Patents

Literature

152results about How to "Improve rotational flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low dielectric constant materials and method

InactiveUS6051321AImprove rotational flexibilityTightly boundSemiconductor/solid-state device detailsSynthetic resin layered productsElectrical conductorCopper

Intermetal dielectric (IMD) and interlevel dielectric (ILD) that have dielectric constants (K) ranging from 2.0 to 2.6 are prepared from plasma or photon assisted CVD (PACVD) or transport polymerization (TP). The low K dielectric (LKD) materials are prepared from PACVD or TP of some selected siloxanes and F-containing aromatic compounds. The thin films combine barrier and adhesion layer functions with low dielectric constant functions, thus eliminating the necessity for separate adhesion and barrier layers, and layers of low dielectric constant. The LKD materials disclosed in this invention are particularly useful for <0.18 .mu.m ICs, or when copper is used as conductor in future ICs.

Owner:CANON USA

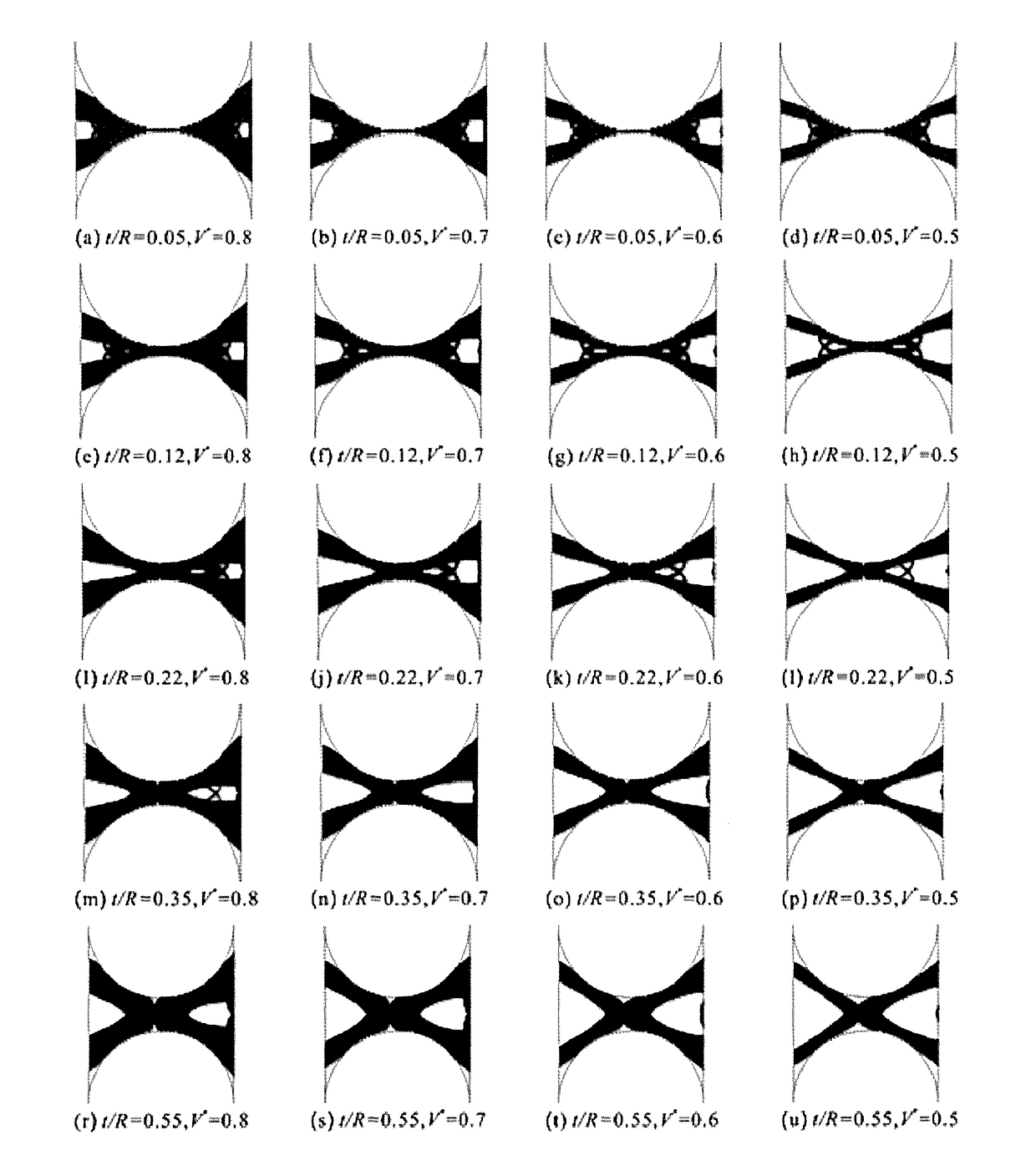

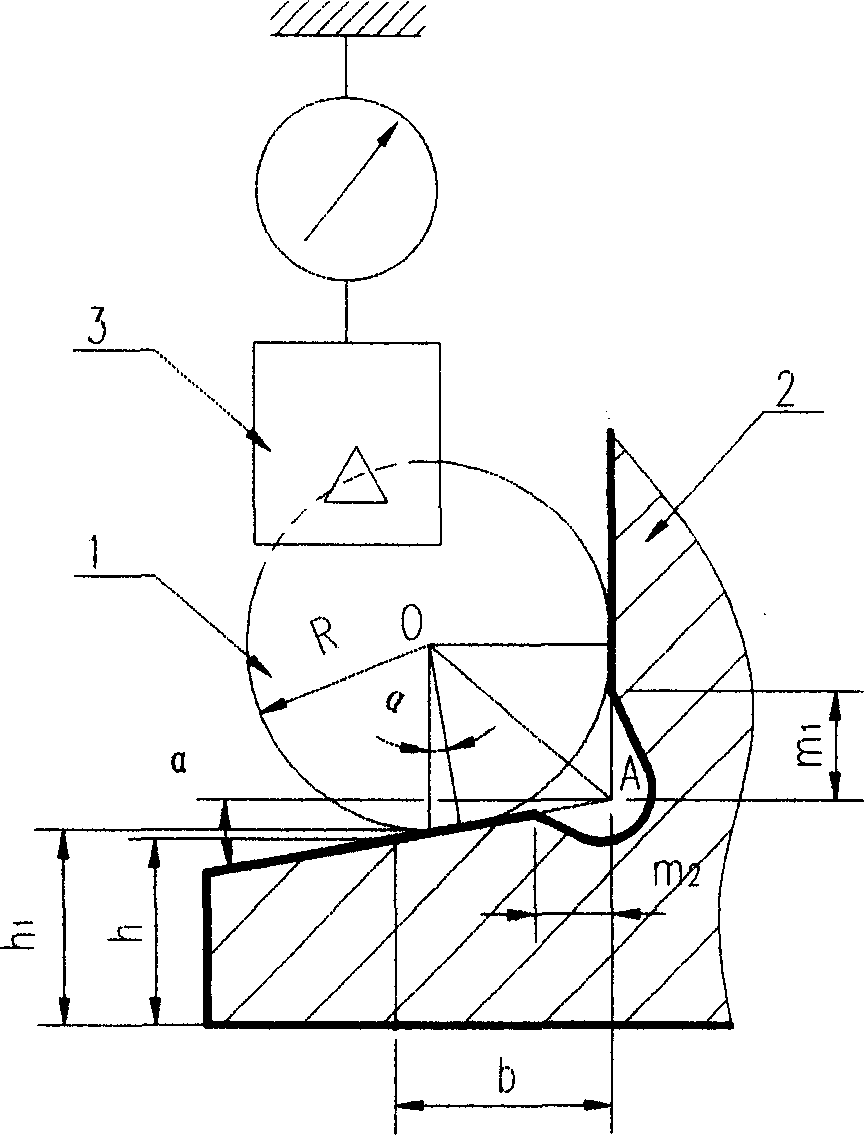

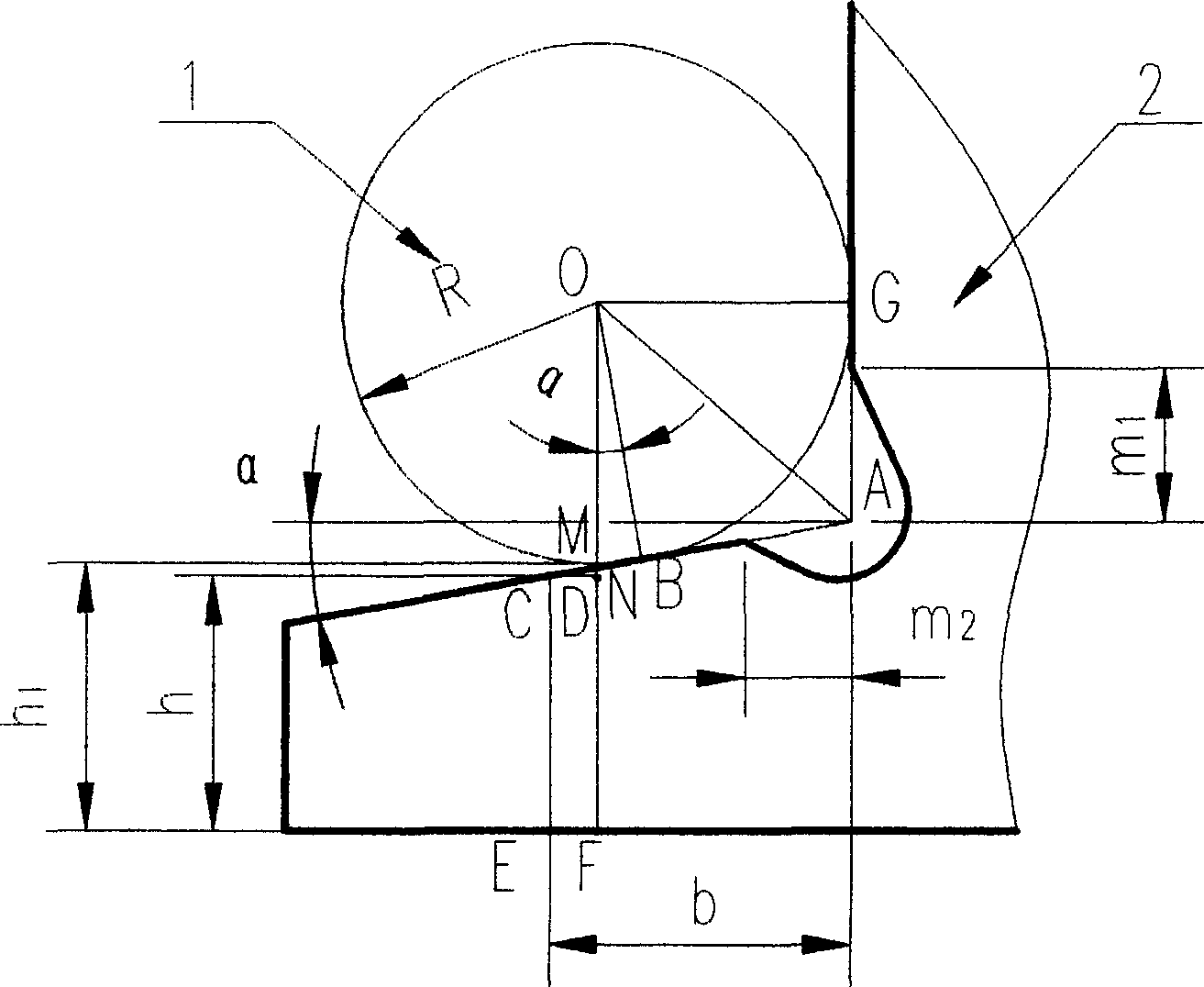

Design method of topology optimization for flexible hinge

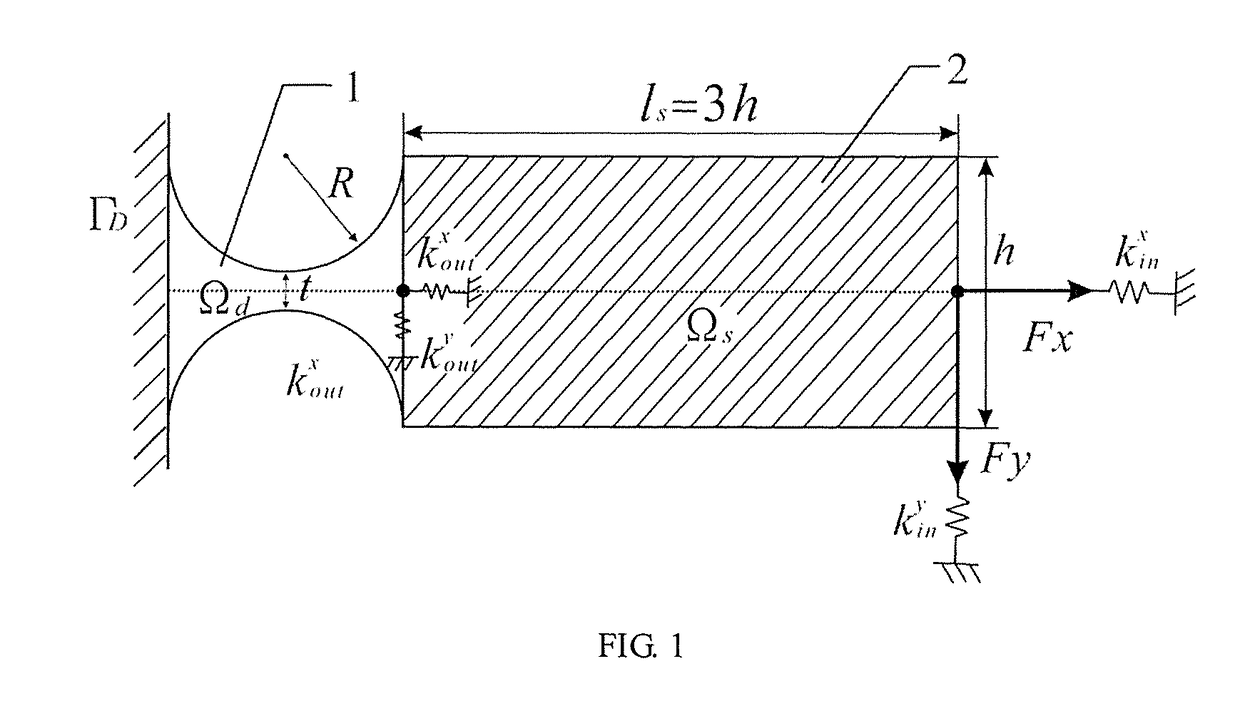

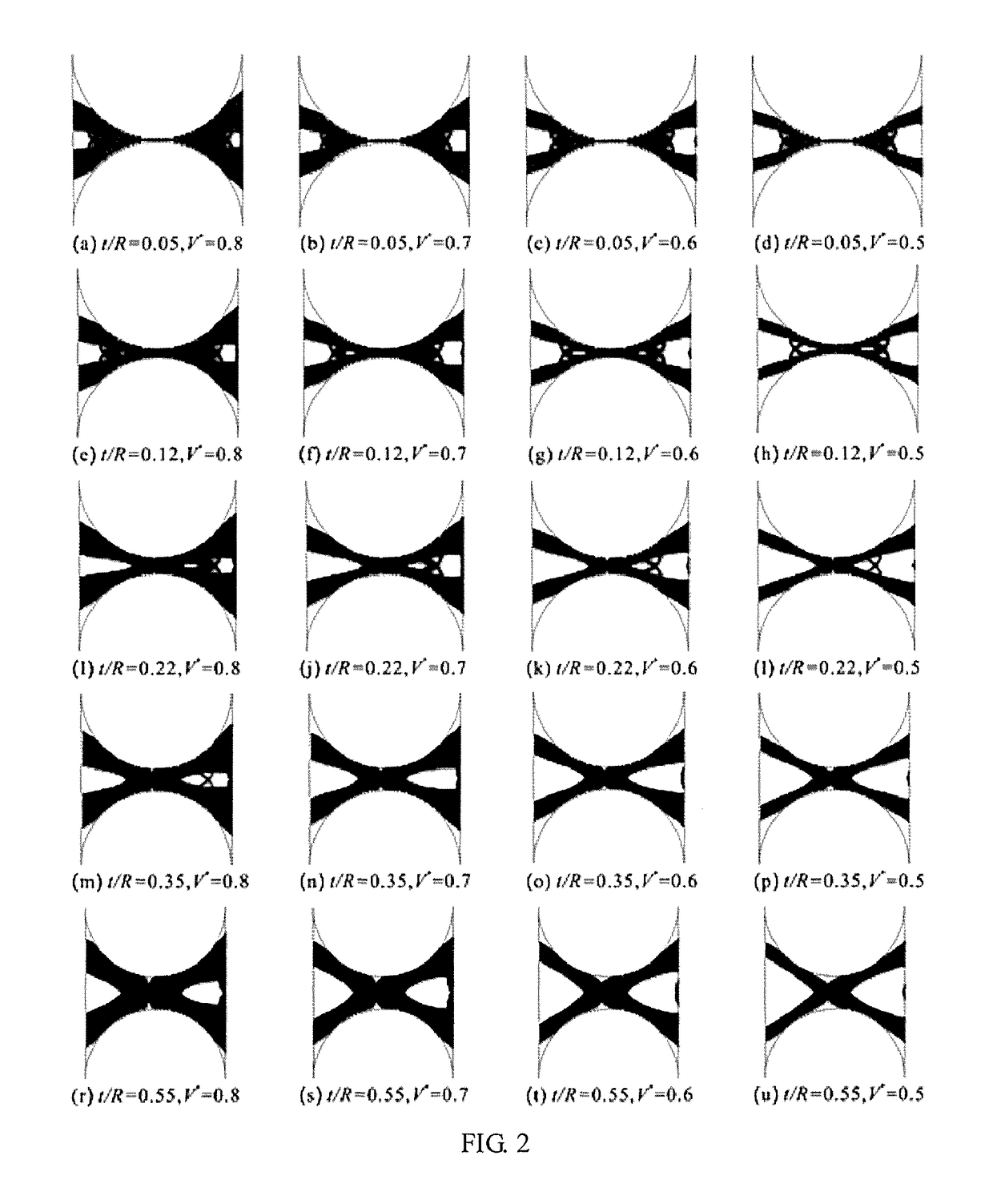

ActiveUS20180210983A1Improve performanceMaterial removalGeometric CADDigital data processing detailsElement modelTruss topology optimization

A design method of topology optimization for flexible hinge is disclosed in the invention, comprising following steps: step 1: establishing a design model of topology optimization for flexible hinge, setting an outline of flexible hinge with a typical notch as a shape of design domain and defining a rigid region (non-design domain); step 2: establishing a finite element model of topology optimization for flexible hinge; step 3: establishing a mathematical model of topology optimization problem for flexible hinge based on the finite element model; step 4: calculating a sensitivity of topology optimization problem for flexible hinge; step 5: employing an optimization algorithm to solve the topology optimization problem for flexible hinge, updating a design variable and obtaining a final topology result graph; step 6: according to the final topology result graph obtained by the topology optimization, extracting its outline and obtaining a novel flexible hinge by appropriate modification. Using the method of topology optimization, the invention designs the flexible hinge on a concept level. The novel flexible hinge can be designed with a more complex structure and more excellent performances, having a larger flexibility, a higher precision and a smaller maximum stress.

Owner:SOUTH CHINA UNIV OF TECH

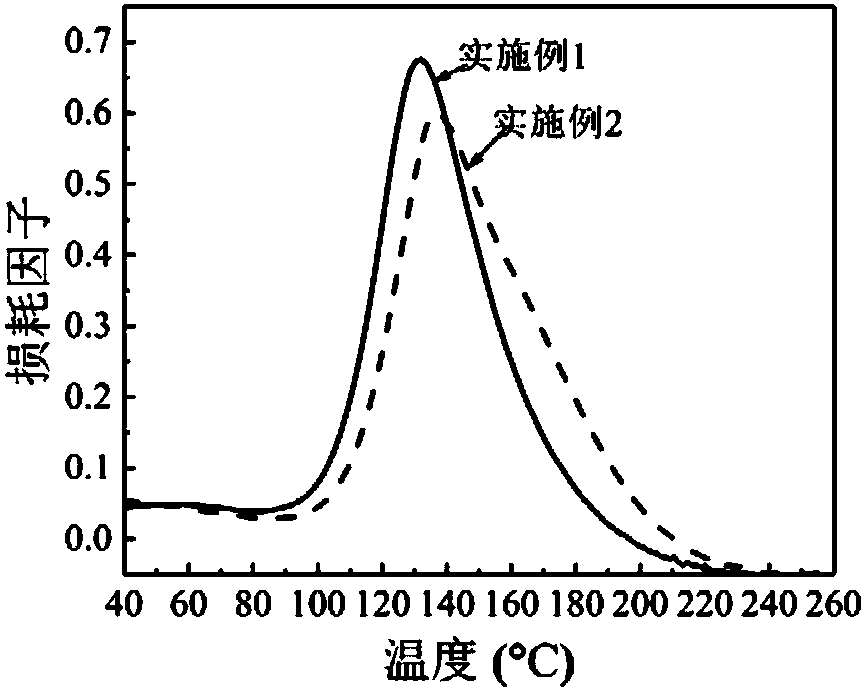

Thermosetting shape memory resin based on bismaleimide and preparation method thereof

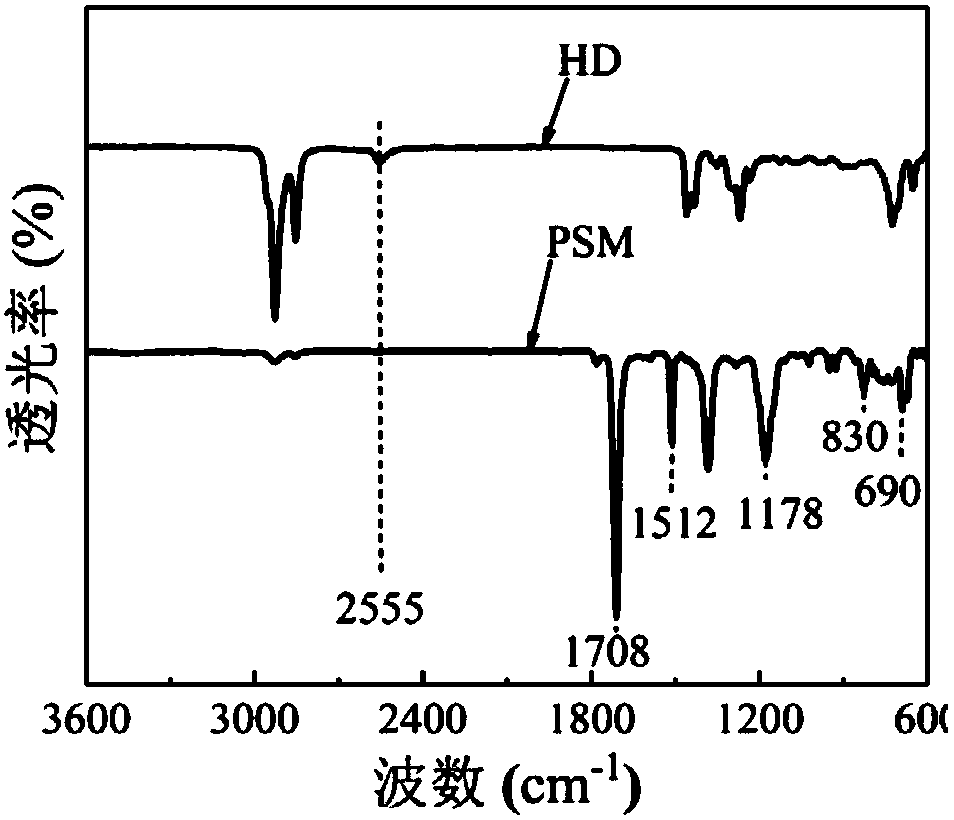

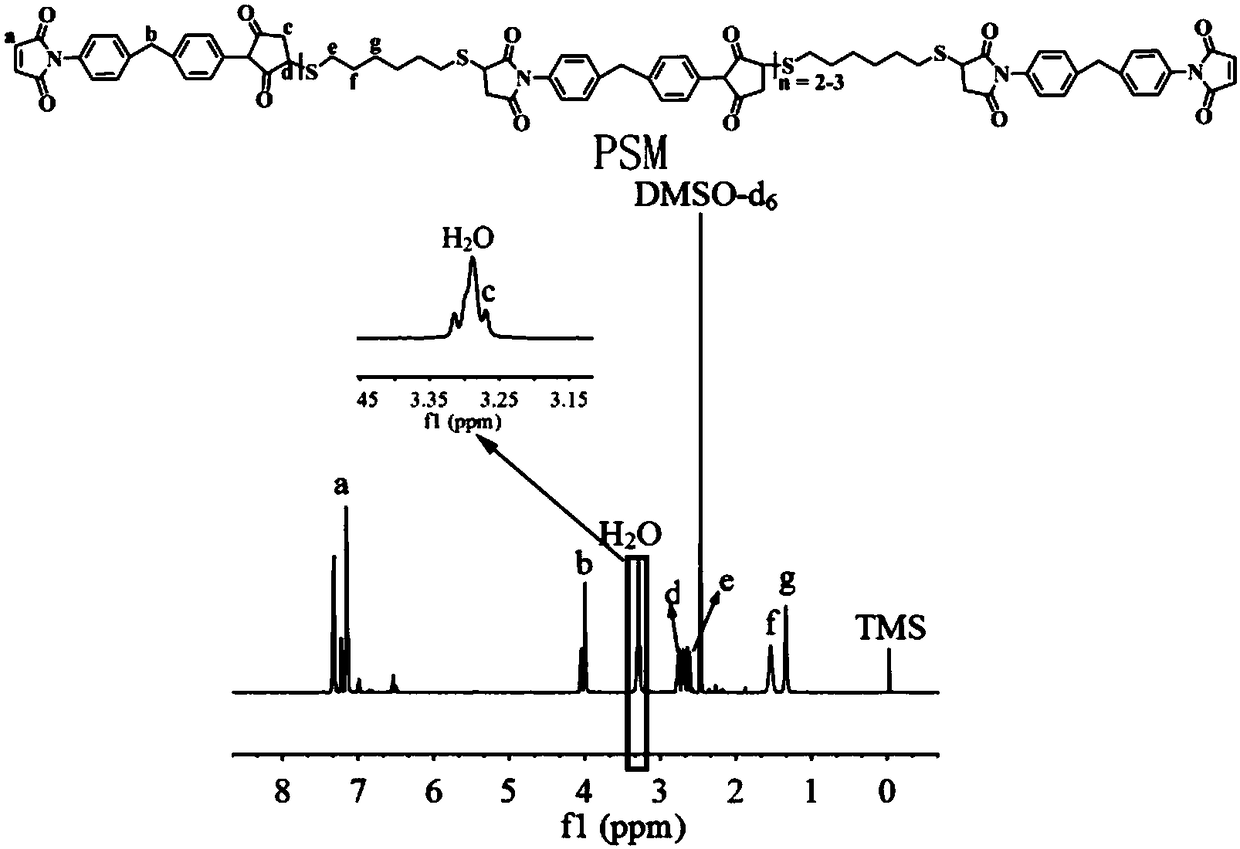

The invention relates to high-deformation thermosetting shape memory resin based on bismaleimide and a preparation method thereof. The method includes the following steps that the bismaleimide and 1,6-ethanthiol are added into m-cresol to form a solution; triethylamine is added into the solution dropwisely, and under the protection of N2 and a stirring condition, a reaction is carried out at roomtemperature to obtain a linear oligomer; the bismaleimide, the linear oligomer and O,O'-diallylbisphenol A are mixed by mass, and the reaction is carried out at 130-150 DEG C for 25-45 min to obtain aprepolymer; the prepolymer is subjected to vacuum defoamation at the temperature of 130-150 DEG C, and through solidification and post-treatment, the thermosetting shape memory resin based on the bismaleimide is obtained. Compared with the prior art, the resin has a high deformation capability, and the breaking elongation of the resin at programming temperatures is higher than 30%; moreover, thethermosetting resin has both high glass-transition temperature (larger than 131 DEG C) and initial decomposition temperature (larger than 370 DEG C), high tenacity and outstanding shape memory performance.

