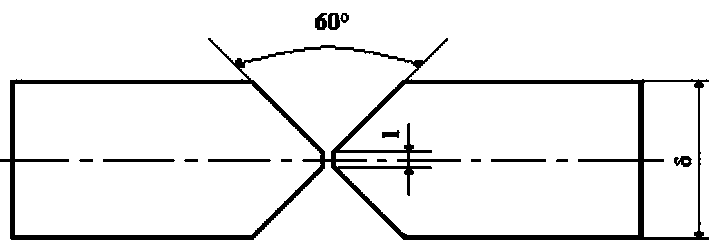

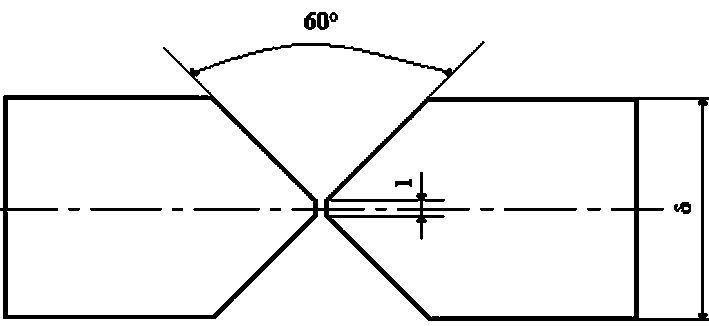

Submerged arc composite welding method of bridge steel thick plate with tensile strength greater than or equal to 810MPa

ActiveCN108746945AMeet the key manufacturing technology of submerged arc welding processImprove crack resistanceArc welding apparatusThick plateMechanical property

The invention discloses a submerged arc composite welding method of a bridge steel thick plate with the tensile strength greater than or equal to 810MPa. The submerged arc composite welding method comprises the steps that according to the mechanical properties of a substrate, ReL is greater than or equal to 690 MPa, Rm is greater than or equal to 810MPa, A is greater than or equal to 14%, and -40DEG C KV2 ballistic work is greater than or equal to 120J; 32mm and 50mm equal thickness bridge steel welding is performed; a groove is a double-sided V-shaped symmetrical groove, the angle of the groove is 60 degrees, and the truncated edge is 1mm; welding wires comprising a welding wire for submerged-arc welding and a gas-shielded welding wire are selected; and welding process is performed, specifically, gas shielded arc welding backing is firstly performed, and then capping is subjected to submerged-arc welding. According to joint performance, Rm of a weld joint is greater than or equal to810MPa, the joint cold bending d is 3a, the qualified angle is 180 degrees, the weld joint ballistic work -40 DEG C KV2 is greater than or equal to 100J, fusion line ballistic work -40 DEG C KV2 is greater than or equal to 106J, heat affected zone (1mm) -40 DEG C KV2 is greater than or equal to 160J, the average impact work of weld joint three areas is much higher than a standard value, the corrosion resistance index I value of the weld joint is greater than or equal to 8.78. The weld joint three areas have high impact toughness reserve and safety margin.

Owner:武汉钢铁有限公司

Polyether-ether ketone composite material and preparation method thereof

The invention belongs to the field of special engineering plastics and particularly discloses a polyether-ether ketone composite material. The polyether-ether ketone composite material is characterized by comprising the materials of polyether-ether ketone fine powder, polyether-ether ketone coarse powder, carbon fiber, graphite, polytetrafluoroethylene and a dispersing agent, wherein the mass ratio of the dispersing agent, the carbon fiber, the polytetrafluoroethylene, the graphite, the polyether-ether ketone fine powder to the polyether-ether ketone coarse powder is 1:(11-13):(9-10):(6-8):(7-9):(60-65). The polyether-ether ketone composite material adopts the polyether-ether ketone as a base material, is compounded with a highly-wear-resistant material (carbon fiber), a high-lubricity material (graphite) and a wear-reducing material (polytetrafluoroethylene), comprises the polyether-ether ketone fine powder and the polyether-ether ketone coarse powder and is added with the dispersing agent, so that the fluidity of a product is effectively improved, the stability of the product is improved, the properties of high strength and high wear resistance and the like of the product are further optimized; and the temperature can reach more than 300 DEG C after long-time use, and the melting point is about 356 DEG C, so that the application field of the material is expanded.

Owner:YIBIN TIANYUAN GRP CO LTD

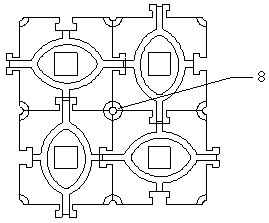

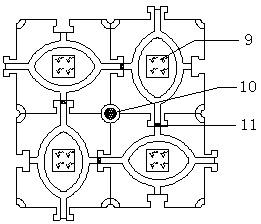

Concrete slope protection building block with drainage and greening functions and construction method thereof

PendingCN111206603AQuality assuranceFast constructionCoastlines protectionExcavationsSurface cleaningArchitectural engineering

The invention discloses a concrete slope protection building block with drainage and greening functions and a construction method thereof. The concrete slope protection building block comprises a building block body, a vegetation growth through groove is formed in the middle of the building block body, third drainage grooves are formed in the periphery of the vegetation growth through groove, twoT-shaped mortises and two T-shaped tenons are arranged on the four side faces of the building block body in total, at least one T-shaped mortise or one T-shaped tenon is arranged on each side face, and a second drainage groove and a first drainage groove which are communicated with the third drainage grooves are sequentially formed in the middle of the surface of each T-shaped mortise and the middle of the surface of each T-shaped tenon. The construction method comprises the following steps of excavating or filling a side slope; slope surface cleaning; paving a gravel cushion layer; paving concrete slope protection building blocks; planting green vegetation; and building a drainage facility connected between the slope bottom concrete blocks and the side ditches. The concrete block has theadvantages of being good in fastening degree, high in adaptability, capable of allowing differential settlement or frost heaving deformation of a slope foundation within a certain range, free of instability damage, small in structural material consumption, attractive, economical and the like.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

DH590MPa acid rolling production technology control method

ActiveCN107557684ARealize industrial productionExcellent high strengthContinuous rollingDual-phase steel

The invention belongs to the technical field of dual-phase steel rolling, and discloses a DH590MPa acid rolling production technology control method. The method includes the following steps of hot-rolled coil unwinding, coiled plate welding, coiled plate withdrawal and straightening, acid pickling, cold continuous rolling and reeling into cold hardened coils. A hot-rolled coil comprises 0.13%-0.148% of C, 1.6%-2.05% of Mn, 0.37%-0.43% of Si, 0.014%-0.015% of P, 0.003%-0.005% of S and 0.45%-0.55% of Alt. Dual-phase steel with good plate shape and thickness deviation is provided.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

High-strength high-modulus double-phase magnesium-lithium alloy and preparation method thereof

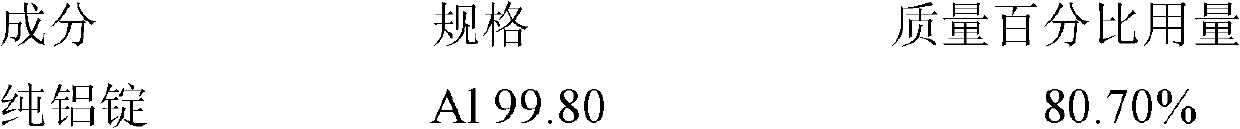

The invention discloses a high-strength high-modulus double-phase magnesium-lithium alloy and a preparation method thereof, and belongs to the technical field of metal material magnesium alloys. The high-strength and high-modulus double-phase magnesium-lithium alloy is prepared from the following components in percentage by mass: 0.05 to 4 percent of Gd, 0.5 to 5 percent of Al, 0.05 to 8 percent of Y, 5 to 10 percent of Li, 0 to 5 percent of Zn, 0.05 to 4 percent of Mn and the balance of Mg and inevitable impurities. Wherein the content of the Zn element cannot be 0. The preparation method comprises a raw material preparation stage, a raw material preheating stage, a heat treatment furnace atmosphere adjustment stage, a vacuum melting stage, a vacuum tube furnace atmosphere adjustment stage and a heat treatment stage. The microalloying and heat treatment combined mode is adopted, the low density of the double-phase magnesium-lithium alloy can be controlled, and meanwhile the strength, the ductility and the elastic modulus of the double-phase magnesium-lithium alloy are cooperatively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

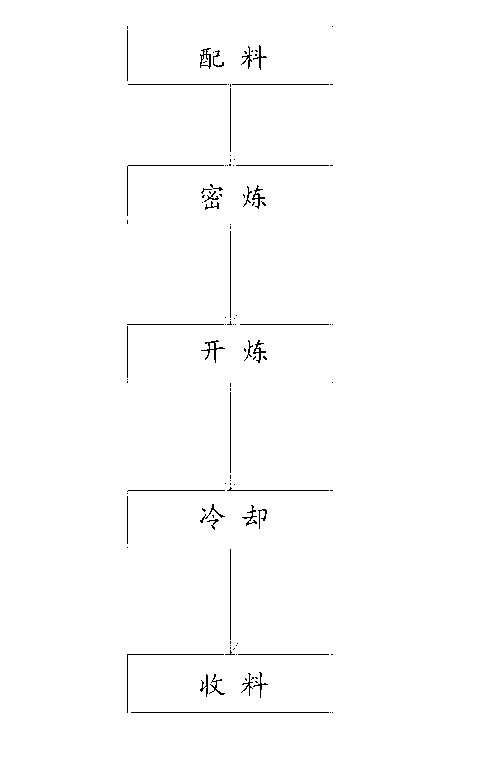

Rubber track plastics for engineering vehicle and preparation method thereof.

The present invention discloses a kind of rubber track plastics for engineering vehicle and a preparation method thereof. Plastic components are changed, and natural rubber and styrene-butadiene rubber are used in the rubber track plastics for engineering vehicle. Natural rubber has good processing property and high strength. Styrene-butadiene rubber has good wear-resistant properties and relatively low price. The natural rubber and styrene butadiene rubber are used together, to endow the product with good abrasion resistance, anti-aging characteristics, and good process stability. The use of carbon black can provide product with sufficient physical and mechanical properties and improve the wear resistance of the product. Various antioxidant and paraffin are used together, to effectively improve the product ozone-aging resistance in static and dynamic conditions.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

