Patents

Literature

38results about How to "Improve clamping firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seal head structure part welding dislocation control tool and assembling method

InactiveCN110405400AImprove clamping stabilityReduce welding dislocation deformationWelding/cutting auxillary devicesAuxillary welding devicesDislocationEngineering

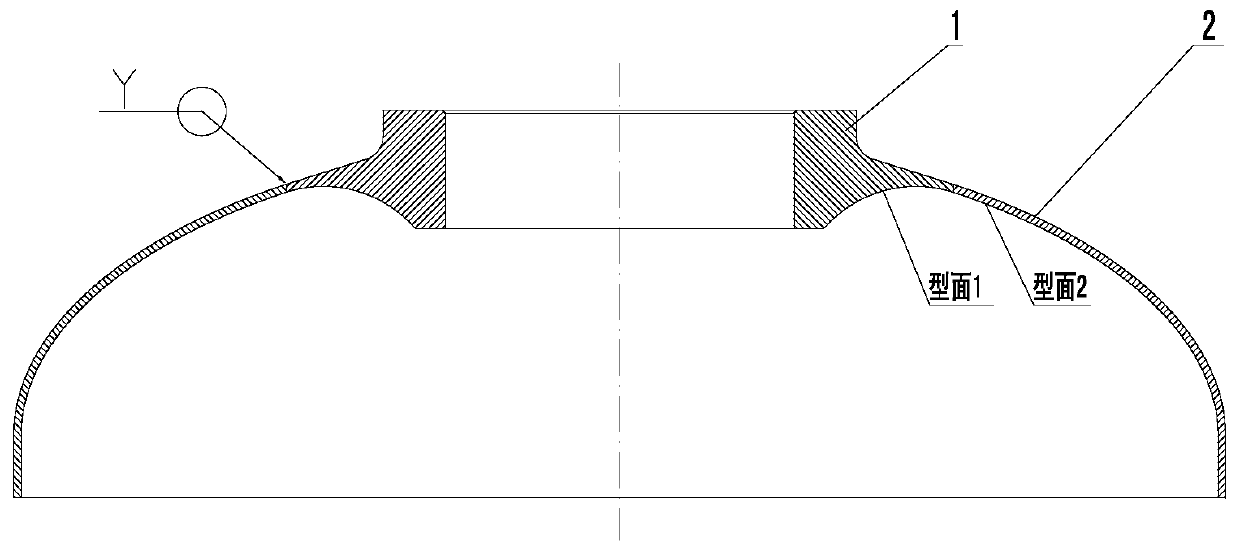

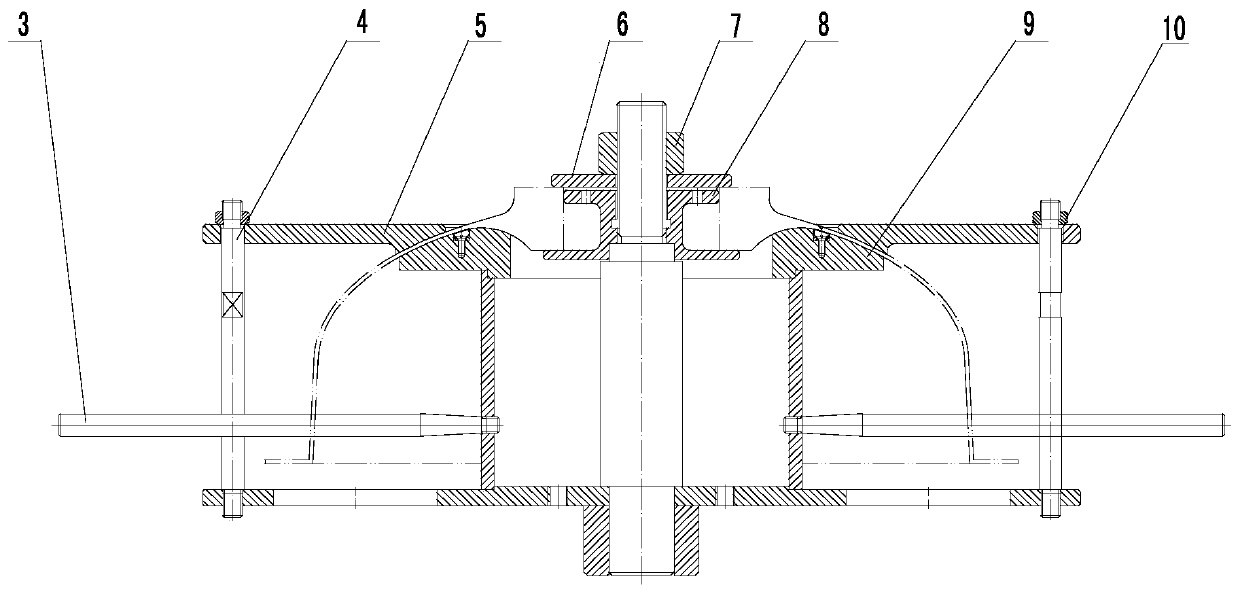

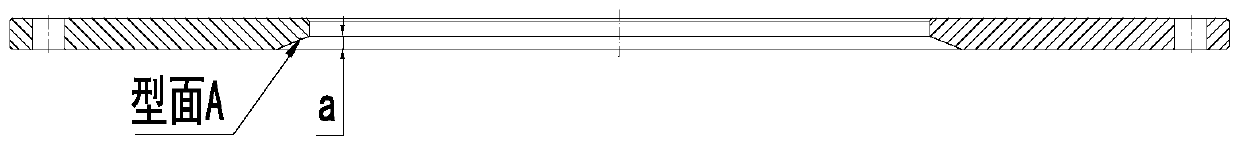

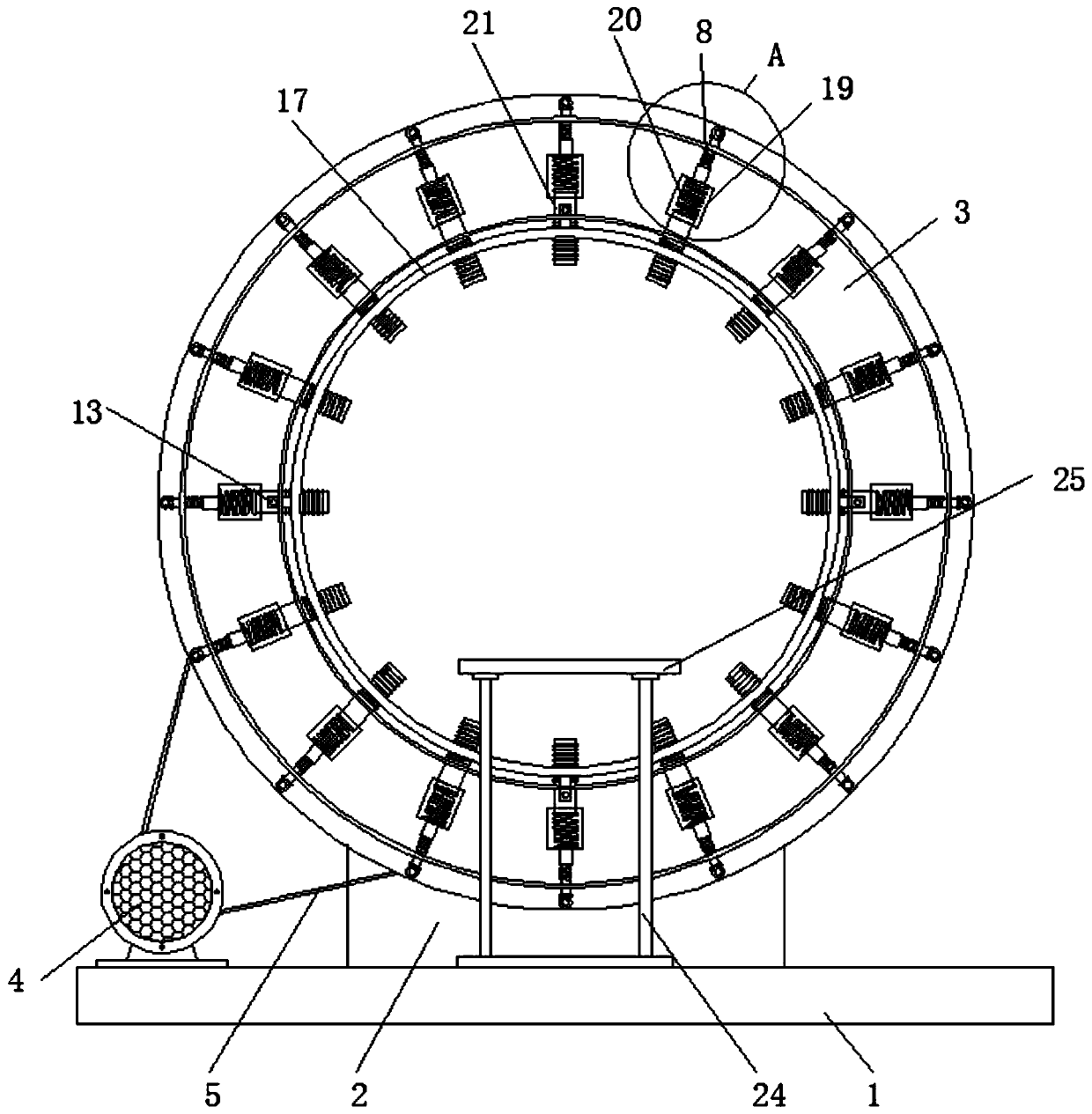

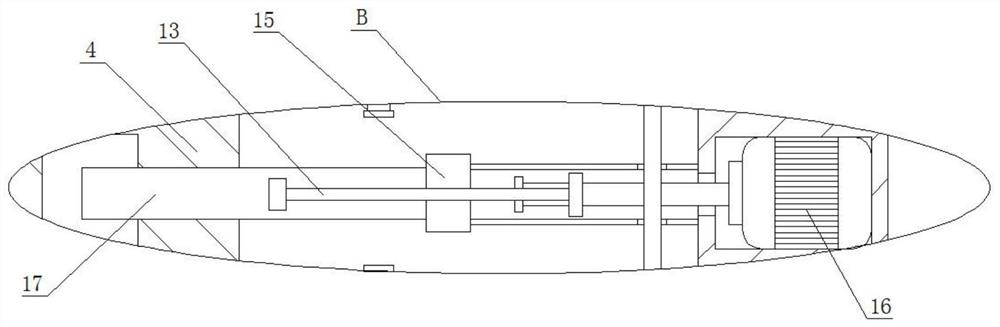

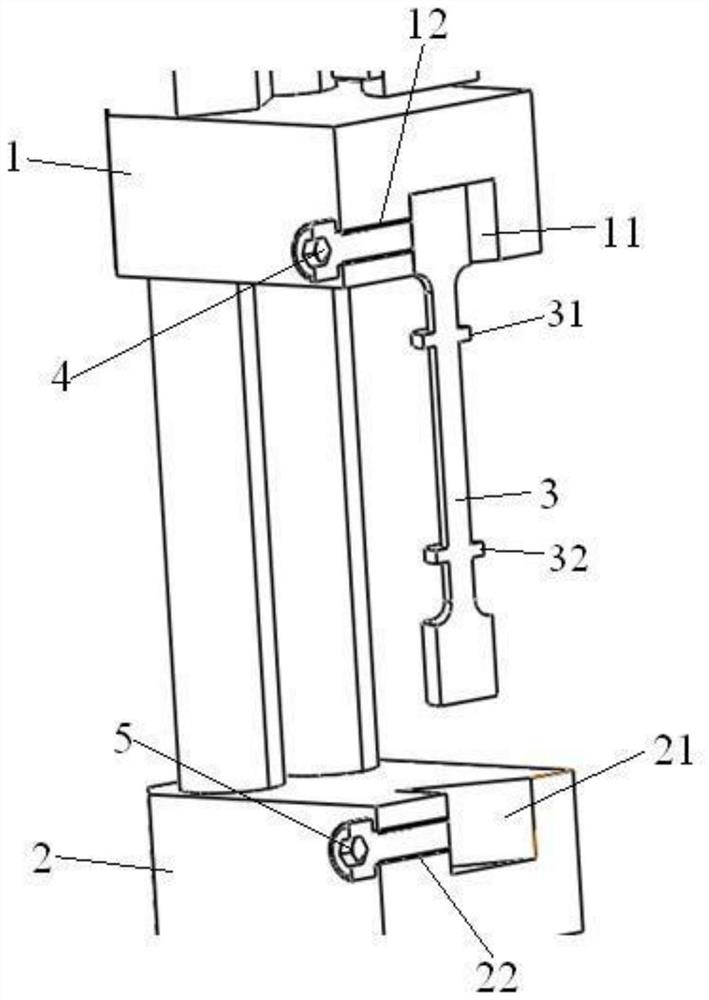

The invention provides a seal head structure part welding dislocation control tool and an assembling method. The tool comprises a pressing disc, a positioning body assembly, a lining and supporting rods. The positioning body assembly comprises a mandrel, a positioning body and a chassis, a hole is formed in the upper surface of the chassis, the mandrel is arranged in a manner of being perpendicular to the chassis, the positioning body is of a ring structure, the positioning body and the mandrel are coaxially mounted on the chassis, the upper surface of the positioning body is tightly attachedto the hemisphere inner wall profile to be welded, the pressing disc is of an annular structure, the inner hole profile is tightly attached to the hemisphere outer wall profile to be welded, the pressing disc is mounted on the chassis through the multiple supporting rods, and is matched with the positioning body, and the position of the hemisphere is fixed. The lining is a hollow step column, an inner hole is in threaded fit with the mandrel, the upper end penetrates through a front joint inner hole to be matched with a gasket and a fastening nut, and the front joint is fixed to the mandrel. The welding process is optimized, the reasonable assembling positioning method is adopted, and the front seal head end face annular line welding dislocation deforming problem of a certain engine is solved.

Owner:西安长峰机电研究所

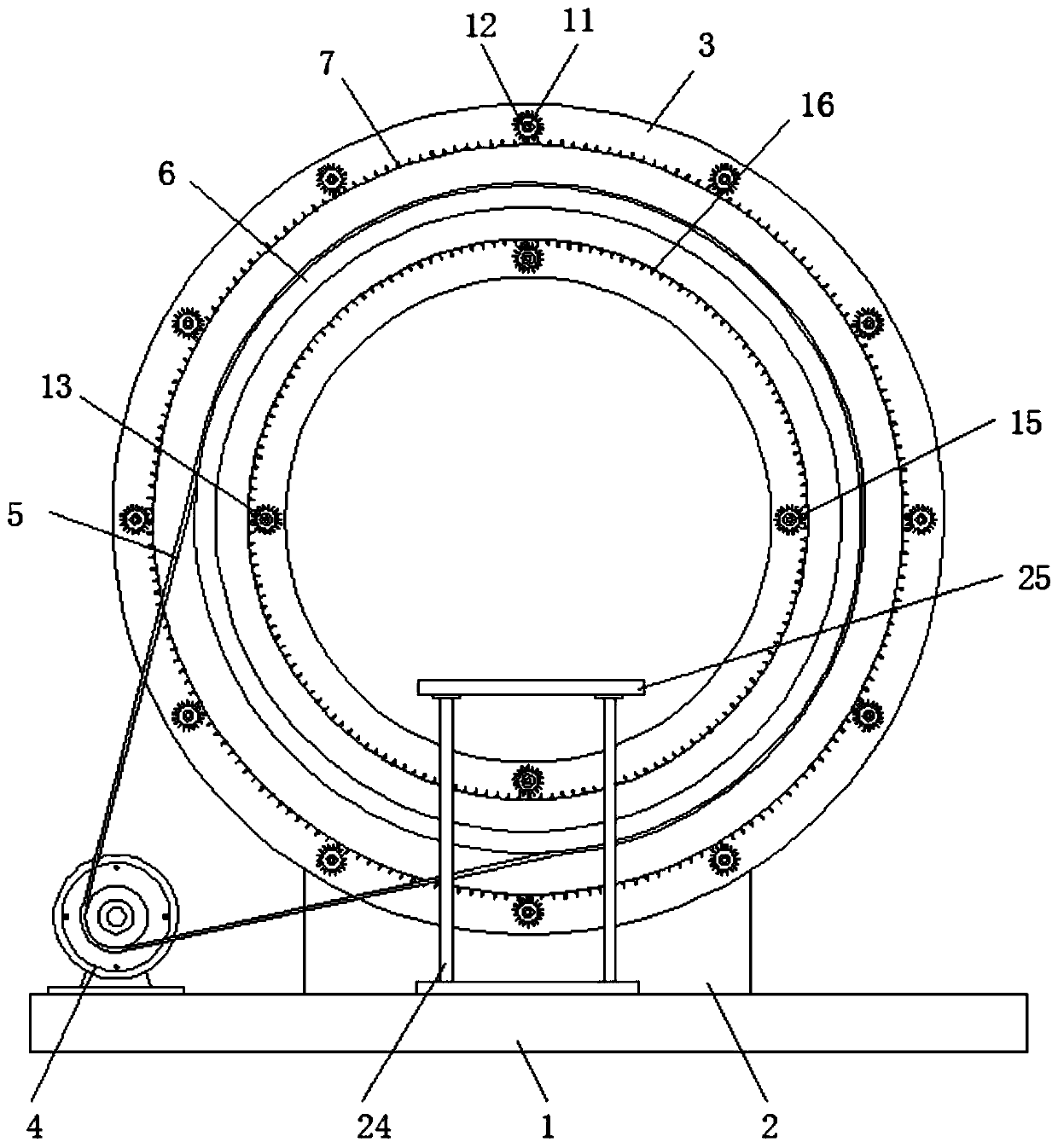

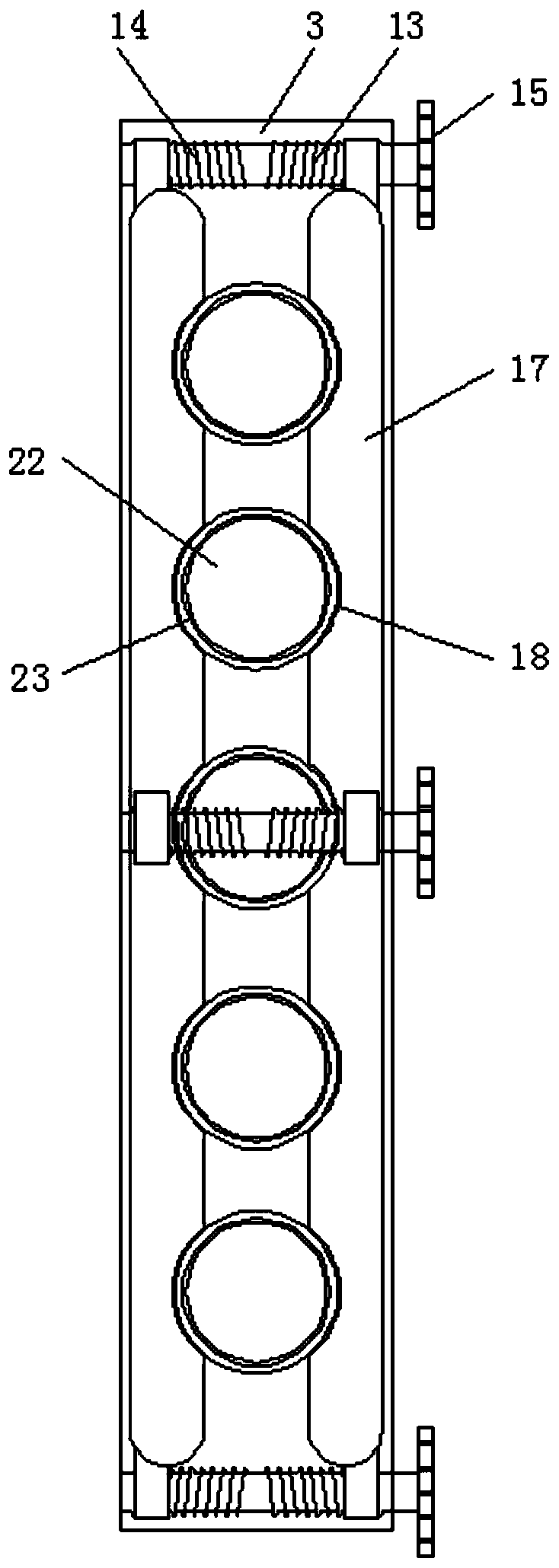

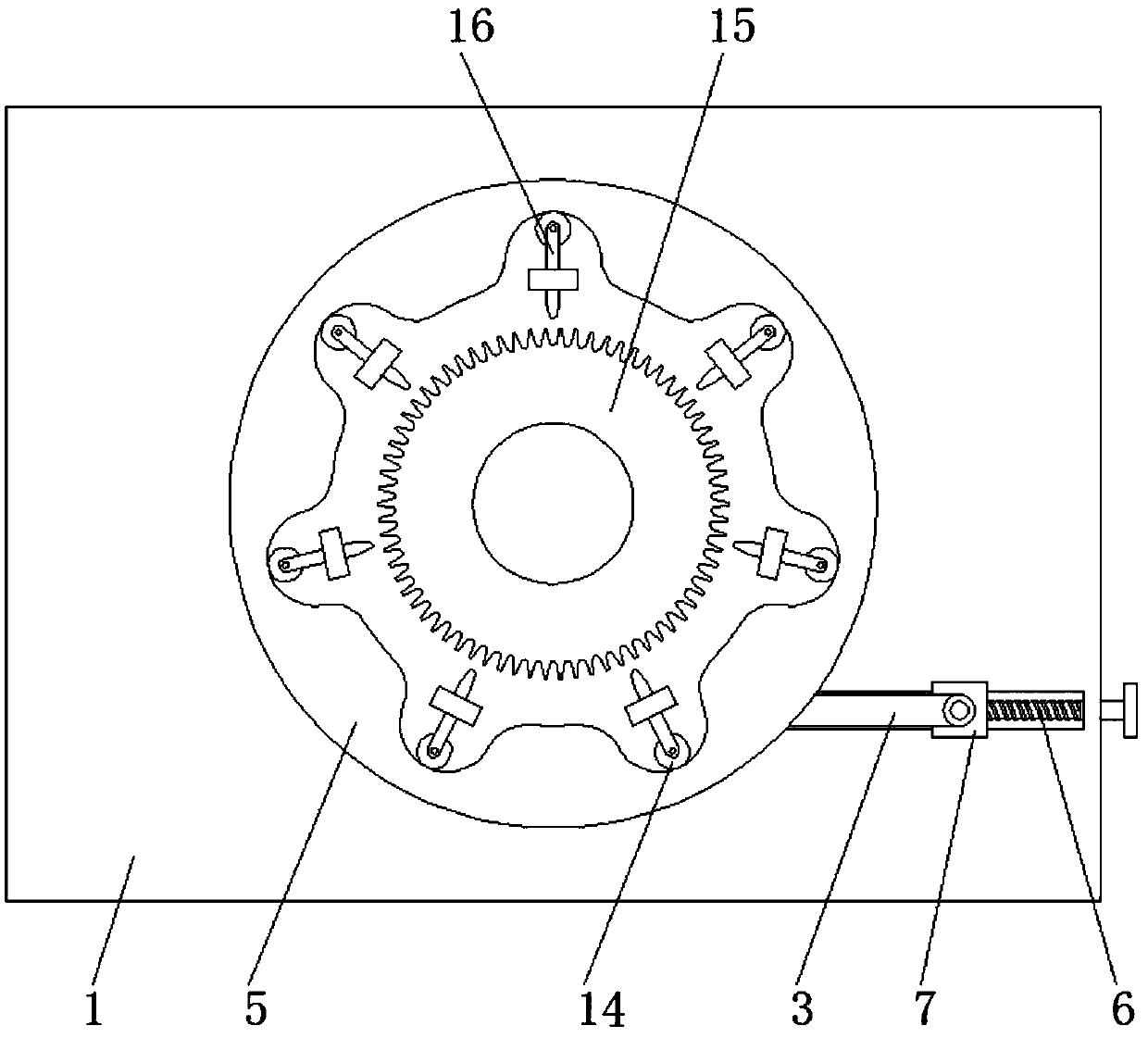

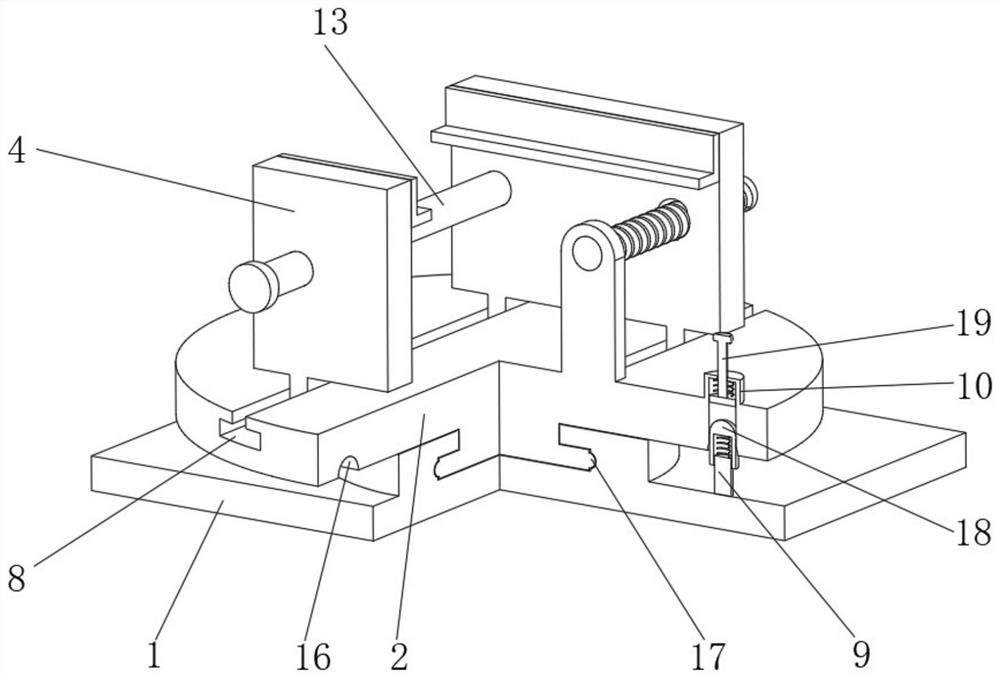

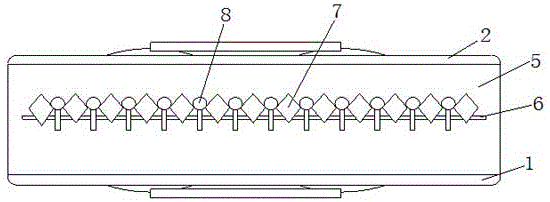

Irregular casting clamping device for casting production

ActiveCN110103163AEffective clampingImprove clamping firmnessWork holdersEngineeringMechanical engineering

