Patents

Literature

293results about How to "High thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low dielectric constant materials and method

InactiveUS6051321AImprove rotational flexibilityTightly boundSemiconductor/solid-state device detailsSynthetic resin layered productsElectrical conductorCopper

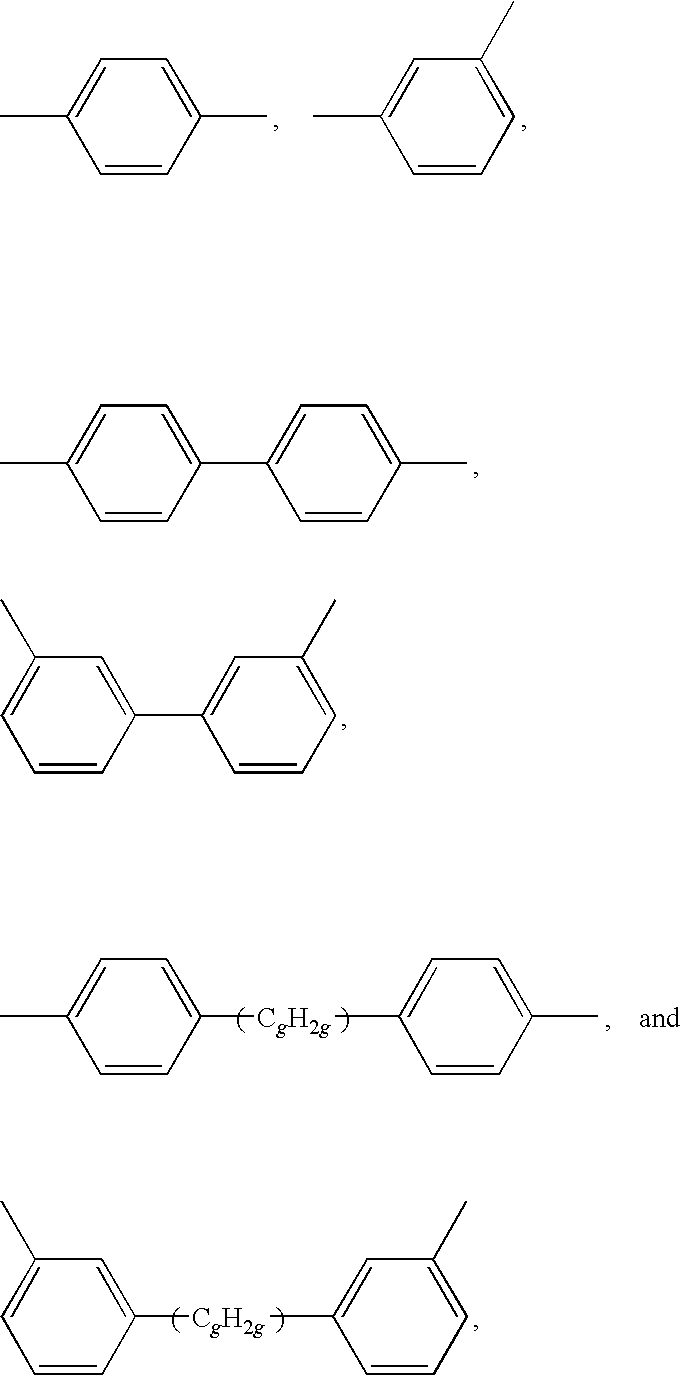

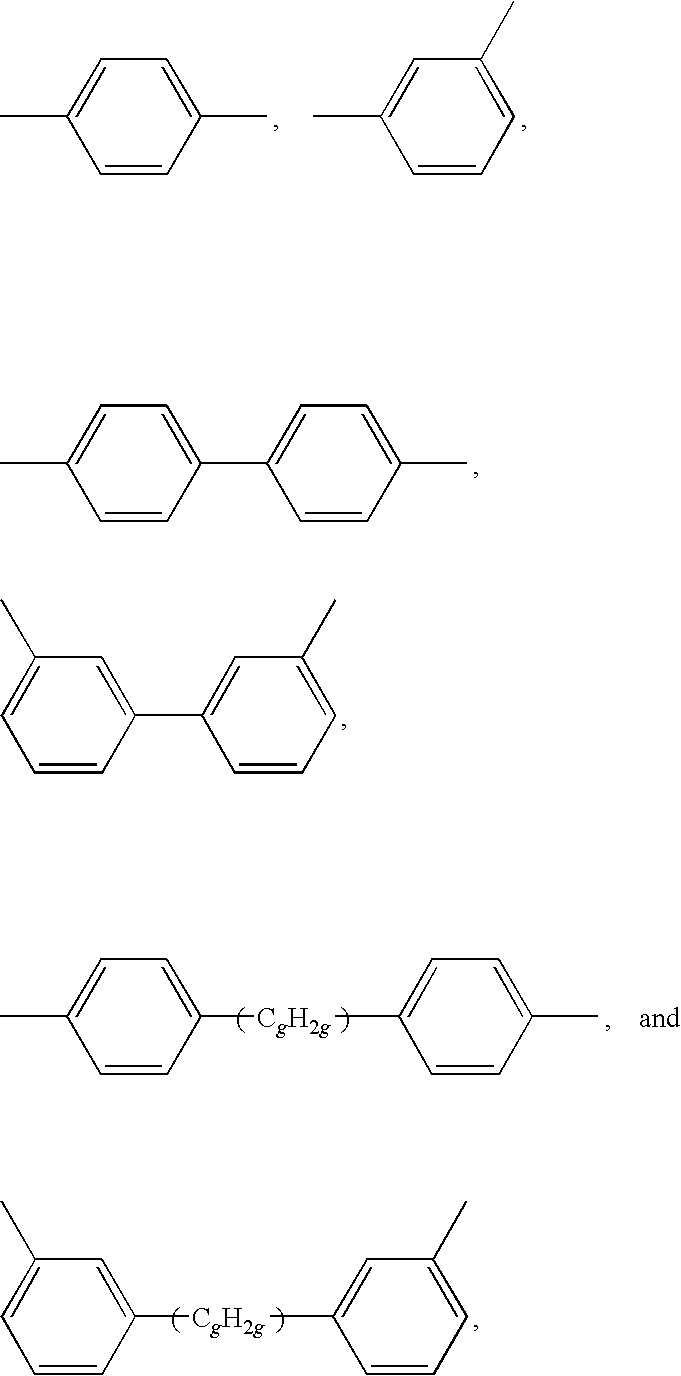

Intermetal dielectric (IMD) and interlevel dielectric (ILD) that have dielectric constants (K) ranging from 2.0 to 2.6 are prepared from plasma or photon assisted CVD (PACVD) or transport polymerization (TP). The low K dielectric (LKD) materials are prepared from PACVD or TP of some selected siloxanes and F-containing aromatic compounds. The thin films combine barrier and adhesion layer functions with low dielectric constant functions, thus eliminating the necessity for separate adhesion and barrier layers, and layers of low dielectric constant. The LKD materials disclosed in this invention are particularly useful for <0.18 .mu.m ICs, or when copper is used as conductor in future ICs.

Owner:CANON USA

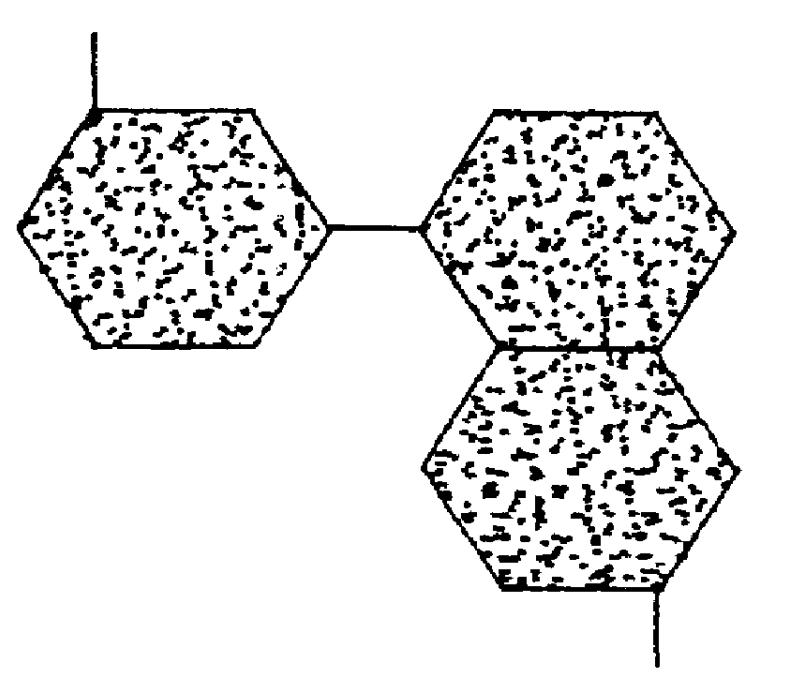

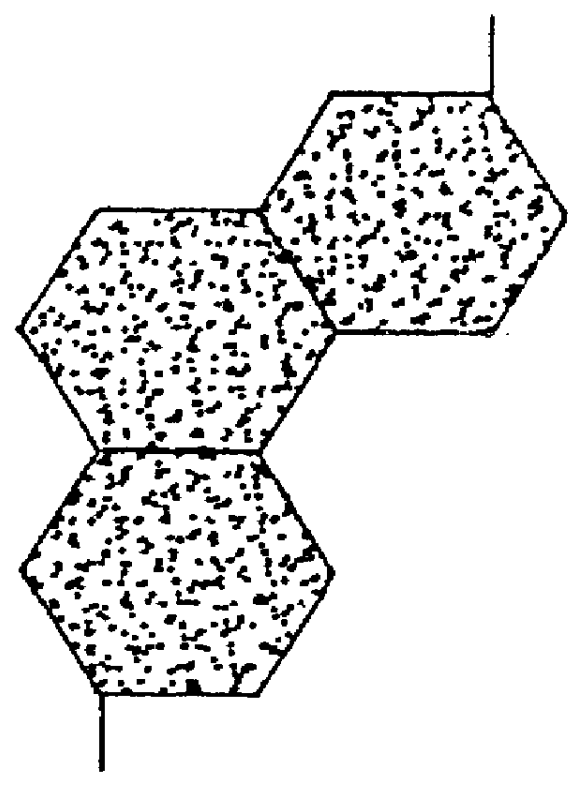

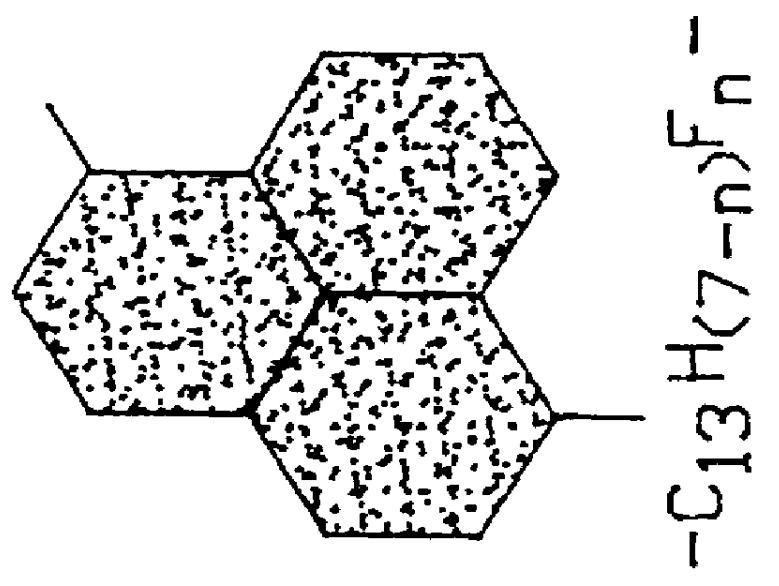

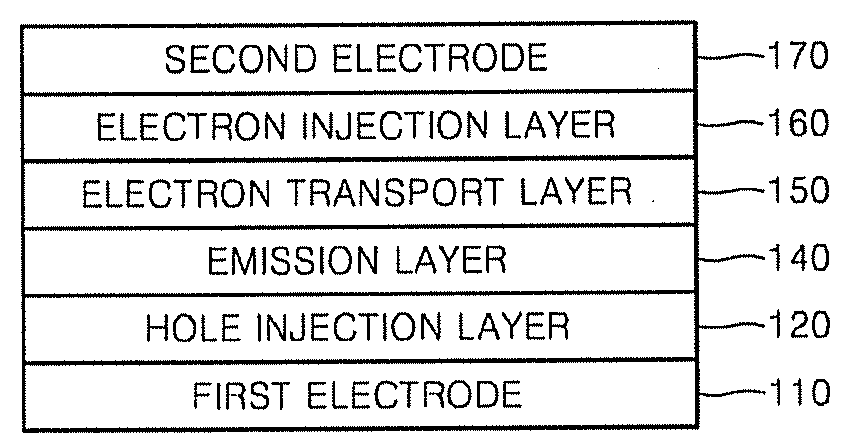

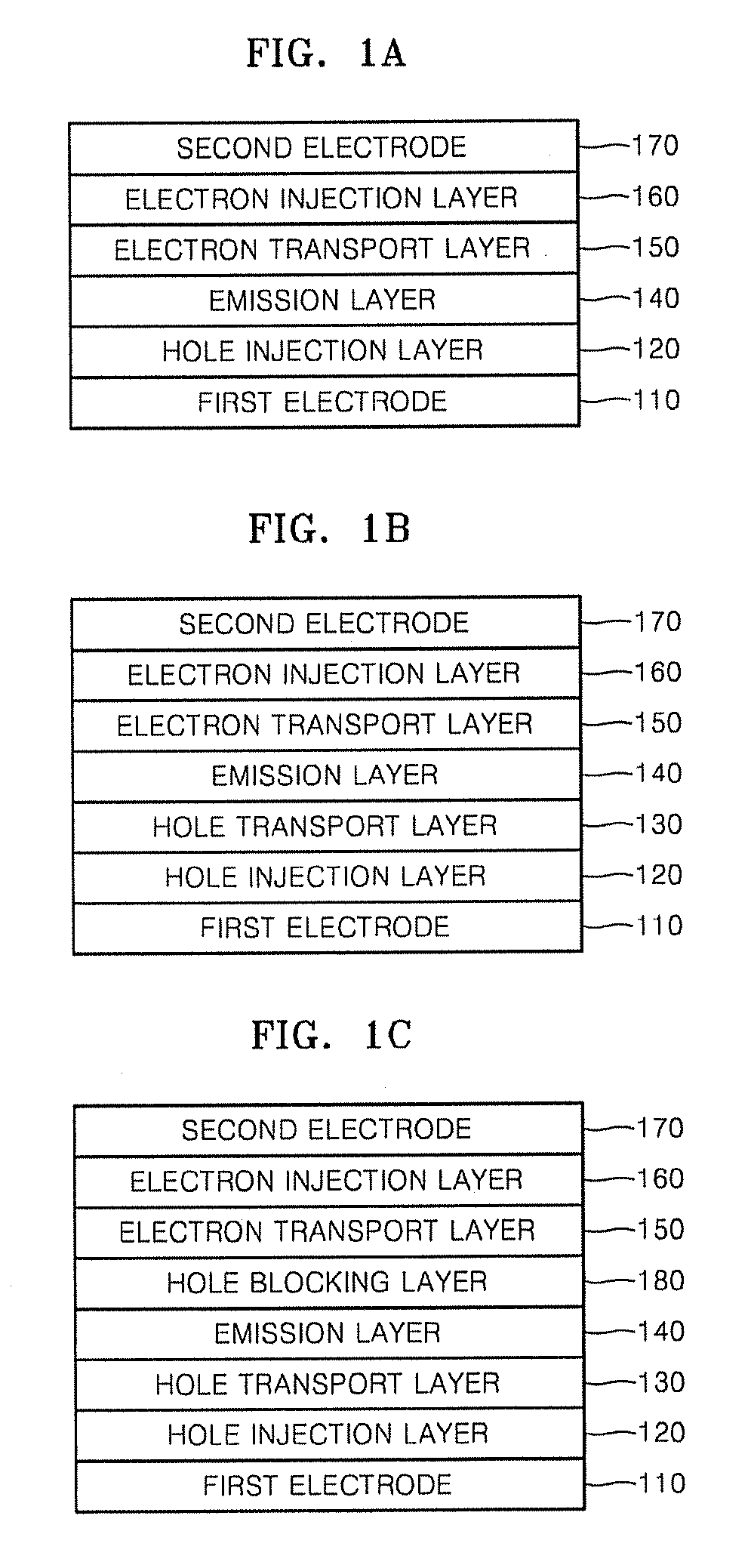

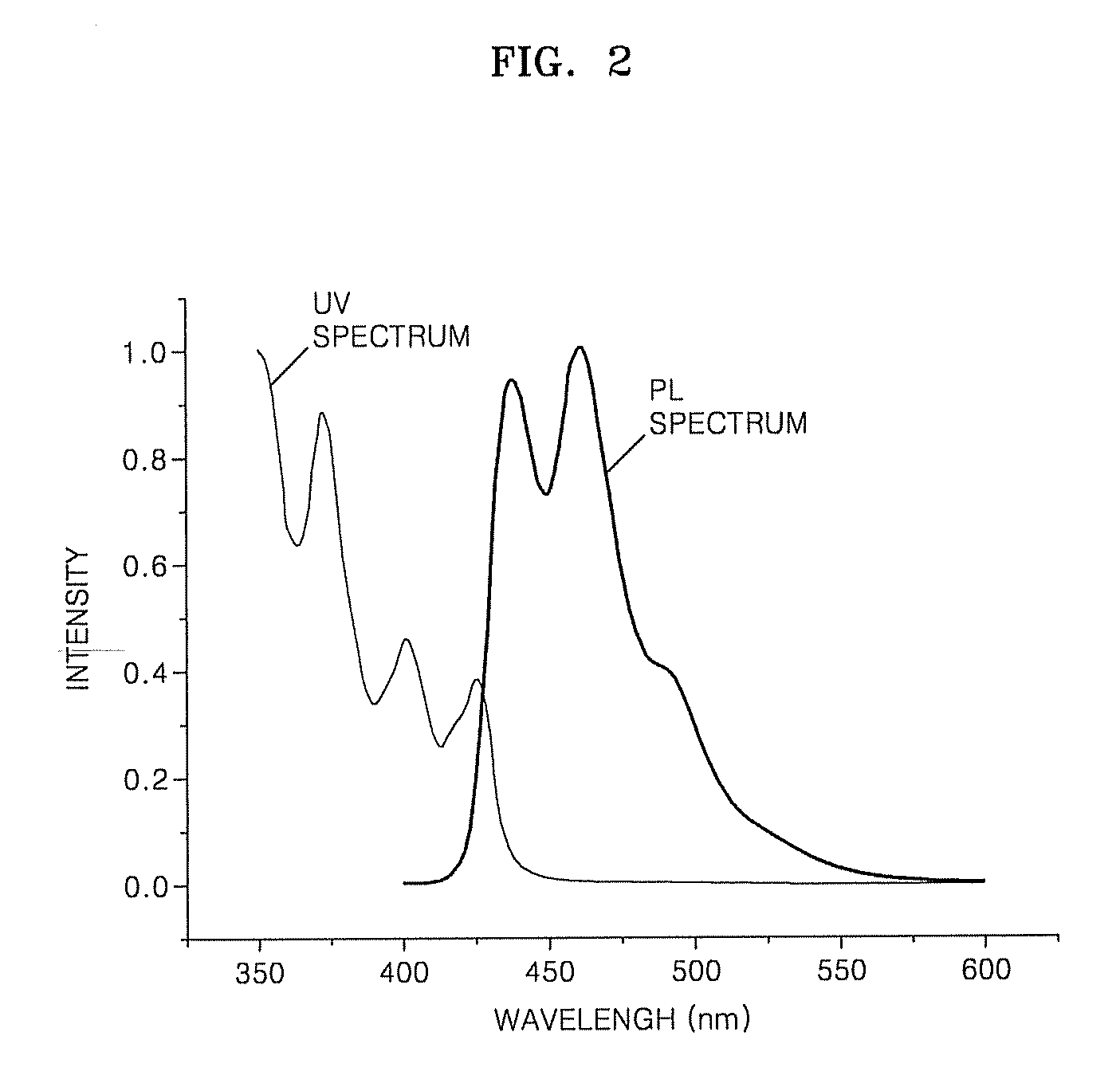

Organic light emitting compound, organic light emitting device comprising the same, and method of manufacturing the organic light emitting device

InactiveUS20080124455A1Improve solubilityImprove thermal stabilityOrganic chemistryDischarge tube luminescnet screensOrganic light emitting deviceHigh luminance

Provided are an organic light emitting compound represented by Formula 1 below, an organic light emitting device comprising the same, and a method of manufacturing the organic light emitting device:where CY1 and CY2 are each independently a fused C6-C50 aromatic ring, Ar1 is a substituted or unsubstituted C6-C50 arylene group, Ar2, Ar3, Ar4, and Ar5 are each independently a substituted or unsubstituted C6-C50 aryl group, m and n are independently 0-3, and R1 and R2 are substituent groups. An organic light emitting device comprising the organic light emitting compound has low turn-on voltage, high efficiency, high color purity and high luminance.

