Patents

Literature

248results about How to "Guaranteed clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

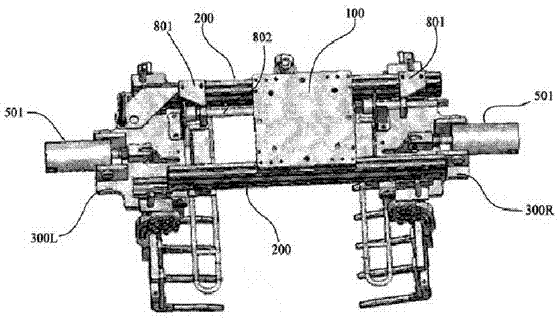

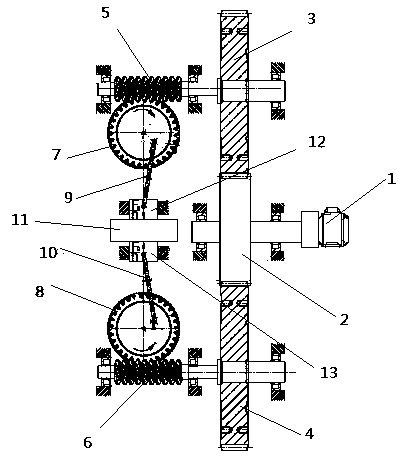

Robot gripper

ActiveCN104260102AImprove overall structural strengthPrevent bolts from falling offGripping headsStacking articlesRotational axisRocker arm

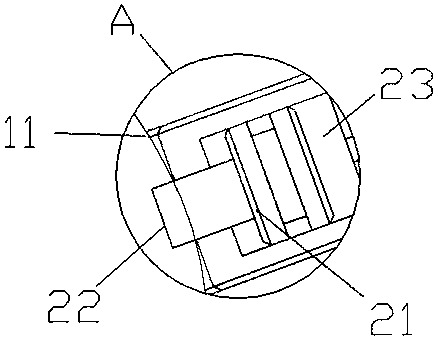

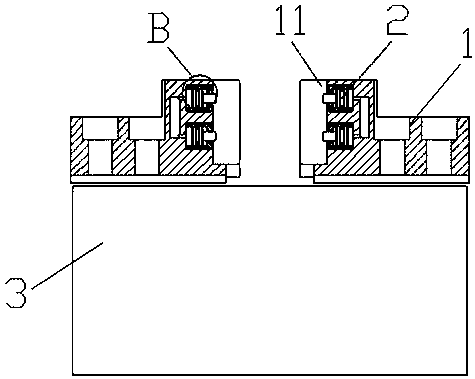

The invention discloses a robot gripper. The robot gripper comprises two parallel cross profiles, two profile side plates and two parallel longitudinal profiles which compose a frame structure; both sides of the parallel cross profiles are connected with the side plates; a pair of the longitudinal profiles perpendicular to the cross profiles are connected between the two side plates, both sides of the longitudinal profiles are provided with a pair of gripper tooth modules, and the gripper tooth modules are hinged to the side plates through a rotating shaft; the two longitudinal profiles are provided with clamping air cylinders, the push rods of the clamping air cylinders are connected with the rotating shaft and drive the gripper tooth modules to fold and unfold the gripper tooth modules. The frame structure composed of the cross profiles, the longitudinal profiles and the side plates are simple, compact and light in weight; the side plates, the cross profiles and the longitudinal profiles are horizontally connected instead of being connected through vertical bolts, so that operators can timely find loosening of bolts during application, and further out-screw of the bolts can be effectively avoided.

Owner:扬州华美知识产权事务有限公司

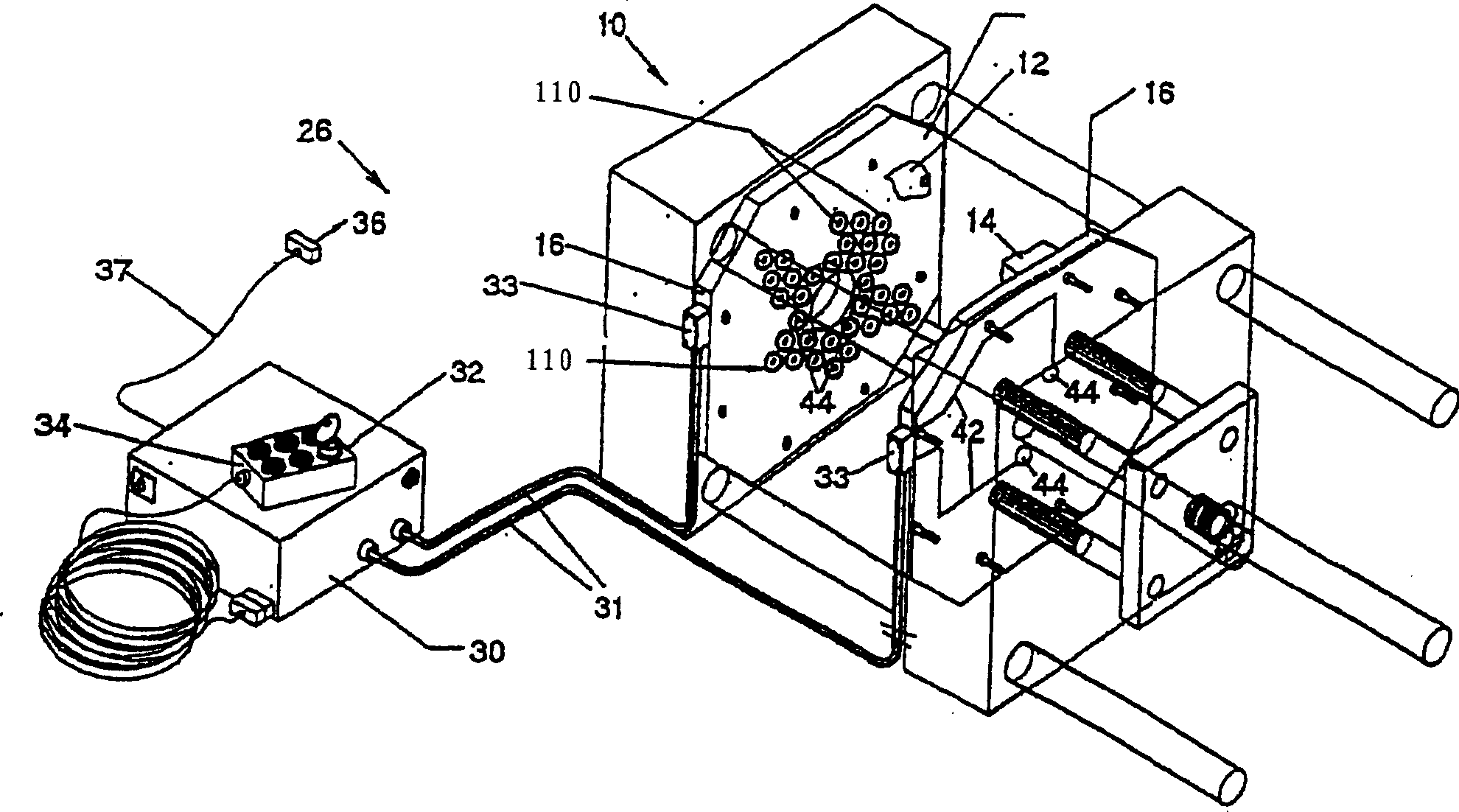

Magnetic clamping device and method for detecting and controlling an operating state of a magnetic clamping device

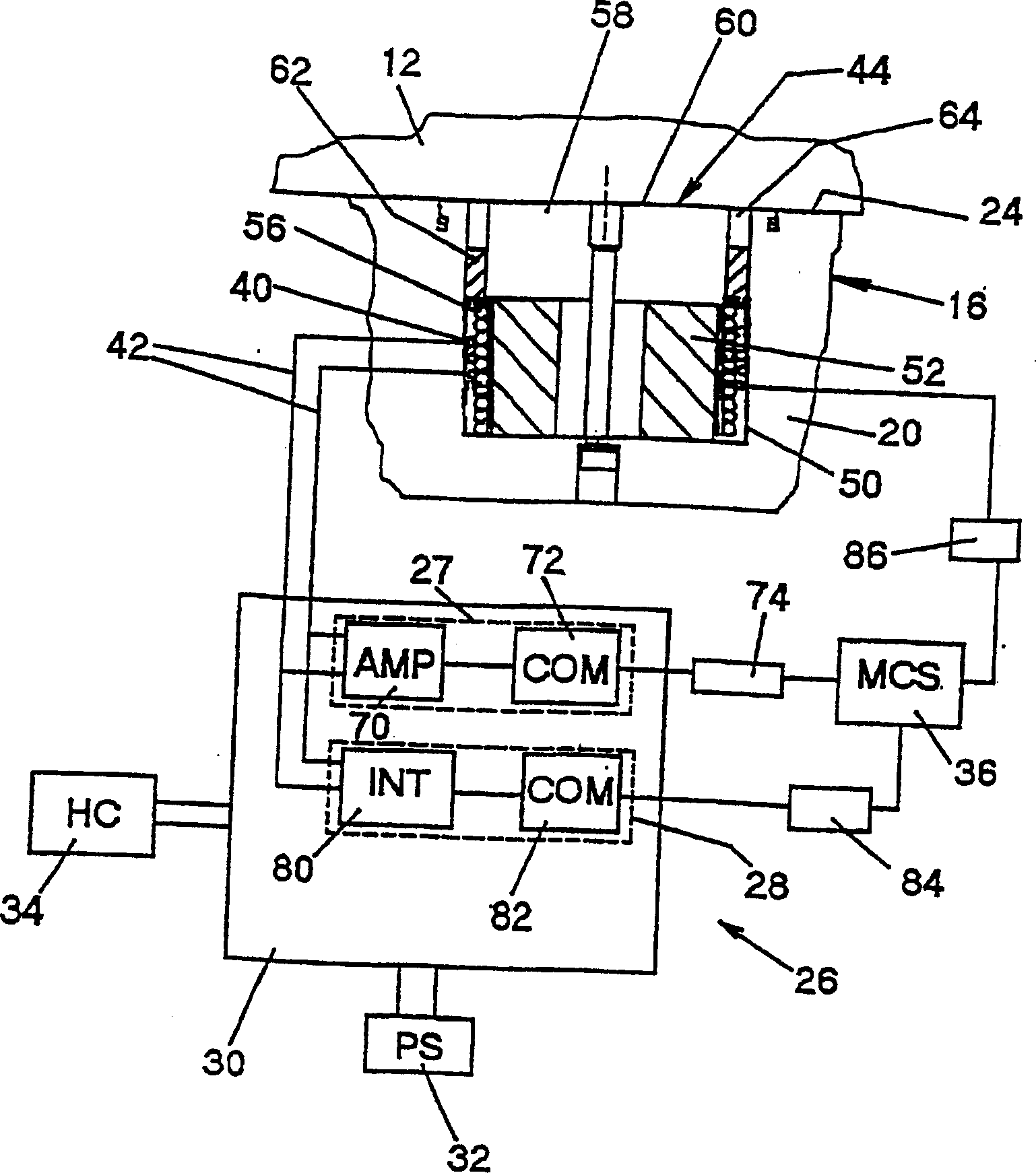

InactiveCN1543388ALow risk of fallingReduced Mounting Alignment ConditionsElectromagnets without armaturesWork holdersEngineeringSearch coil

The present invention discloses a magnetic clamping device having at least one magnetic holding unit comprising a switchable magnet generating a magnetic clamping force at a workpiece and a sensing means, wherein said sensing means comprises a search coil adapted to provide a detection signal indicative of a magnetic flux being applicable for at least approximately determining a clamping force exerted on the workpiece to be clamped and a method for detecting an operating state of a magnetic clamping device.