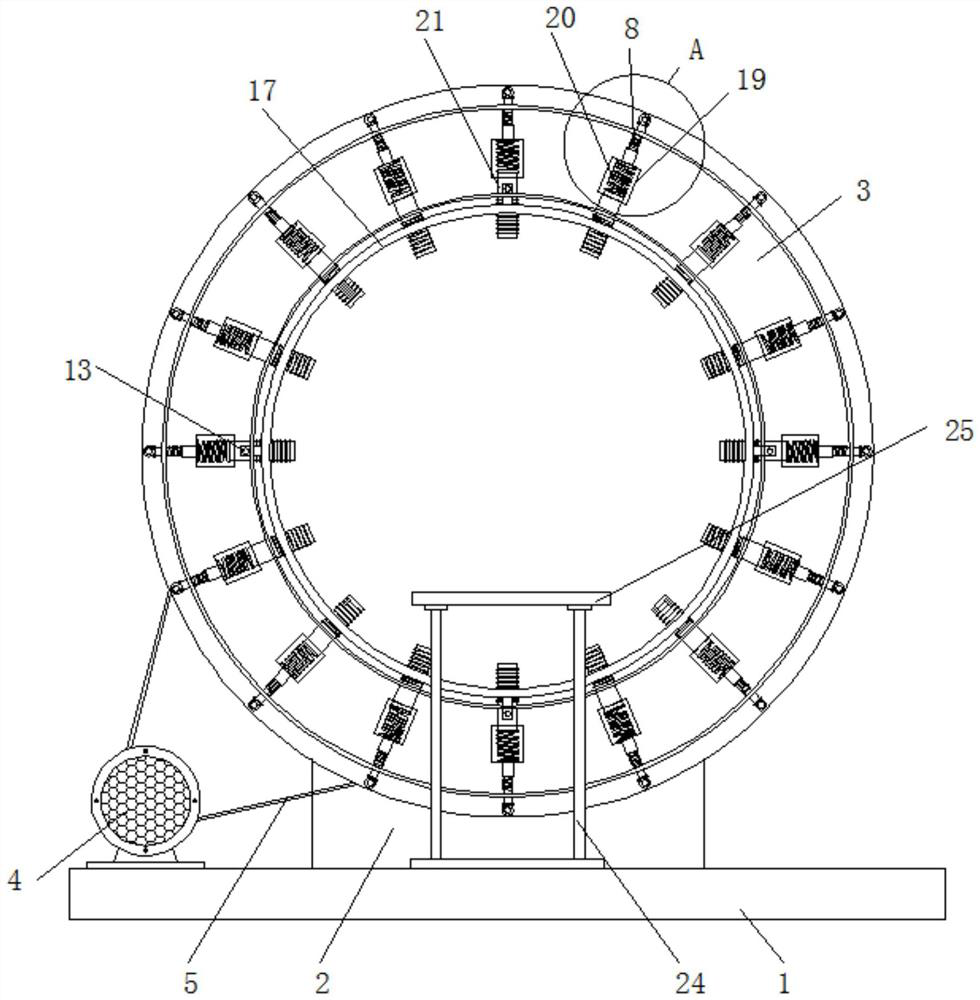

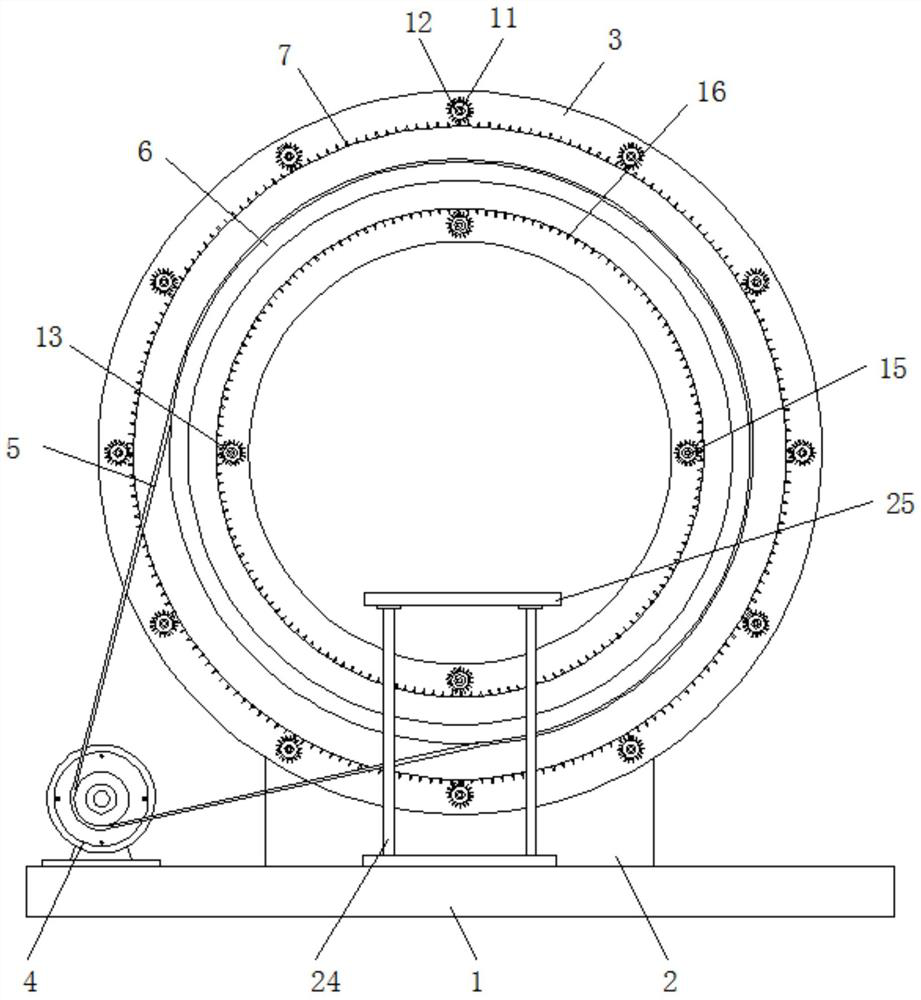

The invention discloses an irregular casting clamping device for casting production. The irregular casting clamping device comprises a foundation, wherein a base is arranged at the top of the foundation, a fixed ring is fixedly connected to the top of the base through bolts, and one side, close to the base, of the top of the base is is fixedly connected to a motor; and one end of the motor is in transmission connection with a rotating cylinder through a belt wheel set, and a first gear ring is arranged on the outer wall of one side of the rotating cylinder. According to the irregular casting clamping device for the casting production, multiple movable clamping columns can be in all-directional contact with the surface of the irregular casting, so that a plurality of directions of supporting force and extrusion force are provided for the irregular casting, then the irregular casting is effectively clamped, the clamping firmness of the clamping device on the irregular casting is effectively improved, the clamping column for extruding the irregular casting can be fixed through movable rings which move oppositely, so that the clamping force is ensured, and the problem that the clampingforce is lost due to loosening and movement of the clamping column is avoided.