Owner:SUZHOU UNIV

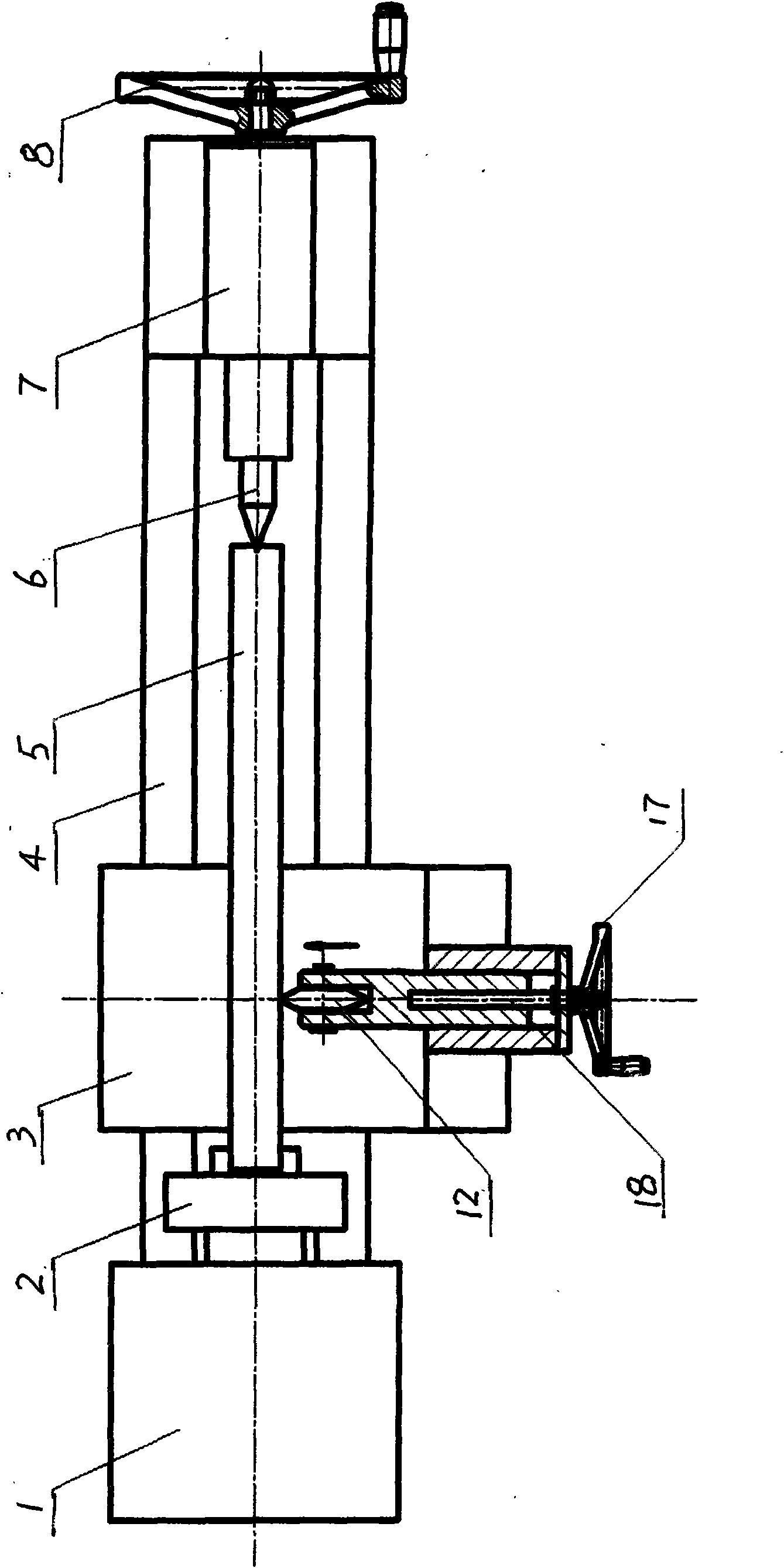

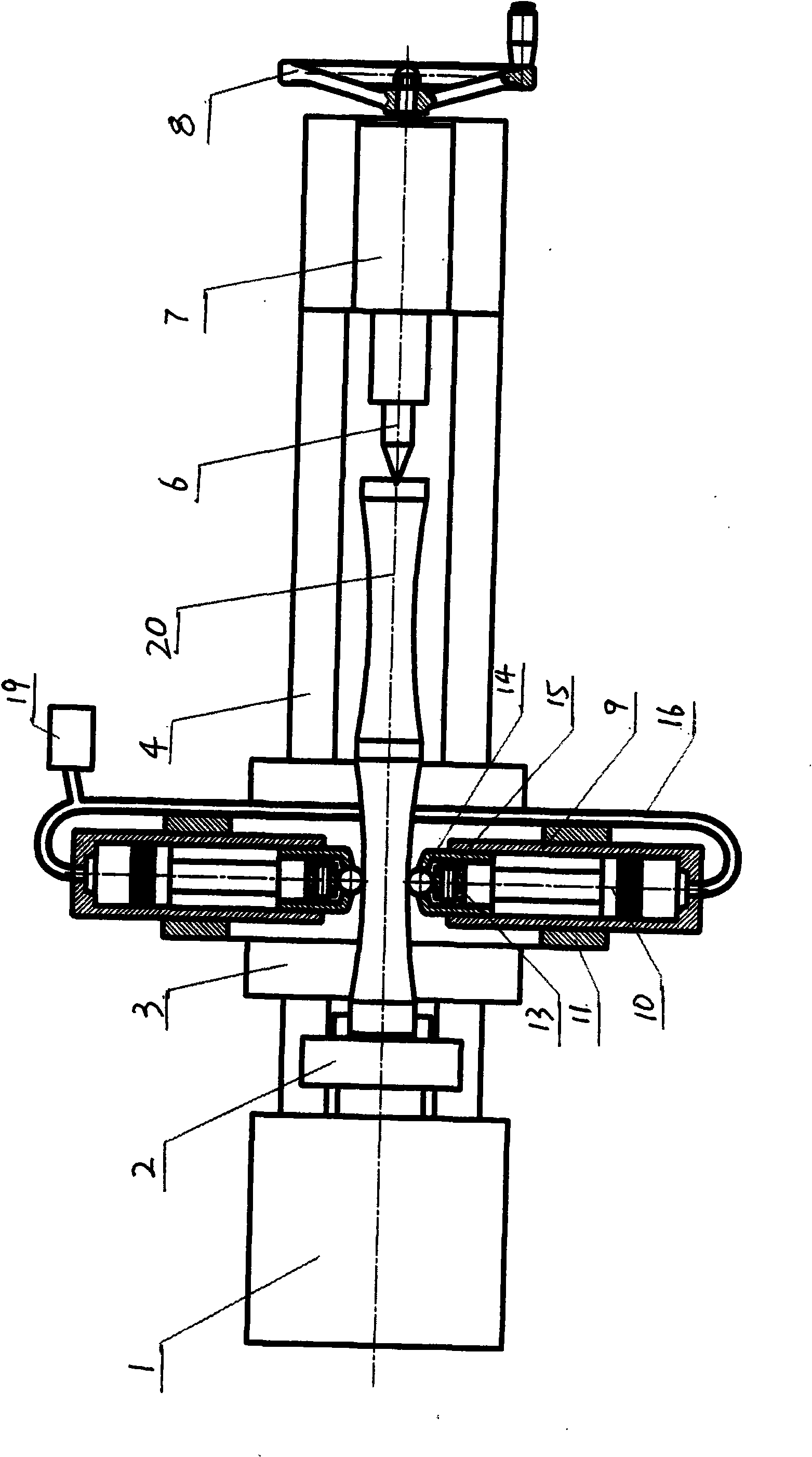

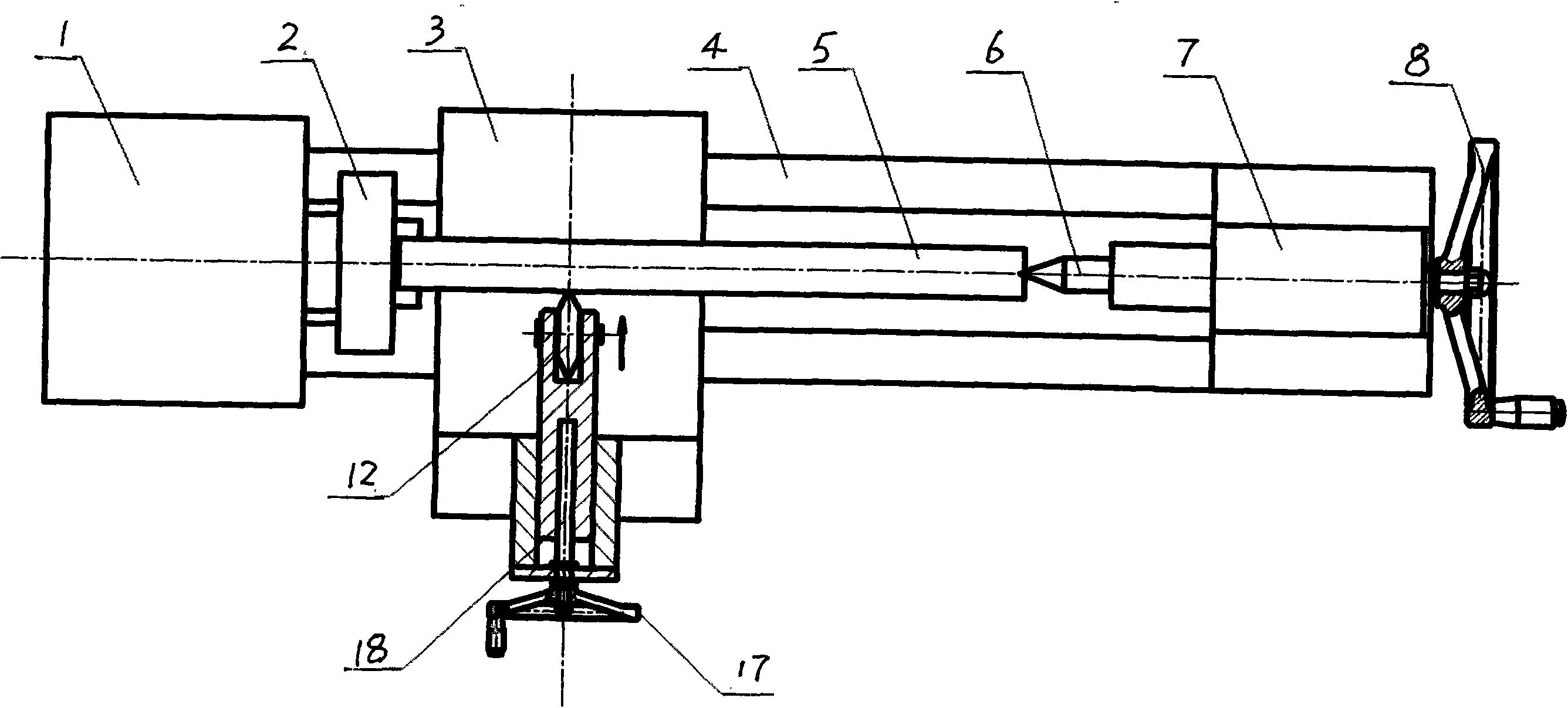

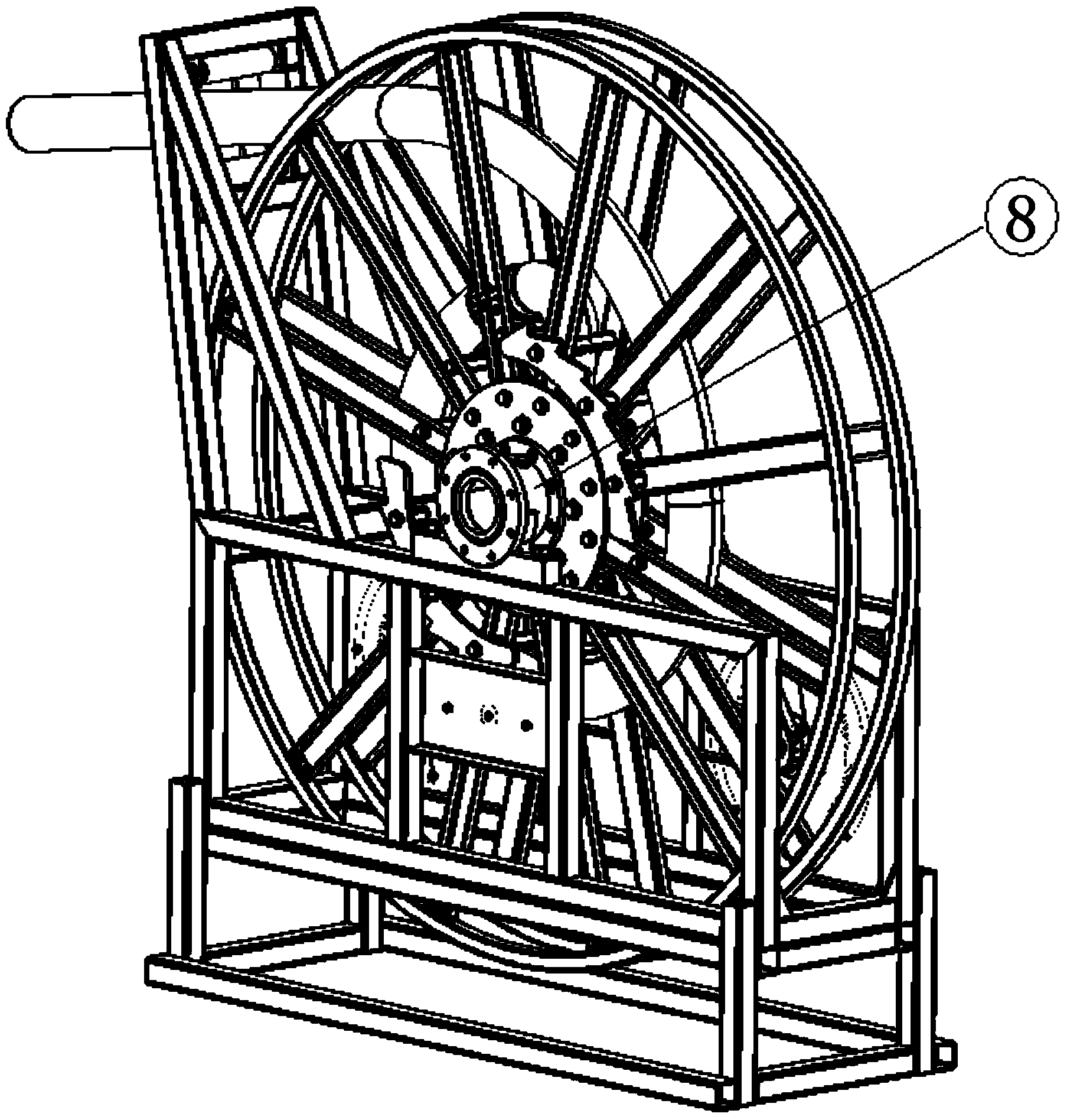

Curve shaft rolling machine

The invention relates to a curve shaft rolling machine belonging to the technical field of processing of shaft rolling machinery. The invention mainly solves the problems that single rolling head and rolling wheel of the traditional rolling machine only can rotate in one direction, so that in the shaft rolling and processing procedure, the rolling head and the rolling wheel are pushed and bent, the rolling quality is poor, the shaft range capable of rolling is small, and the like. The curve shaft rolling machine is mainly characterized by comprising a rotary power mechanism, a horizontal movement mechanism, a workpiece proping mechanism and a stand, wherein the rotary power mechanism comprises a power box and a chuck; the horizontal movement mechanism comprises a sliding table and a guide rail; the workpiece propping mechanism comprises a tip, a tailstock and a hand wheel; a group of rolling heads which are symmetrically distributed by a rotary shaft axis are fixed on the sliding table through a bracket, and each rolling head comprises a cylinder body, a piston, a rolling wheel, steel balls, a retaining sleeve and an oil pipe; the cylinder body is fixed on the bracket; the retaining sleeve is fixed on the piston, and the steel balls are arranged at the end part of the retaining sleeve; the rolling wheel is arranged in the retaining sleeve, and the rolling wheel is in contact with the steel balls; and the oil pipe is connected with a hydraulic station. The invention is mainly used for rolling and processing of various curve shafts.

Owner:南车襄樊机车有限公司

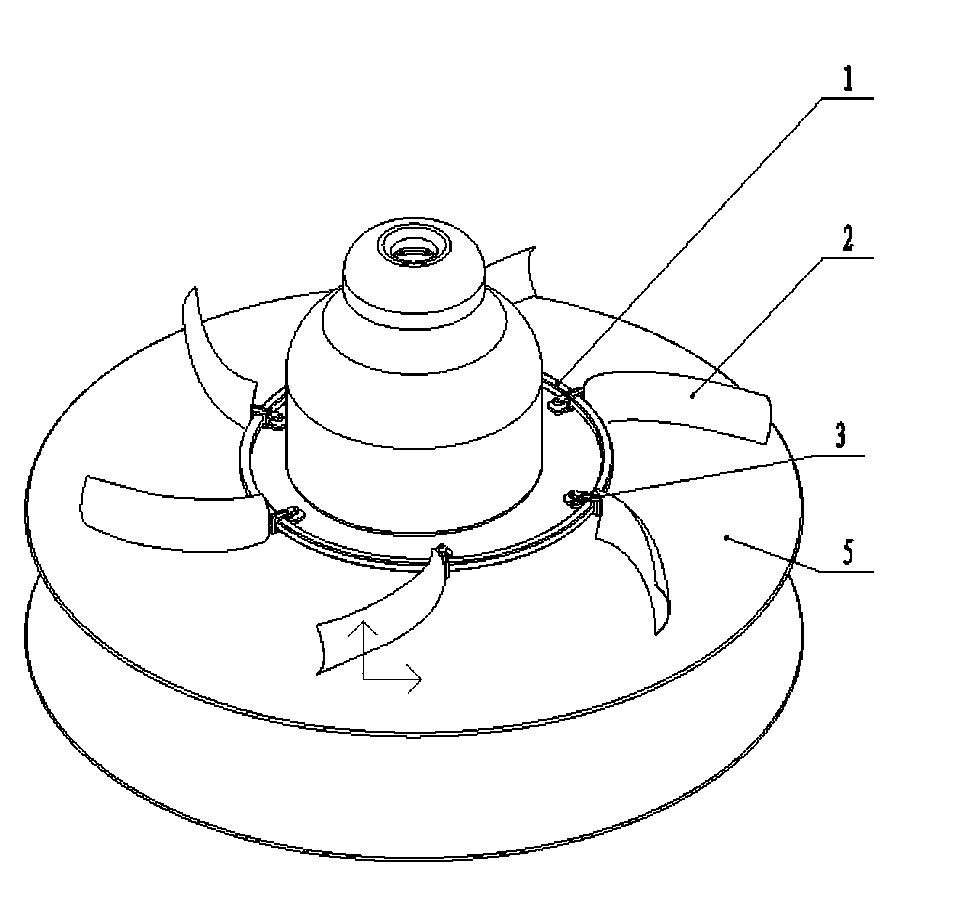

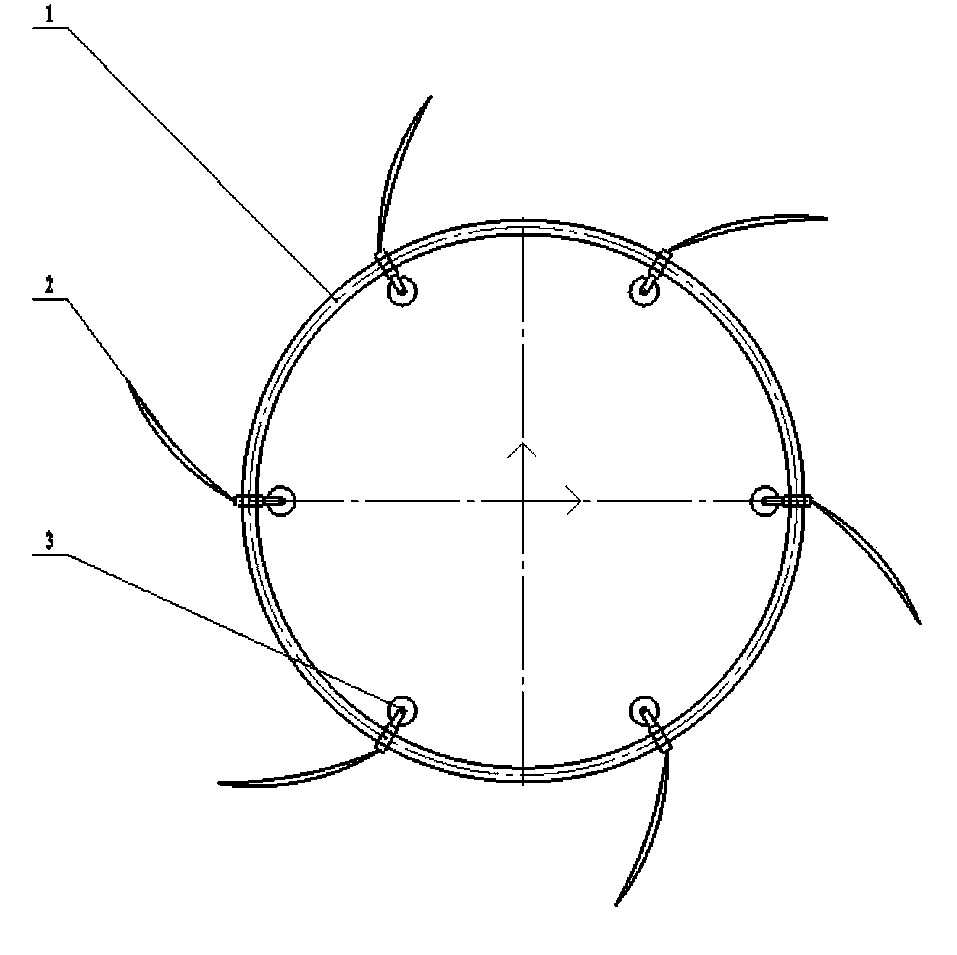

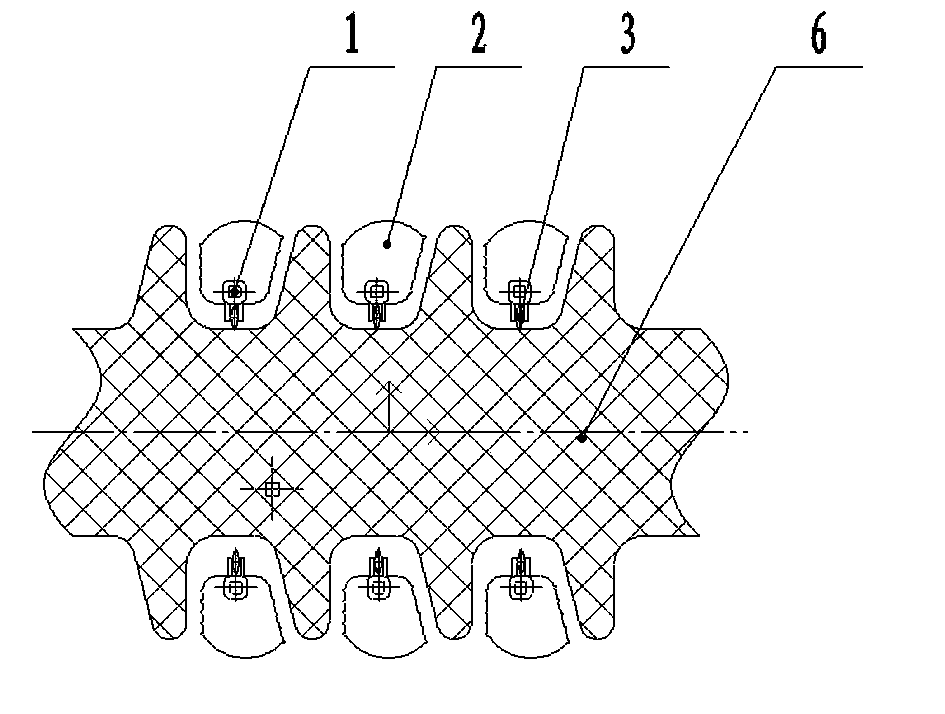

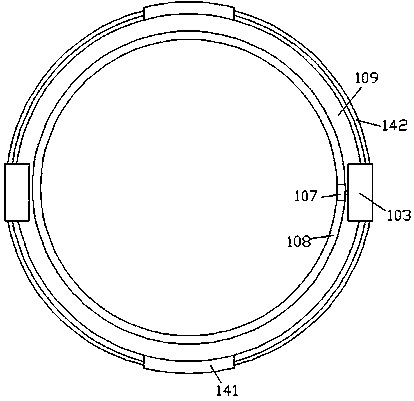

Wind power self-cleaning device for insulator

InactiveCN103456437AEasy to cleanNo secondary fouling pollutionCleaning using toolsInsulatorsElectric power systemWind power

The invention relates to a wind power self-cleaning device for an insulator of an electric power system. According to the structure of the wind power self-cleaning device for the insulator, a plurality of centrifugal type wind guide blades stretching out transversely towards the outer sides are fixedly connected to the outer side edge of an annular ring made of insulating materials, and the centrifugal type wind guide blades are strip sheet-shaped bodies with concave arc faces. A plurality of rolling wheel carriers are arranged on the inner side edge of the annular ring, a transversely-arranged rolling wheel is arranged on each rolling wheel carrier, and the wheel rims of the rolling wheels protrude out of the rolling wheel carriers, so that rolling friction can be formed when the rolling wheels make contact with the insulator. The wind power self-cleaning device for the insulator rotates around the umbrella skirt of the insulator by using wind power, dirt on the surface of the umbrella skirt of the insulator is scraped and removed by using dirt scraping edges on the centrifugal type wind guide blades, and thus the self-cleanness of the insulator is achieved. Therefore, regular manual cleaning work in conventional situations can be removed, the occurrence of pollution flashover accidents can also be avoided effectively, and the safety of the operation of electric transmission lines is improved.