Owner:STAUBLI FAVERGES SA

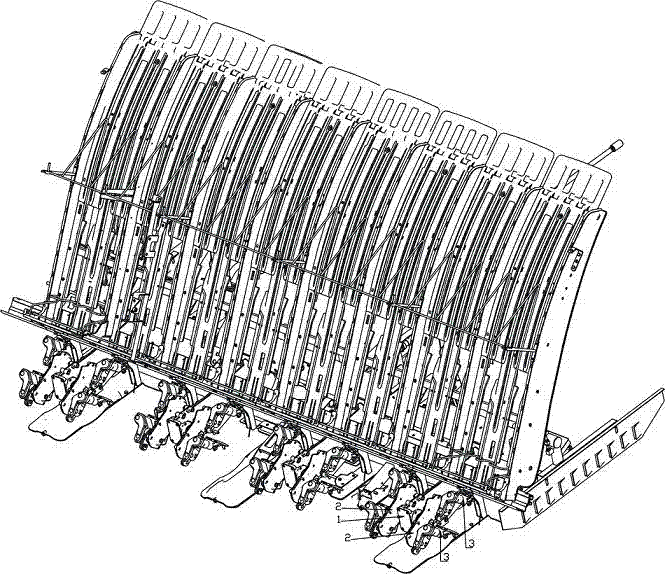

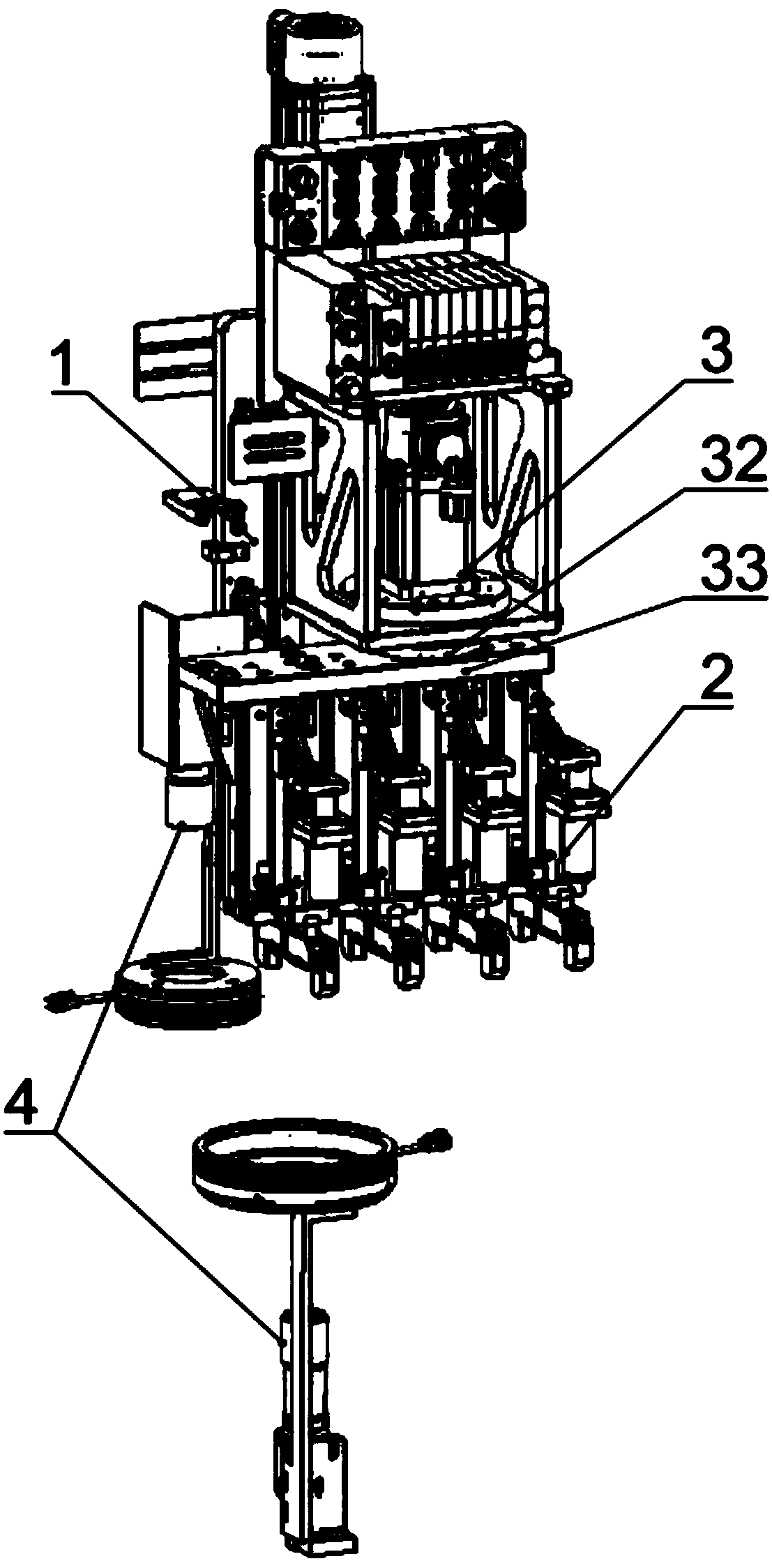

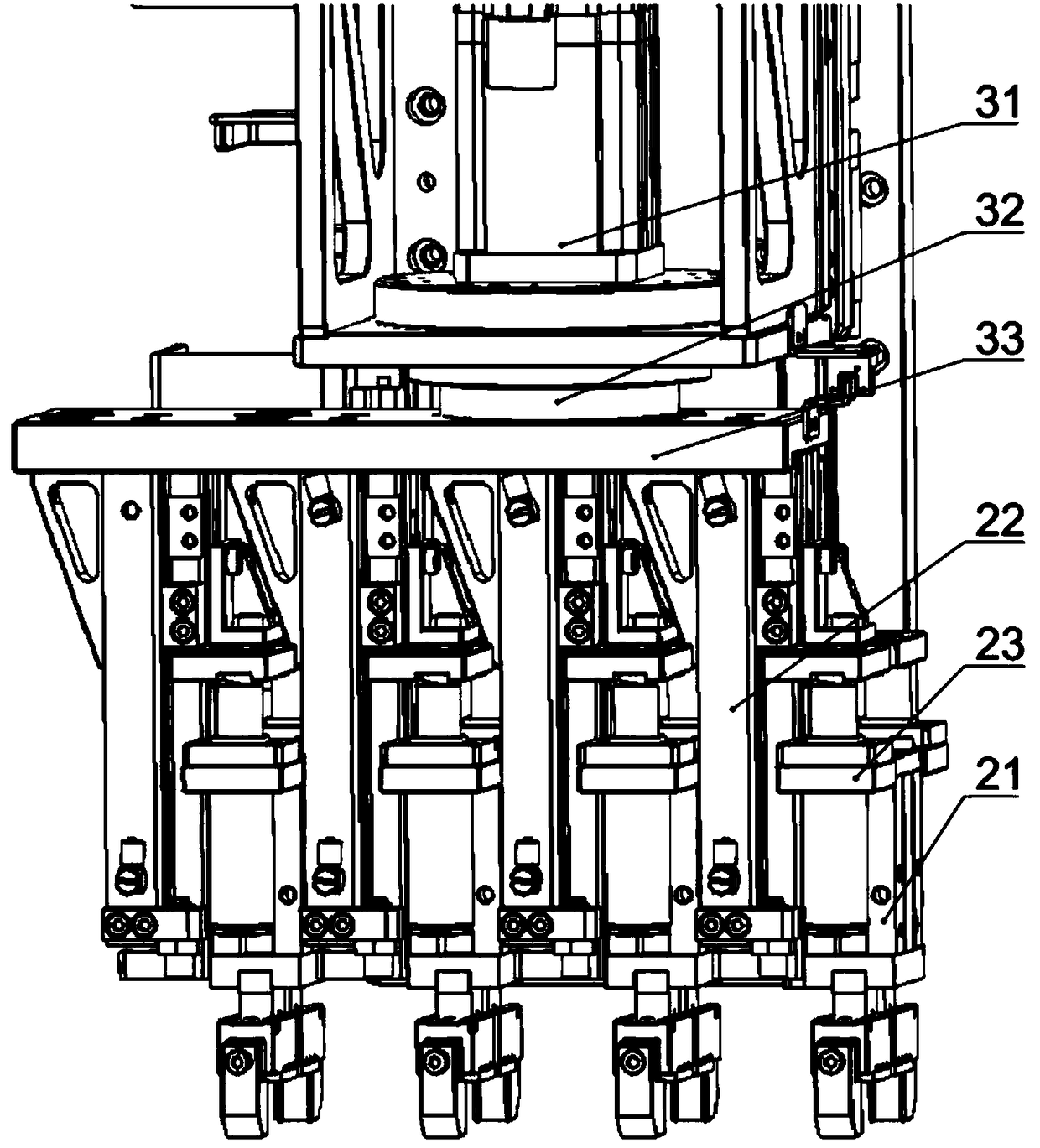

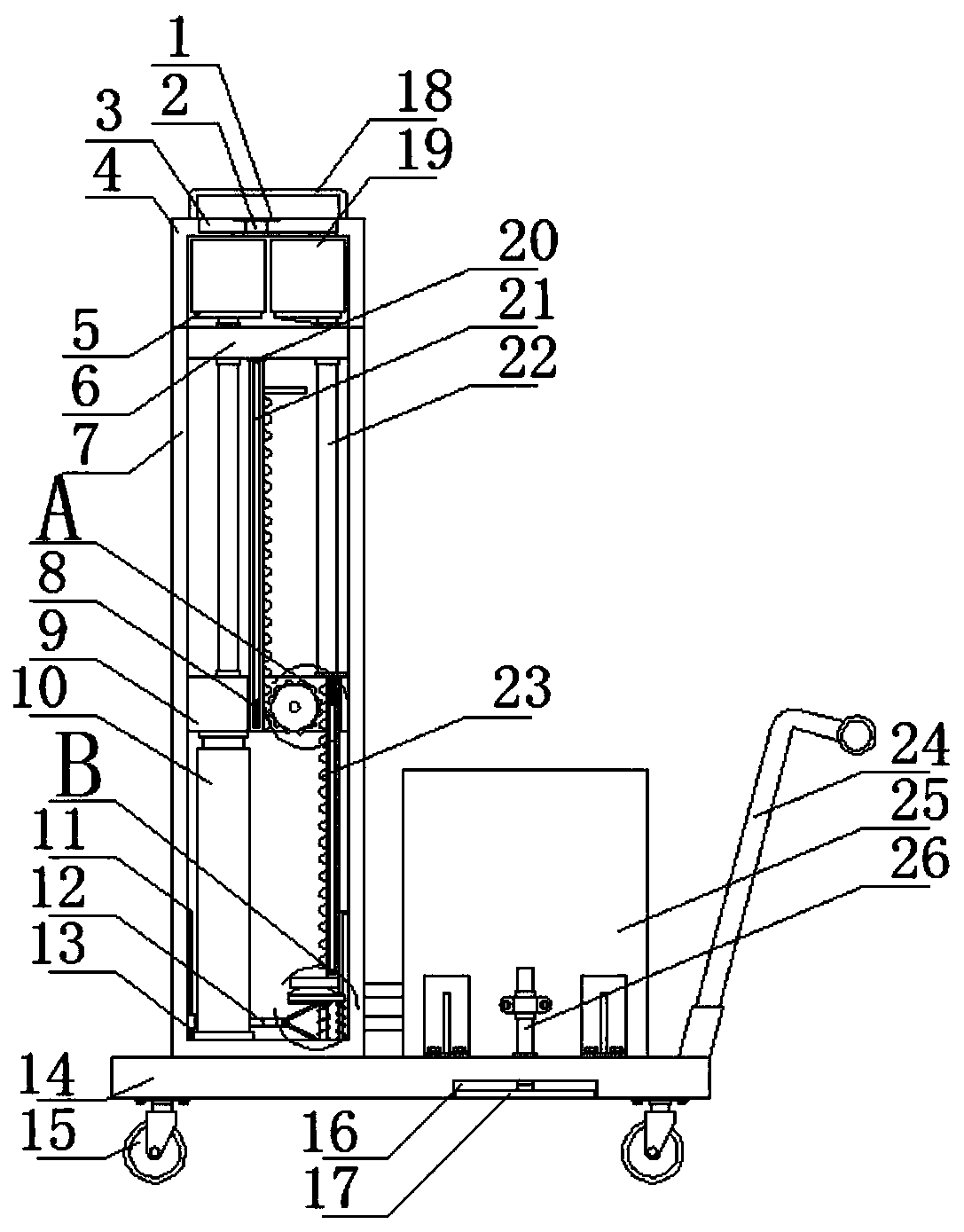

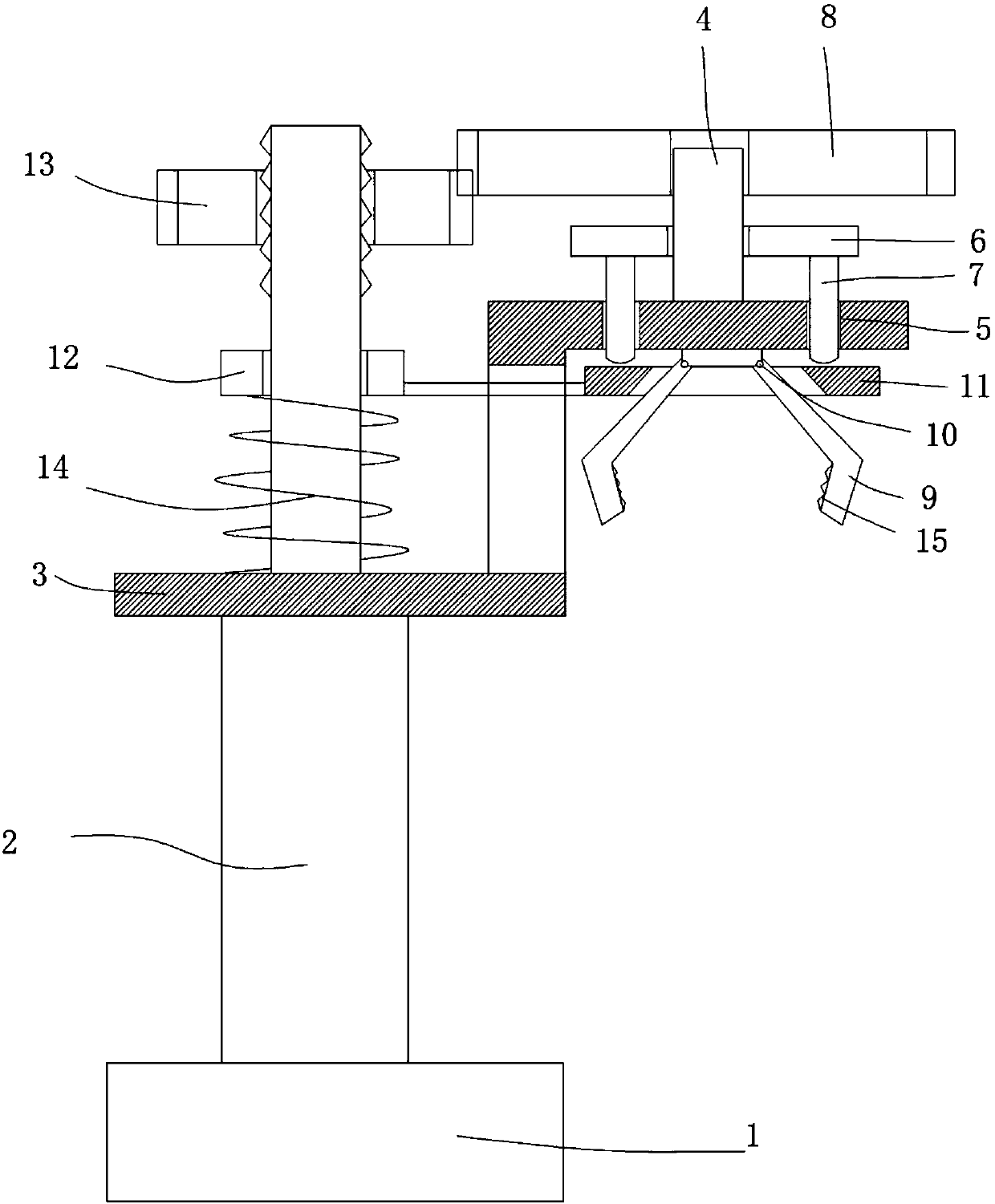

Implanting mechanism of transplanter

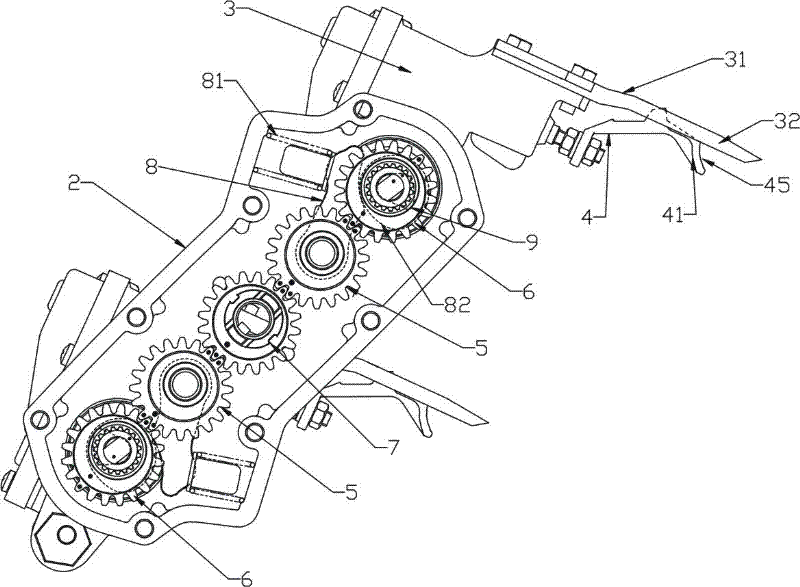

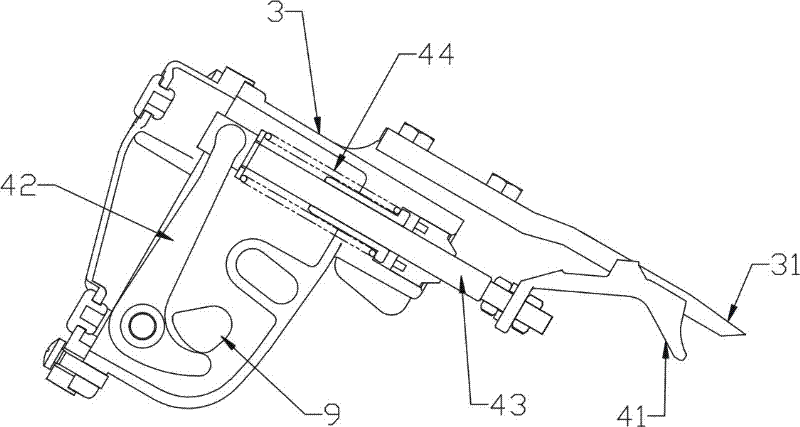

The invention relates to an implanting mechanism of a transplanter. The implanting mechanism of a transplanter comprises implanting cases, rotary cases and implanting claws. A power output shaft of each one of the implanting cases is connected to a rotating shaft of a sun gear arranged in corresponding one of the rotary cases. The tail end of each one of the implanting claws is provided with an outer claw head, wherein the outer claw head comprises two claw fingers; an implanting claw arm is provided with an inner claw and the inner claw has a slidable connection with the implanting claw arm;the implanting claw arm is also provided with an elastic recovery mechanism; the head of the inner claw comprises a single claw finger of which the root is located between the two claw fingers of theouter claw head; an upper end of the inner claw has a rotatable connection with a driving rod; and the driving rod has a rotatable connection with the implanting claw arm and matches with a cam of a wheel shaft of one of second planetary gears. The implanting mechanism of a transplanter can imitate hand gestures in manual transplanting and manual transplanting tracks well, reduce damages of a transplanter on seedlings, and prevent seedling inclination.