Owner:安徽博晟亿电力科技有限公司

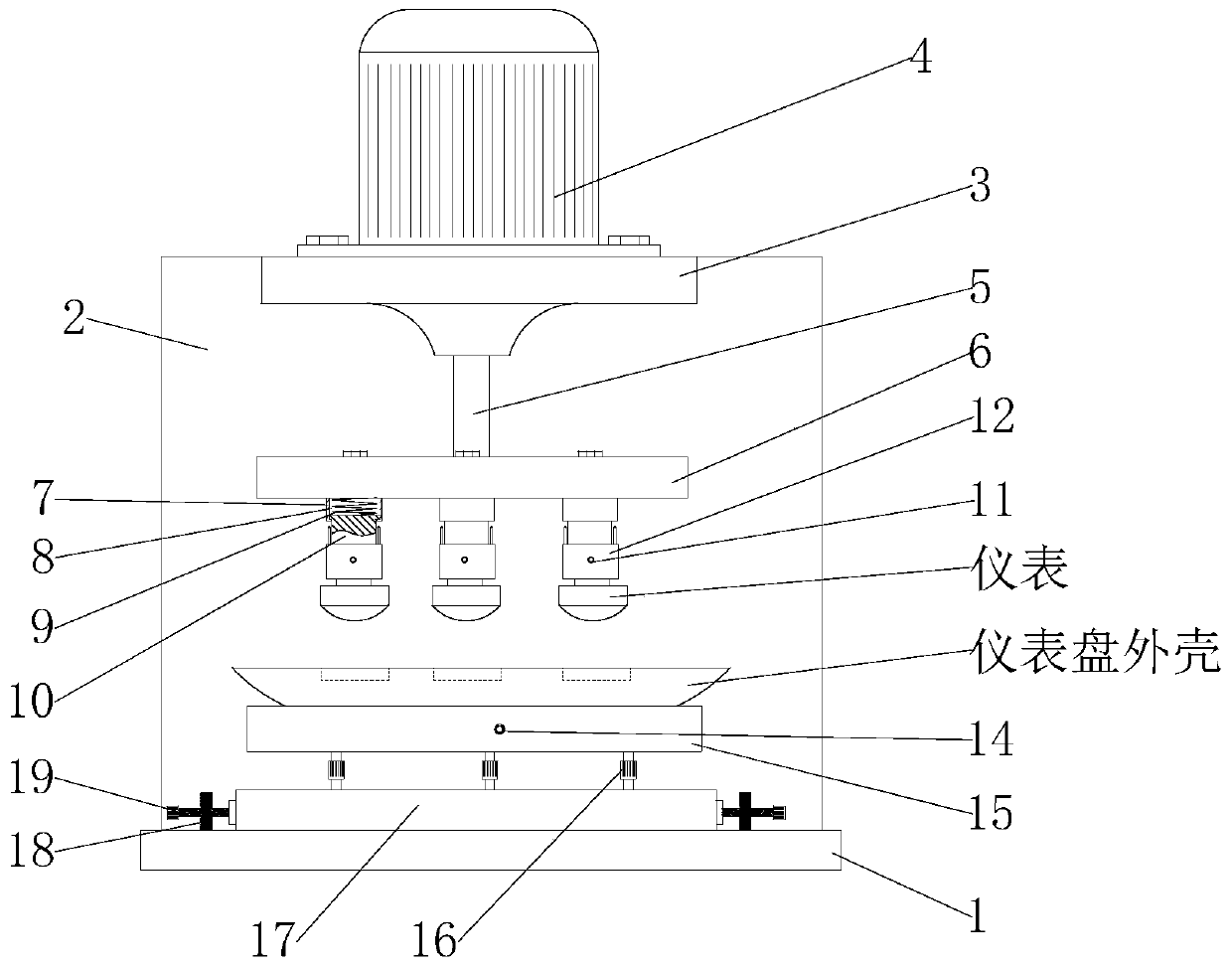

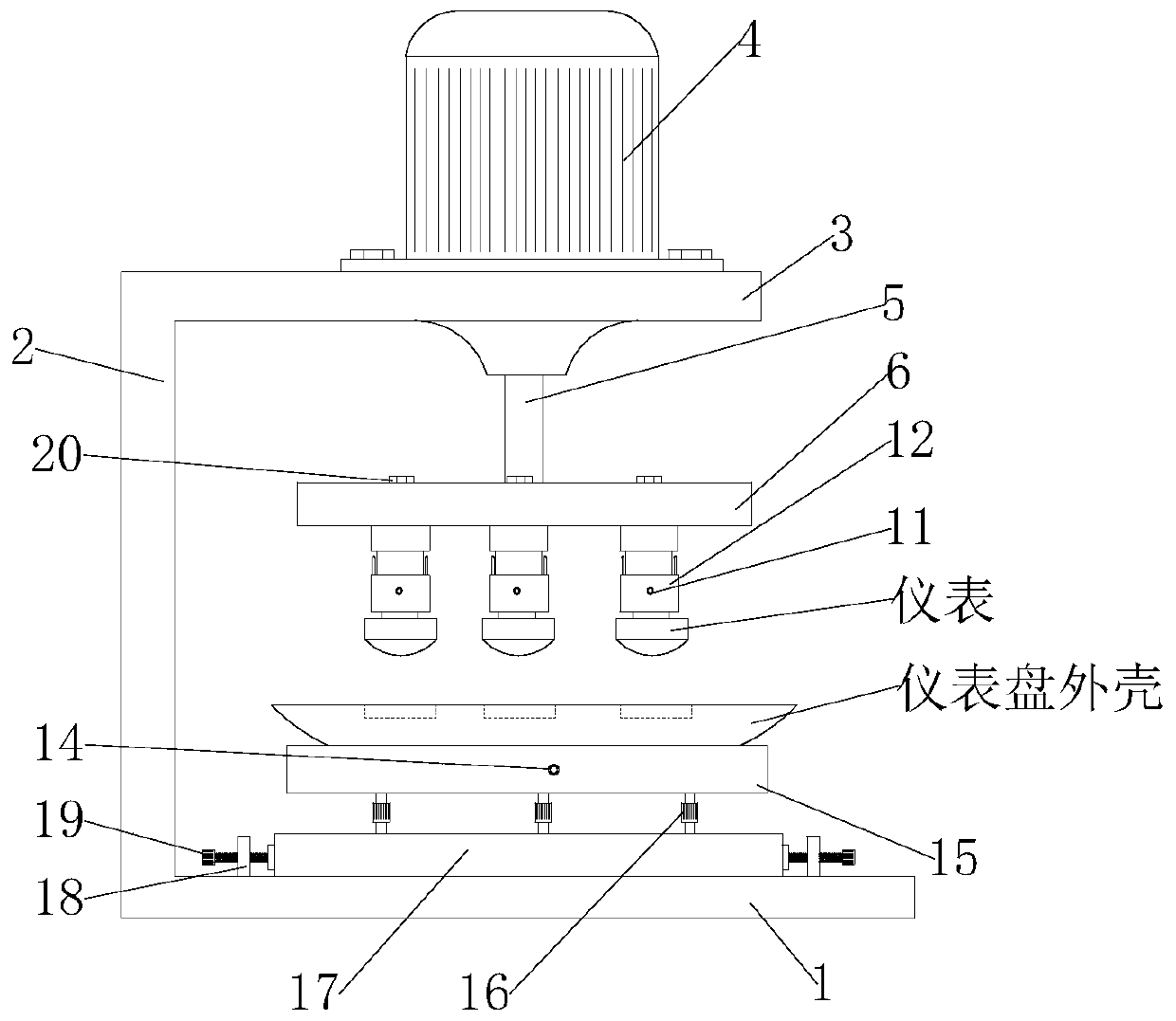

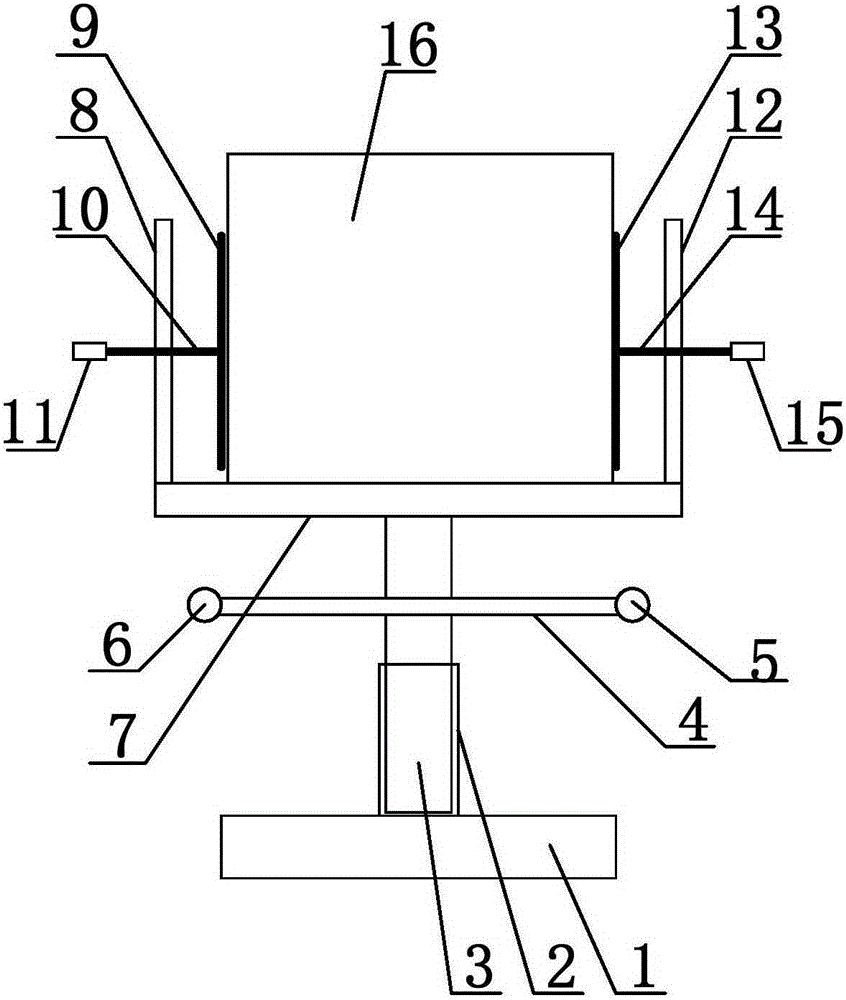

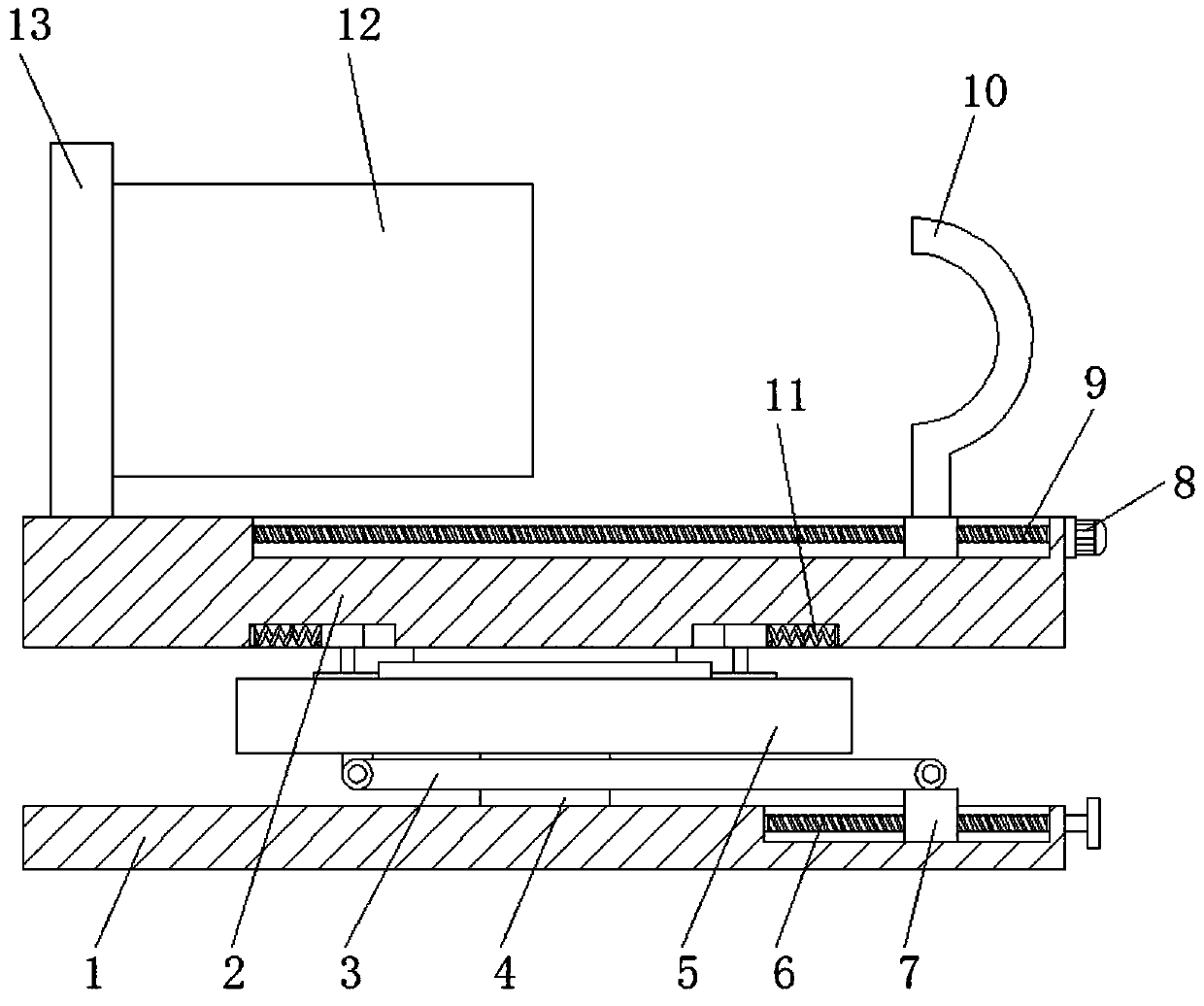

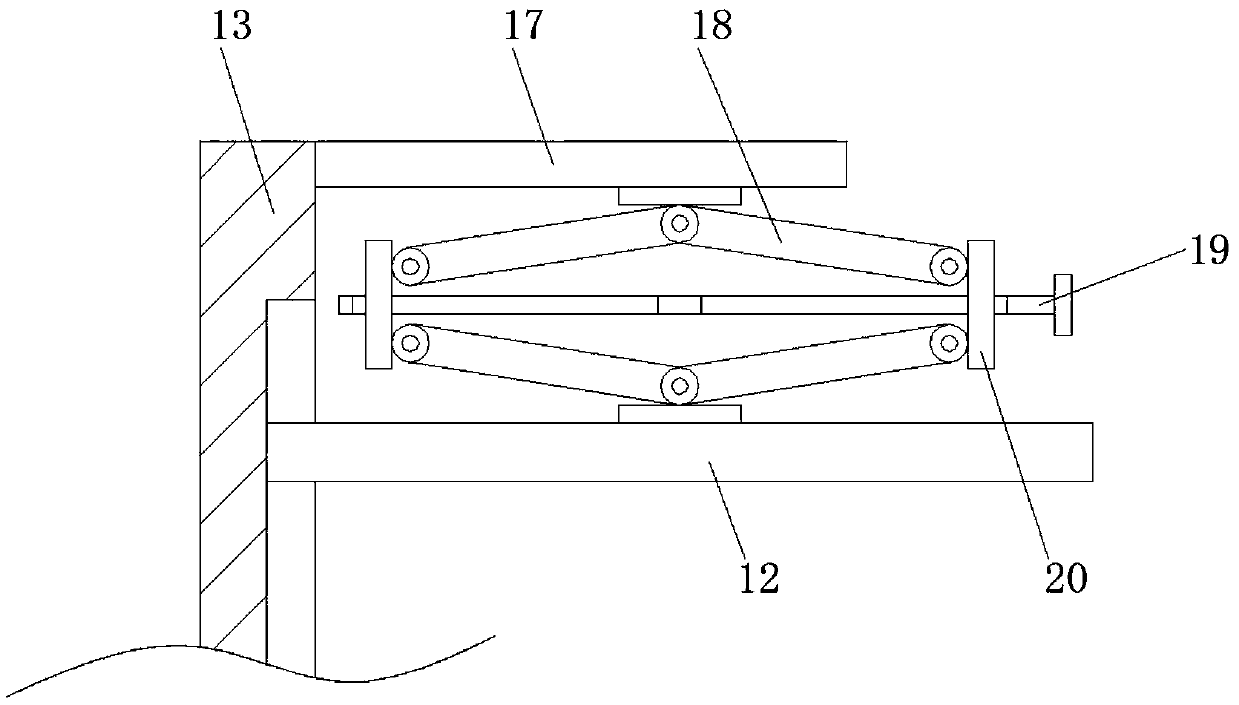

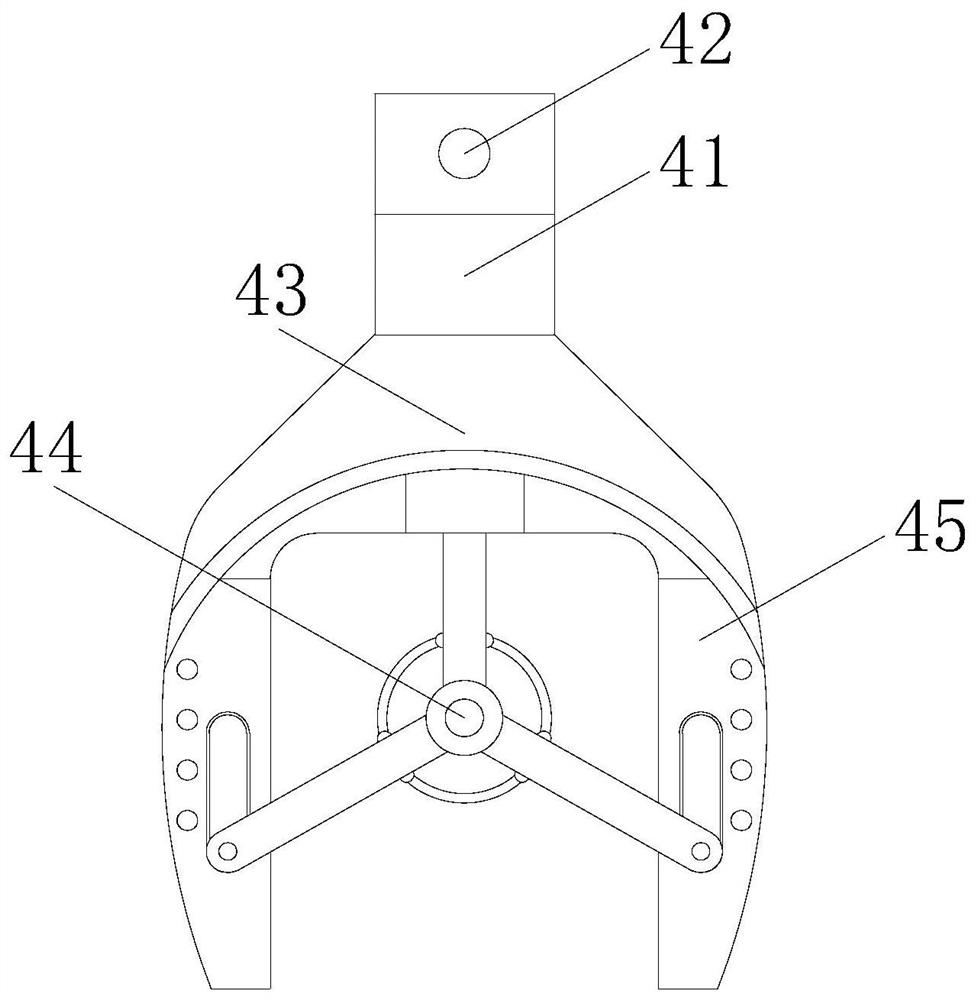

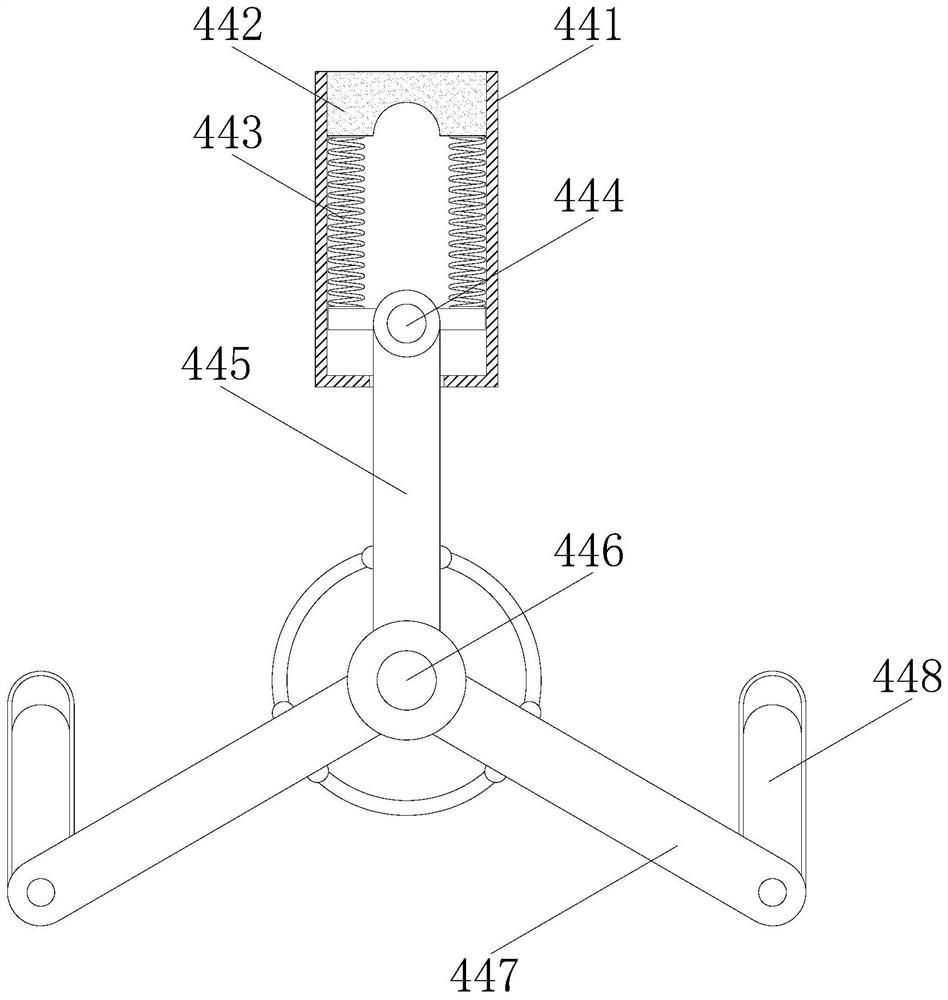

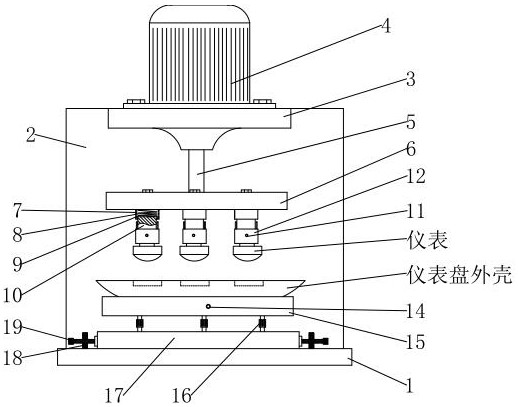

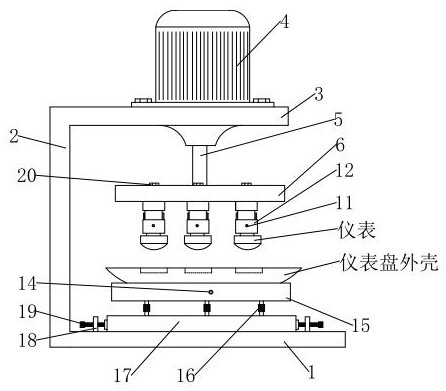

Instrument panel production abutting assembly equipment

ActiveCN111376047APrevent crushingFirmly assembledAssembly machinesMetal working apparatusEngineeringStructural engineering

The invention discloses instrument panel production abutting assembly equipment and relates to the technical field of mechanical production machining. The instrument panel production abutting assemblyequipment comprises a bottom supporting plate, the bottom supporting plate is horizontally fixed, the rear side of the top end of the bottom supporting plate is provided with a side supporting rib plate fixed at the top end of the bottom supporting plate upright, the top end of the side supporting rib plate is provided with a top supporting plate which is horizontally fixed, the top end of the top supporting plate is provided with a pneumatic cylinder, the pneumatic cylinder stretches out a piston rod towards the bottom end, and the bottom end of the piston rod is fixedly provided with a fixed rack. According to the instrument panel production butt-joint assembly equipment, the lower fixed rack is pushed to perform straight-line lifting motions through the pneumatic cylinder, when instruments are abutted and assembled to an instrument panel shell, fixed sleeves are made to move downwards through damping buffer of springs, jacking rods stretching out from the top ends of instrument fixtures are pressed to push the jacking rods to be ejected downwards, secondary pressing is performed on outer ring corners of the instruments assembled on the instrument panel shell, and abutting and assembling of the instruments to the instrument panel shell are made to be more solid and reliable.

Owner:开平市津华仪表科技有限公司

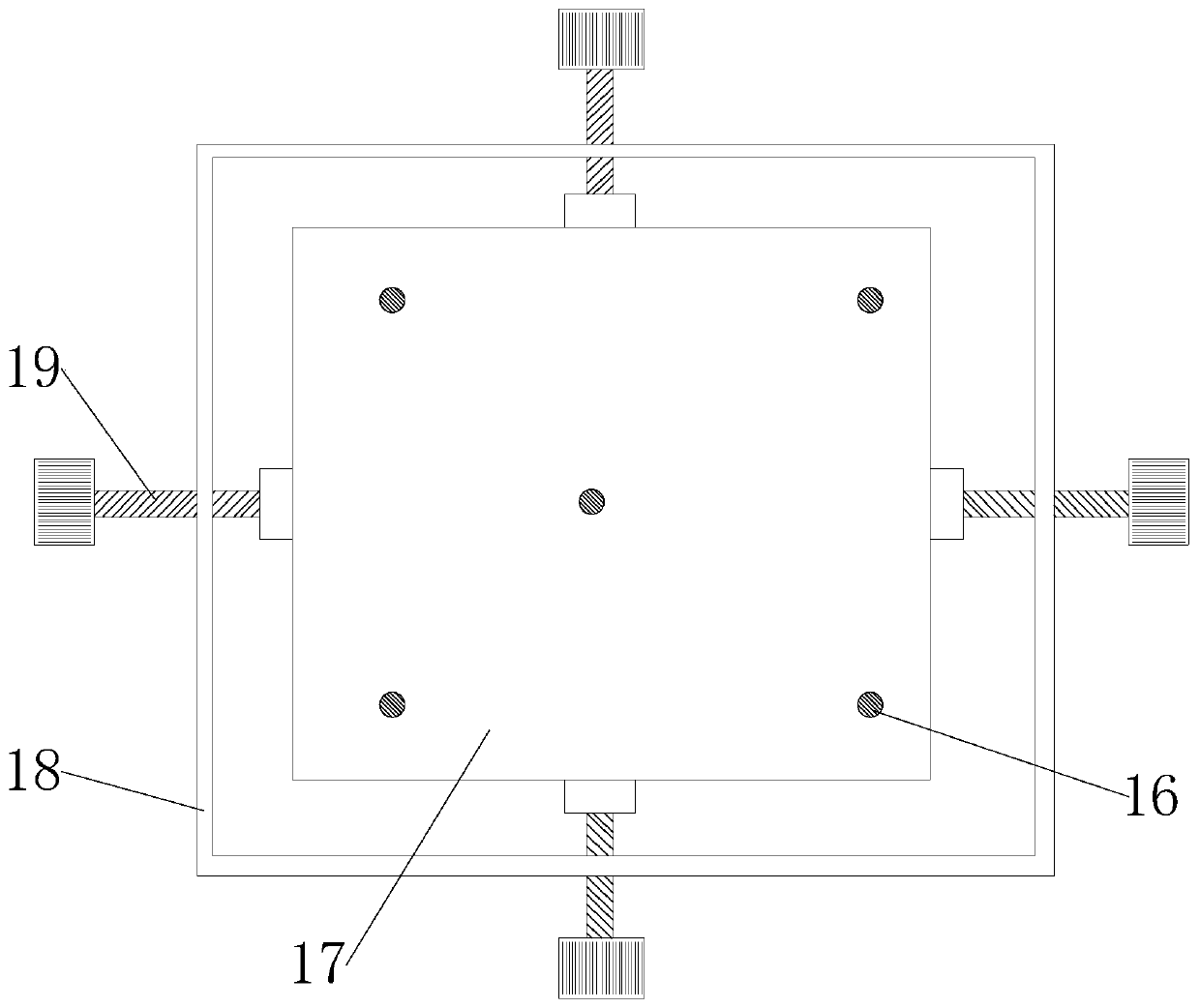

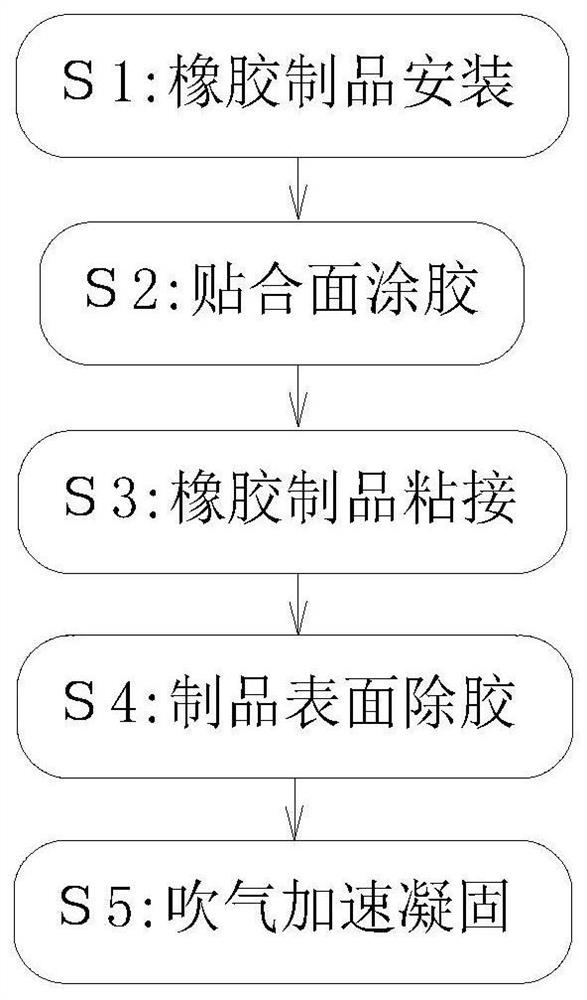

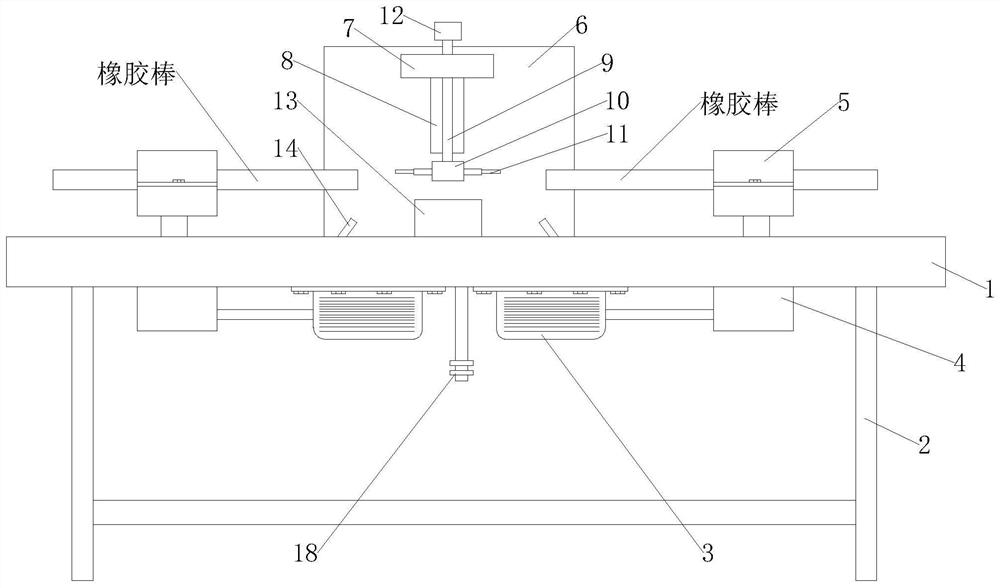

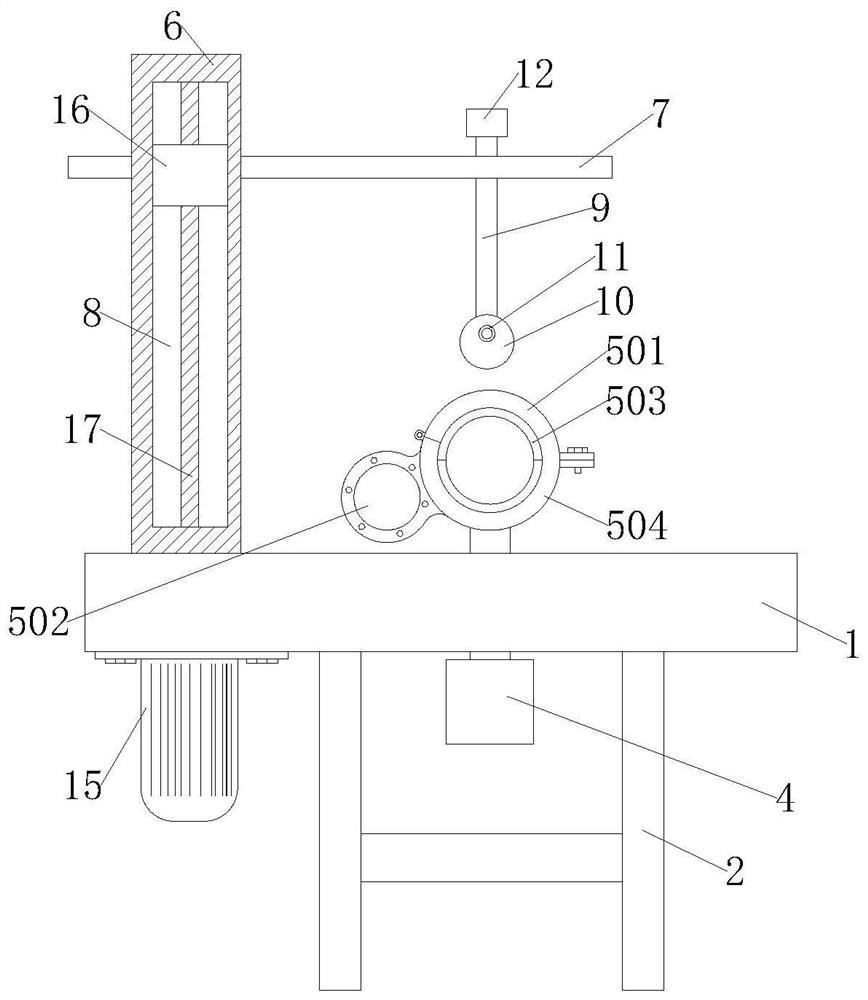

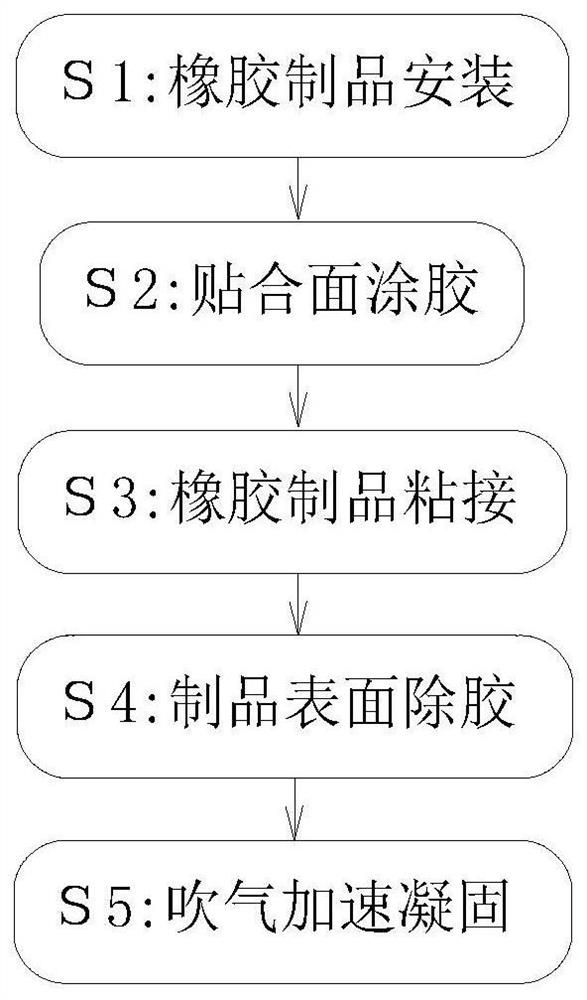

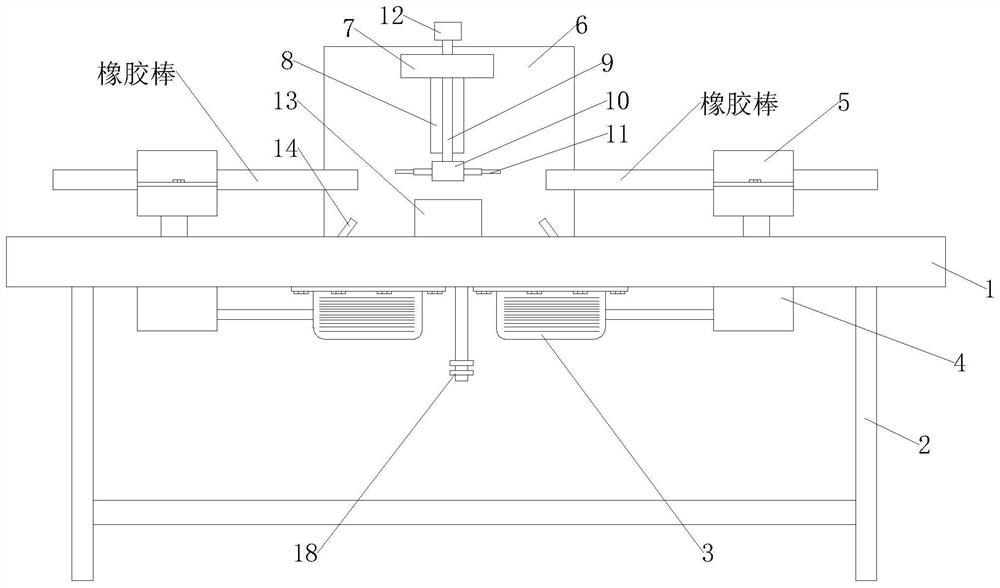

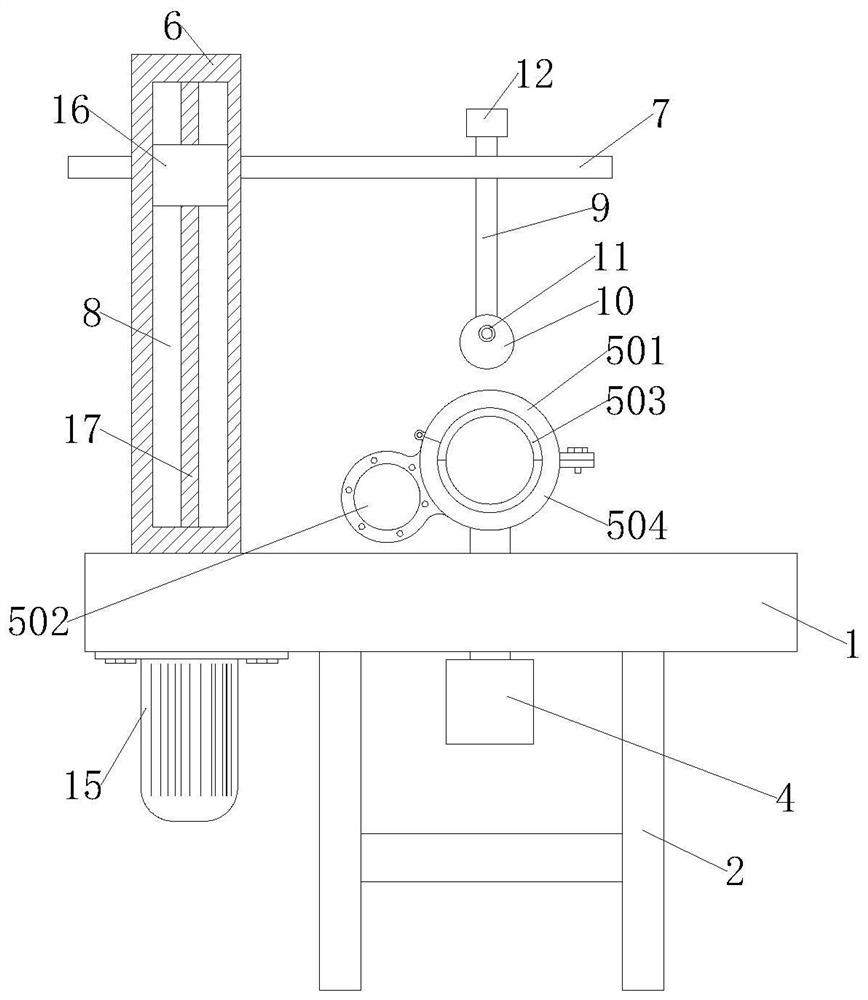

Treatment process for manufacturing and bonding rubber product

ActiveCN111805922AImprove firm performanceImprove connection tightnessCleaning using toolsAdhesive glueSteel ball

The invention provides a treatment process for manufacturing and bonding a rubber product, and relates to the technical field of rubber product production and processing. The treatment process for manufacturing and bonding the rubber product is completed by matching a rubber product manufacturing and bonding processing device. The rubber product manufacturing and bonding processing device comprises a workbench, wherein the bottom of the workbench is provided with four support legs fixed at equal interval; the top end of the workbench is provided with a support rib plate vertical to the top endof the workbench; the front end of the support rib plate is provided with a top support plate parallel to the top end of the workbench; and a through sliding groove is formed in the middle of the support rib plate. According to the treatment process, a sealing steel ball rolls on the bonding surface of a rubber rod, so that the bonding surface of the rubber rod is uniformly glued by a gluing pen;and the sealing steel ball seals glue in a glue injection cavity when the top end of a floating gluing rod is separated from the bonding surface of the rubber rod through the elastic support of a sealing spring, so that the excessive glue is prevented from seeping out of the glue injection cavity.