Owner:SAMSUNG ELECTRONICS CO LTD

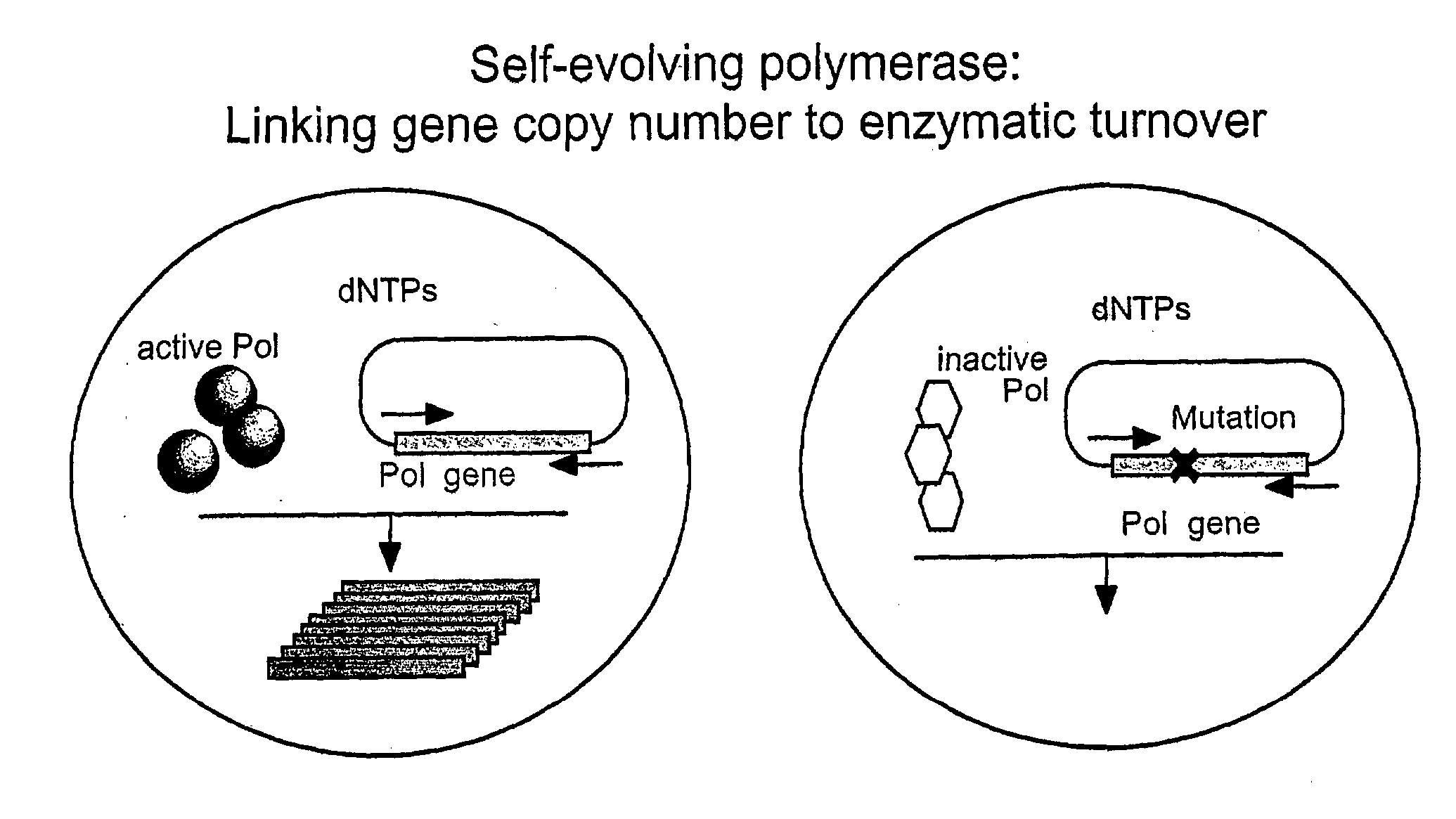

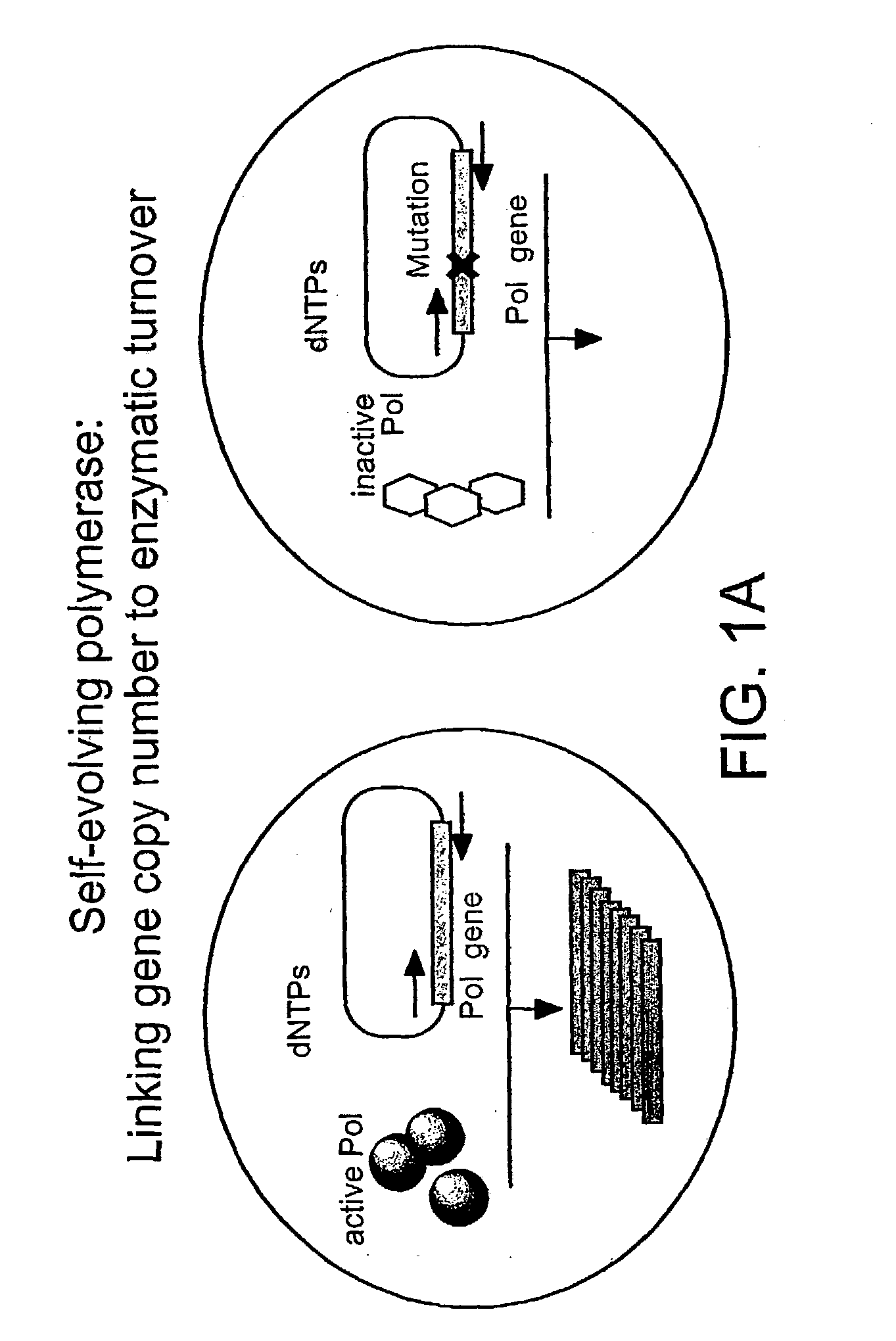

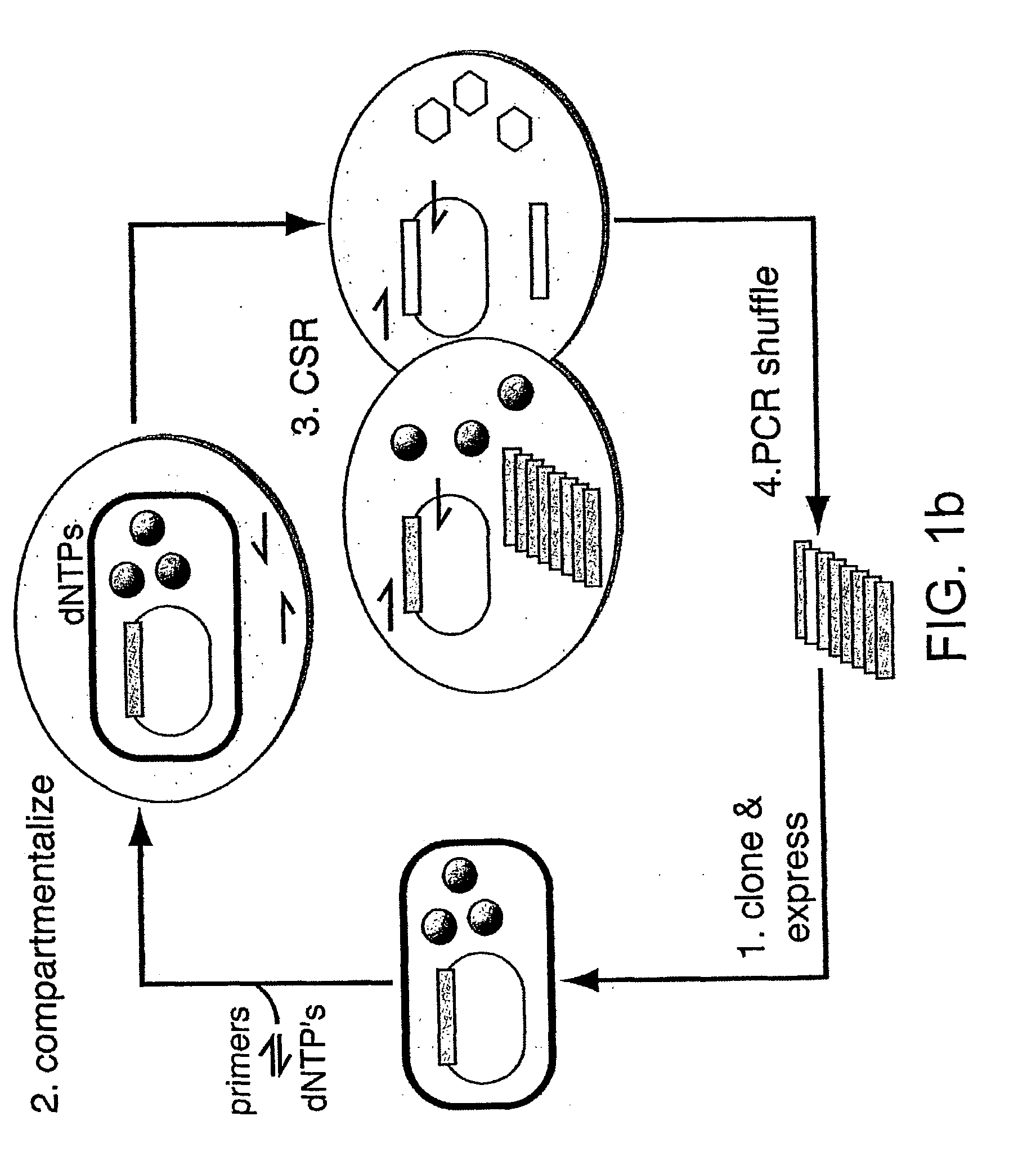

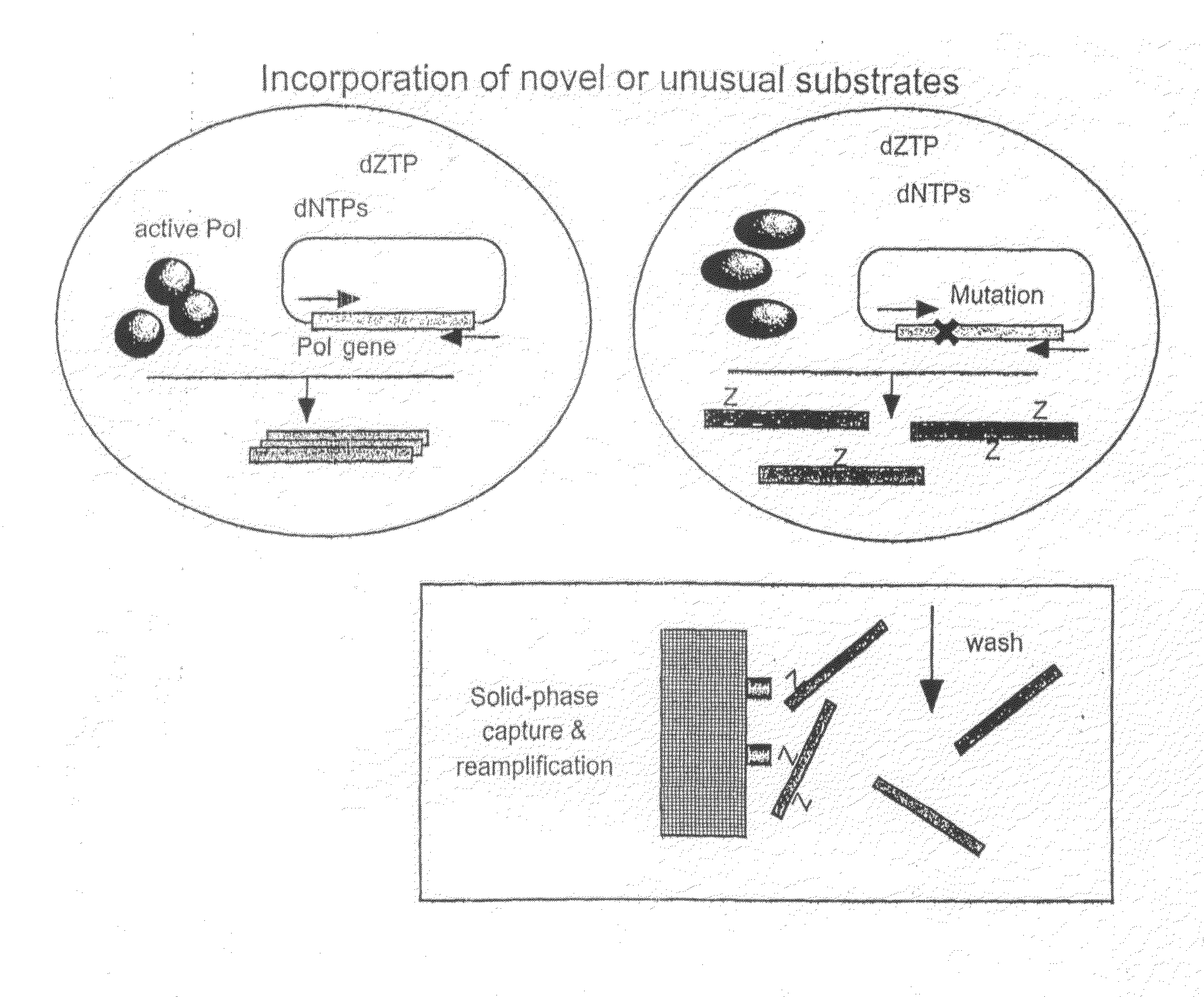

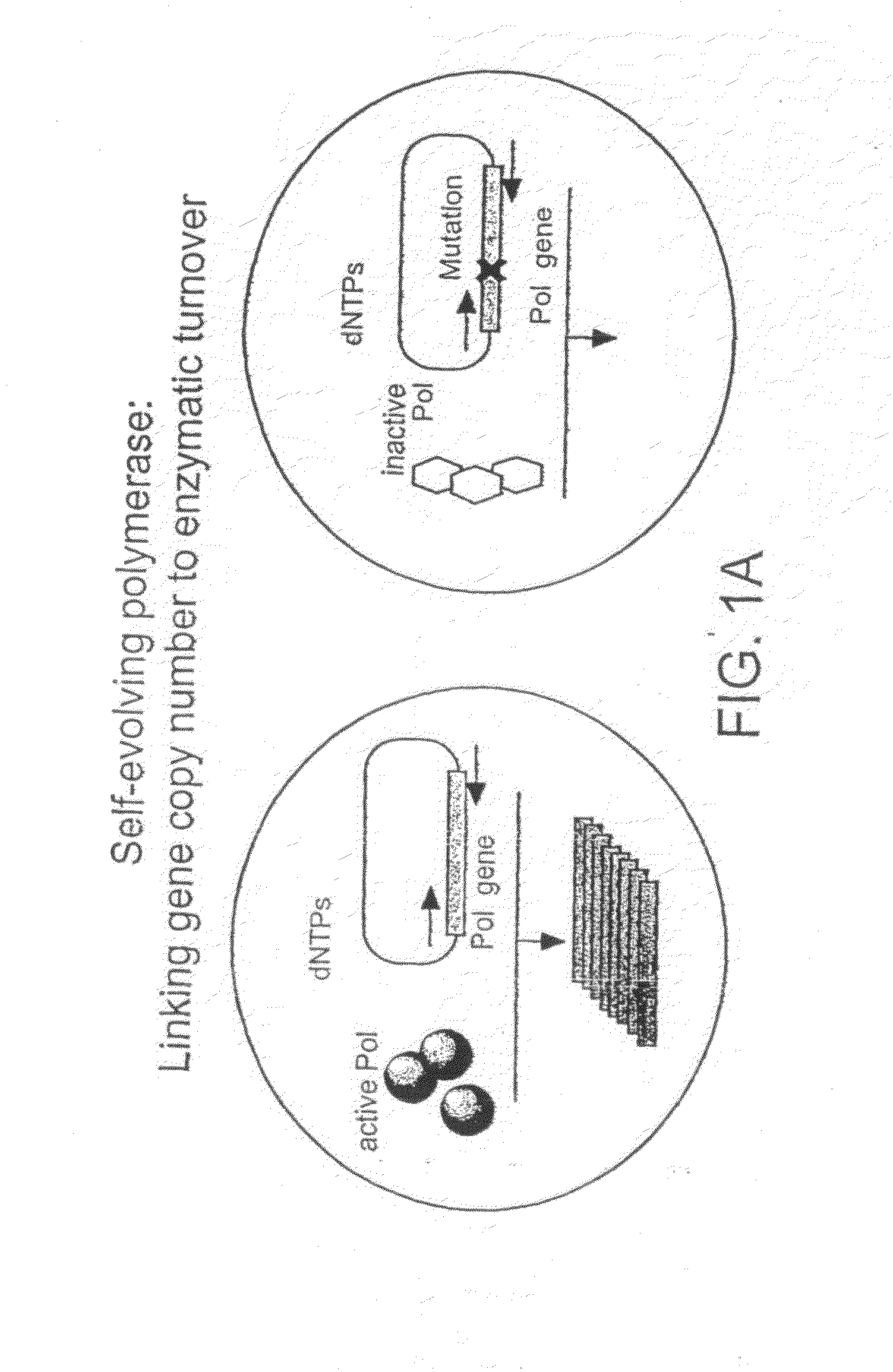

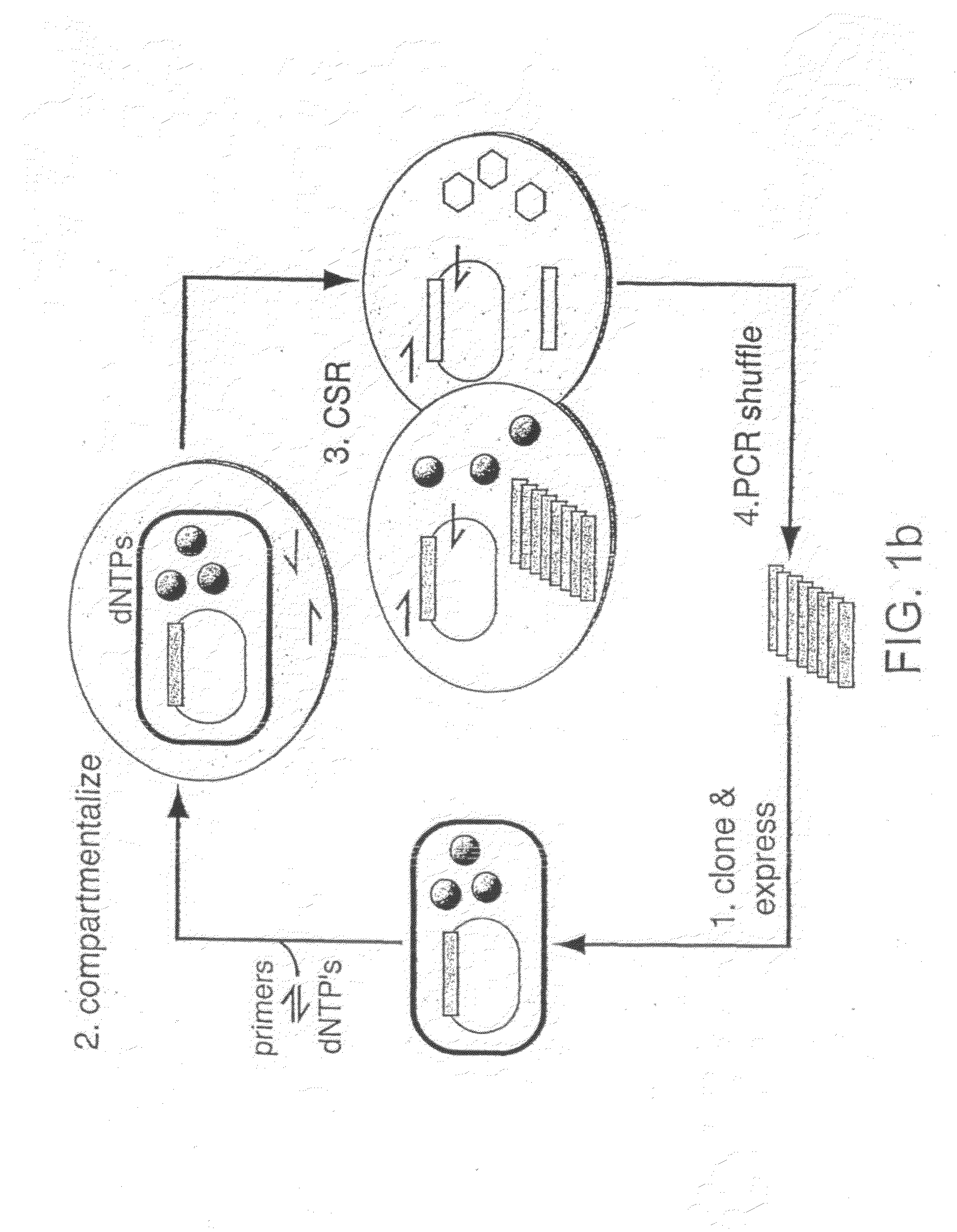

Directed evolution method

We describe a method of selecting an enzyme having replicase activity, the method comprising the steps of: (a) providing a pool of nucleic acids comprising members each encoding a replicase or a variant of the replicase; (b) subdividing the pool of nucleic acids into compartments, such that each compartment comprises a nucleic acid member of the pool together with the replicase or variant encoded by the nucleic acid member; (c) allowing nucleic acid replication to occur; and (d) detecting amplification of the nucleic acid member by the replicase. Methods for selecting agents capable of modulating replicase activity, and for selecting interacting polypeptides are also disclosed.

Owner:UK RES & INNOVATION LTD

Methods of increasing the concentration of a nucleic acid

InactiveUS20080166772A1High thermal stabilityAntibody mimetics/scaffoldsMicrobiological testing/measurementEnzymeNucleic acid

Owner:HOLLINGER PHILLIP +2

High-temperature (800 DEG C) wear-resistant paint and preparation method thereof

The invention discloses high-temperature (800 DEG C) wear-resistant paint and a preparation method thereof. The high-temperature wear-resistant paint comprises a component 1 and a component 2, wherein the component 1 is prepared by mixing a component A and a component B; the component A in the component 1 comprises the following components: black silicon carbide, fine-grain aluminum oxide, dispersing agent, zinc oxide, modified epoxy resin, flatting agent and an auxiliary material; the component B in the component 1 comprises the following components: organic silicon modified epoxy resin, a filler, antimony trioxide, film-forming assistant and thickener; and the component 2 is curing agent and coupling agent. The high-temperature (800 DEG C) wear-resistant paint is prepared by the following steps: mixing the component A and the component B in the component 1, and curing the component 1 with the component 2. The high-temperature wear-resistant paint is prepared by compounding the double components, has excellent high temperature resistance and wear resistance, and also has the fine properties of favorable hardness, high heat stability, ductility, workability and the like. The invention also designs the method for preparing the high-temperature wear-resistant paint. The preparation method is simple and low in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

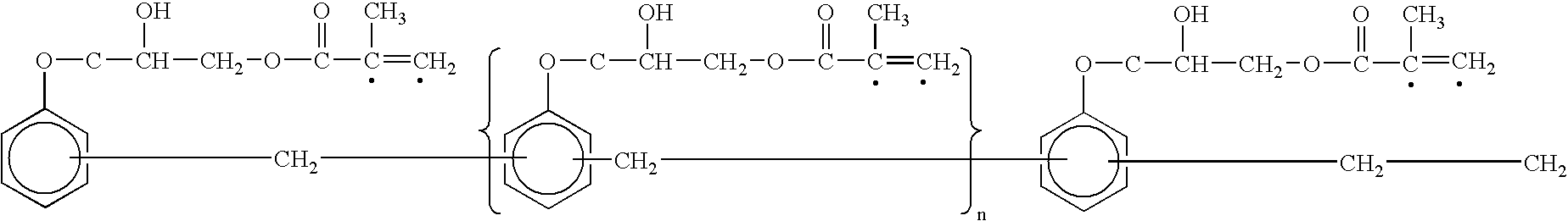

Preparation of fuel cell composite bipolar plate

ActiveUS20050001352A1Improve thermal stabilityImprove mechanical propertiesNon-metal conductorsConductive materialPolymer electrolytesFuel cells

A composite bipolar plate of polymer electrolyte membrane fuel cells (PEMFC) is prepared as follows: a) preparing a bulk molding compound (BMC) material containing a vinyl ester resin and a graphite powder, the graphite powder content of BMC material ranging from 60 wt % to 80 wt %, based on the compounded mixture; b) molding the BMC material from step a) to form a bipolar plate having a desired shape at 80-200° C. and 500-4000 psi, wherein the graphite powder is of 40 mesh-80 mesh.