Owner:孟繁恒

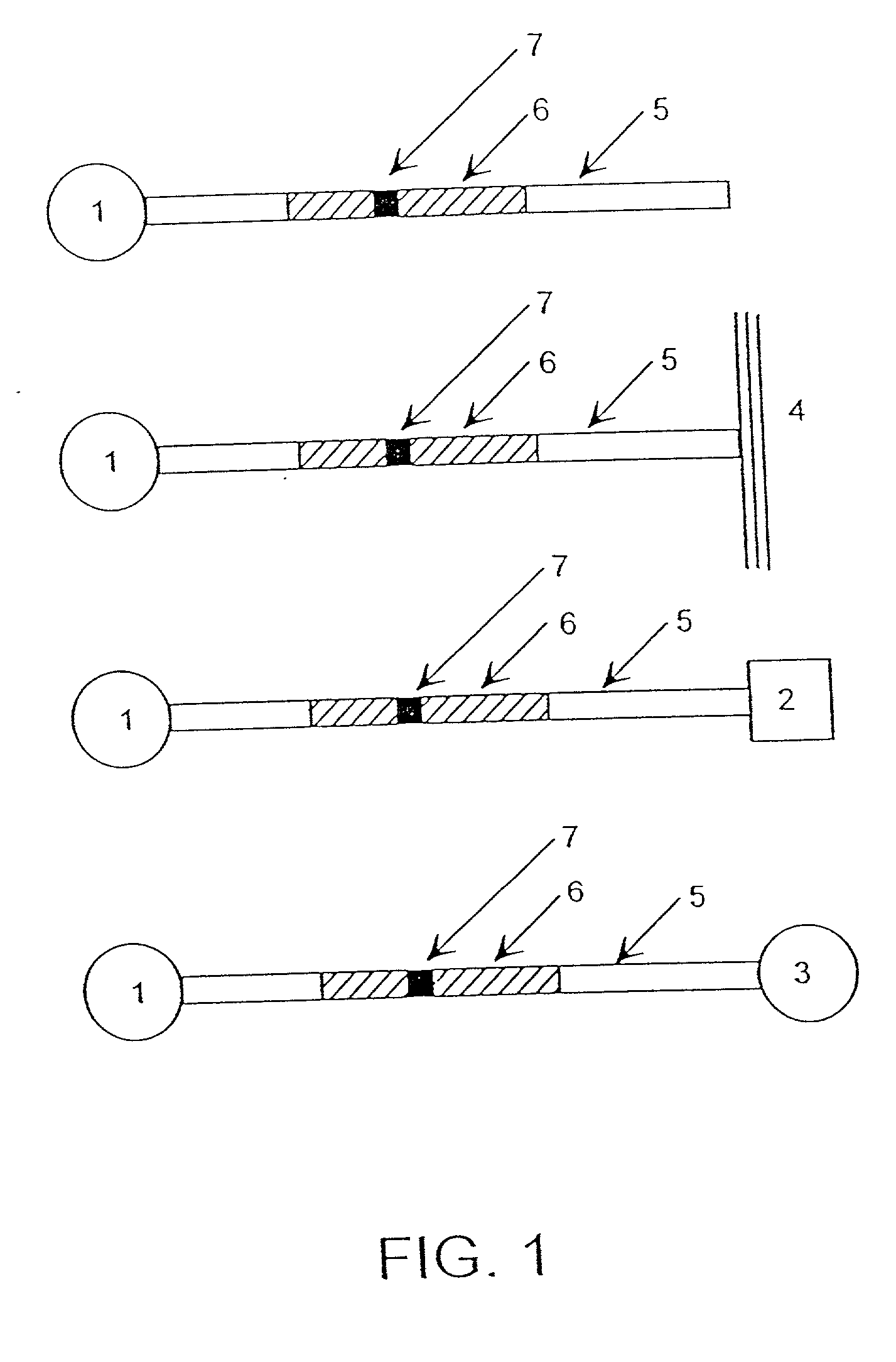

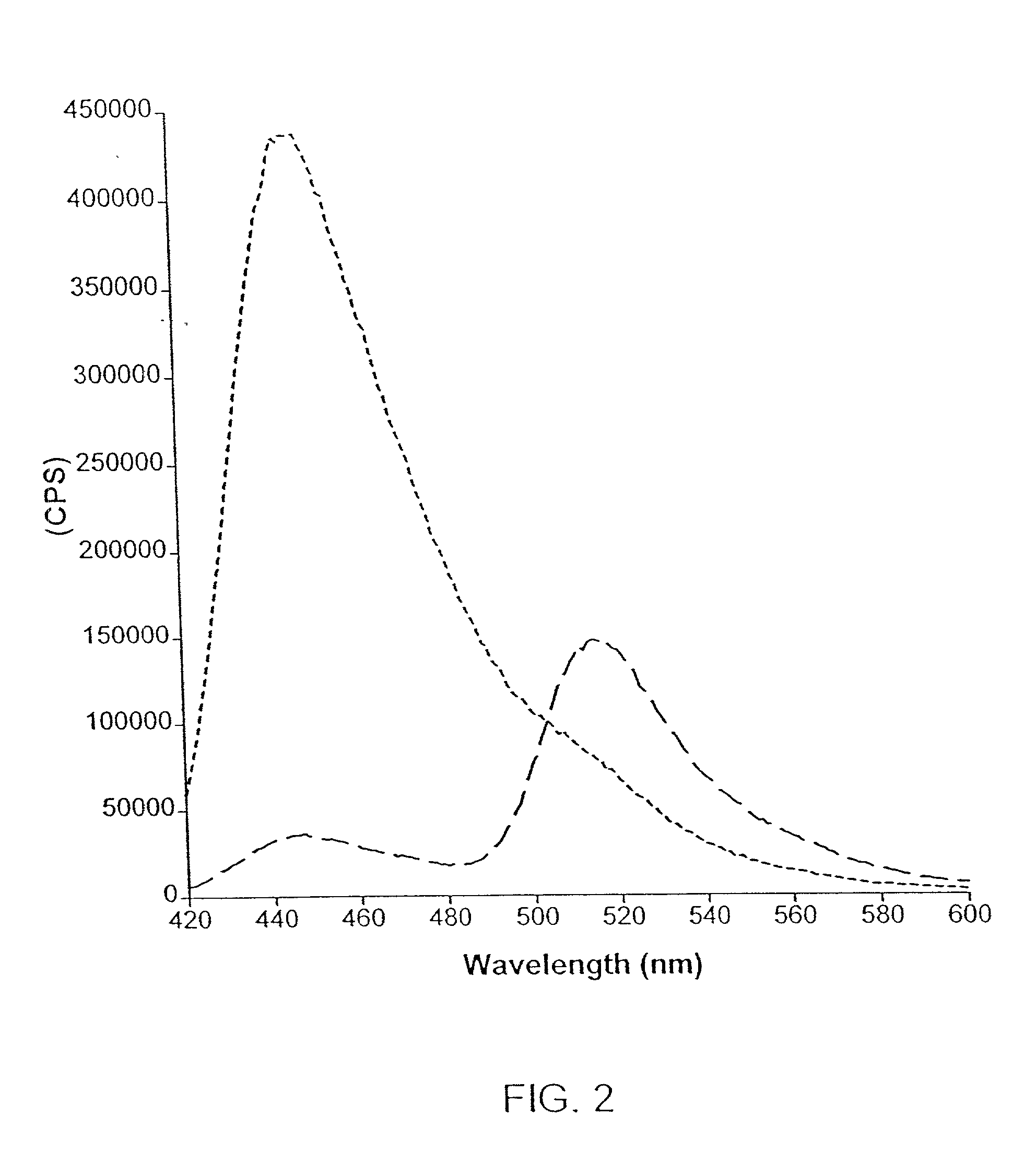

Optical probes and assays

InactiveUS20030087328A1Polarization can be deterioratedEasy to measureBioreactor/fermenter combinationsPeptide librariesPost translationalProteinase activity

This invention provides an optical probe useful as an optical probe or sensor of post translational type modifications, such as phosphorylation. The invention comprises a polypeptide moiety, which contains a recognition motif for a post translational type activity and a protease site, which is coupled to a probe moiety. Modification of the polypeptide, by the post translational type activity, results in a modulation of the rate at which a protease cleaves the polypeptide which is sensed by a measurable change in at least one optical property of the optical probe upon cleavage. The present invention also includes a recombinant nucleic acid molecule that encodes an optical probe and a vector and host cell or library of cells that include the recombinant nucleic acid molecule. The optical probe can be used in methods to determine whether a sample, including a cell or a sample from an organism, contains a post-translational type modification activity. Such methods can also be used to.determine whether a test chemical modulates the activity of a modifying activity, and thus can be used to identify therapeutic compositions. The identification of such therapeutic compositions can be automated using a system that includes an optical probe.

Owner:VERTEX PHARMA SAN DIEGO LLC

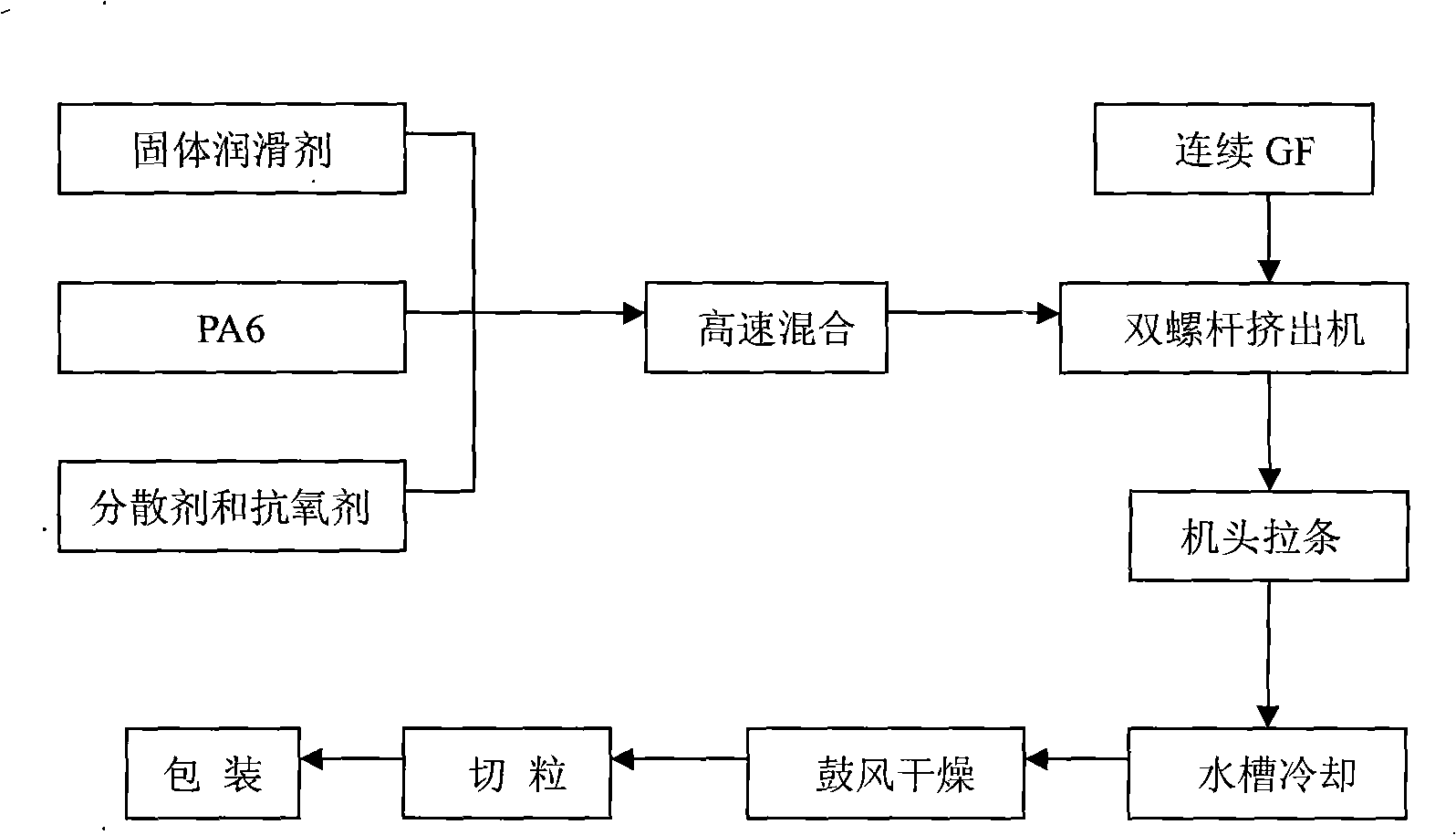

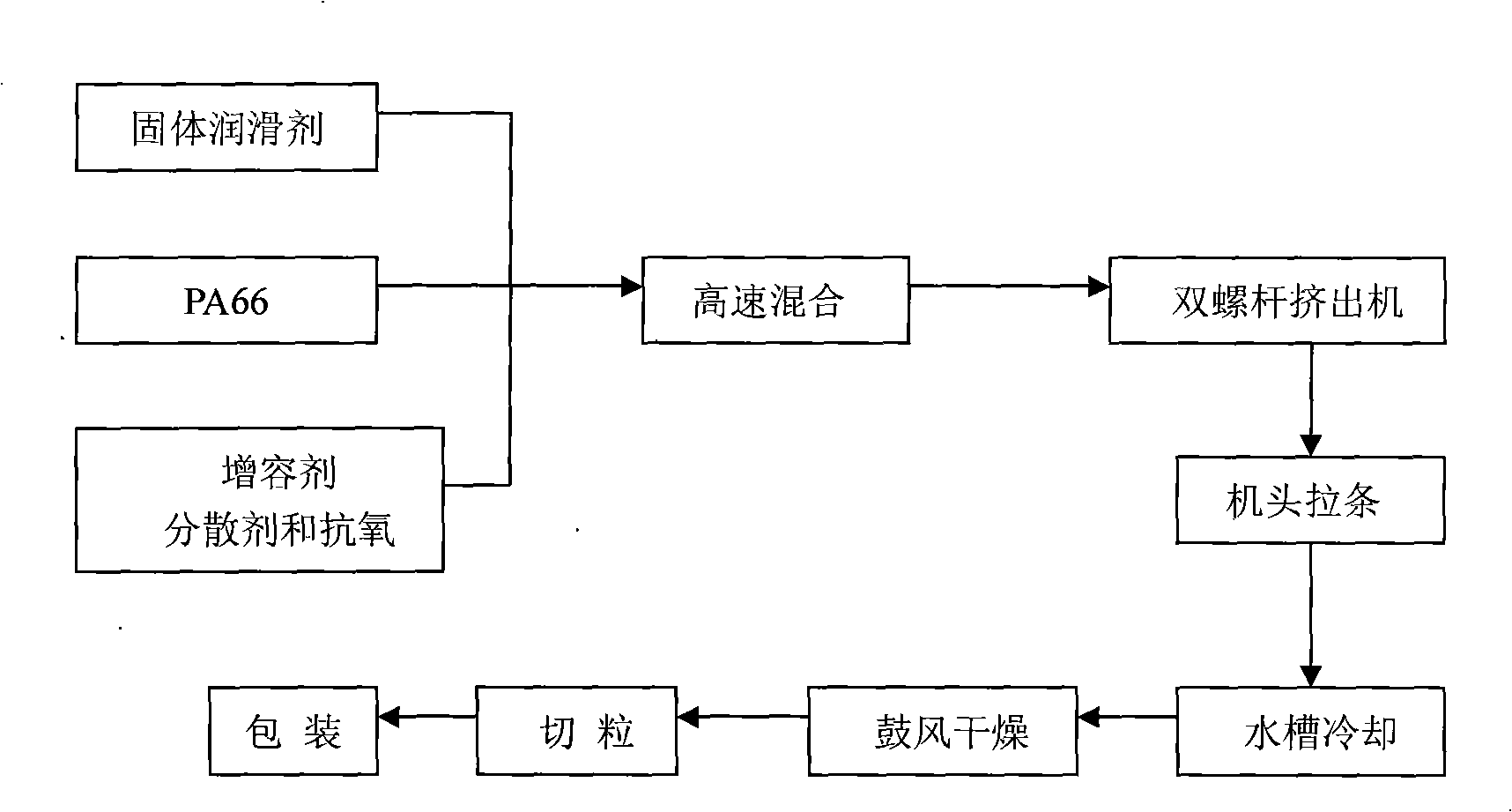

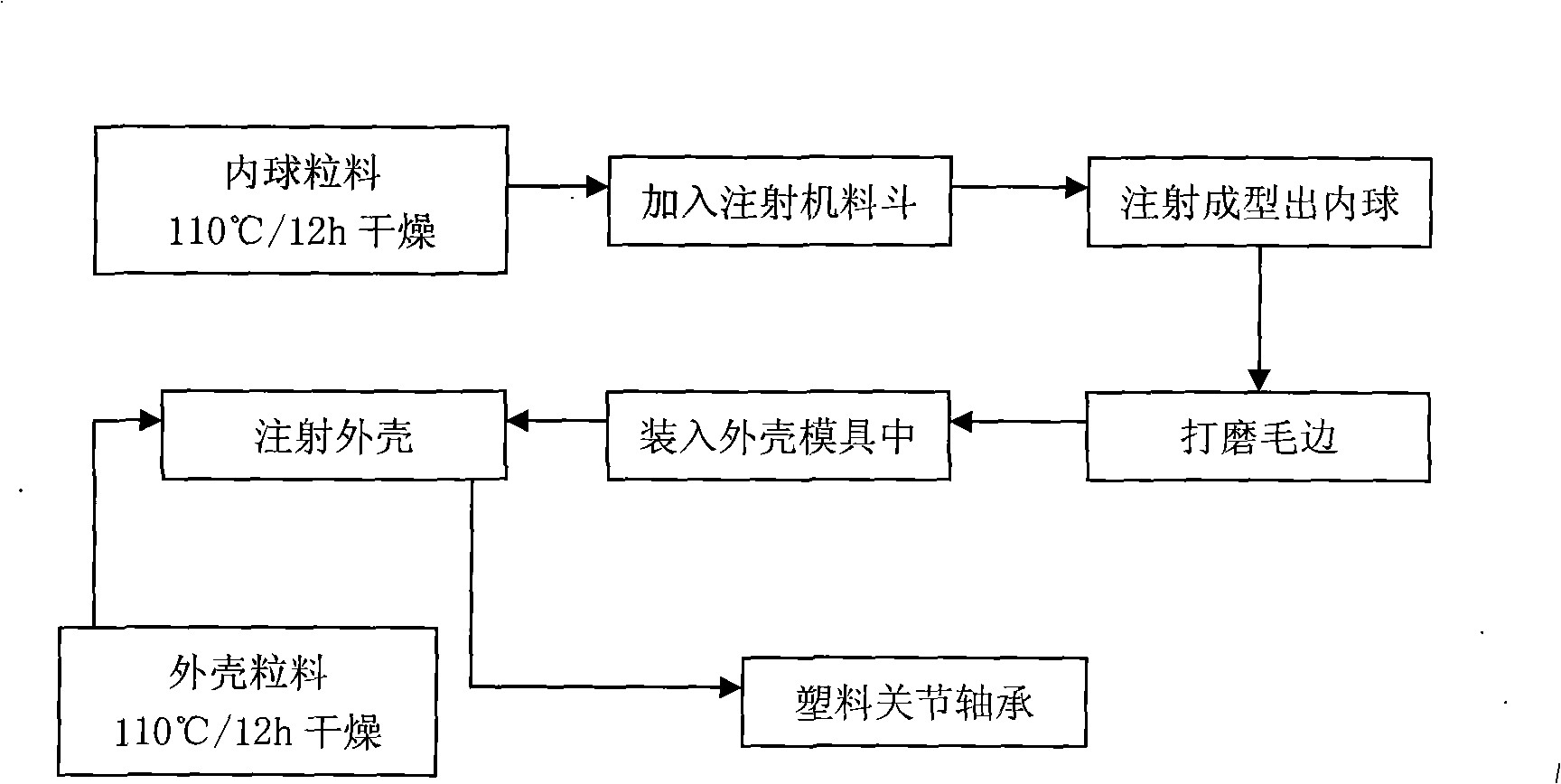

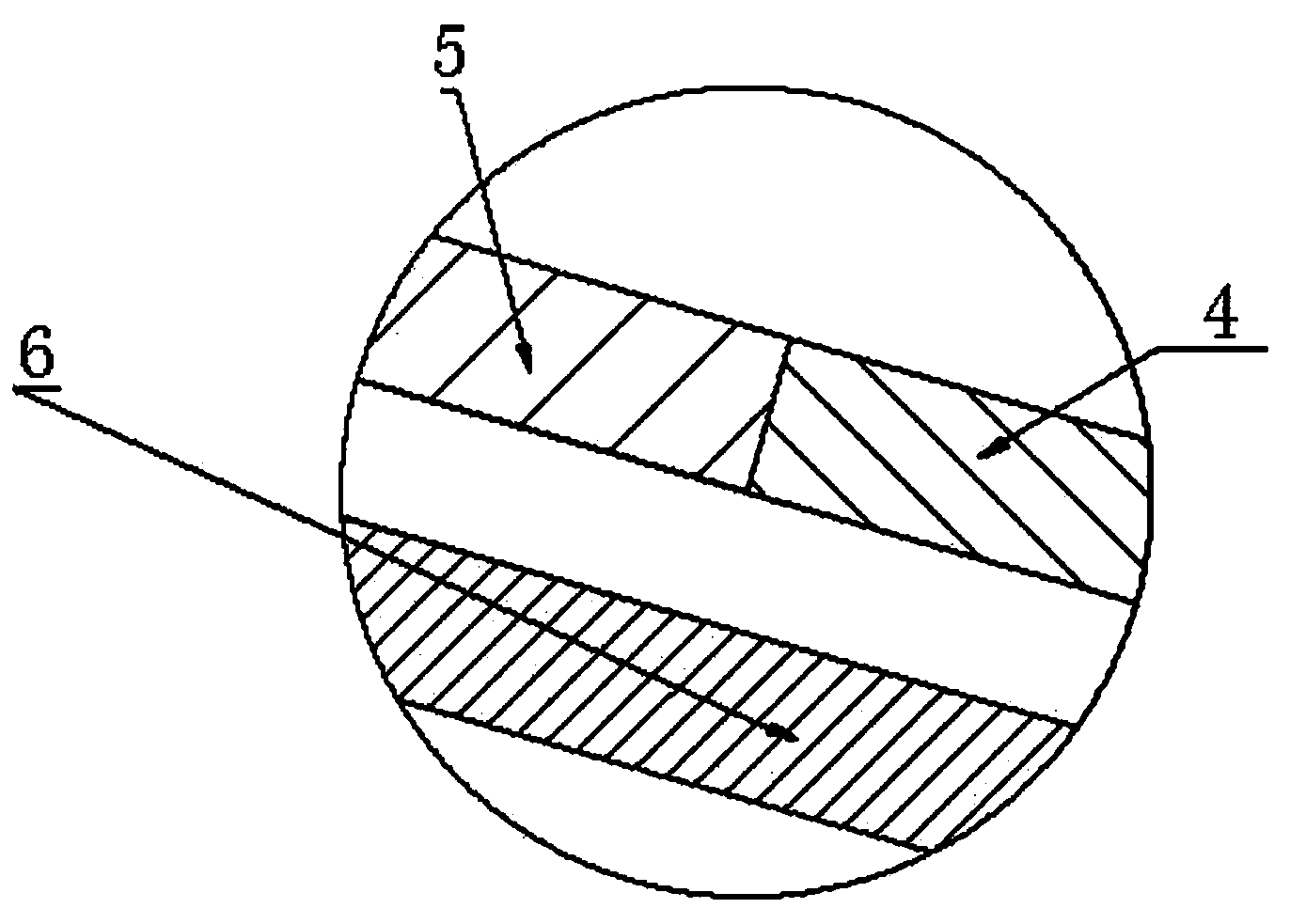

Engineering plastic spherical plain bearing sheathing material, internal sphere material and molding method thereof

InactiveCN101343411AMelting will notReduce coefficient of frictionBearing componentsDomestic articlesGlass fiberEngineering plastic

The invention discloses casing material of an engineering plastic joint bearing. The casing material is characterized in that the casing material comprises polyamide 6 with weight parts of 58.2 to 66.0, glass fibers with weight parts of 28.3 to 38.8, MoS2 with weight parts of 2.4 to 4.7, dispersing agent TAT with weight parts of 0.4 to 0.6, anti-oxidant 168 with weight parts of 0.1 to 0.2 and anti-oxidant 1010 with weight parts of 0.1 to 02. The invention also discloses inner sphere material of the engineering plastic joint bearing. The inner sphere material is characterized in that the inner sphere material comprises polyamide 66 with weight parts of 92.0 to 95.5, solid lubricant with weight parts of 2.5 to 4.8, bulking agent POE-g-MAH with weight parts of 1.5 to 2.4, dispersing agent TAT with weight parts of 0.4 to 0.6 and anti-oxidant 1098 with weight parts of 0.1 to 0.2. In addition, the invention also discloses a moulding method for the engineering plastic joint bearing, firstly, the inner sphere is injected, then the inner sphere is positioned into an outer casing die as an embedding part for injecting the casing, and the engineering plastic joint bearing is positioned into a baking box for final treatment after being molded through injection. By adopting the method, the production efficiency of the technically molded single product in the prior art is enhanced from 30 min to 1 min.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