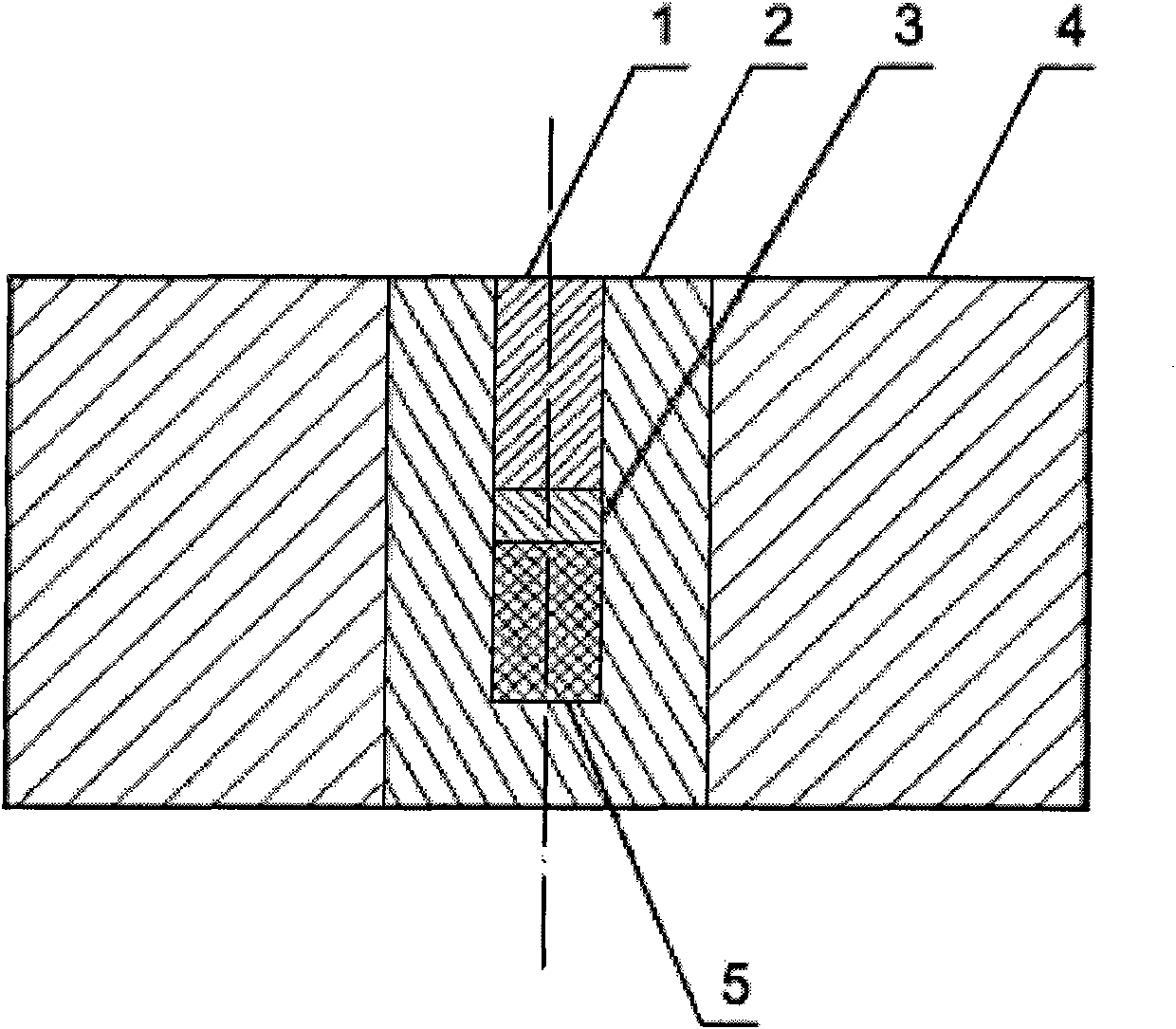

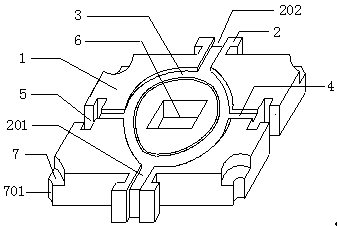

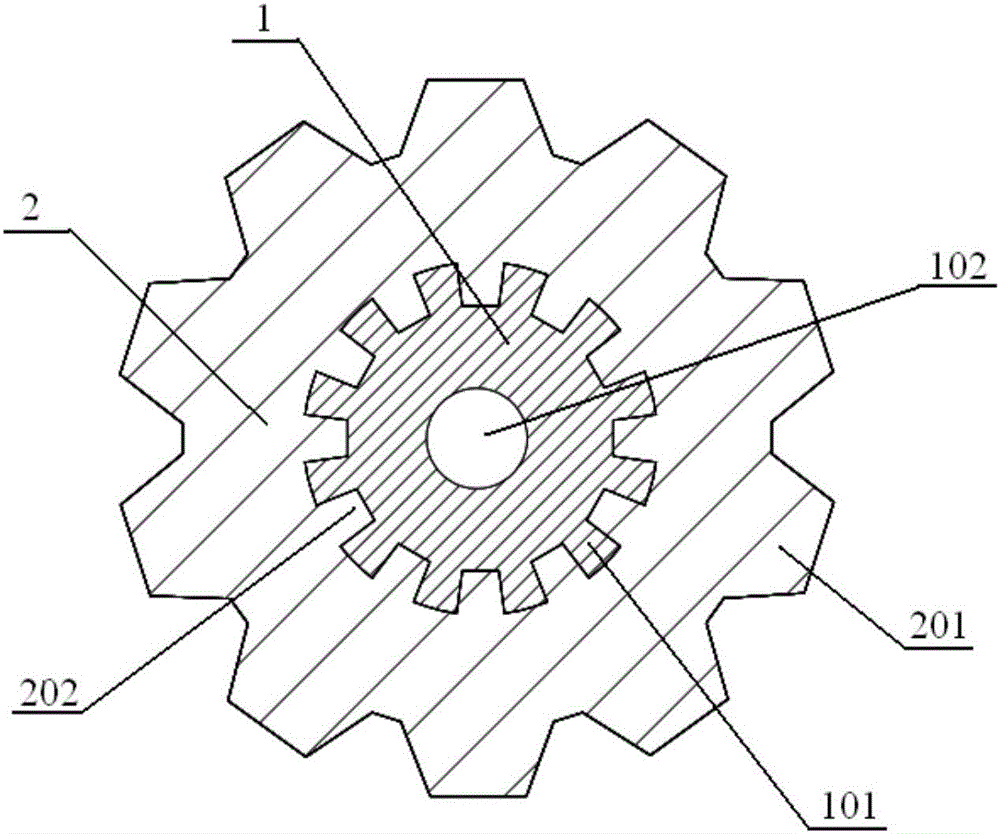

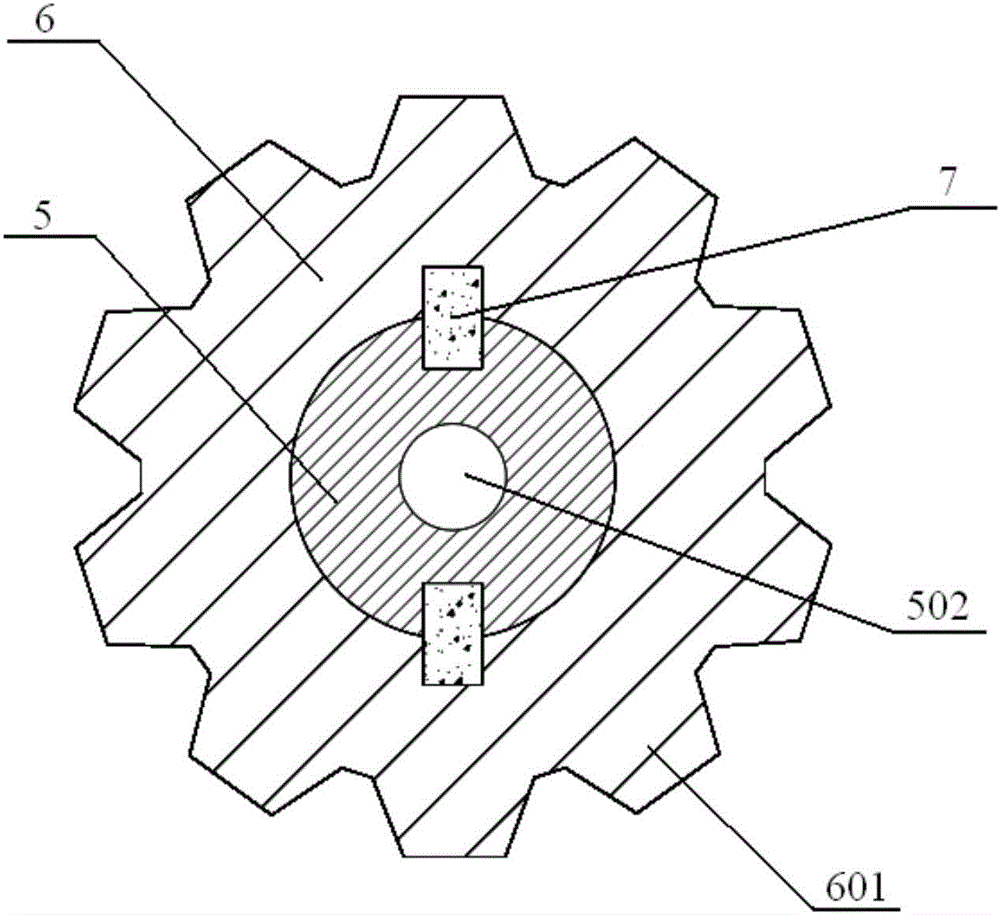

Anti-corrosion nested type gear and gear pump filling machine

InactiveCN106763646ASolve problemsSolve the costPortable liftingGearing elementsWorking environmentEngineering

The invention belongs to the field of mechanical conveying of corrosive liquid chemicals, and particularly relates to an anti-corrosion nested type gear and a gear pump filling machine. The anti-corrosion nested type gear comprises an inner tooth ring and an outer tooth ring, wherein the outer tooth ring is nested at the outer part of the inner tooth ring; an axial hole is formed in the center of the inner tooth ring; multiple first tooth threads are arranged on the outer circumferential surface of the outer tooth ring; the outer tooth ring is made of anti-corrosion plastic. The anti-corrosion nested type gear disclosed by the invention has the beneficial effects that not only can a gear be simply and efficiently disassembled, assembled and replaced, but also a working environment for conveying the corrosive liquid chemicals by the gear pump filling machine can be well adapted, and meanwhile, the service life of the gear is prolonged.

Owner:怀宁县凉亭建材有限责任公司

Organic silicon electronic pouring sealant with good ultraviolet-resisting cooling performance for PCB (Printed Circuit Board)

InactiveCN106634814AHigh tensile strengthSmall molecular weightNon-macromolecular adhesive additivesMacromolecular adhesive additivesIonSilicone resin

The invention discloses an organic silicon electronic pouring sealant with good ultraviolet-resisting cooling performance for a PCB (Printed Circuit Board). The organic silicon electronic pouring sealant is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl end silicone oil-1, 50 to 60 parts of vinyl end silicone oil-2, 0.38 to 0.5 part of 12 percent platinum catalyst, 0.02 to 0.04 part of ethynylcyclohexanol, 25 to 30 parts of vinyl silicone resin, 1-allyloxy-2, 14.8 to 16.8 parts of 3-epoxypropane 1, 23 to 25 parts of 1,3,5,7-tetramethylcyclotetrasiloxane, 2.7 to 3.6 parts of silane coupling agent A171, a proper amount of hydrogen-containing silicone oil, 3.4 to 4 parts of graphene, 0.2 to 0.4 part of silane coupling agent KH1510, a proper amount of acetone and a proper amount of deionized water. The pouring sealant prepared by the invention is simple in preparation process, wide in raw material source, high in operability and high in quality stability of a product; in addition, the pouring sealant has the advantages of excellent weather fastness, heat dissipation, corrosion resistance, high strength and the like, and is worthy of being popularized.

Owner:铜陵安博电路板有限公司

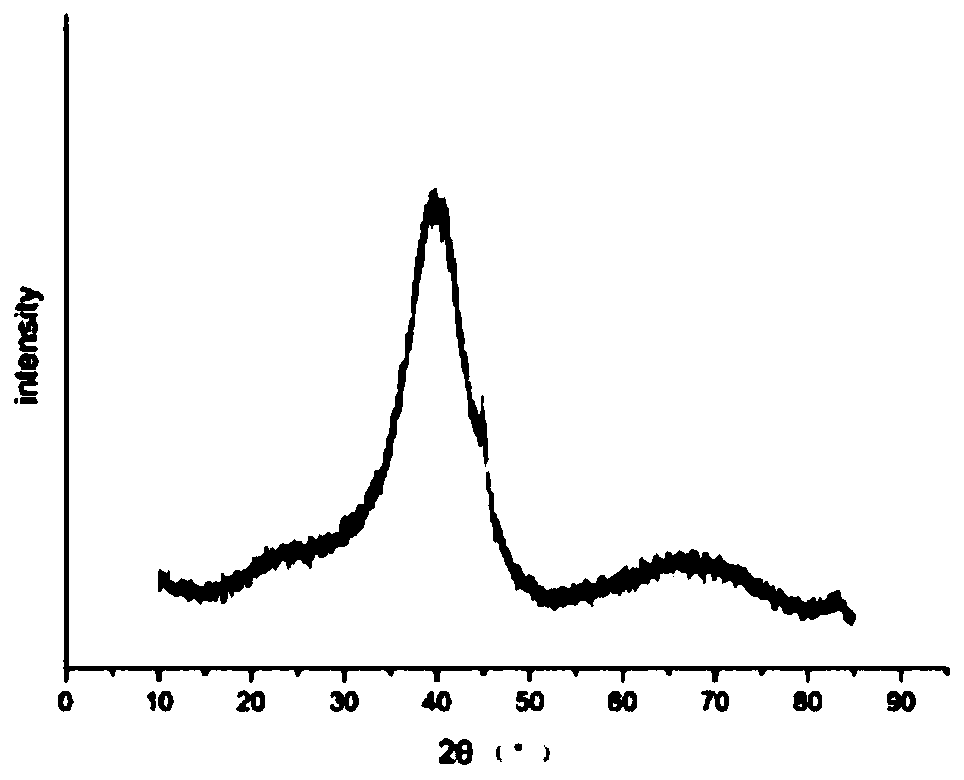

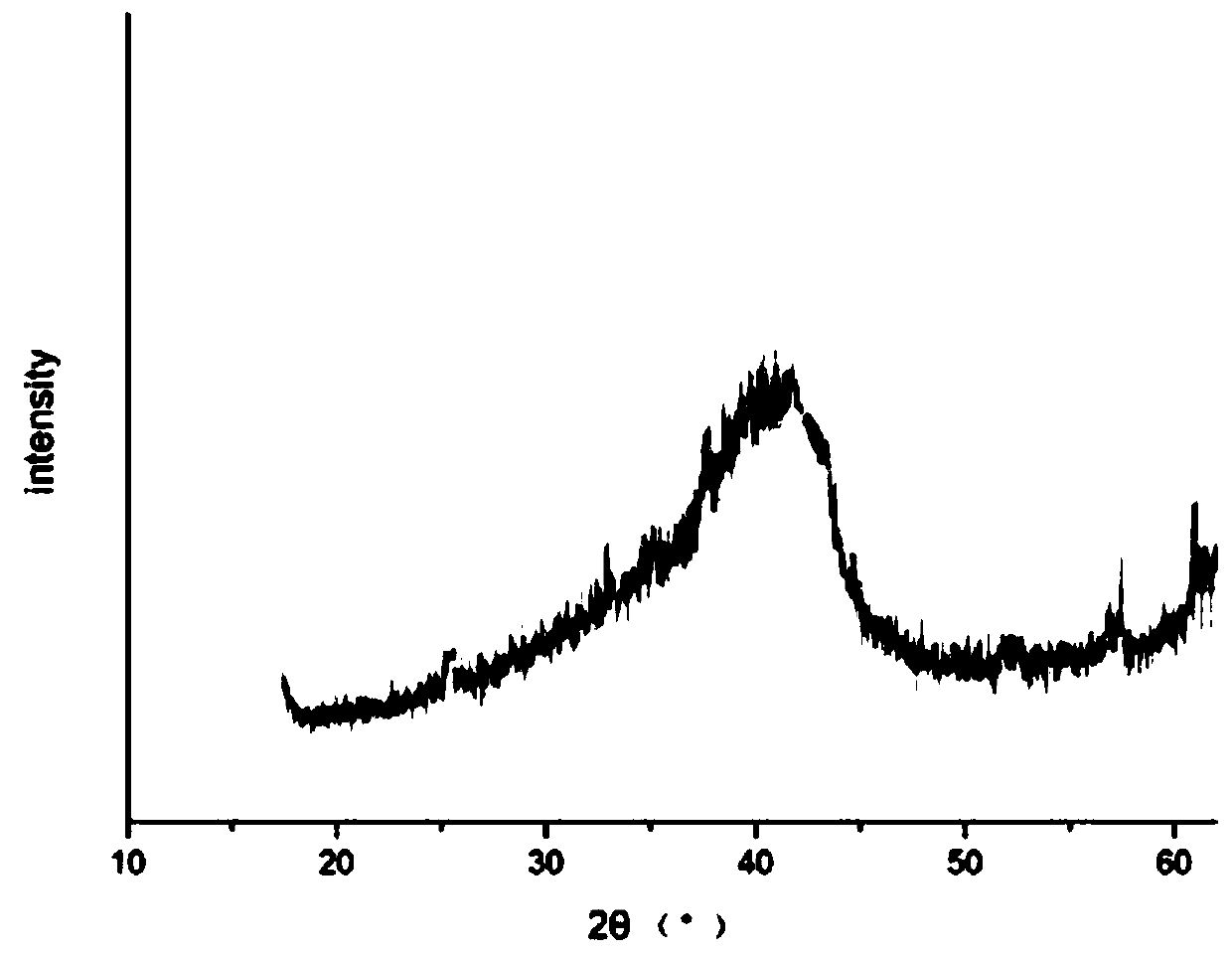

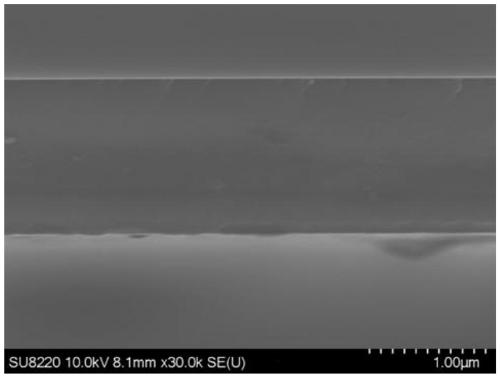

High-entropy alloy composition, high-entropy alloy thin film and preparation method of high-entropy alloy target material and thin film