Owner:琚夏利

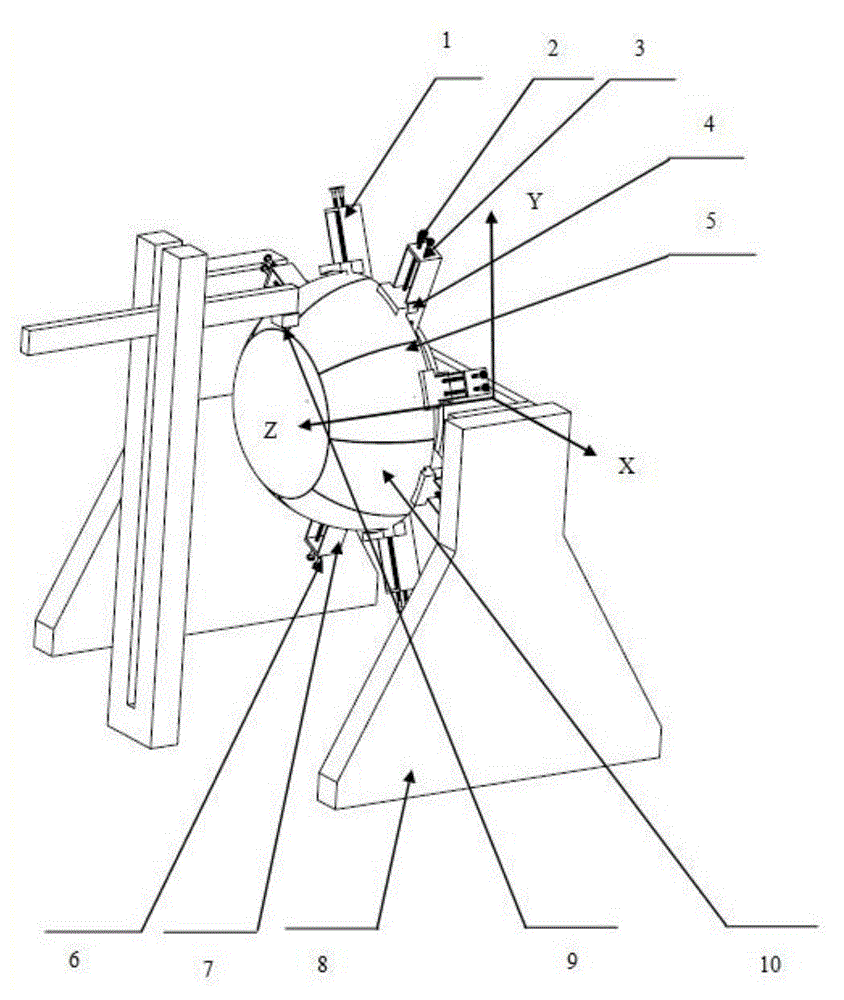

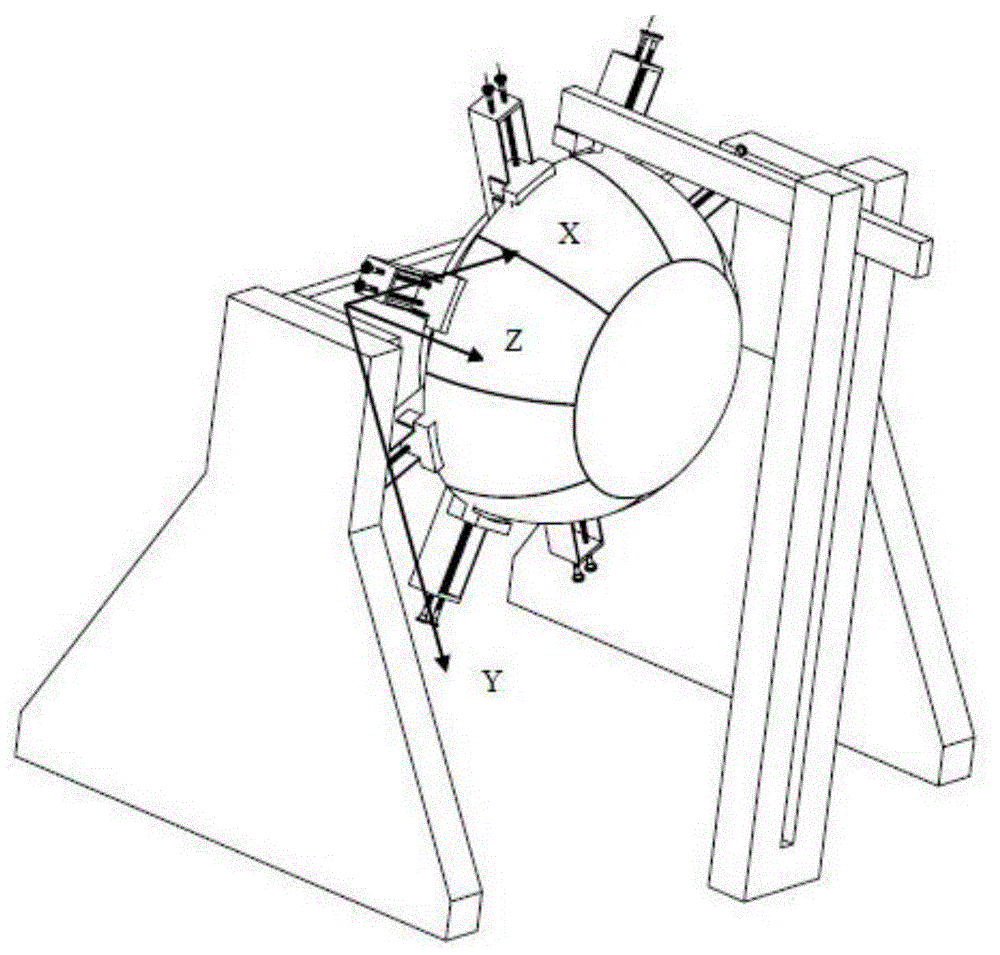

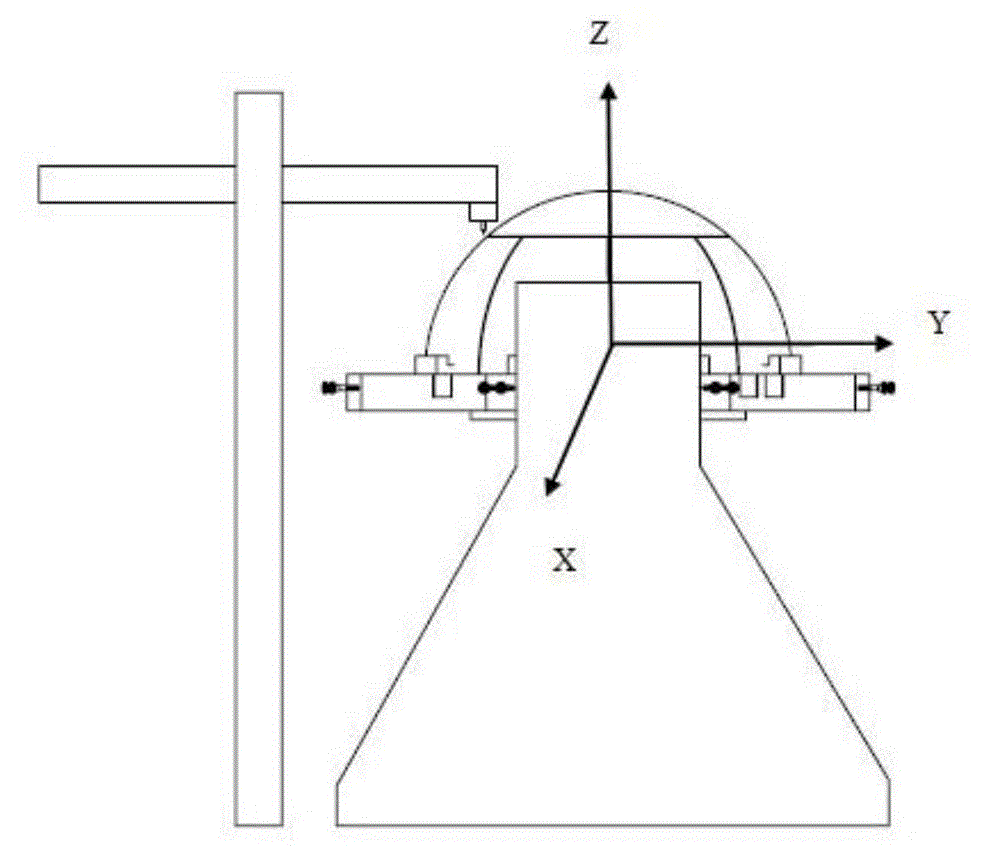

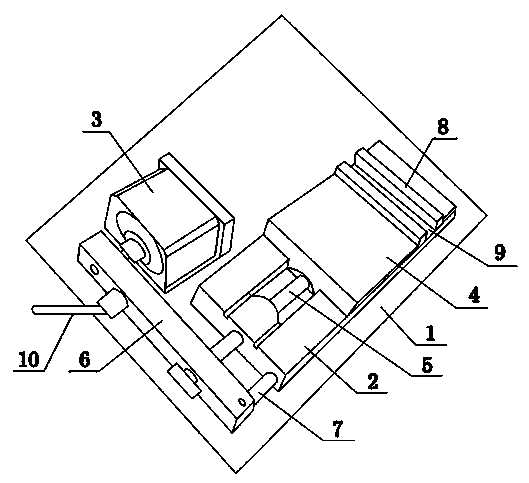

Automatic end socket welding method of automatic welding device based on large-curved-surface end socket welding

InactiveCN104014945AEasy assembly, positioning and clampingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesBall screwEngineering

The invention discloses an automatic end socket welding method of an automatic welding device based on large-curved-surface end socket welding. The device comprises a support base plate, a ball screw, a group of rolling bearings, an external locating block, an internal locating block, a rotary handle, a calibrated scale, a welding positioner, and a welding head realizing automatic welding, and the end socket comprises a plurality of claw end sockets and a segment. The method is characterized by comprising following steps of end socket fixation, welding of external welding line, welding of internal welding line, and annealing heat treatment. The method can be used for automatic welding of large end sockets of various sizes, thus lowering labor intensity of workers, shortening the manufacturing cycle of products, and lowering production cost.