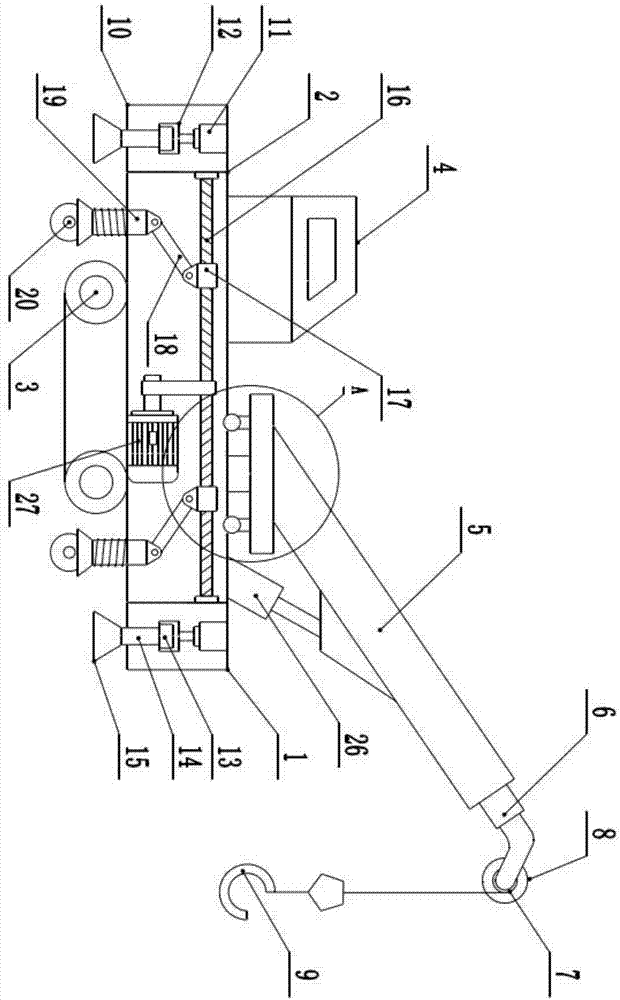

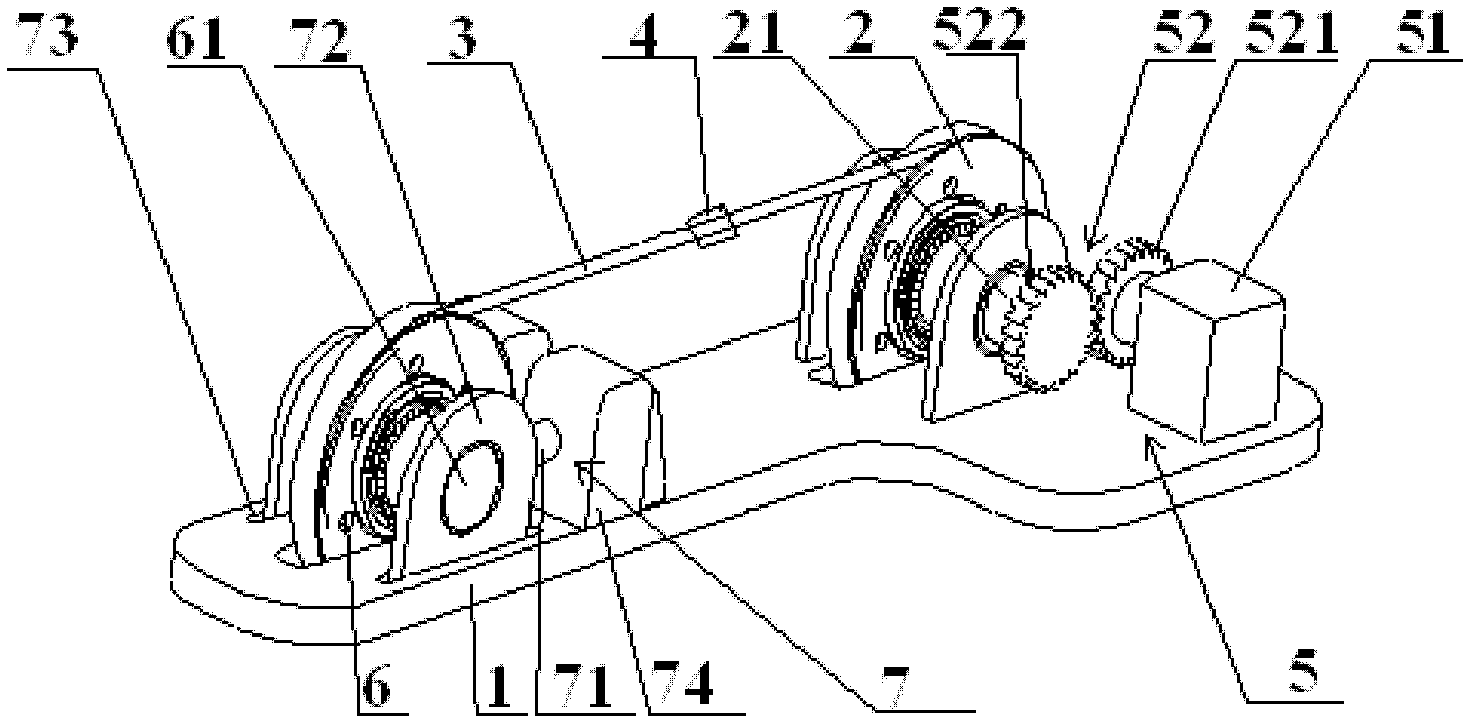

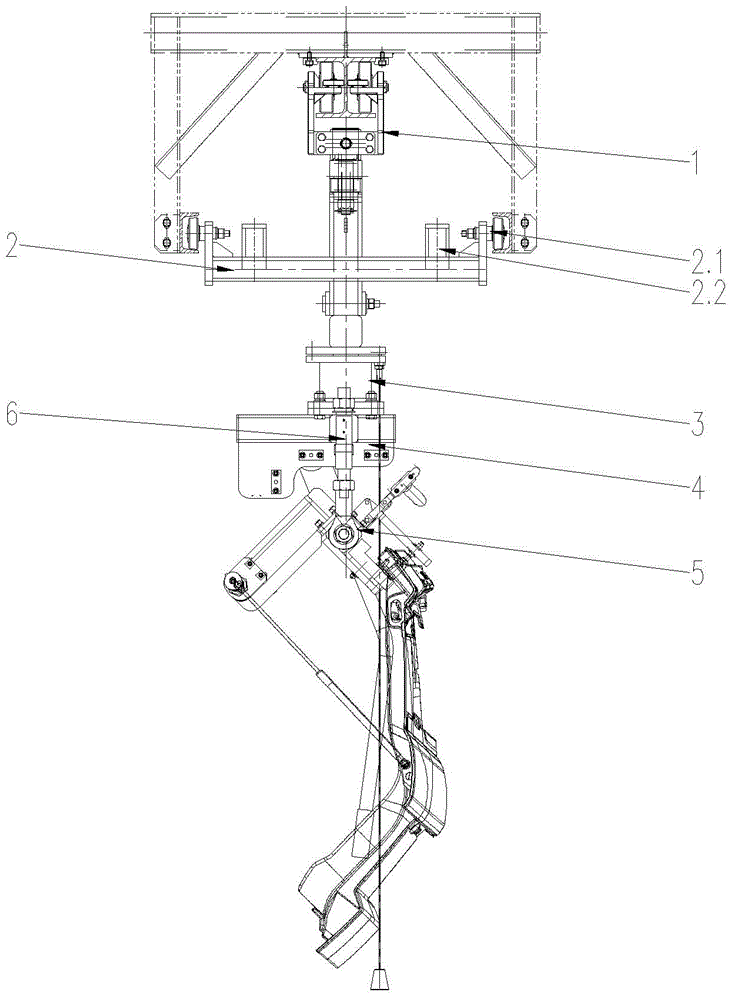

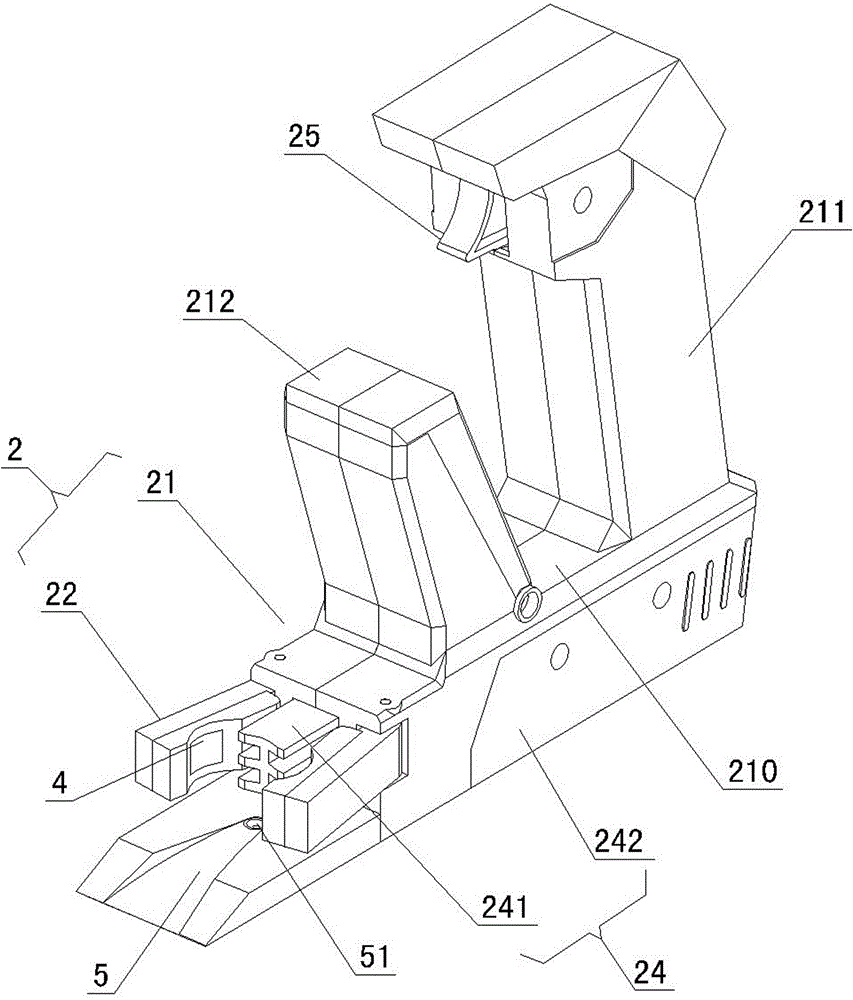

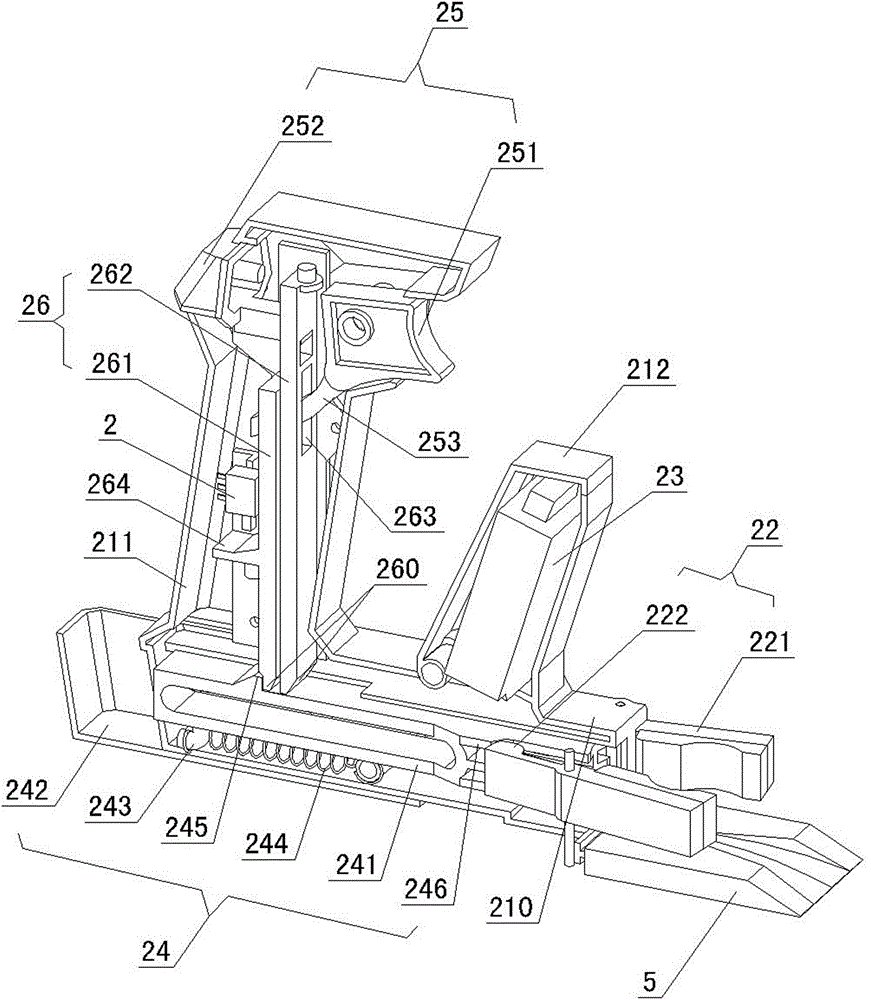

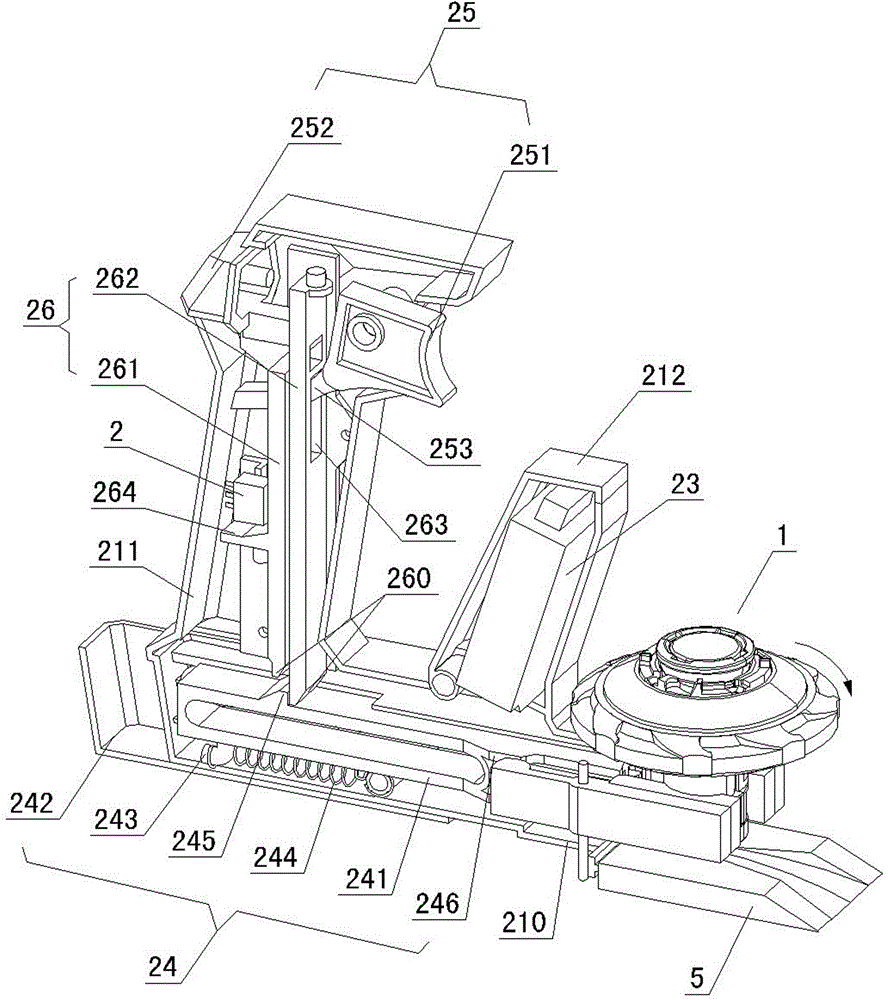

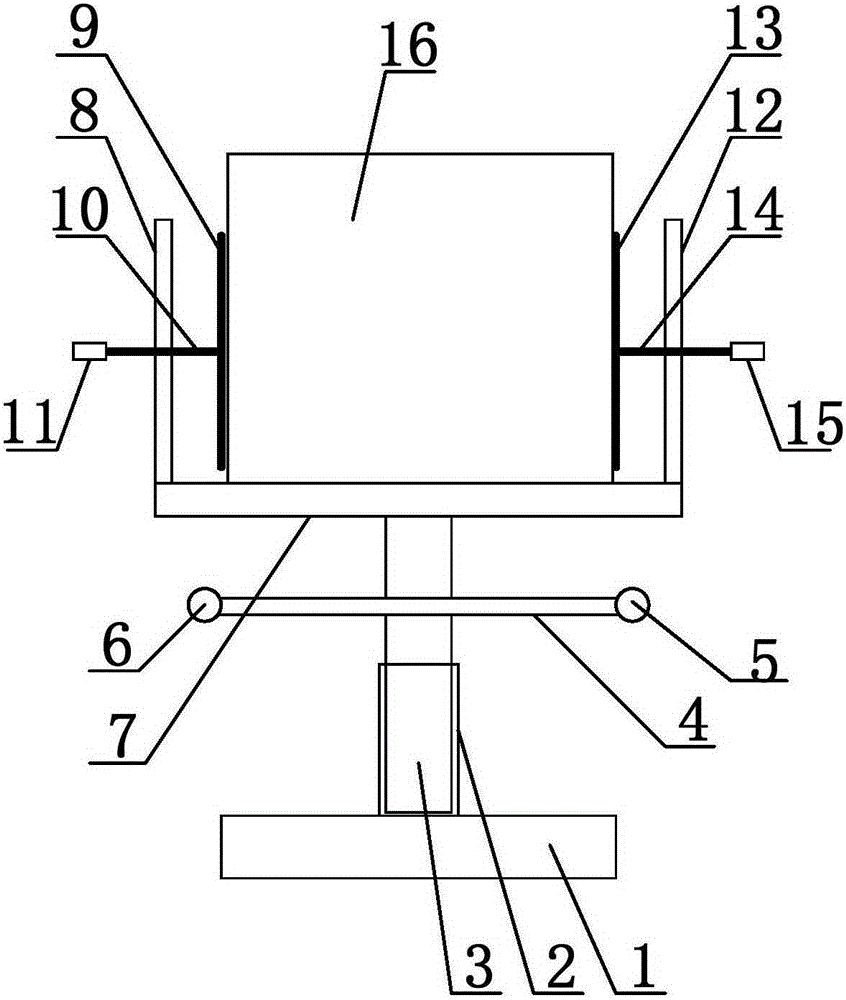

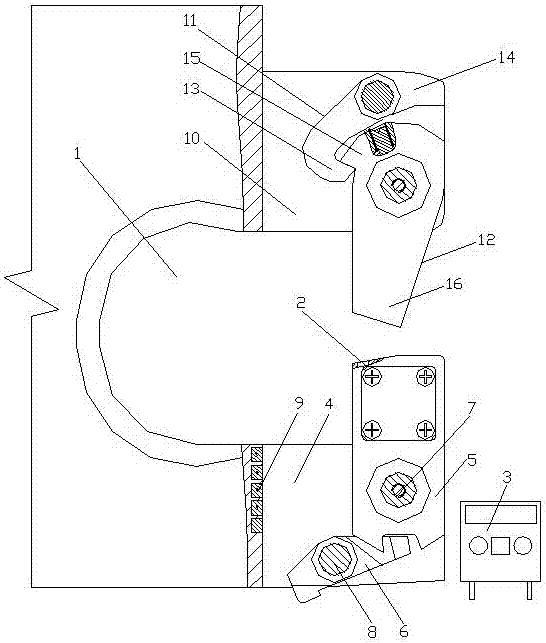

Full-automatic direct-drive gripper

ActiveCN106272338AFree and flexible grippingAchieve crawlingProgramme-controlled manipulatorGripping headsElectric machineryDrive motor

The invention discloses a full-automatic direct-drive gripper, comprising a mounting base, a support bar, a telescopic cylinder, an L-shaped support bar, a direct-drive turnplate, a gripper and a controller and characterized in that the support bar is fixed on the mounting base, the telescopic cylinder is disposed on the support bar, the L-shaped support bar is fixed to a piston rod of the telescopic cylinder, the direct-drive turnplate is disposed on the L-shaped support bar, the gripper is disposed on the direct-drive turnplate and is driven by a double-end cylinder, and the controller controls the direct-drive turnplate and the gripper to move; the gripper can grip freely and flexibly, a positioning component that is provided enables an object to be gripped more stably and provides improved gripping efficiency and accuracy for the gripper, the direct-drive motor drives the gripper to rotate more flexibly, the size of the gripper is decreased, application of a miniature flexible gripper is facilitated, and the gripper is highly symmetric.

Owner:佛山市铭柯智能设备科技有限公司

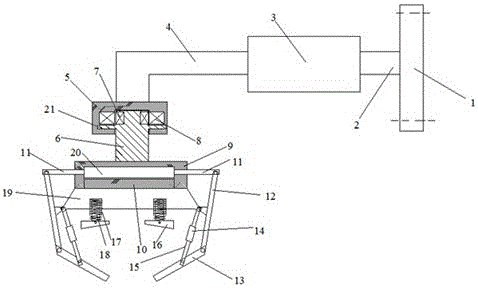

Lifting device with dual-purpose rolling-chain wheel

The invention discloses a lifting device with a dual-purpose rolling-chain wheel. The lifting device comprises a device body, wherein the device body is mainly composed of a shell body, an operation box, a lifting boom, a telescopic boom, a fixed pulley and a hanging hook, wherein a moving element is arranged on a rotary shaft in a sleeving manner, and a connection rod is hinged at the bottom of the moving element; a slide rod is arranged at the bottom of the shell body, stabilization devices are fixedly connected to the two ends of the shell body, a cylinder is fixedly connected to the top in each stabilization device, an installation frame is connected to the bottom of each cylinder through a piston rod, a suction device is fixedly connected in each installation frame, a suction barrel is fixedly connected to the bottom of each installation frame, a rotary disc is connected to the surface of the top of the shell body through a rotary shaft, and rolling balls are fixedly connected to the bottom of the rotary disc through rolling ball shafts; and the lifting boom is fixedly connected to the surface of the rotary disc, a hydraulic cylinder is fixedly connected to the surface of the shell body, and a connection element is fixedly connected to the tail end of a telescopic rod. The device is high in stability and flexibility, and good in shock absorption effect, and facilitates people to use; and moreover, the device is capable of selecting different moving manners according to terrains during a use process, and convenient to use.

Owner:博格昇粉体技术(常州)有限公司

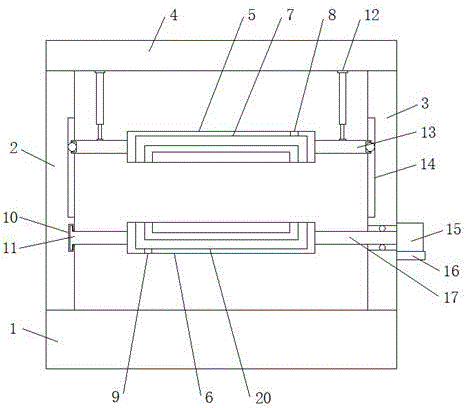

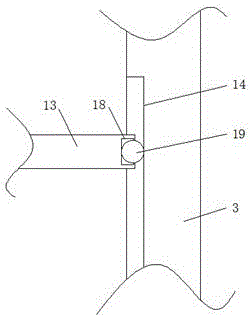

Glove mold for preparing disposable gloves

InactiveCN106827314AImprove rotational flexibilityRealize free dockingDomestic articlesEngineeringSlide plate

The invention discloses a glove mold for preparing disposable gloves, which comprises a base, a first fixing plate vertically arranged on one side of the top of the base, and a vertically arranged first fixing plate on the other side of the top of the base. The second fixed plate, the top of the first fixed plate and the second fixed plate are provided with a support plate, the side of the first fixed plate close to the second fixed plate is provided with a card slot, the first fixed plate and The side close to the second fixed plate is provided with a chute, the side of the second fixed plate far away from the first fixed plate is welded with a mounting plate, the top of the mounting plate is equipped with a rotating motor, the base and the support plate An upper mold base and a lower mold base are respectively arranged horizontally, wherein the upper mold base is provided with a first cooling chamber, and sliding plates are welded on both sides of the upper mold base. The invention has a reasonable design, is convenient for the disposable gloves to automatically fall off and unload and change materials after the preparation is completed, reduces the cost of manual operation, and effectively improves the preparation efficiency of the disposable gloves.

Owner:江苏嘉文医疗用品有限公司

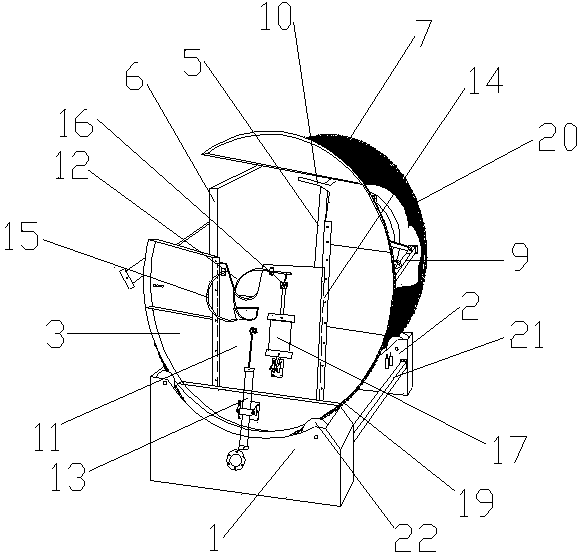

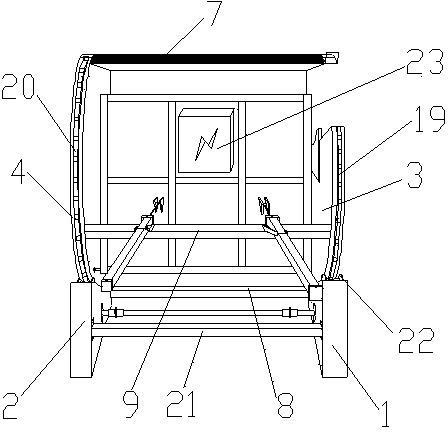

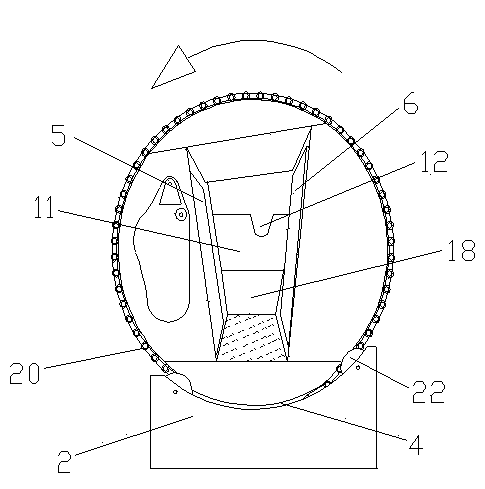

Slaughtering device

InactiveCN103444830AImprove rotational flexibilityExtended service lifeSlaughtering animals fettering apparatusSlaughtering/stunningSafety coefficientDrive shaft

The invention discloses a slaughtering device which comprises a base, a driving mechanism and an imprisoning tank. The imprisoning tank comprises a first rotating table, a second rotating table, a first splint, a second splint, a top cover, a bottom plate and a neck pressure plate; the first rotating table is provided with a neck clamping mechanism and a turnover mechanism; the neck clamping mechanism comprises a neck clamping door and a neck clamping cylinder; the upper part of the neck clamping door is provided with a neck placement concave cavity and the neck placement concave cavity is in slide fit with two parallel guide rails arranged on the first rotating table; the turnover mechanism comprises a fixture and a fixture cylinder; the neck pressure plate is positioned above the first rotating table and the length direction of the neck pressure plate is vertical to the moving direction of the neck clamping door; the driving mechanism comprises a transmission shaft; both a first chain and a second chain are in transmission connection with the transmission shaft; and the transmission shaft is also sequentially connected with a speed reducer and a motor. The slaughtering device provided by the invention has a simple structure and high slaughtering efficiency; labor intensity and cost of workers can be reduced; and the slaughtering device has a high safety coefficient and long service life and is also beneficial for showing live killing and ensuring meat quality of beasts.