ActiveCN111549301AImprove high temperature resistanceImprove corrosion resistanceVacuum evaporation coatingSputtering coatingSputteringHigh entropy alloys

An embodiment of the invention discloses a high-entropy alloy composition, a high-entropy alloy thin film and a preparation method of a high-entropy alloy target material and the thin film. The composition comprises Al, Cr, Ti, Gd and Zr. The thin film is prepared from the composition through vacuum melting and magnetron sputtering. The high-entropy alloy composition, the high-entropy alloy thin film and the preparation method of the high-entropy alloy target material and the thin film have the advantages that 1, through cooperation of specific raw material types, the finally obtained high-entropy alloy thin film has excellent properties such as excellent high temperature resistance, corrosion resistance and high strength; 2, by means of a magnetron sputtering method, a crystalline AlCrTiGdZr alloy in an as-cast state is converted into an amorphous thin film, the compactness of the thin film is greatly improved, the defects of the thin film are reduced, the properties of the thin filmare further improved, and the thin film has wider application prospects; and 3, the whole operation process can be conducted at the room temperature, no pollution emissions are generated, and the whole preparation has the advantages of high efficiency and cleanness.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Preparation method of heat-dissipation coating for led streetlamp

InactiveCN107011780ARich microporous structureImprove cooling effectMechanical apparatusLighting heating/cooling arrangementsCarbon nanotubeHigh intensity

The invention discloses a preparation method of a heat-dissipation coating for a led streetlamp. The preparation method comprises the following steps: mixing carboxyl carbon nano tubes with hydroxylating diatomite at first; modifying the mixture by using thionyl chloride and triethylamine; adding 4-vinylbenzyl chloride and triethanolamine borate in the mixture to obtain amidated esterification monomers; polymerizing the monomers in amphenicol dispersion liquid to obtain polymer which has good heat dissipation property, corrosion resistance and high strength. The heat dissipation property is good due to the fact that the diatomite has abundant micro-pore structures, the triethanolamine borate has good corrosion resistance, by the carbon nano tubes, strength and toughness of the polymer are enhanced, plant ash is further added in the polymer, and therefore, the heat dissipation effect of the finished coating is further improved.

Owner:JIANGXI ZHUOZHAO OPTOELECTRONICS TECH

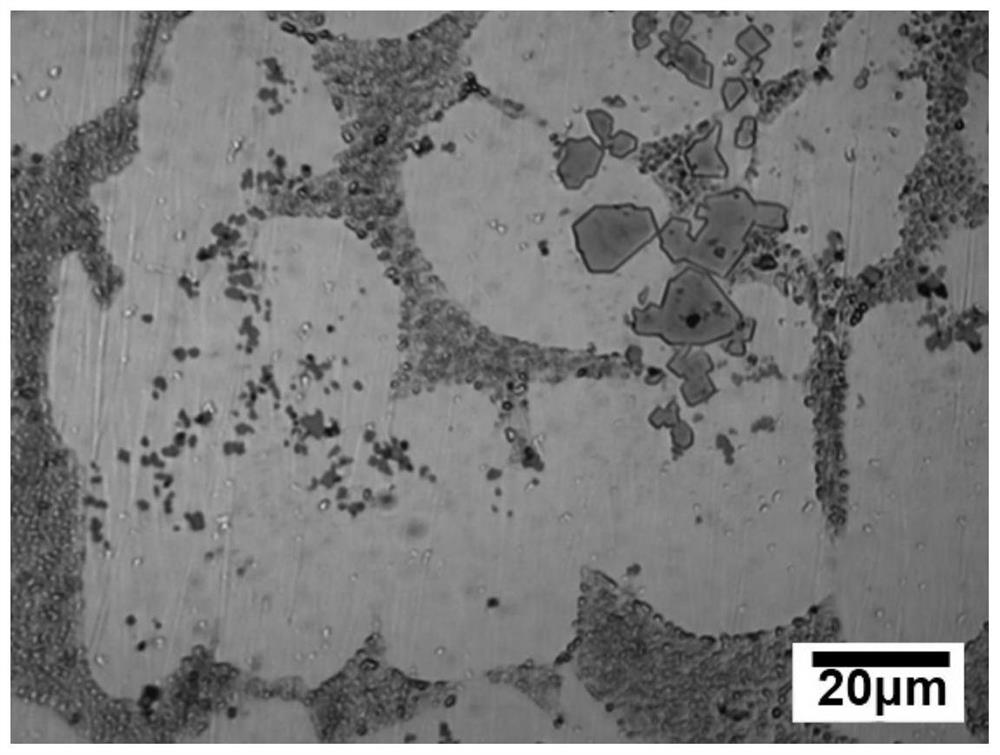

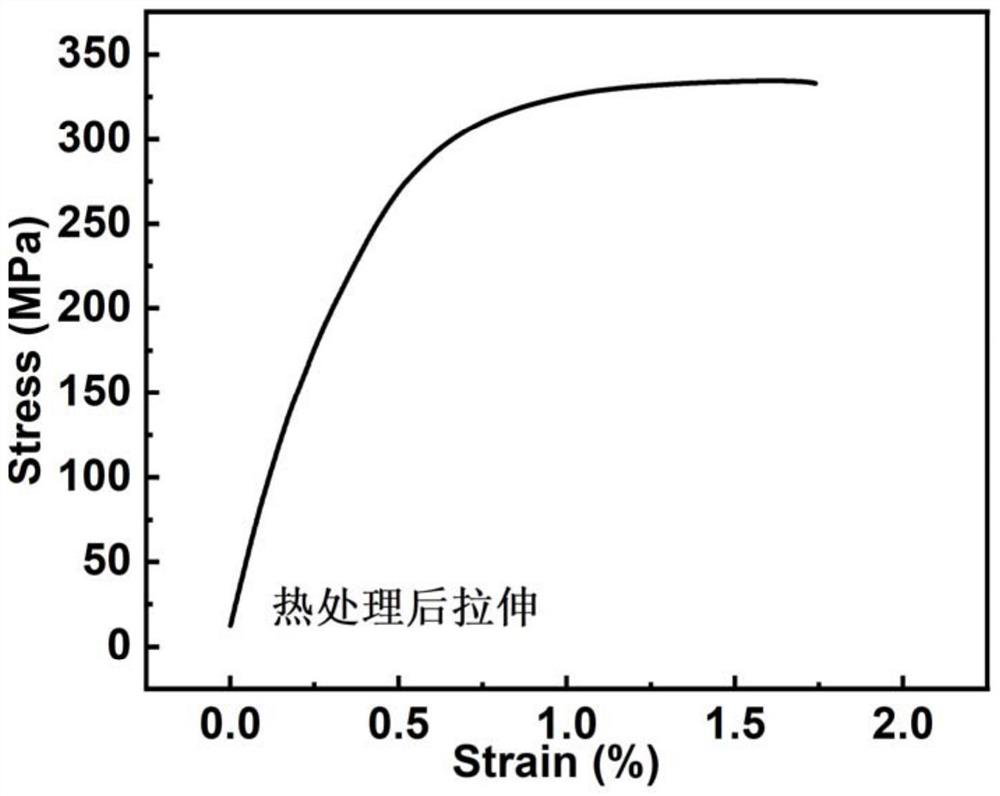

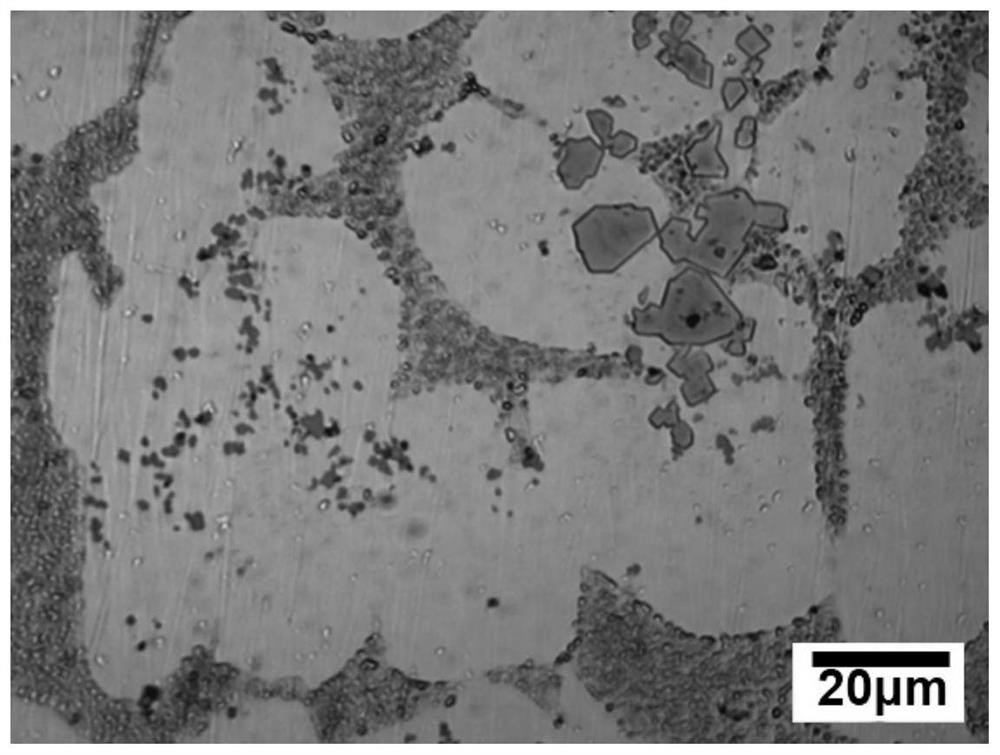

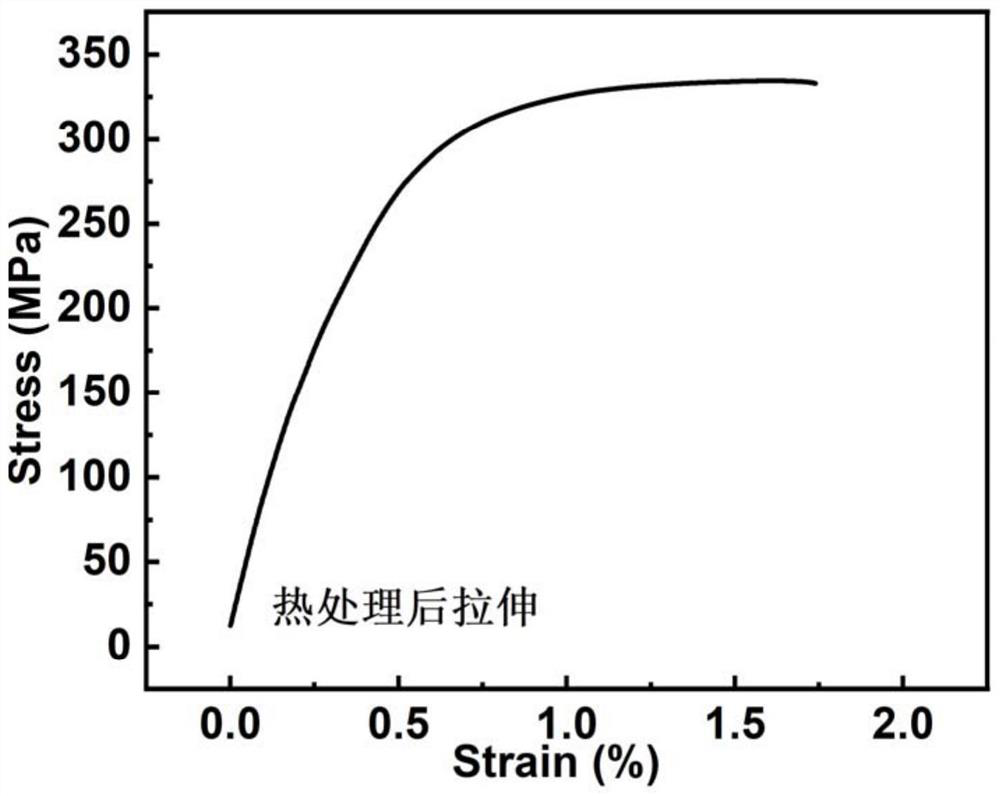

Near-beta type titanium alloy with good matching of strength and plasticity and preparation method thereof

The invention discloses a near-beta type titanium alloy with good matching of strength and plasticity and a preparation method thereof, and belongs to the field of titanium alloys. According to the preparation method, medium-sized crystal grains in the sintered alloy are crushed and refined after upsetting, drawing and cogging in a single-phase region. Then a rolled bar is subjected to one-step quasi-beta bar rolling at a phase transformation point by utilizing a relatively high phase transformation point caused by high oxygen content of the alloy, crystal grains are crushed again, and a coordinated structure of non-uniform crystal grains and a multi-stage layered second phase is realized by virtue of dynamic precipitation and partial recrystallization of the second phase under the actionof thermal coupling. Non-uniform mixed crystals comprise ultrafine beta crystal grains and coarse beta crystal grains, and the multi-stage layered second phase comprises a layered primary alpha phase,a strip-shaped grain boundary alpha phase and a beta transformation structure. After short-time heat treatment, the non-uniform mixed crystal structure is reserved, the multi-stage layered second phase is increased from ternary to quaternary through the separated fine-needle-shaped alpha phase, and the alloy maintains good plasticity while having high strength.

