Ultrasonic self-cleaning anti-scaling ball valve

An ultrasonic and self-cleaning technology, applied to the valve details, valve device, valve shell structure, etc., can solve the problems of sealing failure, affecting the service life of the valve, and easy scaling on the inner wall of the valve cavity, so as to prevent dust accumulation and collision damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following specific descriptions of the present invention are given by the examples, which are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

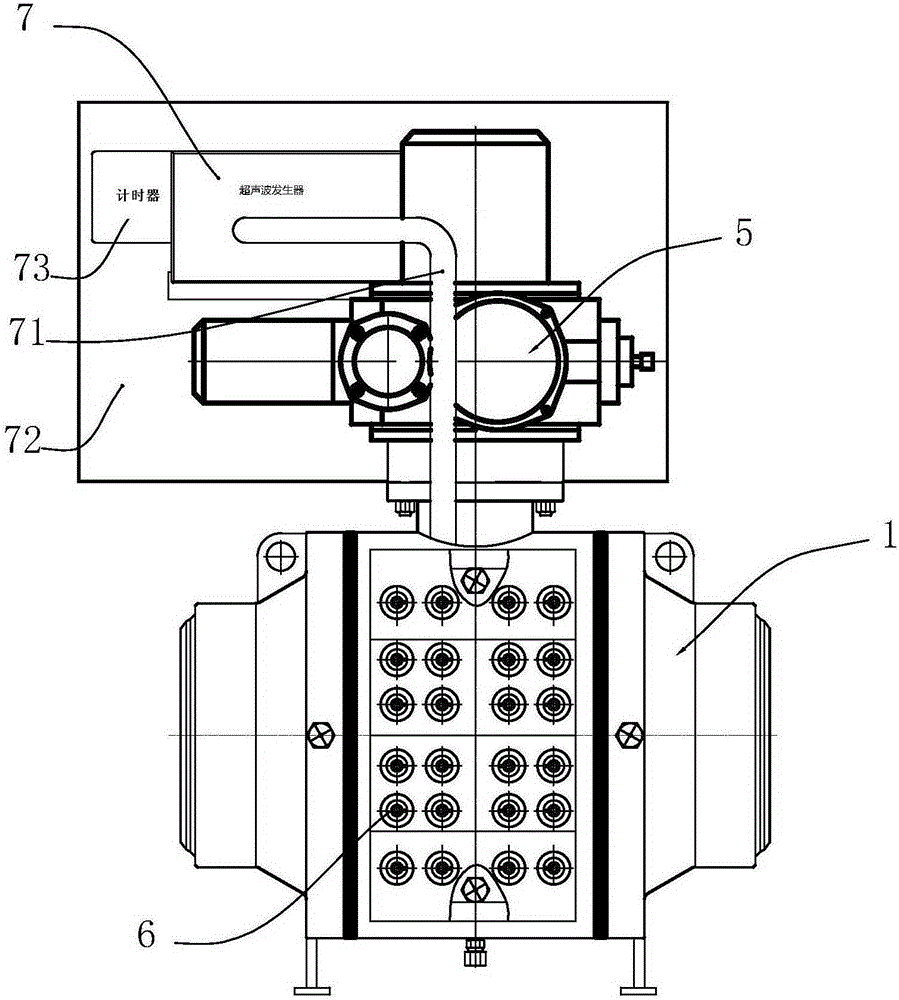

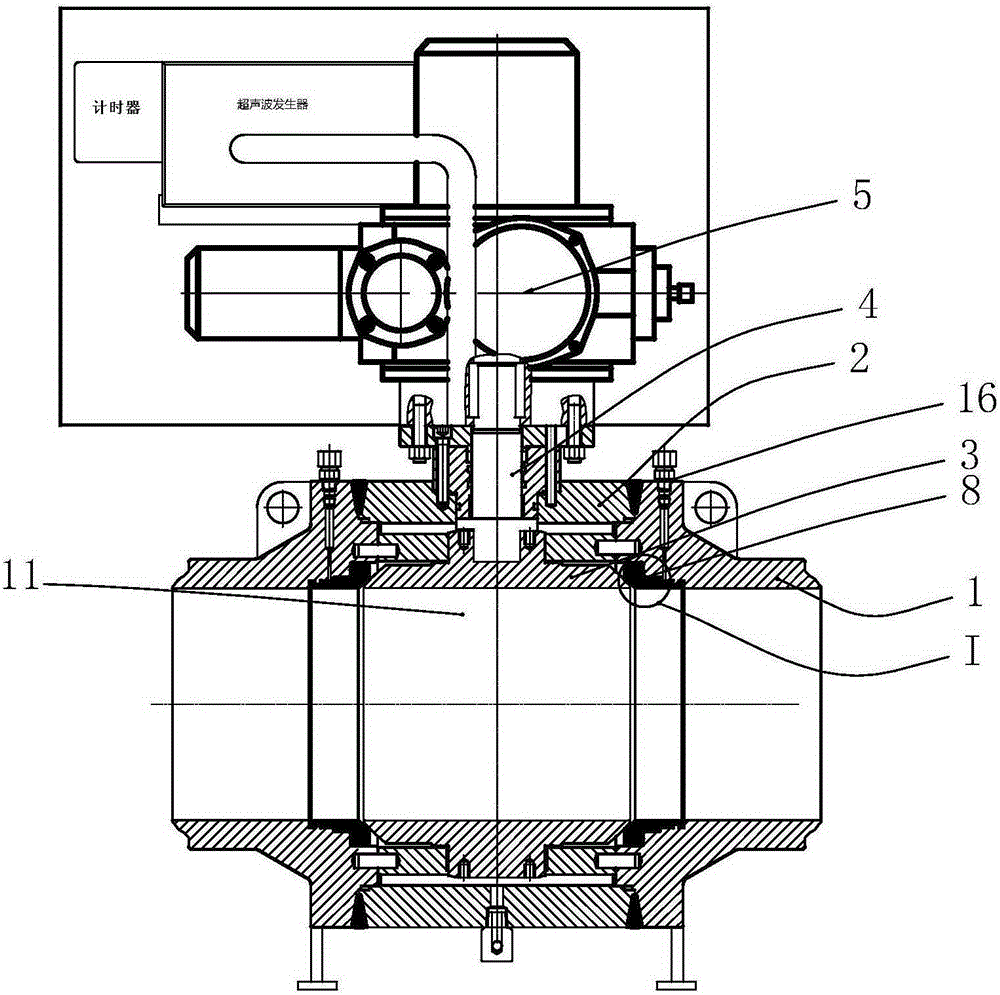

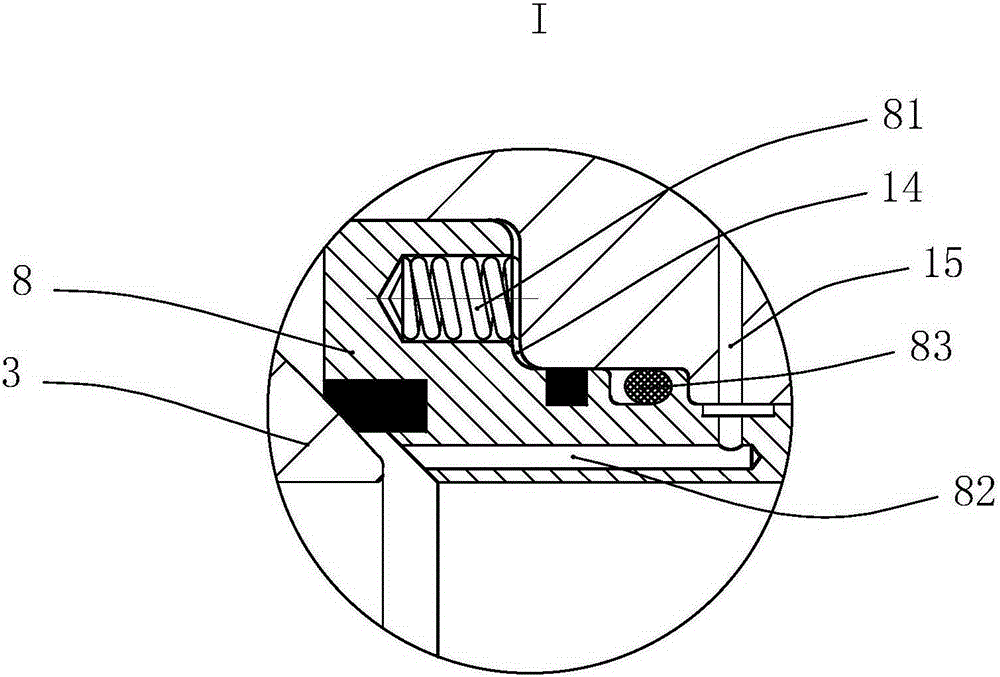

[0019] Such as Figure 1-4 The specific embodiment of the present invention shown is an ultrasonic self-cleaning anti-fouling ball valve, including a valve body 1, a valve cover 2, a ball 3, a valve seat 8, a valve stem 4, and a valve stem driving mechanism 5. On the valve body 1 A valve body flow channel and a valve cavity 11 located on the valve body flow channel are provided, the ball 3 is rotatably set in the valve cavity 11 , the valve stem 4 is rotatably set on the valve body 1 , and the inner end of the valve stem 4 extends into the valve cavity 11 And it cooperates with the sphere 3 in linkage, and the outer end of the valve stem 4 is coordinated with the valve stem driving mechanism 5. The valve stem driving mechanism 5 des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com