Owner:NANJING INST OF TECH

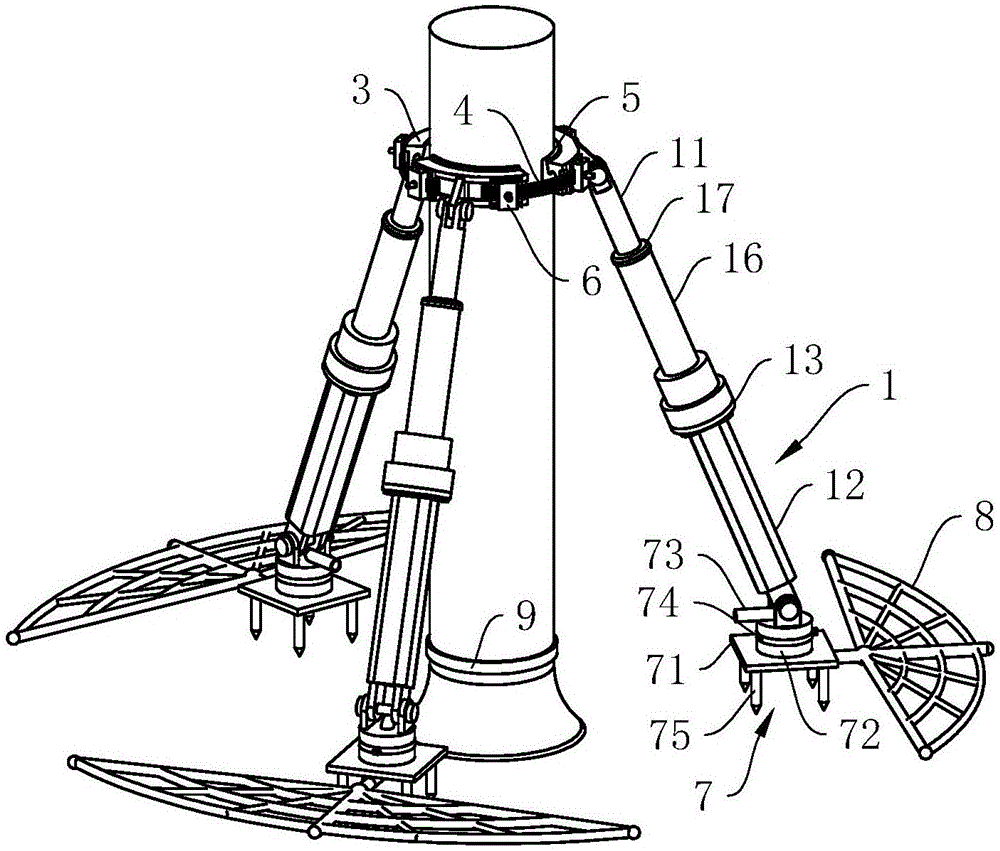

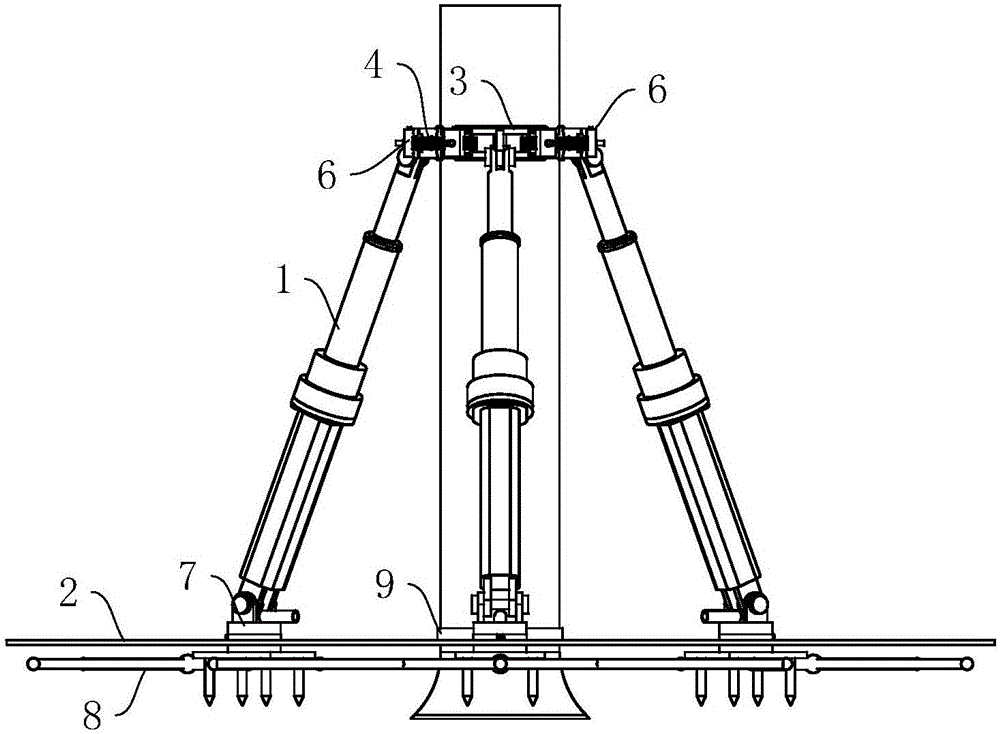

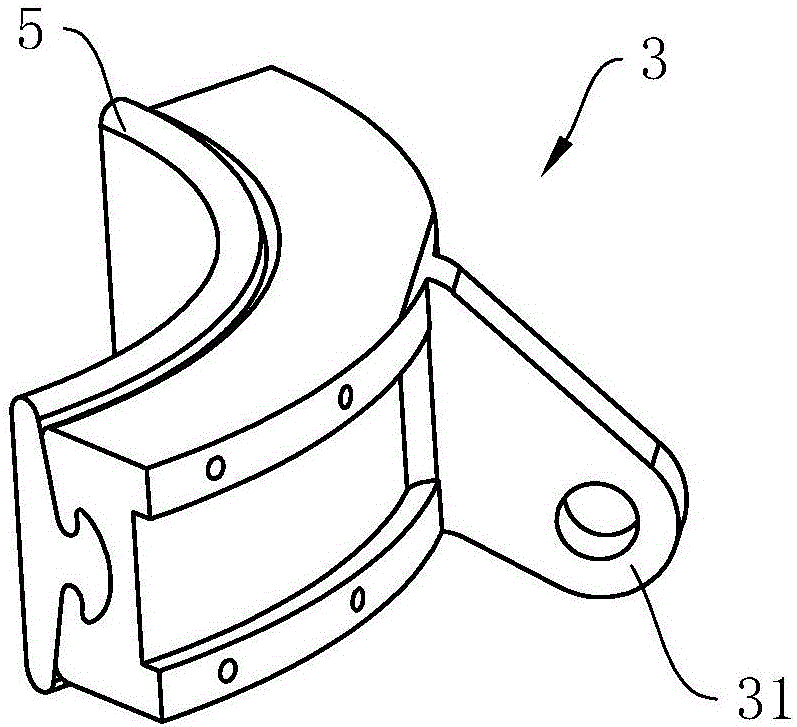

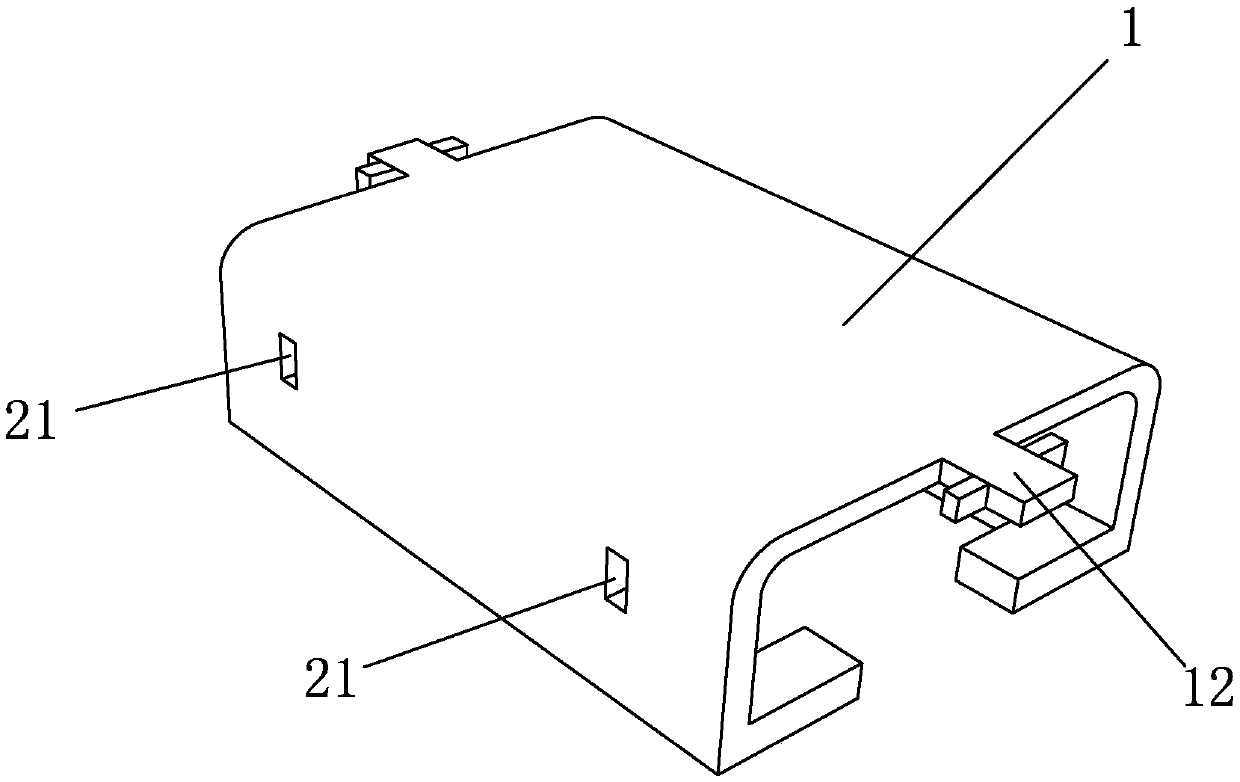

Saline-alkali soil tree protecting device

InactiveCN106550853AEffective protectionGuaranteed clamping forceCultivating equipmentsAlkali soilEngineering

The invention relates to the technical field of saline-alkali soil nursery stock protection, and provides a saline-alkali soil tree protecting device which comprises a supporting frame and a mulching film. The supporting frame comprises at least three clamp hoops, a clamp hoop ribbon which is adjusted and fixed through a ribbon locking device is connected between every two adjacent clamp hoops, and a supporting rod is hinged to a hinging part of a clamp hoop hinging lifting lug on each clamp hoop. Each supporting rod comprises an inner supporting rod body and an outer supporting rod body connected with the inner supporting rod body in a sleeving mode, wherein a directional locking device is arranged at the upper end of the outer supporting rod body, a supporting rod base is hinged to the lower end of the outer supporting rod body, a water injecting pipe penetrates through the supporting rod base, and the output end of the water injecting pipe communicates with a water seepage and ventilation pipe network. Each base table is sleeved with a mulching film tightening clamp hoop, and a tree base is sleeved with a mulching film binding band. The supporting height and surrounding diameter of the saline-alkali soil tree protecting device can be automatically adjusted along with growth of a tree, the tree is effectively supported and protected, the breathing requirement of the root is met, watering and fertilizer and pesticide applying can be conveniently conducted on the tree, and the mulching film can be effectively protected.