Owner:CHANGAN UNIV

Heavy-duty anti-skid lane paint

The invention discloses a heavy-duty anti-skid lane paint. In the prior art, the most of the lane paint has the following advantages that the materials in the formula have significant odor and toxicity, the construction process is complex, and the construction time is long. The purpose of the present invention is to solve the advantages in the prior art. The technical scheme is that the heavy-duty anti-skid lane paint comprises components A, B and C, wherein the component A comprises 0.5-1.5% of a dispersant, 0.5-1.5% of a wetting agent, 0.5-1.5% of a defoamer, 0.5-1.5% of a thickening agent, 0.5-1.5% of a leveling agent, 20-37% of deionized water, 50-70% of a curing agent, 6-12% of pigment paste, and 2-5% of a water reducing agent, the component B comprises an aqueous acrylic amino resin, and the component C comprises 10-15% of white cement, 12-25% of barium sulfate, 6-13% of titanium dioxide, 13-20% of quartz powder, and 27-59% of large color particles. According to the present invention, the heavy-duty anti-skid lane paint with characteristics of environmental protection, no toxicity, spray molding in one time and construction time saving is prepared.

Owner:苏州大乘环保新材有限公司

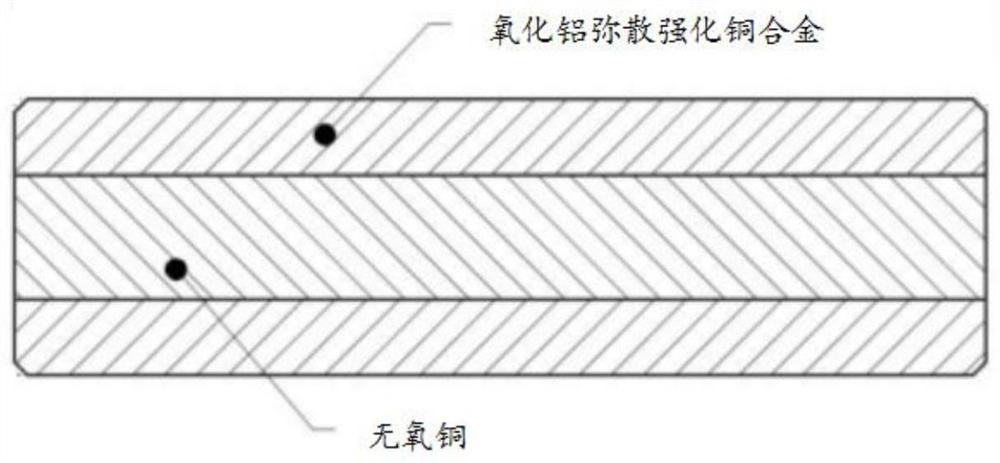

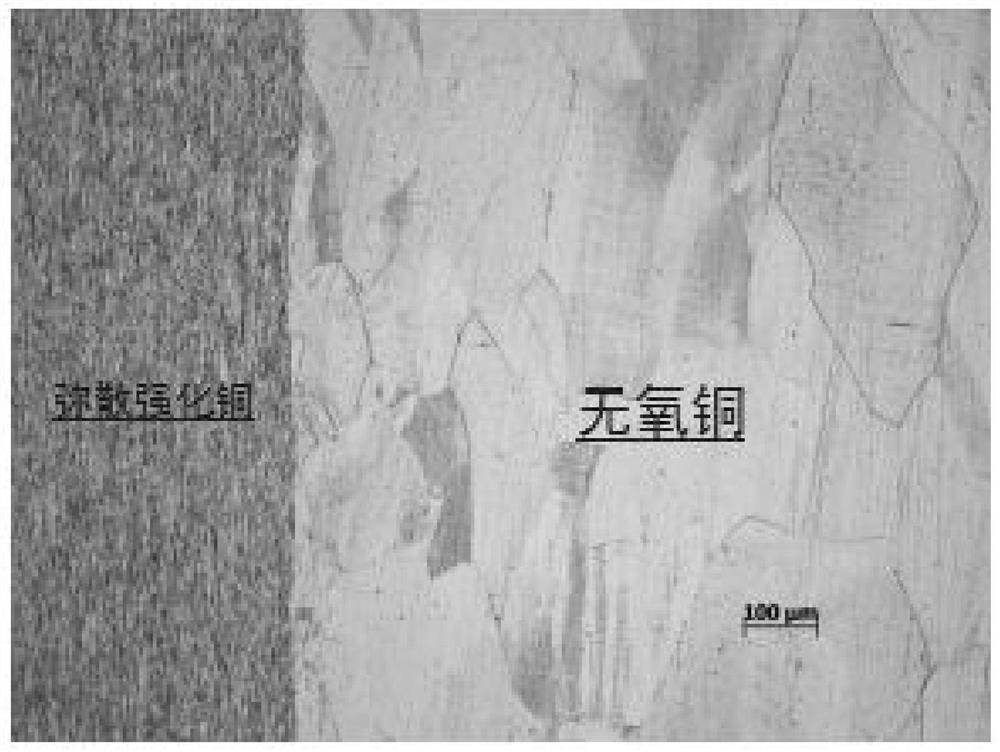

Composite bar and preparation method and application thereof

The invention relates to the technical field of copper alloy powder metallurgy and non-ferrous metal processing, in particular to a composite bar and a preparation method and application thereof. Thecomposite bar comprises a core part and a jacket; the core part is made of oxygen-free copper; and the jacket is made of aluminum oxide dispersion strengthened copper alloys. According to the composite bar, the excellent characteristics of high strength, high conductivity, high-temperature softening resistance and the like of the aluminum oxide dispersion strengthened copper alloys and the good brazing performance of the oxygen-free copper are organically combined to form advantage complementation, so that the composite bar has the excellent characteristics of high strength, high conductivity,high-temperature softening resistance and the like and the good brazing performance at the same time.

Owner:GRIMAT ENG INST CO LTD

Oxidation resistant metal composite material

InactiveCN106335251AComprehensive AntioxidantAvoid corrosionMetal layered productsFiberCarbon fibers

The invention discloses an oxidation resistant metal composite material, which is welded and fixed with three layers of different metal materials, wherein the three layers of different metal materials comprise a stainless steel base layer, a titanium alloy intermediate layer and a carbon fiber bottom layer. The stainless steel base layer can play the role of corrosion prevention, the carbon fiber bottom layer can make antioxidant property of the surface of metal materials more comprehensive, and the titanium alloy intermediate layer is arranged in the middle, and can play better high strength effect. The oxidation resistant metal composite material has the advantages of high strength, long service life, oxidation resistance and no damage.