Owner:IND TECH RES INST +1

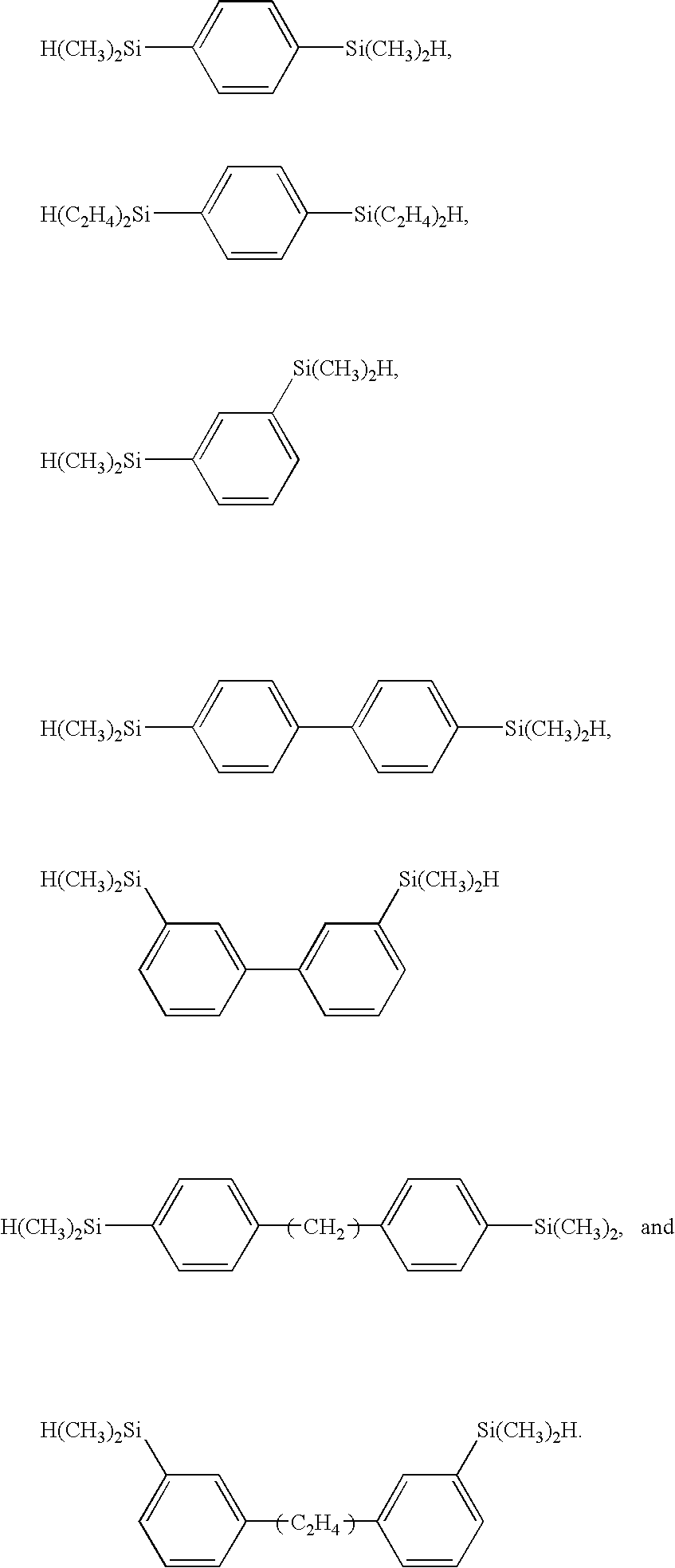

Reinforced silicone resin film and method of preparing same

InactiveUS20090155577A1Reduction factorHigh tensile strengthSynthetic resin layered productsPretreated surfacesPolymer chemistrySilicone

A method of preparing a reinforced silicone resin film, the method comprising the steps of impregnating a fiber reinforcement in a free radical-curable silicone composition comprising a silicone resin, and curing the silicone resin of the impregnated fiber reinforcement; wherein the reinforced silicone resin film comprises from 10 to 99% (w / w) of the cured silicone resin and the film has a thickness of from 15 to 500 μm; and a reinforced silicone resin film prepared according to the method.

Owner:DOW CORNING CORP

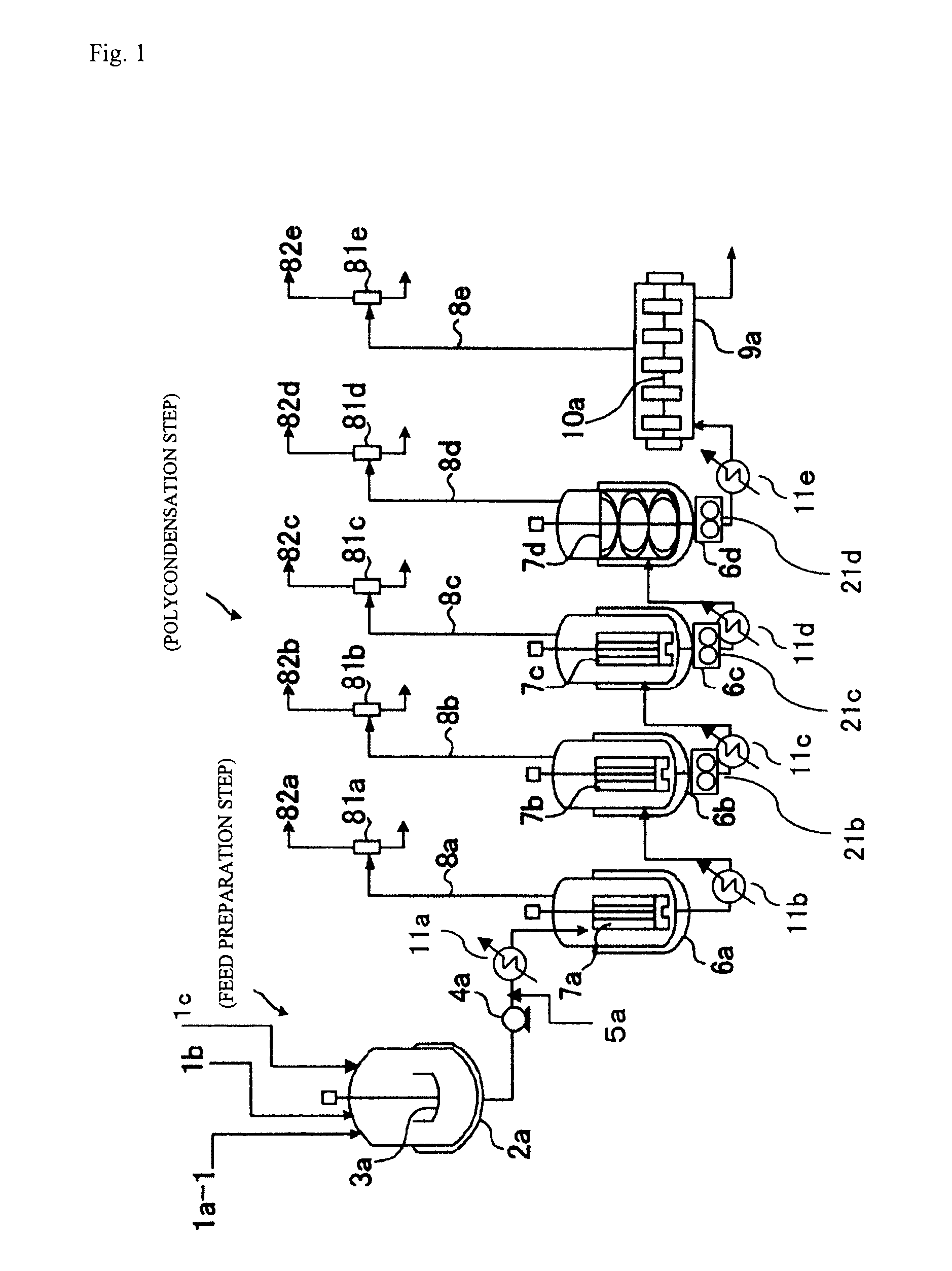

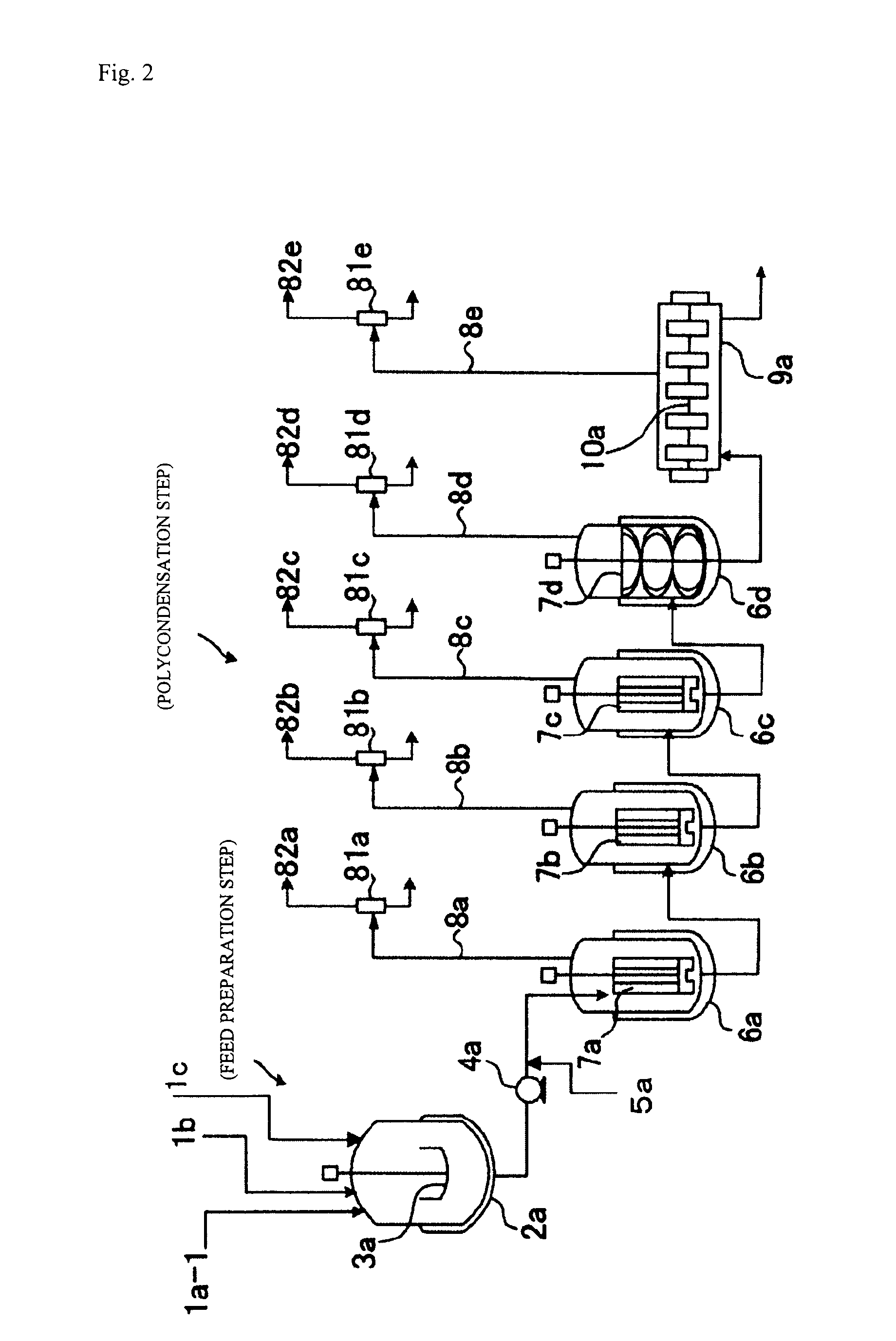

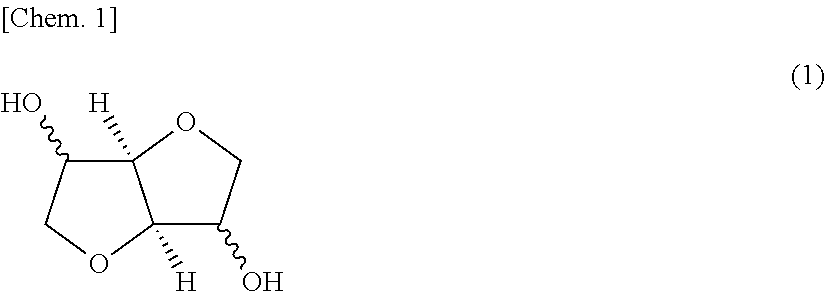

Processes for producing polycarbonate and molded polycarbonate articles

ActiveUS20110003101A1Efficient and stable productionLow refractive indexFlexible coversWrappersHeat resistanceRefractive index

A subject for the invention relates to processes for producing a polycarbonate containing a plant-derived starting material and to molded articles thereof, the polycarbonate having excellent mechanical strength, heat resistance, a low refractive index, a large Abbe number, low birefringence, and excellent transparency. The invention relates to a process for producing a polycarbonate which includes a step in which one or more dihydroxy compounds including a dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof are reacted with a carbonic acid diester in the presence of a polymerization catalyst, wherein the dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof has a formic acid content lower than 20 ppm. The invention further relates to a molded article constituted of a polycarbonate or a composition of the polycarbonate, the polycarbonate being a polycarbonate which contains constituent units derived from a dihydroxy compound having at least one linking group —CH2—O— in the molecule thereof and has an Abbe number of 50 or larger and a 5% weight loss temperature of 340° C. or higher.

Owner:MITSUBISHI CHEM CORP

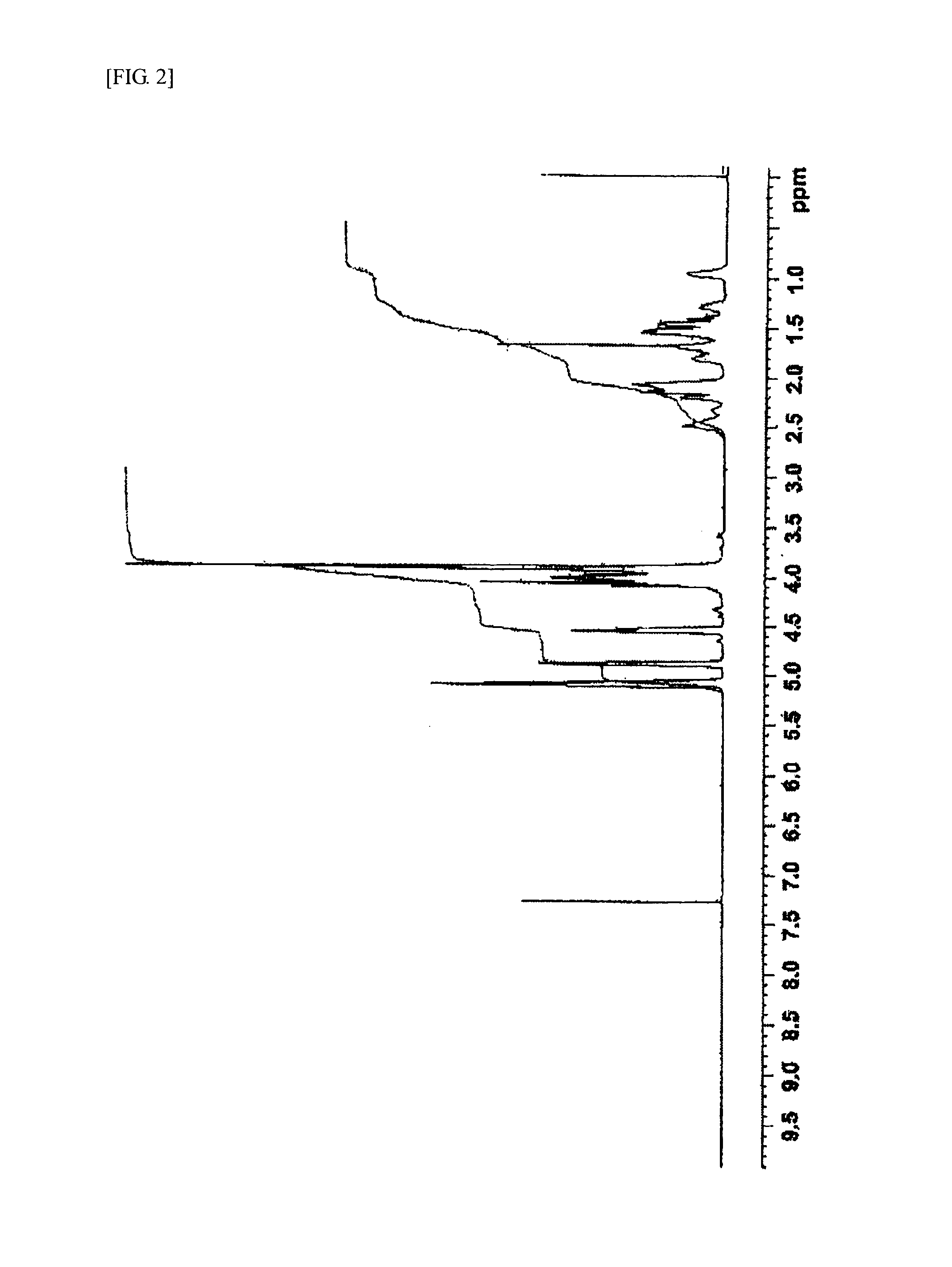

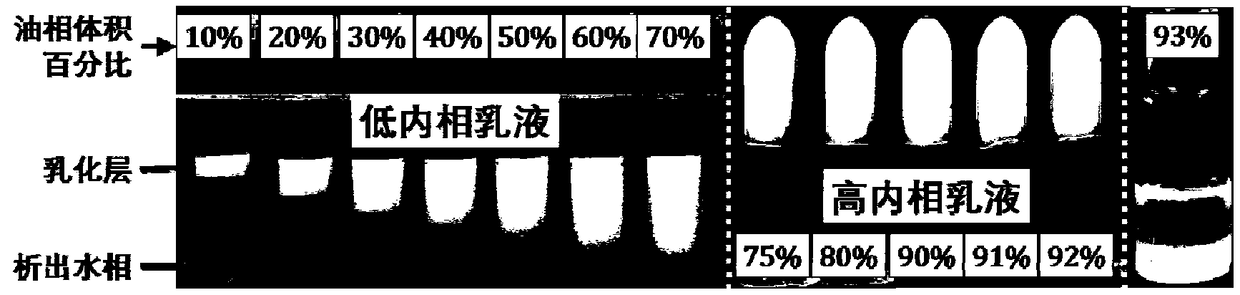

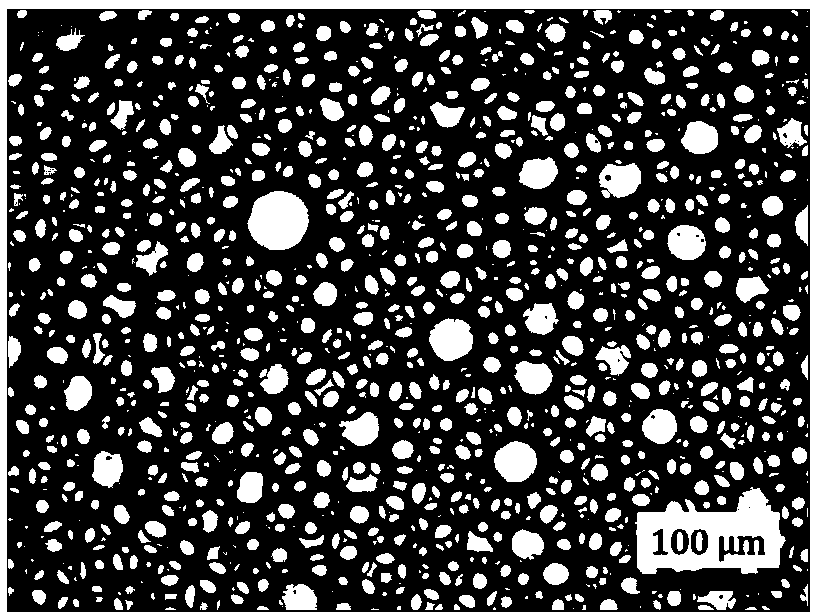

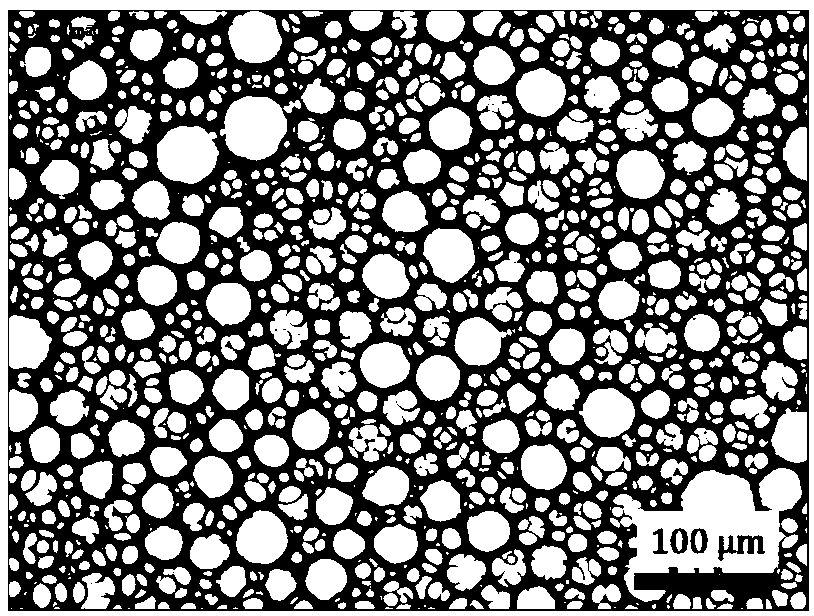

Stable-protein high-internal-phase oil-in-water emulsion and preparation method thereof

The invention belongs to the technical field of emulsion preparation, and discloses a stable-protein high-internal-phase oil-in-water emulsion and a preparation method thereof. The method comprises the following steps: a protein is dispersed into water, after the protein is fully hydrated, an aqueous phase protein solution is obtained, an oil phase is added, emulsification is performed, and therefore the stable-protein high-internal-phase oil-in-water emulsion is obtained. The method disclosed by the invention does not need any coagulants or surfactants, and the obtained high-internal-phase oil-in-water emulsion has good viscoelasticity, high heat stability and storage stability, and an excellent protection or controlled release effect on the oil phase; and the emulsion has good gelling performance, strong plasticity and remoldability, facilitates further processing, and has good application prospects in the fields of chemical products, daily chemicals, pharmaceuticals, food and healthcare products.