Owner:湖南铭弘体育产业股份有限公司

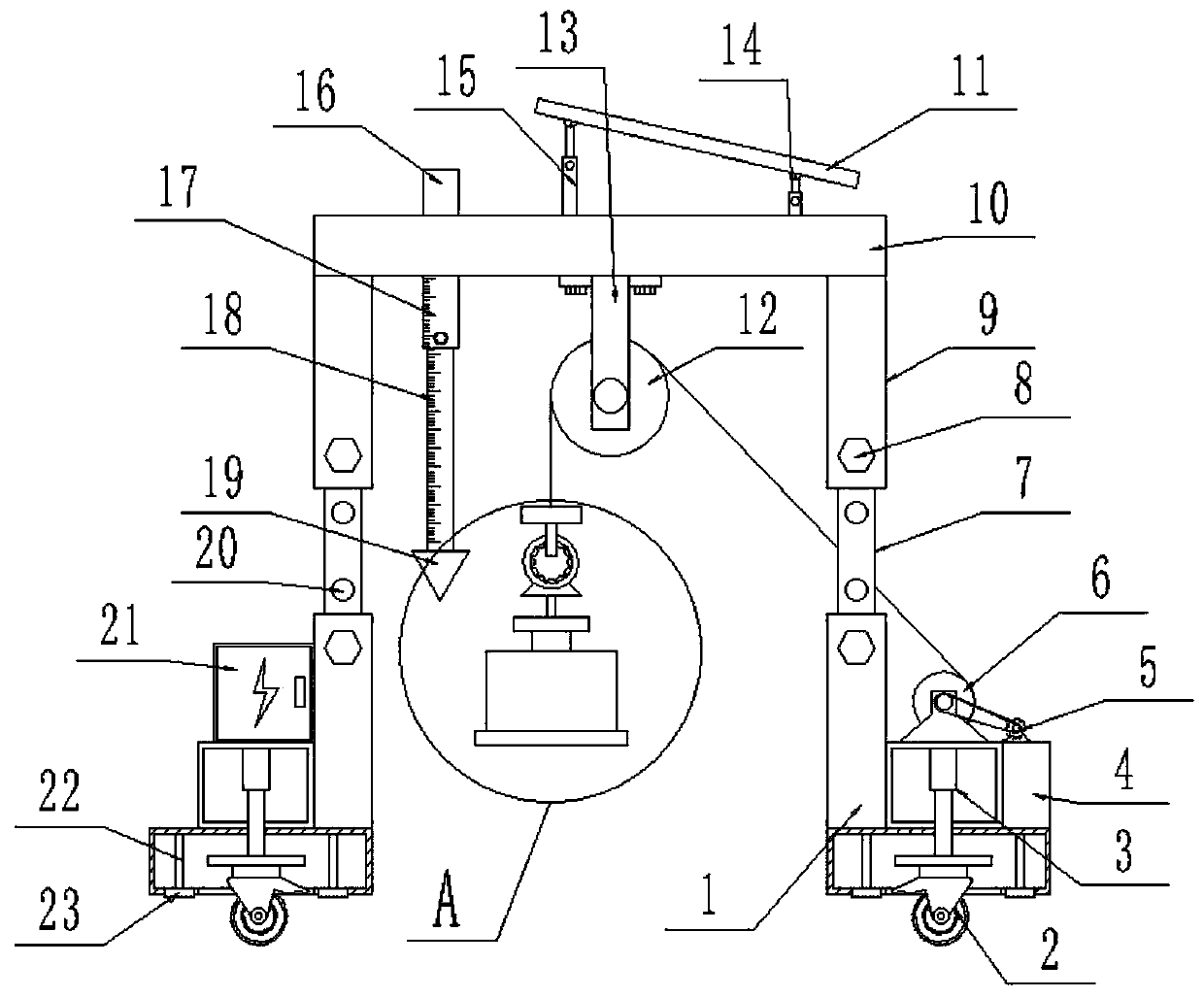

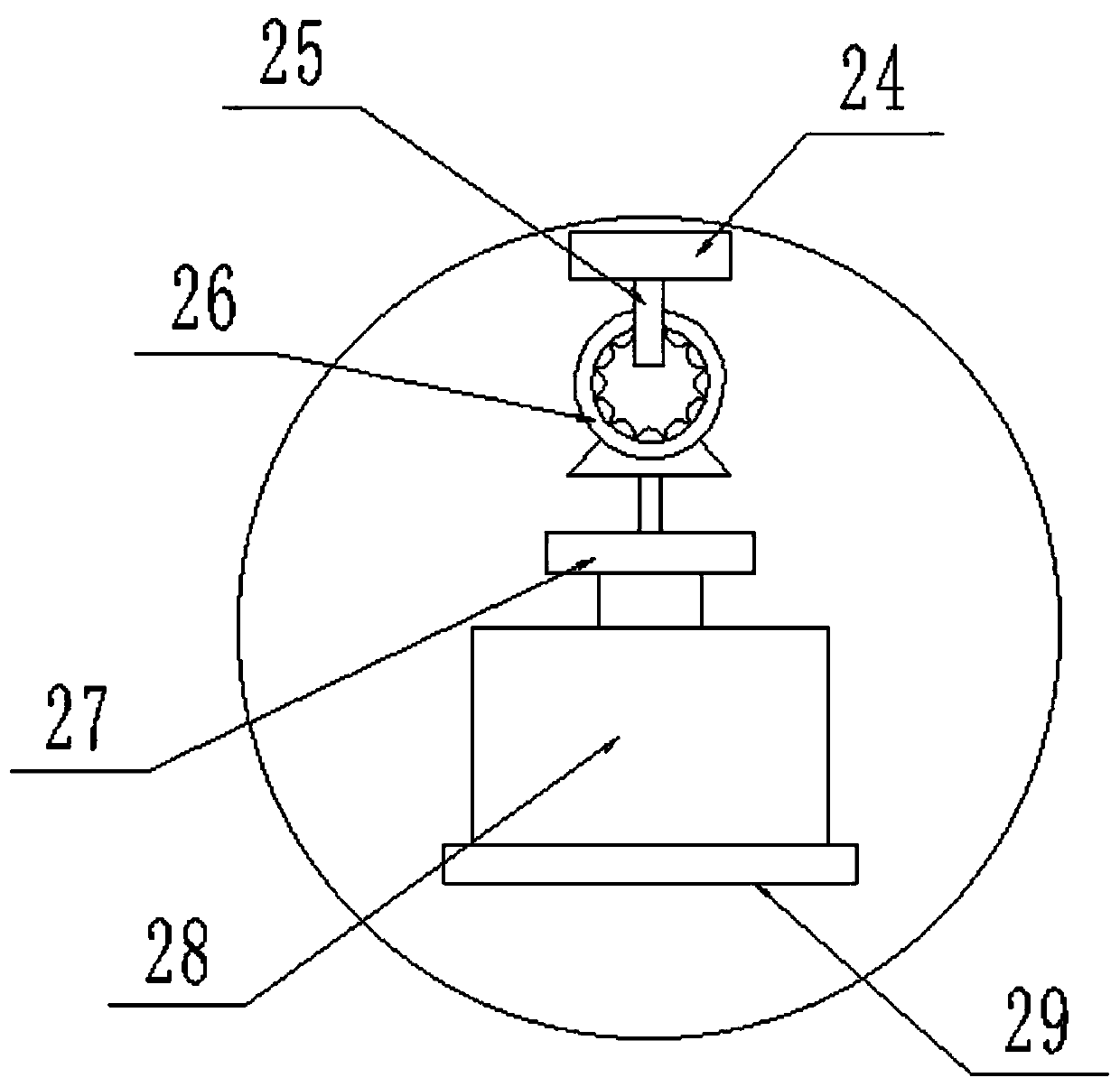

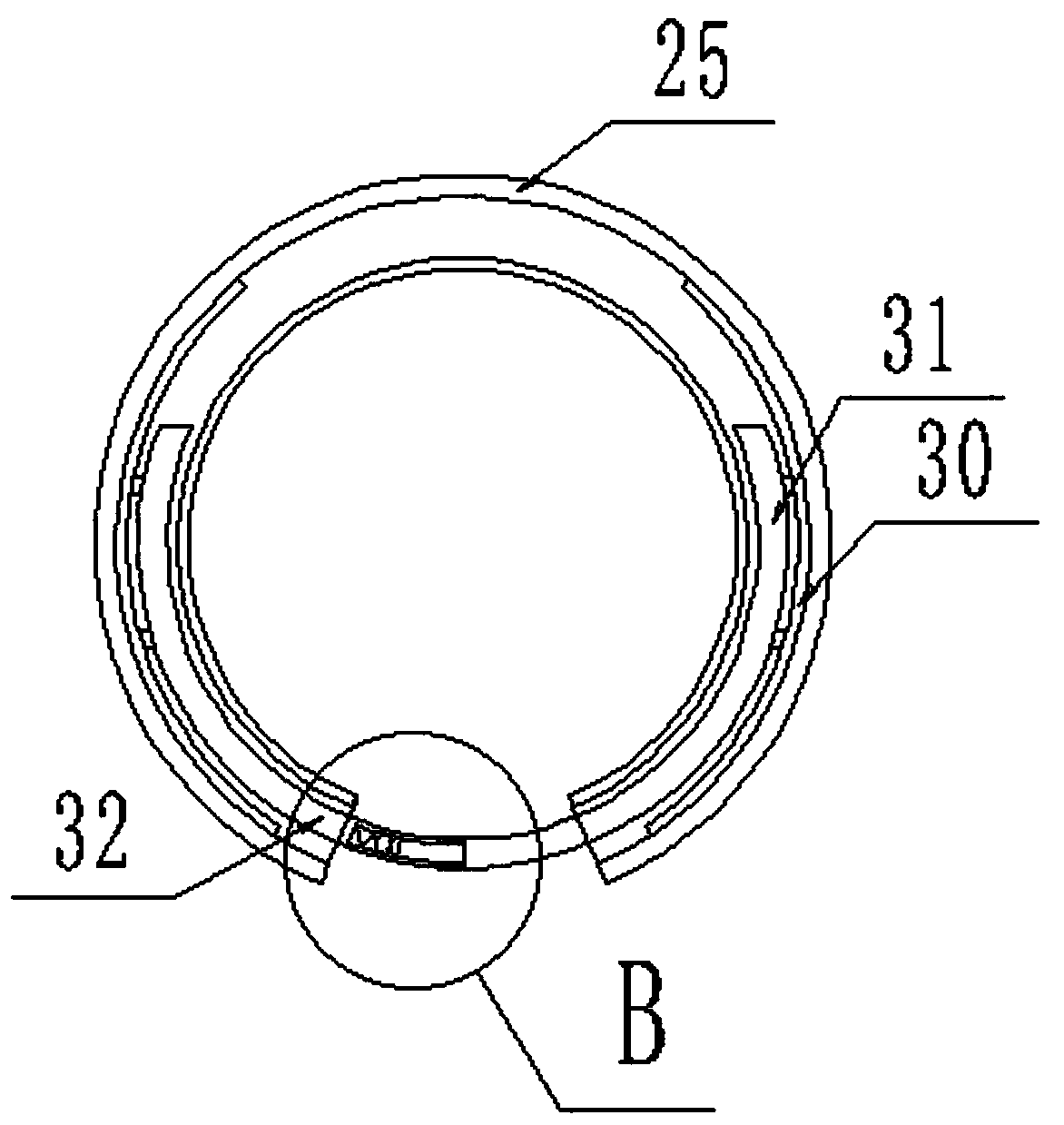

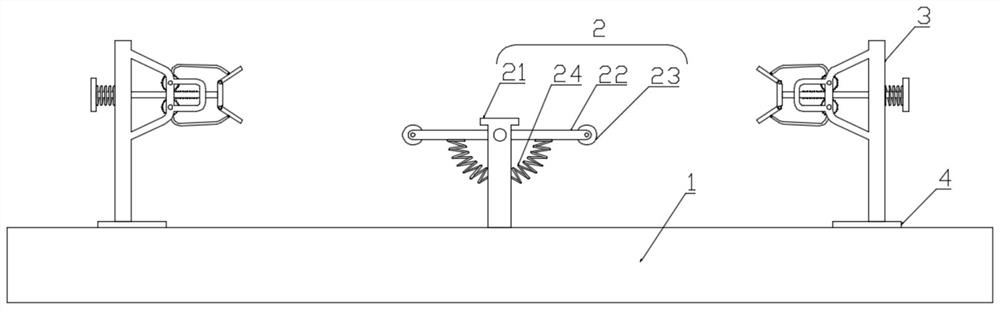

Artificial seismic source device for geophysical exploration

The invention discloses an artificial seismic source device for geophysical exploration. The artificial seismic source device comprises two standing columns I, middle columns, and standing columns II.A bottom box is arranged at the bottoms of the standing columns I; a drive box is arranged at the top of the bottom box; and a telescopic moving mechanism is arranged at the inner wall of the drive box. A plurality of fixing holes distributed uniformly at equal intervals are formed in the outer walls of the middle columns. The middle columns are fixed at the inner tops of the standing columns I and the inner bottoms of the standing columns II by fastening bolts I; and one same top plate is arrange at the tops of the two standing columns II. A power supply mechanism is arranged at the top of the top plate; two fixed frames are arranged at the bottom of the top plate; and same directional wheels are arranged at opposite sides of the two fixed frames. According to the invention, on the basisof an electric hydraulic push rod driving mode, the height of the universal wheel is adjusted freely, the ground gripping effect of the device is improved; the light energy utilization rate is increased; the effects of energy conservation and environment protection are realized; and the wearing of the metal-structure hanging ring is avoided.

Owner:XIAN UNIV OF SCI & TECH

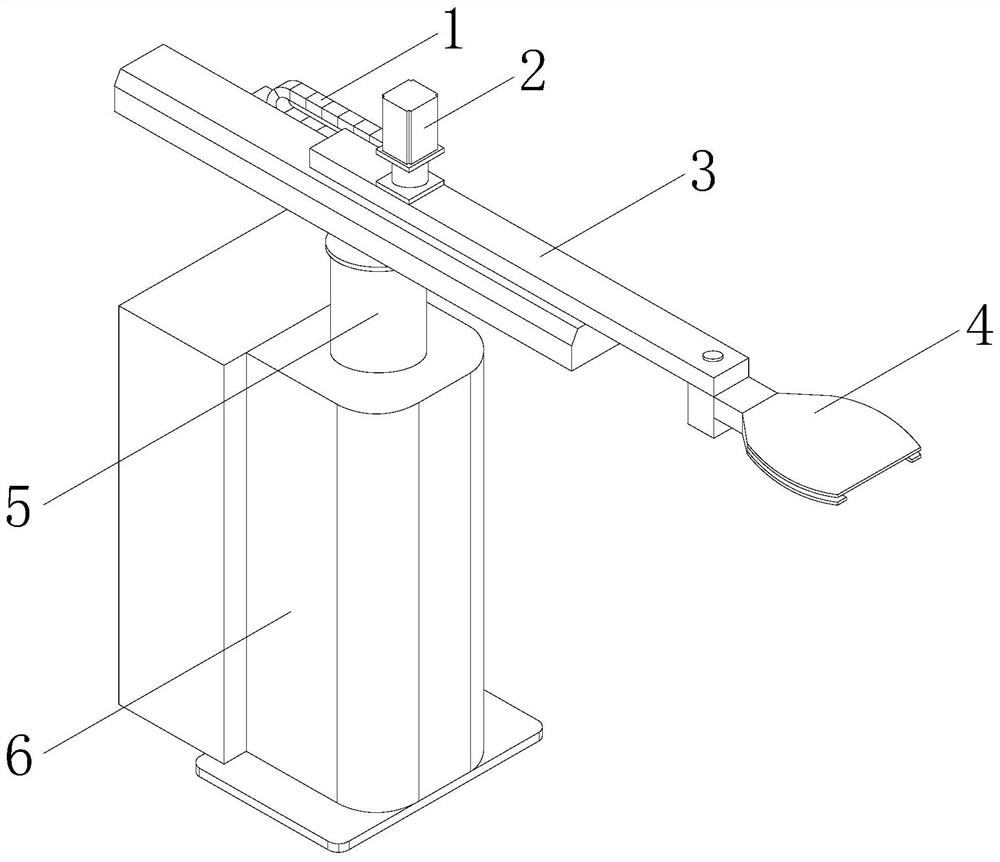

Rotation adjusting mechanism of network intelligent release terminal equipment

InactiveCN105291065AImprove clamping firmnessConvenient horizontal rotation adjustmentWork benchesNetwork intelligenceTerminal equipment

The invention discloses a rotation adjusting mechanism of network intelligent release terminal equipment. The rotation adjusting mechanism comprises a base. A guide pipe is arranged on the base. A rotating pipe is sleeved with the guide pipe. A carrying plate is arranged at the end of the rotating pipe and provided with the intelligent terminal equipment and a limiting plate. The face, facing inwards, of the limiting plate is provided with a lock piece, and the lock piece is arranged on the outer side wall of the intelligent terminal equipment. The limiting plate is connected with a lock rod in an insertion manner. The outer end of the lock rod is a free end, and the inner end of the lock rod is connected with the lock piece. By means of the rotation adjusting mechanism, the intelligent terminal device can be conveniently and horizontally rotated and adjusted, and the rotation adjusting flexibility is better.

Owner:U COM TELECOM EQUIP CO LTD

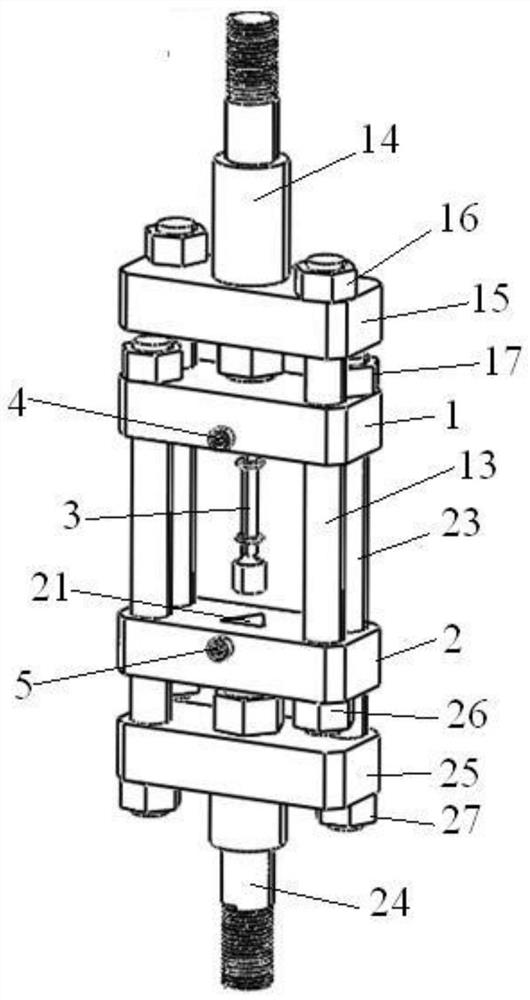

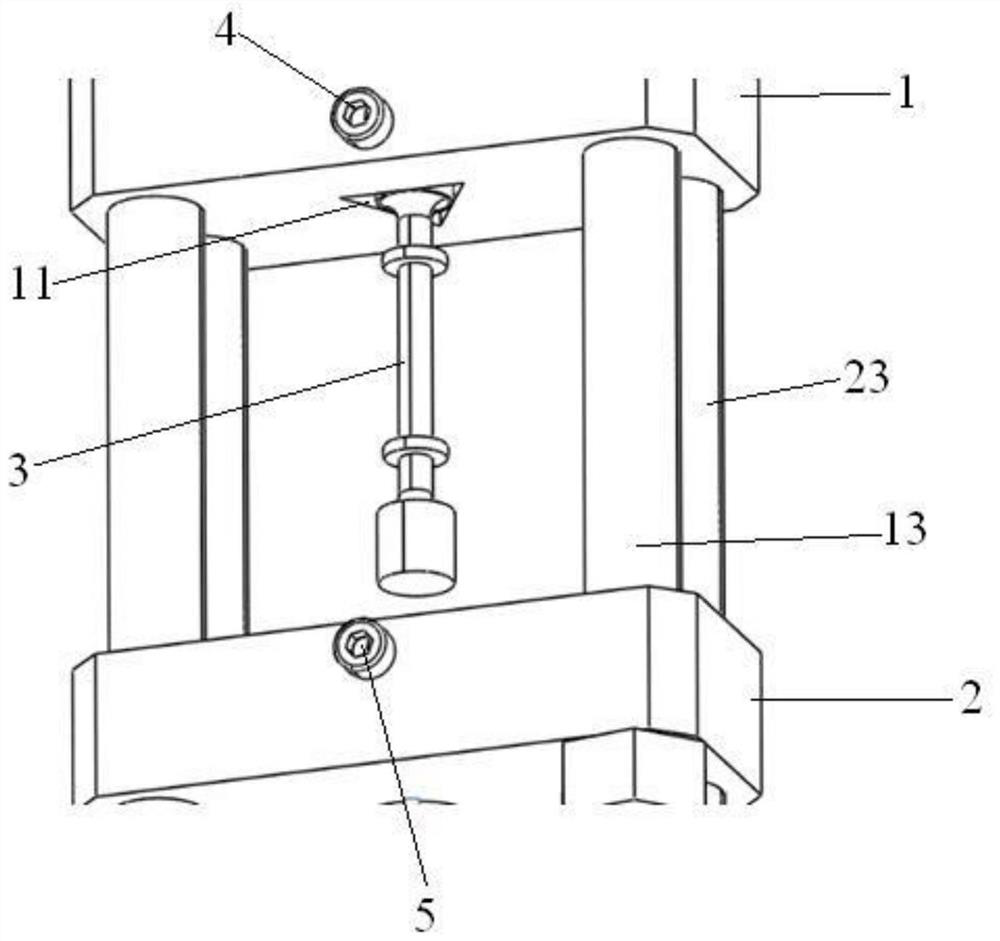

Compressive yield strength test method for material

ActiveCN110595889AAvoid influenceImprove parallelismMaterial strength using tensile/compressive forcesEngineeringUniversal testing machine