Owner:LIANNUOOU MACHINERY TECHOLOGY JIANGSU CO LTD

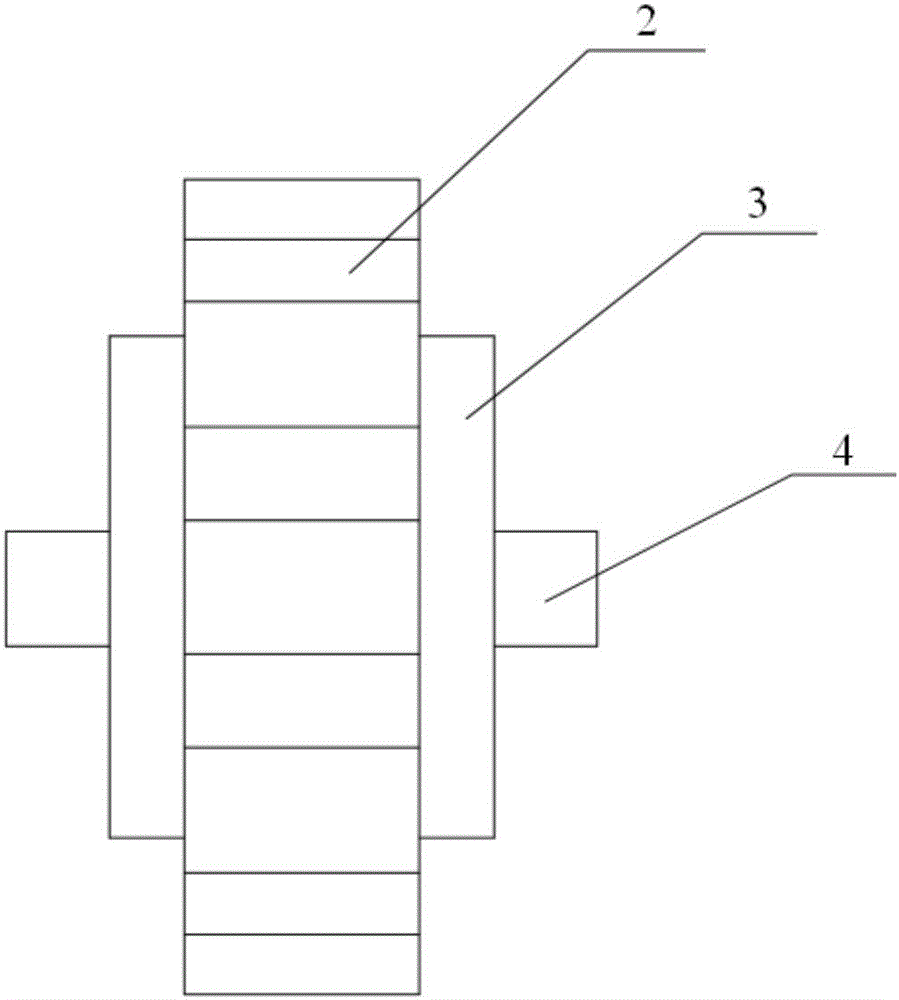

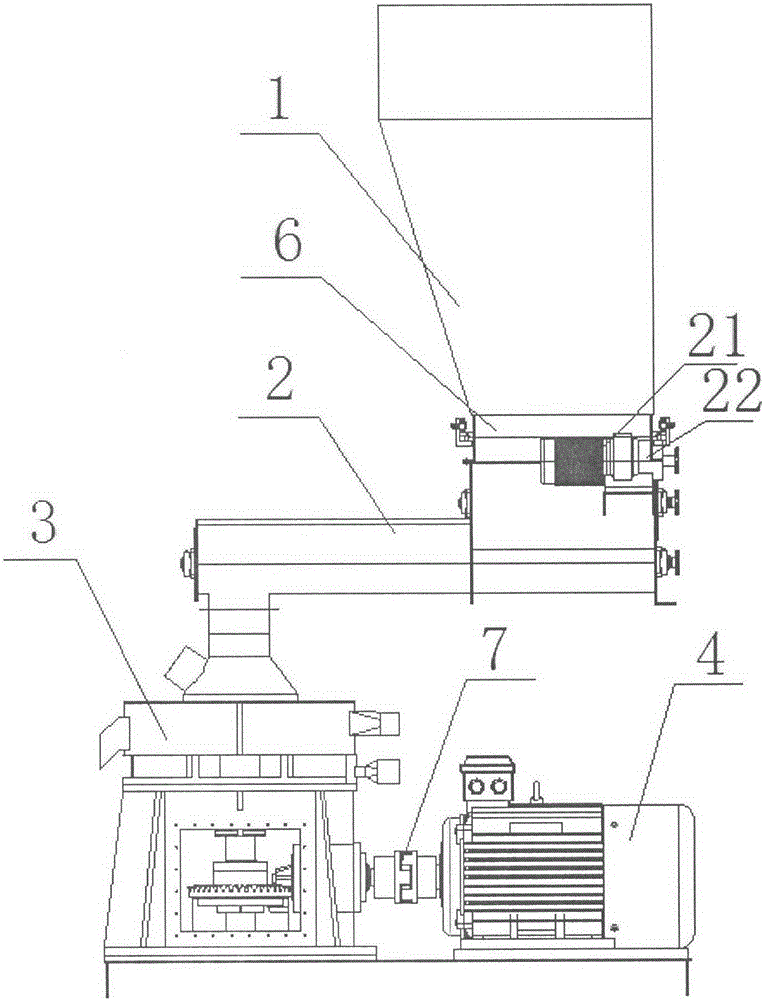

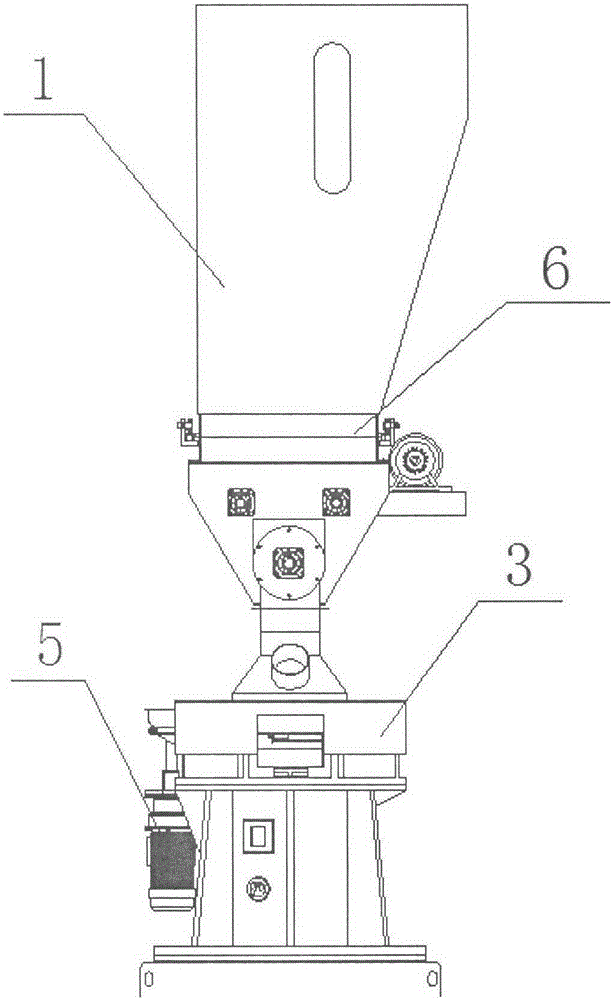

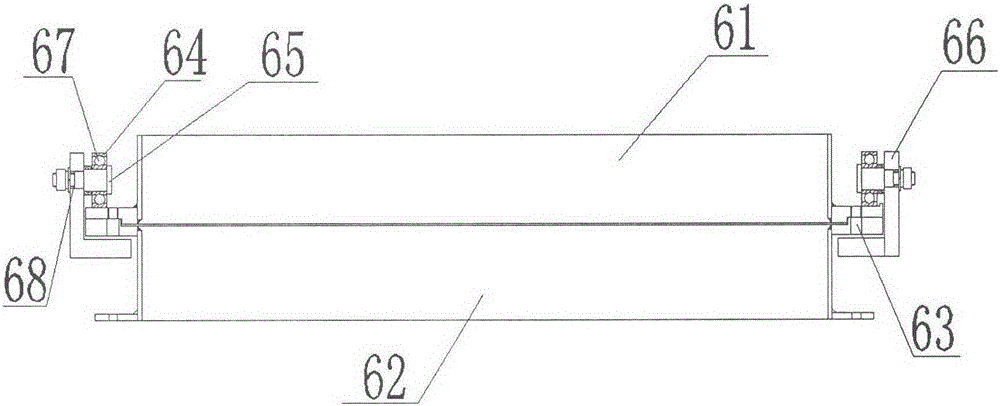

Granulator

InactiveCN106540633AReduce energy consumptionIncrease productionGranulation by pressingCouplingEngineering

The invention relates to a granulator which is fixed to a base. The granulator comprises a to-be-granulated bin, a feeding device, a press device, a main motor and a distributing motor; the lower end of the to-be-granulated bin is connected with a feeding opening of the feeding device through a movable connecting mechanism; a discharging opening of the feeding device is in soft connection with a feeding opening of the press device; the main motor is connected with the press device through an elastic coupler; and the distributing motor is arranged on the side wall of the press device. The granulator is high in yield, high in granule molding rate, good in strength and basically free of cracks and powder.

Owner:JIANGSU JINWU MACHINERY CO LTD

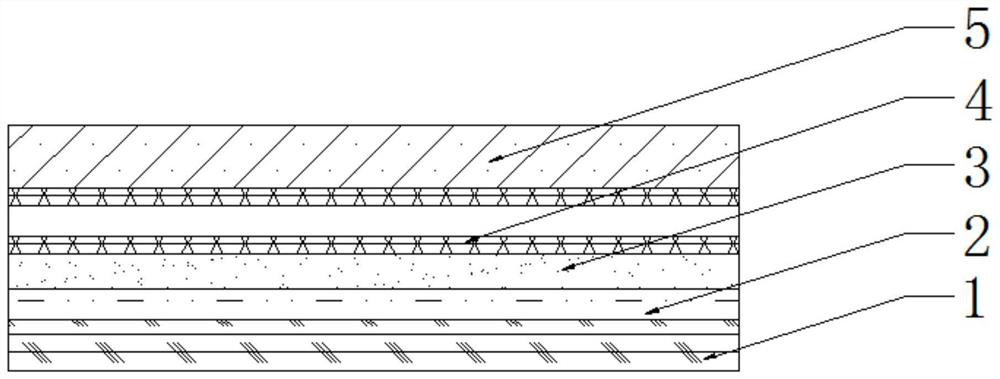

Lightweight environment-friendly smokeless thermal insulation material for household appliances

PendingCN113715425AImprove structural strengthWeight increaseSynthetic resin layered productsGlass/slag layered productsPolyesterFiber

The invention discloses a lightweight environment-friendly smokeless thermal insulation material for household appliances, and relates to the technical field of thermal insulation materials. The lightweight environment-friendly smokeless thermal insulation material comprises a base material layer and a thermal insulation layer, wherein an anti-corrosion cloth layer is fixed on the upper side of the base material layer, a flame retardant layer is fixed on the upper side of the anti-corrosion cloth layer, reinforcing nets are fixed above the flame retardant layer, sound insulation layers are arranged among the reinforcing nets, and the thermal insulation layer is fixed above the reinforcing nets. The light environment-friendly smokeless thermal insulation material for household appliances is formed by pressing the carbon fiber base layer, a composite polyester fiber layer, a composite flame-retardant fiber layer, a glass fiber gridding cloth foam cotton layer and a glass cotton layer; the carbon fiber base layer is light in weight and can resist high temperature; the composite polyester fiber layer is good in elasticity and has a certain corrosion-resistant effect; thermoplastic resin is added in a preparation process, so corrosion-resistant performance is further enhanced; the composite flame-retardant fiber layer is prepared in a blended mode and has flame-retardant and heat-insulating performance; and glass fiber gridding cloth has the advantages of being high in strength and light in weight.

Owner:无锡海跃船舶新材料科技有限公司

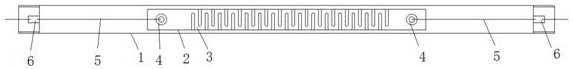

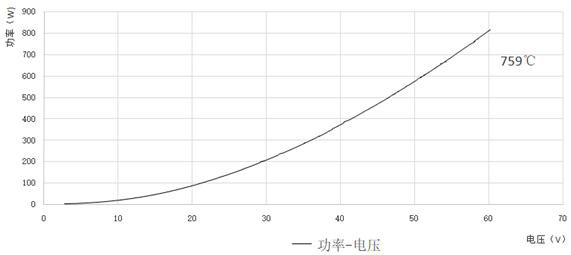

Graphene electrothermal film quartz heating tube

InactiveCN111698804AWith transparentImprove thermal conductivityHeater elementsHeating element shapesGraphiteGraphene membrane

The invention relates to the technical field of graphene, and discloses a graphene electrothermal film quartz heating tube which comprises a quartz tube and a graphene electrothermal film arranged inthe quartz tube, terminals are designed at the two ends of the graphene electrothermal film, molybdenum rods are connected to the terminals at the two ends, and the molybdenum rods extend out of the two ends of the quartz tube and are connected to a power supply. According to the invention, the graphene film is arranged in the quartz tube, so that the electro-thermal conversion efficiency of the graphene film is greatly improved, and the far infrared transmission efficiency is higher.

Owner:吴国明

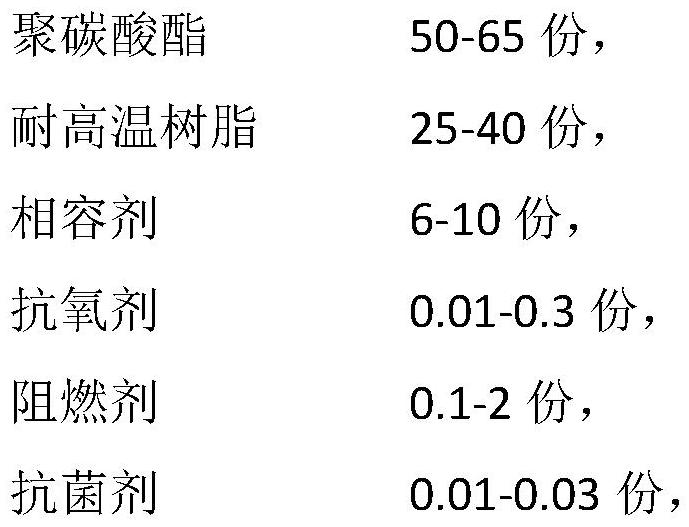

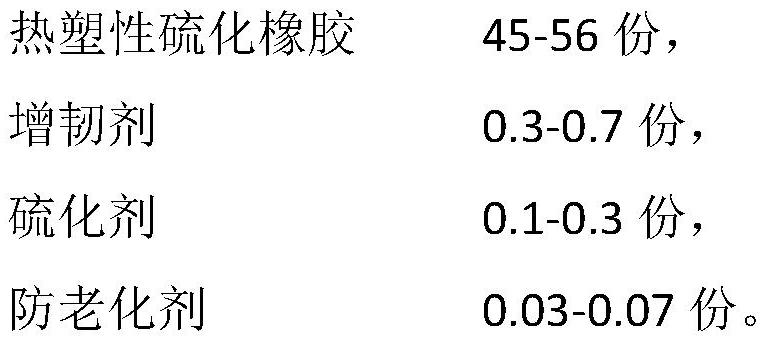

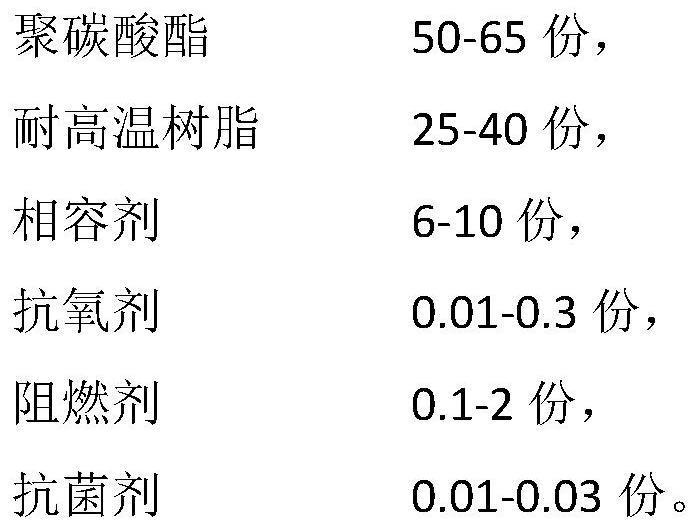

Protective eyeshade with cleaning-resistant, high-temperature-resistant, damp-heat-resistant and sterilizing composition

The invention provides a protective eyeshade with a cleaning-resistant, high-temperature-resistant, damp-heat-resistant and sterilizing composition. The protective eyeshade comprises a protective lens, an eyeshade frame and a fixing part. The protective lens is embedded into the eyeshade frame, the eyeshade frame and a woven tape are fixed together through the fixing part, the protective lens is composed of a modified polycarbonate composition, and the modified polycarbonate composition comprises polycarbonate, high-temperature-resistant resin, a compatilizer, an antioxidant, a flame retardantand an antibacterial agent. The eyeshade frame and the fixing part are both composed of a modified thermoplastic vulcanized rubber composition. The modified thermoplastic vulcanized rubber composition comprises thermoplastic vulcanized rubber, a flexibilizer, a vulcanizing agent and an anti-aging agent. The protective eyeshade is prepared from the modified polycarbonate composition and the modified thermoplastic vulcanized rubber composition so that the protective eyeshade has the characteristics of high temperature resistance, cleaning resistance, good impact resistance, high strength, goodantibacterial property, good flame retardant property, aging resistance and the like, has good elasticity and compression deformation resistance and can be repeatedly used.