Owner:NANJING RESISTANCE HOP SLAUGHTER MACHINERY MFG

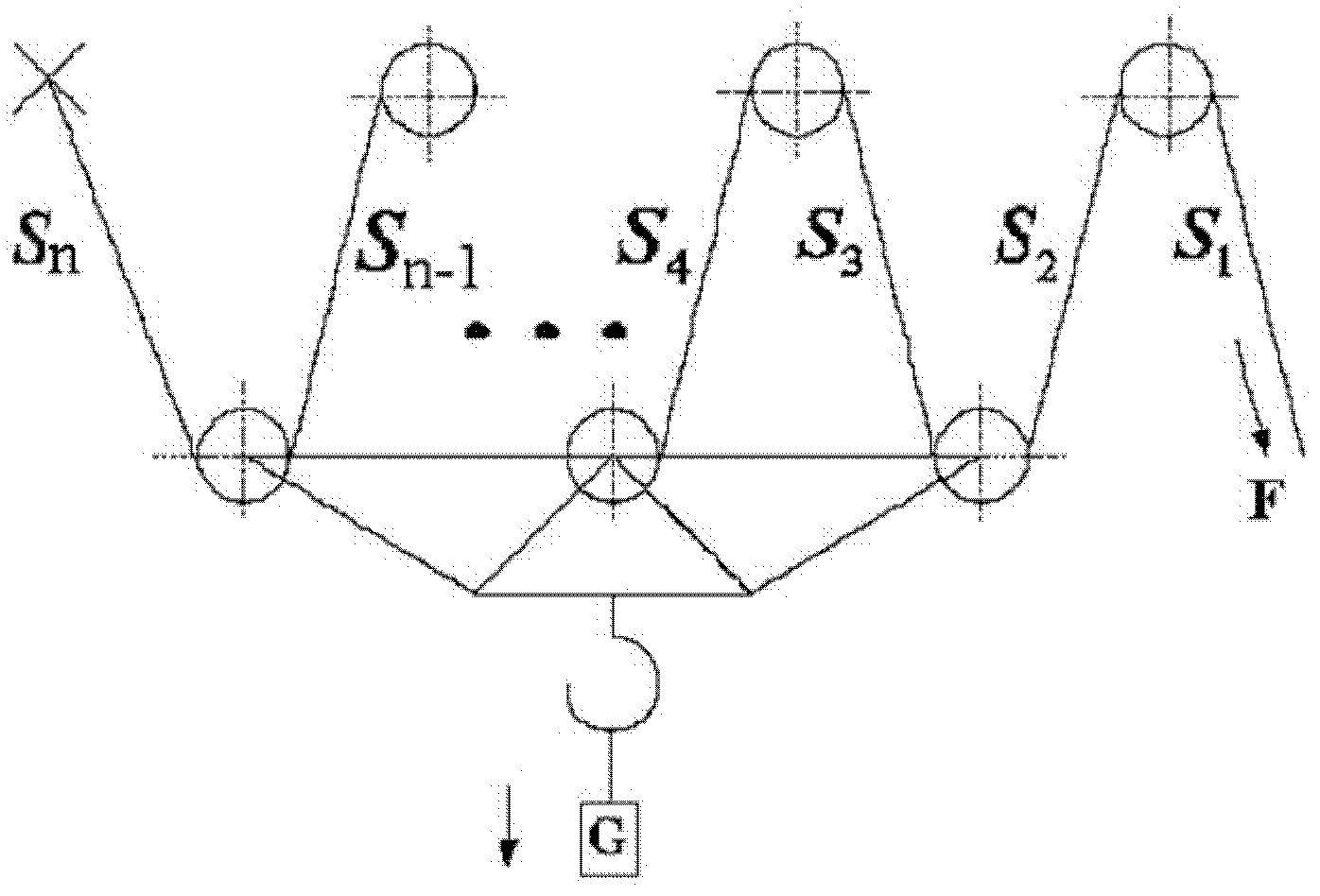

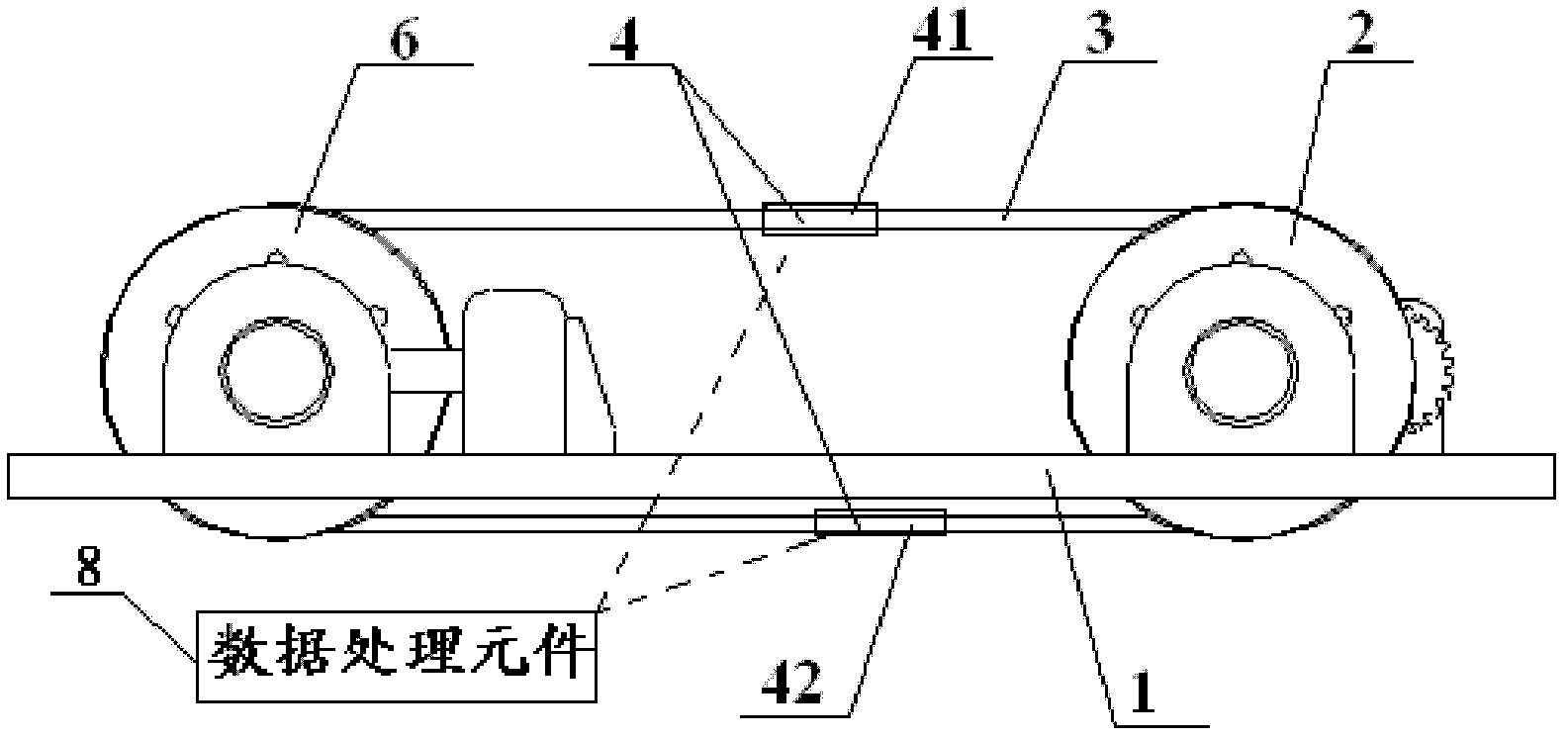

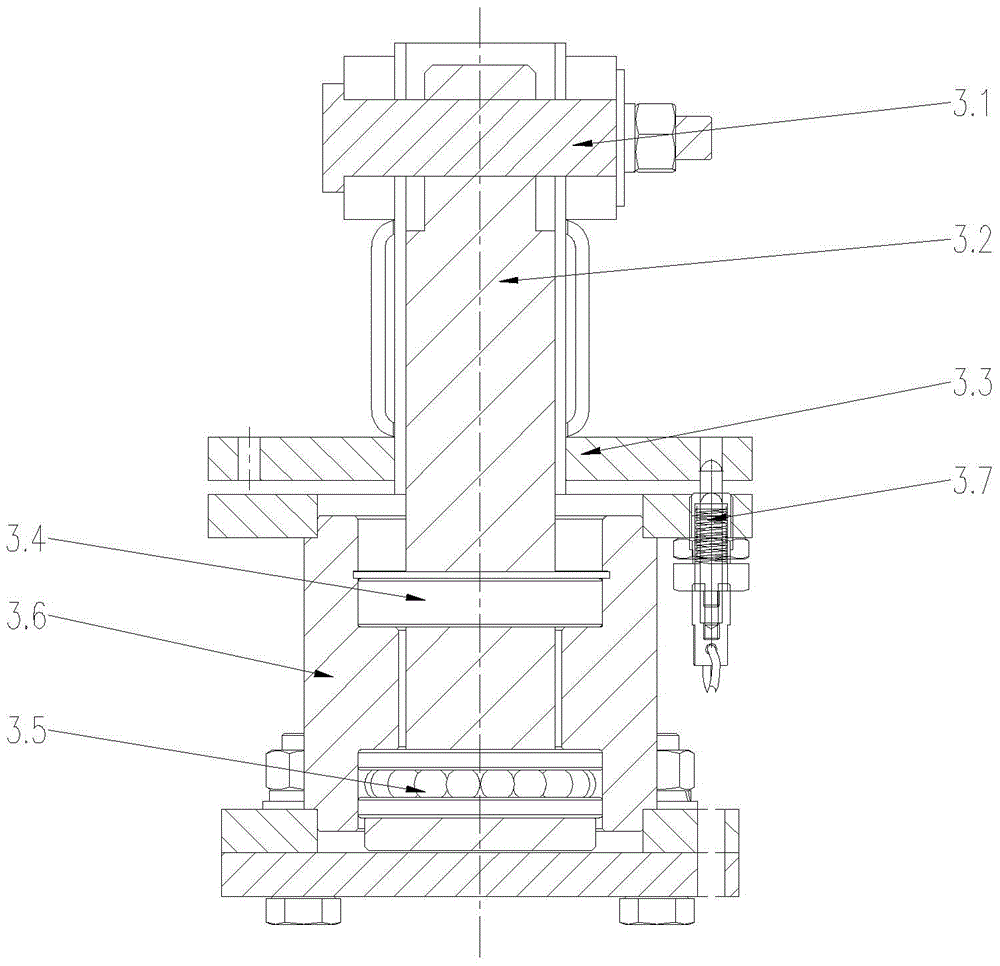

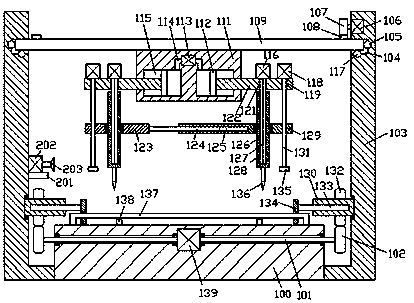

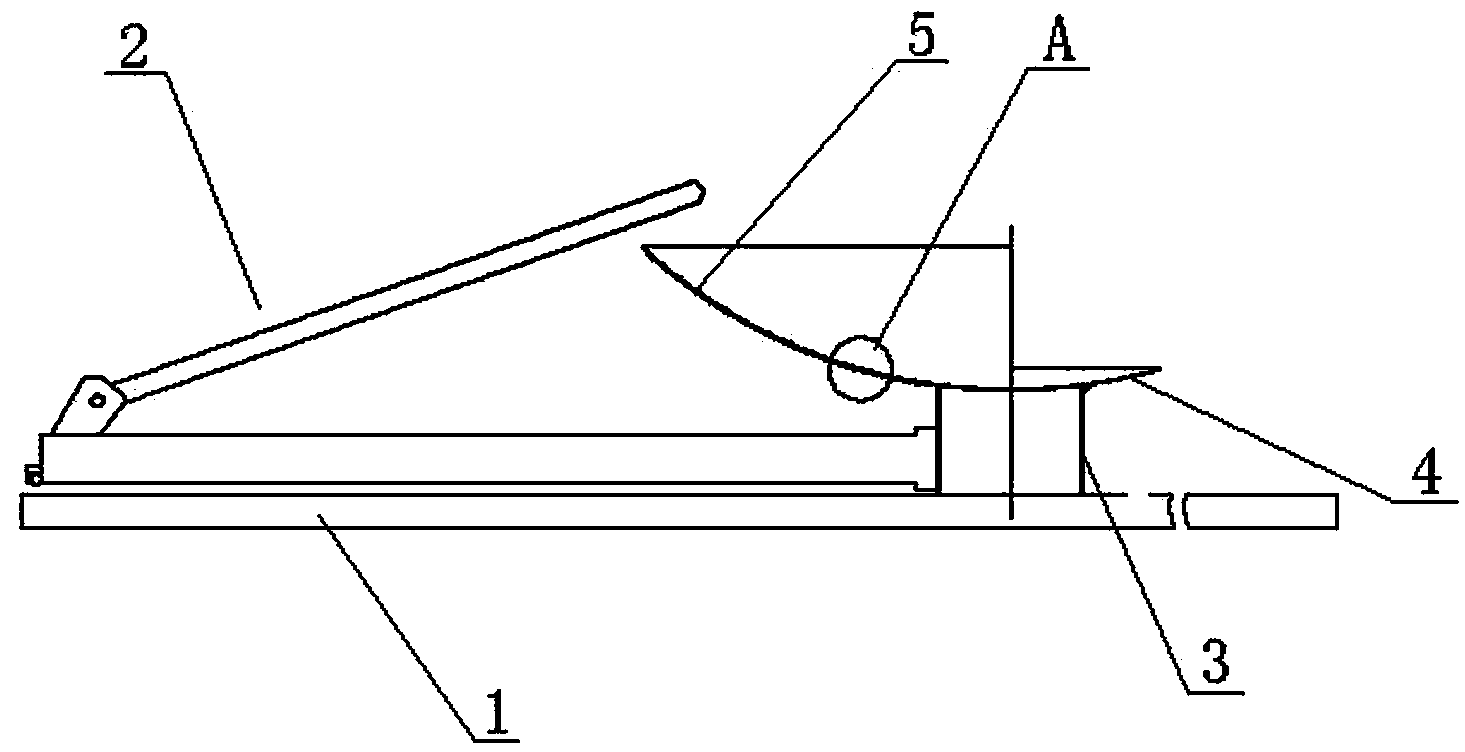

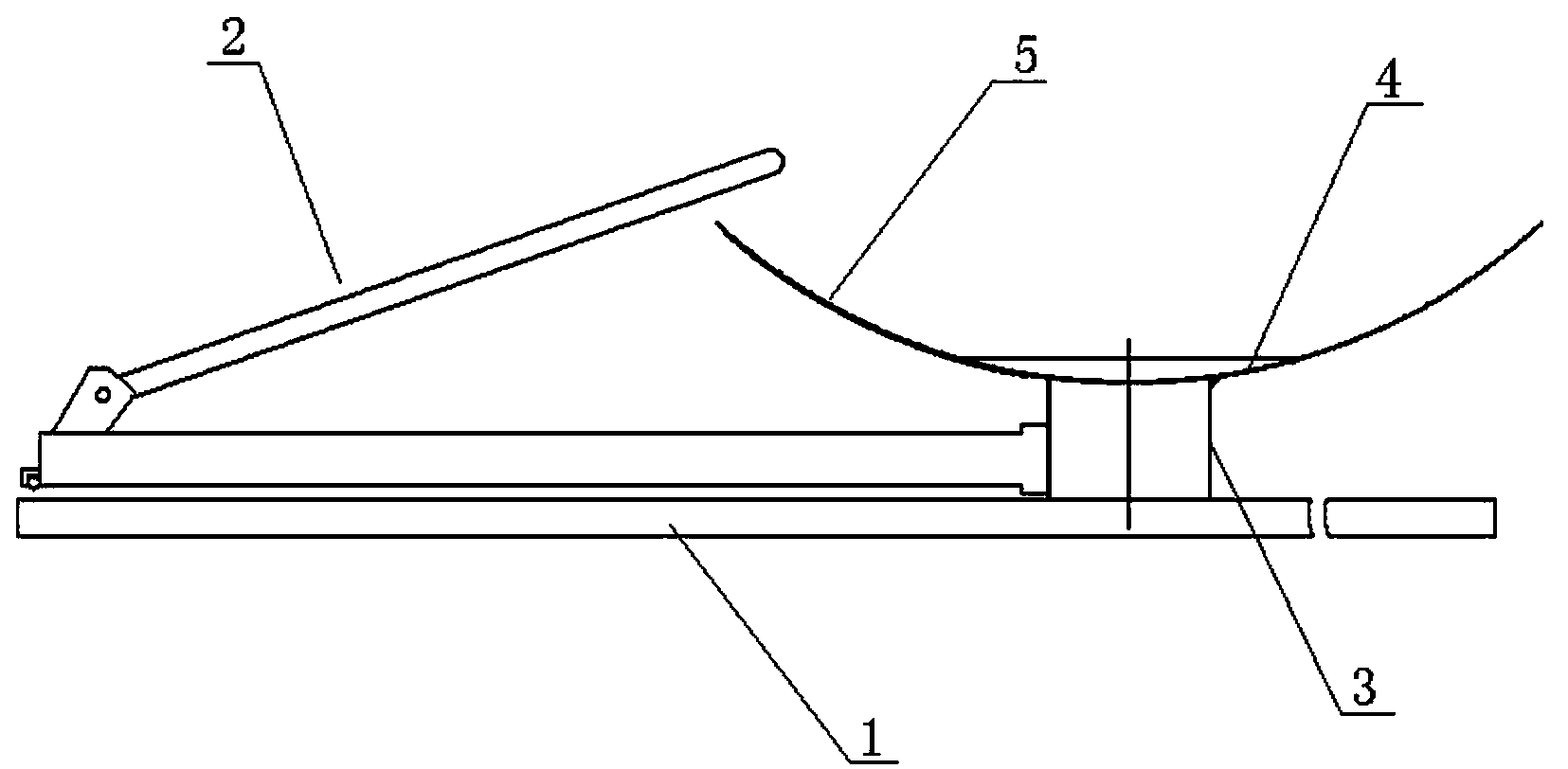

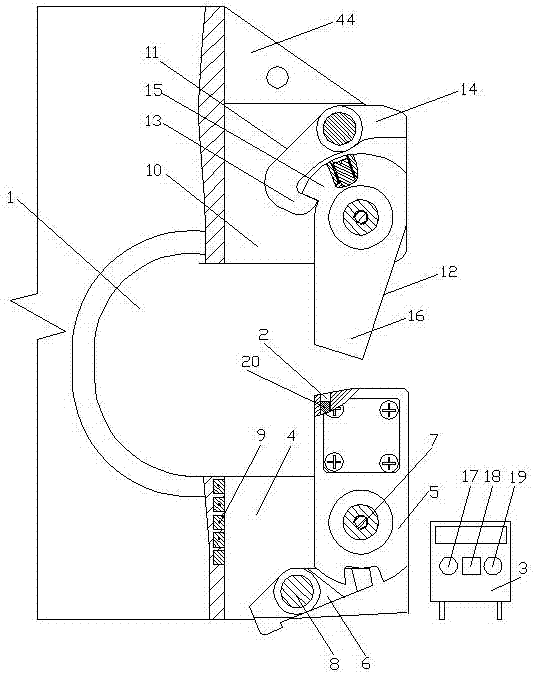

Pulley rotating flexibility detection device and detection method using same

ActiveCN103134668AAccurate valueImprove detection accuracyMachine part testingTension measurementElectrical and Electronics engineeringPulley

The invention discloses a pulley rotating flexibility detection device and a method for detecting pulley rotating flexibility by using the pulley rotating flexibility detection device. The pulley rotating flexibility detection device comprises a base, transmission wheels, ropes, a tension detector and a power mechanism. The transmission wheels are movably connected with the base through a first rotating shaft. The ropes are sleeved on pulleys to be detected and the transmission wheels. The tension detector is fixedly connected with the ropes and is used for detecting tension values borne by the rope moving in the direction close to the pulleys to be detected and the rope moving in the direction far away from the pulleys to be detected. The power mechanism is connected with one of the transmission wheels or one of the pulleys to be detected and is used for driving the transmission wheels or the pulleys to be detected connected with the power mechanism to rotate and driving a pulley to be detected or the transmission wheels not connected with the power mechanism to rotate by aid of the rotating transmission wheels or the pulleys to be detected and the ropes. The pulley rotating flexibility detection device and the method for detecting pulley rotating flexibility by using the pulley rotating flexibility detection device solve the technical problems in the prior art that the pulley flexibility detection accuracy is low and pulleys with different flexibilities are difficult to be quantitatively distinguished.