Owner:SOUTH CHINA UNIV OF TECH

Antioxidant, anti-wear and antirust lubricating oil for automobile gear and preparation method thereof

The invention discloses antioxidant, anti-wear and antirust lubricating oil for an automobile gear. The lubricating oil is characterized by being prepared from the following raw materials: base oil, a clearing agent, a dispersing agent, a preservative, an extreme-pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirust agent, a pour point depressant and an antifoaming agent, wherein in the base oil of the lubricating oil, the kinematic viscosity below 100 DEG C is 1.5-40mm<2> / s, the viscosity index is over 100, the pour point is below -25 DEG C, and the sulfur content is below 0.01% by mass. The lubricating oil for an automobile gear, disclosed by the invention, has the advantages of simple composition, low cost, relatively good viscosity index, high anti-wear property and long service life; the compatibility between the lubricating oil additive and the base oil is relatively good, and the lubricating oil is of relatively high stability; and compared with existing automobile lubricating oil, the automobile lubricating oil disclosed by the invention has high corrosion resistance, the preparation technology of the lubricating oil is simple, and the steps are simple and environment-friendly and easy to implement.

Owner:高安市超鹰科技有限公司

Methane oxidation coupling catalyst and preparation method thereof

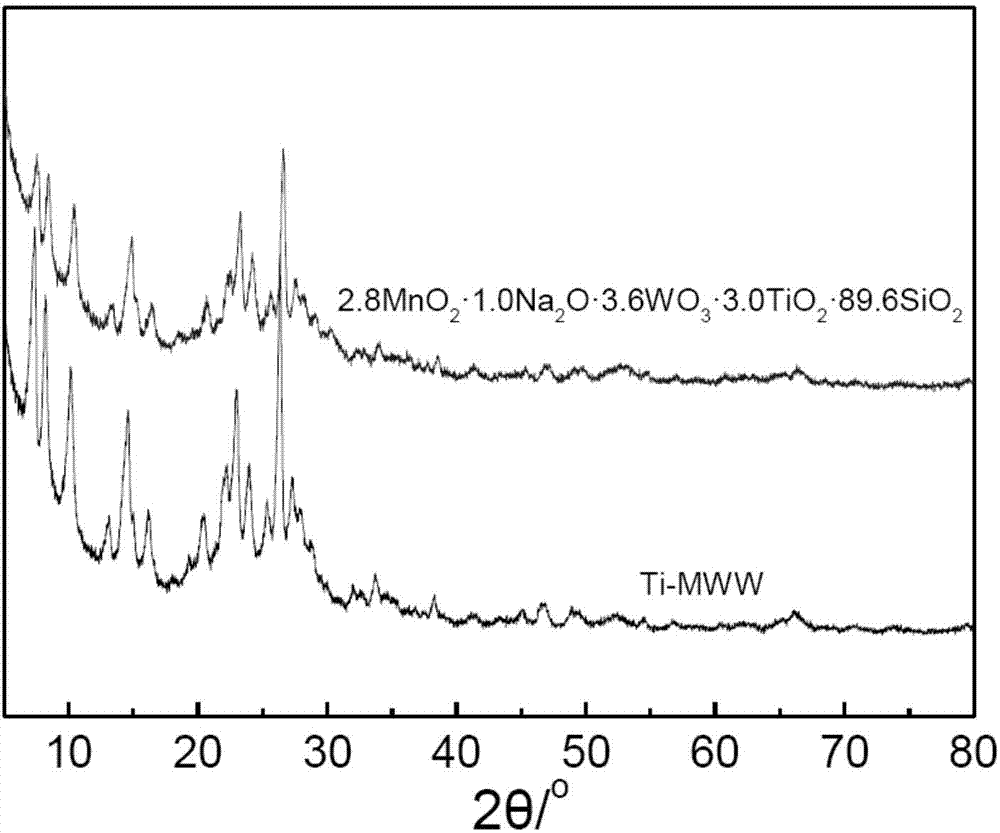

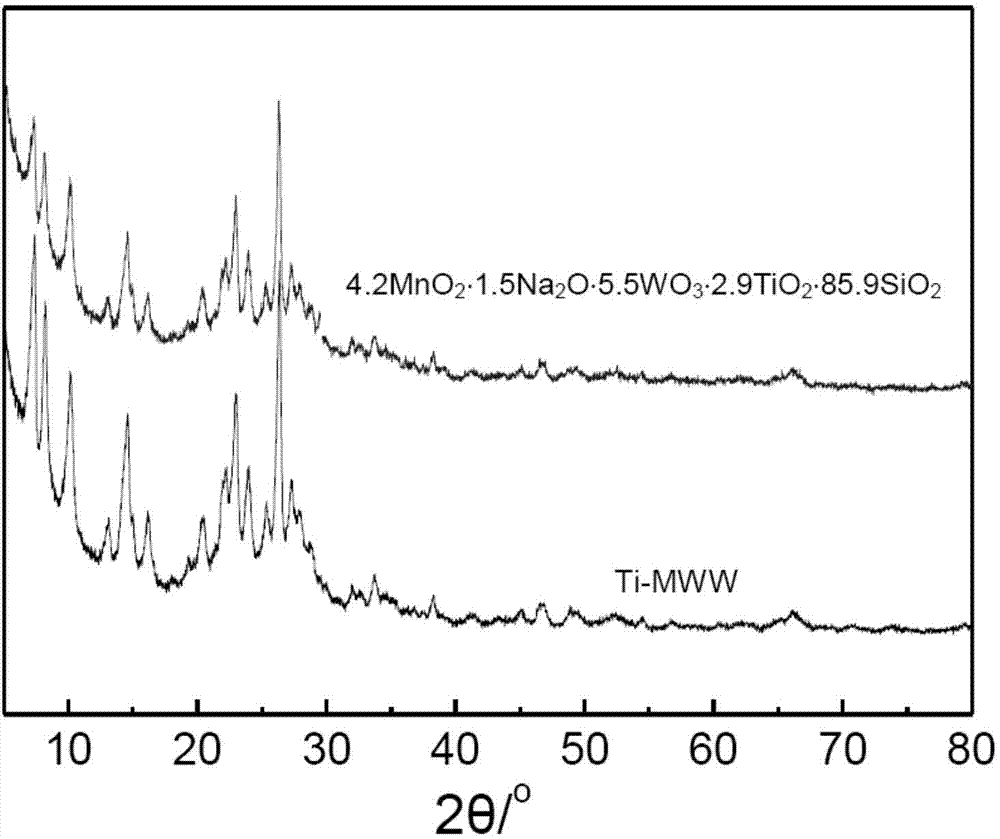

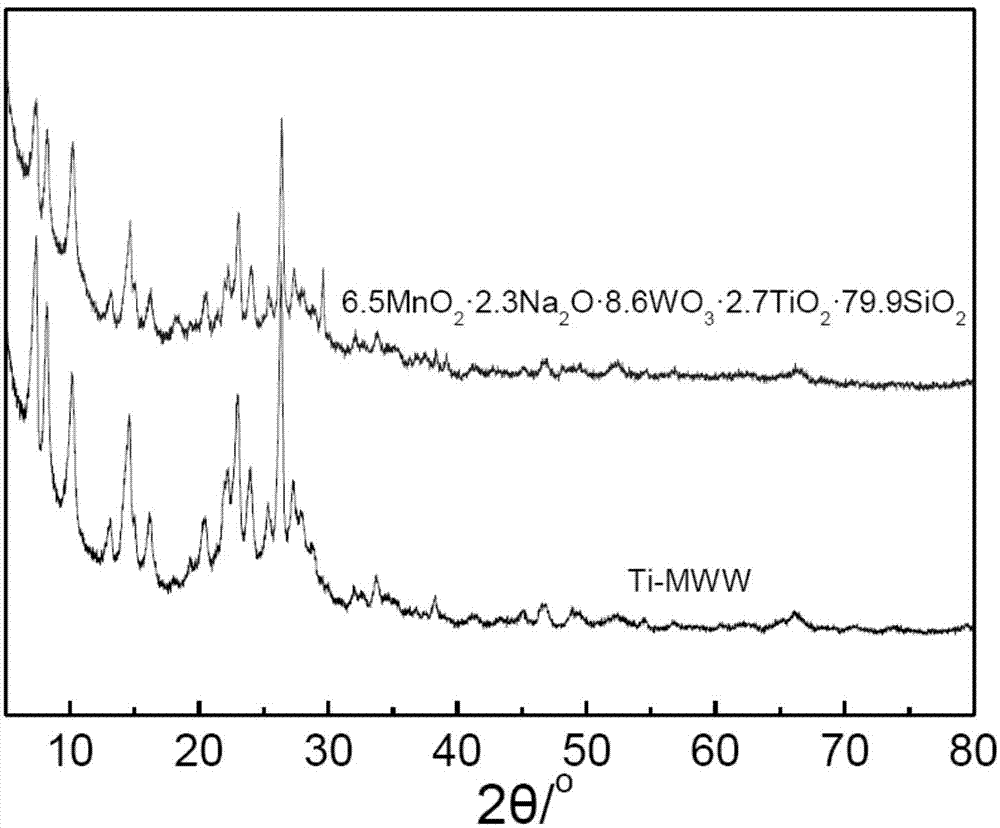

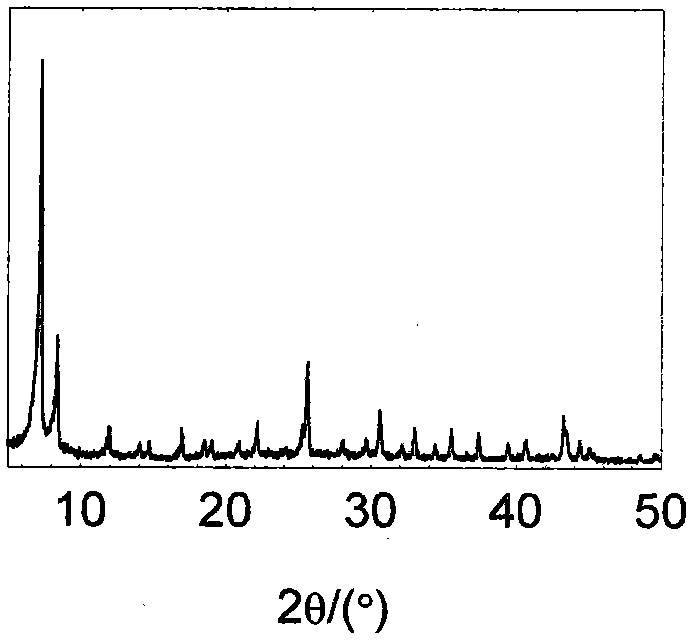

ActiveCN104759291AGood activity at low temperatureHigh selectivityMolecular sieve catalystsHeterogenous catalyst chemical elementsManganese oxideStructural formula

The present invention discloses a manganese-sodium-tungsten-silicon composite oxide oxidative coupling of methane catalyst containing or not containing titanium, obtained by loading manganese-sodium-tungsten onto a titanium-silicon molecular sieve or a pure silicon molecular sieve by means of a step-by-step impregnation method and calcination. The manganese-sodium-tungsten-silicon composite oxide catalyst containing or not containing titanium has the following structural formula: vMnO2·xNa2O·yWO3·zTiO2·(100-v-x-y-z)SiO2, the v, x, y, and z respectively representing the fractional quality occupied by metal manganese oxide, sodium oxide, tungsten oxide and titanium oxide, 0.3≤v≤16, 0.1≤x≤5, 0.6≤y≤21, 0.0≤z≤4. The manganese-sodium-tungsten-silicon composite oxide catalyst containing or not containing titanium set forth in the present invention is used for oxidative coupling of methane reactions, having excellent low-temperature catalytic activity and ethylene / propylene selectivity generation and reaction stability.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

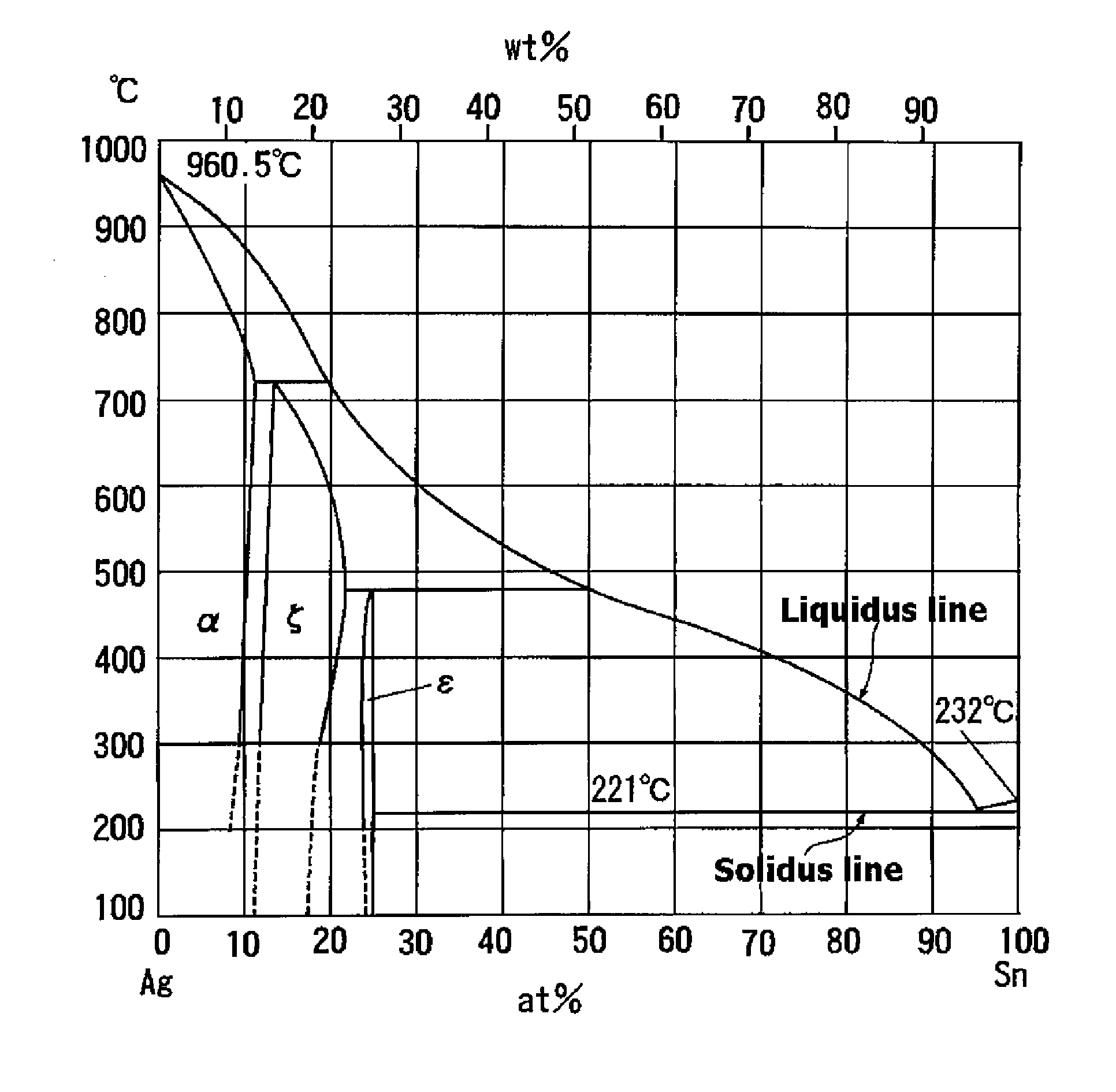

Cream solder and method of soldering electronic part

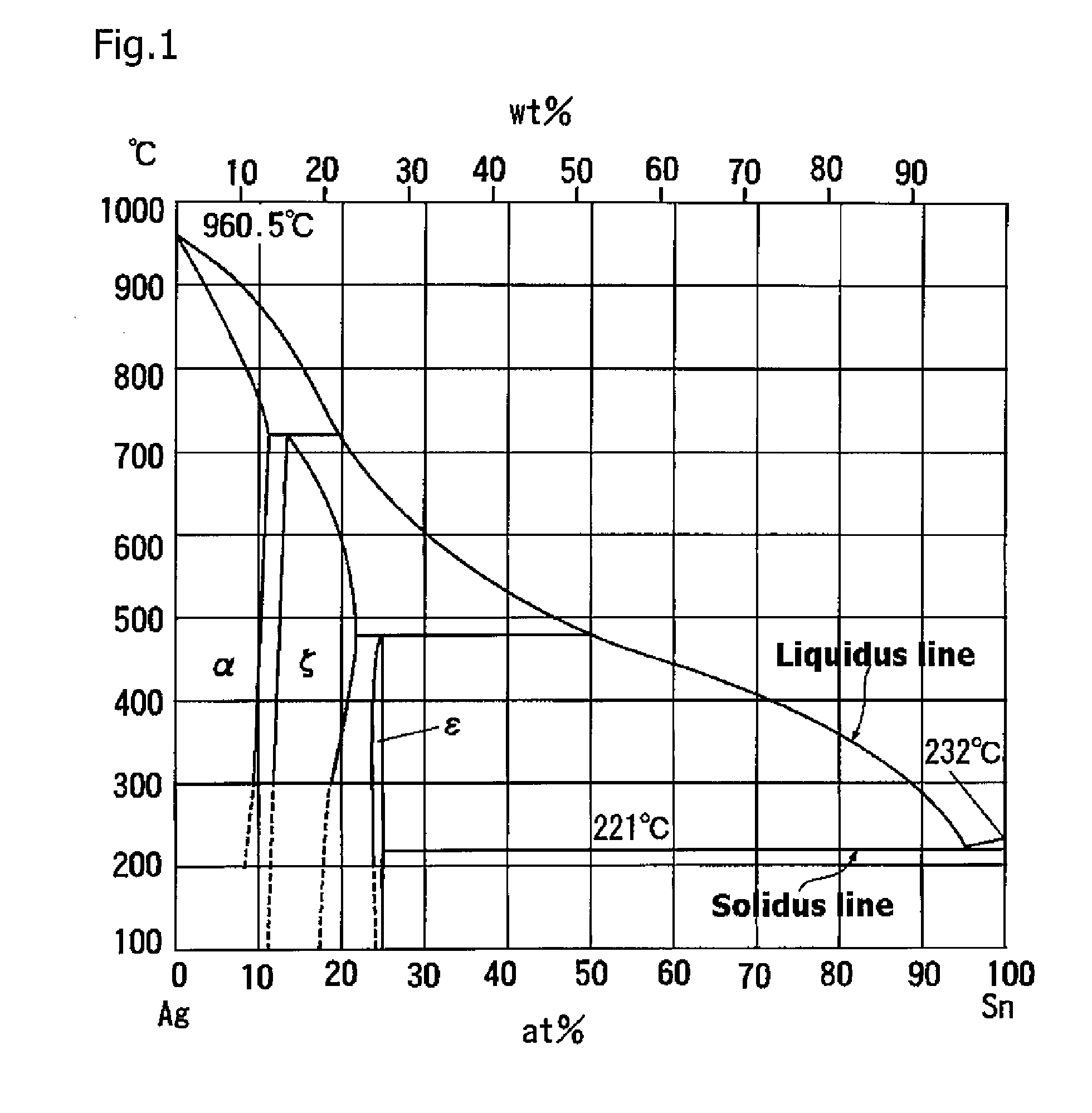

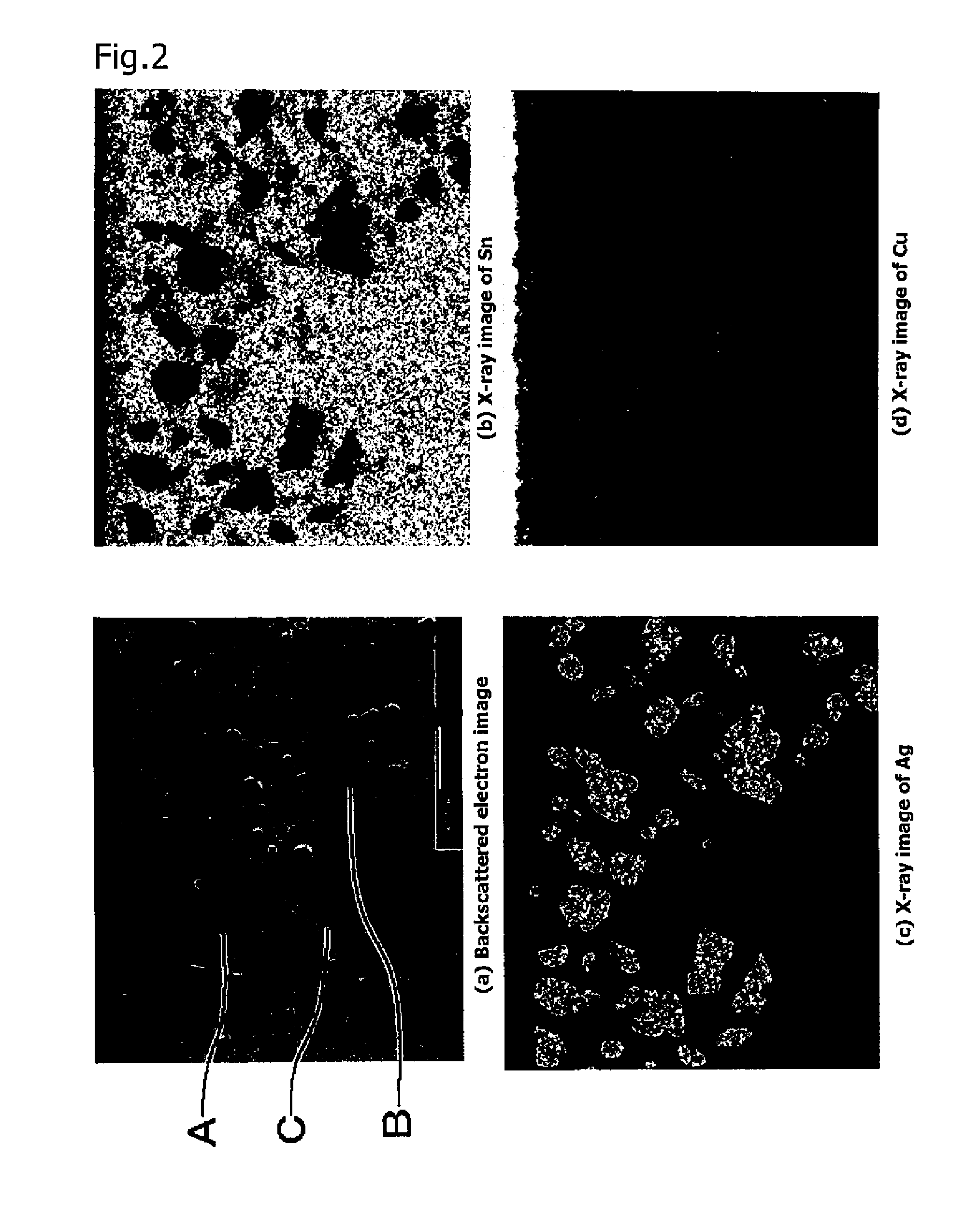

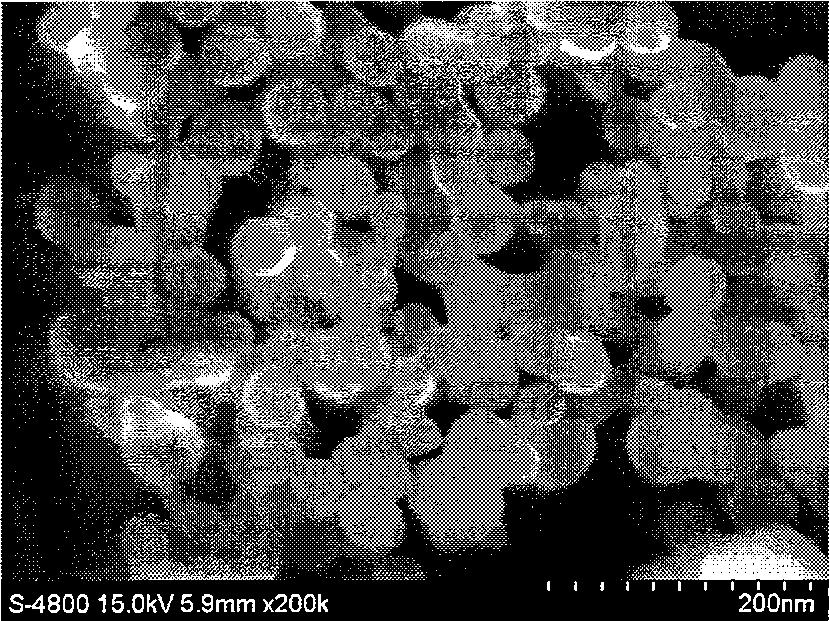

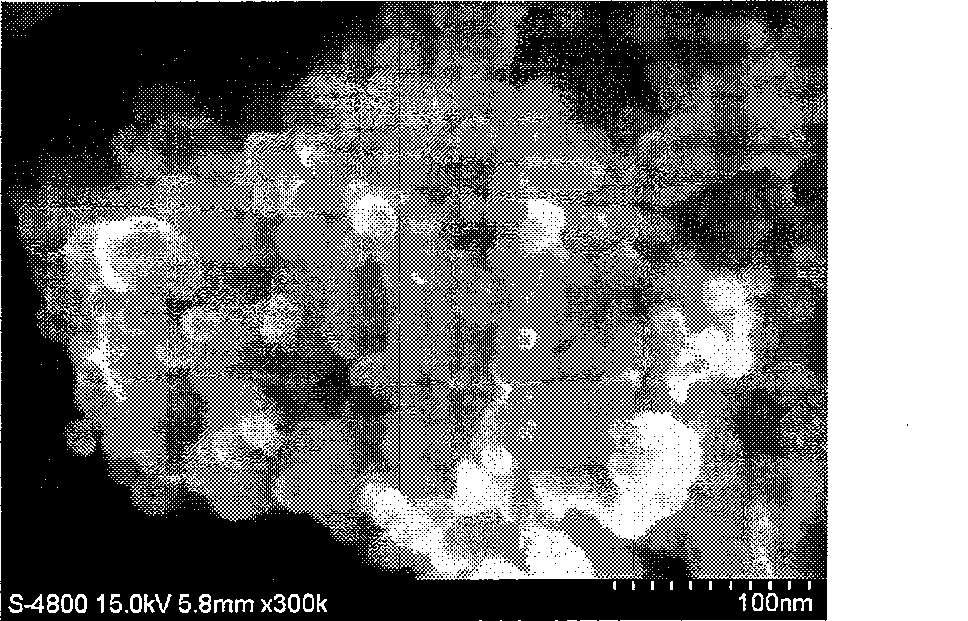

ActiveUS20120018048A1Improve adhesionHigh strength stabilityPrinted circuit assemblingPrinted circuit aspectsThermal stabilityUltimate tensile strength