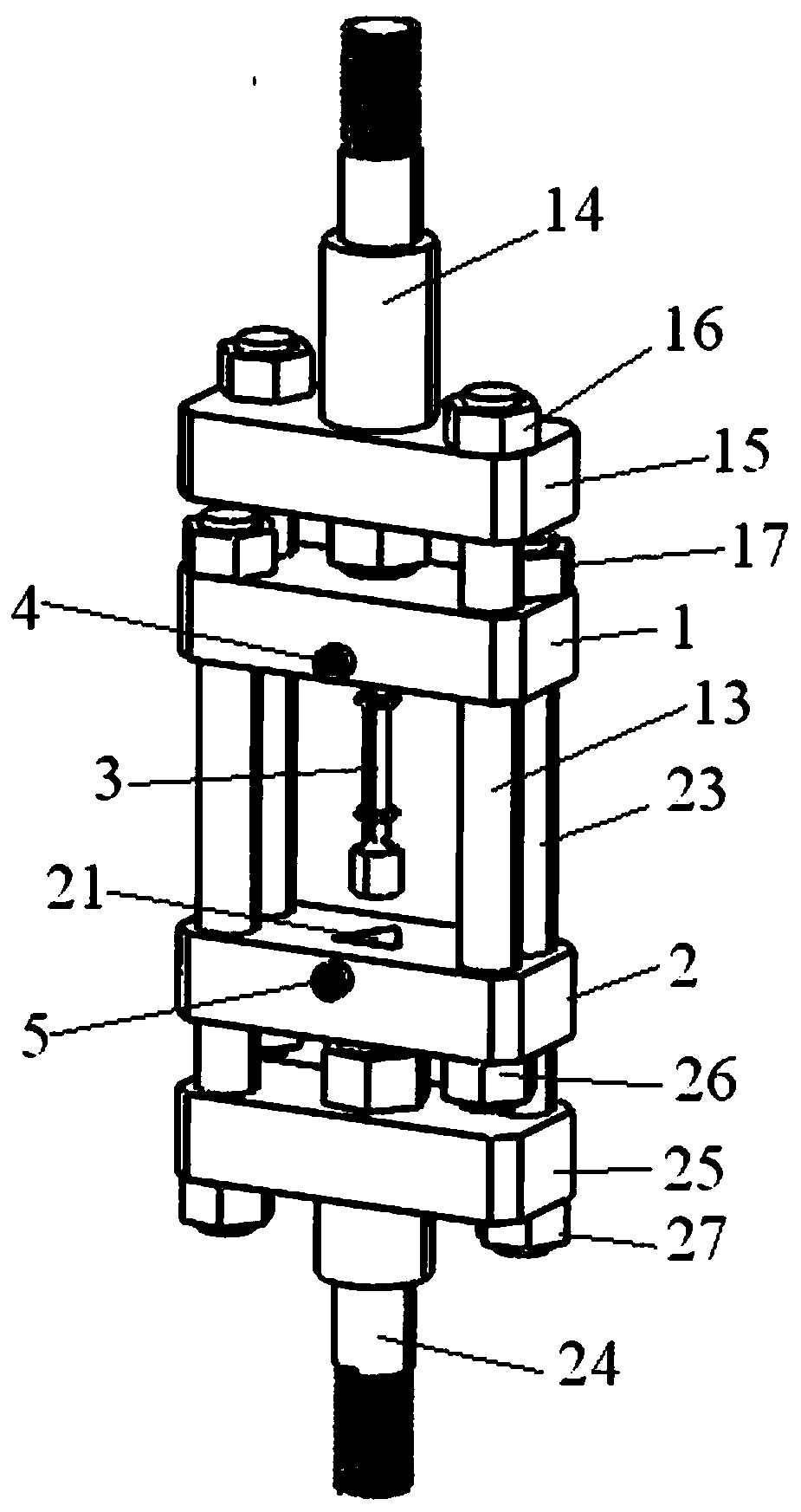

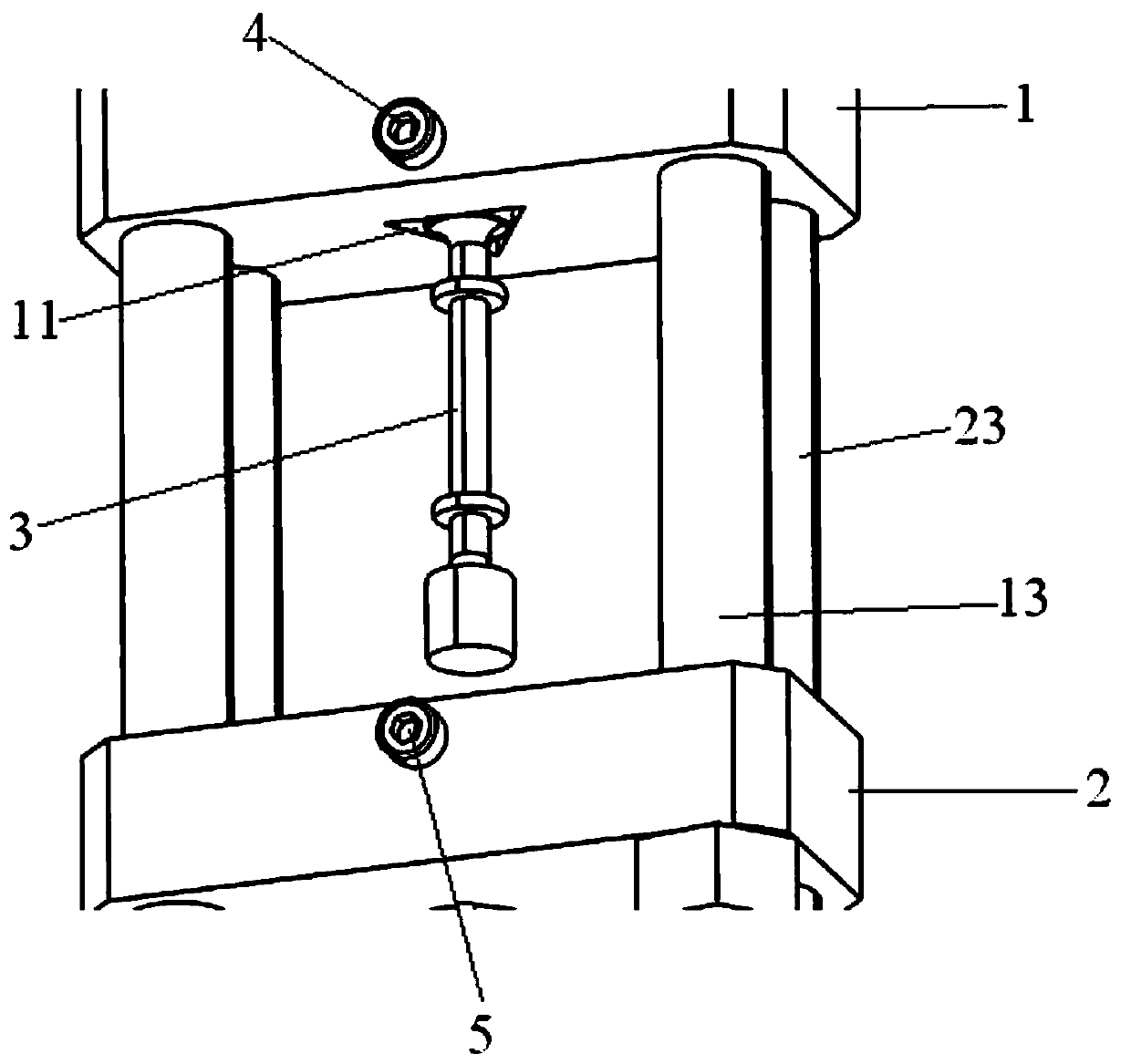

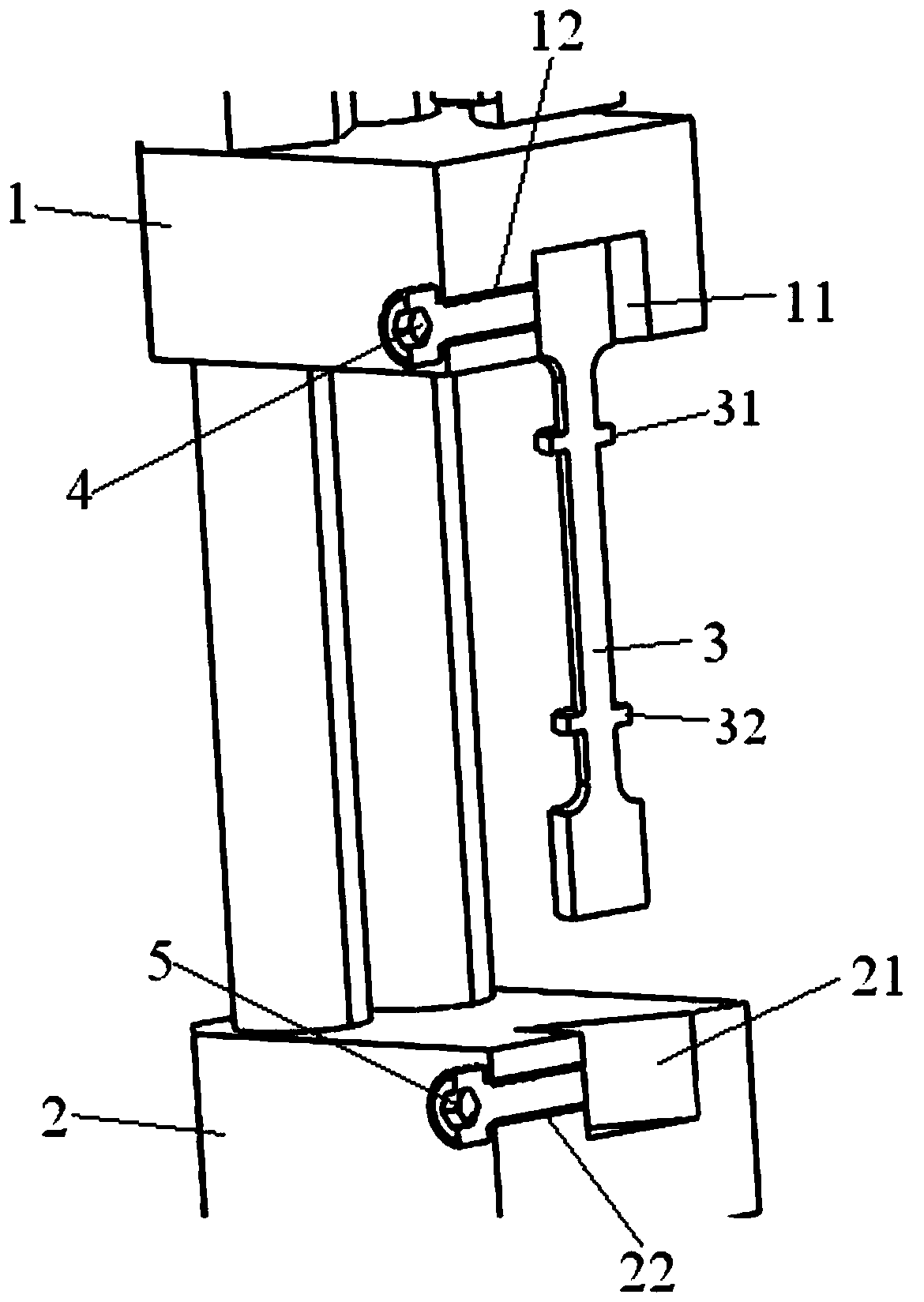

The invention provides a compressive yield strength test method for a material. A normal-temperature compression loading test is carried out on the material by using a universal testing machine and acompression clamp, the compression clamp comprises an upper jacking component, a lower jacking component and a commutator used for being connected between an upper connecting head and a lower connecting head of the universal testing machine, the commutator comprises an upper pressing block and a lower pressing block, the distance between the upper pressing block and the lower pressing block alongthe tensile direction of the universal testing machine for installing a sample is kept, the distance value can be adjusted, the upper pressing block and the lower pressing block are used for clampingand fixing the sample in a jacking mode that triangular prism-shaped positioning holes are matched with the jacking components along the racial direction of the sample. According to the method provided by the invention, the diameter of the rod-shaped sample is thickened, the time for obviously bending the sample is delayed, the safety of a test machine and an operation process is guaranteed, the end part of the sample is changed into a smooth cylindrical structure from a threaded structure, the clamping firmness of the sample is enhanced, the steps required for processing the sample into a finished product are reduced, and the neutralization of the sample can also be enhanced.

Owner:CENT SOUTH UNIV

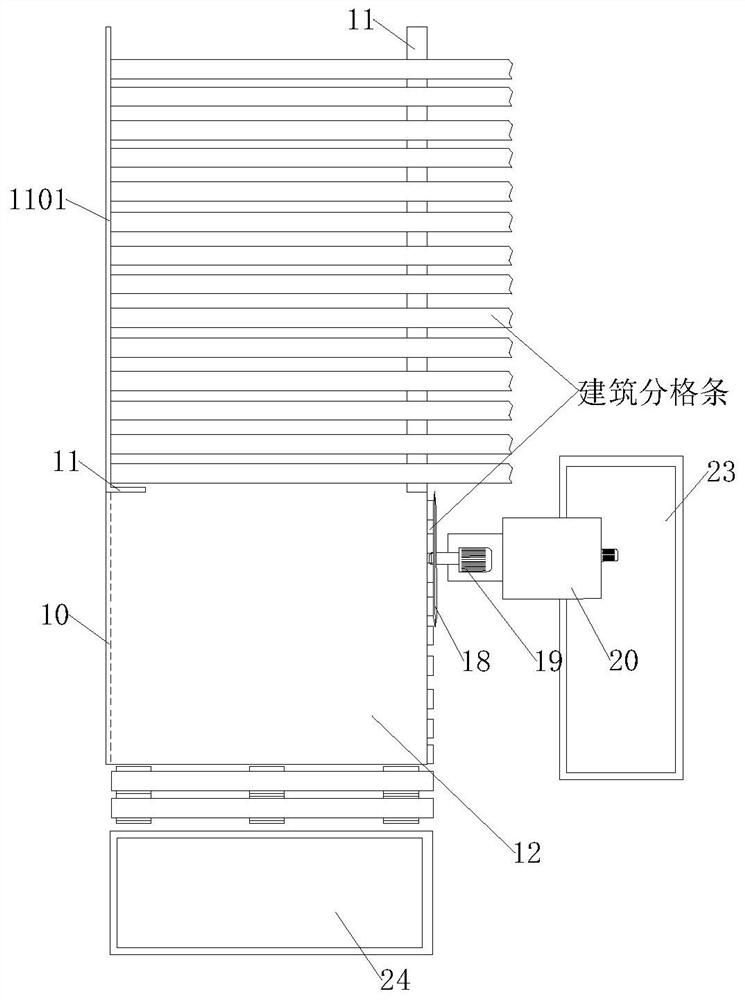

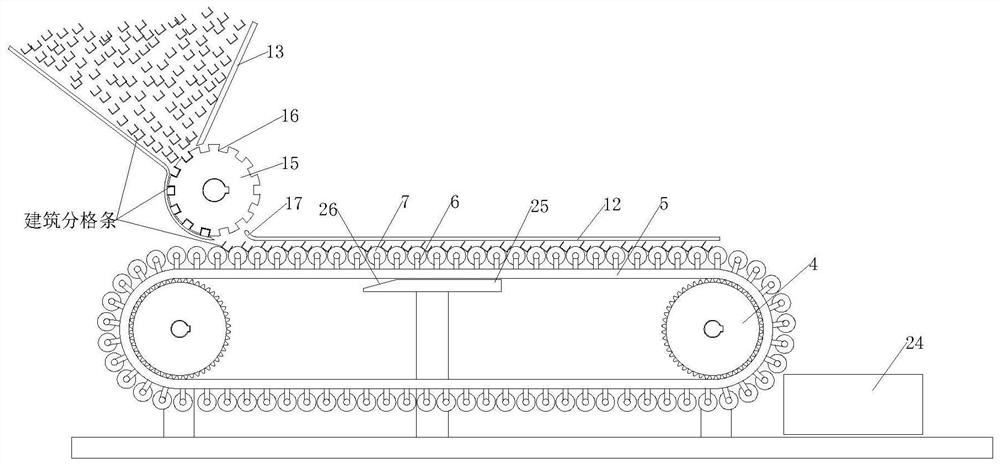

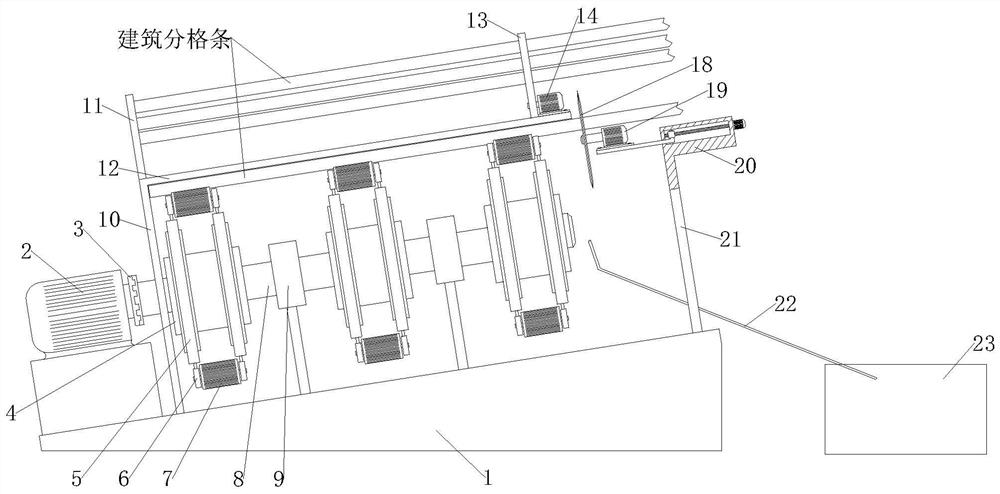

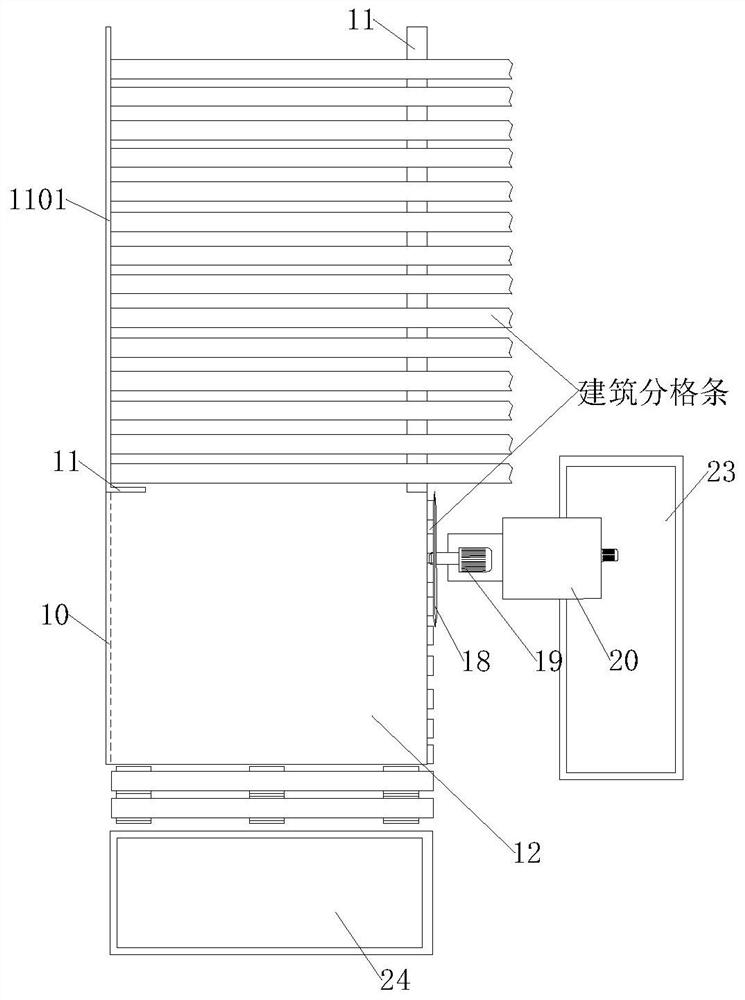

House building dividing strip constant-size processing device

ActiveCN111823294AFacilitate equidistant machiningSame lengthMetal sawing devicesPolishing machinesAgricultural scienceElectric machine

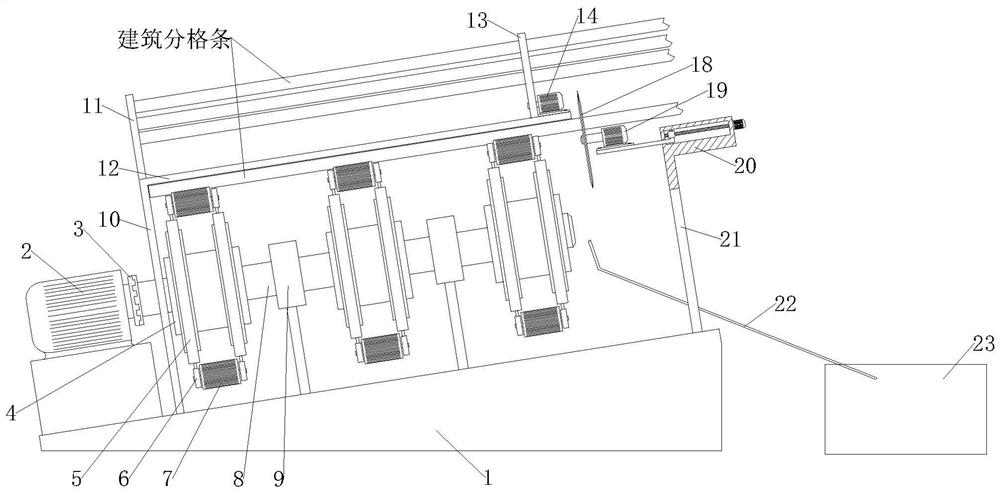

The invention provides a house building dividing strip constant-size processing device, and relates to the technical field of house building construction. The house building dividing strip constant-size processing device comprises a base, the top end of the base is provided with an inclined surface, the top end of the base is provided with a plurality of columns of circulating moving rollers, andthe rollers in every two adjacent columns are arranged at equal intervals. The two ends of each roller are mounted on a roller support through bearings, and the bottom, on the two sides of the rollers, of the roller support is fixed to a transmission belt. The two ends of an inner ring of the transmission belt are provided with driving rollers. A cutting blade is driven by a third motor to rotate,the third motor is fixedly installed on a motor supporting plate which is driven by a threaded lead screw to rotate, the length of the portion, extending on a motor supporting base, of the motor supporting plate is controlled, and the working position of the cutting blade is adjusted, so that the processing device can be used for processing building dividing strips with different lengths in batches.