Owner:WEIFANG UNIVERSITY

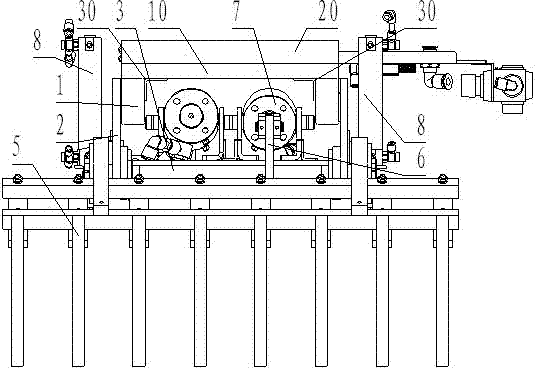

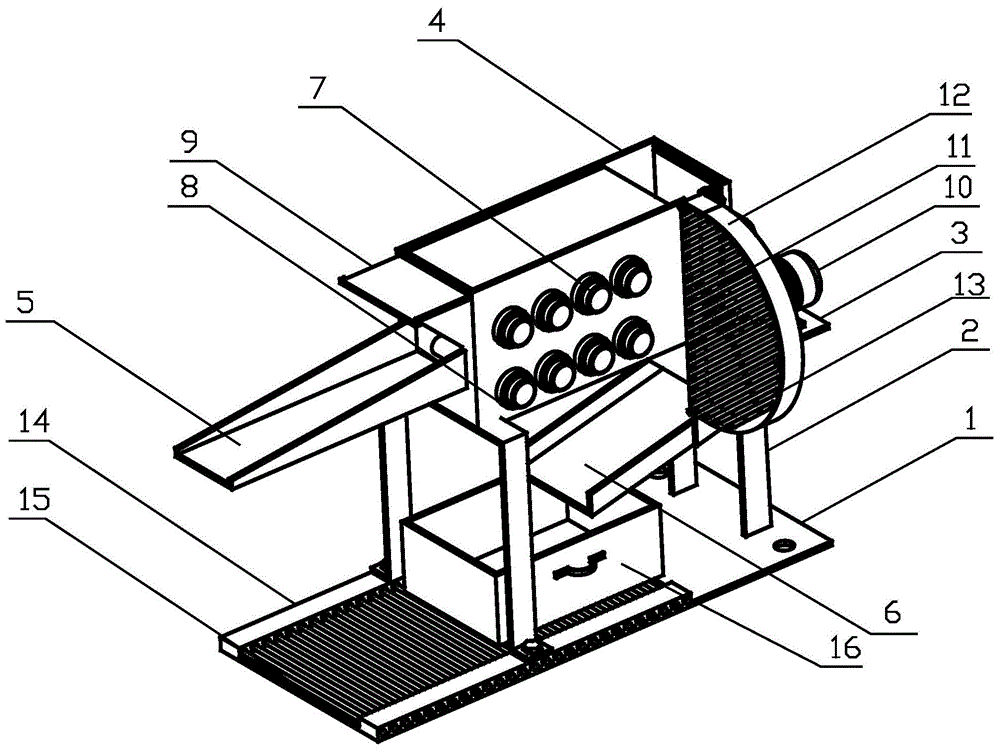

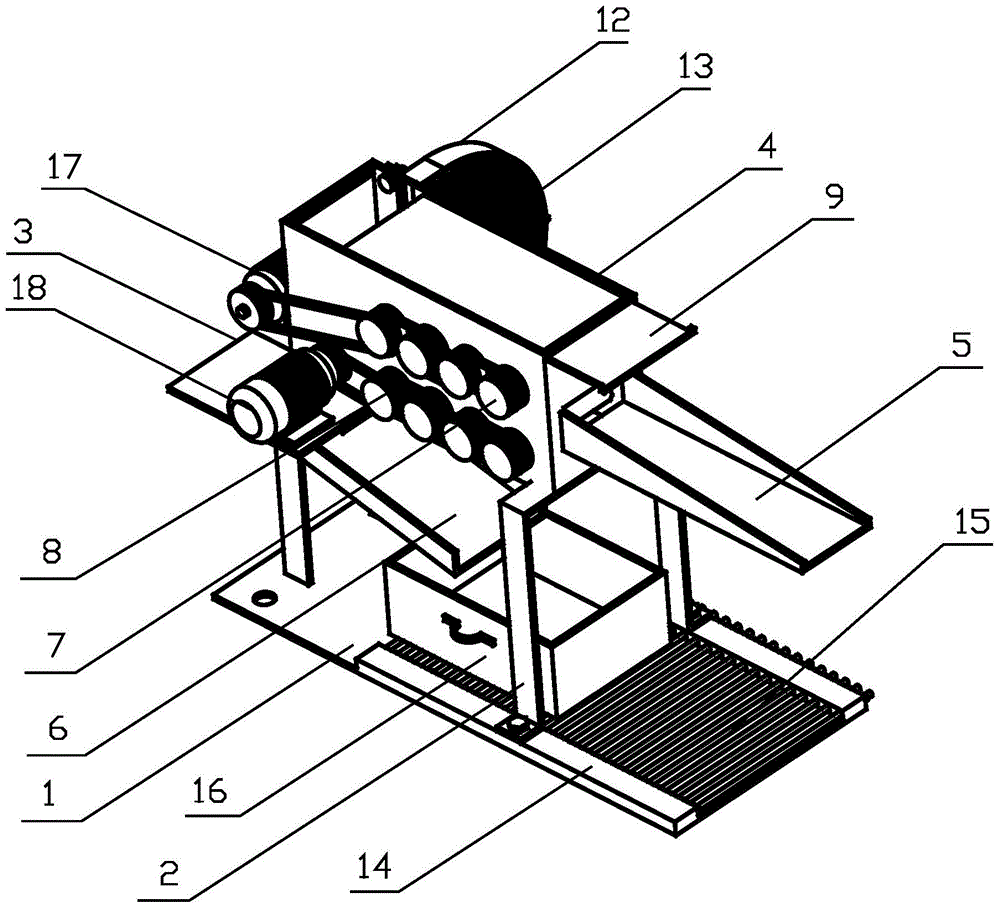

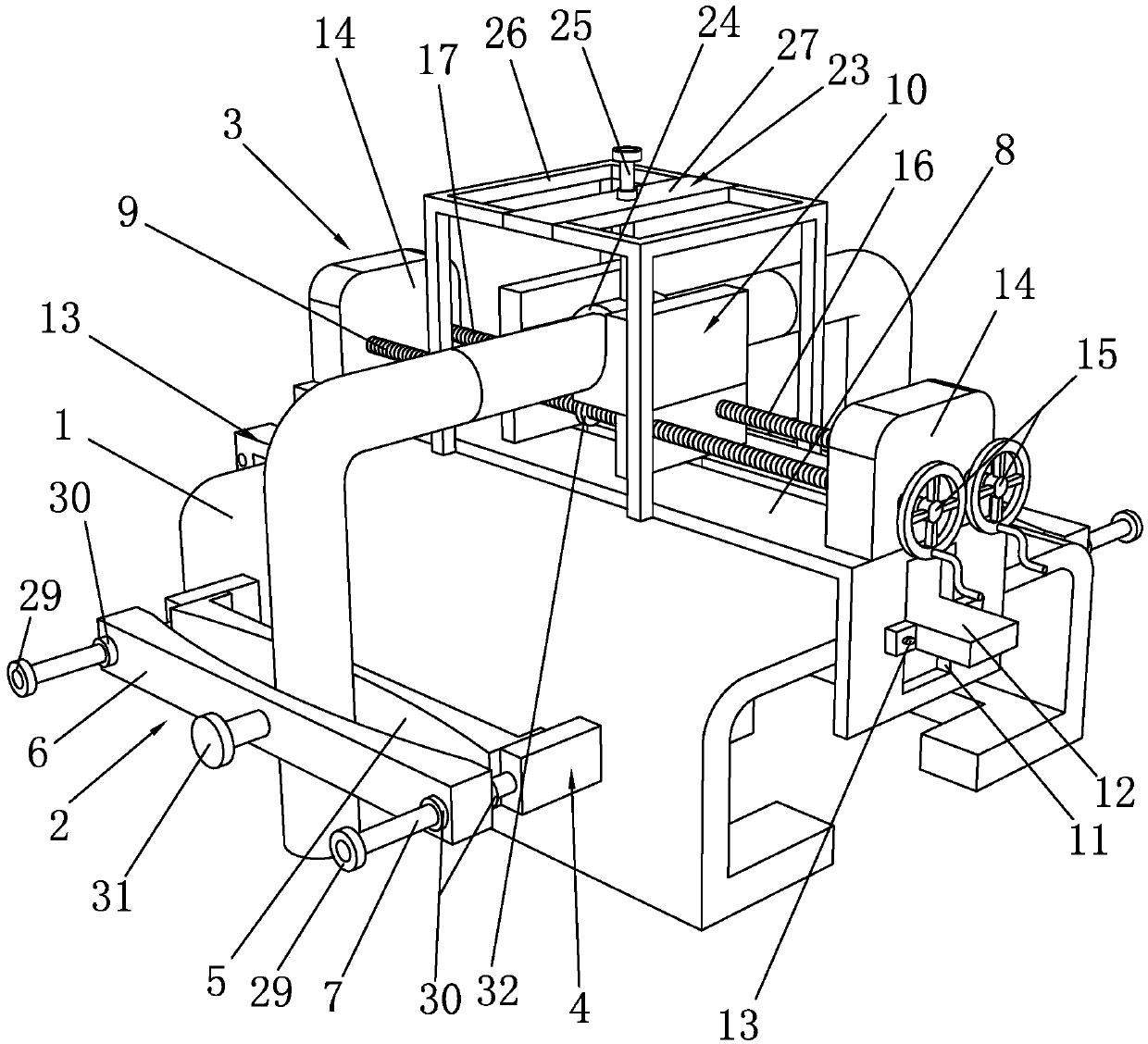

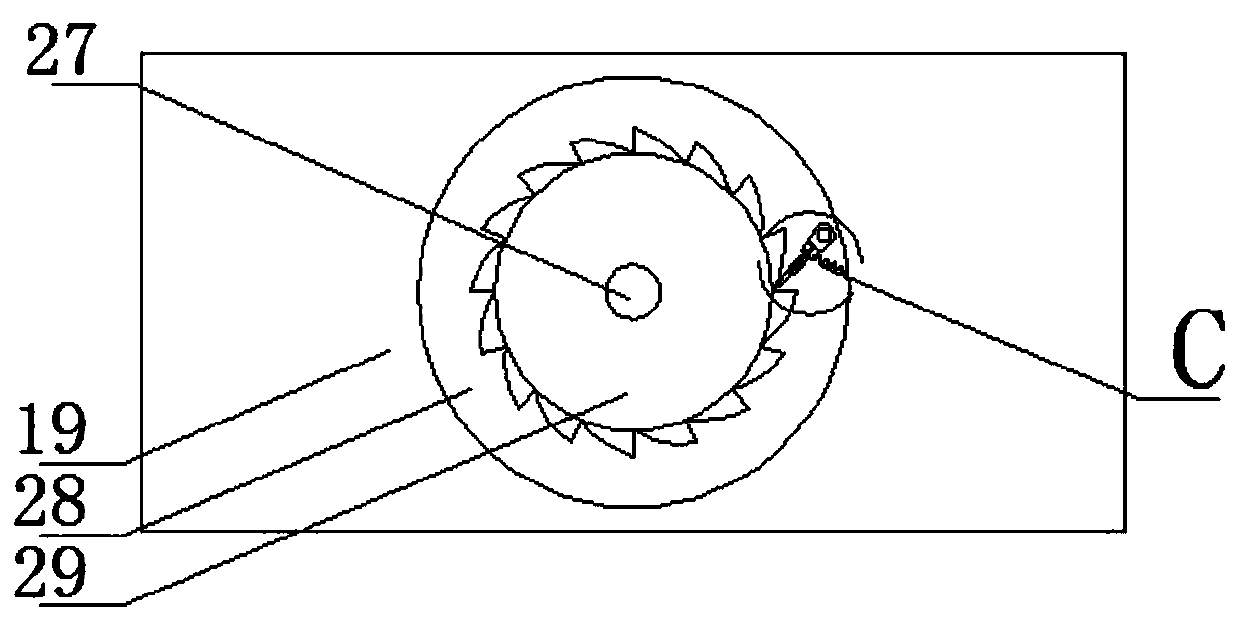

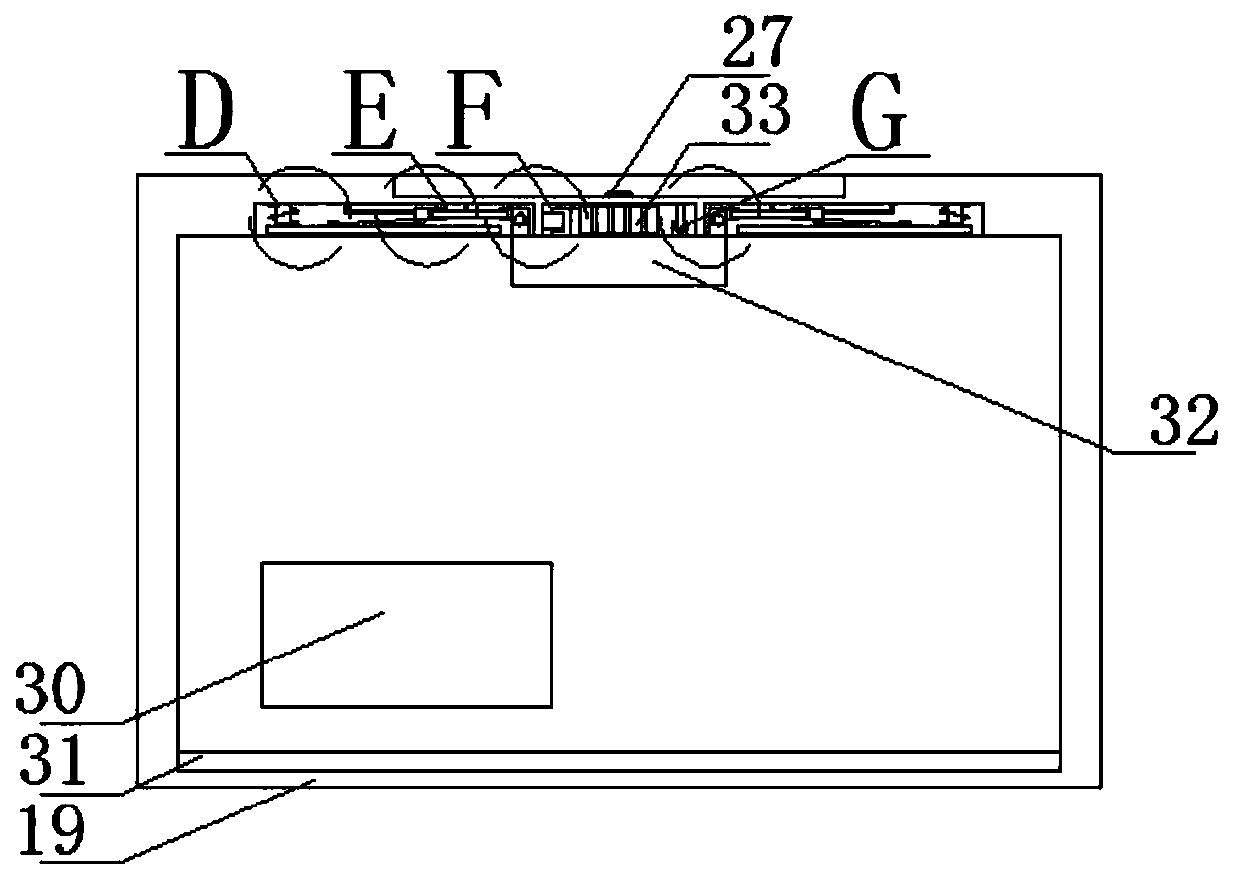

Chinese herbal medicine slicing machine

The invention relates to Chinese herbal medicine processing equipment, in particular to a Chinese herbal medicine slicing machine. The Chinese herbal medicine slicing machine comprises a supporting body, a box body, a feeding structure, a slicing mechanism, a discharging mechanism and a power transferring mechanism. A supporting frame is arranged on a base. A case is fixed to the supporting frame. An upper shifting roller set, a bottom shifting roller set, a slicing table (not marked in the figure), and a cutting feed port are arranged in the case. A feed hopper is arranged on one side of the outside of the case. A discharge hopper is arranged below the slicing table of the case. A platform is arranged on the other side of the case. A first motor, a second motor and a third motor are arranged on the platform. The discharge hopper is arranged below a receiving box. The Chinese herbal medicine slicing machine has the beneficial effects that cut openings of Chinese herbal medicine are flush, and the slicing speed is high; the shifting roller sets are used for feeding, and the slice thicknesses are uniform; the distance between the shifting roller sets can be adjusted, and thus the application range is wide; and elastic shaft sleeves are arranged on the shifting rollers, so that the herbal medicine is protected against crushing damage, and the slicing operation is safe.