Owner:SHANGHAI JIABO CLOTHING SCI & TECH

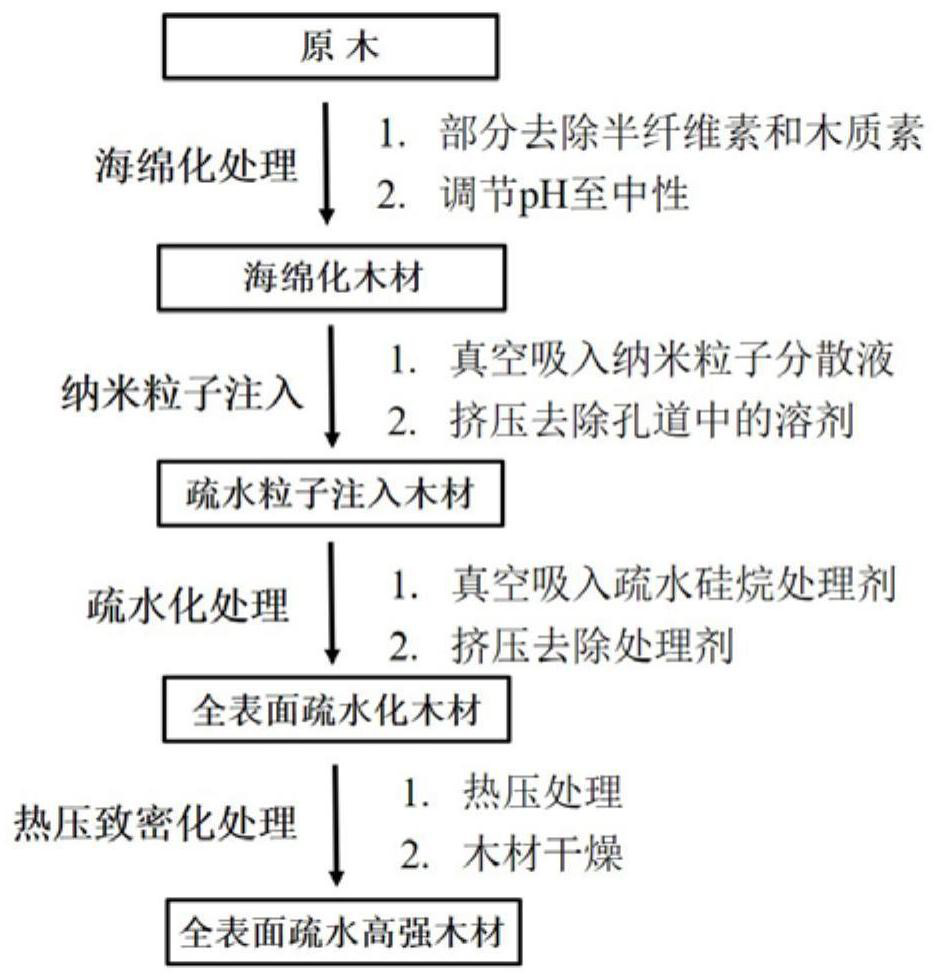

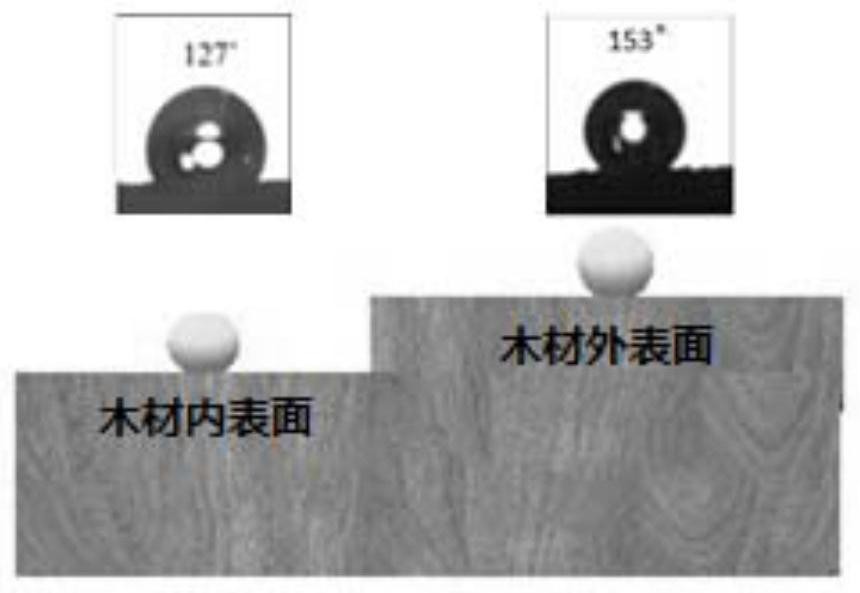

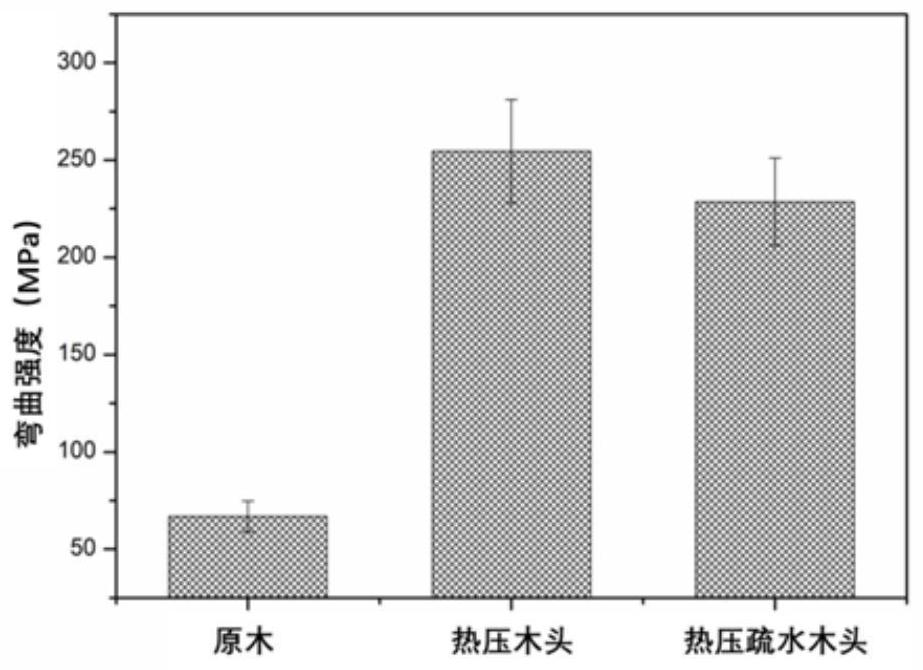

A full-surface super-hydrophobic antifreeze high-strength wood and its manufacturing method

ActiveCN111015857BImprove frost resistanceExcellent high strengthWood treatment detailsPretreatment apparatusPolymer scienceHemicellulose

Owner:DONGHUA UNIV

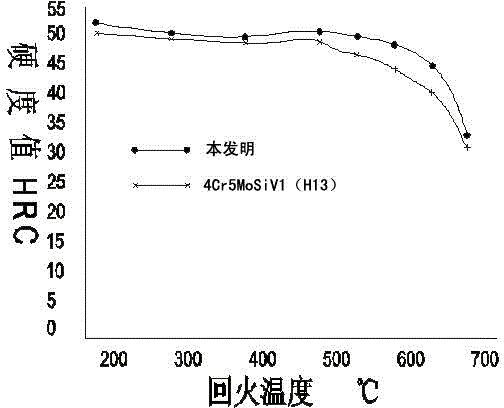

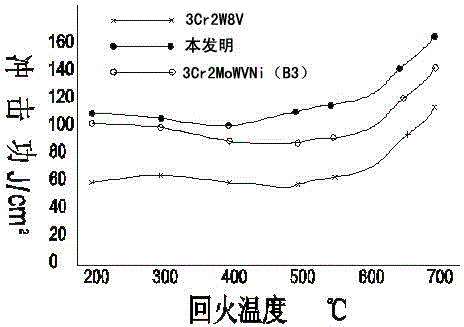

B3R hot work die steel with high strength and toughness and resistance to tempering, and preparation process thereof

The invention provides 4Cr3MoWVNi (B3R) hot work die steel with high strength and toughness and resistance to tempering, and a preparation process thereof. Raw materials for preparing the B3R hot work die steel comprise, by weight, C 0.35 to 0.42%, Si 0.15 to 0.35%, Mn 0.3 to 0.5%, Cr 2.50 to 3.50%, Mo 1.00 to 1.50%, W 0.50 to 0.80%, V 0.50 to 0.80%, Ni 1.45 to 1.85%, S 0.003 to 0.010% and P 0.008 to 0.018%, with the balance being Fe. The preparation process comprises the following steps: smelting at intermediate frequency--remelting (refining) of electroslag-diffusion hydrogen of electroslagingots, annealing treatment of electroslag ingots--forging--annealing of forging stocks--rough machining--vacuum heat treatment, and secondary tempering so as to obtain the novel product of die steel. The hot work die steel prepared in the invention has high Rockwell hardness, excellent impact toughness and tempering (thermal fatigue) resistance, and the advantages of optimized collocation of components, pure steel quality, a uniform structure, high strength, strong toughness, good tempering resistance, etc.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