Owner:宜昌华鼎建筑工程有限公司

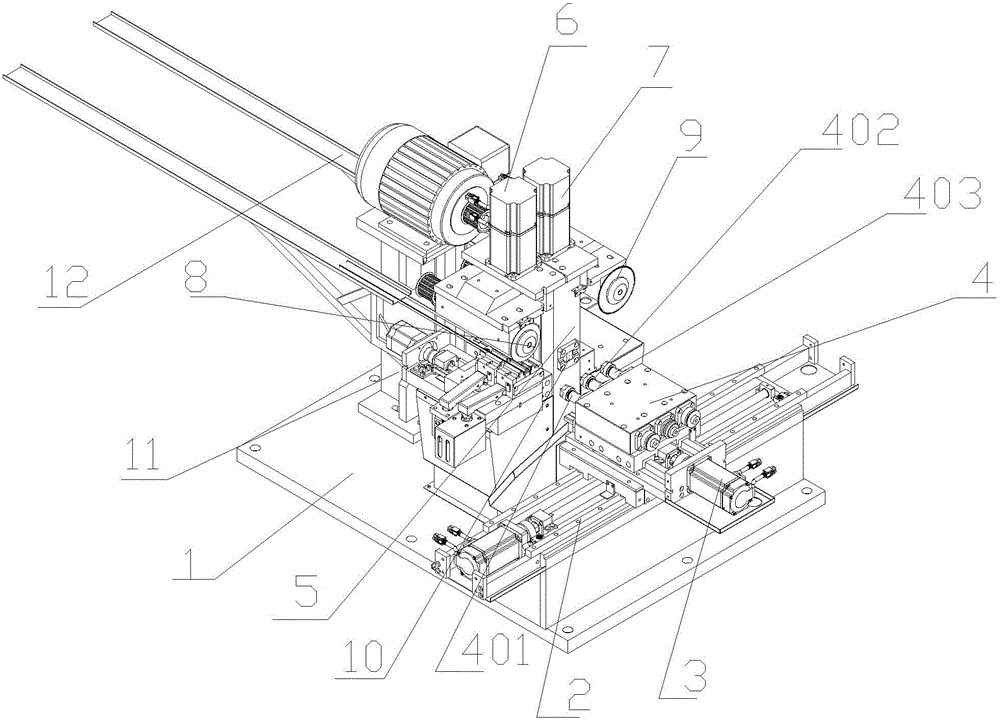

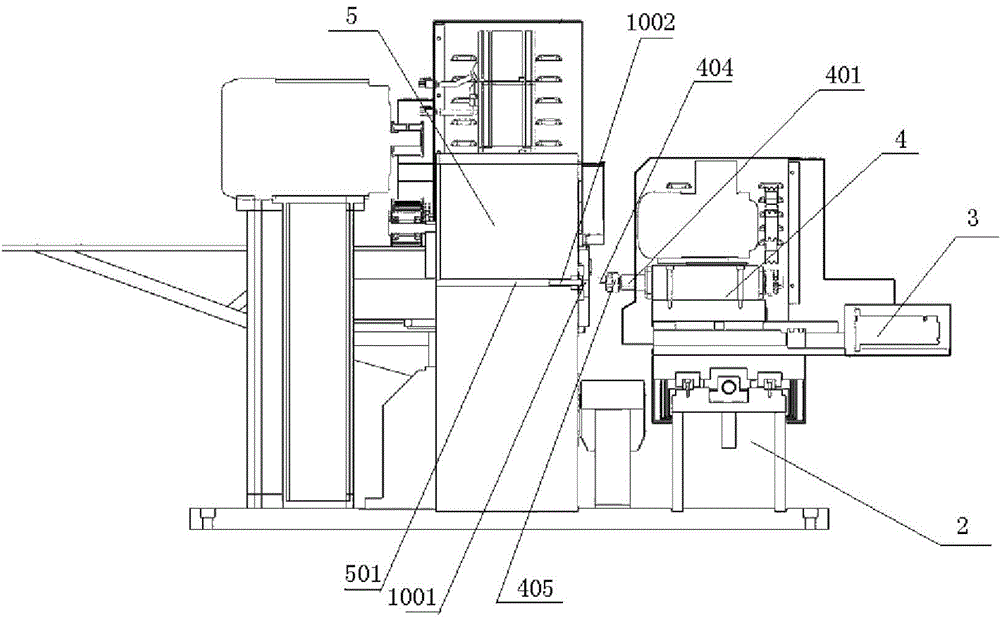

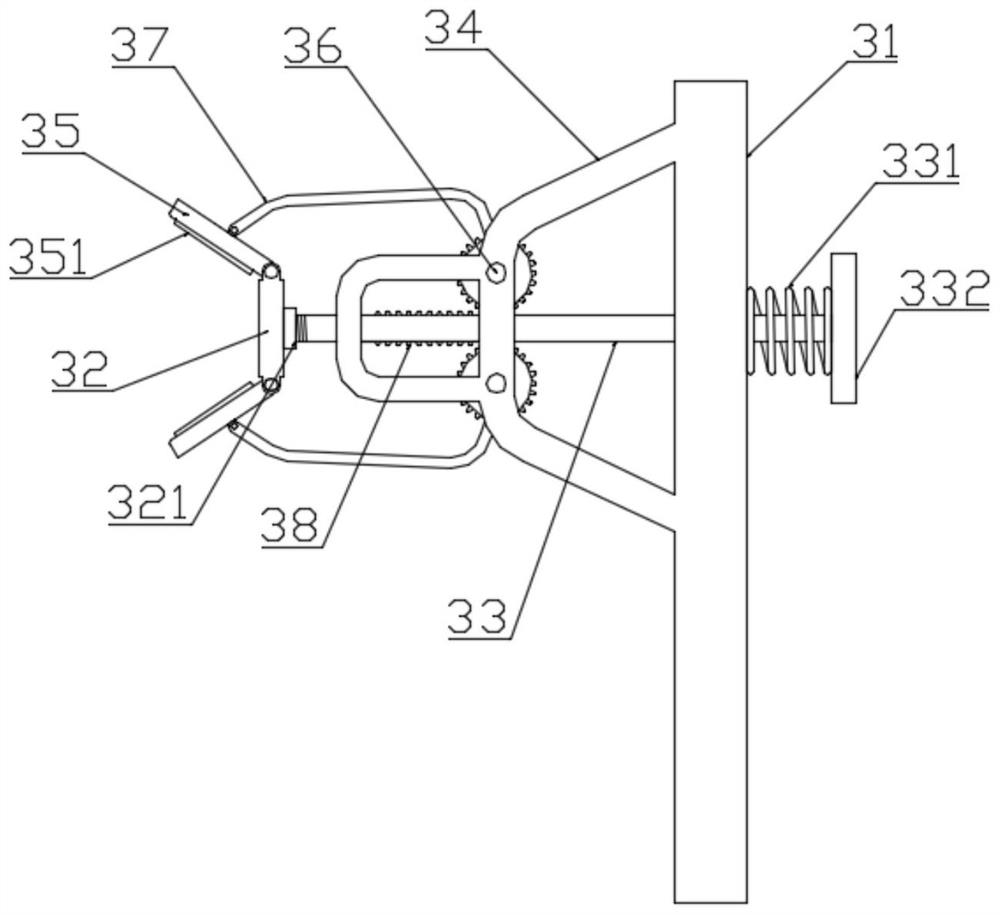

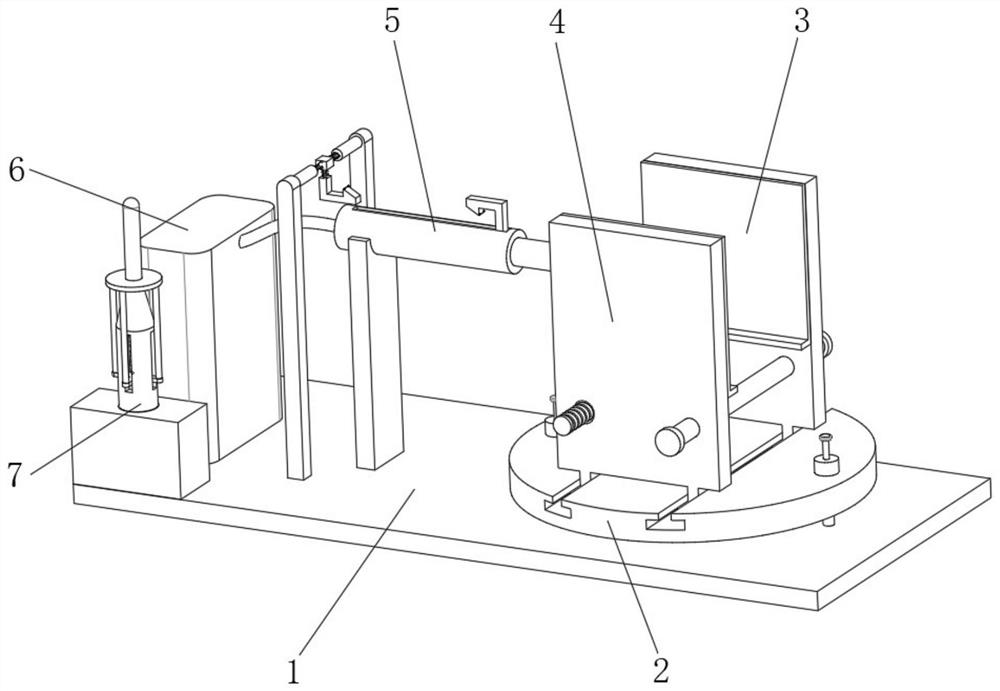

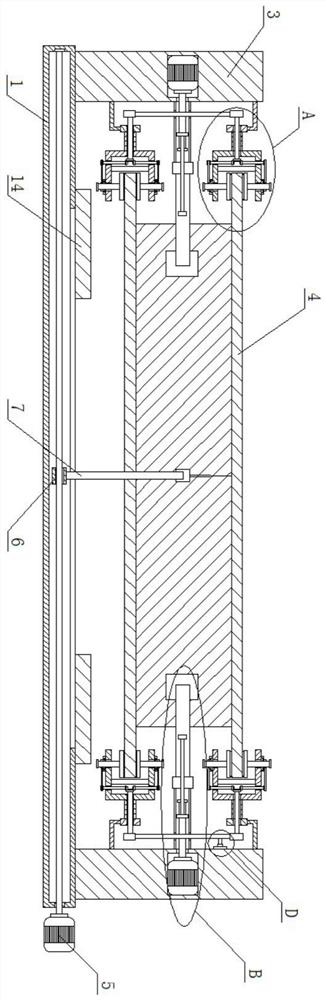

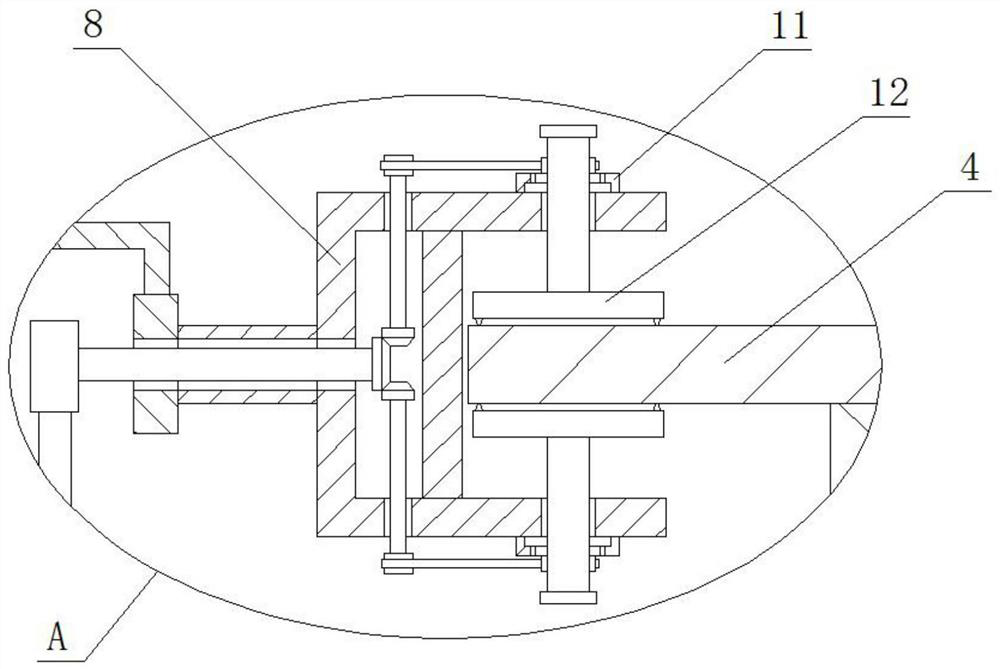

Drilling and cutting integrated machine and machining method thereof

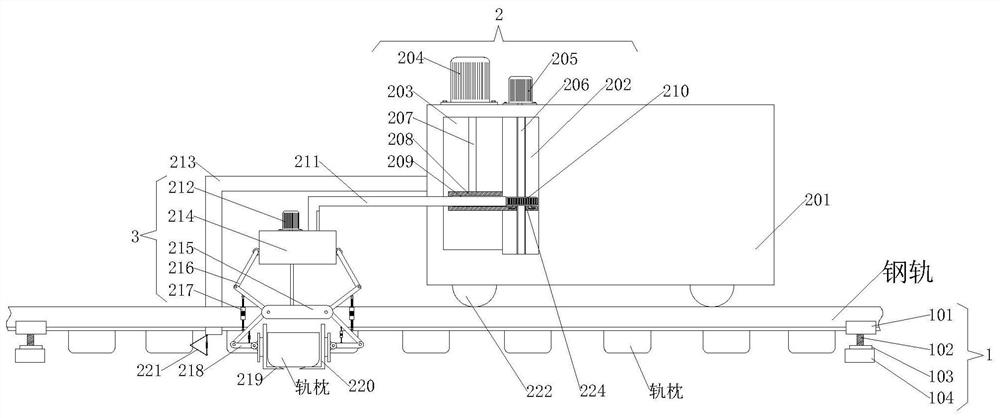

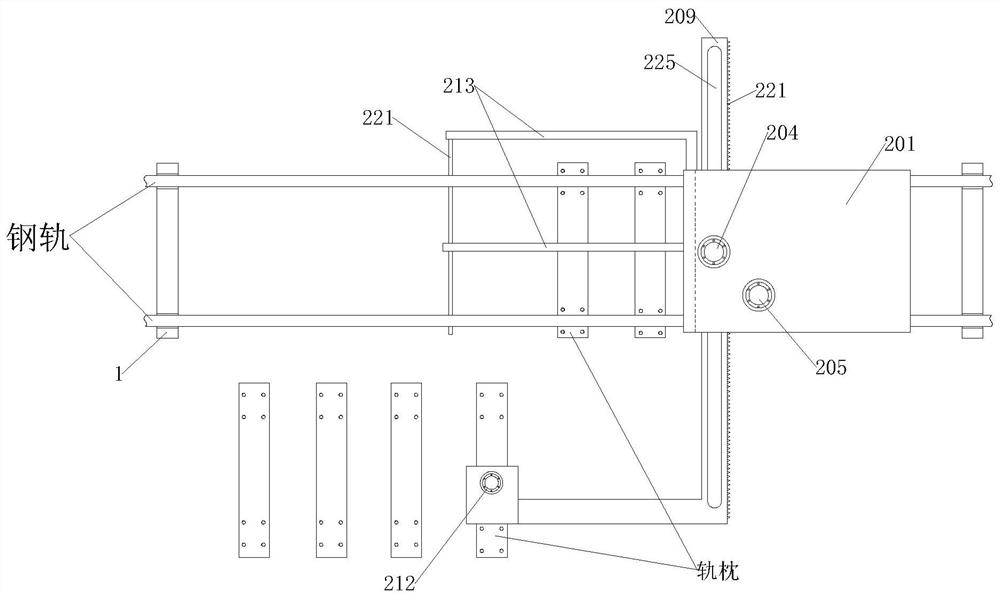

InactiveCN105312901ASave time waiting for drillingGuaranteed consistent drilling depthOther manufacturing equipments/toolsMetal working apparatusControl systemEngineering

The invention provides a drilling and cutting integrated machine and a machining method thereof. The drilling and cutting integrated machine comprises a machine base, a drilling part, a cutting part, a feeding part and a control system, wherein the feeding part and the cutting part are arranged on the left side of the machine base, and the drilling part is arranged on the right side of the machine base; the cutting part comprises a stand column fixed to the machine base, a front cutter mechanism, a rear cutter mechanism, a B-axis movable mechanism and an A-axis movable mechanism; the feeding part comprises a front feeding mechanism and a rear feeding mechanism which are of the same structure and located below the front cutter mechanism and the rear cutter mechanism respectively and on the machine base; a tool setting gauge is arranged on the stand column and located below the cutter mechanisms, and the tool setting gauge and the drilling part are located on the same horizontal plane. When the drilling and cutting integrated machine is adopted for machining, drilling and cutting are conducted at the same time, and time for waiting for drilling is saved; when drilling is conducted on profiled materials, uniformity of drill depths of all drilling bits can be guaranteed.

Owner:深圳市群鑫自动化设备有限公司

Automobile front floor welding clamp

InactiveCN114310118AImprove clamping firmnessImprove clamping strengthWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention discloses an automobile front floor welding clamp, and relates to the technical field of automobile accessory machining, the welding clamp comprises a clamp base, a center bearing part and at least one pair of end clamping assemblies, and further comprises a clamping driving component, each end clamping assembly comprises a fixing support, a forward abutting part, an abutting rod, a mounting support body and two side clamping parts, the fixing support is installed on the clamp base and connected with the clamping driving component, the installation support body is arranged on the fixing support and provided with two clamping rotating shafts in rotating fit with the installation support body, each clamping rotating shaft is provided with a gear and a push rod, the abutting rod is provided with a rack capable of being meshed with the gear, and the clamping driving component is arranged on the abutting rod. The side part of the side clamping part is connected with the push rod; the end, away from the forward abutting part, of the abutting rod is provided with an elastic pressing piece. The automobile front floor clamping device is simple in structure, capable of achieving clamping rapidly, suitable for the shape of the clamped end of an automobile front floor, firm in clamping and high in practicability.

Owner:王江红

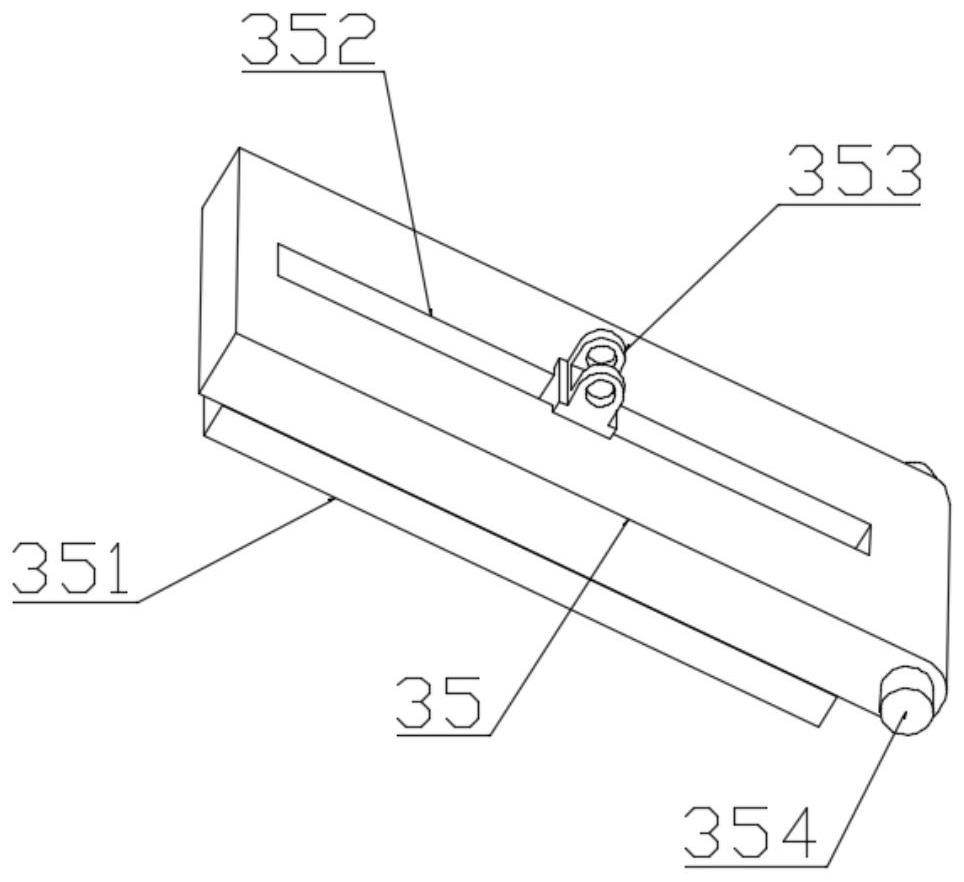

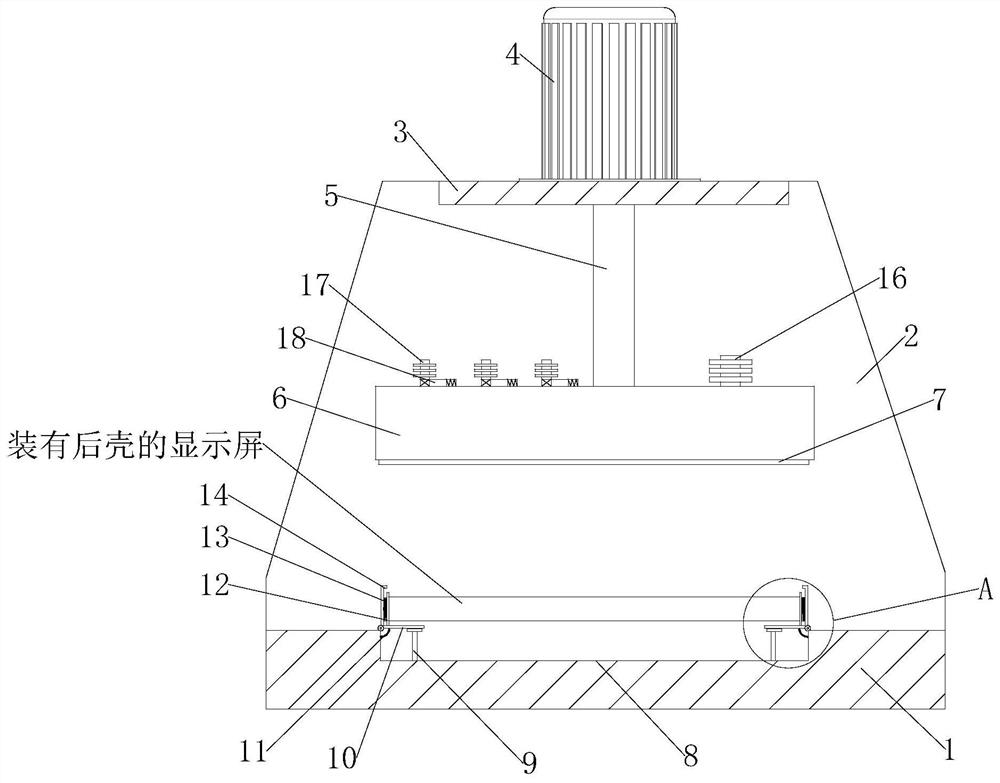

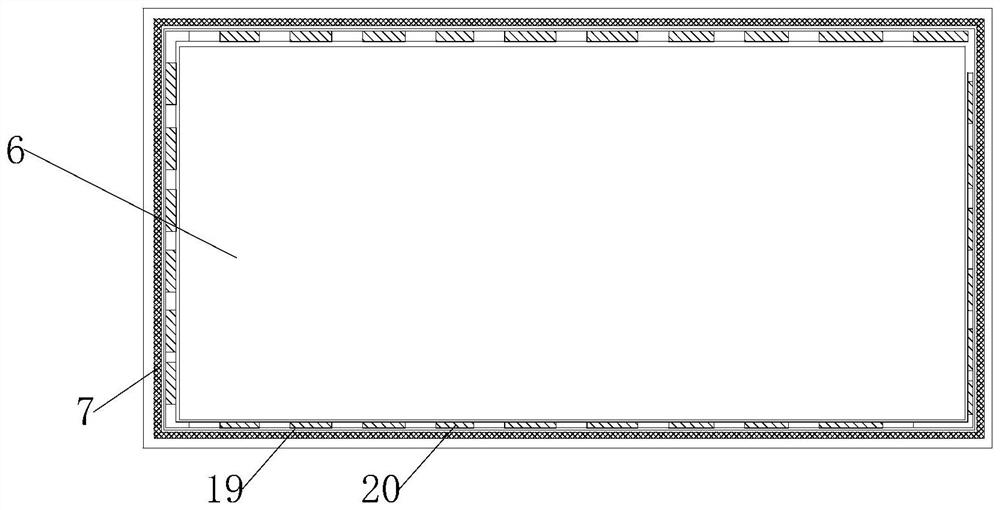

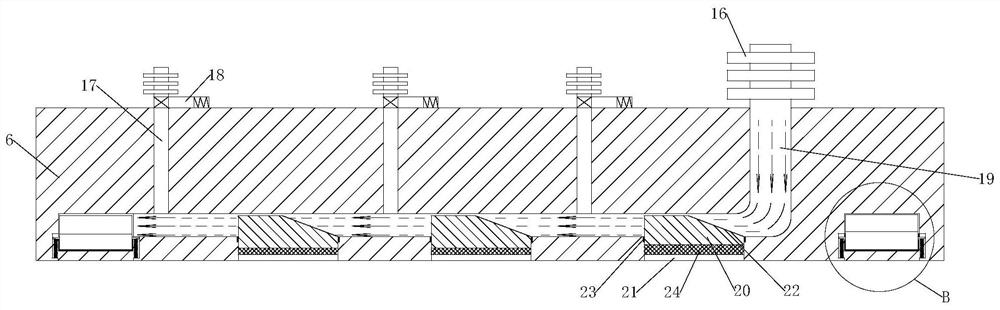

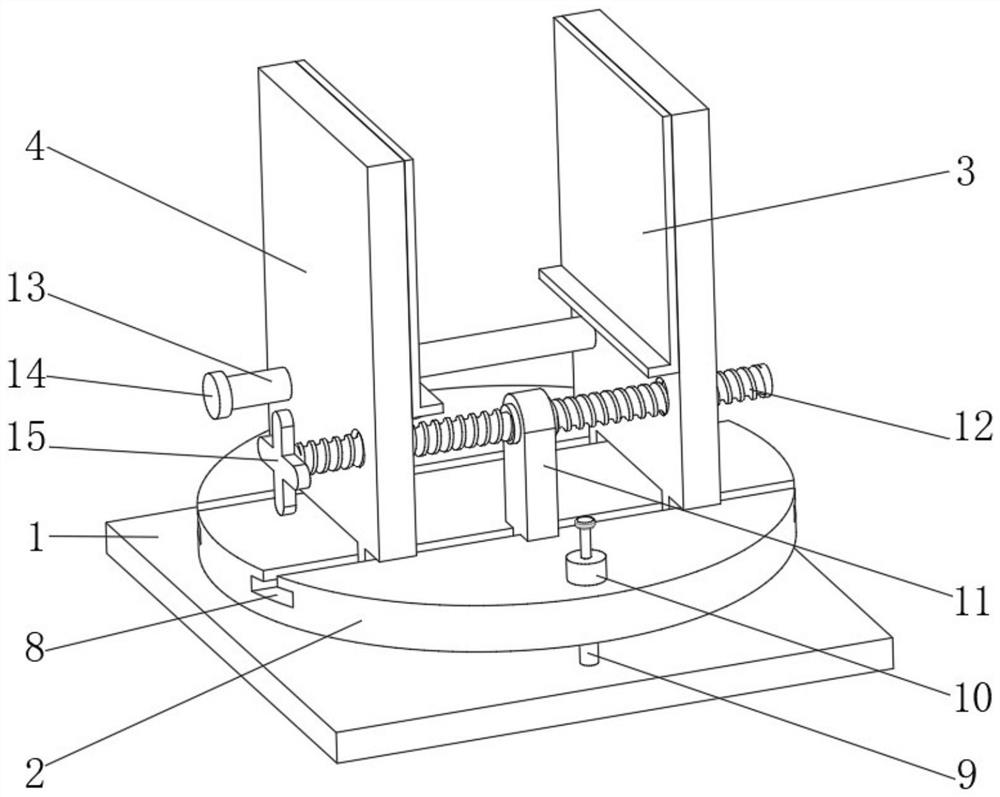

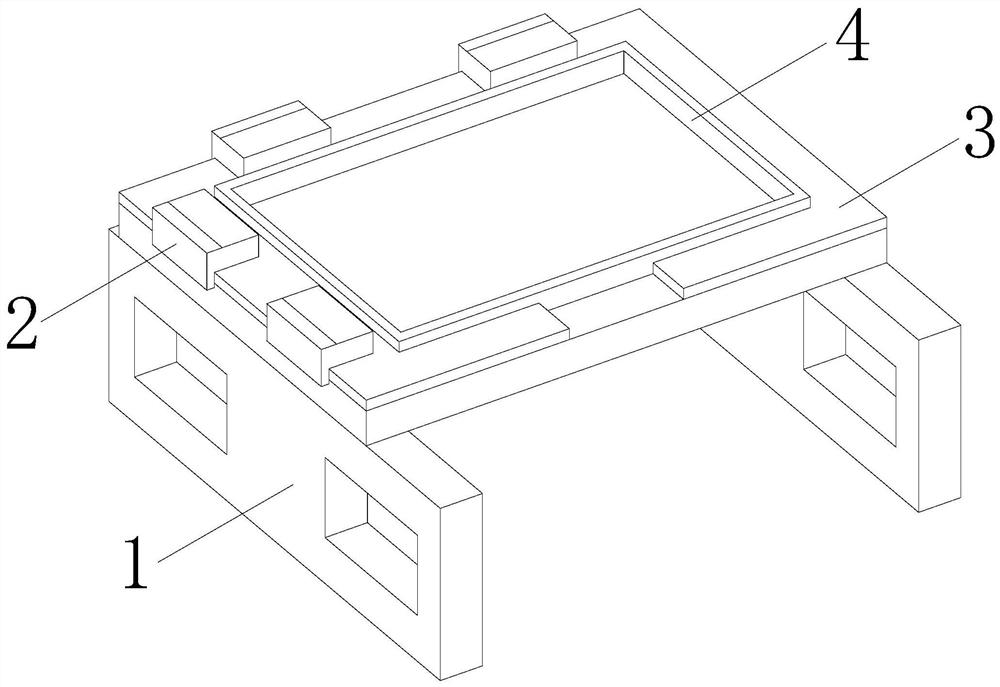

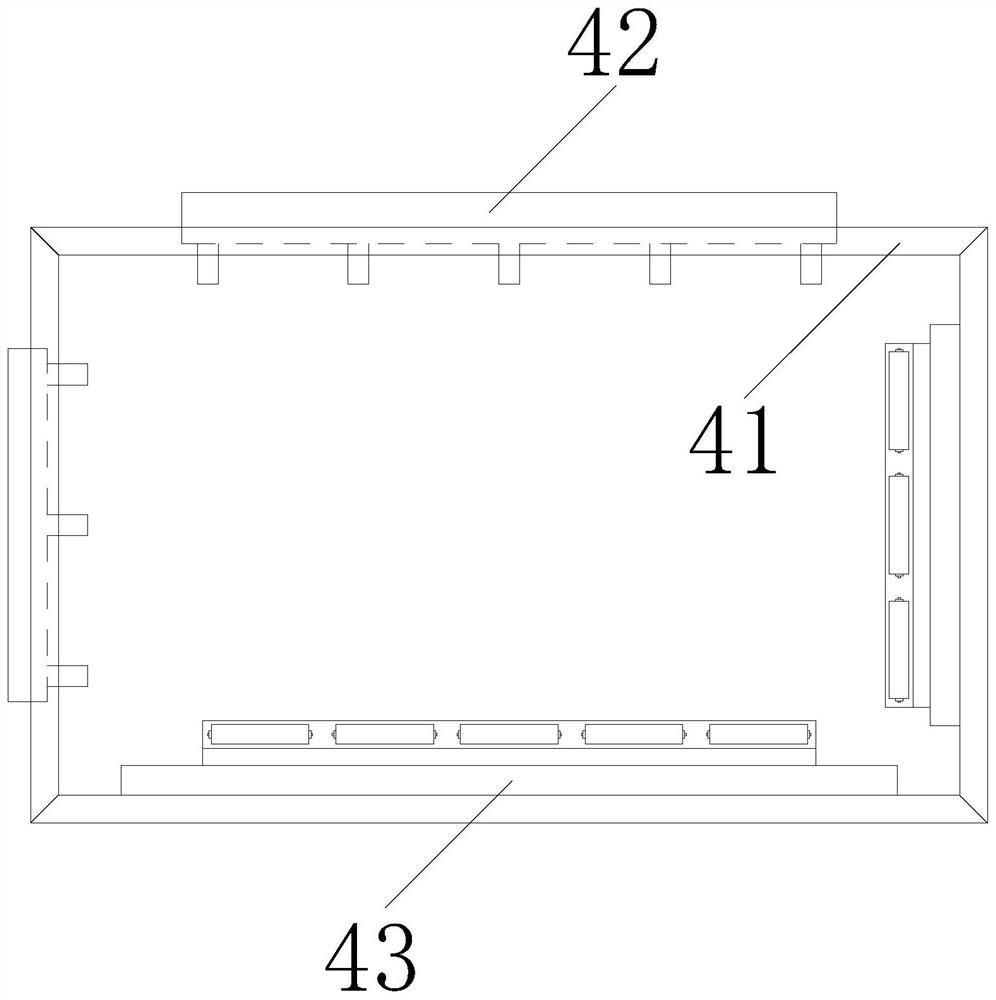

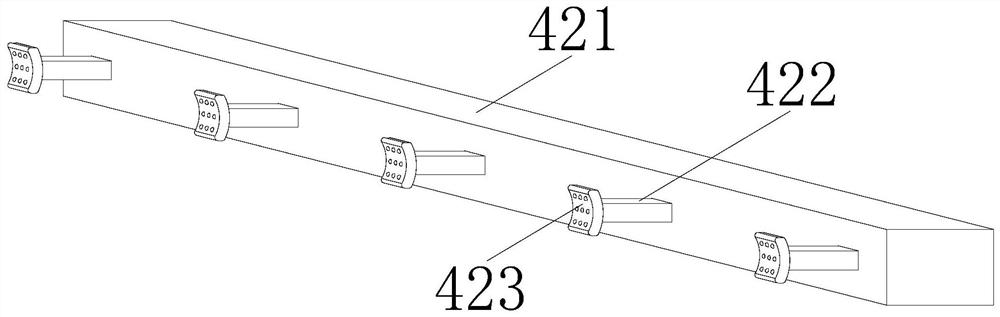

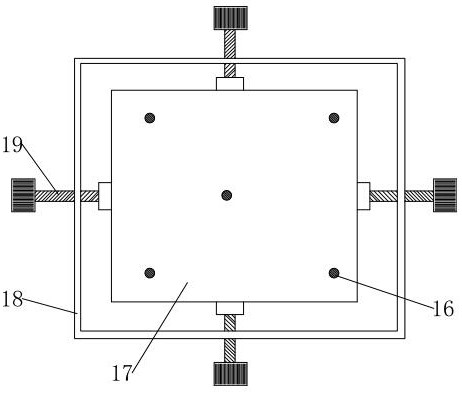

An auxiliary tooling for assembling the outer frame of a computer liquid crystal display

ActiveCN111590301BImprove clamping firmnessEasy to placeMetal working apparatusLiquid-crystal displayEngineering

The invention provides an auxiliary tool for assembling the outer frame of a computer liquid crystal display, which relates to the technical field of liquid crystal display production and processing, and includes a bottom support plate, the top of which is provided with a side support rib standing upright on the top of the bottom support plate , the top of the side support ribs is provided with a horizontally fixed top support plate, the top of the top support plate is fixedly installed with a pneumatic cylinder, and the pneumatic cylinder protrudes downwards with a piston rod, and the bottom of the piston rod A square block-shaped pressing block is provided at the end, and a raised pressing pad is provided at the bottom of the pressing block; the present invention is supported by a supporting column so that the bottoms of the clamping frames on both sides are fixed horizontally, and through the The protruding block on the top of the clamping frame clamps the two sides of the display screen equipped with the back shell, so that the display screen equipped with the back shell is installed and fixed on the clamping frames on both sides, and the display screen equipped with the back shell is improved. clamping firmness.