Owner:裴佩

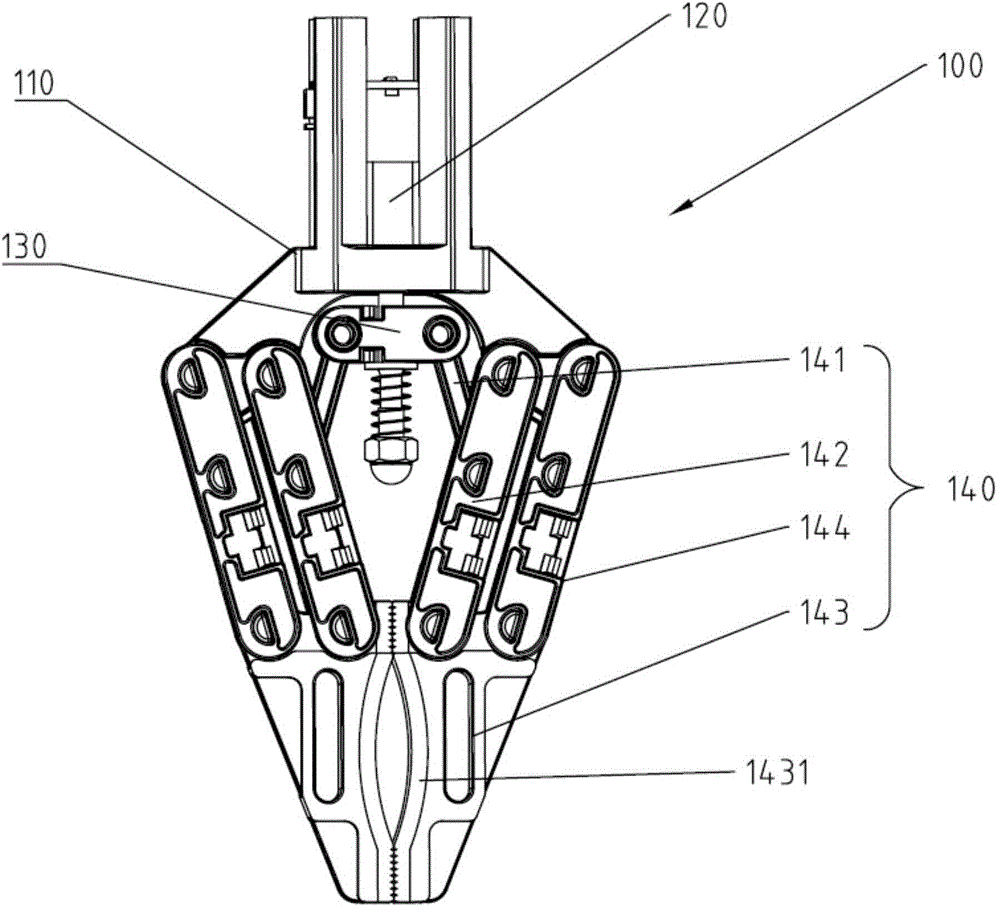

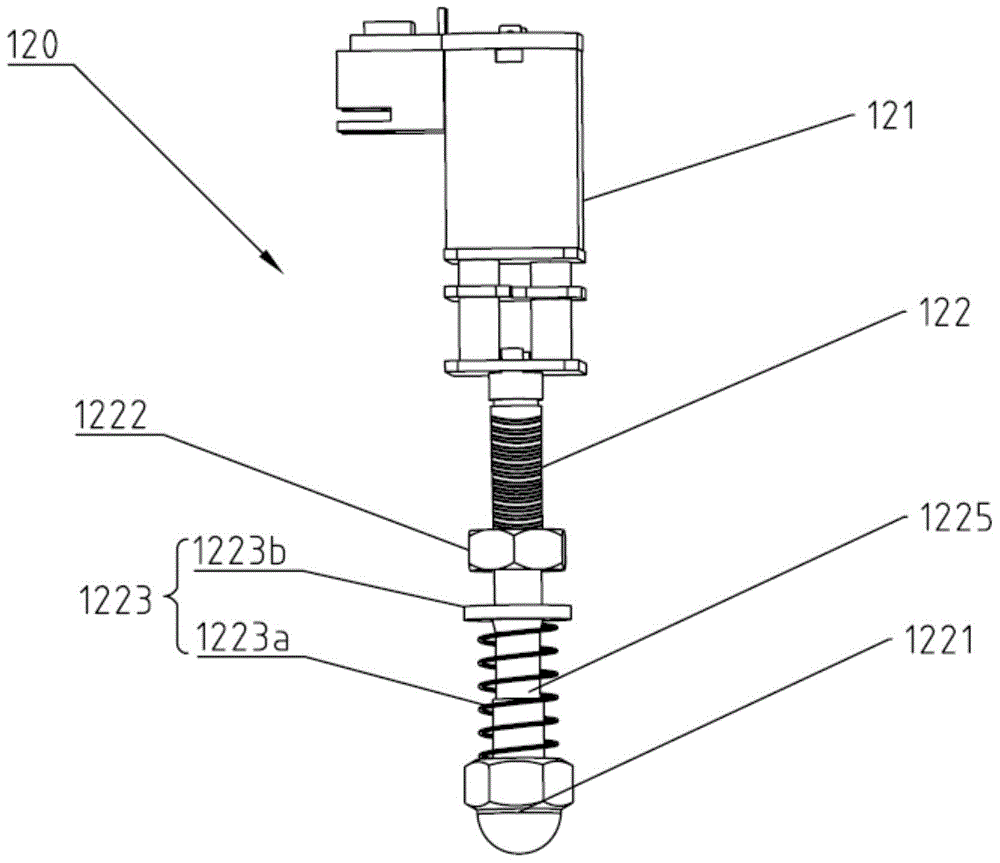

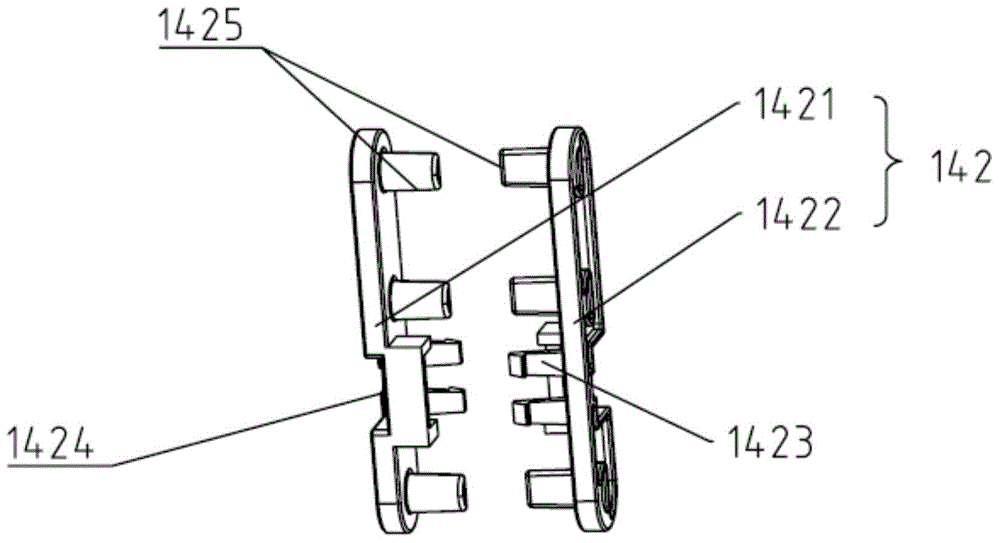

Material picking device and workpiece carrying mechanism

PendingCN109132525AAvoid damageProtection is in progressConveyorsControl devices for conveyorsEngineeringMechanical engineering

Owner:SUZHOU RS TECH

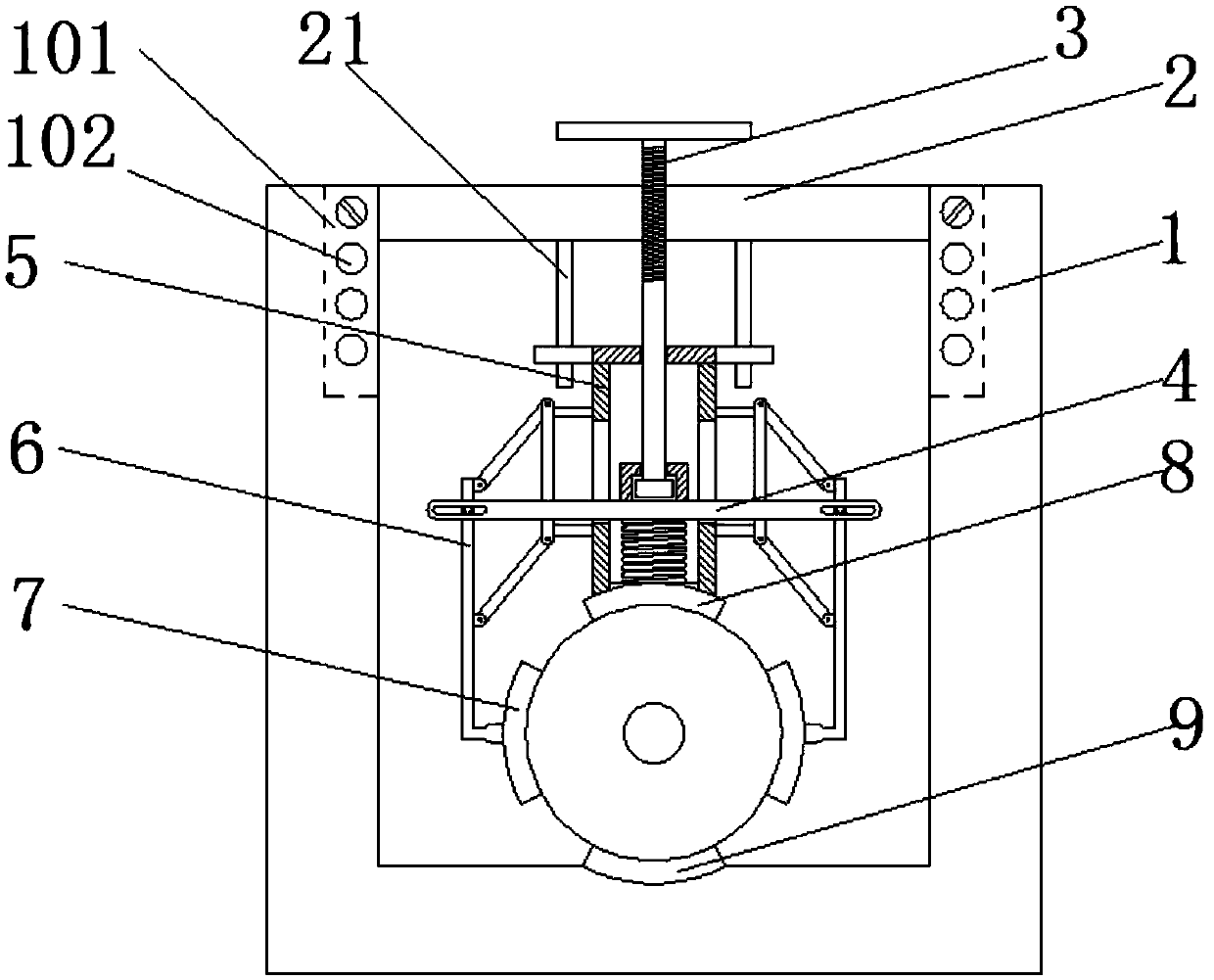

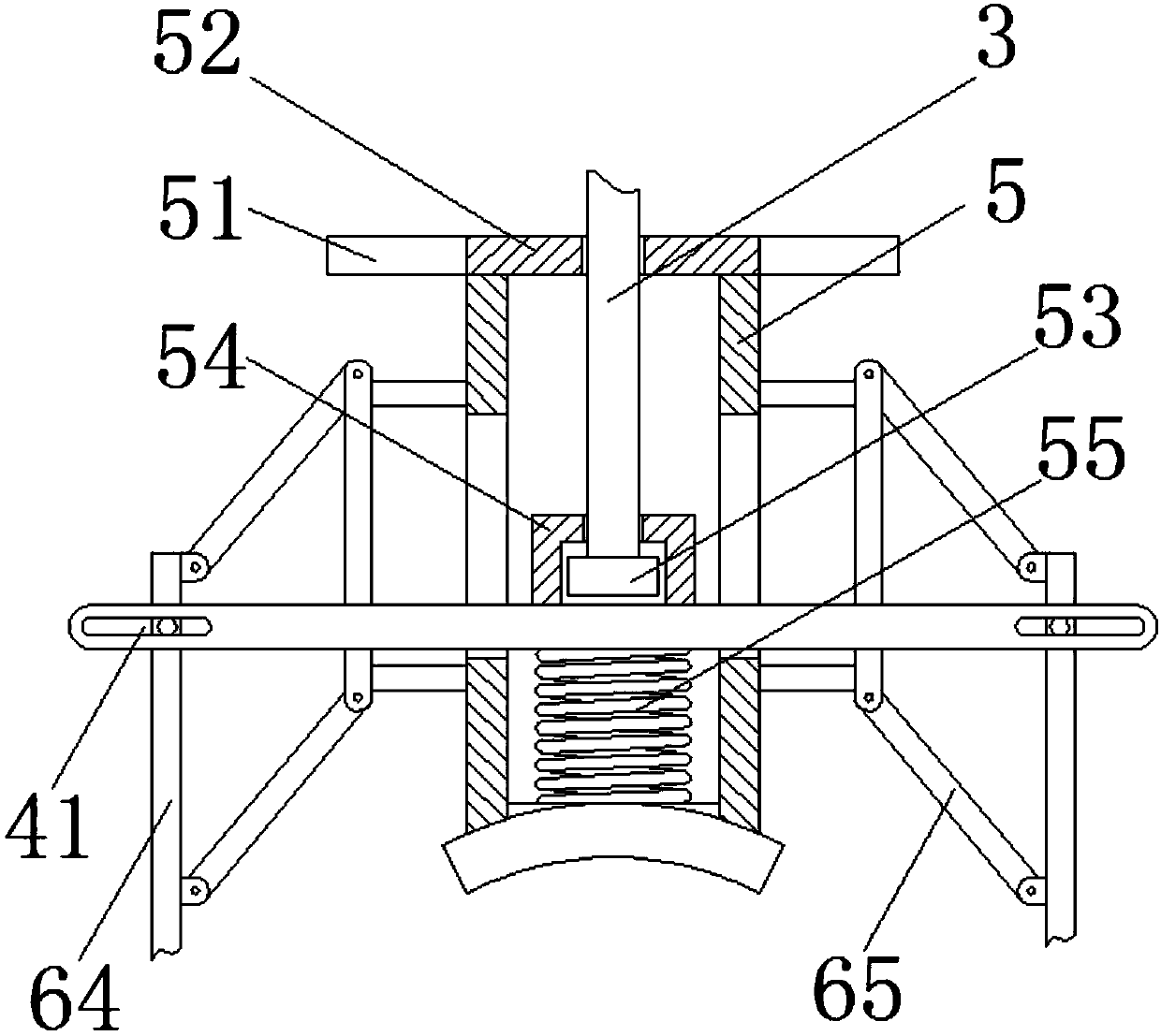

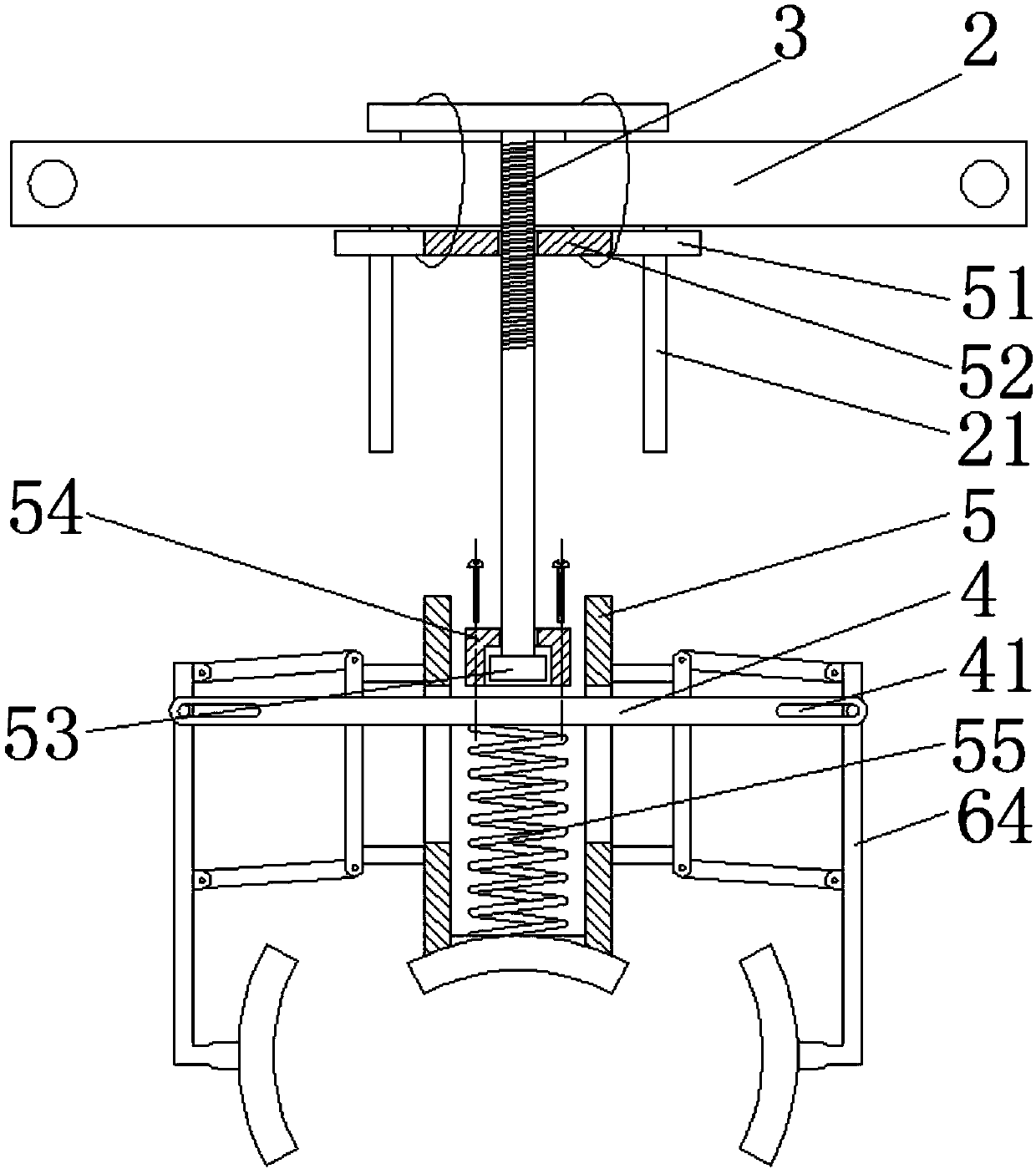

Assembling method of device for clamping insulator

The invention belongs to the technical field of insulator clamping equipment, and particularly relates to an assembling method of a device for clamping an insulator. The device for clamping the insulator comprises a U-shaped frame and an opening cross rod, and the two ends of the opening cross rod are inserted into sliding grooves formed in the two sides of the U-shaped frame and fixed through bolts; a screwing rod is arranged in the middle of the opening cross rod, the lower end of the screwing rod penetrates through a sleeve flange disc to enter a fixing sleeve, a fixing block is connected to the lower end of the screwing rod and arranged in a fixing cavity, the lower end of the fixing cavity is connected with a horizontal cross rod, and a spring is arranged between the horizontal crossrod and the bottom of the fixing sleeve; and quadrangular connecting rod frames are connected to the two ends of the horizontal cross rod separately, side face clamping blocks are hinged to the lowerends of movable rods, an upper end clamping block is arranged at the lower end of the fixing sleeve, and a lower end clamping block is arranged at the bottom of the U-shaped frame. The insulator doesnot need to be disassembled in the clamping process, the clamping position is automatically positioned, and a clamping mode with both fixed clamping force and variable clamping force is formed.