A cream solder obtained by kneading an Sn—Ag—Cu alloy together with a flux, wherein the Sn—Ag—Cu alloy includes a mixture of a first powdery alloy and a second powdery alloy, the first powdery alloy is represented by an Sn—Ag phase diagram having a solid-liquid coexistence region and has a given silver amount which is larger than that in the eutectic composition (3.5 wt. % silver), and the second powdery alloy has a silver amount which is that in the eutectic composition (3.5 wt. % silver) or which is close to that in the eutectic composition and is smaller than that in the first powdery alloy. This cream solder has excellent strength and thermal stability, and satisfactory bonding properties. It is based on an inexpensive Sn—Ag—Cu solder alloy. It is suitable for use as a high-temperature-side lead-free solder material conformable to temperature gradation bonding. Also provided is a method of soldering.

Owner:NIHON HANDA +1

Ion thermal growth method of near infrared light upper conversion fluoride nano crystal

InactiveCN101476151ALow melting pointNon-volatilePolycrystalline material growthFrom normal temperature solutionsSolubilityLuminous intensity

The invention relates to an ion thermal growth method for converting fluoride nano crystal near infrared light which includes steps as follows: weighing some solid yttrium nitrate (lanthanum nitrate), ytterbium nitrate, erbium nitrate (thulium nitrate or holmium nitrate) pro rata. Mol ratio of the rare earth ion is that yttrium ion (lanthanum ion) : ytterbium ion : erbium ion (thulium ion, holmium ion) equal to 70-90 : 0 : 0.001-15; adding tetrafluoroborate type ion liquor into the mixing solid, selective adding some NaCl solid according with various basic, then placing the mixing solution into a high pressure reaction kettle with polyfluortetraethylene lining, placing into an oven for heating reacting, finally, washing, centrifugating, drying and obtaining the product. The prepared nano upper converting fluorescence material has small and uniform granule, strong lighting strength, better water-solubility and can satisfy need of biomolecule fluorescence mark material.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

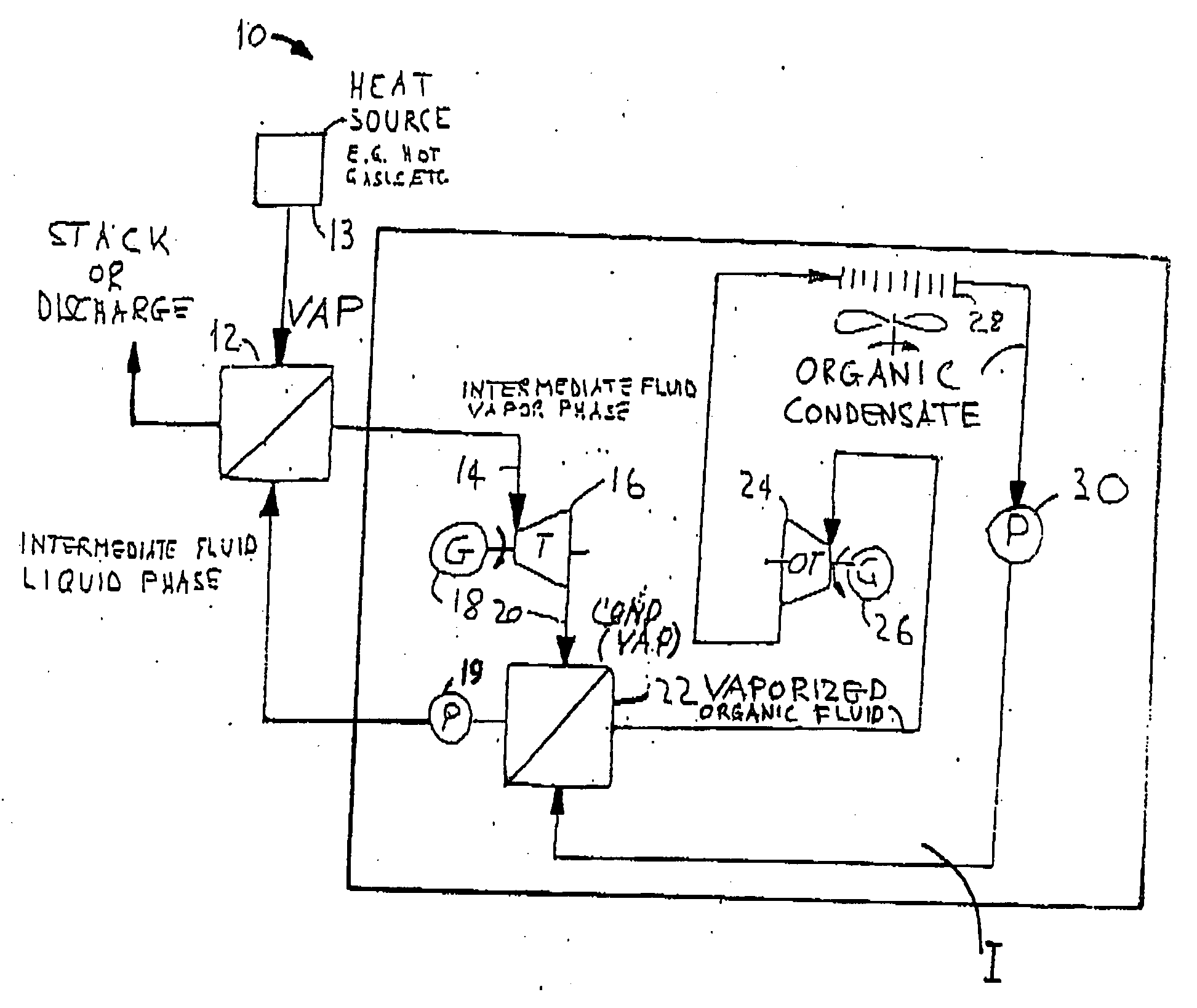

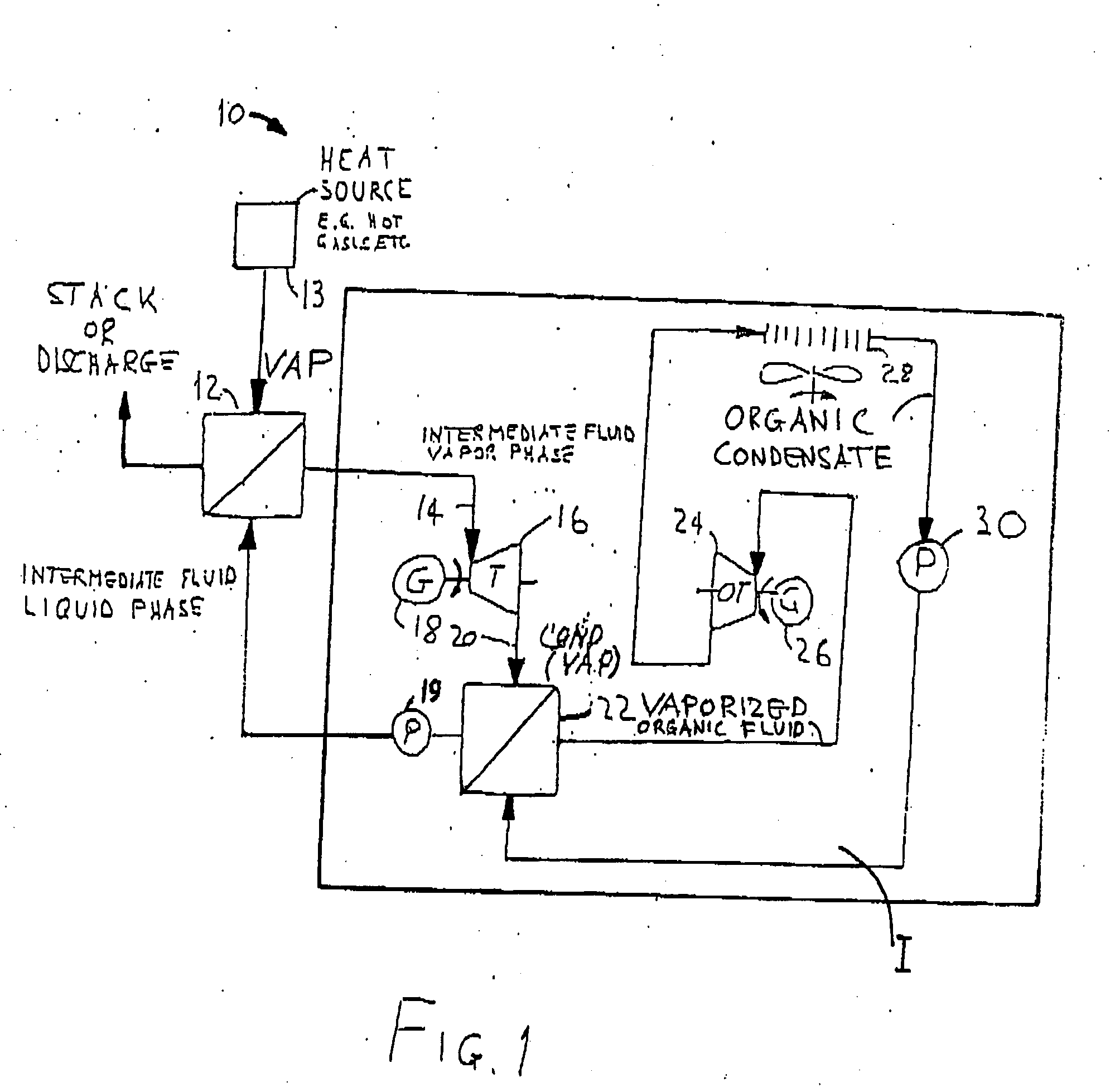

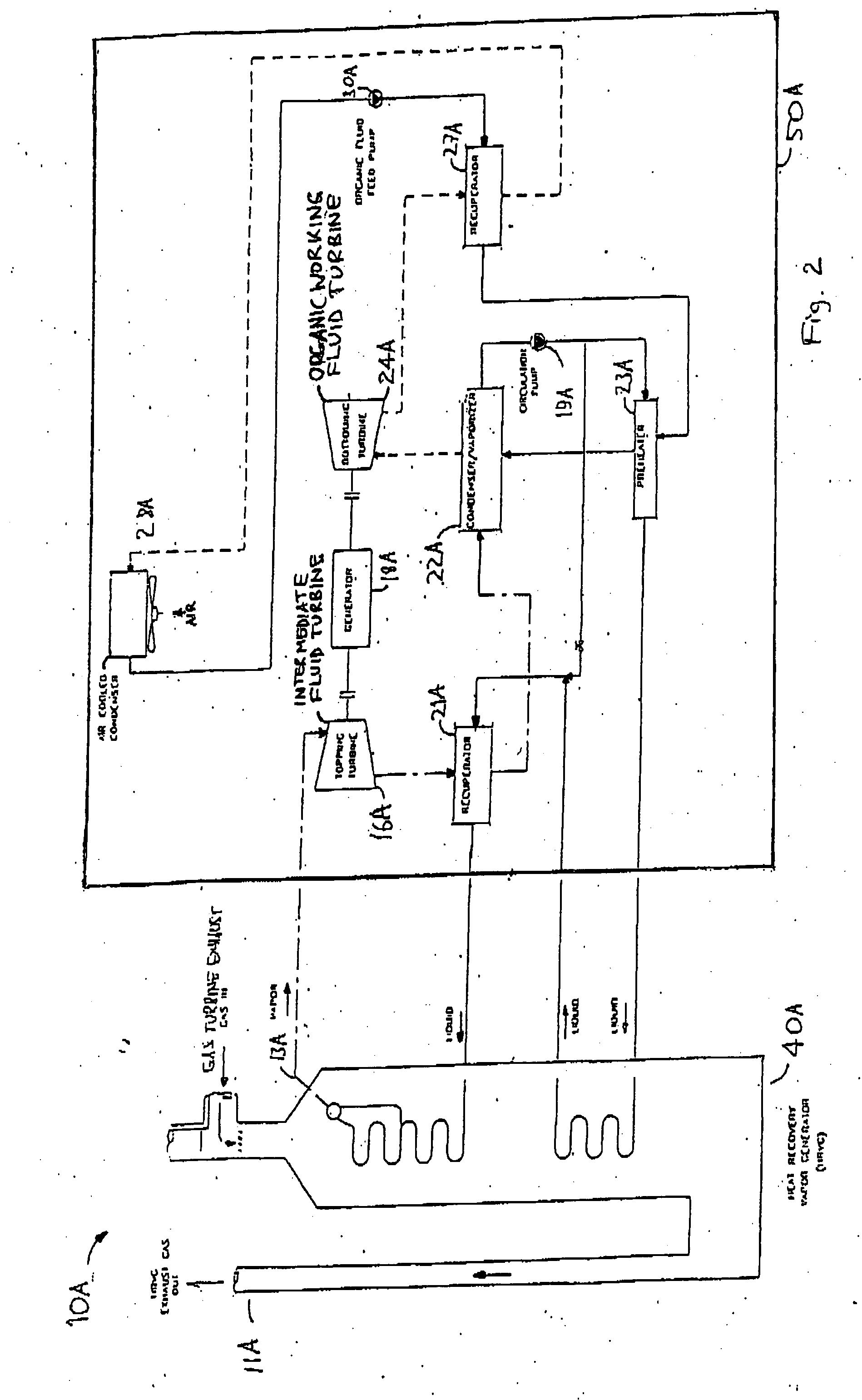

Organic working fluids

ActiveUS20060196187A1High thermal stabilitySafe to useAuxillary drivesFrom solar energyHigh critical temperaturePARAFFIN HYDROCARBONS

The present invention provides an improved, commercially available organic working fluid, which is operable under a broad range of temperatures, is thermally stable, has a high auto-ignition temperature, low freezing point and high critical temperature and is benign to the environment, and safe for human use. Such an organic working fluid is useful in organic Rankine cycle (ORC) power plants or units and other systems of the like; as an intermediate fluid for heat-recovery wherein heat from various heat sources is transferred using the intermediate fluid to a further working fluid and converted into work, and the intermediate fluid is also exploited to produce electricity. Such organic working fluids are also operable as heat transfer fluids either in ORC power plants or units or in other heat transfer systems. For this purpose the present invention presents a working fluid comprising at least one highly branched, heavy iso-paraffin hydrocarbons, or a mixture of two or more of such hydrocarbons. Preferably, at least one highly branched iso-paraffin hydrocarbon is present as the major component (i.e. at least 50% by volume) in the working fluid. A preferred sub-class of the class of the branched iso-paraffins which are suitable to be incorporated in organic working fluids of the present invention includes 8 to 20 carbon atom-containing hydrocarbons having at least one methyl radical (CH3) arranged to achieve a highly stable compound.

Owner:ORMAT TECHNOLOGIES INC

Silicone Resin Film and Method of Preparing Same

InactiveUS20090246499A1Reduction factorHigh tensile strengthSynthetic resin layered productsLaminationPolymer scienceThin membrane

A method of preparing a silicone resin film comprising coating a first release liner with a filled silicone composition comprising a hydrosilylation-curable silicone composition and a flame retardant filler, applying a second release liner to the coated first release liner to form an assembly, compressing the assembly; and curing the silicone resin of the compressed assembly, wherein the silicone resin film has a thickness of from 1 to 500 μm; and a silicone resin film.

Owner:DOW CORNING TORAY CO LTD +1

Engine lubricant with enhanced thermal stability

ActiveUS20080153722A1High thermal stabilityLow levelOrganic chemistryLiquid carbonaceous fuelsEngineeringBase oil

Provided are formulations, methods of making, and methods of using one or more Fischer-Tropsch Base Oils of the present invention in a low sulfur, low sulfated ash, and low phosphorus engine lubricant to enhance thermal stability of the lubricant as well as the high-temperature preformance of an engine housing the lubricant.

Owner:CHEVRON ORONITE TECH BV

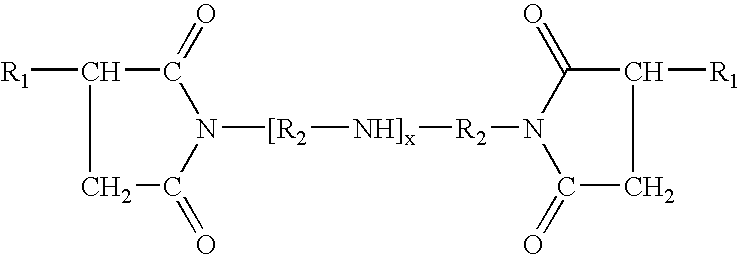

Polyimide film

ActiveUS20100255221A1Superior mechanical propertyHigh thermal stabilityLiquid crystal compositionsSynthetic resin layered productsChemistryPolyimide

Disclosed is a polyimide film, which is colorless and transparent, with superior mechanical properties and high thermal stability.

Owner:KOLON IND INC

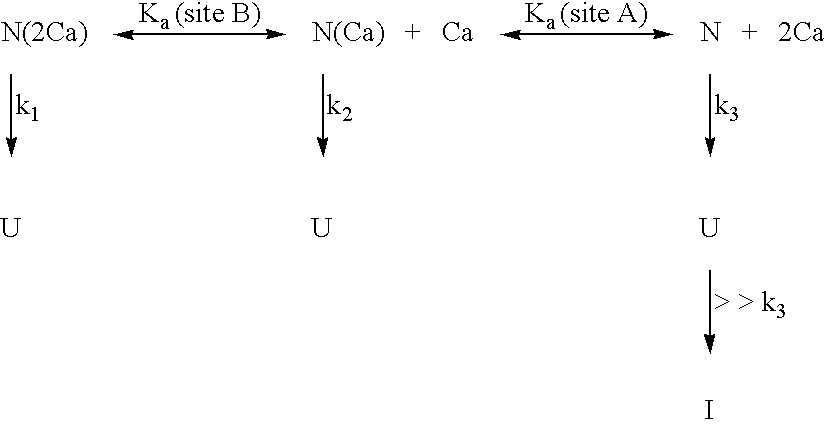

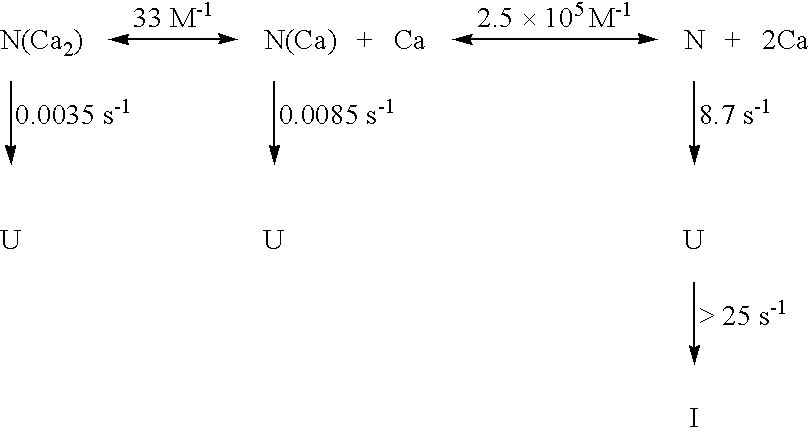

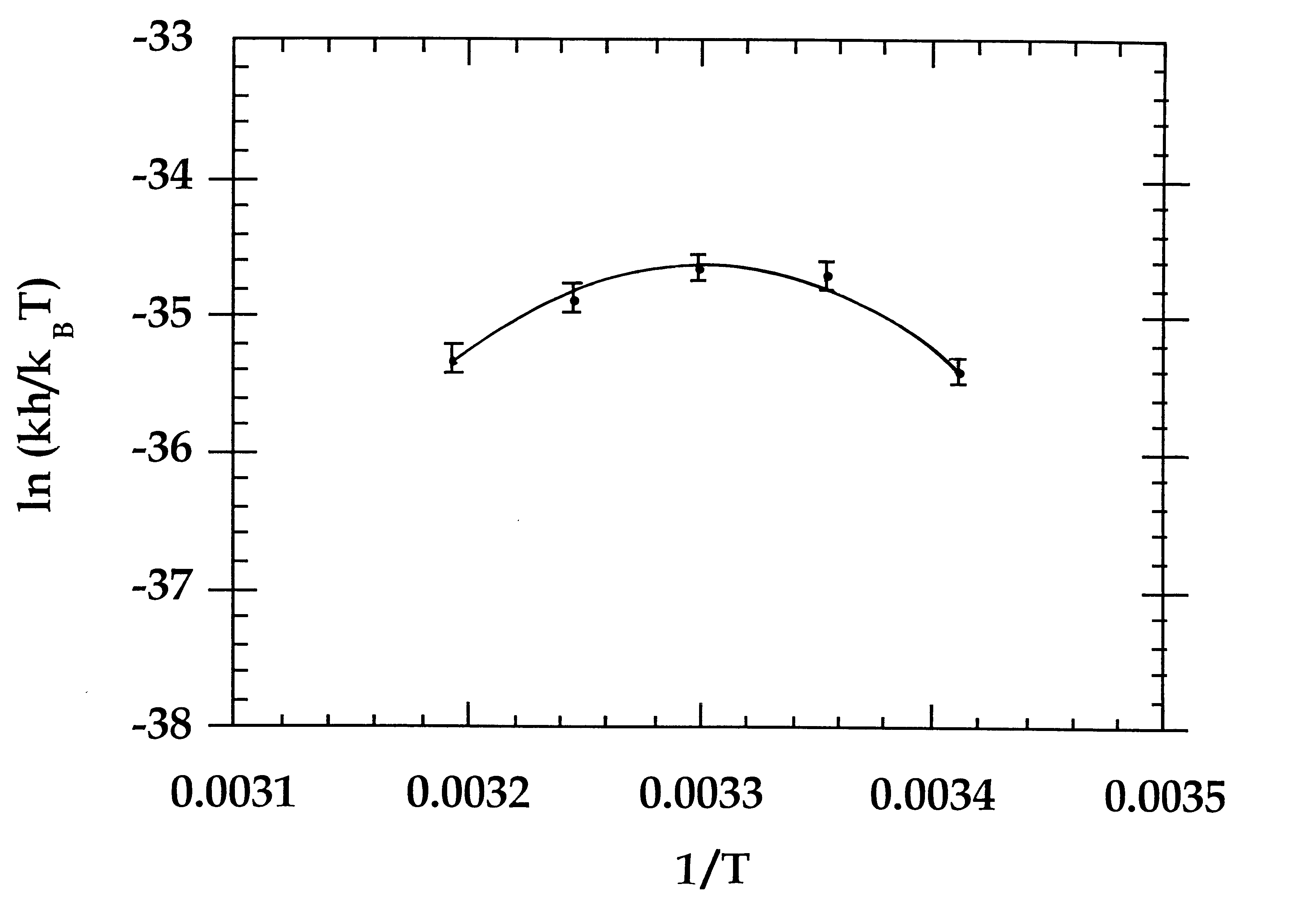

Calcium free subtilisin mutants

InactiveUS6541234B1Improve thermal stabilityImprove robustnessBacteriaSugar derivativesSubtilisinMutant

Novel calcium free subtilisin mutants are taught, in particular subtilisins which have been mutated to eliminate amino acids 75-83 and which retain enzymatic activity and stability. Recombinant methods for producing same and recombinant DNA encoding for such subtilisin mutants are also provided.