Owner:XCMG CONSTR MACHINERY

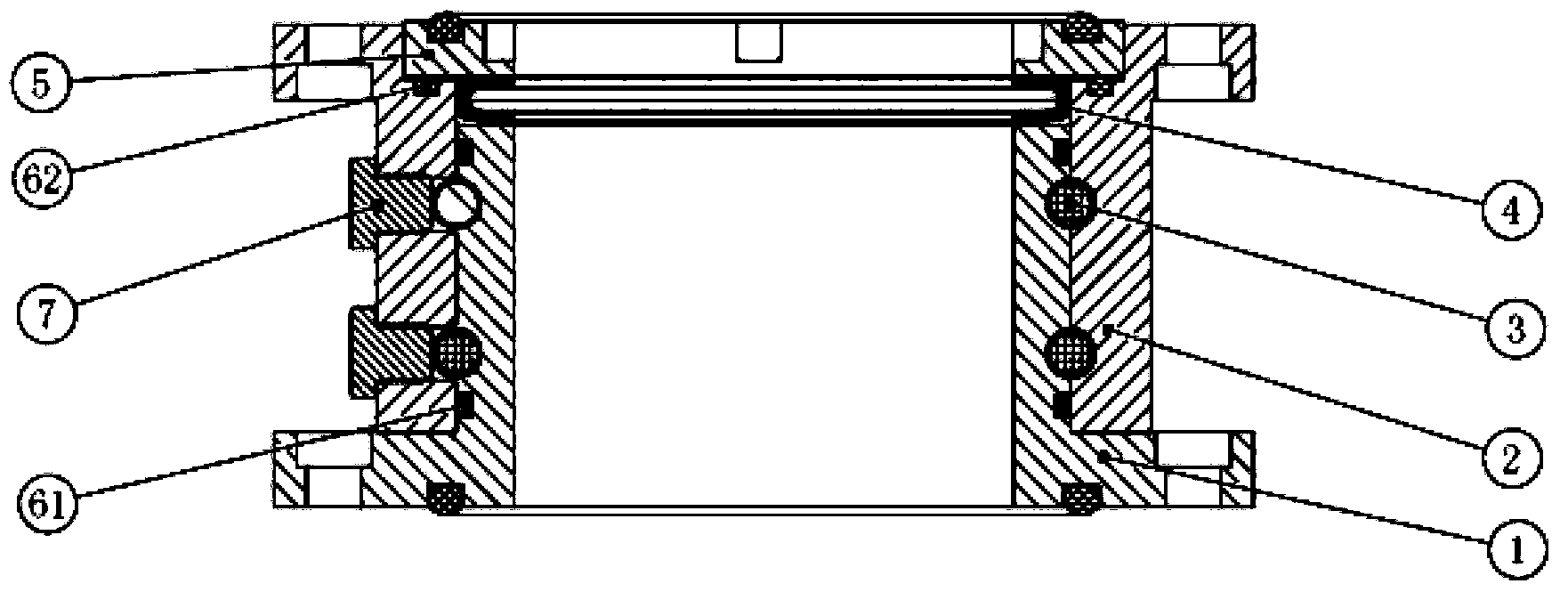

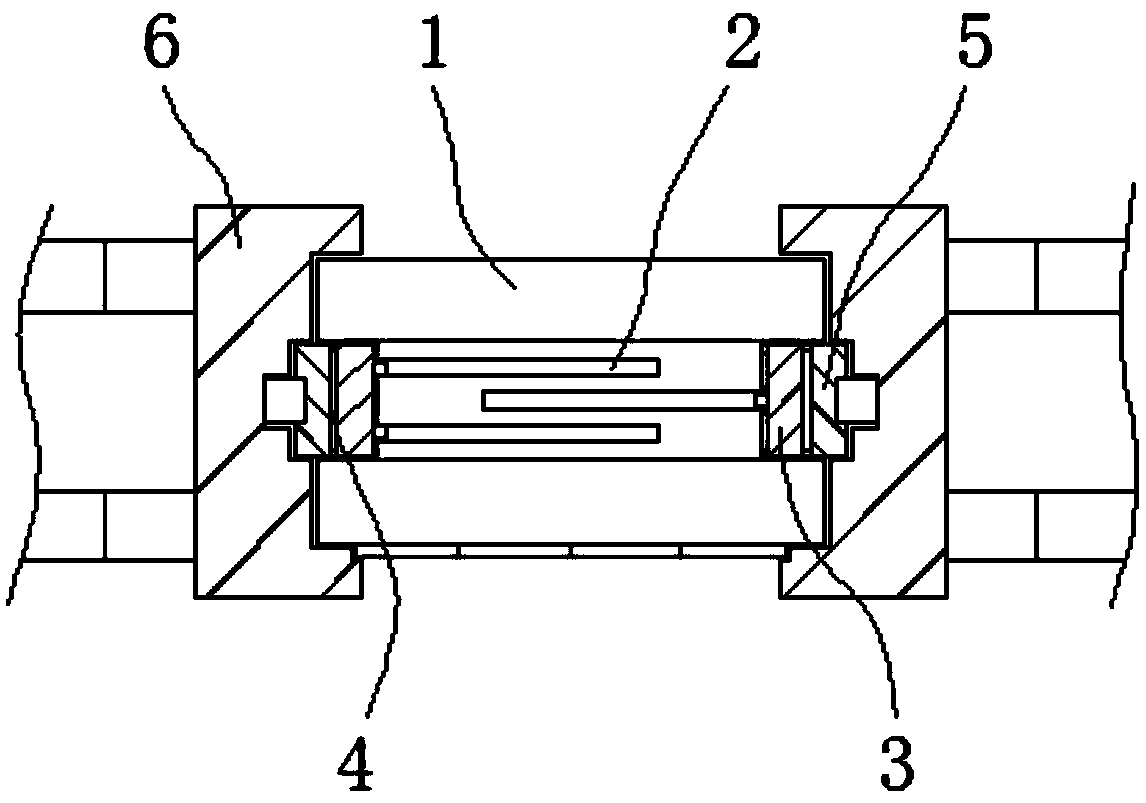

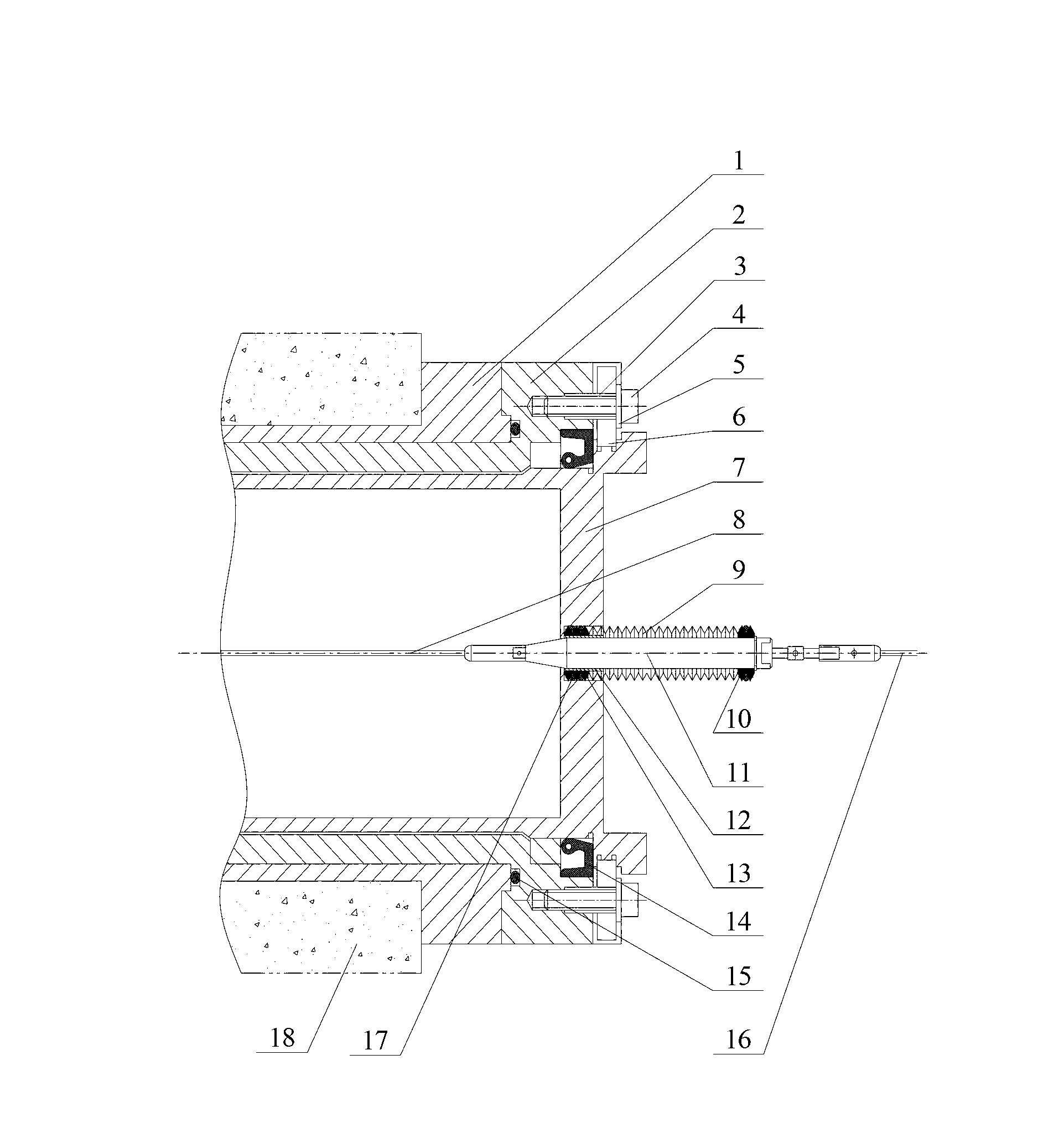

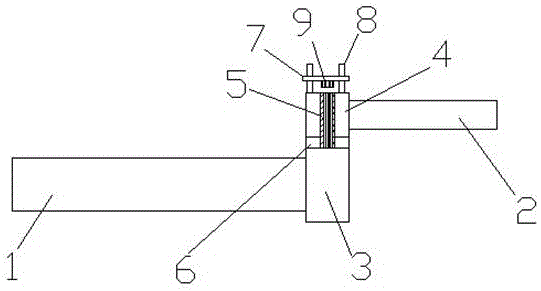

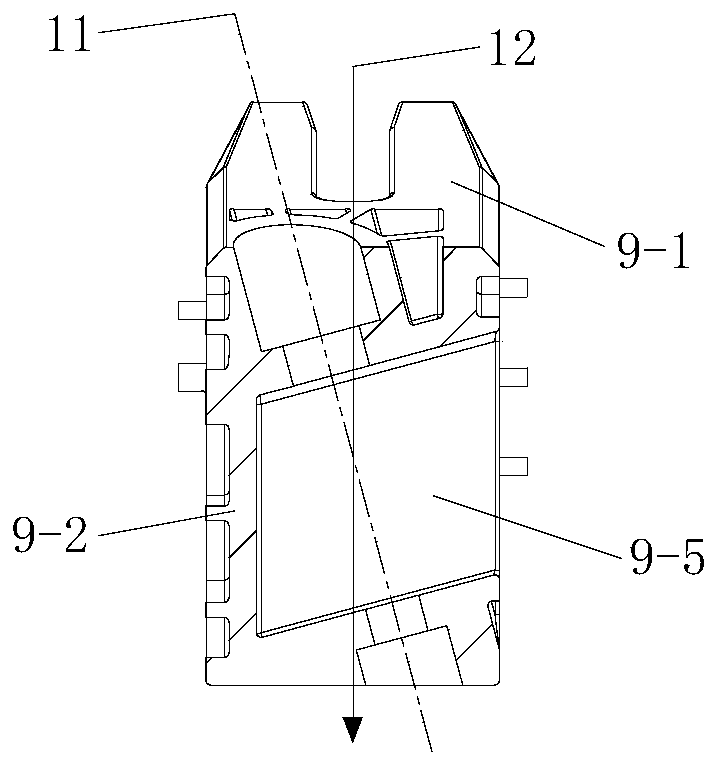

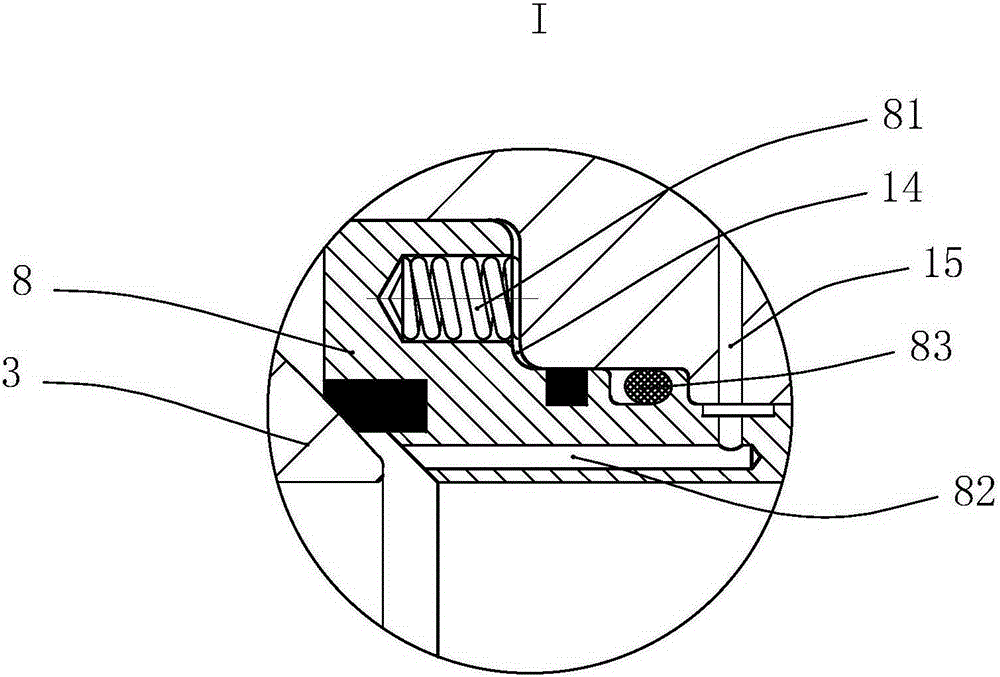

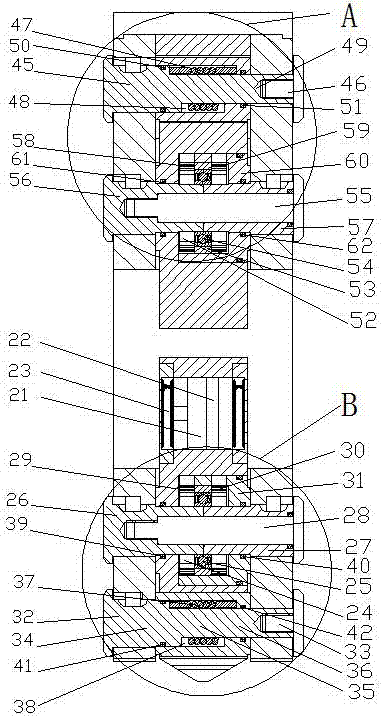

Bidirectional fully-sealed rotary joint for fluid conveying

InactiveCN103438308AImprove rotational flexibilityImprove sealingAdjustable jointsLubricationRotational axis

The invention discloses a bidirectional fully-sealed rotary joint for fluid conveying. The bidirectional fully-sealed rotary joint comprises a rotary shaft, a shell, balls in bulk, a primary seal, a compression ring, auxiliary seals and a set screw, wherein a groove is arranged in the outer circumference of the rotary shaft, one auxiliary seal is arranged in the groove, the rotary shaft and the shell are mounted concentrically, a roller way is arranged between the shell and the rotary shaft, the balls are mounted in the roller way, and the balls can be mounted and dismounted through a threaded hole and the set screw arranged on the roller way of the shell; the compression ring is arranged on the end surface of the upper part of the rotary shaft, the primary seal is arranged between the compression ring and the end surface of the upper part of the rotary shaft, and the primary seal is compressed by the primary seal; a groove is arranged in the end surface between the compression ring and the shell, and the other auxiliary seal is mounted in the groove. Therefore, the rotary joint provided by the invention has the characteristics that the structure is compact, the sealing performance is good, the service life is long, no lubrication is needed, the rotation is flexible and the like.

Owner:PLA AIR FORCE OIL MATERIAL RES INST

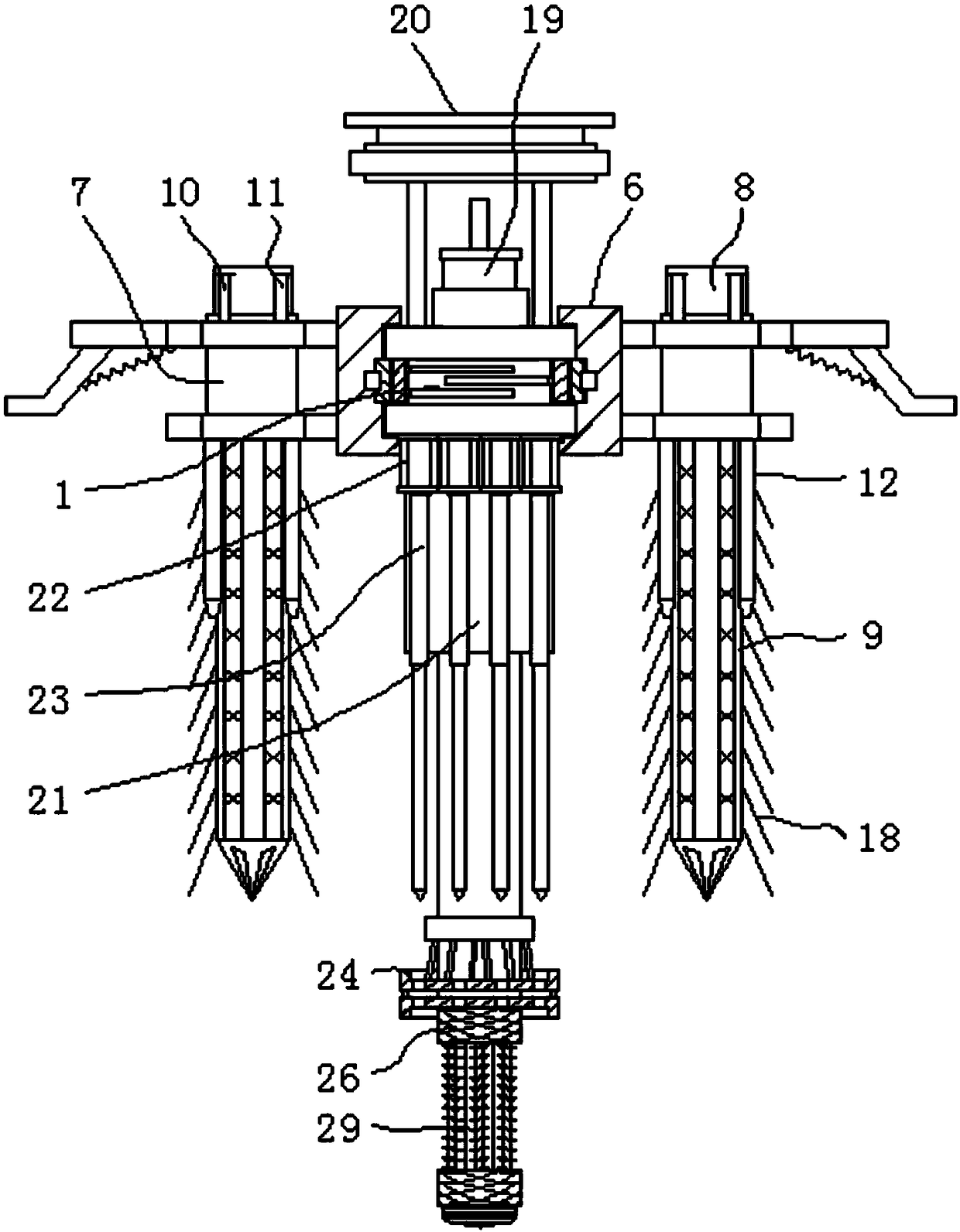

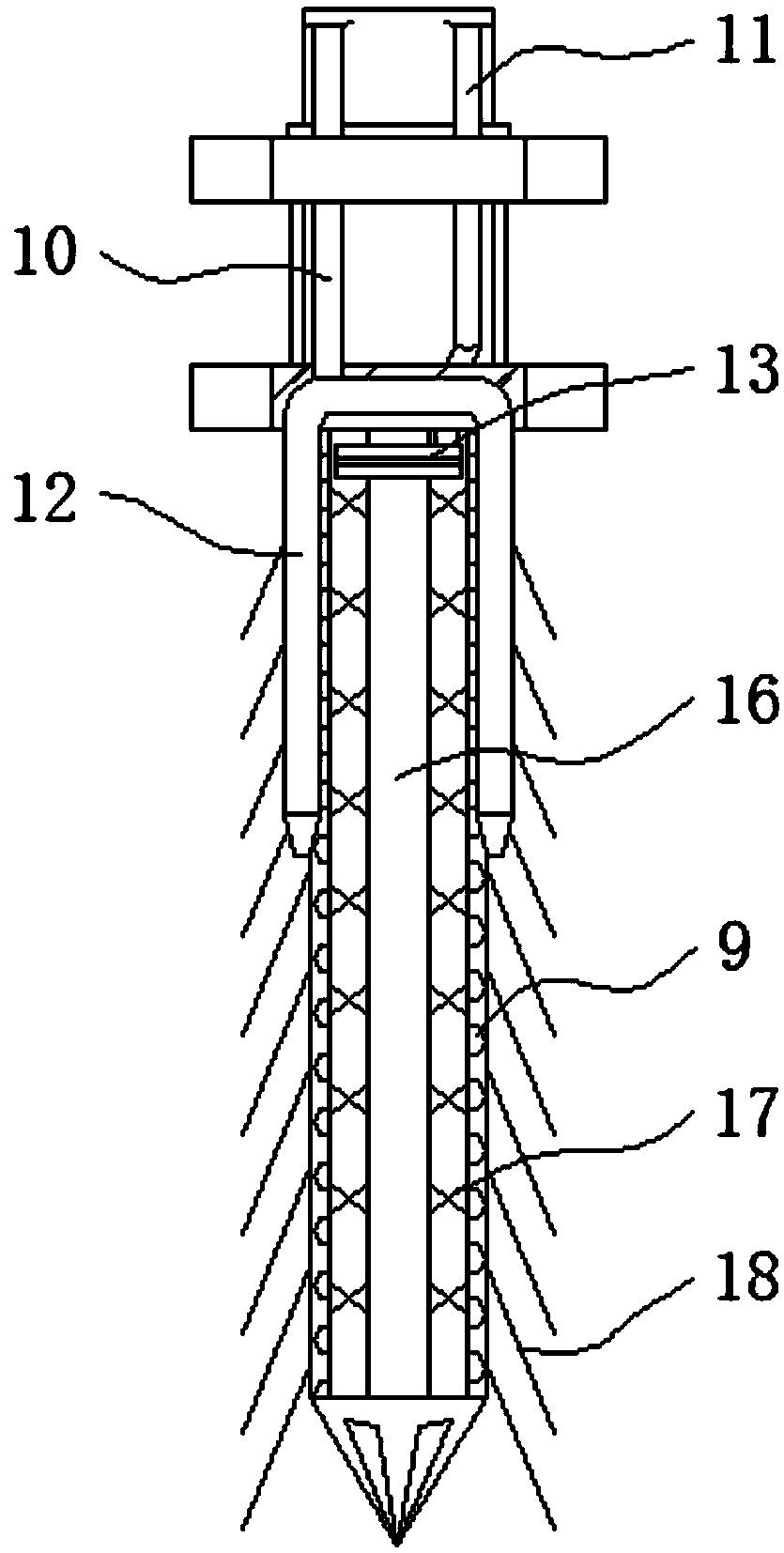

Anchor drilling machine provided with protection function and used for oil drilling

InactiveCN109322684AImprove rotational flexibilityGuaranteed rotational flexibilityEarth drilling toolsConstructionsHydraulic cylinderOil drilling

The invention discloses an anchor drilling machine provided with a protection function and used for oil drilling. The anchor drilling machine provided with the protection function and used for oil drilling comprises an installation top seat, auxiliary drilling rods and a main drilling rod. A sliding groove is formed in the surface of the installation top seat, an inner sliding ring is arranged onthe outer side of the middle of the installation top seat, a control motor seat is arranged at the upper end of the auxiliary drilling rod, the auxiliary drilling rods are separately positioned on theleft and right sides of a collar plate, a hydraulic cylinder is arranged above the outer side of the main drilling rod, and the main drilling rod is positioned below the collar plate. According to the anchor drilling machine provided with the protection function and used for oil drilling, the sizes of the collar plate and an outer sliding ring are matched with each other, the outer sliding ring is arranged on the outer side of the mounting top seat in a clamped mode and is attached to a cushion layer on the outer wall of the inner sliding ring, and the size of the inner sliding ring is matched with the size of the sliding groove on the installation top seat, namely, the inner sliding ring has rotating capability on the installation top seat, the outer sliding ring has rotating capabilityon the cushion layer, and the collar plate has rotating capability on the outer sliding ring, so that the collar plate has very high rotating flexibility in a layer-by-layer nesting mode.

Owner:魏武康

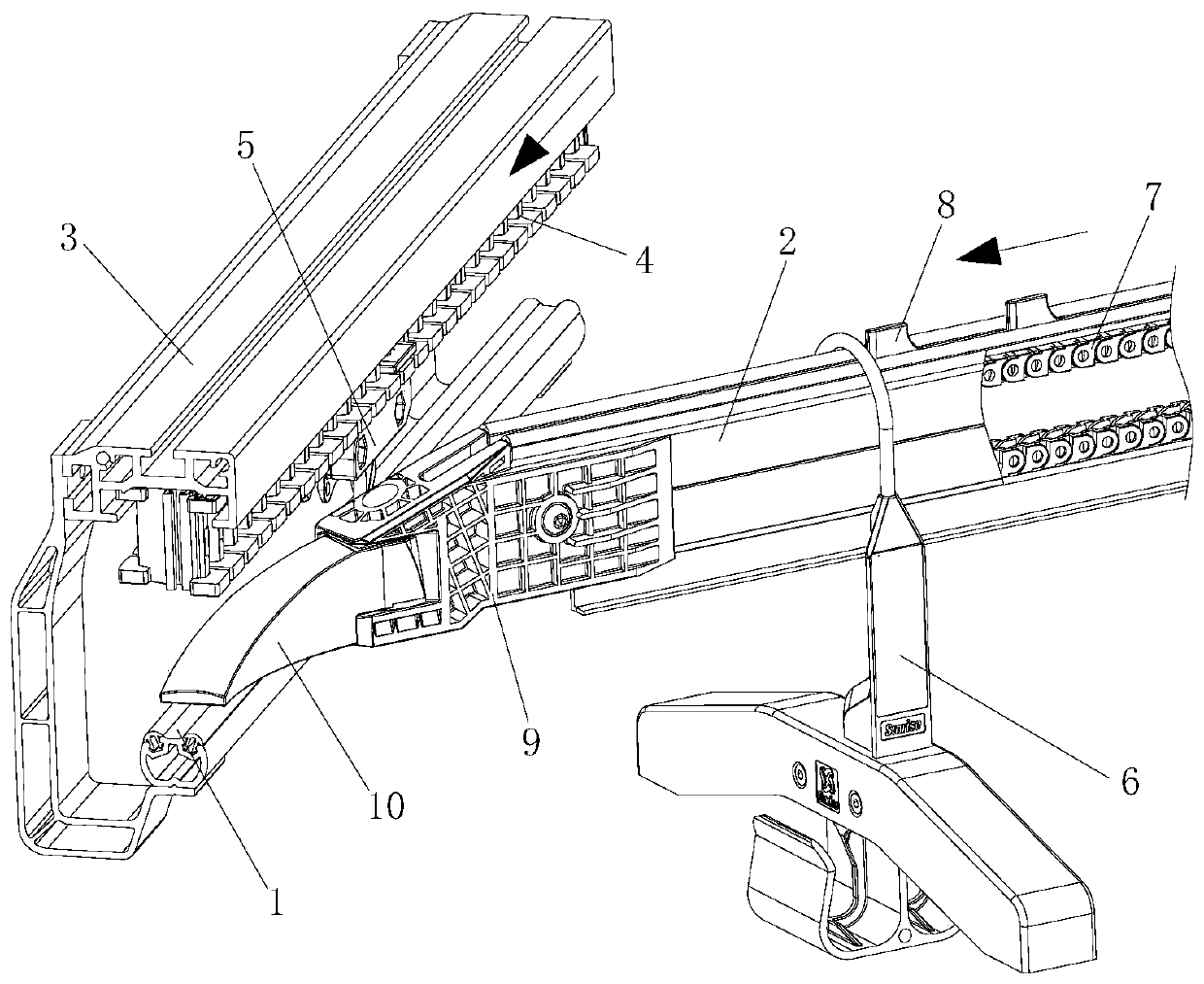

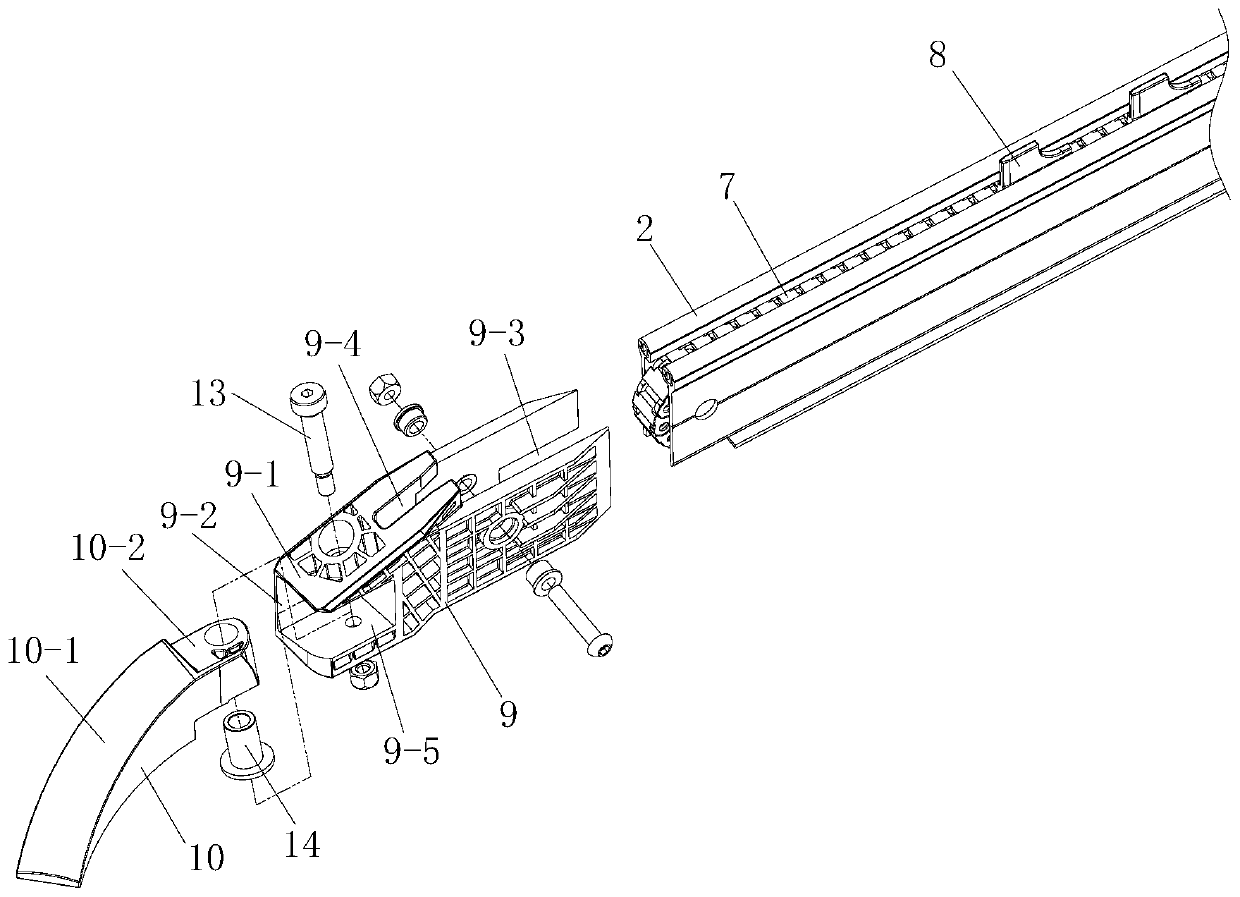

Lifting appliance for automobile tail gate

The invention relates to a lifting appliance and in particular relates to a lifting appliance for an automobile tail gate, belonging to the technical field of an automobile production line. The lifting appliance for the automobile tail gate comprises a connecting rod assembly, a bearing hanging bracket, a rotating shaft assembly, a rotating hanging bracket and a loading gate main body, wherein the lower end of the connecting rod assembly is connected with the bearing hanging bracket, the lower end of the bearing hanging bracket is connected with the rotating hanging bracket by the rotating shaft assembly, the rotating hanging bracket can rotate around the center of the rotating shaft assembly due to the rotating shaft assembly, a stud is arranged on the rotating hanging bracket, and the lower end of the stud is connected with the loading door main body by a knuckle bearing. The lifting appliance has a simple, compact and reasonable structure, the manufacture cost is low, the lifting appliance can rotate flexibly, has the high safety and can be maintained conveniently, the automobile tail gate can be loaded stably, the operation is convenient, and the tail gate can be well protected in a transportation process.

Owner:MIRACLE AUTOMATION ENG CO LTD

Top toy device capable of being accelerated

The invention discloses a top toy device capable of being accelerated. The top toy device comprises a top toy and a remote control device and is characterized in that the top toy comprises a rotating body and a top body, a motor is arranged in the middle of the top body, a rotating shaft of the motor is located on the central axis of the top body and extends upwards to be connected with the rotating body so that the motor can drive the rotating body to rotate, the rotating body rotates to exert reactive force on the top body to make the top body rotate reversely, and then the whole top toy is driven to rotate. The top toy is simple in structure and low in cost, the gravity is stable and centralized, rotation is more stable and longer, the remote control device is designed in the mode that the motor of the top toy is controlled to act through a vibration control part, when played, the top toy can be controlled just by shaking the remote control device, the control mode is more novel and advanced, the top toy device can be popular with children better, the problem that the top toy can not be controlled in the fighting process is solved, and the interactivity and the interestingness of the top toy in the playing process are effectively improved.

