A kind of magnesium-lithium alloy with low density, high strength and high modulus and preparation method thereof

A magnesium-lithium alloy, high-strength technology, applied in the field of magnesium alloy metal materials, can solve the problems of impurity introduction, increase of Mg-Al-Li ingot density, loss of raw materials, etc., and achieve the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

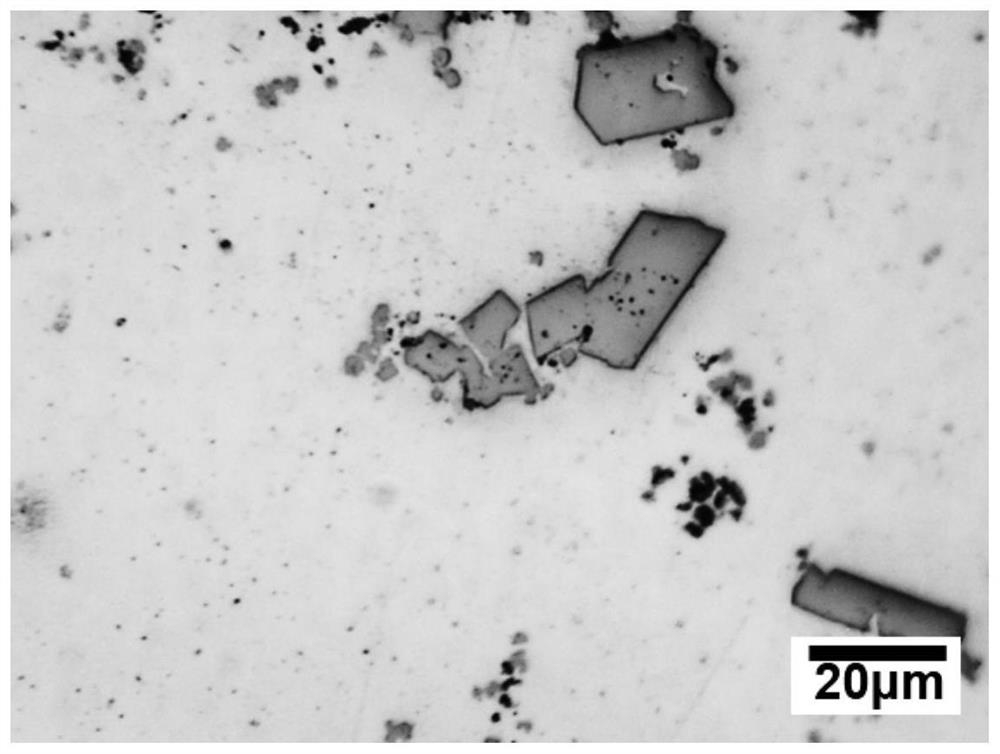

Embodiment 1

[0056] The chemical composition of a low-density, high-strength, and high-modulus magnesium-lithium alloy is: Gd: 1.5wt.%; Al: 5wt.%; Y: 4wt.%; Li: 10wt.%; Zr: 0.5 wt.%; the total amount of impurity elements Si, Fe, Cu, Ni, and Mn is less than 0.03 wt.%; the remainder is Mg.

[0057] The preparation method of the low-density, high-strength, and high-modulus magnesium-lithium alloy of the above-mentioned components comprises the following steps:

[0058] S1, alloy ingredients

[0059] According to the ratio of magnesium-lithium alloy raw materials, the total mass of Mg-30wt.%Gd master alloy containing 1.5wt.%Gd, the Mg-30wt.%Y master alloy containing 4wt.%Y, and the Mg-30wt.%Y master alloy containing 0.5wt.%Zr were prepared. Mg-30wt.% Zr master alloy, 10wt.% pure Li, 5wt.% pure aluminum foil, and the balance is pure magnesium; wherein, pure lithium is wrapped with pure aluminum foil;

[0060] S2, baking material

[0061] Preheat the prepared raw materials (pure magnesium, Mg...