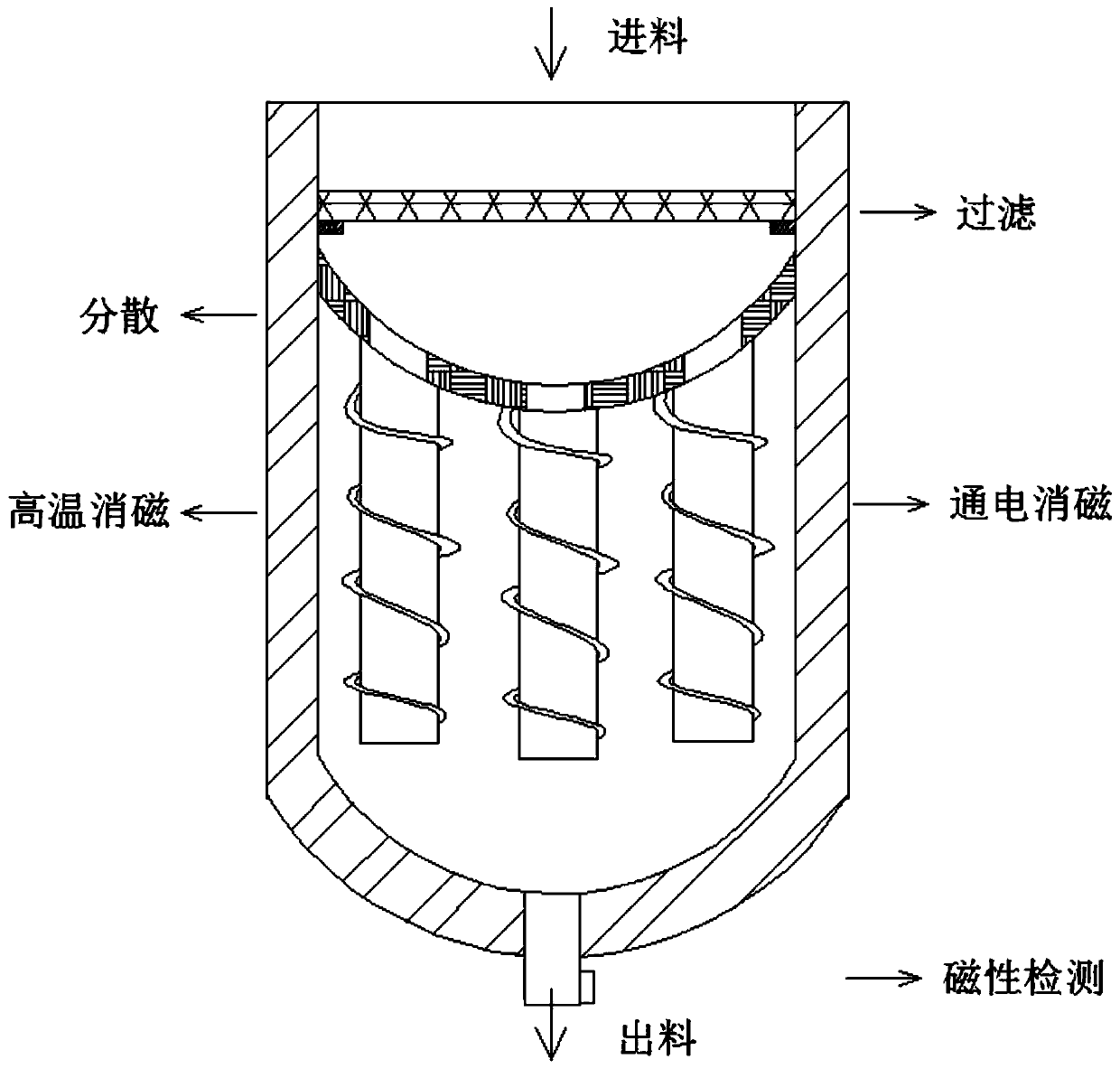

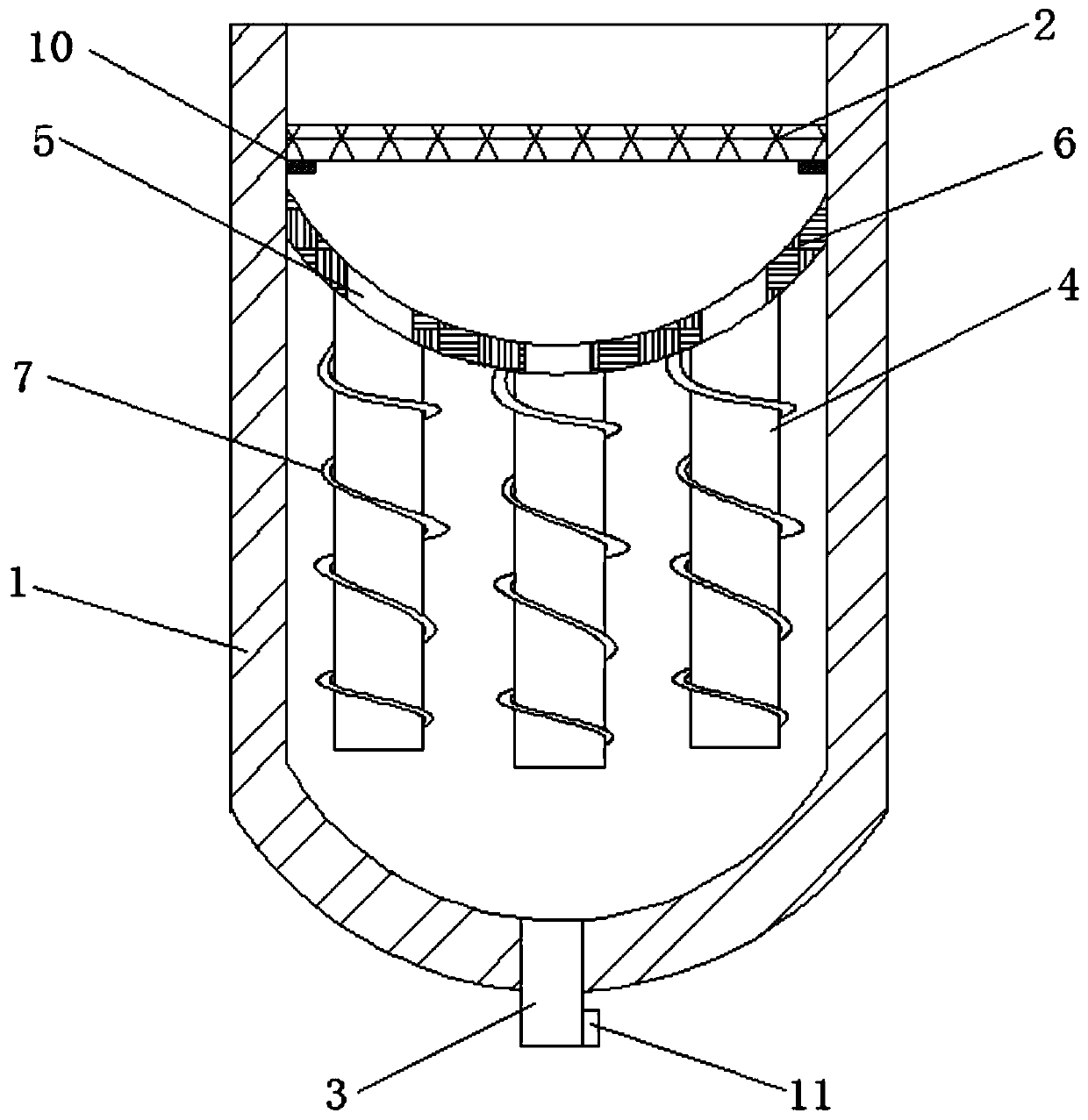

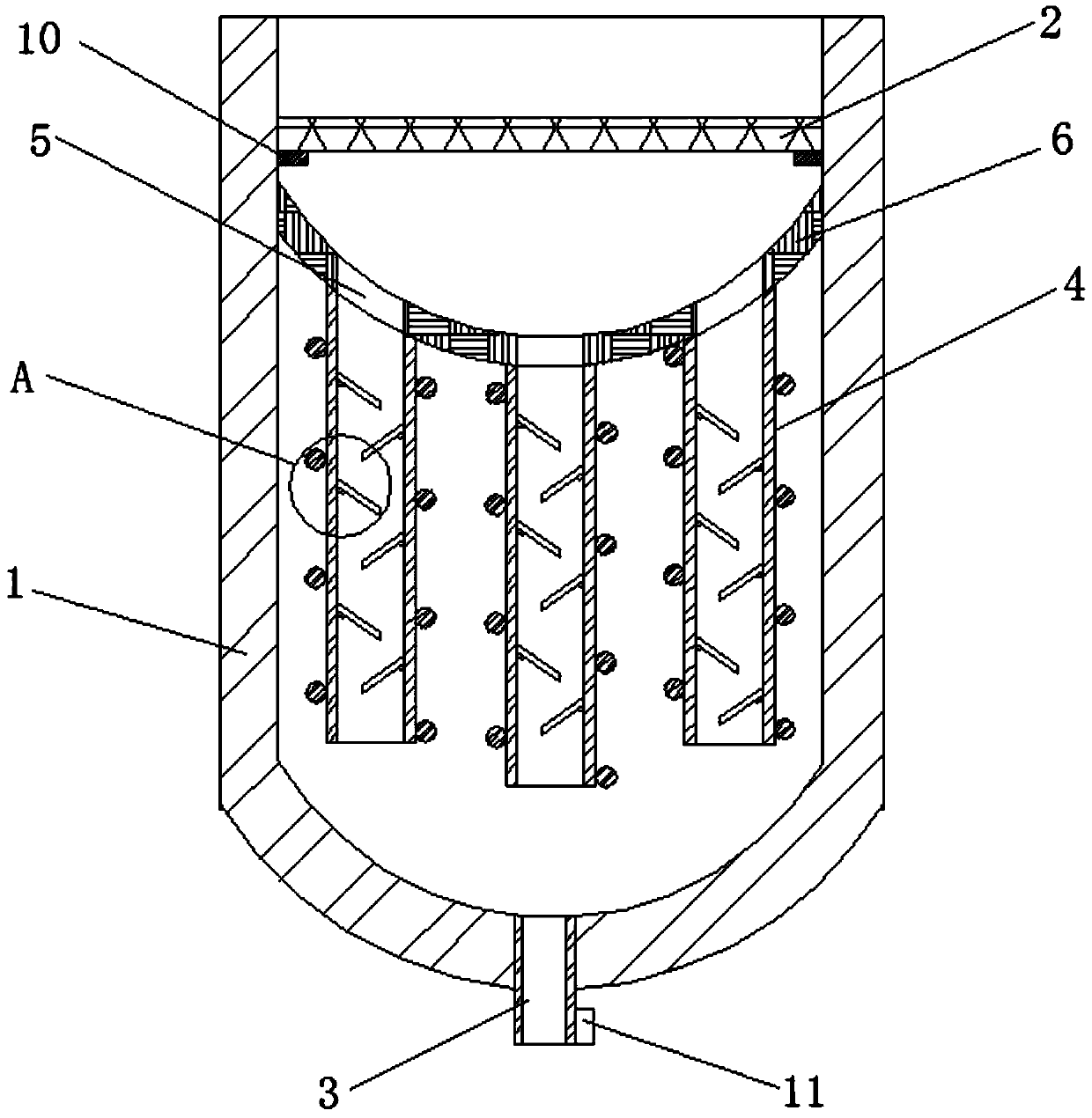

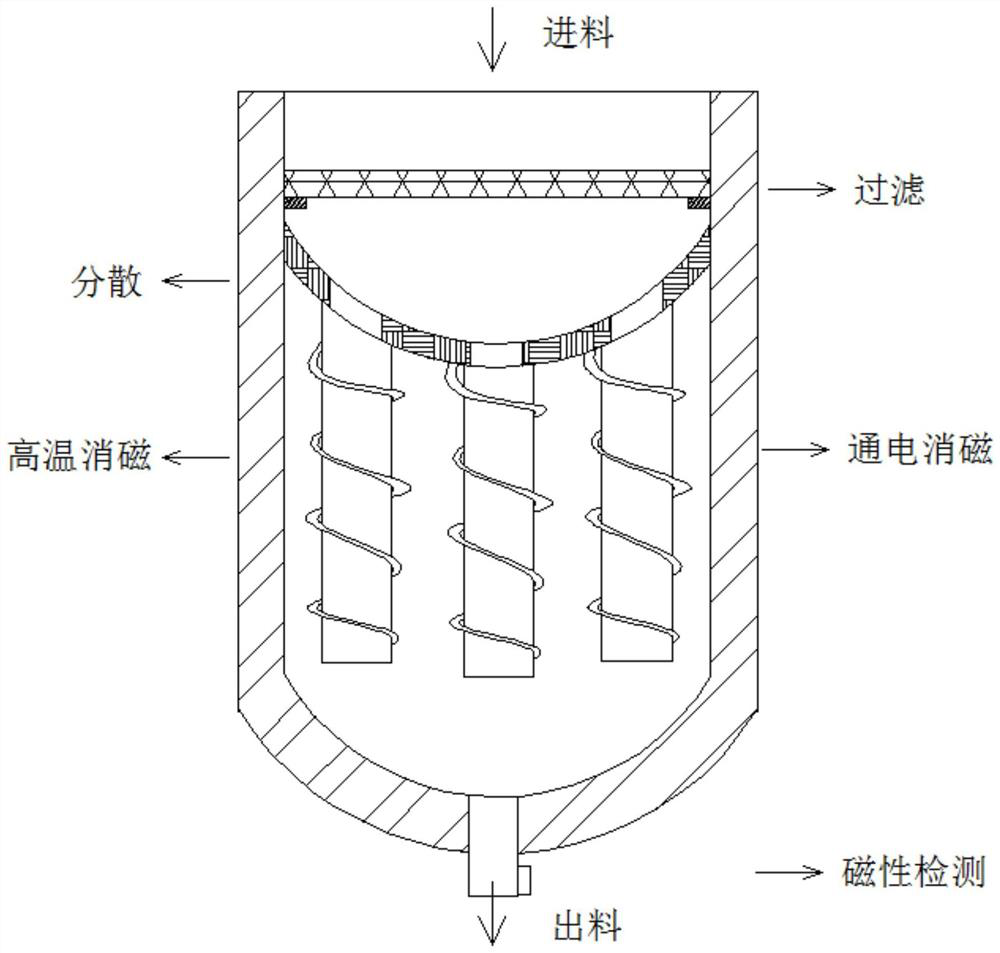

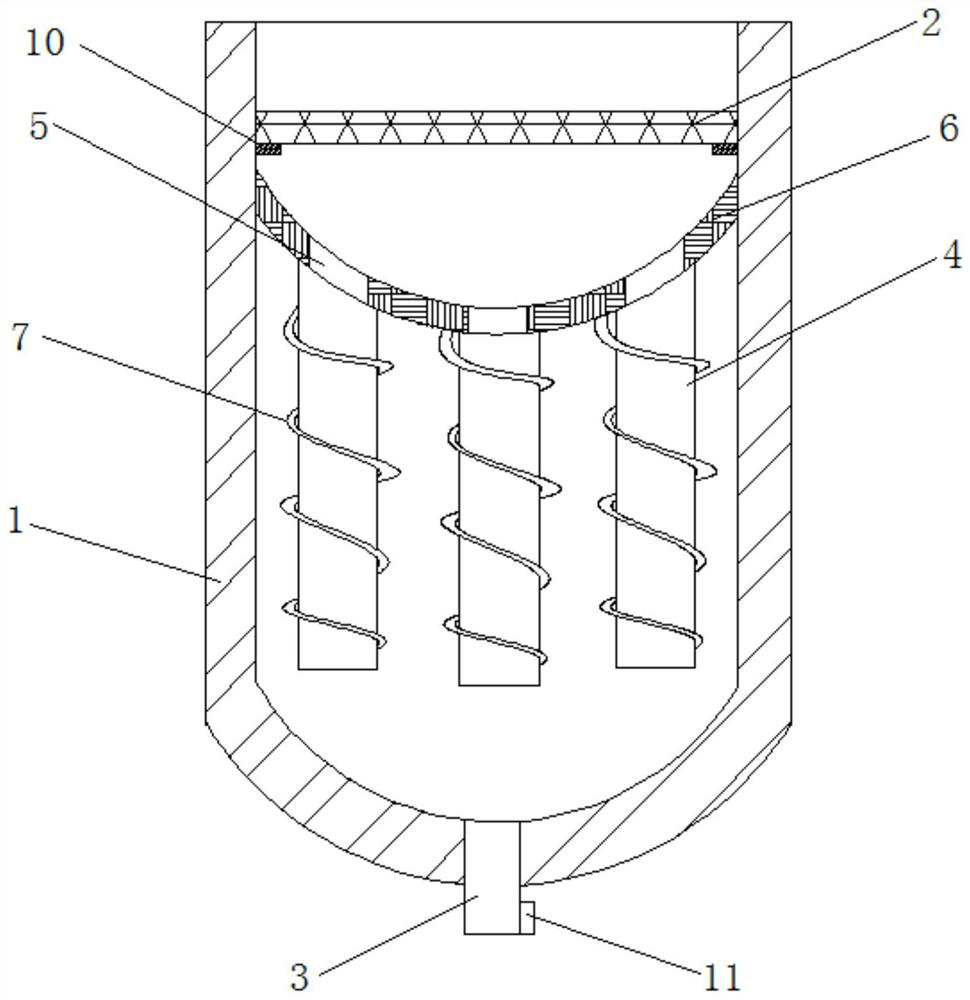

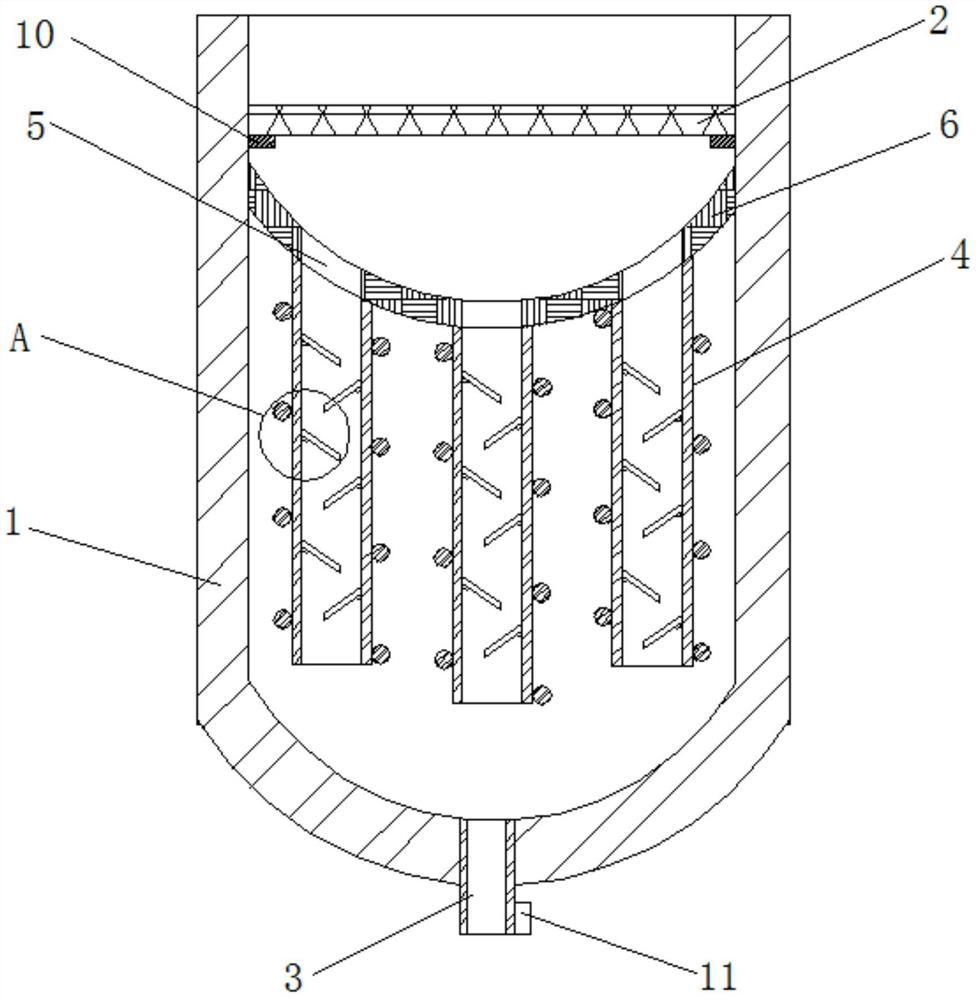

Preparation method of skutterudite preheated cement

Belonging to the technical field of cement preparation, the invention discloses a preparation method of skutterudite preheated cement. The preparation method of skutterudite preheated cement utilizesa dual demagnetization component in a powerful demagnetizing cylinder to realize high-temperature demagnetization and electrified demagnetization of cement, i.e. high temperature heat storage and heatconductive pies and snake-shaped conductive columns respectively perform high-temperature autoclaving and "ionization" on the falling cement raw material for demagnetization treatment on magnetic substances in the cement raw material, and high-temperature demagnetization and electrified demagnetization are carried out simultaneously to reach the purpose of dual reinforced demagnetization, when the demagnetized raw material falls to the lower end of the powerful demagnetizing cylinder, and a miniature magnetic detector disposed on a side of a leaking material receiving pipe is utilized to detect the content of interior magnetic substances, thus ensuring minimization of the magnetic substance content of the cement raw material. The method provided by the invention prepares qualified cementraw material into cement, basically eliminates the influence of magnetic substances on the cement quality, significantly improves the stability of cement buildings and enhances the safety coefficientsof high-rise buildings.