Owner:MARYLAND UNIV OF

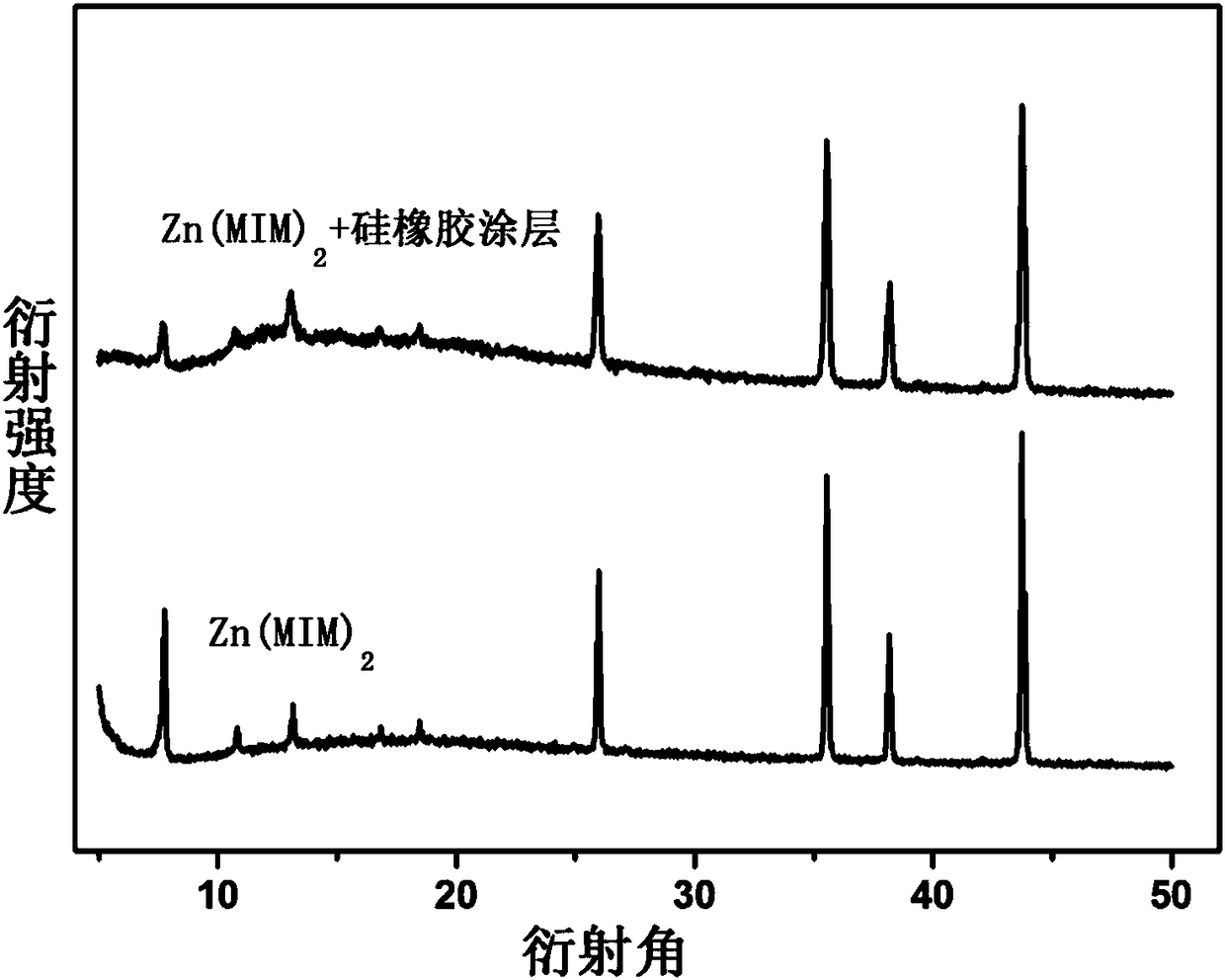

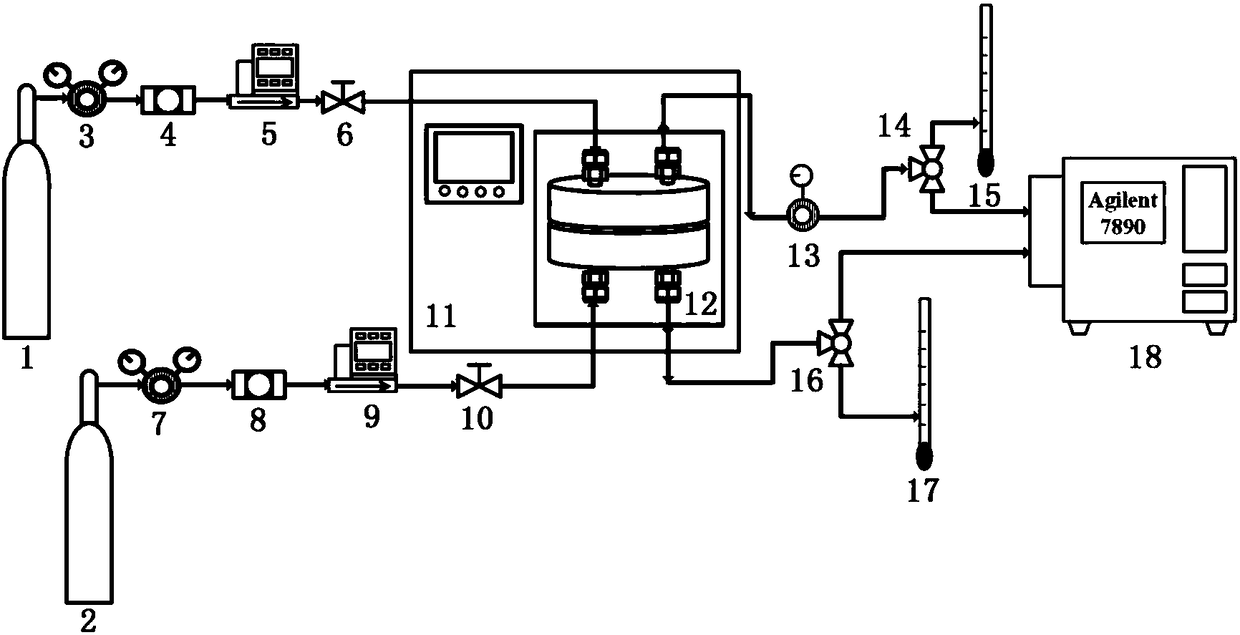

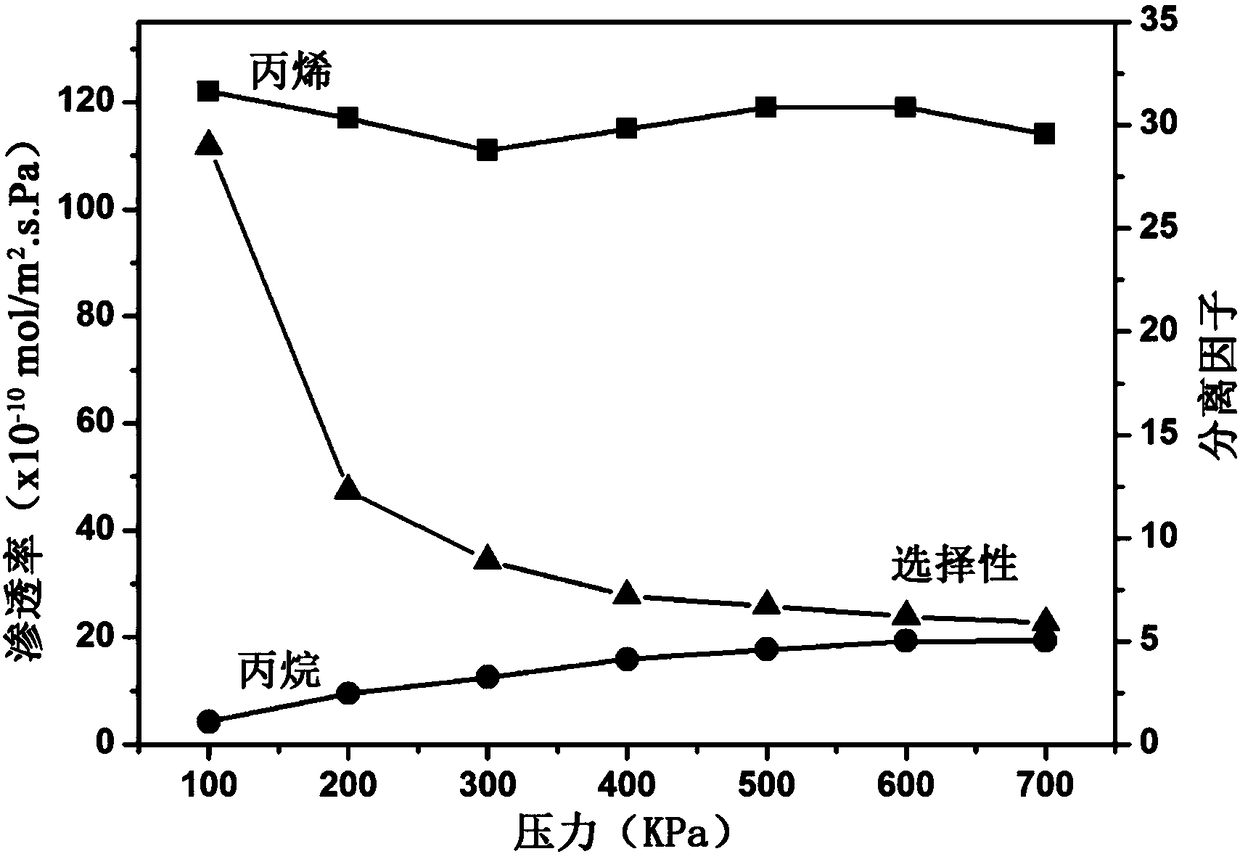

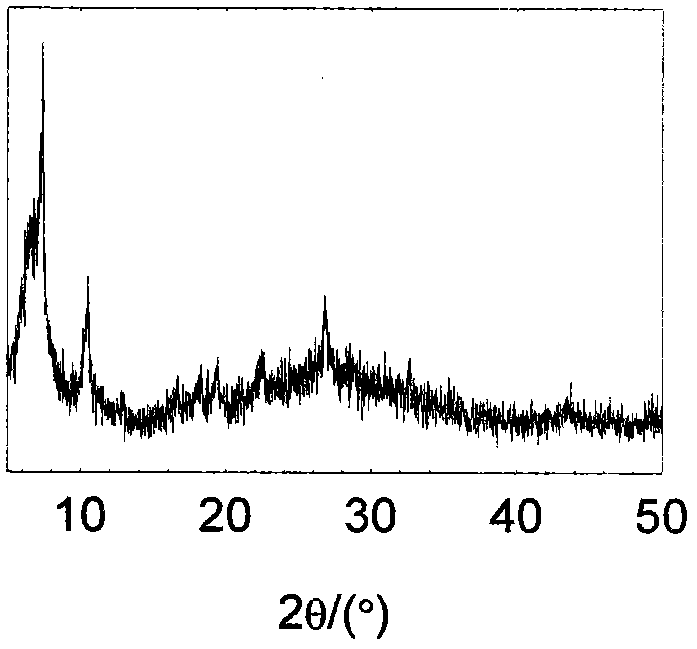

Method for improving the gas separation performance of supported MOF membrane by utilizing polymer coating

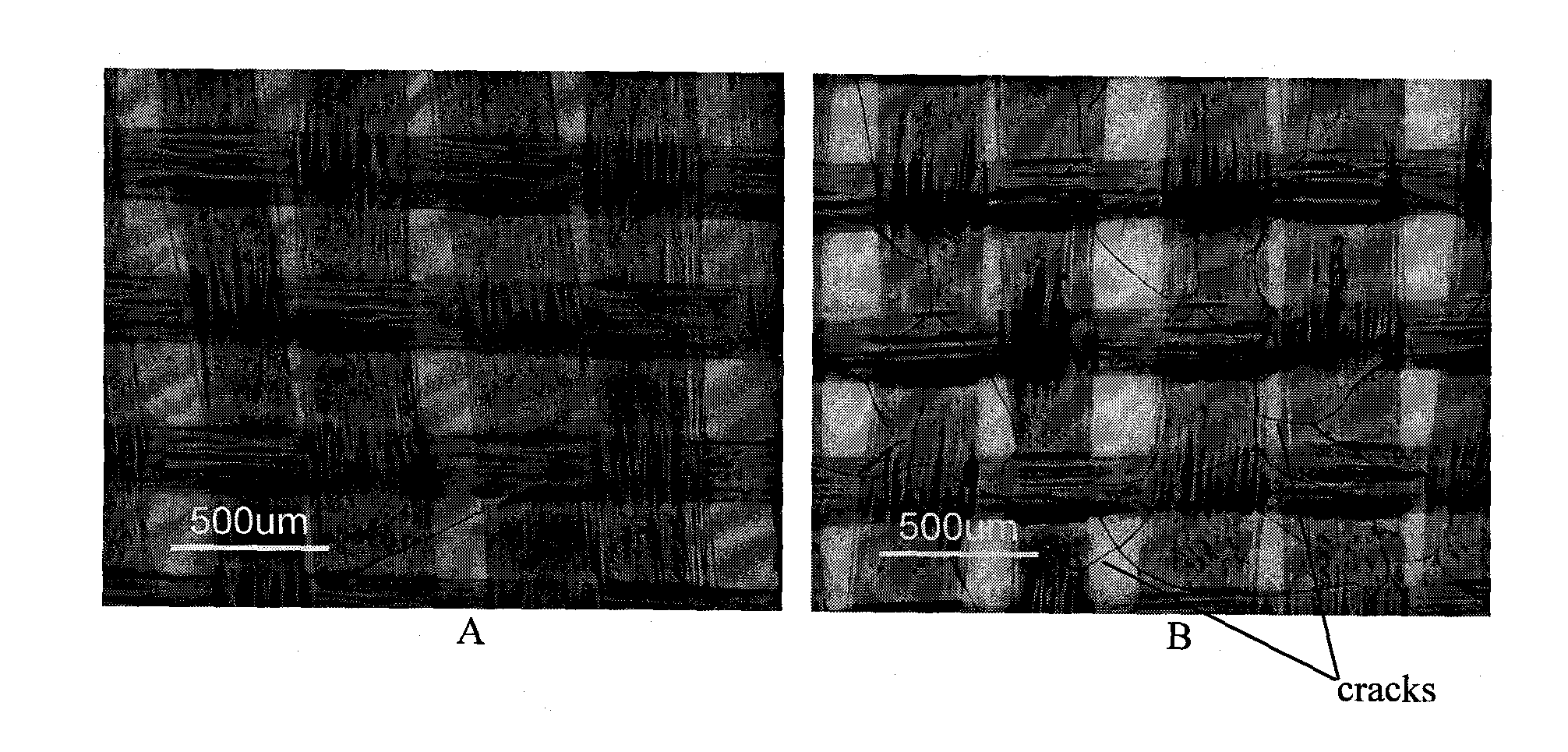

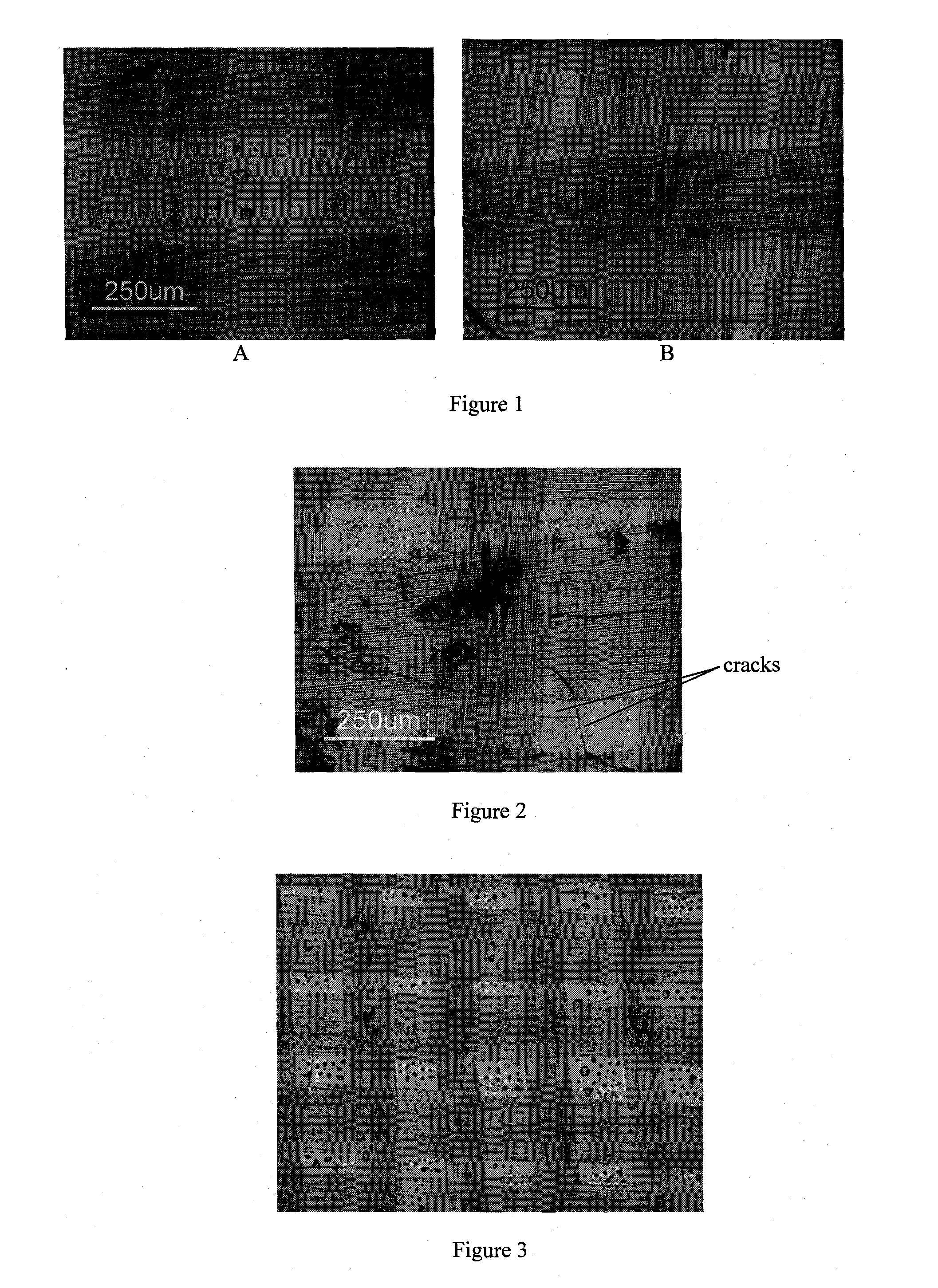

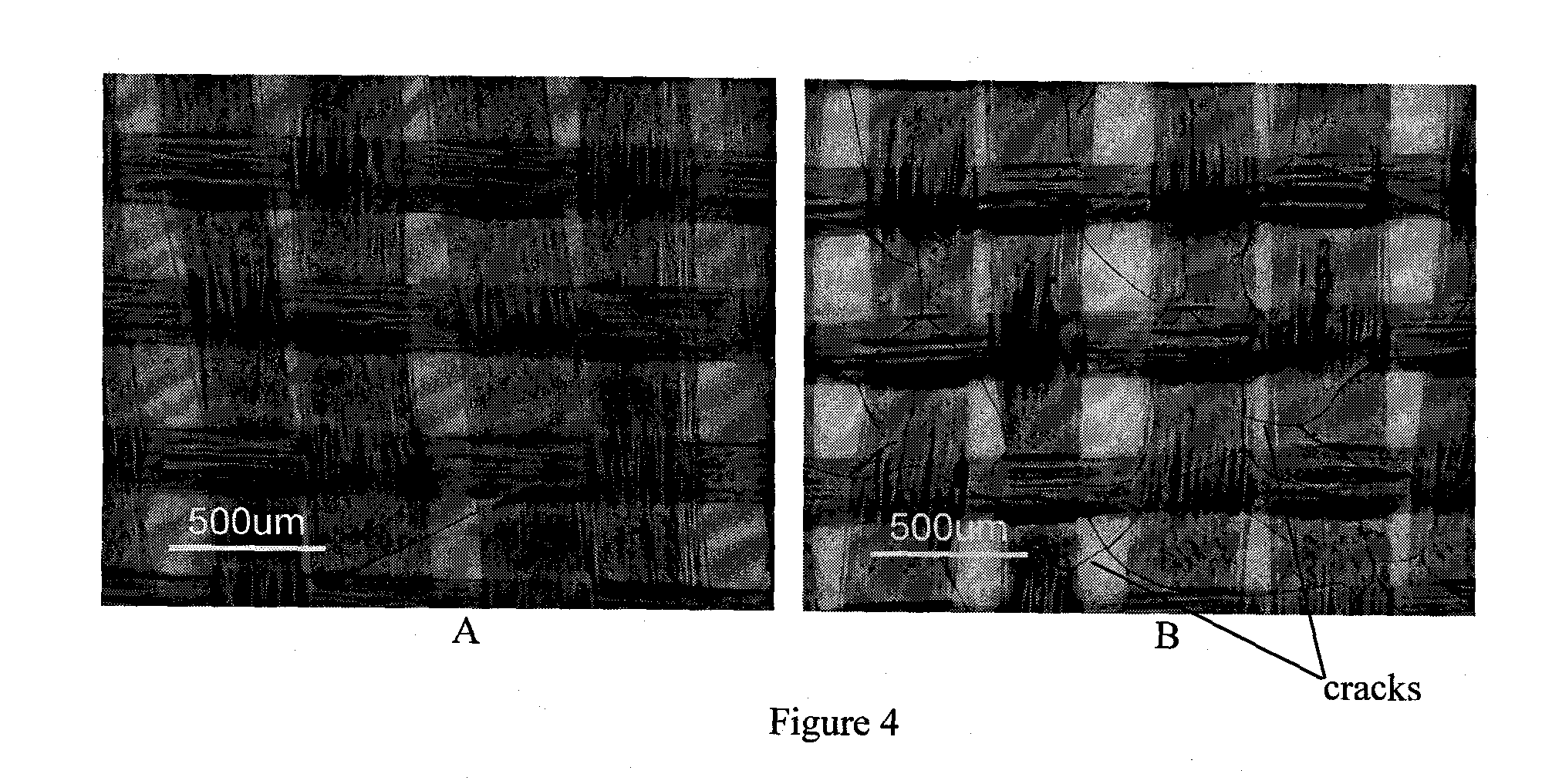

ActiveCN108939958AEasy to separateGood repeatabilitySemi-permeable membranesDispersed particle separationPolymer coatingsBrittleness

The invention provides a method for improving the gas separation performance of a supported MOF membrane by utilizing a polymer coating, wherein the surface of the MOF membrane is coated with the polymer coating, and the defect of the MOF membrane can be repaired. At the same time, coating of the polymer coating can effectively prevent the flexibility of MOF skeleton and limit the expansion of itspore size, so as to effectively improve the gas separation performance. In addition, the hydrothermal stability of the MOF membrane can be greatly improved by externally coating of the polymer coating, and the brittleness of the MOF membrane can be effectively protected by the coatings. The method for repairing the MOF membrane by using the polymer coating has wide application value in the fieldof gas separation.

