Bidirectional fully-sealed rotary joint for fluid conveying

A rotary joint and fluid delivery technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., to achieve the effects of reducing friction, improving wear resistance, and improving rotation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

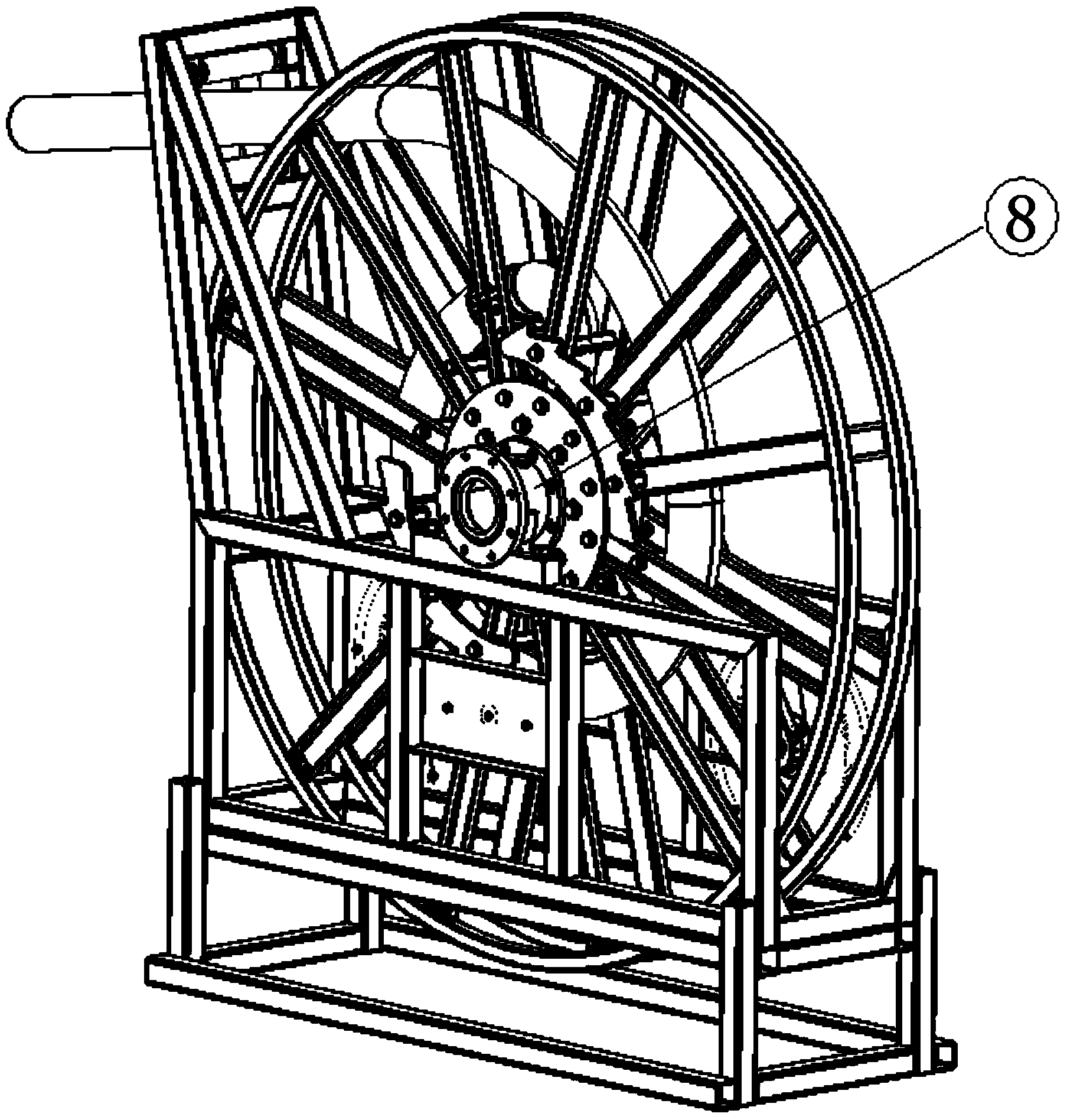

Image

Examples

Embodiment Construction

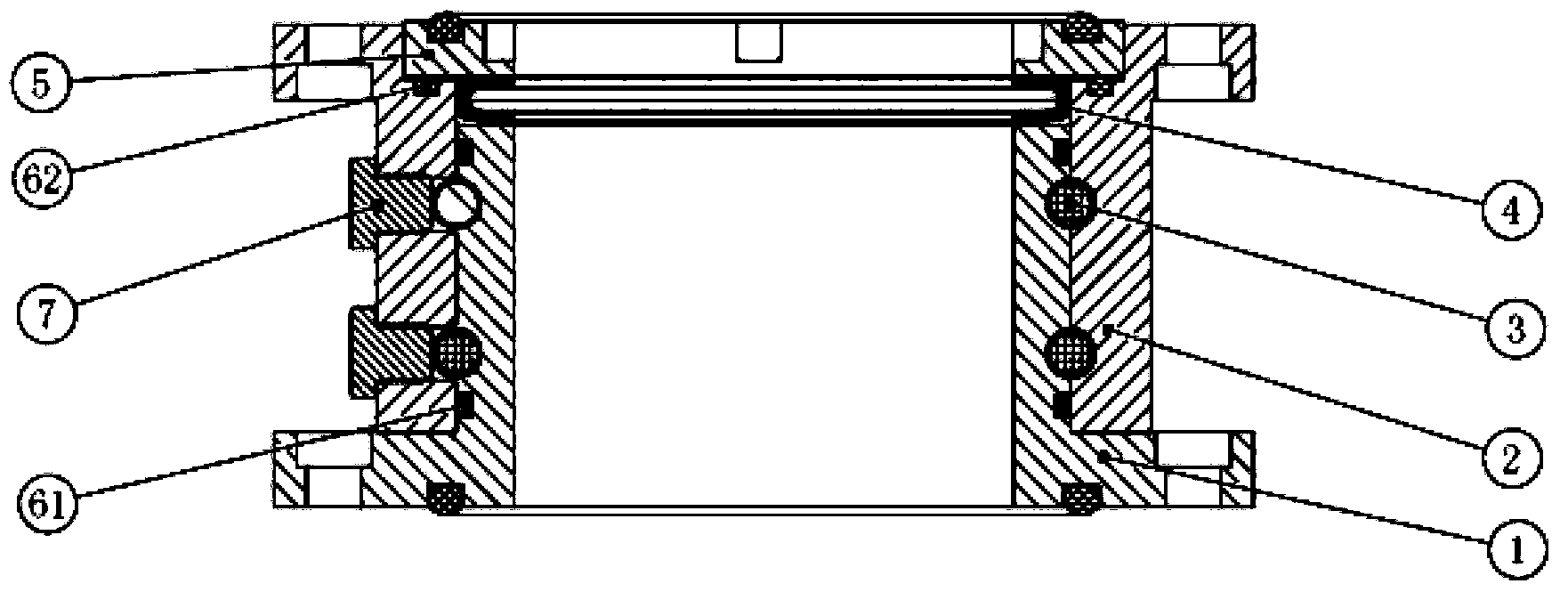

[0013] The term "two-way" used in the present invention indicates that fluid can flow in through any end of the rotary joint and flow out from the other end without affecting the use effect of the rotary joint.

[0014] The term "full seal" used in the present invention indicates that the rotary joint adopts the multiple seal