Owner:温州炘都工业设计有限公司

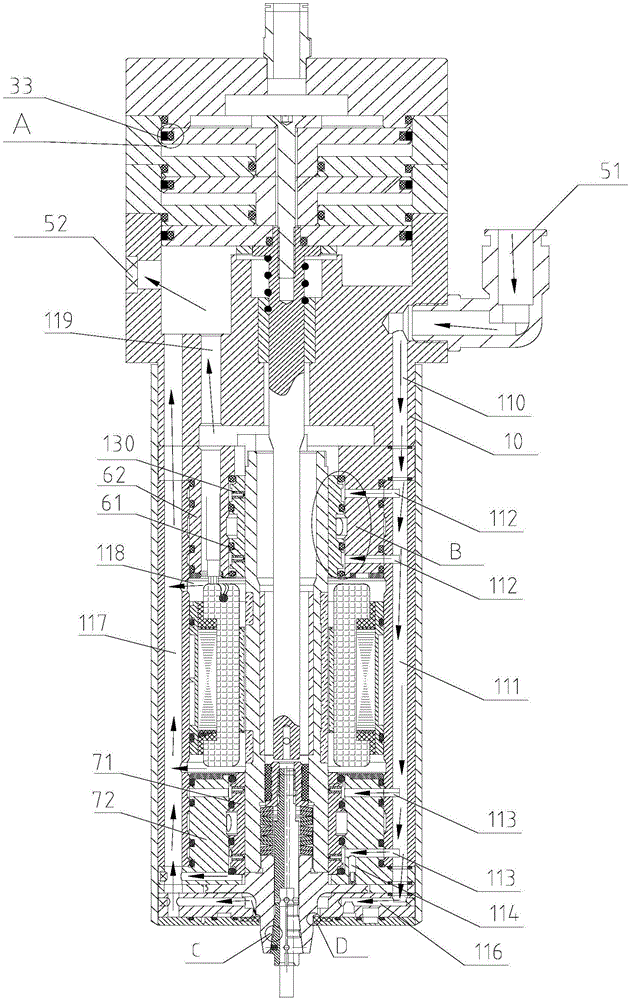

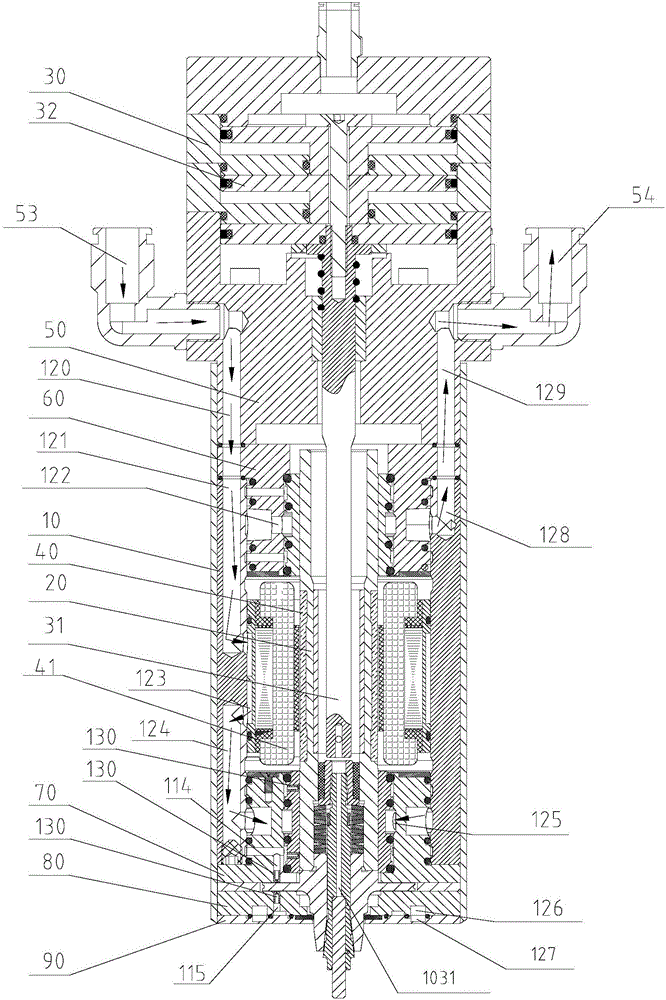

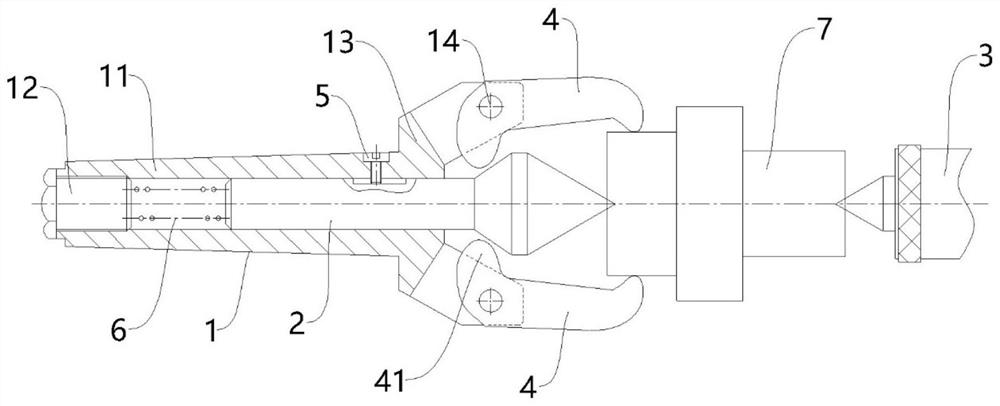

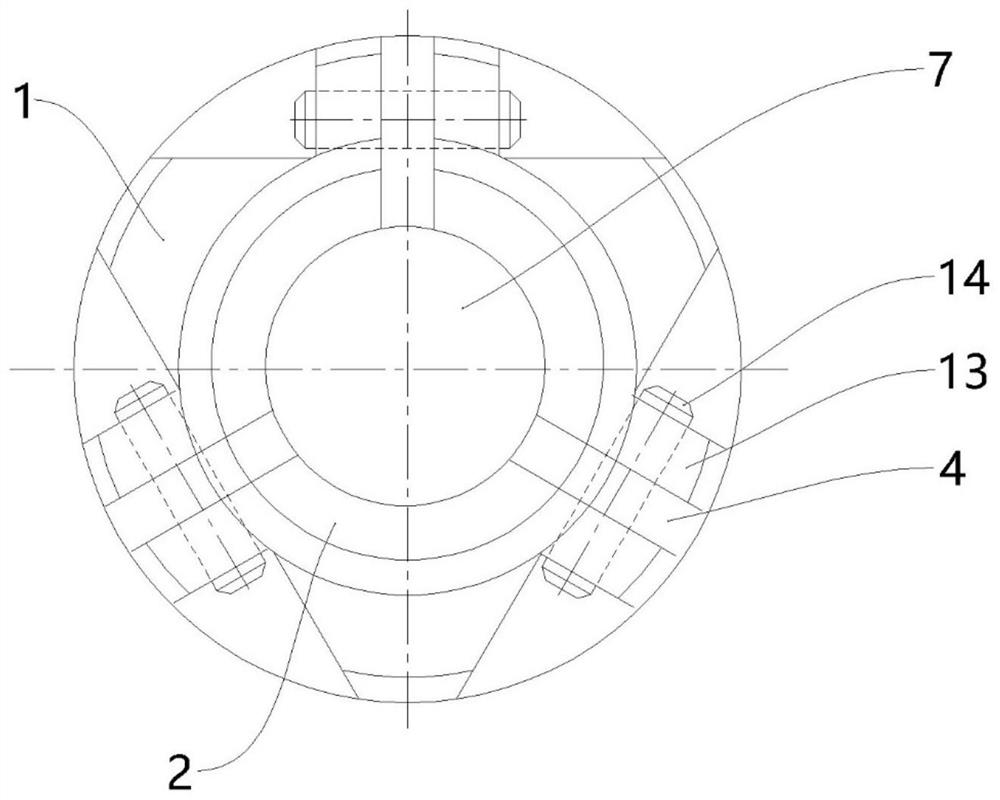

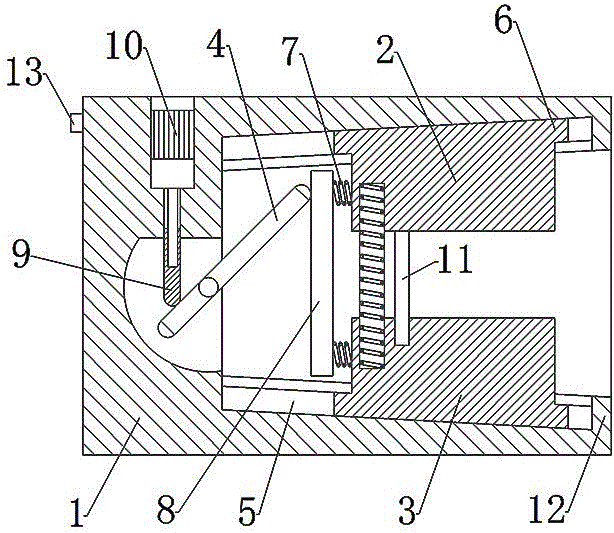

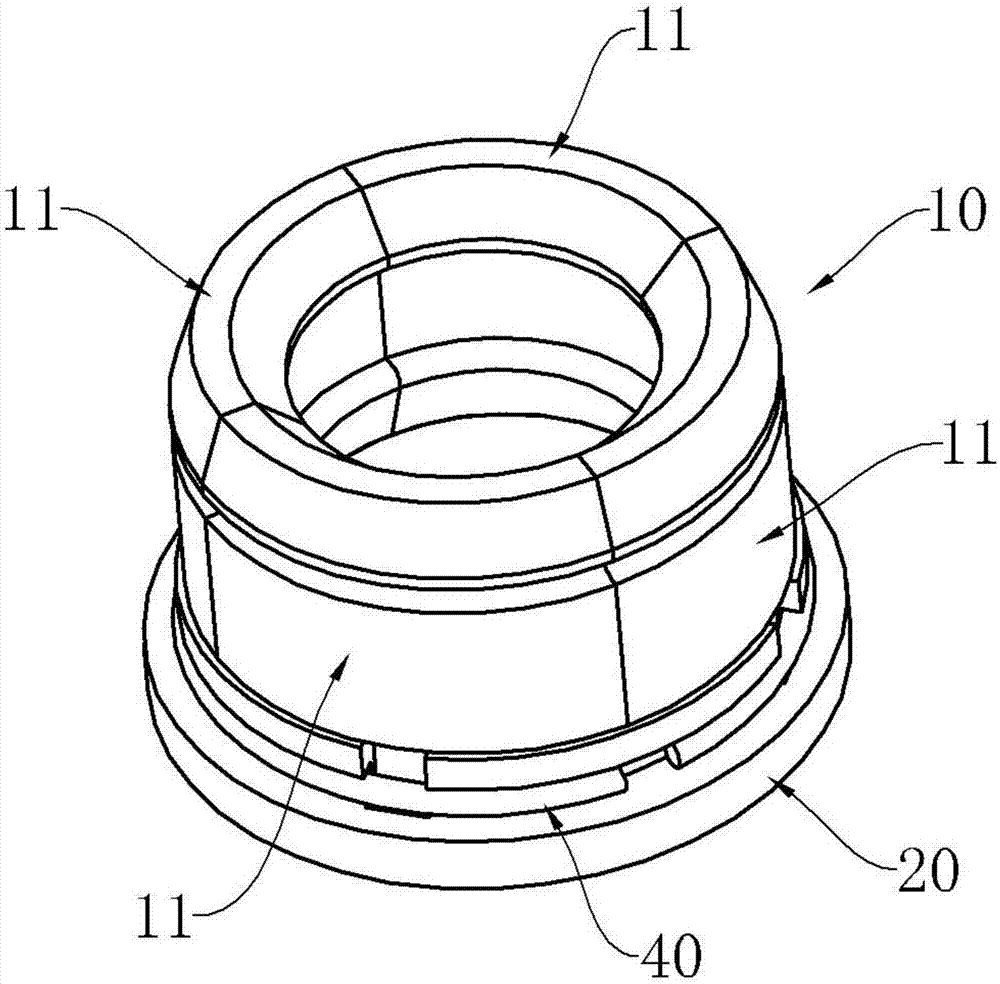

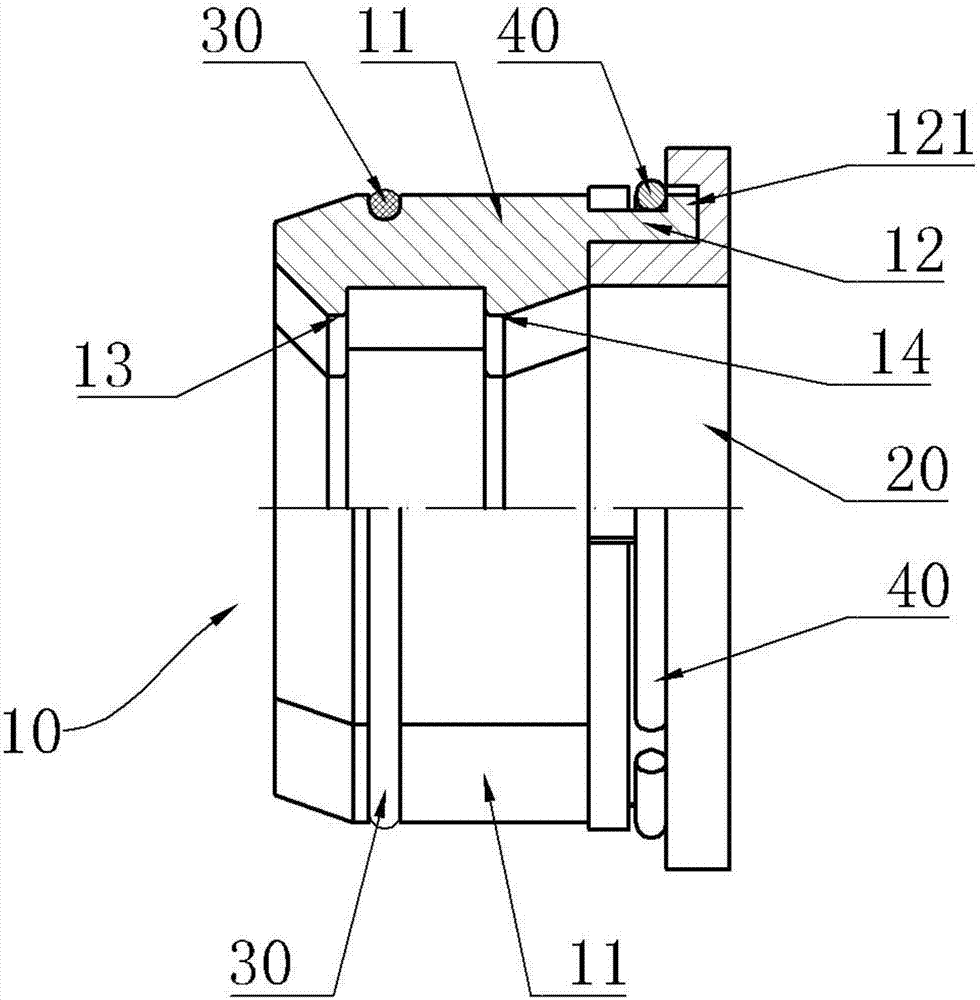

Air bearing spindle with speed measurement function

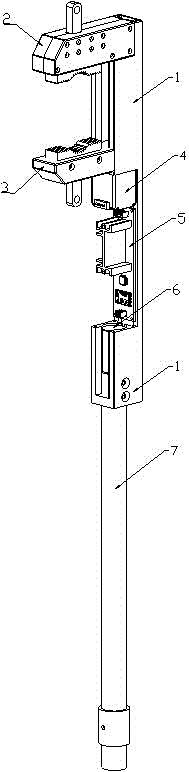

ActiveCN106563818AWith speed measurement functionReasonable designMeasurement/indication equipmentsLarge fixed membersAir bearingThrust bearing

The invention discloses an air bearing spindle with a speed measurement function. The air bearing spindle with the speed measurement function comprises a body, a spindle core assembly, a power assembly, an aluminum water jacket, a cylinder, an upper bearing assembly, a lower bearing assembly, a thrust bearing assembly and a cover plate assembly, wherein the body is of a cavity structure; the spindle core assembly comprises a rotating shaft section and a chuck section; the rotating shaft section sleeves the chuck section; speed measurement grooves are formed in the rotating shaft section; the power assembly comprises a copper bordered rotor and a stator assembly; the copper bordered rotor is inlaid into the rotating shaft section; the stator assembly is arranged in the body and is opposite to the copper bordered rotor; the upper bearing assembly is arranged on the upper part of the rotating shaft section; speed measurement sensors are arranged on the upper part of the upper bearing assembly and correspond to the speed measurement grooves; the lower bearing assembly is arranged on the lower part of the rotating shaft section; the thrust bearing assembly is arranged on the chuck section; the cover plate assembly is arranged at the bottom of the thrust bearing assembly; the aluminum water jacket is arranged on the top of the upper bearing assembly; and the cylinder is arranged on the top of the aluminum water jacket. The air bearing spindle with the speed measurement function is easy to process, simple in structure and good in heat dissipation effect, and runs stably.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