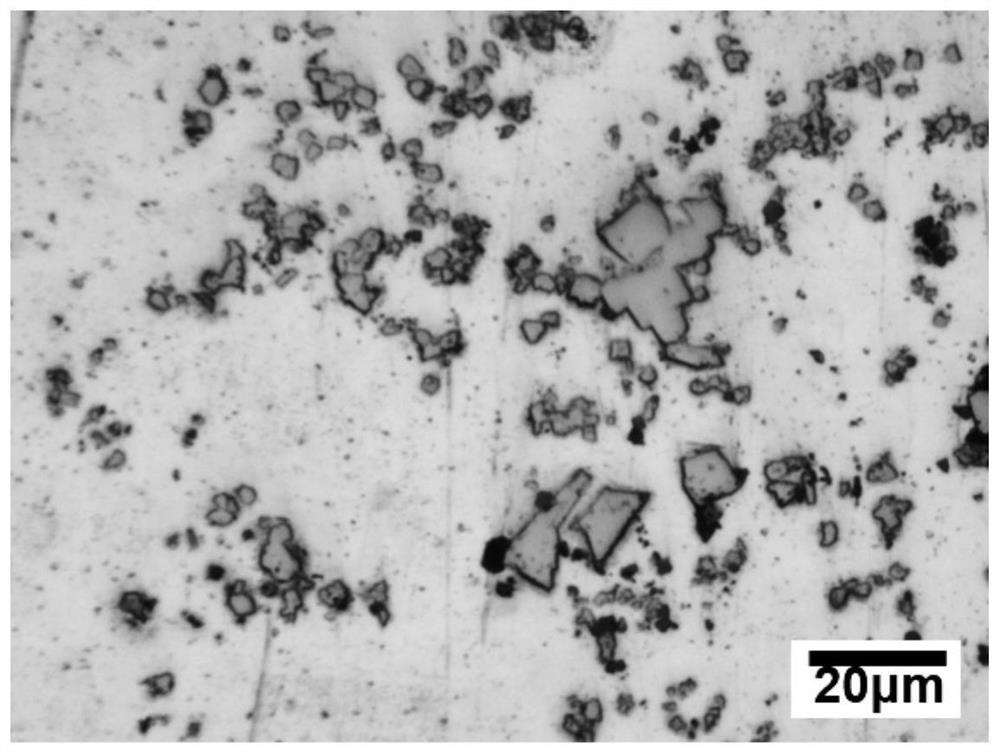

Embodiment 2

[0068] The chemical composition of a low-density, high-strength, and high-modulus magnesium-lithium alloy is calculated by mass percentage: Gd: 1wt.%; Al: 6wt.%; Y: 5wt.%; Li: 15wt.%; Zr: 0.5wt% %; the total amount of impurity elements Si, Fe, Cu, Ni, and Mn is less than 0.03wt.%; the remainder is Mg.

[0069] The preparation method of the low-density, high-strength, and high-modulus magnesium-lithium alloy of the above-mentioned components comprises the following steps:

[0070] S1, alloy ingredients

[0071] According to the ratio of magnesium-lithium alloy raw materials, the total mass of Mg-20wt.%Gd master alloy containing 1wt.%Gd, the Mg-20wt.%Y master alloy containing 5wt.%Y, and the Mg containing 0.5wt.%Zr were prepared. -20wt.% Zr master alloy, 15wt.% pure Li, 6wt.% pure aluminum foil, and the balance is pure magnesium; in which, pure lithium is wrapped with pure aluminum foil;

[0072] S2, baking material

[0073] Preheat the prepared raw materials (pure magnesium,...

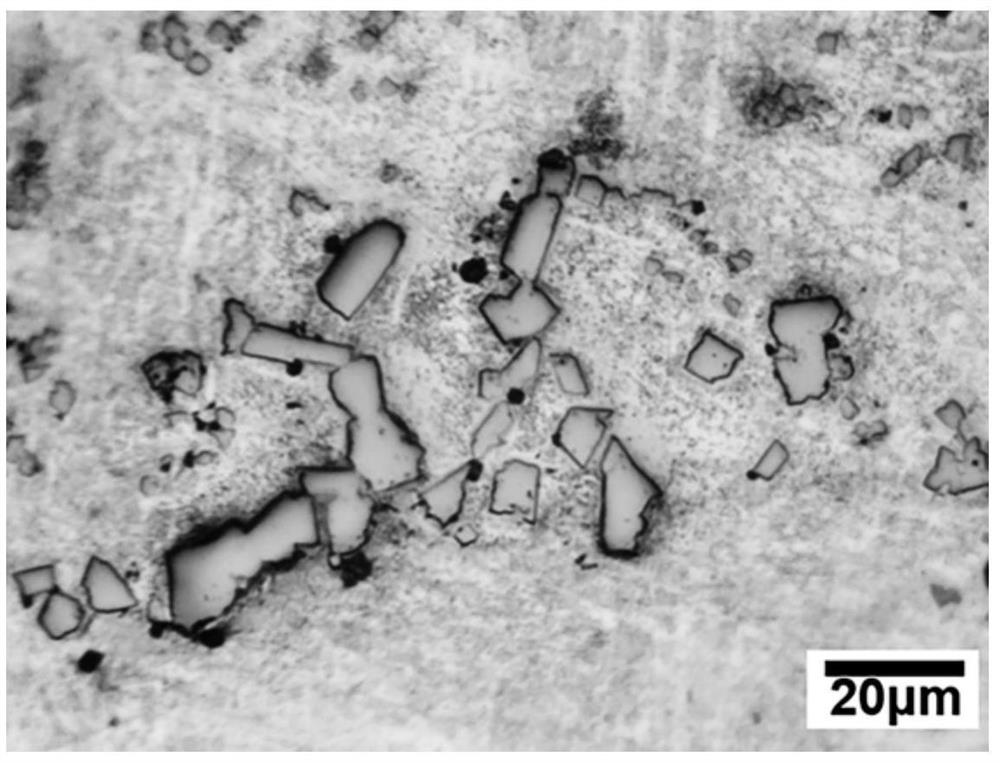

Embodiment 3

[0080] The chemical composition of a low-density, high-strength, and high-modulus magnesium-lithium alloy is: Gd: 3wt.%; Al: 4wt.%; Y: 8wt.%; Li: 15wt.%; Zr: 0.5wt% %; the total amount of impurity elements Si, Fe, Cu, Ni, and Mn is less than 0.03wt.%; the remainder is Mg.

[0081] The preparation method of the low-density, high-strength, and high-modulus magnesium-lithium alloy of the above-mentioned components comprises the following steps:

[0082] S1, alloy ingredients

[0083] According to the ratio of magnesium-lithium alloy raw materials, the total mass of Mg-30wt.%Gd master alloy containing 3wt.%Gd, the Mg-30wt.%Y master alloy containing 8wt.%Y, and the Mg containing 0.5wt.%Zr were prepared. -30wt.% Zr master alloy, 15wt.% pure Li, 4wt.% pure aluminum foil, and the balance is pure magnesium; in which, pure lithium is wrapped with pure aluminum foil;

[0084] S2, baking material

[0085] Preheat the prepared raw materials (pure magnesium, Mg-Gd master alloy, Mg-Y mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com