form of main seal and auxiliary seal, which can not only prevent internal fluid leakage, but also prevent external debris from entering the fluid interior.

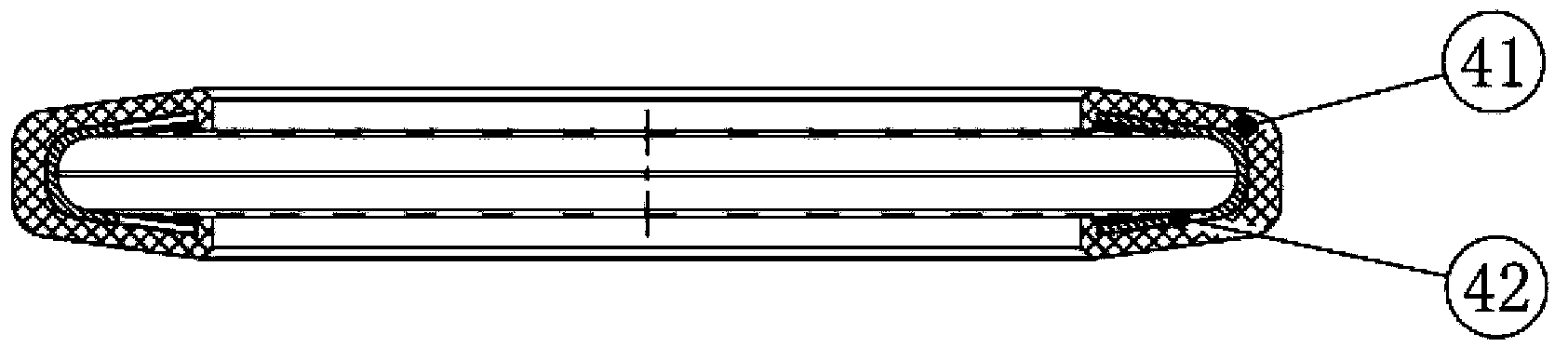

[0015] A two-way fully sealed rotary joint, including a rotary shaft 1, a housing 2, loose balls 3, a main seal 4, a compression ring 5, auxiliary seals 61 and 62, set screws 7, and the like. Wherein, a groove is provided on the outer circumference of the rotating shaft 1, the groove is equipped with an auxiliary seal 61, the rotating shaft 1 is concentrically installed inside the housing 2, a raceway is provided between the housing 2 and the rotating shaft 1, and the raceway is equipped with The bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com