Owner:SHANDONG POLYTECHNIC COLLEGE

Clamping device with good firmness for drilling machine machining

InactiveCN108673196AImprove clamping firmnessImprove operation conveniencePositioning apparatusMetal-working holdersSlide plateDrilling machines

The invention discloses a clamping device with good firmness for drilling machine machining. The clamping device comprises a base, a support column is fixed to the top outer wall of the base through screws, and the top and bottom of the outer wall of one side of the support column are separately connected with a limiting wheel and a rotating wheel in a sleeved mode. A moving block sliding groove is formed in the outer wall of the top of the base, and the inner wall of the moving block sliding groove is slidably connected with a moving block. A threaded rod mounting hole is formed in the outerwall of one side of the base, and the inner wall of the threaded rod mounting hole is connected with a threaded rod in a sleeving mode. A working table is fixed to the top outer wall of the limiting wheel through screws, and a fixed clamping plate is fixed to one side of the top outer wall of the working table through screws. The distance between a sliding clamping plate and the fixed clamping plate and the distance between two sliding plates can be adjusted, a workpiece can be clamped and fixed from multi-directions, the improvement of the clamping firmness is facilitated, it is beneficial toimprove the operation convenience and the stability of the working table, and the possibility of workpiece movement during machining can be reduced.

Owner:湖北睿臣装备技术有限公司

Solenoid valve group assembly auxiliary device

ActiveCN112276551BEasy to fixGuaranteed reliabilityAssembly machinesWork holdersSolenoid valveScrew thread

Owner:嘉兴达鼎自动化科技有限公司

A rubber product manufacturing bonding process

ActiveCN111805922BImprove firm performanceImprove connection tightnessCleaning using toolsAdhesive glueSteel ball

Owner:湖南铭弘体育产业股份有限公司

A kind of dimensioning processing equipment for building grid strips

ActiveCN111823294BFacilitate equidistant machiningSame lengthMetal sawing devicesPolishing machinesTransmission beltConstruction engineering

The invention provides a processing equipment for sizing grid strips of house construction, which relates to the technical field of house construction. There are multiple rows of circularly moving rollers, and the rollers in two adjacent rows are arranged at equal intervals, wherein, the two ends of each roller are mounted on the roller bracket through bearings, and the bottom of the roller bracket located at the two ends of the roller It is fixed on the transmission belt, and driving rollers are installed at both ends of the inner ring of the transmission belt; in the present invention, the cutting piece is driven to rotate by the No. 3 motor, and the No. 3 motor is fixedly installed on the motor support plate, and the motor support plate is driven by a threaded screw. Rotate, control the protruding length of the motor support plate on the motor support seat, adjust the working position of the cutting piece, so that the processing equipment of the present invention can process building grid strips of different lengths in batches.

Owner:宜昌华鼎建筑工程有限公司

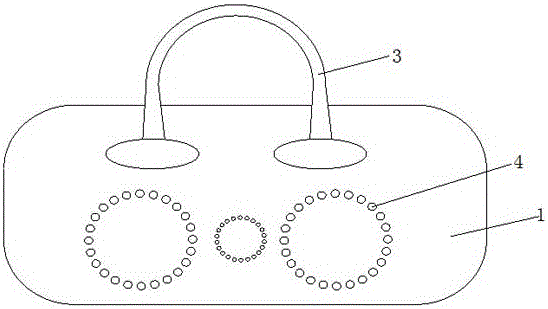

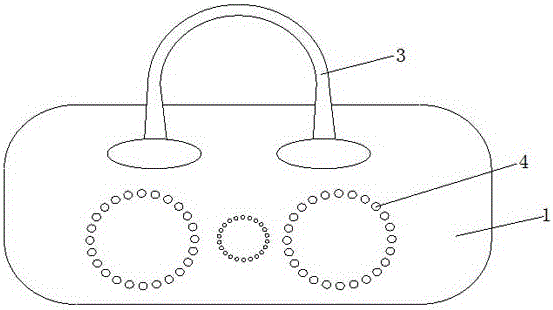

Improved pearl embroidered handbag

The invention discloses an improved bead embroidery handbag, which comprises a bag body. The bag body includes a front end face and a rear end face parallel to each other. A ring-shaped handle is arranged on the top of the front end face and the rear end face. There are several bead embroidery beads, and the bead embroidery beads are sewn on the front face and the rear end face; a middle connecting strip is arranged between the front end face and the rear end face, the middle connecting strip is a strip of cloth, and the middle connecting strip is bent into a ring shape The back is fixedly connected with the edge of the front end surface and the rear end surface; a linear slit is arranged in the middle of the middle connecting strip, and a closing mechanism is arranged on the linear slit; the closing mechanism includes several mother beads and child beads, and the mother bead The beads are evenly arranged on one side of the linear slit, and the beads are evenly arranged on the other side of the linear slit. The invention has the advantages that it can overcome the disadvantages of the prior art, and the structural design is reasonable and novel.

Owner:江阴市天工礼品有限公司

Steel structure support manufacturing equipment for building construction of steel structure factory building and using method of steel structure support manufacturing equipment

InactiveCN114074242AImprove clamping firmnessStrong clamping stabilityWelding/cutting auxillary devicesAuxillary welding devicesManufacturing engineeringConstruction engineering

The invention discloses steel structure support manufacturing equipment for steel structure factory building construction, the steel structure support manufacturing equipment comprises a base and a steel structure support body, the steel structure support body is located at the position, close to the center, of the top of the base, and fixing blocks are fixedly connected to the positions, close to the left side and the right side, of the top of the base. The equipment has the advantages that through the arrangement, the clamping firmness of the steel structure support body is high, the clamping stability is high, the later installation of the steel structure support body during assembling is facilitated, the situations of uneven angles and inclined installation during installation are greatly reduced, the welding problem is avoided, materials are saved, the welding effect is straight, the conditions of welding skips and uneven welding during manual welding are avoided, the labor amount of manual welding is greatly reduced, meanwhile, the production efficiency is improved, and the welding effect of the equipment is far higher than that of manual welding.

Owner:XIJING UNIV

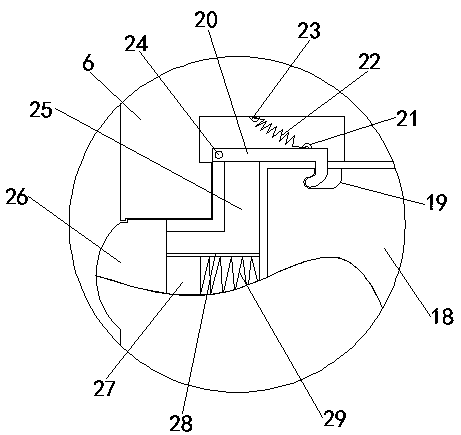

Stable textile machinery supporting device

InactiveCN108591705AImprove stabilityWeaken the forceNon-rotating vibration suppressionEngine bedsAgricultural engineeringTextile

The invention relates to the technical field of textile machinery and discloses a stable textile machinery supporting device. The stable textile machinery supporting device comprises mounting machinery, wherein a fixed bar is fixedly connected to the front surface of the mounting machinery; a supporting framework is arranged in the bottom of the mounting machinery; first screws are in threaded connection to the left and right sides of the supporting framework; sealing blocks are in threaded connection to the back surfaces of the first screws; the opposite surfaces of the two sealing blocks arefixedly connected to auxiliary rods; the fixed rod is fixedly connected to the front surfaces of the auxiliary rods; a fixed block is fixedly connected to the bottom of the supporting framework; a first spring is fixedly connected to the bottom of the fixed block; a bottom block is fixedly connected to the bottom of the first spring; a first hinge is fixedly connected to the top of the bottom block; and a first connecting rod is fixedly connected to the top of the first hinge. The stable textile machinery supporting device achieves the purpose of being high in stability and excellent in shockabsorbing effect.

Owner:李丽倩

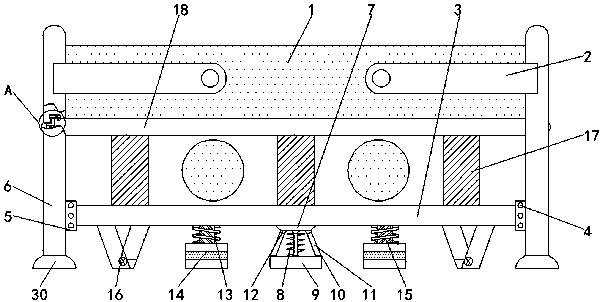

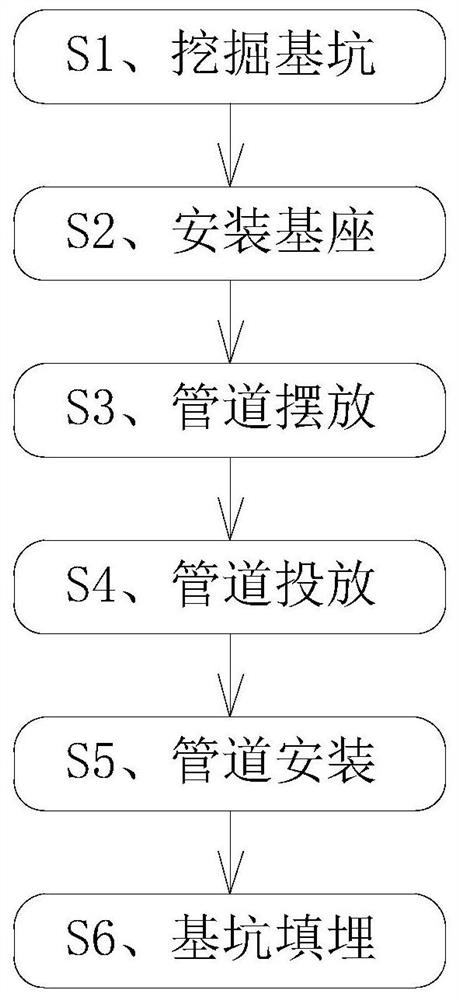

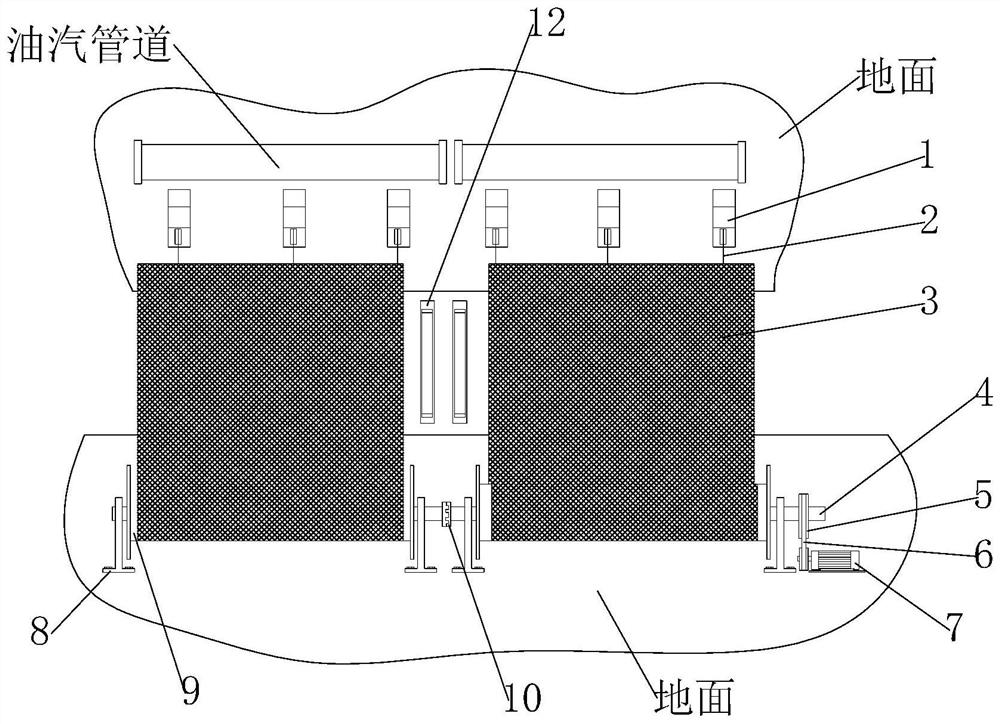

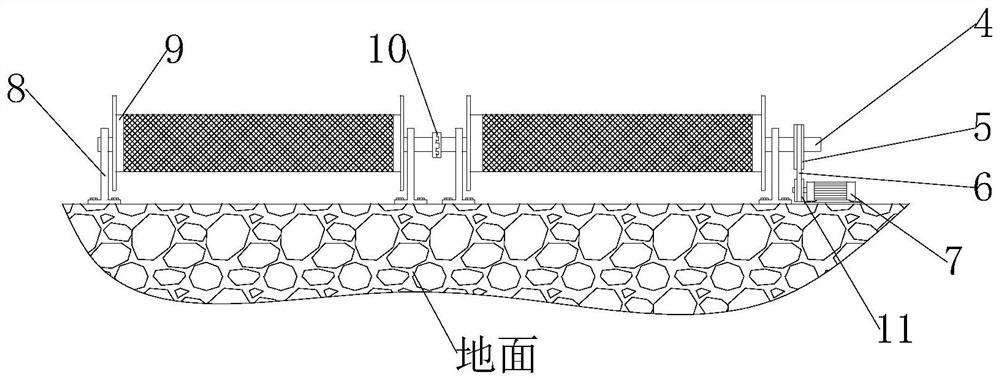

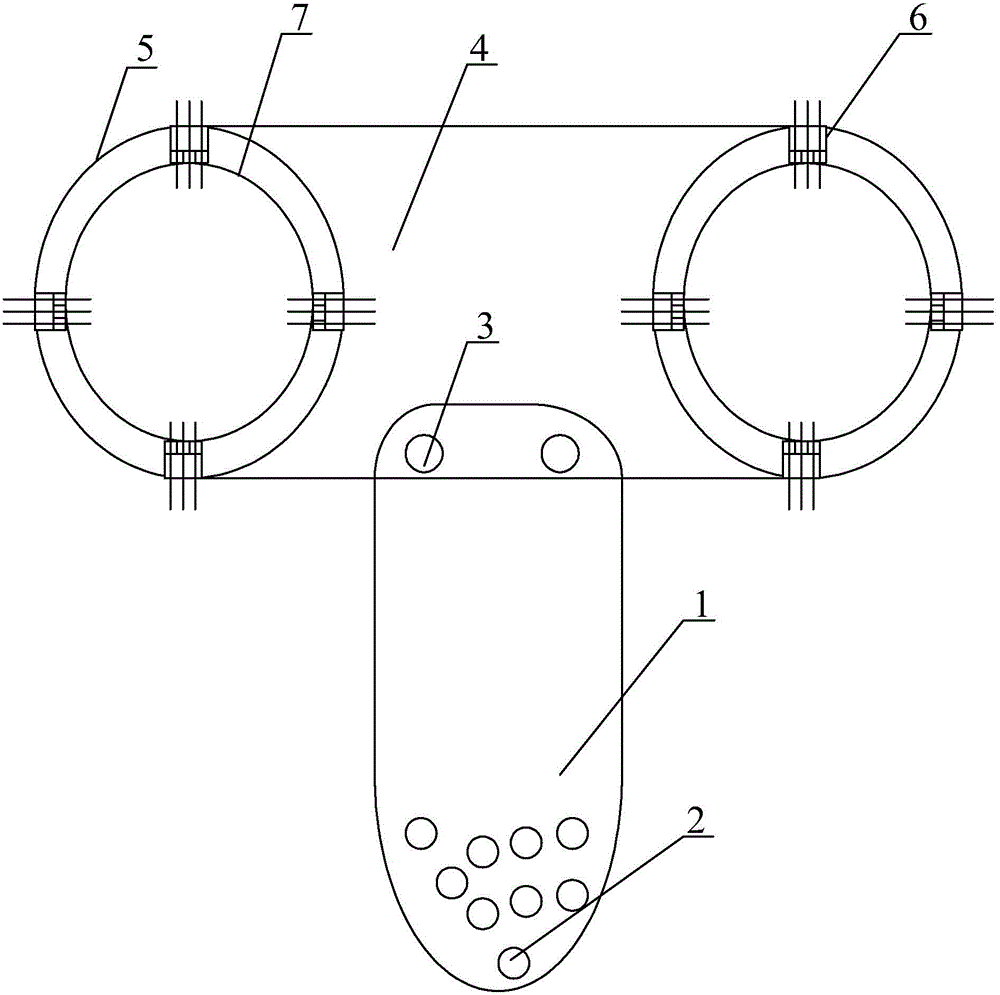

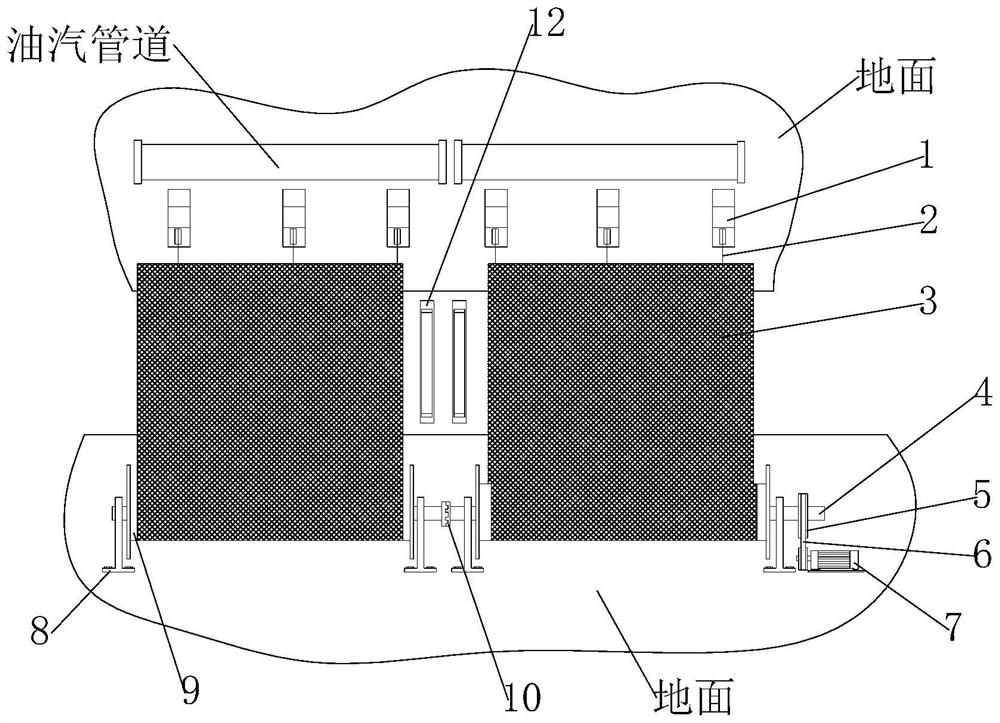

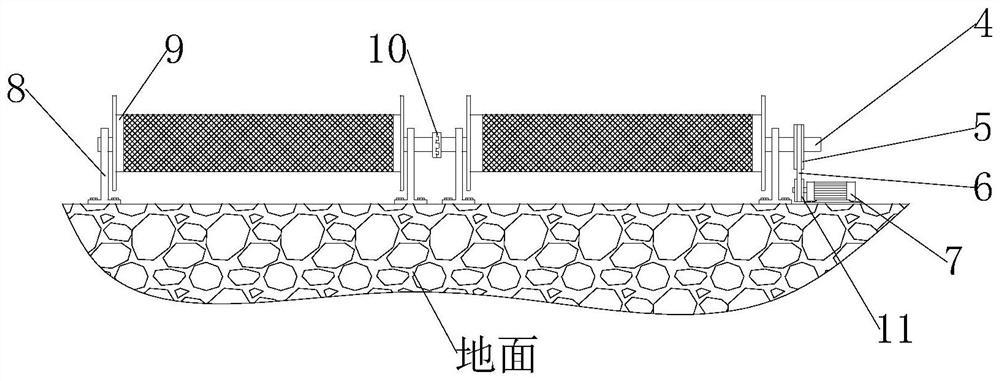

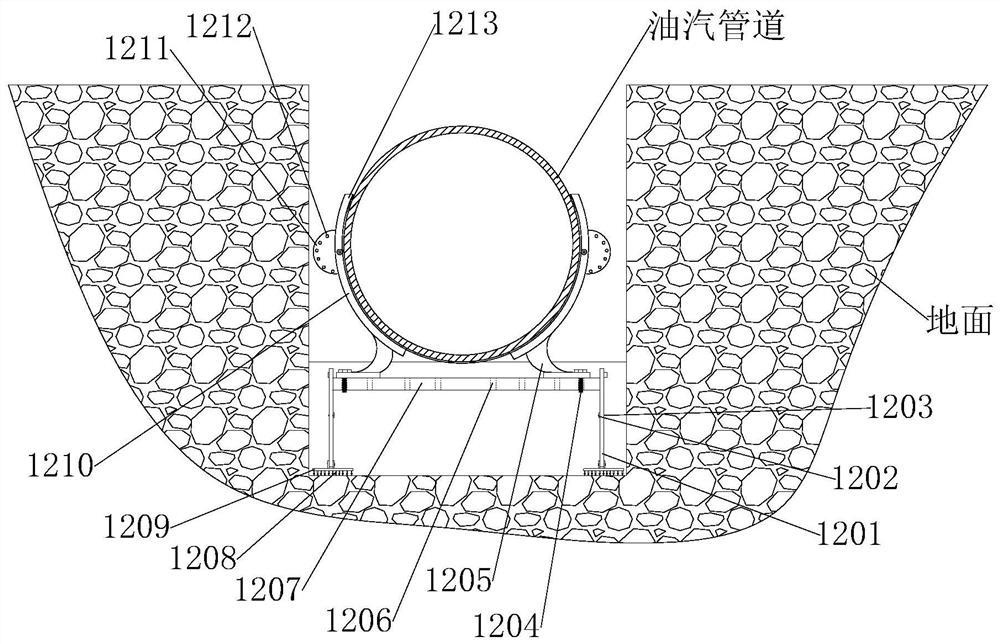

A long-distance oil and gas pipeline laying and installation construction method

ActiveCN111350878BPlace stableEven by forcePipe supportsPipe laying and repairArchitectural engineeringMachining

The invention discloses a method for laying and installing long-distance oil and gas pipelines, and relates to the technical field of building construction. The method for laying and installing long-distance oil and gas pipelines specifically includes the following steps: S1. Excavating foundation pits: excavating on the ground For the foundation pit for laying oil and gas pipelines, the opening of the foundation pit faces upwards, and the wall of the foundation pit is perpendicular to the bottom of the foundation pit; S2. Installing the base: place the foundation pit for supporting the oil and gas pipelines in the foundation pit that has been excavated in step S1. Base, place multiple bases, and fix the two adjacent bases at equal intervals on the bottom of the foundation pit; S3, pipeline placement: place multiple oil and gas pipelines near the foundation pit that has been excavated in step 1 , place the oil and gas pipeline parallel to the foundation pit. In the present invention, a number of equidistant threaded holes are provided on the top of the support base, so that the distance between the support ribs on both sides of the top of the support base can be adjusted, which is convenient for adaptive adjustment according to the different diameters of oil and gas pipelines .