Owner:NANJING UNIV OF TECH

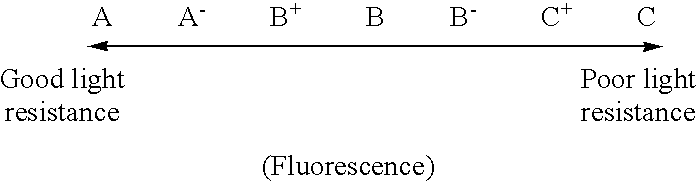

Process for producing hydrogenated C9 petroleum resin and hydrogenated C9 petroleum resin obtained by the process

InactiveUS6458902B1Improve light resistanceImprove thermal stabilityMineral oil hydrocarbon copolymer adhesivesBuilding insulationsPetroleum resinFluorescence

Disclosed is a process for preparing a hydrogenated C9 petroleum resin, the process comprising hydrogenating a C9 petroleum resin obtained by polymerizing polymerizable monomers of a C9 fraction using a non-phenolic Friedel-Crafts catalyst in the presence or absence of a non-phenolic molecular weight modifier. The hydrogenated C9 petroleum resin obtained according to the present invention retains the characteristics of known hydrogenated C9 petroleum resins and has high thermal stability, good light resistance, and remarkably low fluorescence.

Owner:ARAKAWA CHEM IND LTD

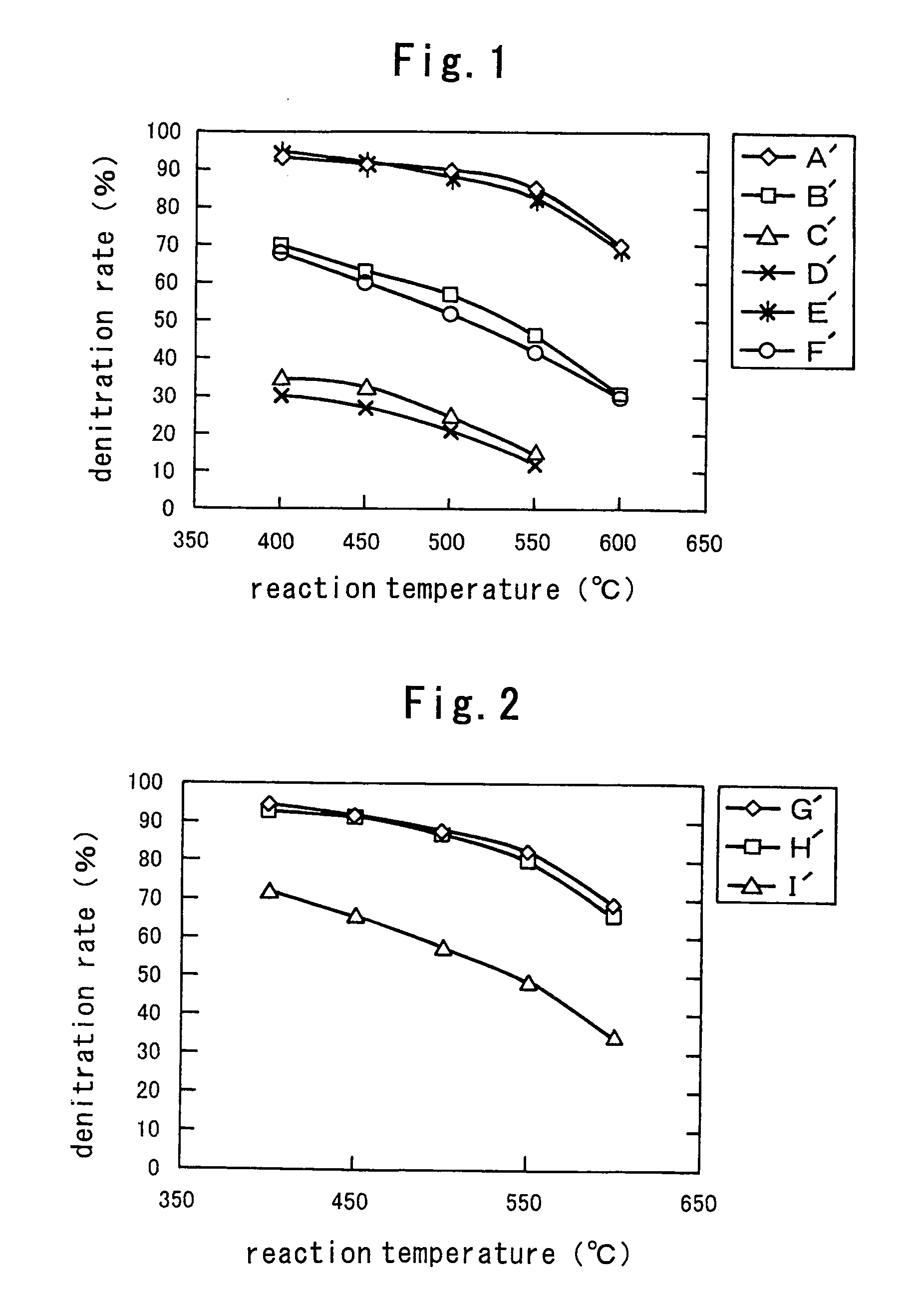

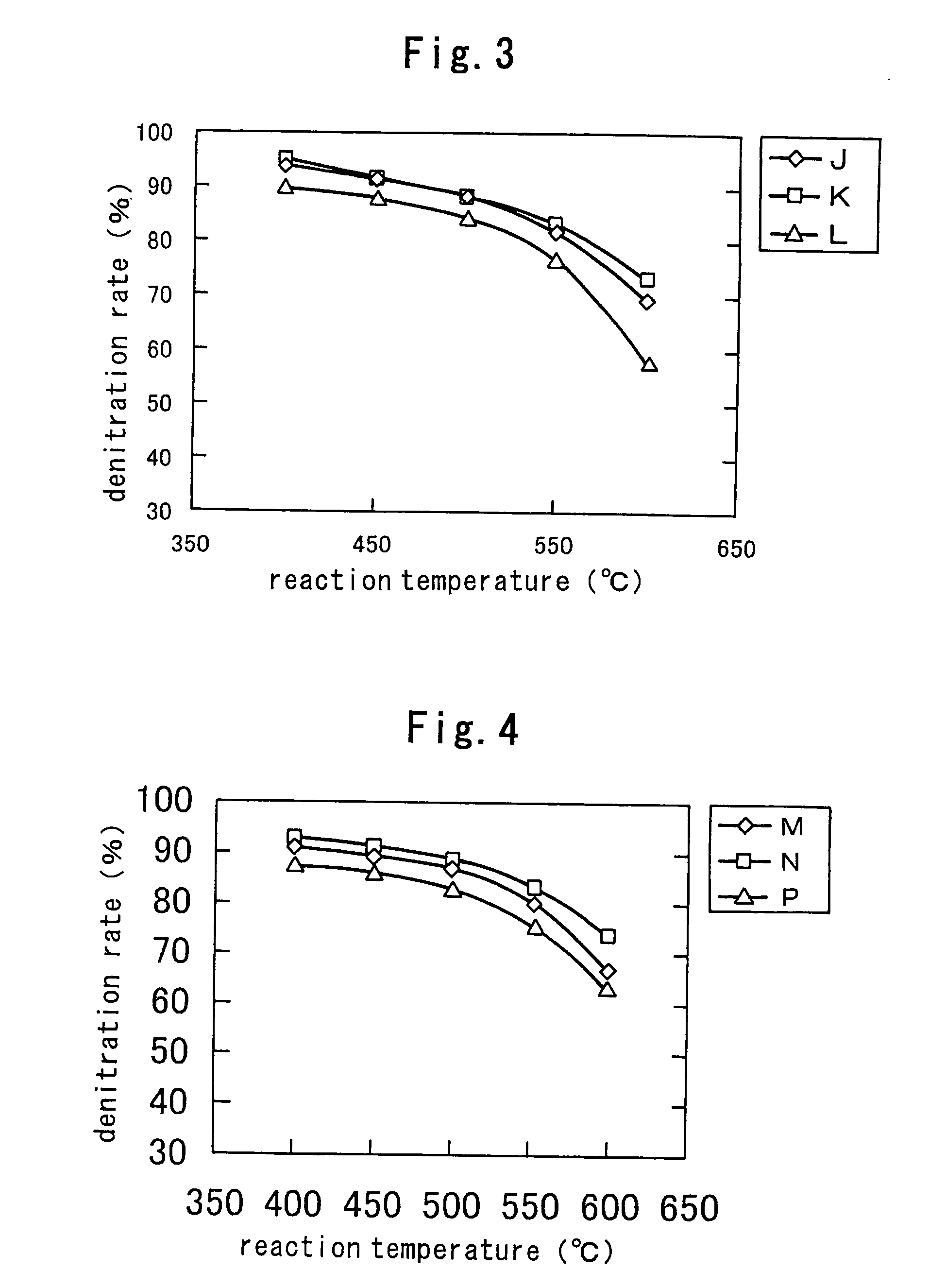

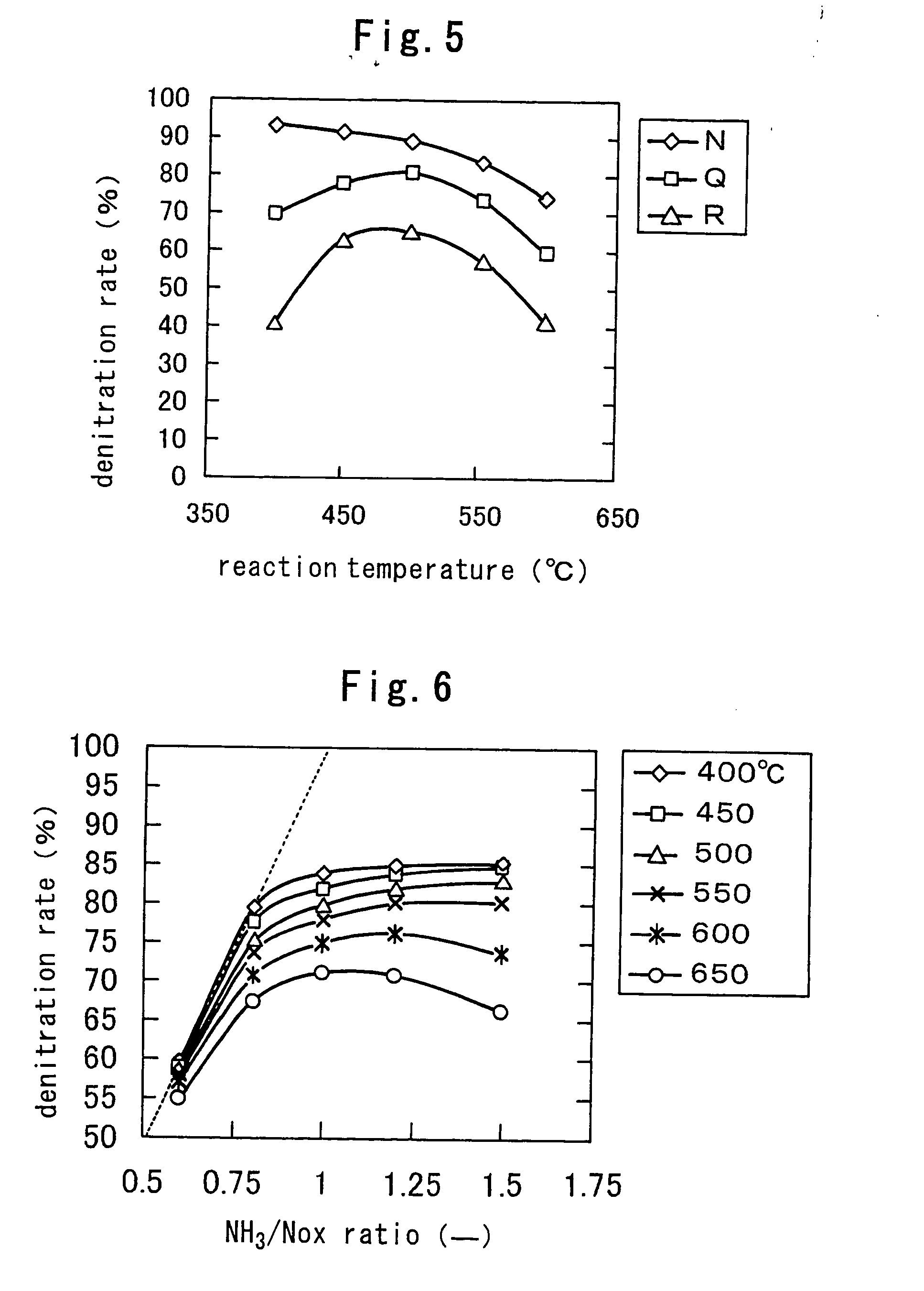

High temperature denitrification catalyst and method for preparation thereof

ActiveUS20050159304A1Large surface acidHigh thermal stabilityNitrogen compoundsDispersed particle separationExhaust gasComposite oxide

A purpose of the present invention is to provide a method of enabling denitration of an exhaust gas effectively at 450° to 600° C. and catalysts to be used for the method. A first catalyst comprises a composite oxide composed of titanium oxide and at least one of tungsten oxide, molybdenum oxide and boron oxide and having solid acid strength (Ho) of −11.93 or lower. A second catalyst is a high-temperature denitration catalyst which comprises zirconium oxide and SO3 or SO42−, has solid acid strength (Ho) of −11.93 or lower and is used at a reaction temperature of 450° to 800° C. A third catalyst is a high-temperature denitration catalyst wherein at least one of tungsten oxide, molybdenum oxide and boron oxide is supported on a carrier comprising zirconium oxide and SO3 or SO42− and having solid acid strength (Ho) of −11.93 or lower and which is used at a reaction temperature of 450° to 800° C.

Owner:HITACHI ZOSEN CORP

Reinforced Silicone Resin Film and Method of Preparing Same

InactiveUS20100087581A1Reduction factorIncrease resistanceMaterial nanotechnologySpecial tyresCarbon nanomaterialsPolymer chemistry

A method of preparing a reinforced silicone resin film comprising impregnating a fiber reinforcement in a nano-material-filled silicone composition comprising a condensation-curable silicone composition and a carbon nanomaterial, and curing the silicone resin of the impregnated fiber reinforcement; and a reinforced silicone resin film prepared according to the preceding method.

Owner:DOW CORNING CORP

Cellulose/layered boron nitride high-dielectric nano-composite film and preparation method thereof

The invention relates to a cellulose / layered boron nitride high-dielectric nano-composite film and preparation method of the cellulose / layered boron nitride high-dielectric nano-composite film. The cellulose / layered boron nitride high-dielectric nano-composite film has an obvious layered structure and comprises cellulose and boron nitride nanosheet layers uniformly dispersed in the cellulose. Thepreparation comprises the following steps: 1) preparing a boron nitride peeling layer dispersion liquid; 2) preparing a cellulose / boron nitride composite liquid: cooling the boron nitride peeling layer dispersion liquid obtained in the step 1) to below 0 DEG C, adding the cellulose according to the mass ratio of the boron nitride and the cellulose of (5: 95) to (15: 85), rapidly stirring and dissolving, performing centrifugation to remove impurities, thereby obtaining the cellulose / boron nitride composite liquid; 3) carrying out film formation on the prepared cellulose / boron nitride compositeliquid prepared in the step 2) in a coagulation bath to obtain the cellulose / layered boron nitride high-dielectric nano-composite film. The composite material provided by the invention has the layeredstructure and very high dielectric properties and high thermal conductivity (the breakdown voltage reaches 300 to 450 MVm<-1>, and the energy storage density is as high as 4 Jcm<-3> about, the thermal conductivity is about 2Wm<-1>K<-1>), and the cellulose / layered boron nitride high-dielectric nano-composite film has broad application prospects in the field of photovoltaic energy storage materials.