Owner:ALPHA GRP CO LTD +2

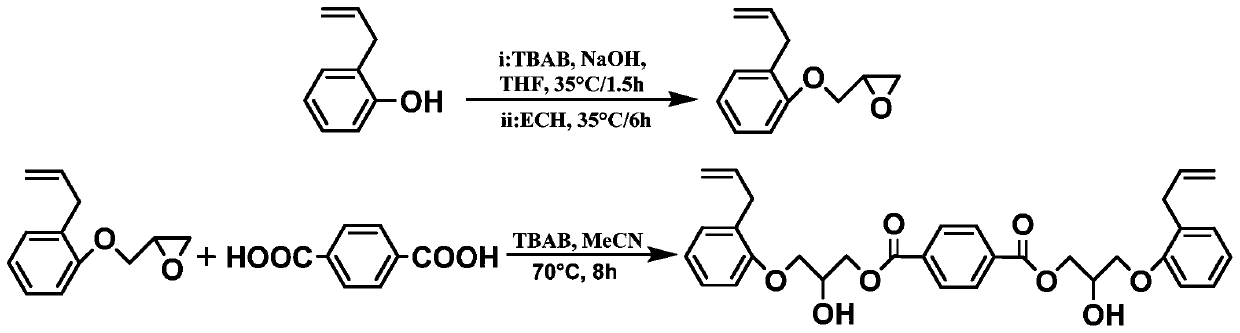

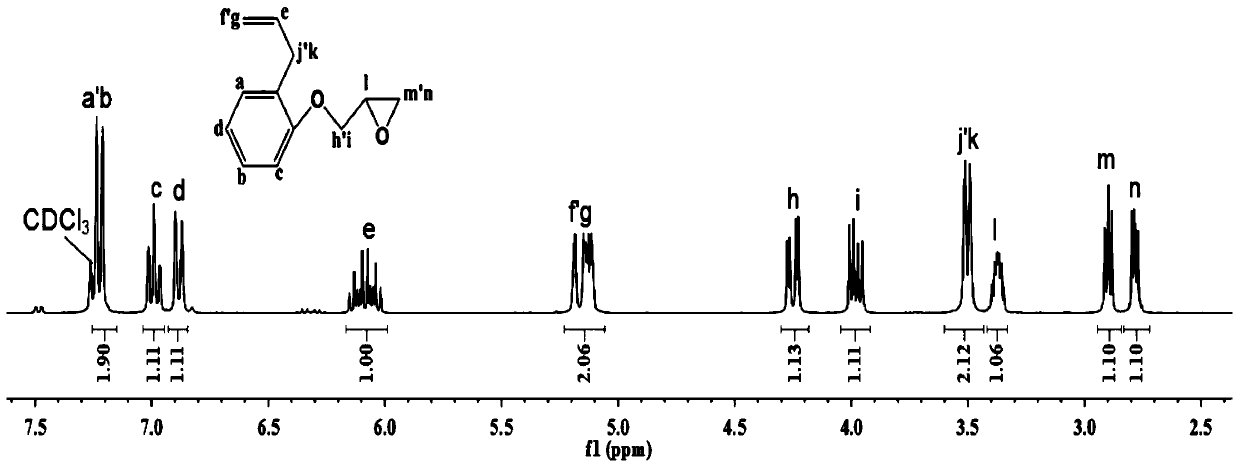

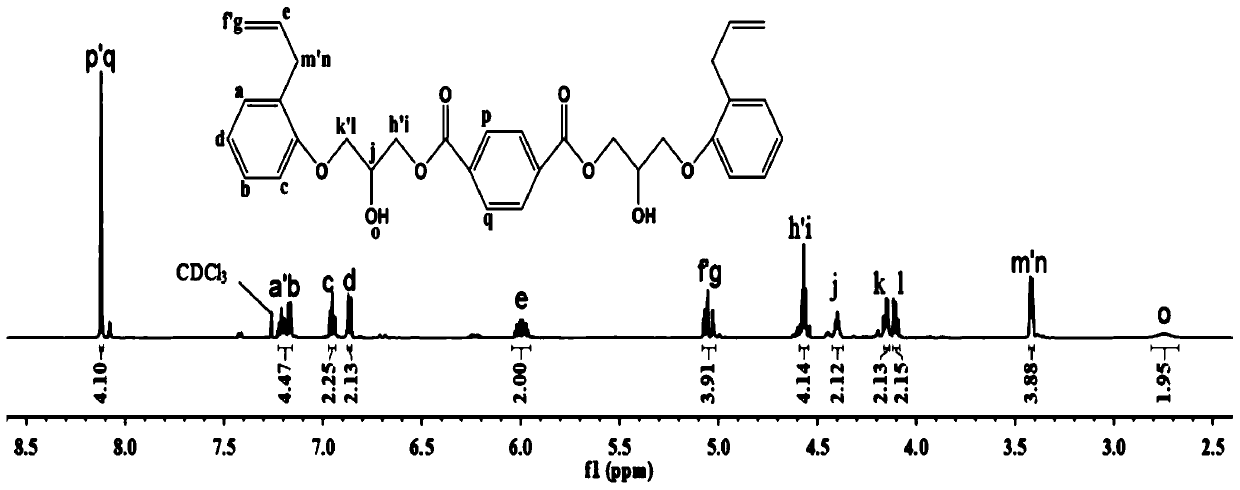

Remoldable bismaleimide resin and application thereof

The invention discloses a remoldable bismaleimide resin and an application thereof. The remoldable bismaleimide resin is prepared by the following steps: blending 2-allylphenyl glycidyl ether with terephthalic acid in acetonitrile, carrying out an esterification reaction with a quaternary ammonium salt as a catalyst to obtain a bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate containing a reversible dynamic group; and uniformly mixing the bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate with bismaleimide, and curing the obtained mixture to obtain the remoldable bismaleimide resin. Theremoldable bismaleimide resin prepared in the present invention has excellent heat resistance and excellent mechanical properties, and can be remolded under a hot pressing condition. The preparation method of the remoldable bismaleimide resin has the characteristics of wide sources of raw materials, and simple process, and the has remoldable bismaleimide resin broad application prospects in industrial fields of aerospace, transportation, electronic information, new energy and insulated electrics.

Owner:SUZHOU UNIV

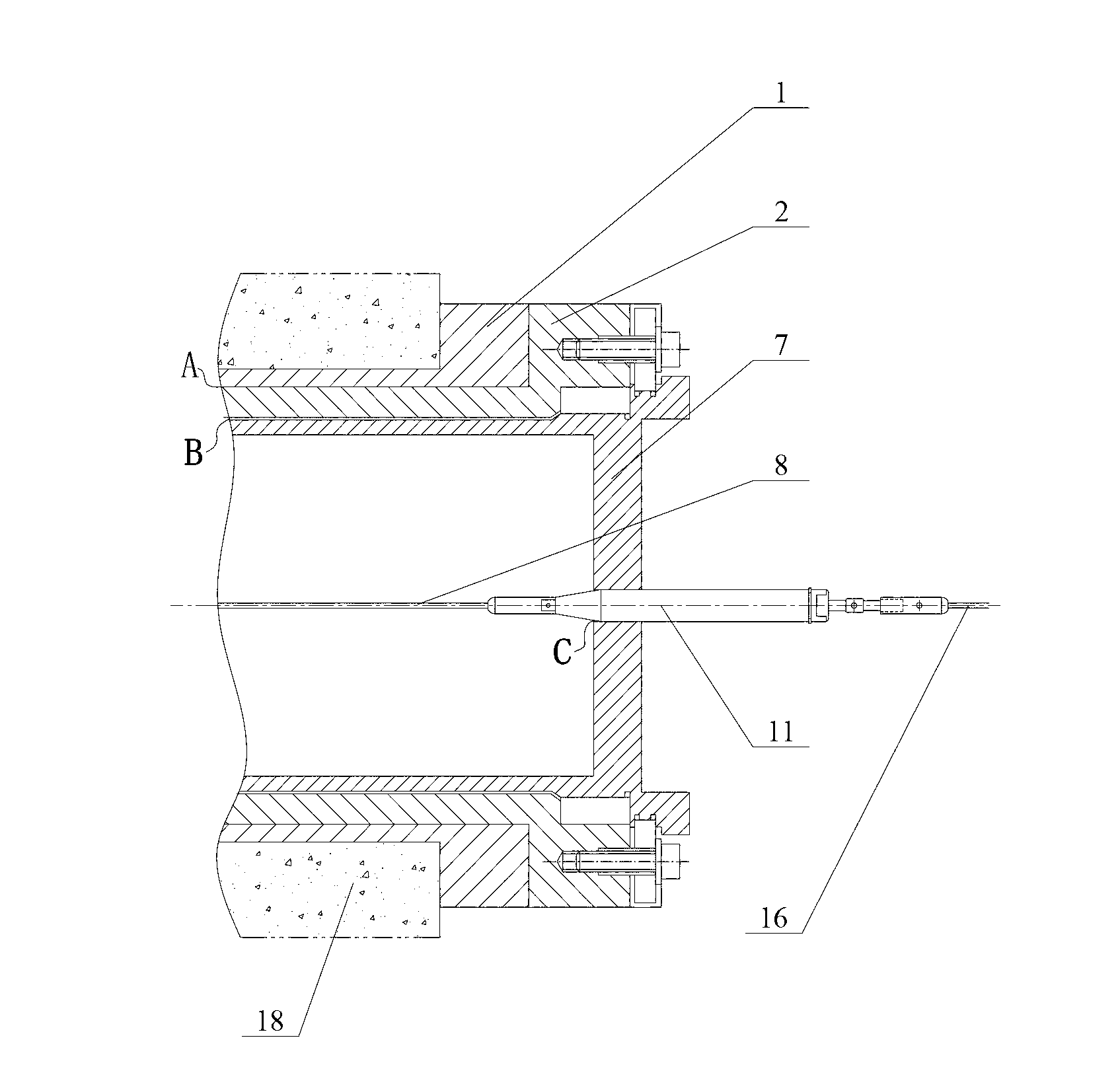

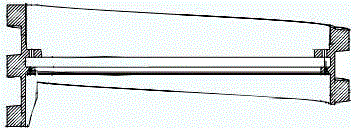

Sealed steel wire rope drive system

The invention discloses a sealed steel wire rope drive system. The system comprises a wall penetrating pipe assembly and a steel wire rope assembly, wherein the wall penetrating pipe assembly penetrates through a wall body; the steel wire rope assembly penetrates through the wall penetrating pipe assembly, and comprises an indoor steel wire rope (8), an outdoor steel wire rope (16) and a connecting shaft (11); the indoor steel wire rope (8) is connected and fixed to a first end of the connecting shaft (11); the outdoor steel wire rope (16) is connected and fixed to a second end of the connecting shaft (11); a corrugated pipe (9) is sleeved on the connecting shaft (11); a first end of the corrugated pipe (9) is fixed on the wall penetrating pipe assembly in a sealed mode; and a second end of the corrugated pipe (9) is fixed on a second end of the connecting shaft (11) in a sealed mode. According to the invention, during the process of axial moving of the connecting shaft, the corrugated pipe stretches along with the moving of the connecting shaft, so that the problem that radioactive harmful gases such as Alpha aerosols leak through a clearance between the connecting shaft and the wall penetrating pipe assembly is solved, and the safety of operators is ensured.

Owner:CHINA NUCLEAR POWER ENG CO LTD

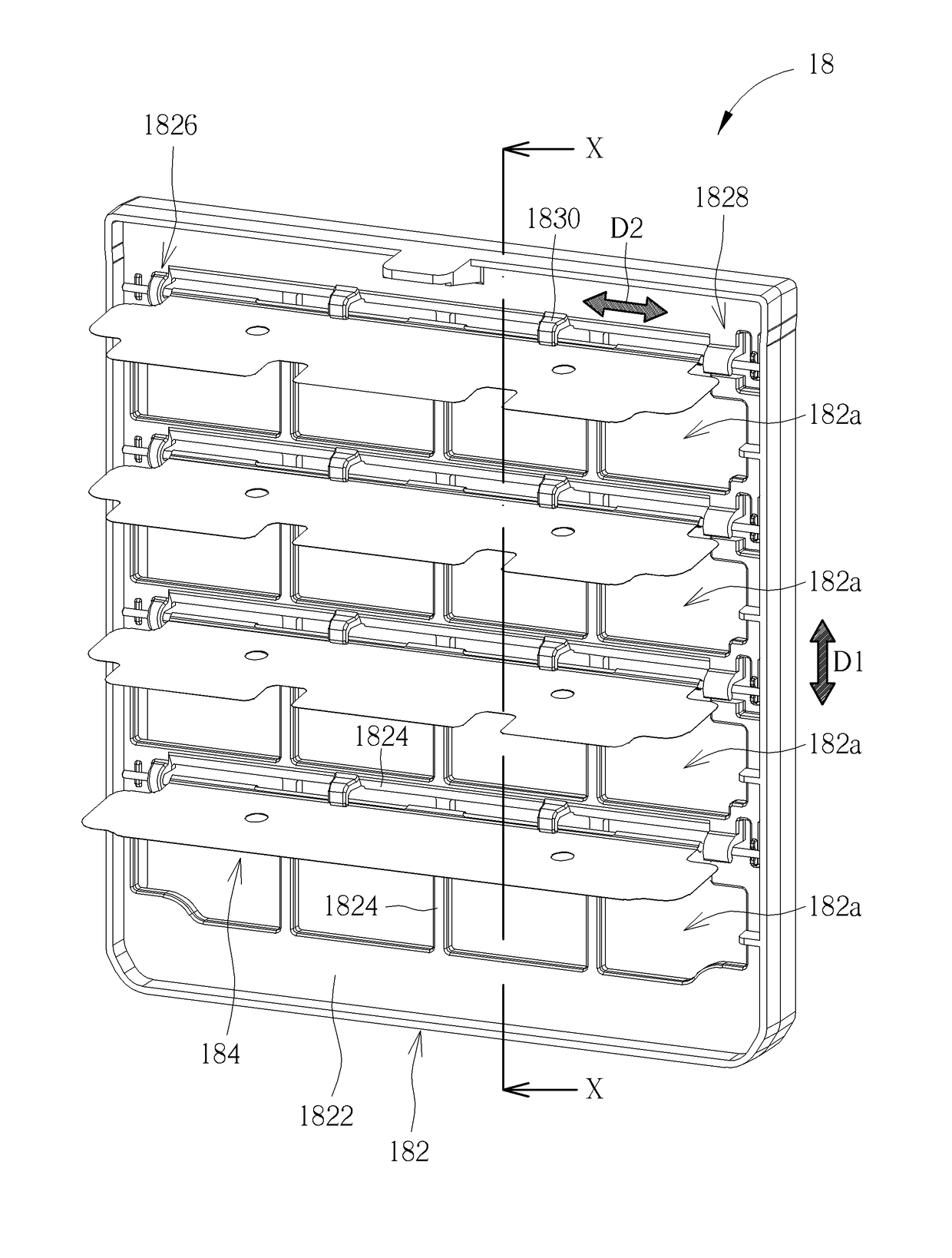

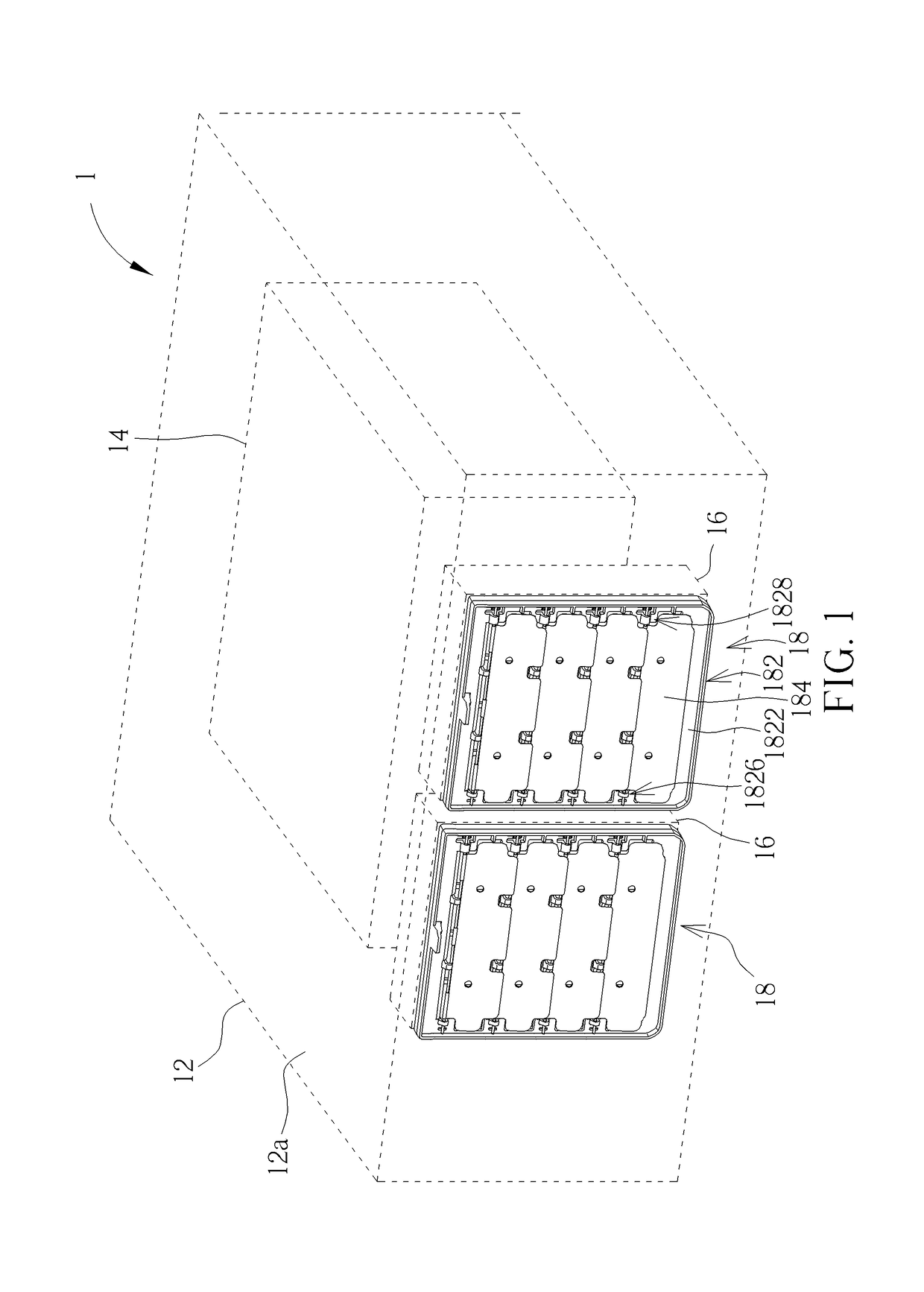

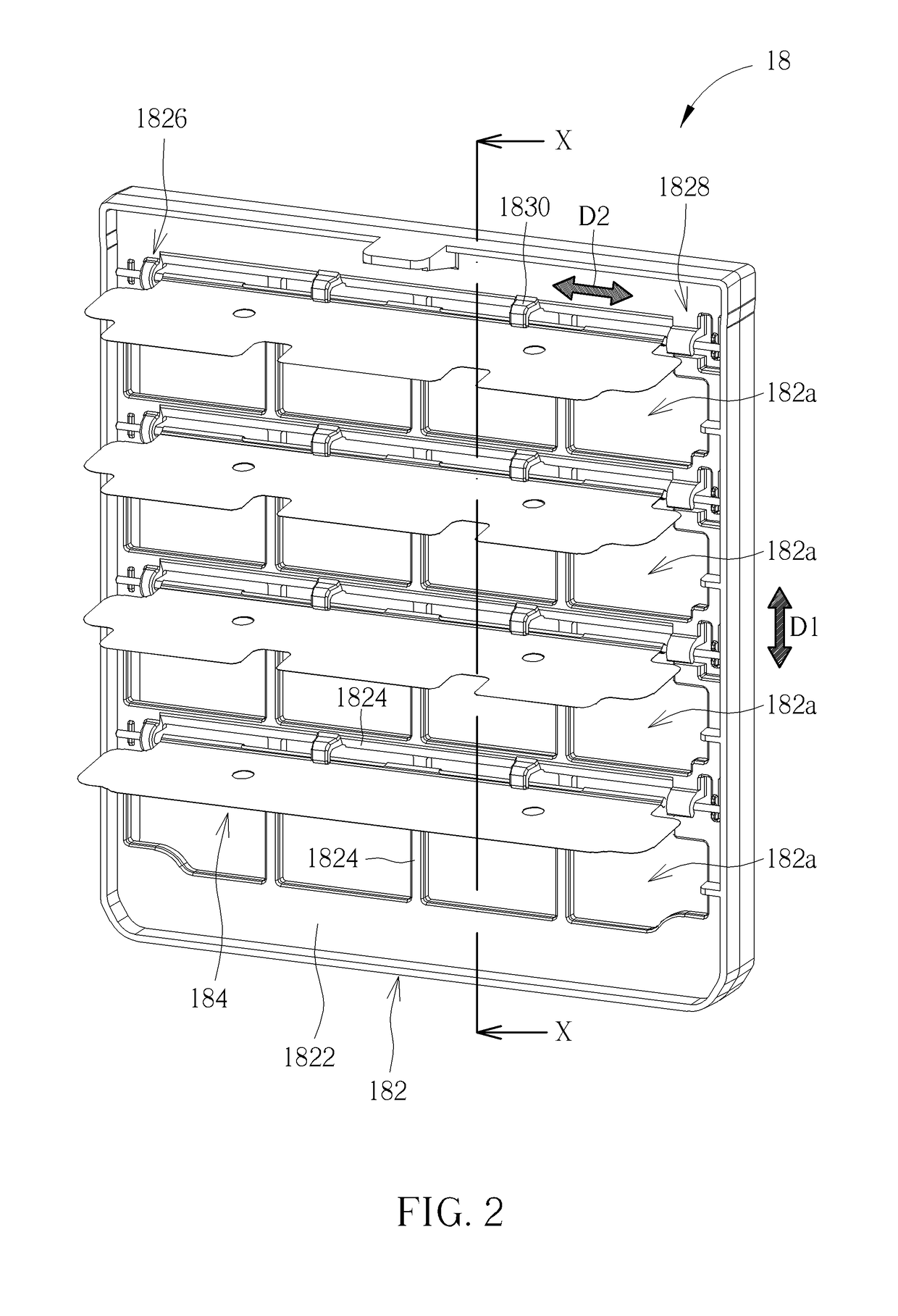

Vent structure and electronic apparatus therewith

ActiveUS9888610B2Improve rotational flexibilityReduce noiseLighting and heating apparatusAir-flow control membersWindow shutterEngineering

An electronic apparatus includes a casing, a vent structure on the casing, and an electronic device inside the casing. The vent structure is used for a unidirectional flow and includes a frame and a louver. The louver includes a sheet body and a shaft. The sheet body includes a bent portion, a first and a second portion which oppositely extend from the bent portion and bind together. The shaft passes through a through hole formed by the bent portion and is connected to the frame, so that the sheet body is rotatable. When the louver is located at a closed position, the sheet body covers at least a portion of an opening structure of the frame. The louver is structurally simple and can be made of light material, which is conducive to improving the rotation agility of the louver and reducing the noise probably produced when in operation.

Owner:WISTRON CORP

Method for quantitative measuring height of inclined flange for cylinder roller bearing ring

InactiveCN1743787ANot easy to wearImprove rotational flexibilityMachine bearings testingMechanical measuring arrangementsEngineeringSteel ball

This invention discloses a method for quantitative measuring the inclined stop edge height of cylindrical roller bearing ring, which contains selecting standard measuring steel ball, calculating the standard block size used for measuring stop edge, comparing said standard block with the height of stop edge to make quantitative measurement for cylindrical roller bearing ring.

Owner:LUOYANG BEARING GROUP

Thermoplastic polymer material equipment

InactiveCN109015879ASimple and convenient clamping workImprove work efficiencyMetal working apparatusEngineeringPneumatic cylinder

The invention discloses thermoplastic polymer material equipment. The equipment comprises a bottom frame and supports fixedly arranged on the left and right sides of the bottom frame in a bilaterallysymmetric manner; a turning disk is mounted between the supports on the left and right sides in a running fit manner; a manufacturing frame is fixedly arranged on the end surface of the bottom of theturning disk; pneumatic cavities are bilaterally symmetrically formed in the manufacturing frame; ejecting push plates are mounted inside the pneumatic cavities in a sliding fit manner; adjusting frames are fixedly arranged on the end surfaces of the sides, opposite to each other, of the ejecting push plates on the left and right sides; the adjusting frames extend out of the outer side end of themanufacturing frame and are connected with the manufacturing frame in a sliding fit manner; pneumatic holes are formed in the top walls of the pneumatic cavities in a communicating manner; the pneumatic holes in the left and right sides are connected with a pneumatic cylinder; the pneumatic cylinder is fixedly arranged inside the manufacturing frame; first penetrating openings are formed in an up-and-down penetrating manner in the adjusting frames extending out of the outer side end of the manufacturing frame; and spline shafts are mounted inside the first penetrating openings in a clearance fit manner.

Owner:福建泉州远方致远自动化科技有限公司

Industrial cantilever with high stability

The invention discloses an industrial cantilever with high stability. The industrial cantilever comprises a first tube arm and a second tube arm, the second tube arm is located above the first tube arm, a first connector is arranged at the end of the first tube arm, and a second connector corresponding to the first connector is arranged at the end of the second tube arm; and the first connector is provided with an internal spline extending into the second connector, the second connector is provided with two guide columns extending upwards, a sliding plate is arranged on the two guide columns, and an external spline facing the internal spline is arranged at the bottom of the sliding plate. By means of the above manner, according to the industrial cantilever with the high stability, the internal spline is arranged between the first tube arm and the second tube arm for rotation connection, the rotation flexibility is high, after rotation adjustment is carried out, the external spline falls to be fixedly combined with the internal spline, swing between the first tube arm and the second tube arm is avoided, and the using stability is promoted.

Owner:TAICANG WANG YU MACHINERY TECH CO LTD

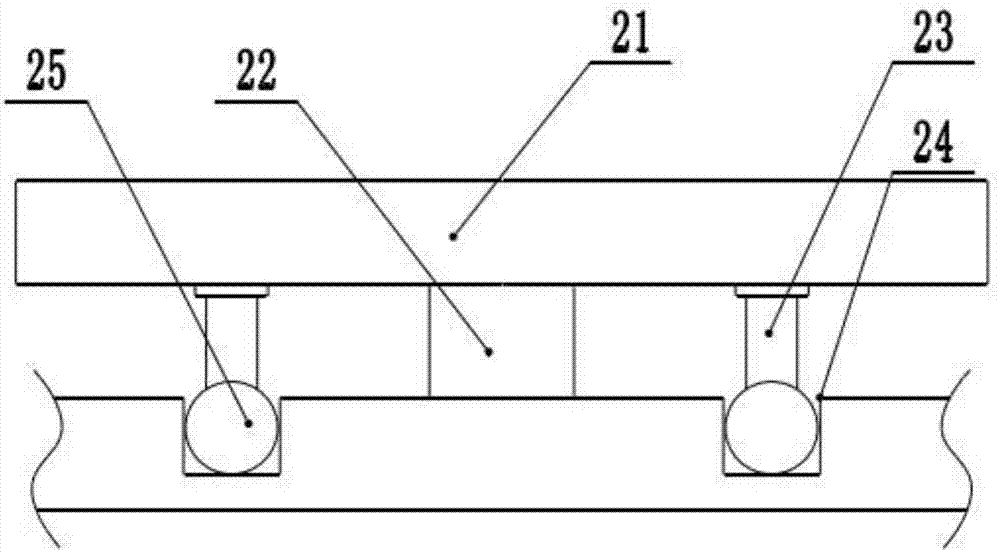

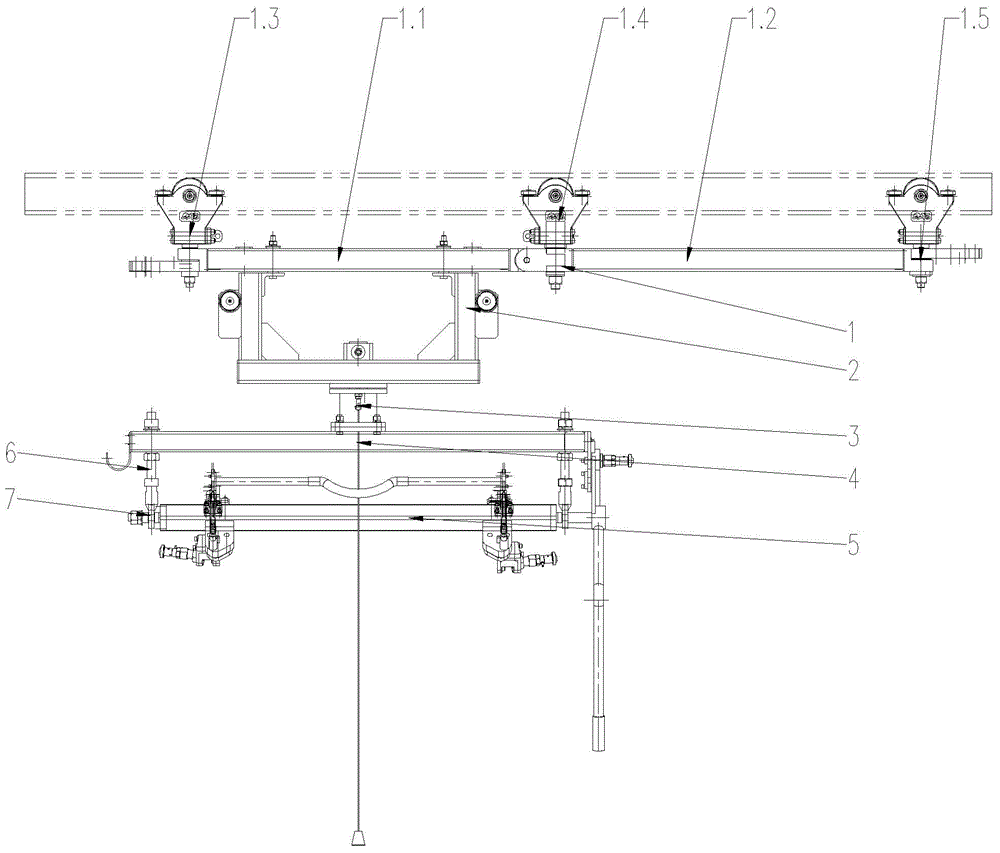

Conveyor line flow-combination mechanism

PendingCN109911515ATo achieve the purpose of automatic resetReduce settingsConveyorsConveyor partsAssembly lineEngineering

The invention provides a conveyor line flow-combination mechanism which is used for connecting rails. The rails comprise a main rail and a branch rail; the conveyor line flow-combination mechanism isarranged on the branch rail and comprises a fixed seat and a swinging head; one end of the fixed seat is connected with the branch rail; the swinging head can be rotatably arranged at the other end ofthe fixed seat; the free end of the swinging head is located above the main rail; the swinging head can be pushed away from the upper part of the main rail through an acting force along the main railrunning direction; the conveyor line flow-combination mechanism further comprises a swinging head resetting mechanism; and after the acting force along the main rail running direction is disappeared,the swinging head is reset under the action of the swinging head resetting mechanism. The conveyor line flow-combination mechanism provided by the invention not only can be applied to a roller clothes hanger hanging assembly line but also can be applied to a pothook carrier assembly line.

