Composite bar and preparation method and application thereof

A composite rod and alloy technology, applied in the field of copper alloy powder metallurgy and non-ferrous metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the composite rod described in the above technical solution, comprising the following steps:

[0041] Mixing copper-aluminum alloy powder and cuprous oxide to obtain a mixture;

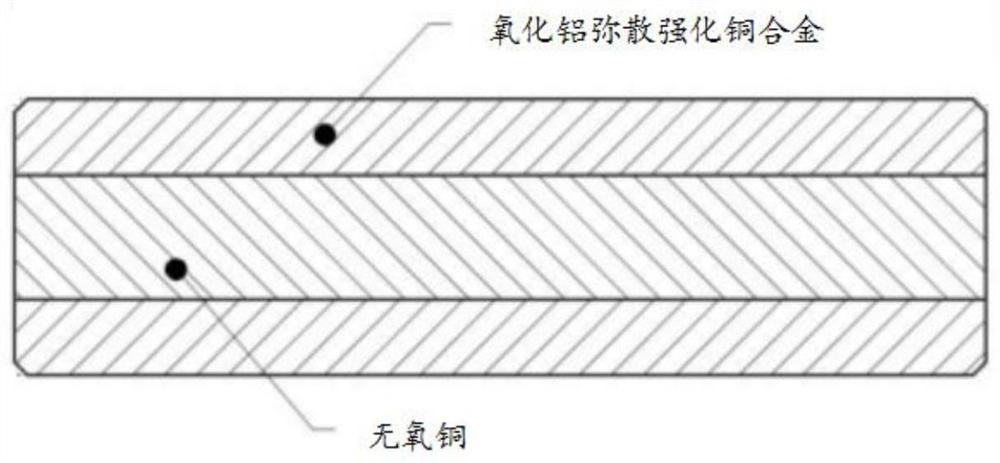

[0042] Fixing the oxygen-free copper rod in the center of the cold isostatic pressing mold, uniformly filling the mixture around the oxygen-free copper rod, and performing cold isostatic pressing to obtain a cold isostatic pressing composite billet;

[0043] The cold isostatic pressing composite billet is sequentially subjected to heat treatment, hot extrusion compounding and drawing straightening to obtain the composite rod;

[0044] The heat treatment includes sequential internal oxidation, reduction and sintering.

[0045] In the present invention, unless otherwise specified, all raw materials are commercially available products of resins by those skilled in the art.

[0046] The invention mixes the copper-aluminum alloy powder and...

Embodiment 1

[0062] Water-atomized copper-aluminum alloy powder with a particle size of -100 mesh (the mass percentage of Al is 0.1%) and commercially available cuprous oxide are produced according to the Al and O reaction. 2 o 3 The ratio and according to the excess coefficient of O is 0.8 to mix 4h, the mixing is carried out in a double-cone mixer to obtain a mixture;

[0063] Be that the diameter is 25mm, the oxygen-free copper rod that brand is TU2 is fixed in the center of the mold for cold isostatic pressing, then the mixture is evenly filled around the oxygen-free copper rod, and the mold is tightly plugged with a rubber stopper. The metal wire is tightly sealed to prevent the pressurized medium liquid from penetrating into the powder. Place the installed mold in a cold isostatic press for compression molding. The pressure of cold isostatic pressing is 200 MPa, and the pressure holding time is 8 minutes. After three-stage pressure relief is used for pressure relief, a cold isostati...

Embodiment 2

[0069] Water-atomized copper-aluminum alloy powder with a particle size of -100 mesh (the mass percentage of Al is 1.2%) and commercially available cuprous oxide are produced according to the Al and O reaction. 2 o 3 The ratio and according to the excess coefficient of O is 1.3 to carry out mixing 10h, and described mixing is carried out in double-cone mixer, obtains mixture;

[0070] The diameter is 40mm, and the oxygen-free copper rod that brand is TU0 is fixed on the center of the mold for cold isostatic pressing, and then the mixture is evenly filled around the oxygen-free copper rod, and the mold is tightly plugged with a rubber stopper. The metal wire is tightly sealed to prevent the pressurized medium liquid from penetrating into the powder. Place the installed mold in a cold isostatic press for compression molding. The pressure of cold isostatic pressing is 240 MPa, and the holding time is 12 minutes. After three-stage pressure relief is used for pressure relief, a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com