A jig for mirror polishing processing of metal middle frame

A mirror polishing and fixture technology, applied in the direction of grinding workpiece brackets, etc., can solve the problems of reducing the firmness of the middle frame, reducing the fit of the middle frame, and excessive extrusion, so as to avoid offset and improve the clamping firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

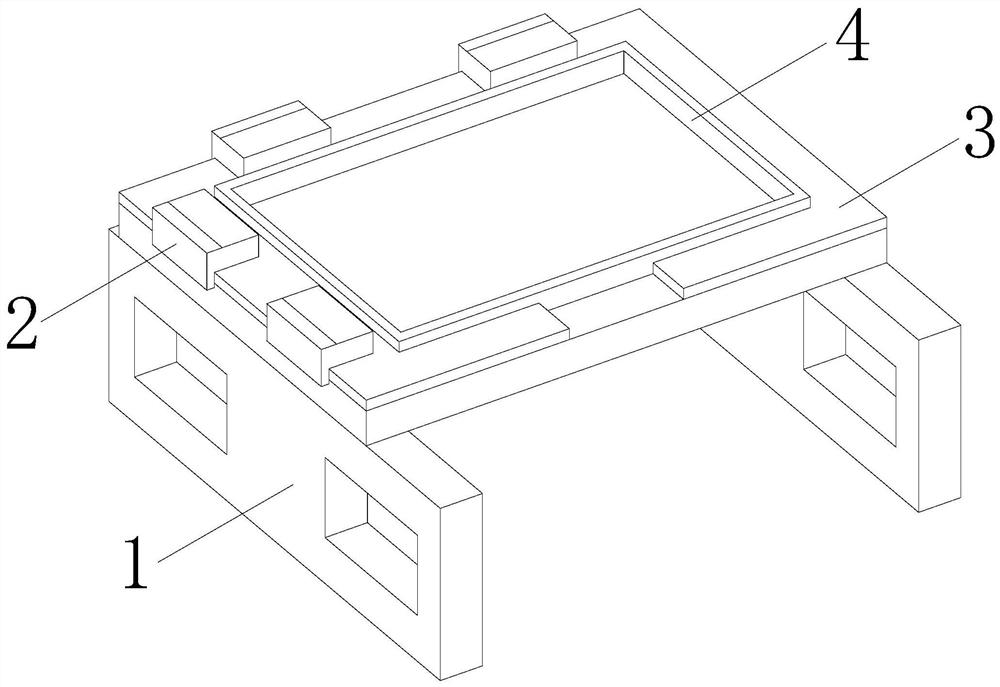

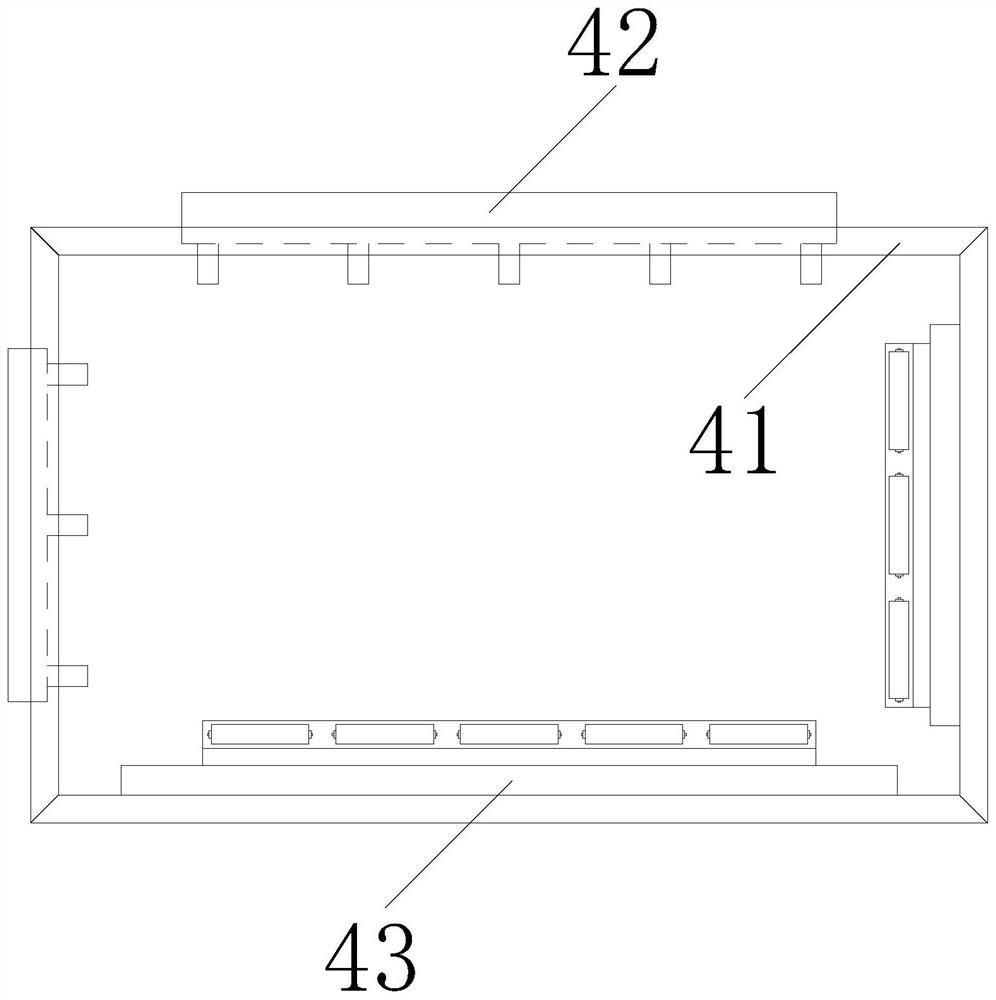

[0022] as attached figure 1 to attach Figure 4 Shown:

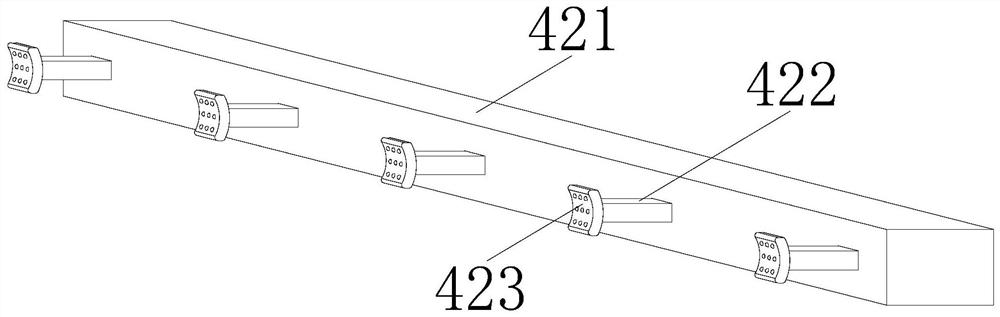

[0023] The present invention is a jig for mirror polishing processing of a metal middle frame, and its structure includes a mounting frame 1, a propulsion block 2, a supporting base plate 3, and a clamping mechanism 4. The top of the mounting frame 1 is welded to the bottom surface of the supporting base plate 3, and the supporting base plate 3. A clamping mechanism 4 is fixedly installed inside the upper end. A pusher block 2 is provided on the outside of the clamping mechanism 4. The pusher block 2 is installed on the upper end of the outer side of the support base plate 3 by clearance fit. The clamping mechanism 4 includes a limit Frame 41, a propulsion mechanism 42, and a snap-fit mechanism 43, the limit frame 41 is embedded and installed inside the upper end of the support base plate 3, the outer side of the propulsion mechanism 42 is fixed with the propulsion block 2, and the propulsion mechanism 42 uses clearan...

Embodiment 2

[0029] as attached Figure 5 to attach Figure 6 Shown:

[0030]Wherein, the engaging mechanism 43 includes a compression spring 431, a fixed splint 432, and a rotation resistance mechanism 433. The compression spring 431 is fixedly installed inside the limit frame 41, and one end of the compression spring 431 is fixed to the fixed splint 432. The fixed splint 432 is mounted on the inner side of the limit frame 41 by clearance fit, the lower end of the rotating interference mechanism 433 is installed inside the support base plate 3, and the rotating interference mechanism 433 is located inside the fixed splint 432, and the contact between the fixed splint 432 and the middle frame of the flat plate The end has an arc surface structure, which matches the arc surface of the middle frame of the plate, and improves the fitting degree of clamping. There are five rotating interference mechanisms 433, and they are evenly distributed on the inner side of the fixed splint 432, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com