Owner:沈阳瑞晟智能装备有限公司 +1

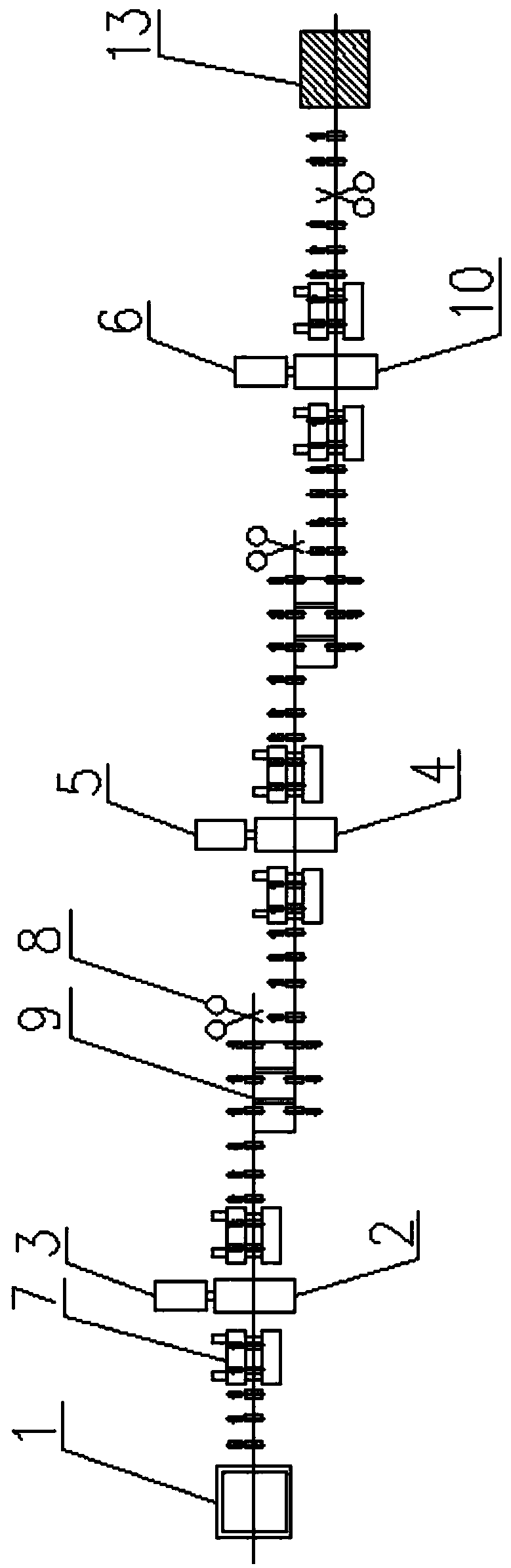

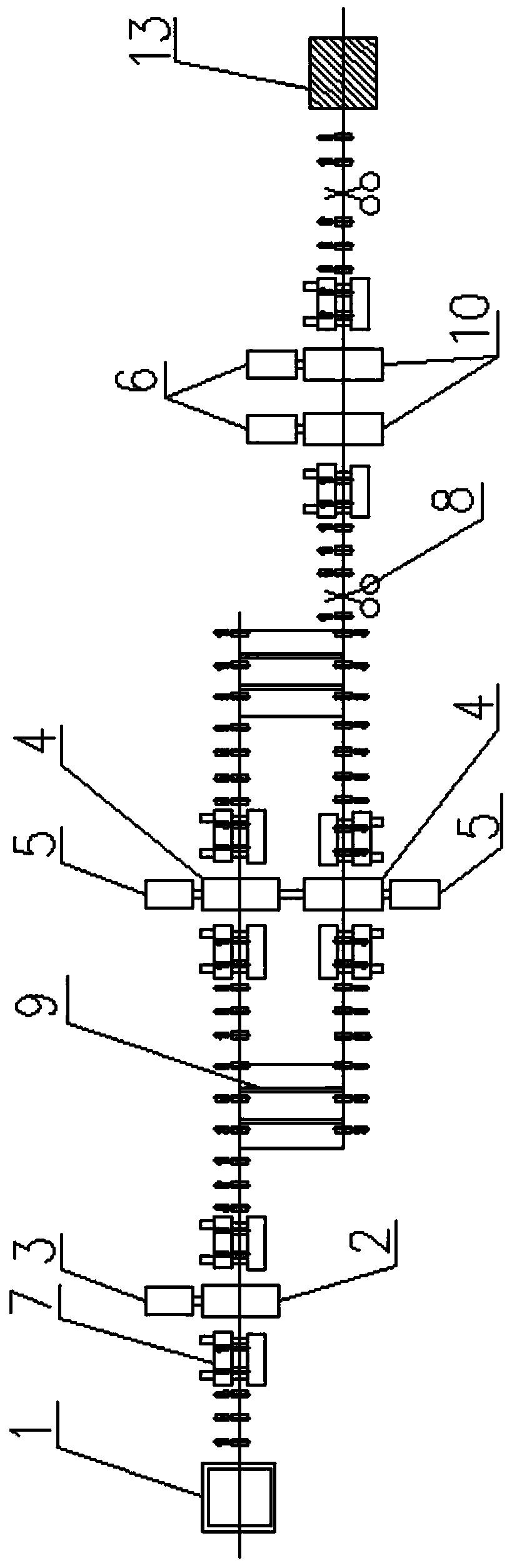

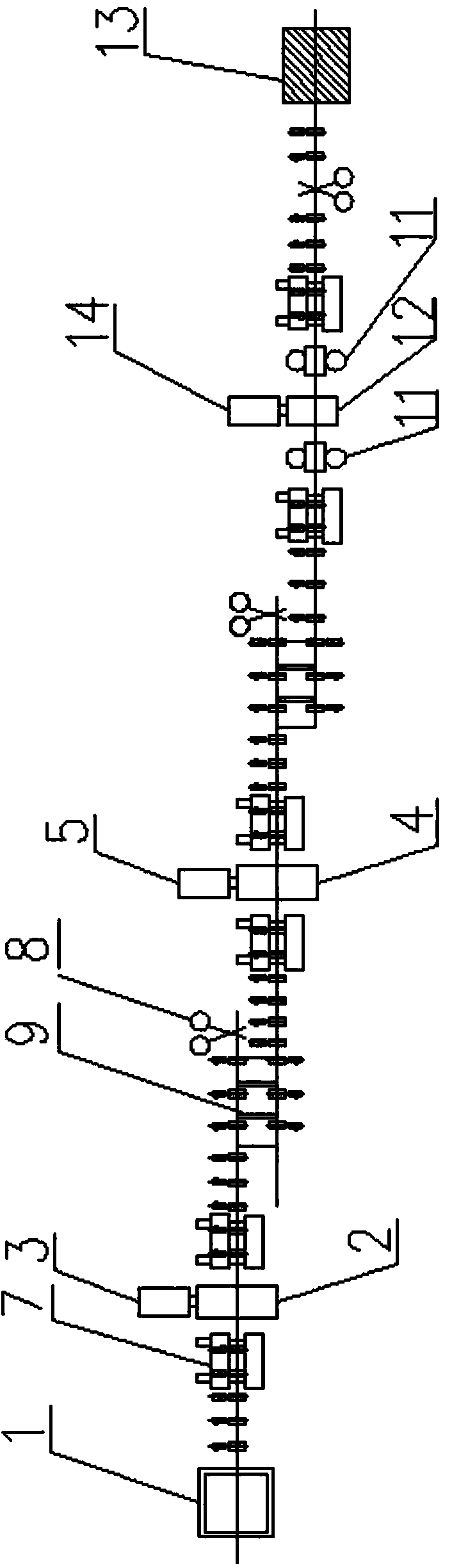

Profile steel rolling production line and production method thereof

ActiveCN103433276AReduce in quantityShorten the lengthMetal rolling arrangementsProduction lineMaterials science

The invention relates to a profile steel rolling production line and a production method thereof. The profile steel rolling production line comprises a heating unit, a rough rolling unit, a medium rolling unit, a fine rolling unit and a finishing unit, wherein each of the rough rolling unit and the medium rolling unit comprises a rolling mill and a driving device for driving the rolling mill to move along the axial direction of a rolling roller; the rolling rollers of the rolling mills are provided with rolling grooves with different groove holes; the fine rolling unit comprises a two-roller rolling mill or the fine rolling unit comprises a four-roller universal rolling mill, a two-roller edging mill and a four-roller universal rolling mill which are arranged in sequence; the two-roller rolling mill and the two-roller edging mill are provided with driving devices which move along the axial direction of rolling rollers I; the rolling rollers I are further provided with rolling grooves I with different groove holes. After a rolling piece is heated and is sequentially rolled by the upper and lower different rolling grooves through the corresponding rolling rollers on the rough rolling unit, the rolling piece enters the medium rolling unit to be sequentially rolled by the upper and lower different rolling grooves through the corresponding rolling rollers; finally, the rolling piece enters the fine rolling unit to be rolled to form a finished-product sectional material. According to the profile steel rolling production line and the production method thereof, the quantity of the rolling mills is reduced, the weight of a conveying roller bed is reduced, the production line is simplified and the production efficiency is improved.

Owner:CISDI ENG CO LTD

Spherical metal shell assembling method and detection tool special for implementing same

ActiveCN104128718AAvoid lostSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMetal

The invention relates to a spherical metal shell assembling method and a detection tool special for implementing the same. The spherical metal shell assembling method includes 1) feeding to obtain a spherical-crown shell and groups of spherical bend plates, and assembling each group of spherical bend plates end to end to surround one layer of spherical rings; 2) arranging the spherical-crown shell on a support pipe column and detecting the spherical-crown shell by the detection tool to enable the upper edges of the spherical-crown shell to be on the same plane and fixed; 3) sequentially arranging the spherical bend plates in the first group corresponding to the first layer of spherical rings at the corresponding positions arranged at the upper edges of the spherical-crown shell, detecting, adjusting and fixing by the detection tool, and finally, enabling the upper edges of the spherical bend plates to be on the same circumference line; 4) adjusting angle of a detection arm, sequentially assembling until a spherical shell not larger than a hemisphere is assembled. By detecting and adjusting while fixing and assembling, the detection tool is simple in structure and convenient to operate, roundness of the sphere and assembly accuracy and quality are guaranteed.

Owner:STATE GRID CORP OF CHINA +1

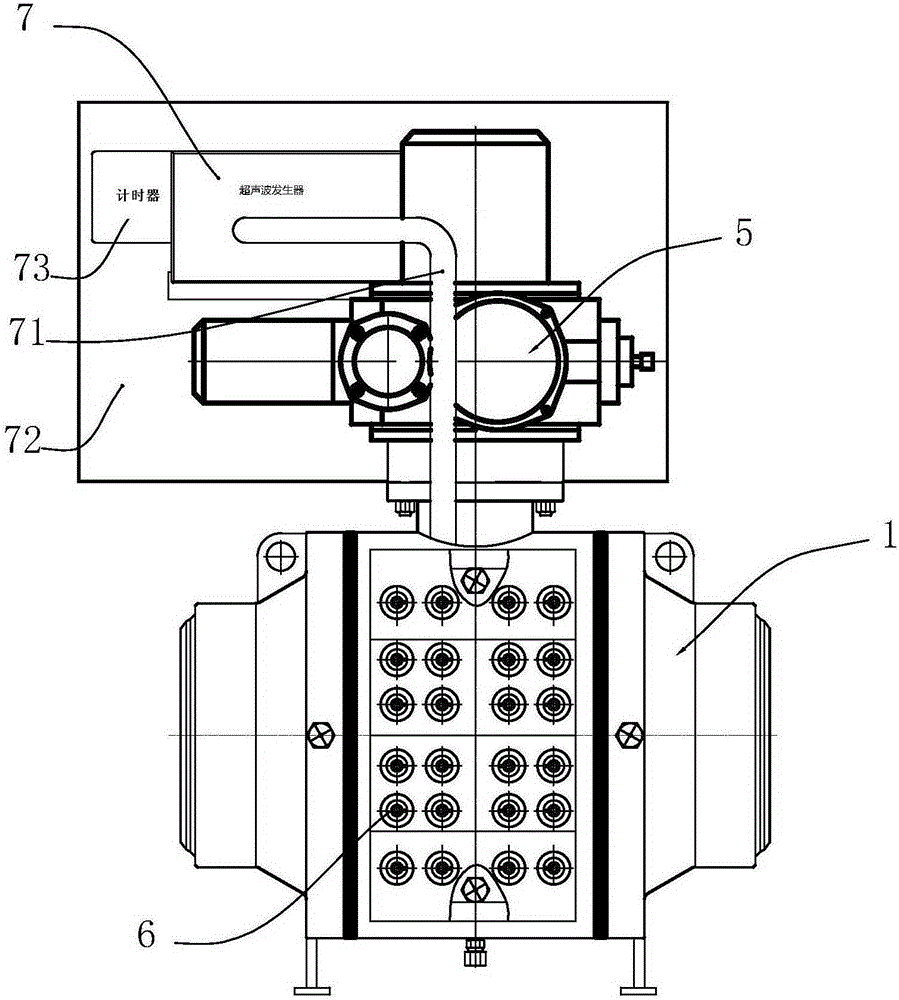

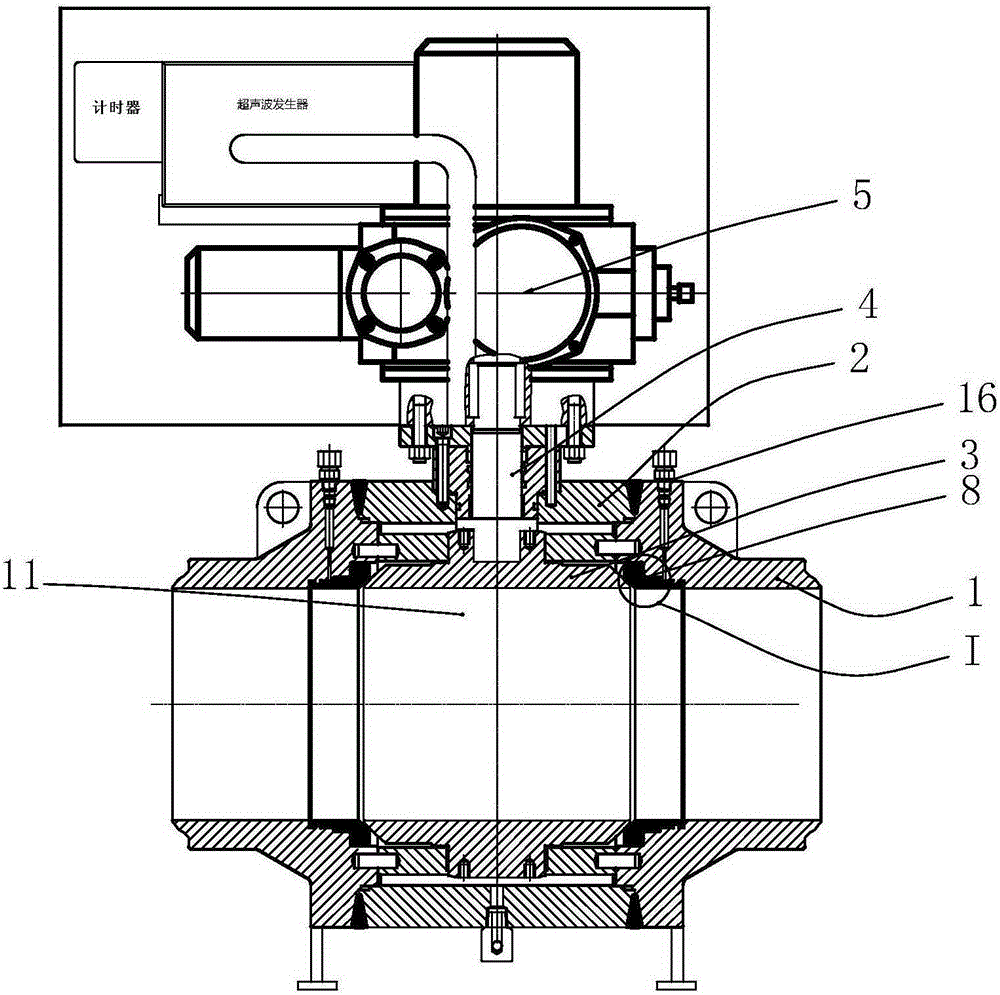

Ultrasonic self-cleaning anti-scaling ball valve

InactiveCN105318034AImprove protectionAvoid accumulationPlug valvesValve housingsTransducerEngineering

The invention discloses an ultrasonic self-cleaning anti-scaling ball valve. The ball valve comprises a valve body, a valve deck, a ball body, a valve rod and a valve rod driving mechanism. The valve body is provided with a valve body flow channel and a valve cavity located on the valve body flow channel. The ball body is rotationally arranged in the valve cavity. The valve rod is rotationally arranged on the valve body. The inner end of the valve rod stretches into the valve cavity and is matched with the ball body in a linked mode. The outer end of the valve rod is matched with the valve rod driving mechanism in a linked mode. A plurality of transducers are arranged on the outer sidewall, corresponding to the position of the valve cavity, of the valve body. The ultrasonic self-cleaning anti-scaling ball valve further comprises an ultrasonic generator. The transducers are connected with the ultrasonic generator through transducer connecting pipes. The ultrasonic self-cleaning anti-scaling ball valve has the advantage of being capable of preventing the valve cavity from scaling, thereby improving the rotation flexibility and airtightness of the ball body.

Owner:温州欧拉姆品牌运营管理中心(有限合伙)

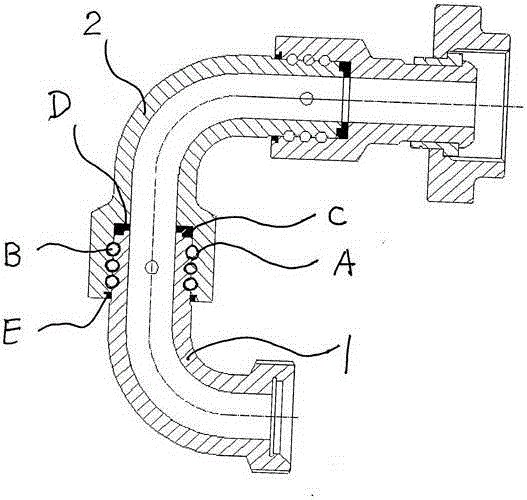

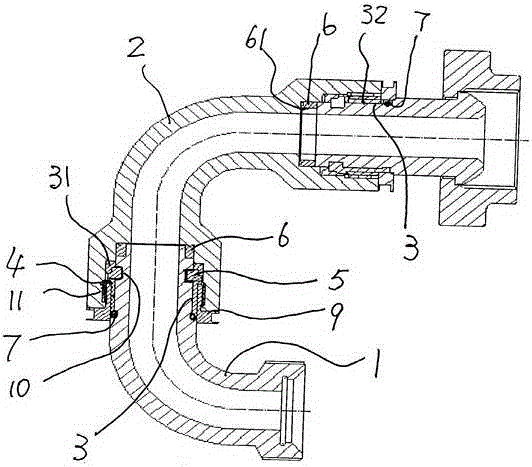

High-pressure movable elbow

InactiveCN105333260AExtended service lifeImprove rotational flexibilityAdjustable jointsSiphonsPhysical medicine and rehabilitationEngineering

The invention belongs to the technical field of pipe elbows and particularly relates to a high-pressure movable elbow used for a cementing manifold and a circulating pipeline. According to the main technical scheme, the high-pressure movable elbow comprises an elbow body male head and an elbow body female head which are connected in an inserted mode. A protruding anti-disengagement mechanism is arranged on the outer wall of the part, inserted into the elbow body female head, of the elbow body male head. A barrel-shaped compression threaded rod abuts against the anti-disengagement mechanism, the outer side face of the barrel-shaped compression threaded rod is in screw connection with the inner wall face of the elbow body female head, and the inner wall face of the barrel-shaped compression threaded rod is in friction connection with the outer wall face of the elbow body male head. The high-pressure movable elbow has the characteristics of being flexible to use and rotate, good in sealing performance and long in service life.

Owner:甘育宝 +1

Rotation adjusting mechanism of network intelligent release terminal equipment

InactiveCN105291065AImprove clamping firmnessConvenient horizontal rotation adjustmentWork benchesNetwork intelligenceTerminal equipment

The invention discloses a rotation adjusting mechanism of network intelligent release terminal equipment. The rotation adjusting mechanism comprises a base. A guide pipe is arranged on the base. A rotating pipe is sleeved with the guide pipe. A carrying plate is arranged at the end of the rotating pipe and provided with the intelligent terminal equipment and a limiting plate. The face, facing inwards, of the limiting plate is provided with a lock piece, and the lock piece is arranged on the outer side wall of the intelligent terminal equipment. The limiting plate is connected with a lock rod in an insertion manner. The outer end of the lock rod is a free end, and the inner end of the lock rod is connected with the lock piece. By means of the rotation adjusting mechanism, the intelligent terminal device can be conveniently and horizontally rotated and adjusted, and the rotation adjusting flexibility is better.

Owner:U COM TELECOM EQUIP CO LTD

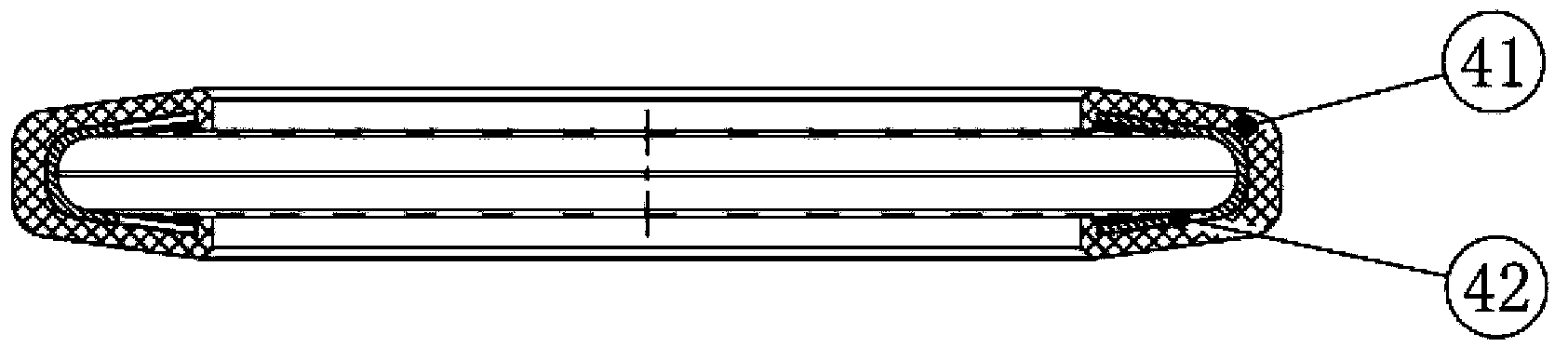

Method for preventing drop and hoisting of single hanging ring

The invention discloses a method for preventing drop and hoisting of a single hanging ring. The method comprises the steps that a, a drop preventing mechanism of a system for preventing drop and hoisting of the single hanging ring is opened and made to be in an unlocking state; b, when one of the hanging rings is mounted in the position, on one side of an elevator, of a lug hole of a lifting lug, an induction part of a drop preventing part sends a signal, after receiving the signal, a controller forbids moving of a runner wagon, the runner wagon is in a stop state, and after the hanging ring enters the lug hole, the drop preventing mechanism is in a locking state, and the hanging ring is blocked in the lug hole; and c, and the other hanging ring is mounted in the position, on the other side of the elevator, inside the lug hole of the lifting lug, the induction part of the drop preventing part sends a signal, and after receiving the signal, the controller allows the runner wagon to move. It can be effectively guaranteed that the two hanging rings both enter the lug hole, so that single hanging ring hoisting is avoided. Through the joint effect of the drop preventing mechanism and the drop preventing part, the hanging rings can be blocked firmly in the lug hole, slipping is avoided, the working stability and reliability of the elevator are improved, and the safety accident is eradicated.

Owner:CHENGDU ZHUOXIN IND

Manufacturing and processing method for spiral gear capable of axially moving

InactiveCN105522355AHigh strengthImprove rotational flexibilityBlast furnace componentsBlast furnace detailsHobbingWorking environment

The invention provides a manufacturing and processing method for a spiral gear capable of axially moving. The manufacturing and processing method comprises the following steps: casting, roughly turning each surface, carrying out UT checking, hardening and tempering, carrying out semi-finishing on each surface, carrying out primary making-out, drawing out a central line and a bearing line of each angle, milling and boring a spiral structure on the outer surface, checking spiral surface allowance, carrying out turning, processing inner and outer circles and an axial dimension, carrying out gear hobbing, clamping a lower end surface, carrying out secondary marking-out, drawing the positions of the bearing lines and relative bearings of holes, carrying out drilling processing, drilling threaded holes in a step of an inner wall, tapping, tapping pipe threads, carrying out precision boring, carrying out finish-milling on a spiral surface, carrying out distribution drilling and removing burrs. Components processed by the method meet requirements of a blast furnace working environment, so that the components have relatively good strength and rotation flexibility, and are longer in service lives; and under the action of a drive gear, the spiral gear axially moves along a guide part, and therefore, the manufacturing and processing method is suitable for large-scale popularization.

Owner:中冶南方(武汉)重工制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com