Owner:肇庆市金岗水泥有限公司

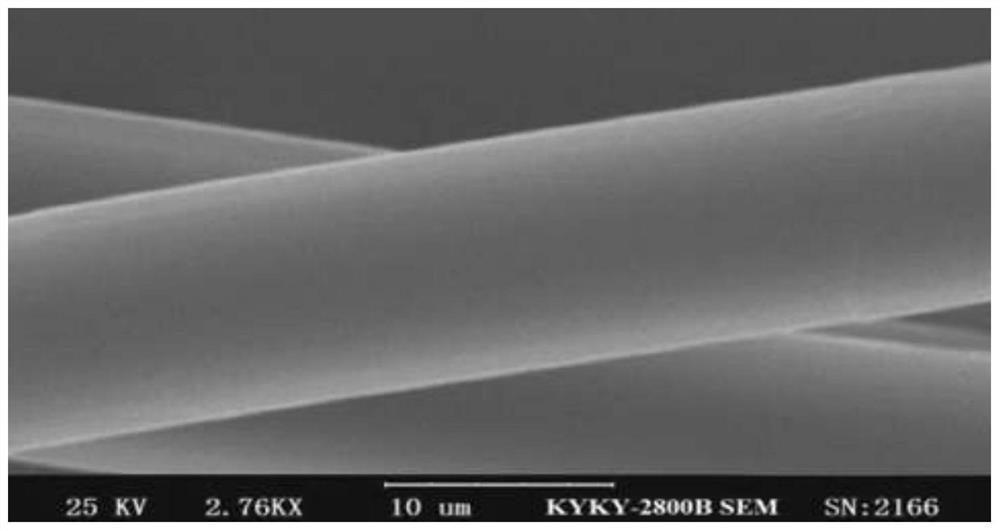

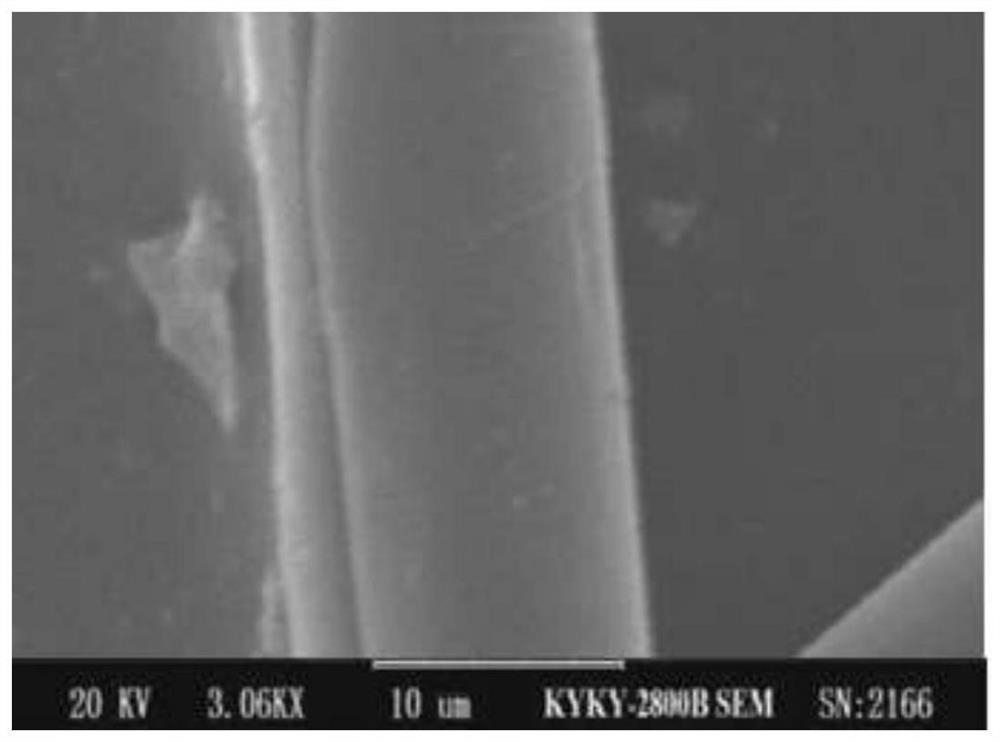

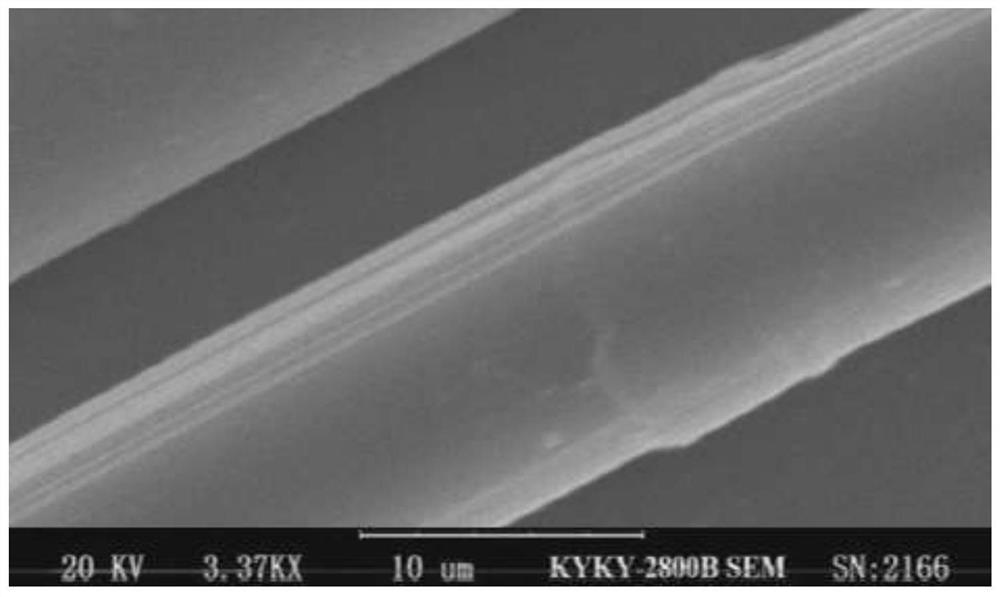

Shell-core nano coating PBO fiber and preparation method thereof

PendingCN112921656AImproved resistance to UV radiationGood application effectFibre typesFiberAcrylonitrile

The invention discloses a preparation method of a shell-core nano-coating PBO fiber. The preparation method is specifically implemented according to the following steps: step 1, adding a nano-shell material into polyethylene acrylate, organic silicon polyvinyl ester emulsion or polyacrylic acid acrylonitrile emulsion, and mixing to obtain nano-coating emulsion; and step 2, adding PBO fibers into the nano coating emulsion prepared in the step 1, uniformly stirring, and reacting for a certain time at a certain reaction temperature to obtain finished products. According to the method, the ultraviolet radiation resistance of the PBO fiber can be improved, excellent high-strength performance can be kept in a strong sunlight environment, and the application performance of the PBO fiber is greatly improved. The invention also provides the shell-core nano coating PBO fiber prepared by the method.

Owner:XI'AN POLYTECHNIC UNIVERSITY +1

A kind of high-strength and high-modulus dual-phase magnesium-lithium alloy and preparation method thereof

The invention discloses a high-strength and high-modulus dual-phase magnesium-lithium alloy and a preparation method, and belongs to the technical field of metal material magnesium alloys. The mass percentage of the high-strength and high-modulus dual-phase magnesium-lithium alloy is: Gd: 0.05-4wt.%, Al: 0.5-5wt.%, Y: 0.05-8wt.%, Li: 5-10wt.%. %, Zn: 0-5wt.%, Mn: 0.05-4wt.% The balance is Mg and inevitable impurities; wherein: the content of Zn element cannot be selected as 0. The preparation method includes a raw material preparation stage, a preheating raw material stage, a heat treatment furnace atmosphere adjustment, a vacuum smelting stage, a vacuum tube furnace atmosphere adjustment and a heat treatment stage. The invention adopts the combination of microalloying and heat treatment, which can synergistically improve the strength, elongation and elastic modulus of the dual-phase magnesium-lithium alloy while controlling the low density of the dual-phase magnesium-lithium alloy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of magnesium-lithium alloy with low density, high strength and high modulus and preparation method thereof

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of preparation method of skutterudite preheating cement

ActiveCN109721263BLow magnetic substanceReduce the content of magnetic substancesMagnetic bodiesSkutteruditeMining engineering

The invention discloses a method for preparing skutterudite preheated cement, which belongs to the technical field of cement preparation. A method for preparing skutterudite preheated cement utilizes double degaussing components in a powerful degaussing cylinder to demagnetize cement at high temperature and demagnetize cement, namely The high-temperature heat storage heat conduction tube and the serpentine conductive column perform high-temperature autoclaving and "ionization" on the falling cement raw materials respectively, and demagnetize the magnetic substances in the cement raw materials, and the high-temperature degaussing and power-on degaussing are carried out at the same time to achieve double enhanced demagnetization. Purpose: When the degaussed cement raw material falls to the lower end of the powerful degaussing cylinder, use the miniature magnetic detector installed at the side end of the leaking material connection pipe to detect the content of magnetic substances inside, so as to ensure that the content of magnetic substances in the cement raw material is reduced to the minimum. Prepare qualified cement raw materials into cement, basically eliminate the influence of magnetic substances on cement quality, significantly improve the stability of cement buildings, and improve the safety factor of high-rise buildings.

Owner:肇庆市金岗水泥有限公司

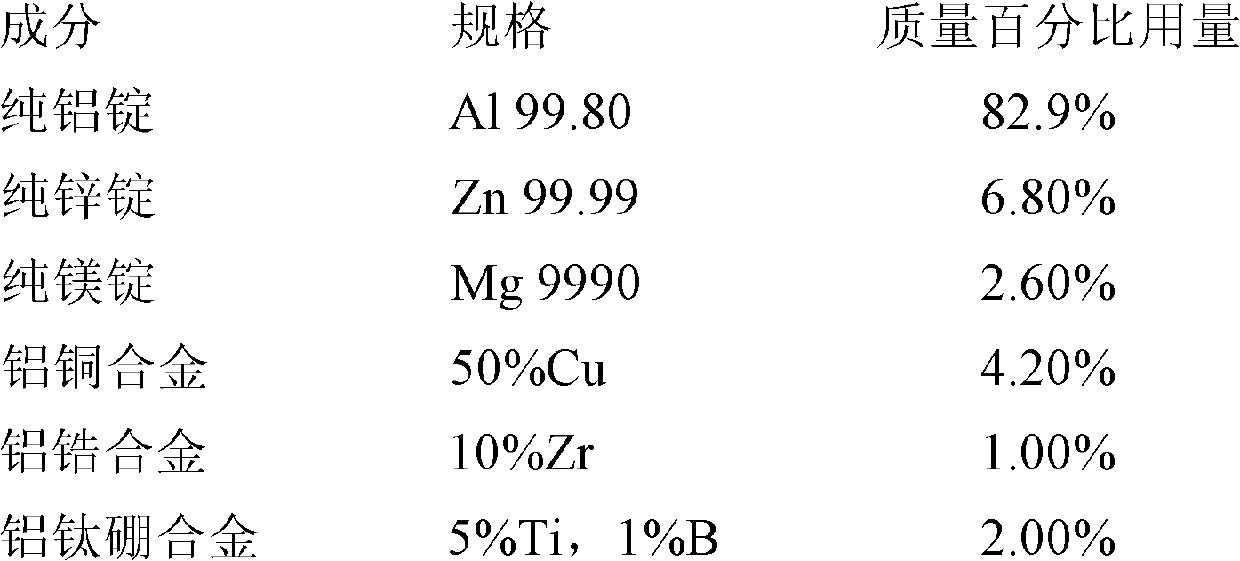

Extrusion casted Al-Zn alloy material with high toughness

The invention provides an extrusion casted aluminum-zinc-magnesium-copper alloy material with high toughness. The alloy material is a high-toughness extrusion casted Al-Zn alloy material obtained by using an extrusion casting technology at an extrusion specific pressure of 25-75 Mpa and using solution treatment and an artificial aging process; the alloy material comprises the main components in percentage by mass: 6.50-7.50 % of zinc, 2.00-3.00 % of magnesium, 1.80-2.20 % of copper, 0.22-0.60 % of trace alloy enhancing elements and the balance of aluminum and inevitable impurities. The alloy material provided by the invention has the advantages of reasonable component design, excellent comprehensive mechanical property, good cast forming performance and lower cost, can be used for manufacturing parts with lightweight and weight reduction requirements, such as airplane wings, knuckles, connecting bars and other structural pieces, and has broad application prospect in the fields like automobile, transportation, aviation, aerospace and the like.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com