Owner:东营市东凯新材料技术研发有限责任公司

Portable novel roller cleaning clamp for diaphragm product

InactiveCN105618404AImprove clamping firmnessReduce maintenance costsCleaning using toolsOrganic solventEngineering

The invention provides a portable novel roller cleaning clamp for a diaphragm product. The portable novel roller cleaning clamp comprises a handle, anti-skidding balls, connecting bolts, a clamp sleeve, an outer layer of the clamp sleeve, a clamp device and a lining of the clamp sleeve. The handle is arranged at the lower part of the middle position of the clamp sleeve. The anti-skidding balls are arranged outside of the handle. The connecting bolts are fixedly connected with the clamp sleeve and the handle. The clamp sleeve is arranged at the upper part of the handle. The outer layer of the clamp sleeve is arranged at the outermost position of the clamp sleeve. The clamp lining is arranged on the innermost side of the clamp sleeve. The portable novel roller cleaning clamp for the diaphragm product has following beneficial effects: by means of a partition board of the clamp device, cleaning labels of the clamp device and the anti-skidding balls, firm clamping is improved so that the roller surface is favorably protected; in combination with organic solvent, dirt is completely cleaned so that safety performance is further improved; a skidding phenomenon during application is avoided; the clamp is used conveniently so that maintenance cost is reduced; and service lifetime is prolonged.

Owner:派尼尔科技(天津)有限公司

A jig for mirror polishing processing of metal middle frame

ActiveCN112917389BImprove clamping firmnessAvoid over-squeezingGrinding work supportsPolishingAirbag

The invention discloses a fixture for mirror polishing of a metal middle frame. The structure includes a mounting frame, a propulsion block, a supporting bottom plate, and a clamping mechanism. The clamping mechanism, the push rod drives the moving clip to move, and the arc surface of the moving clip reduces the gap with the fitting surface of the outer end of the middle frame of the tablet, and the airbag membrane bulges to protect the outer end of the middle frame of the flat panel, improving the The clamping firmness on the outside of the middle frame of the flat plate is protected at the same time. Through the torsion rotation of the torsion shaft, the connecting rod rotates in an arc around the center end of the torsion shaft. The extrusion of the top spring increases the friction between the rubber strip and the inside of the middle frame of the tablet, ensuring that the clamping force is applied to the inner side of the middle frame of the tablet, and avoids the deviation of the middle frame of the tablet during the polishing process.

Owner:宁德鑫旺达智能科技有限公司

A handling robot

Owner:深圳市大族贝金装备有限公司

An instrument panel production butt joint assembly equipment

ActiveCN111376047BPrevent crushingFirmly assembledAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses an instrument panel production butt joint assembly equipment, which relates to the technical field of mechanical production and processing. The instrument panel production butt joint assembly equipment includes a bottom support plate, and the bottom support plate is fixed horizontally, so the rear side of the top of the bottom support plate is arranged There are side support ribs upright and fixed on the top of the bottom support plate, the top of the side support ribs is provided with a horizontally fixed top support plate, and a pneumatic cylinder is installed on the top of the top support plate, and the air cylinder moves toward the bottom A piston rod protrudes from the end, and a fixed frame is fixed at the bottom end of the piston rod. In the present invention, the pneumatic cylinder pushes the lower fixed frame to carry out linear lifting movement. When the instrument is docked and assembled on the instrument panel shell, the fixed sleeve moves downward through the shock absorption and buffering of the spring, and presses the ejector rod protruding from the top of the instrument fixture. Push the ejector rod downward to pop up, and press the corners of the outer circle of the instrument assembled on the instrument panel shell twice, so that the instrument docking assembly on the instrument panel shell is more firm and reliable.

Owner:开平市津华仪表科技有限公司

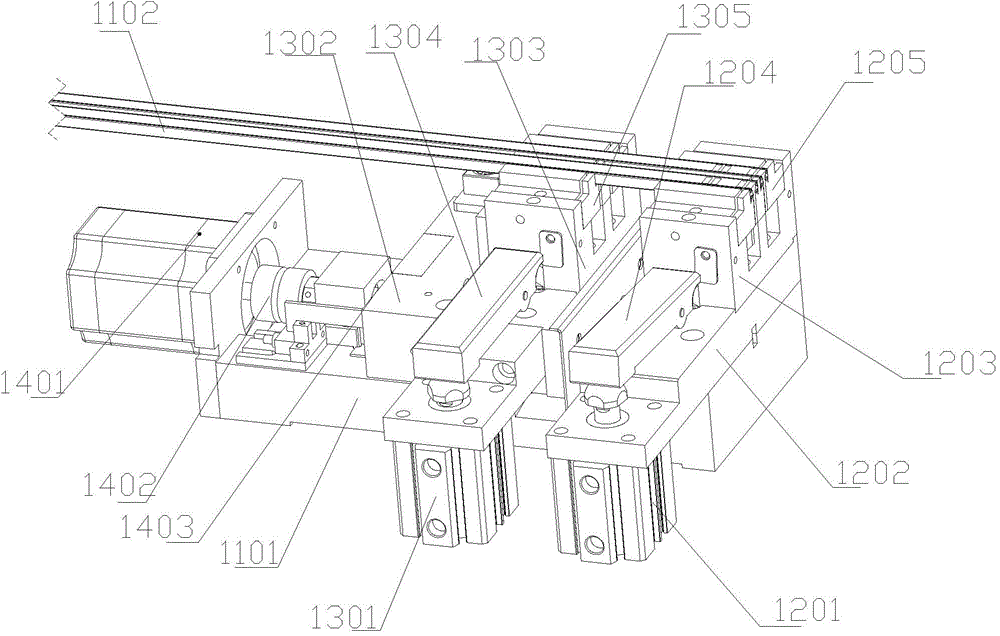

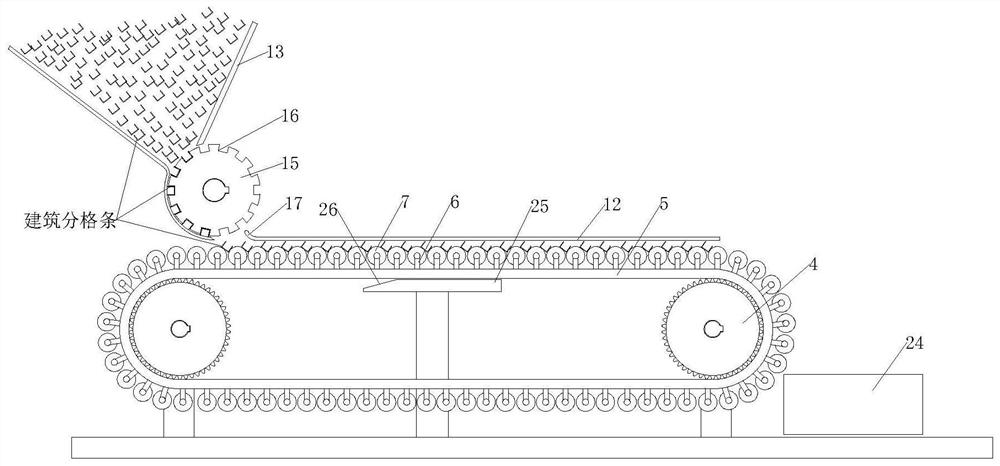

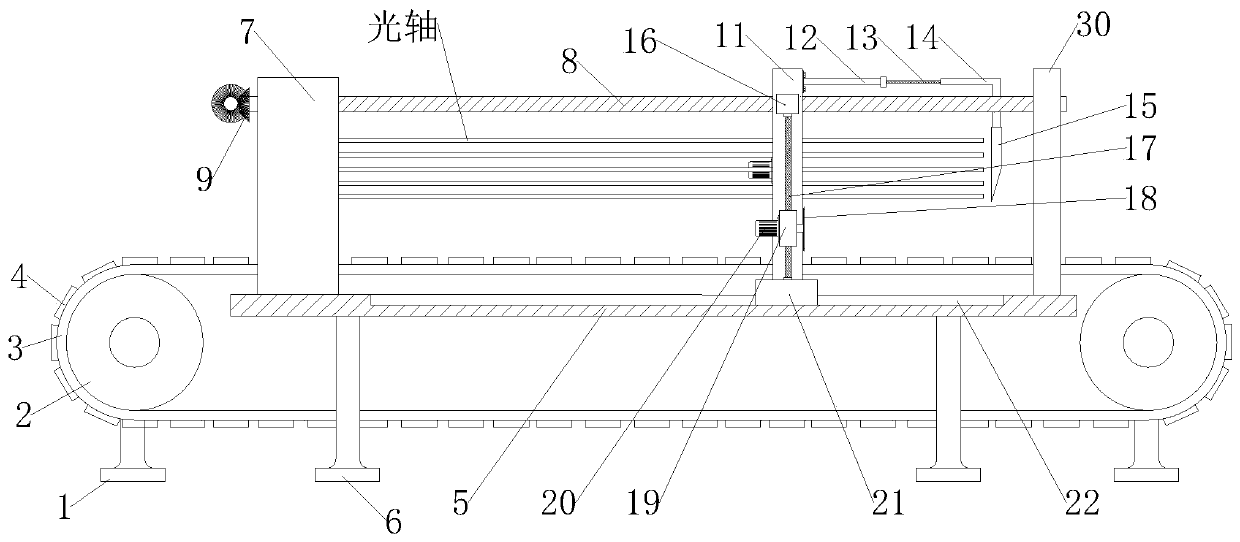

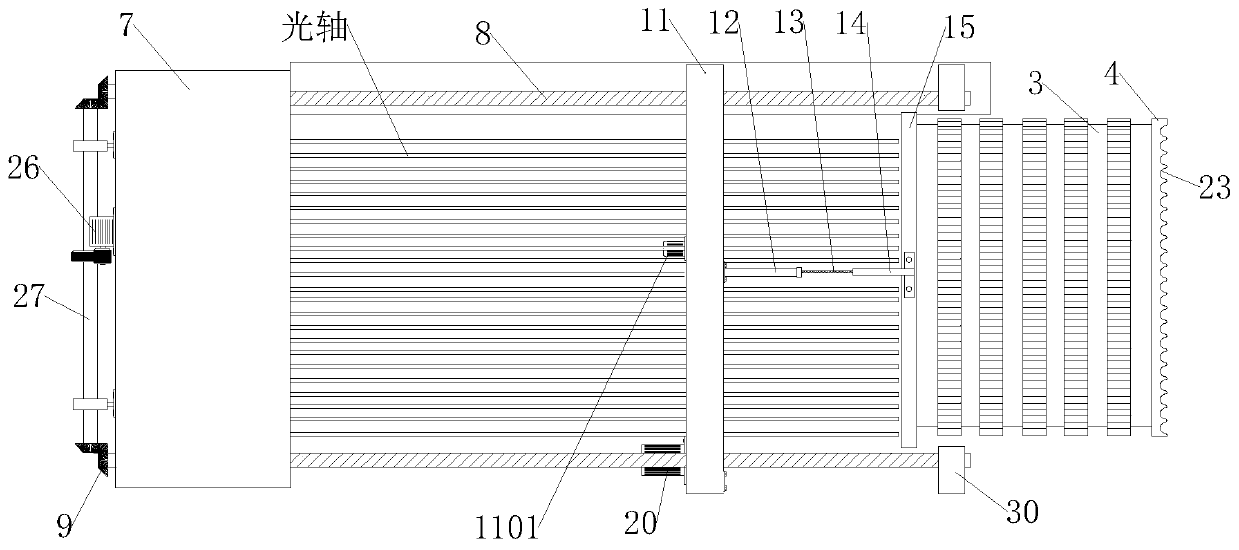

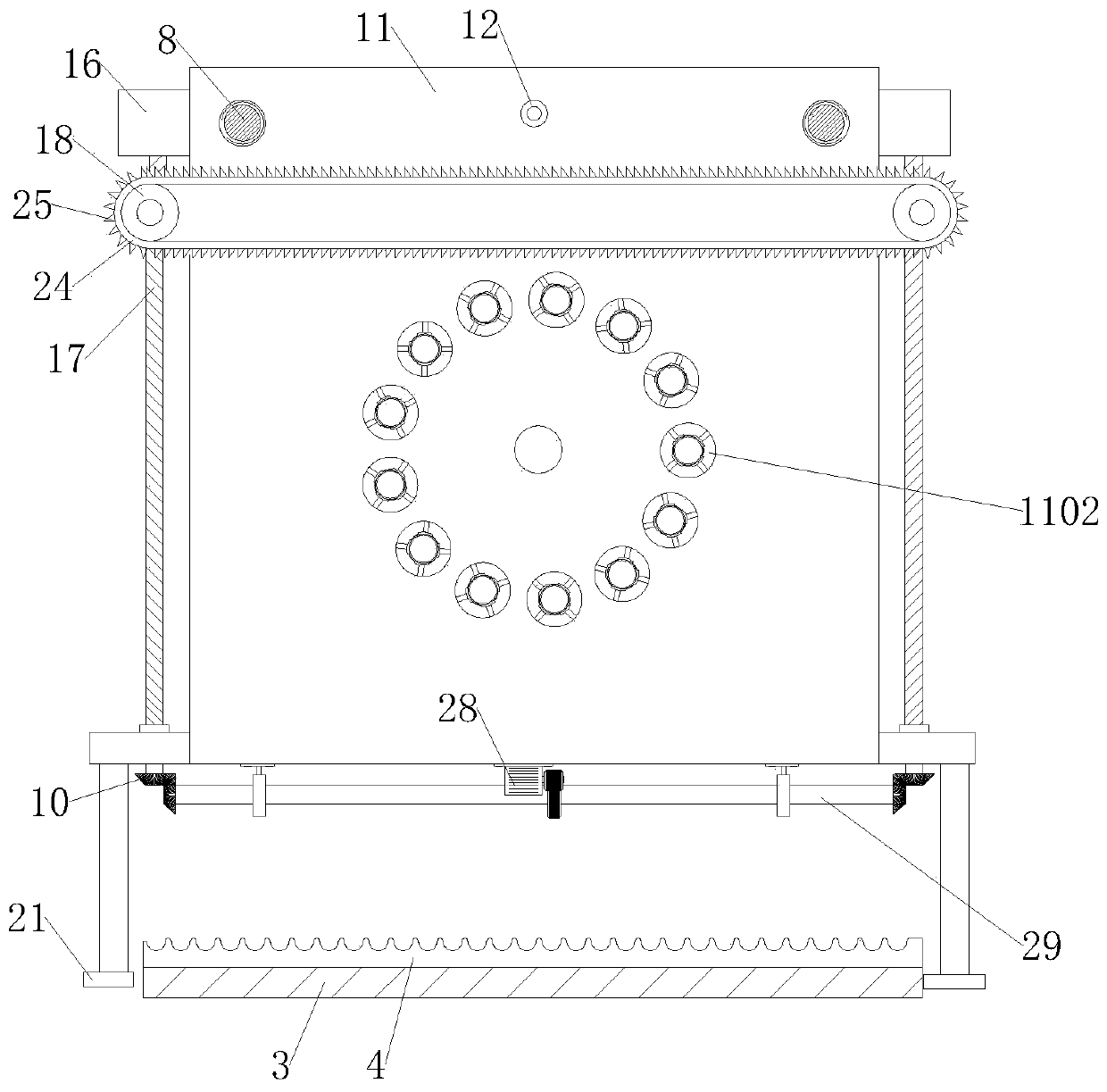

Chromium-plated linear optical shaft batch machining and processing system

InactiveCN111515467AImprove batch cutting efficiencyImprove clamping firmnessWork clamping meansPositioning apparatusOptical axisStructural engineering

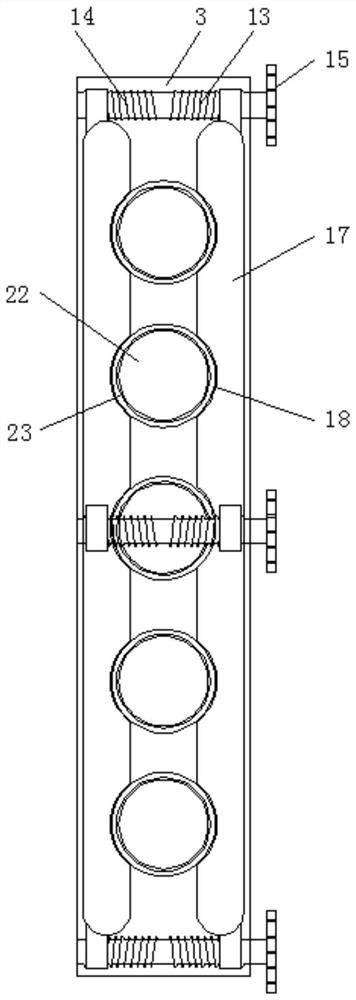

The invention provides a chromium-plated linear optical shaft batch machining and processing system, and relates to the technical field of machining. The system comprises a conveying belt which rotates circularly and a sliding rack installed at the top end of the conveying belt, wherein rollers are arranged at the left end and right end of an inner ring of the conveying belt; first feet are installed and fixed at the two ends of the rollers through bearings; and a plurality of optical shaft brackets are arranged on the outer wall of the conveying belt at equal intervals. According to the chromium-plated linear optical shaft batch machining and processing system, two fixed supporting rods and one movable rod are arranged in each clamping hole of the sliding rack, and the top ends of the twofixed supporting rods and the top end of the movable rod are each hinged with a movable clamping claw which is bent in an arc shape; and through the hinge and swing of every two movable clamping claws, the adaptive clamping is carried out through the automatic swing of the movable clamping claws when the corresponding movable rod stretches and retracts in the corresponding clamping hole, so thata chromium-plated linear optical shaft installed in each clamping hole is clamped and fixed, and the clamping firmness of the chromium-plated linear optical shafts is improved.

Owner:张明杰

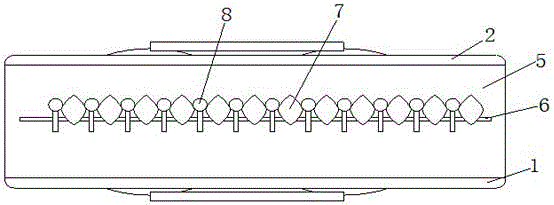

Tight-buckling bead embroidery handbag

InactiveCN106165953AEasy accessImprove clamping firmnessHandbagsLuggageEngineeringMechanical engineering

The invention discloses a tight-buckling bead embroidery handbag, which comprises a bag body, wherein the bag body comprises a front end surface and a rear end surface, the front end surface and the rear end surface are arranged in a parallel and opposite manner, the top portions of the front end surface and the rear end surface are provided with annular handles, the front end surface and the rear end surface are provided with a plurality of bead embroidery beads, the bead embroidery beads are sewn on the front end surface and the rear end surface, a middle portion connection strip is arranged between the front end surface and the rear end surface and is a strip-shaped cloth, the middle portion connection strip is fixedly connected to the edges of the front end surface and the rear end surface after the middle portion connection strip is bent, the middle part of the middle portion connection strip is provided with a linear slit, the linear slit is provided with a closing mechanism, the closing mechanism comprises a plurality of mother beads and a plurality of sub-beads, the mother beads are linearly arranged on one side of the linear slit at uniform intervals, and the sub-beads are linearly arranged on the other side of the linear slit at uniform intervals. According to the present invention, the drawbacks in the prior art can be overcome, and the structure design is reasonable and novel.

Owner:江阴市天工礼品有限公司

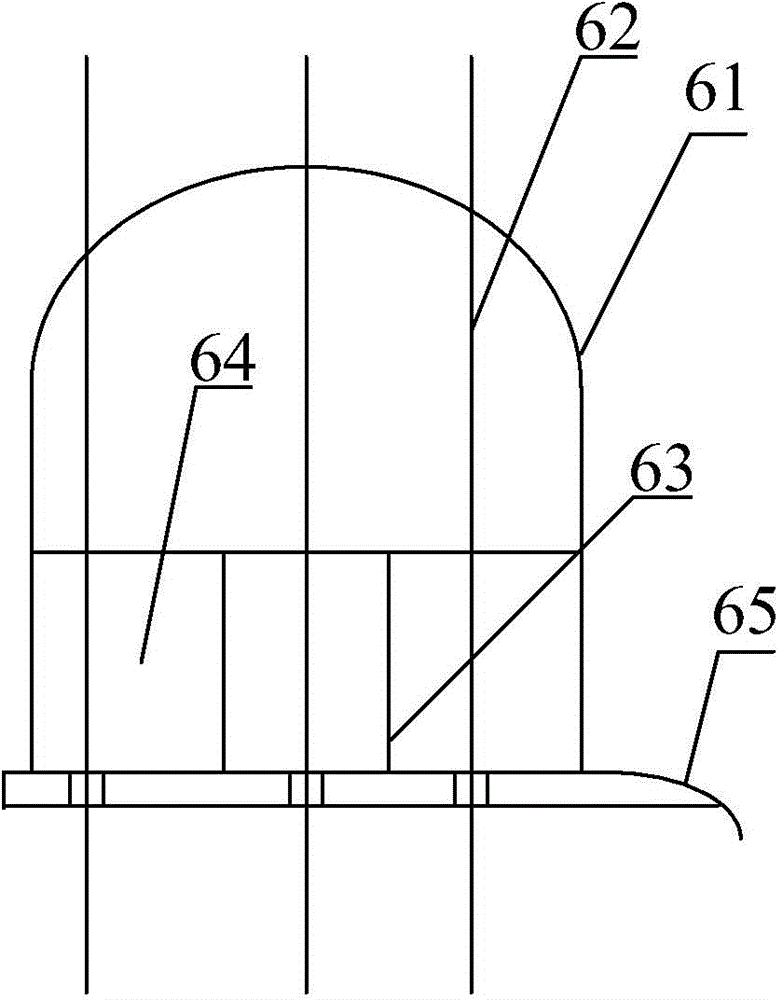

A long-distance oil and gas pipeline laying installation construction equipment

ActiveCN111336316BPlace stableEven by forcePipe supportsPipe laying and repairMarine engineeringCoupling

The invention discloses far-distance oil-gas pipeline laying installation and construction equipment. The equipment comprises a plurality of lock catches fixed to one side of a foundation pit and a plurality of rollers mounted on the other side of the foundation pit. The two ends of each roller are provided with shaft levers. The shaft levers at the two ends of the rollers are mounted on a rack through bearings. The rack is fixed to the ground close to the foundation pit. The two adjacent rollers are fixedly connected through a coupling, a first chain wheel is mounted at the top end of the corresponding shaft lever of one roller, a servo motor is mounted on the ground close to the first chain wheel, a second chain wheel is mounted at the top end of an output shaft of the servo motor, and the second chain wheel is in driving connection with the first chain wheel through a chain. According to the far-distance oil-gas pipeline laying installation and construction equipment, the top end ofa supporting base is provided with a plurality of equidistant threaded holes so that the spacing between supporting rid plates on the two sides of the top end of the supporting base can be adjusted,and the far-distance oil-gas pipeline laying installation and construction equipment can be adjusted adaptively according to different diameters of oil-gas pipelines.

Owner:泰州市新滨江开发有限责任公司

A test method for high temperature compressive yield strength of materials

ActiveCN110567819BChange sizeAvoid neutral influencesMaterial strength using tensile/compressive forcesStructural engineeringUltimate tensile strength

The invention provides a high-temperature compression yield strength test method for materials, which uses a creep testing machine and a compression fixture to perform a high-temperature compression loading test on the material. The compression fixture includes upper and lower clamping parts and is used to connect between the upper and lower connectors of the creep testing machine Between the commutator, the commutator includes the upper and lower pressure blocks, and there is a distance between the upper and lower pressure blocks along the tensile direction of the creep testing machine for installing the sample, and the distance value can be Adjustment, the upper and lower pressure blocks use triangular prism-shaped positioning holes to cooperate with the clamping parts to clamp and fix the sample in the radial direction of the sample. The method of the present invention thickens the diameter of the rod-shaped sample and delays The time for obvious bending ensures the safety of the test machine and the operation process, and changes the end of the sample from a threaded structure to a smooth cylindrical structure, which enhances the clamping firmness of the sample and reduces the time required for processing the sample to the finished product. The steps that go through can also enhance the centering of the specimen.

Owner:CENT SOUTH UNIV

Irregular casting clamping device for casting production

ActiveCN110103163BEffective clampingImprove clamping firmnessWork holdersGear wheelElectric machinery

Owner:安徽博晟亿电力科技有限公司

Mirror polishing clamp for hardware middle frame

ActiveCN112917389AImprove clamping firmnessAvoid over-squeezingGrinding work supportsStructural engineeringFriction force

The invention discloses a mirror polishing clamp for a hardware middle frame. The clamp structurally comprises a mounting frame, a pushing block, a supporting bottom plate and a clamping mechanism, wherein the top of the mounting frame is welded to the bottom surface of the supporting bottom plate, the clamping mechanism is fixedly installed in the upper end of the supporting bottom plate in an embedded mode, and a pushing rod drives a movable clamping piece to move. A gap between an arc surface of the movable clamping piece and an attaching face of the outer side end of a flat plate middle frame is reduced, and an air bag film is bulged to conduct abutting protection on the outer side end of the flat plate middle frame, so that protection is achieved while the clamping firmness of the outer side of the flat plate middle frame is improved. Through torsion rotation of a torsion shaft, the connecting rod rotates in an arc mode around the circle center end of the torsion shaft. The abutting rod abuts against the inner side end of the flat plate middle frame, the friction force generated when the rubber strip abuts against the interior of the flat plate middle frame is increased through extrusion of a jacking spring, so that it is ensured that a clamping force is applied to the inner side end of the flat plate middle frame, and the flat plate middle frame is prevented from deviating in the polishing process.

Owner:宁德鑫旺达智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com