Owner:WUHAN UNIV OF TECH

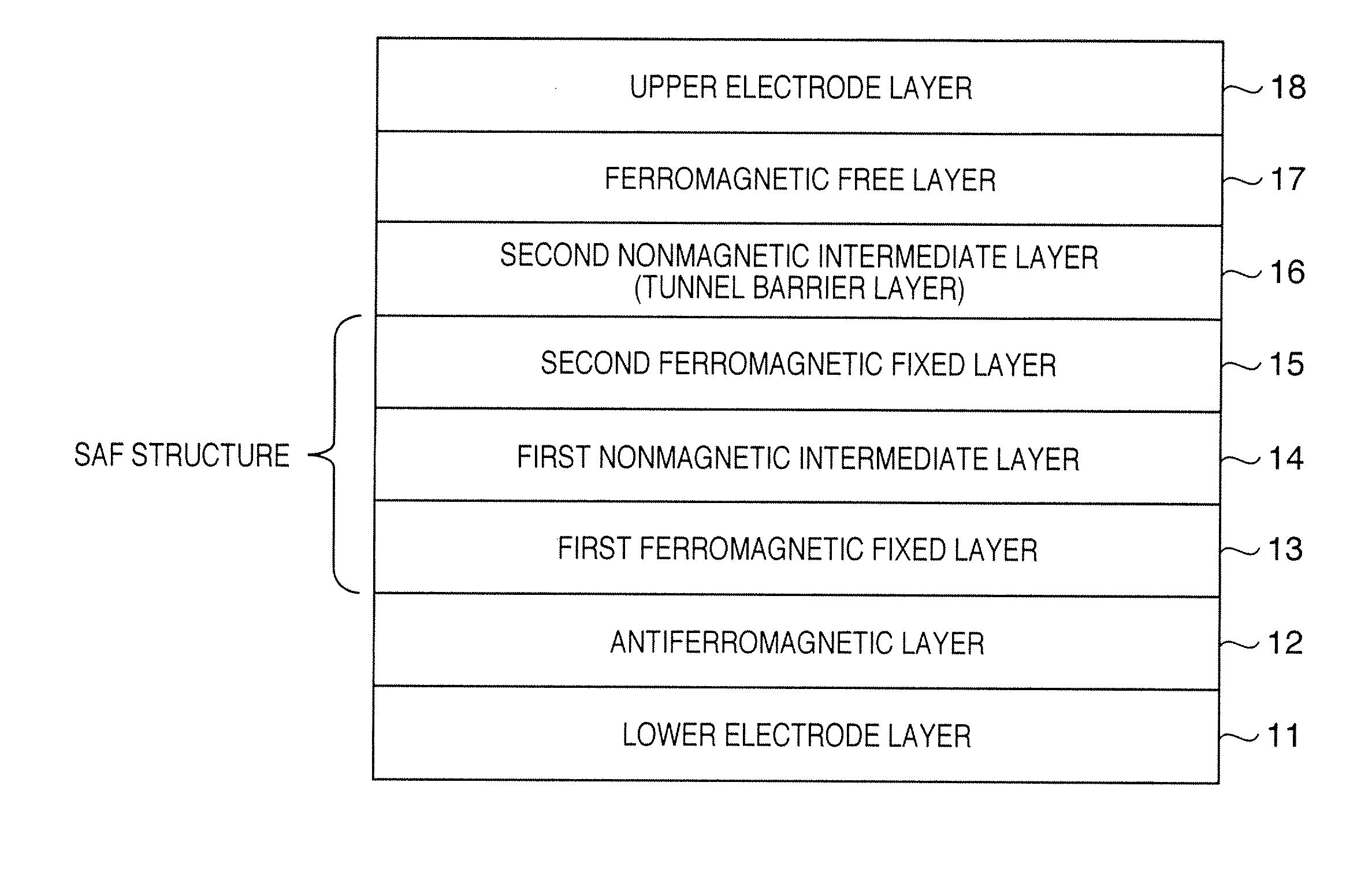

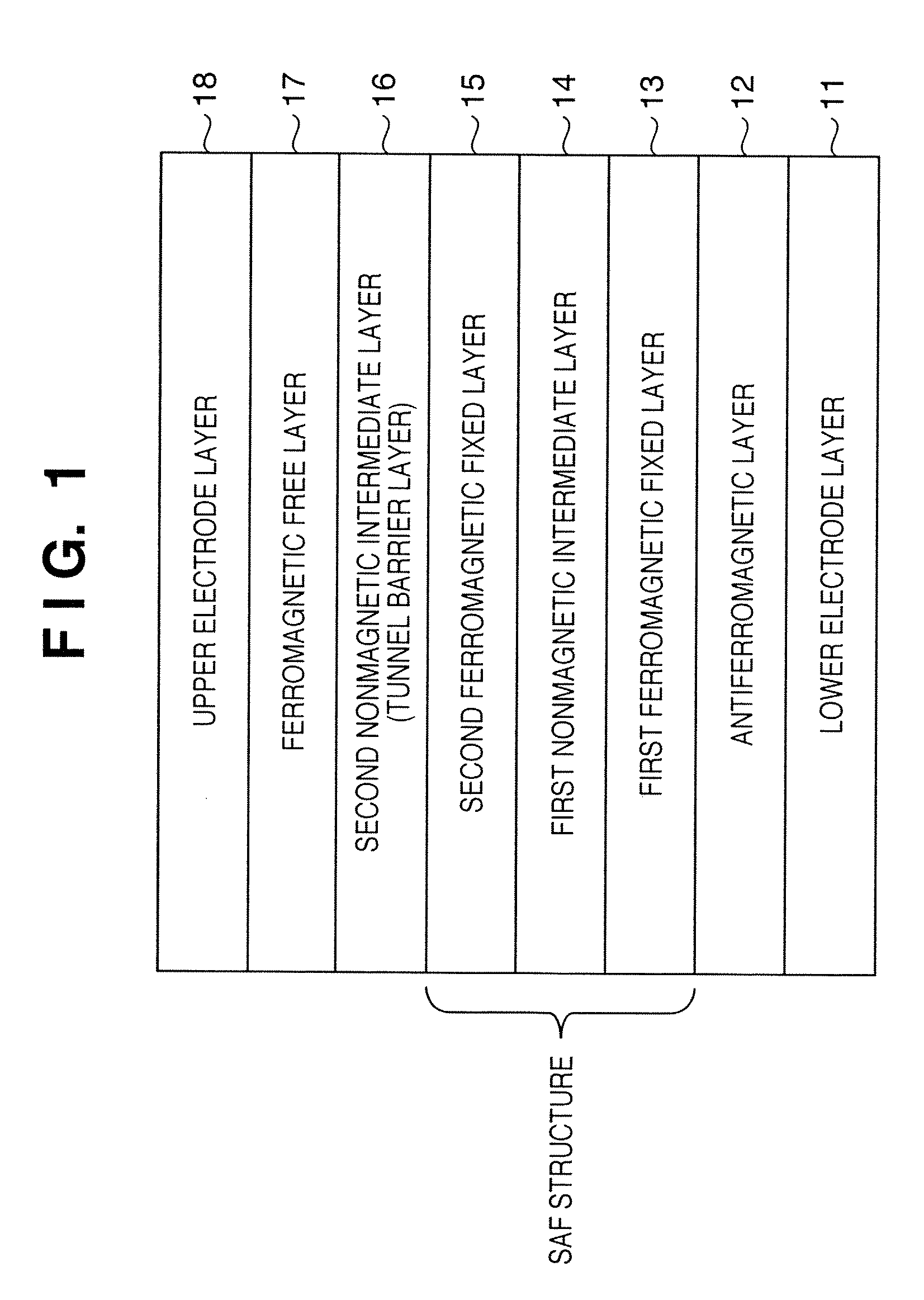

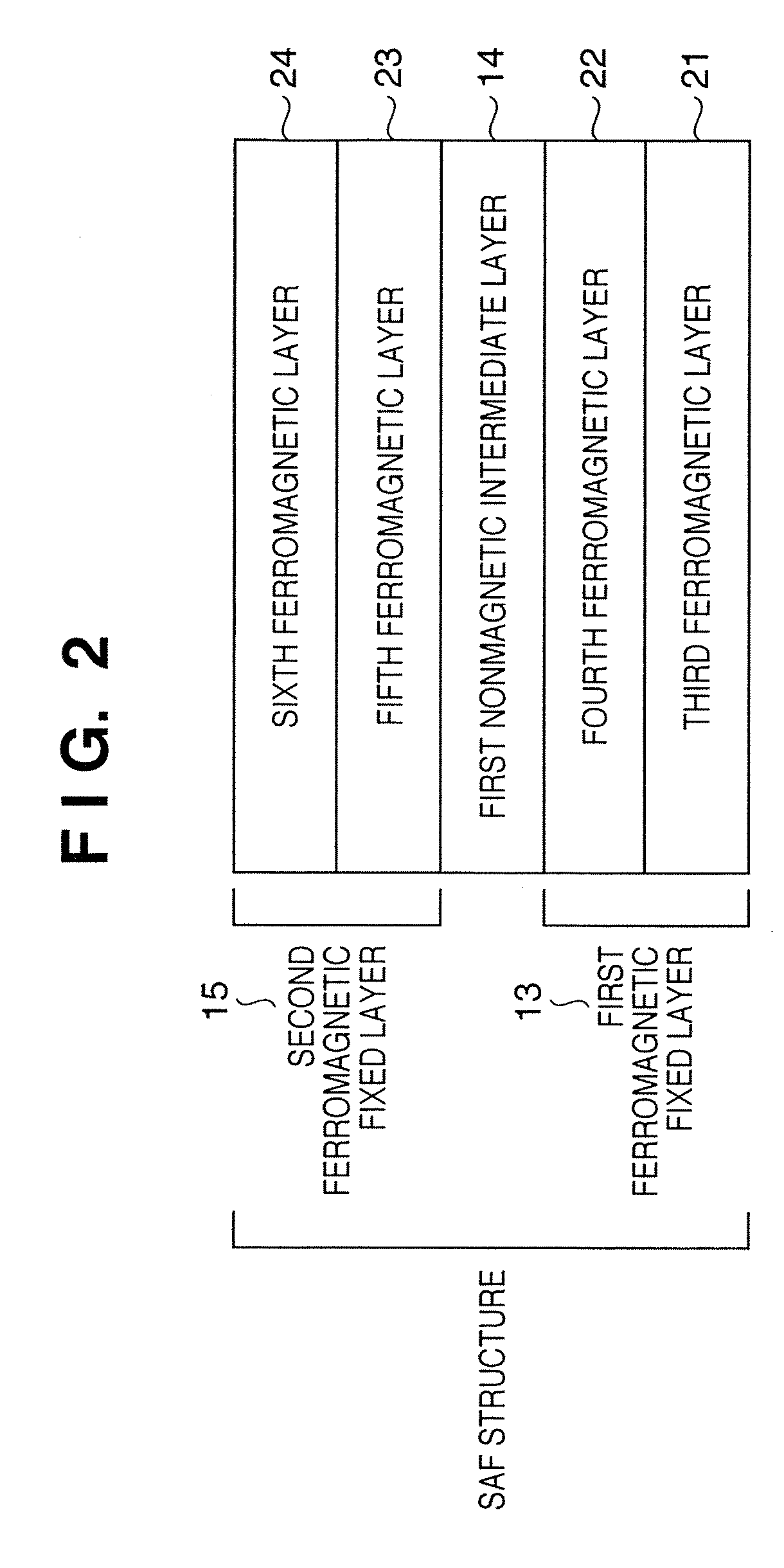

Magnetroresistive element, method of manufacturing the same, and magnetic multilayered film manufacturing apparatus

ActiveUS20080278865A1High thermal stabilityHigh ratioNanomagnetismMagnetic measurementsMagnetic layerOptoelectronics

A magnetoresistive element includes an antiferromagnetic layer formed from a layer containing manganese, a layered magnetization fixed layer which includes a first magnetization fixed layer located over a side of the antiferromagnetic layer and formed from a layer containing a ferromagnetic material and a platinum group metal, a second magnetization fixed layer formed from a layer containing a ferromagnetic material, and a first nonmagnetic intermediate layer located between the first magnetization fixed layer and the second magnetization fixed layer, a magnetic free layer formed from a layer containing a ferromagnetic material, and a second nonmagnetic intermediate layer located between the layered magnetization fixed layer and the magnetic free layer.

Owner:CANON ANELVA CORP

Processes for producing polycarbonate

ActiveUS8445624B2Improve the heating effectHigh strengthSynthetic resin layered productsChemical recyclingPolymer scienceCarbonate ester

Owner:MITSUBISHI CHEM CORP

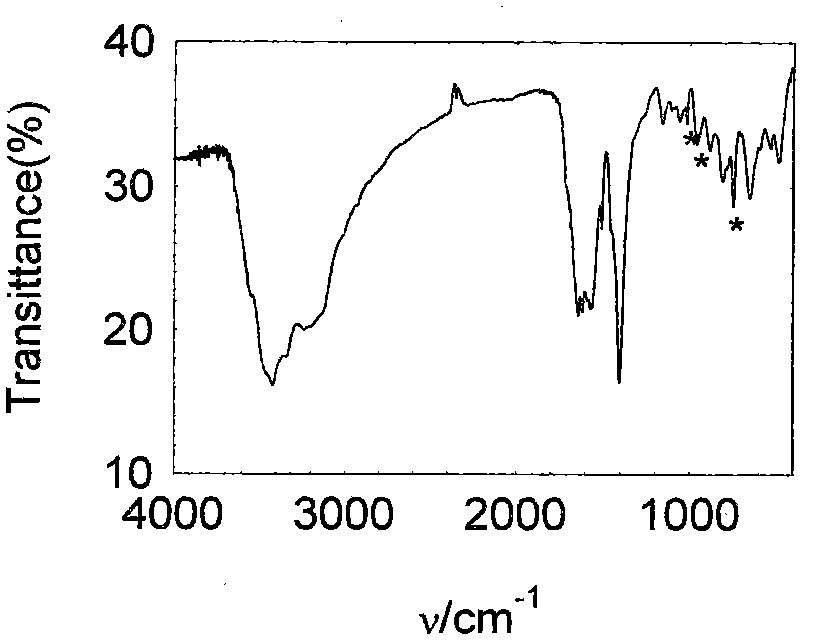

Heteropolyacid or heteropolyacid salt and microporous coordination polymer composite material and preparation method thereof

InactiveCN104607243ADrain controlHigh thermal stabilityOrganic-compounds/hydrides/coordination-complexes catalystsSolventMixed solution

The invention relates to a heteropolyacid or heteropolyacid salt and microporous coordination polymer composite material and a preparation method thereof. The preparation method is characterized by comprising the following steps: a first step of dissolving zirconium salt in a mixed solvent of a modifier and a solvent to form a settled solution while stirring at the normal temperature and under the normal pressure; a step 2 of adding the settled solution obtained in the first step into an organic ligand until the settled solution is dissolved; a third step of adding heteropolyacid or heteropolyacid salt into the settled solution obtained in the second step to prepare a mixed solution and enabling the mixed solution to react to obtain the heteropolyacid or heteropolyacid salt and zirconium-based microporous coordination polymer composite material, wherein by calculating according to the added zirconium salt, the yield of the heteropolyacid or heteropolyacid salt and microporous coordination polymer composite material is 85-93 percent.

Owner:李亚丰

Preparation of fuel cell composite bipolar plate

ActiveUS7090793B2Improve thermal stabilityImprove mechanical propertiesNon-metal conductorsConductive materialPolymer electrolytesFuel cells

A composite bipolar plate of polymer electrolyte membrane fuel cells (PEMFC) is prepared as follows: a) preparing a bulk molding compound (BMC) material containing a vinyl ester resin and a graphite powder, the graphite powder content of BMC material ranging from 60 wt % to 80 wt %, based on the compounded mixture; b) molding the BMC material from step a) to form a bipolar plate having a desired shape at 80–200° C. and 500–4000 psi, wherein the graphite powder is of 40 mesh–80 mesh.

Owner:IND TECH RES INST +1

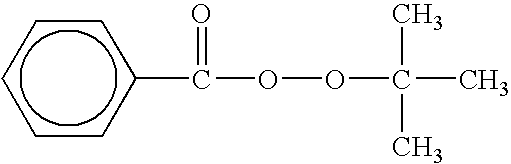

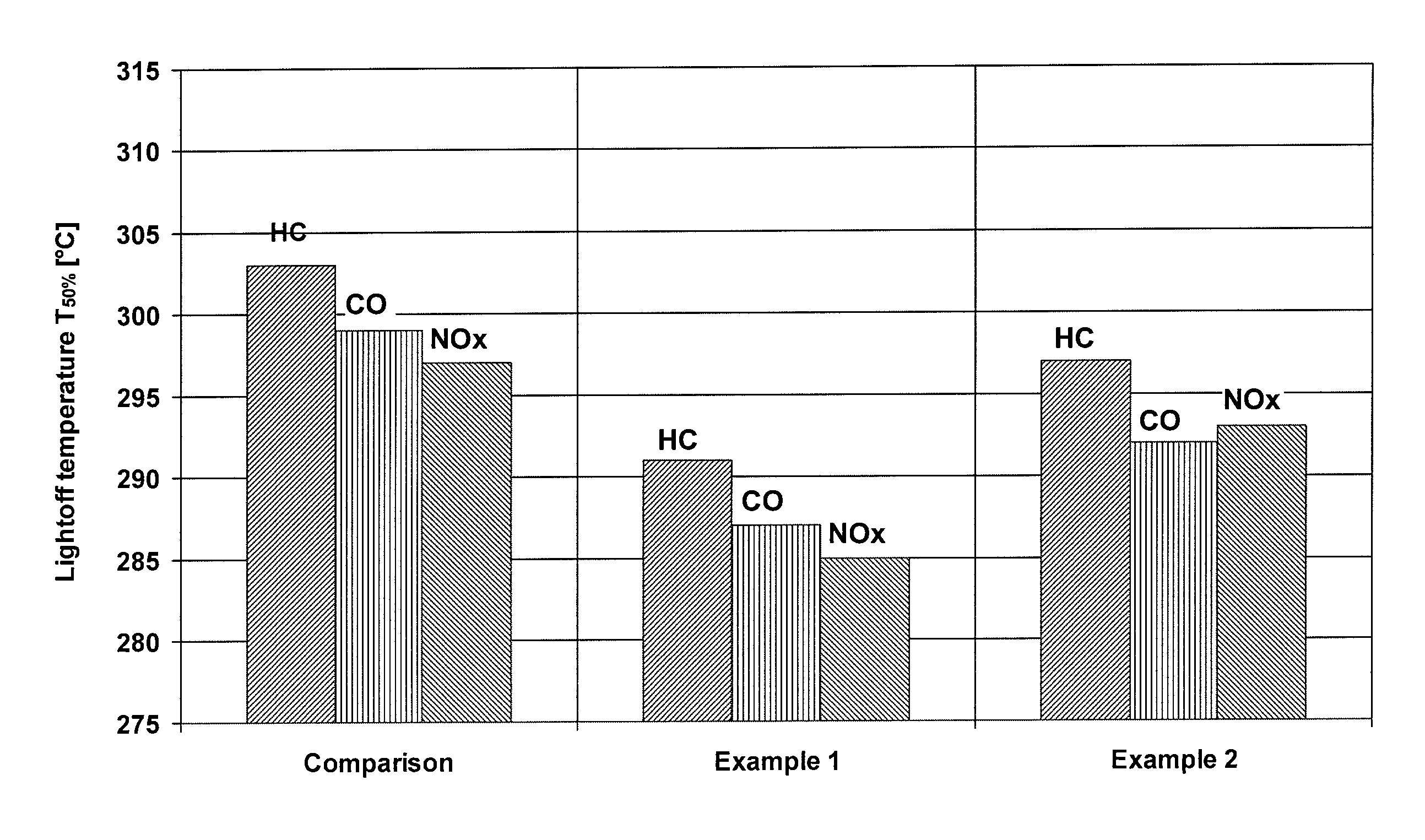

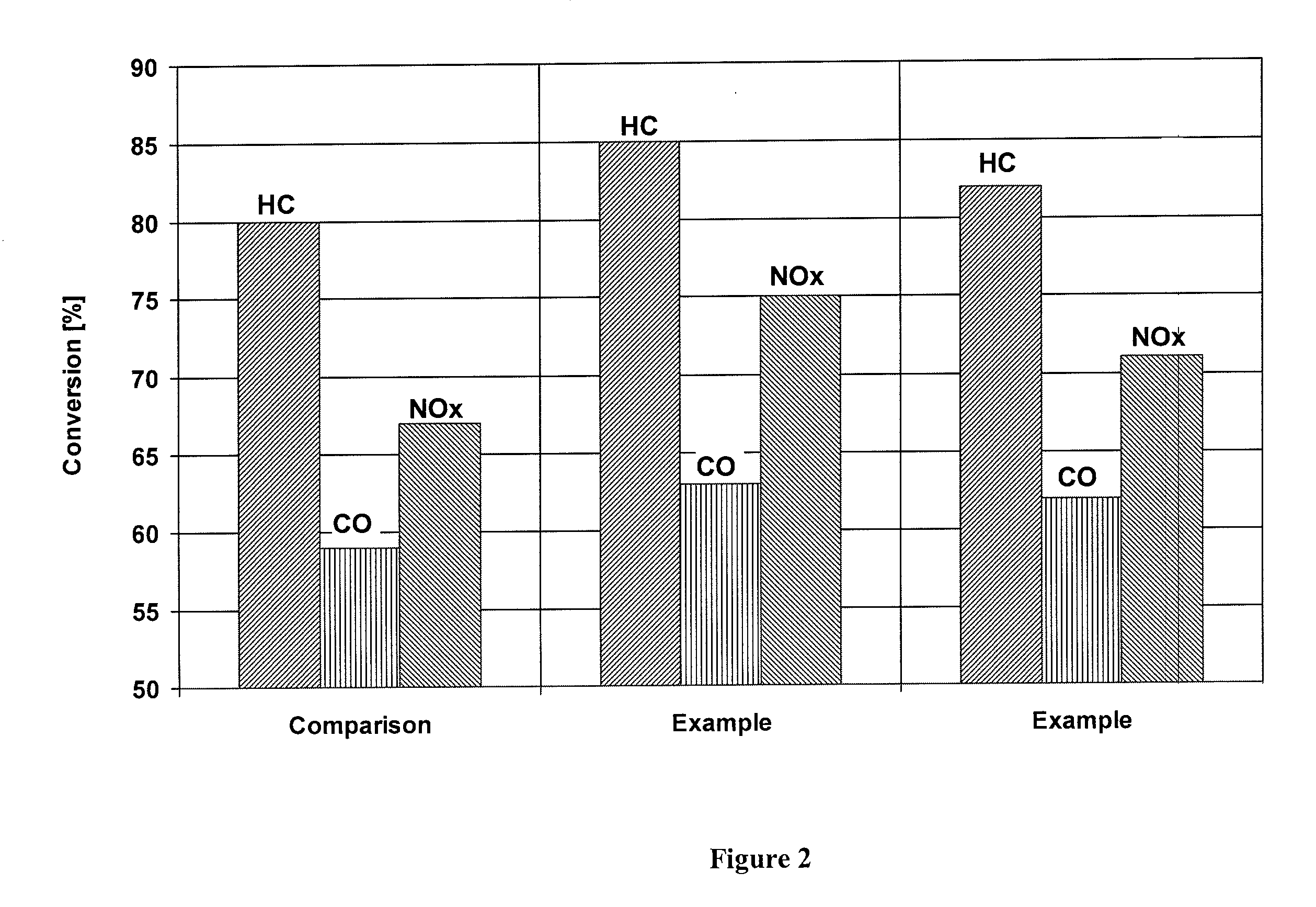

Palladium—rhodium single-layer catalyst

ActiveUS9156023B2Good lightoff performanceHigh thermal stabilityInternal combustion piston enginesExhaust apparatusPalladiumAluminium oxide

A one-layer three-way catalyst is described for the cleaning of the exhaust gases of internal combustion engines with outstanding activity and thermal stability. The catalyst comprises an active aluminum oxide, a first cerium / zirconium mixed oxide and a second cerium / zirconium mixed oxide. The first cerium / zirconium mixed oxide has a higher zirconium oxide content than the second mixed oxide. The first cerium / zirconium mixed oxide is catalytically activated with rhodium and the second cerium / zirconium mixed oxide with palladium.

Owner:UMICORE AG & CO KG

Fischer-Tropsch synthesis catalyst, and preparation method and application thereof

ActiveCN104588023AImprove structural stabilityHigh thermal stabilityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsEvaporationRare earth

The invention discloses a Fischer-Tropsch synthesis catalyst, and a preparation method and an application thereof. The catalyst is a composite metal oxide with a perovskite structure, and the general formula of the catalyst is A<x>A'<1-x>B<y>B'<1-y>O<3>, wherein A is rare earth metal lanthanum, A' is metallic potassium, B is transition metal nickel, B' is transition metal cobalt, x is greater than 0.7 and smaller than 1, and y is greater than 0 and smaller than 0.35. The preparation method of the cobalt-based Fischer-Tropsch synthesis catalyst comprises the following steps: preparing a solution with cobalt nitrate, nickel nitrate, potassium nitrate and lanthanum nitrate as precursors and citric acid or glycol as a complexing agent, uniformly stirring, carrying out water evaporation to make the solution become a viscous gel from a transparent sol, drying, and roasting to obtain the composite oxide Fischer-Tropsch synthesis catalyst with the perovskite structure. The catalyst can be applied to Fischer-Tropsch synthesis reactions. The catalyst can be adopted to make the CO conversion rate reach 90% or more and guarantee very high C<5><+> selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

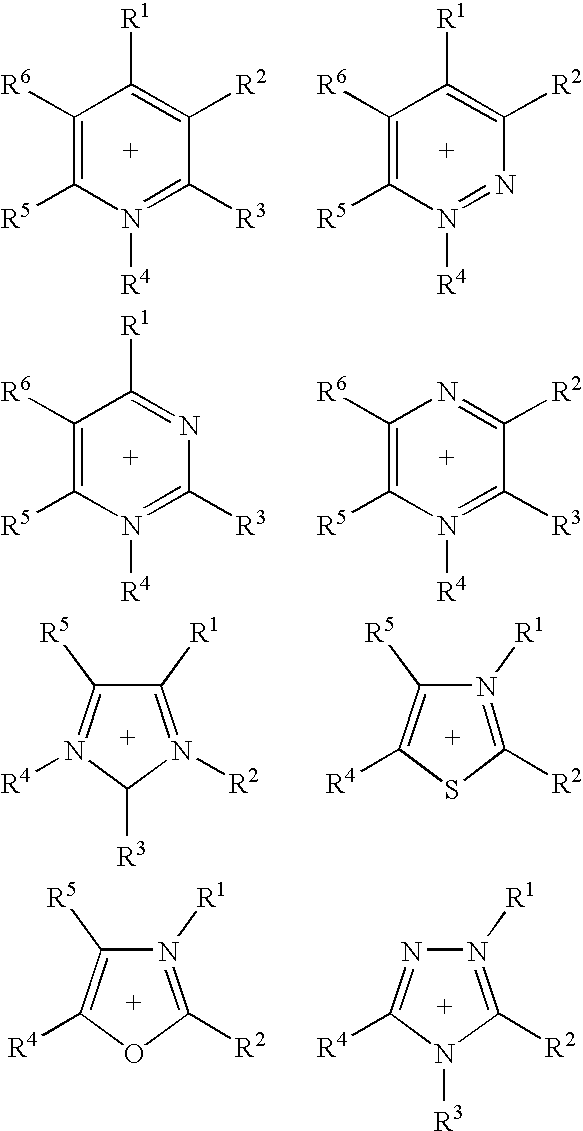

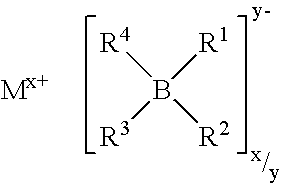

Ionic liquids II

InactiveUS7153974B2Large liquid rangeImprove thermal stabilityCellsLead-acid accumulatorsSolventElectrochemical cell

An ionic liquid of the formula K+A− wherein K+ and A− are as defined herein, are suitable for use in electrochemical cells and capacitors. These ionic liquids can also be used in catalysis, as inert solvents, and as hydraulic liquids.

Owner:MERCK PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com