Manufacturing and processing method for spiral gear capable of axially moving

A technology of helical gear and axial movement, applied in blast furnace parts, furnaces, blast furnace details, etc., can solve the problems that the strength and rotation flexibility of the helical gear cannot meet the working requirements, and the helical gear pair cannot be moved axially. Strength and rotational flexibility, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with specific embodiment, the present invention is further described:

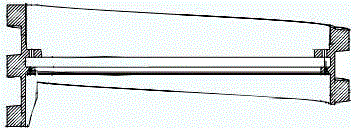

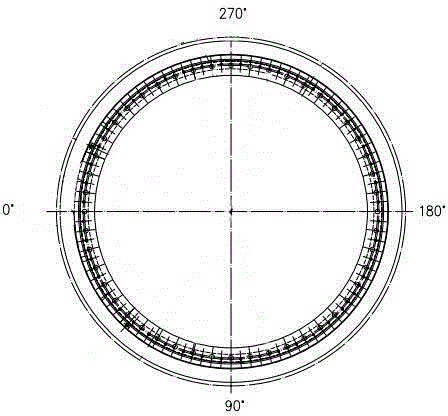

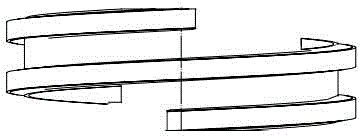

[0049] Such as Figure 1 to Figure 3 The manufacturing and processing method of the axially movable helical gear shown, its steps include:

[0050] 1. Technical requirements: The material of the helical gear is ZG35CrMo;

[0051] 2. Casting and modeling should pay attention to casting 2 pieces of conjoined test blocks, and the allowance of each processing surface of the size should be sufficient;

[0052] 3. Rough turning, each surface of rough turning, leave margin according to the rough order drawing, and check the dimensions according to the rough order drawing;

[0053] 4. UT inspection, the quality level reaches level 2 of JB / T5000.6-98;

[0054] 5. Quenching and tempering to ensure that the hardness of each surface after finishing is within HB207-269, and record the tempering curve;

[0055] 6. For each side of the semi-finishing car, leave a margin of 2.5-3 on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com