External pipeline paving device of large-scale air purifying equipment

The invention discloses an external pipeline paving device of large-scale air purifying equipment. The device comprises a fixing cover, horizontal positioning frames and a vertical positioning frame;the vertical positioning frame comprises a U-shaped bottom plate, transverse sliding rods and supporting brackets, the front end and the rear end of the transverse sliding rods are provided with firstthreaded sections and second threaded sections, and the thread directions of the first thread sections and the second thread sections are opposite, and the first threaded sections and the second threaded sections are provided with supporting brackets. According to the device, the external pipeline is integrally supported and fixed through the paving device, so that the overall stability of the pipeline is ensured, then the paving device and the equipment are connected and fixed, the operation difficulty of directly paving the pipeline on the surface of the equipment is reduced, and the pipeline and the inner pipeline in the equipment can be conveniently connected and fixed, and the tight performance after the pipeline is in butt joint is improved, and the multiple parts of the pipeline can be simultaneously supported and positioned through the paving device, the structure stability of the external pipeline is effectively ensured, and the effects of damping and noise reducing are achieved.

Owner:嘉兴市良友制衣有限公司

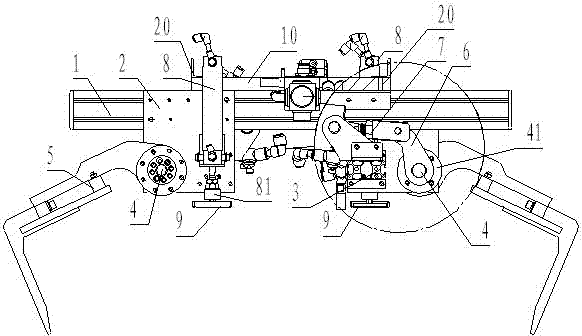

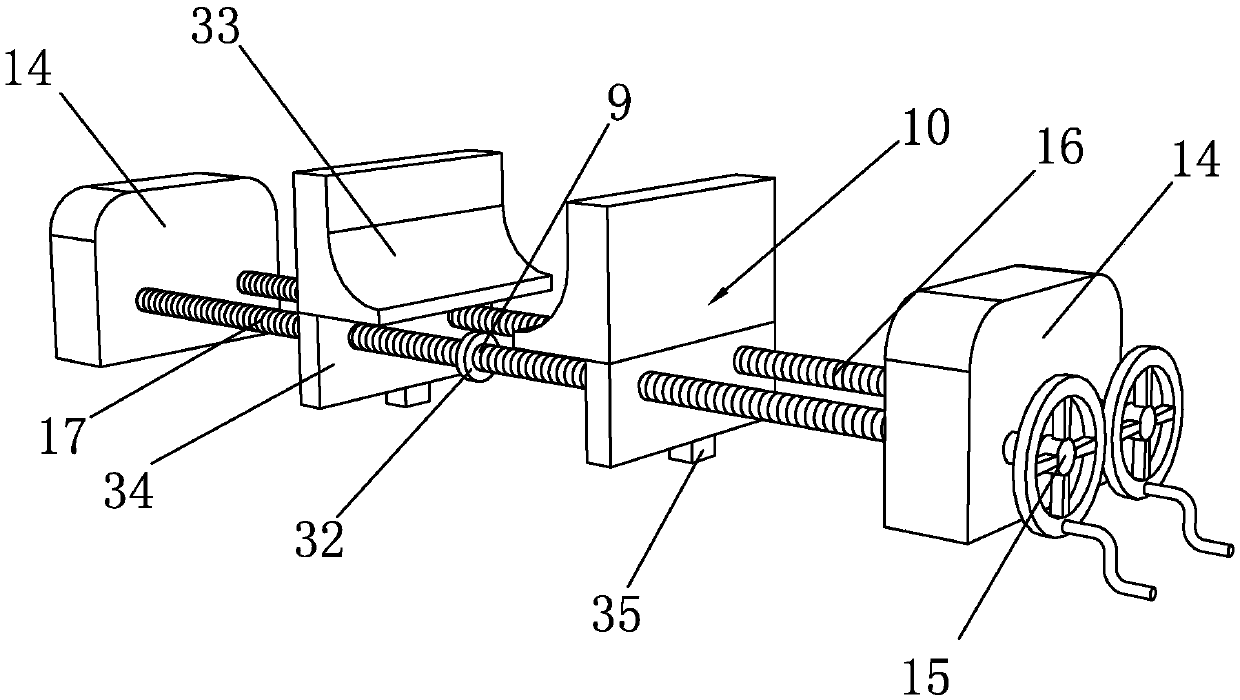

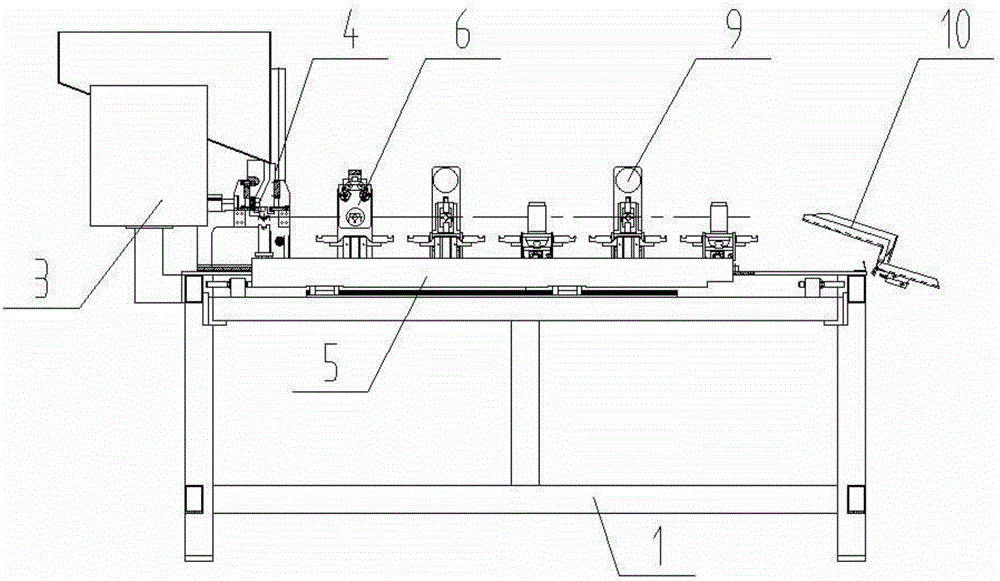

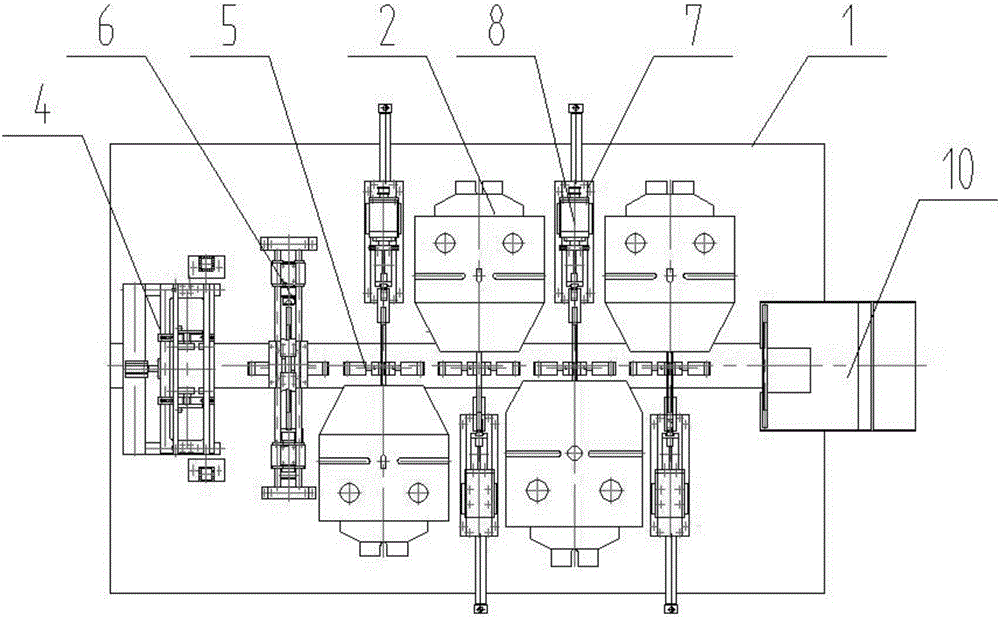

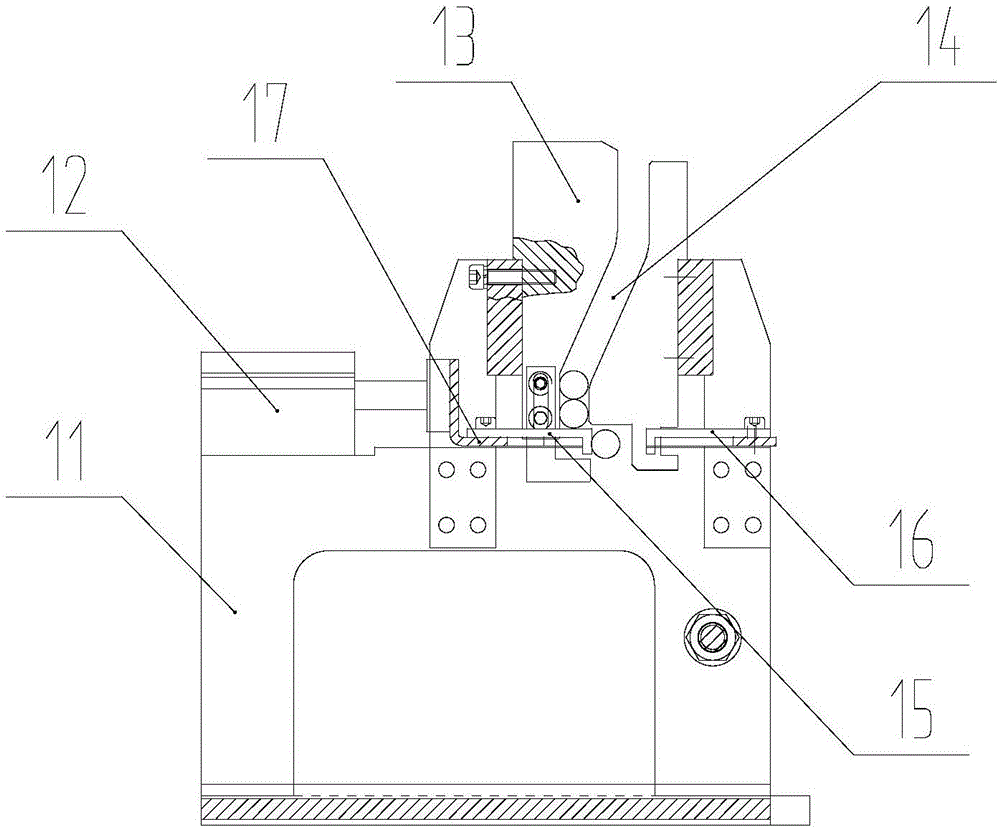

Umbrella handle rod automatic continuous stamping equipment

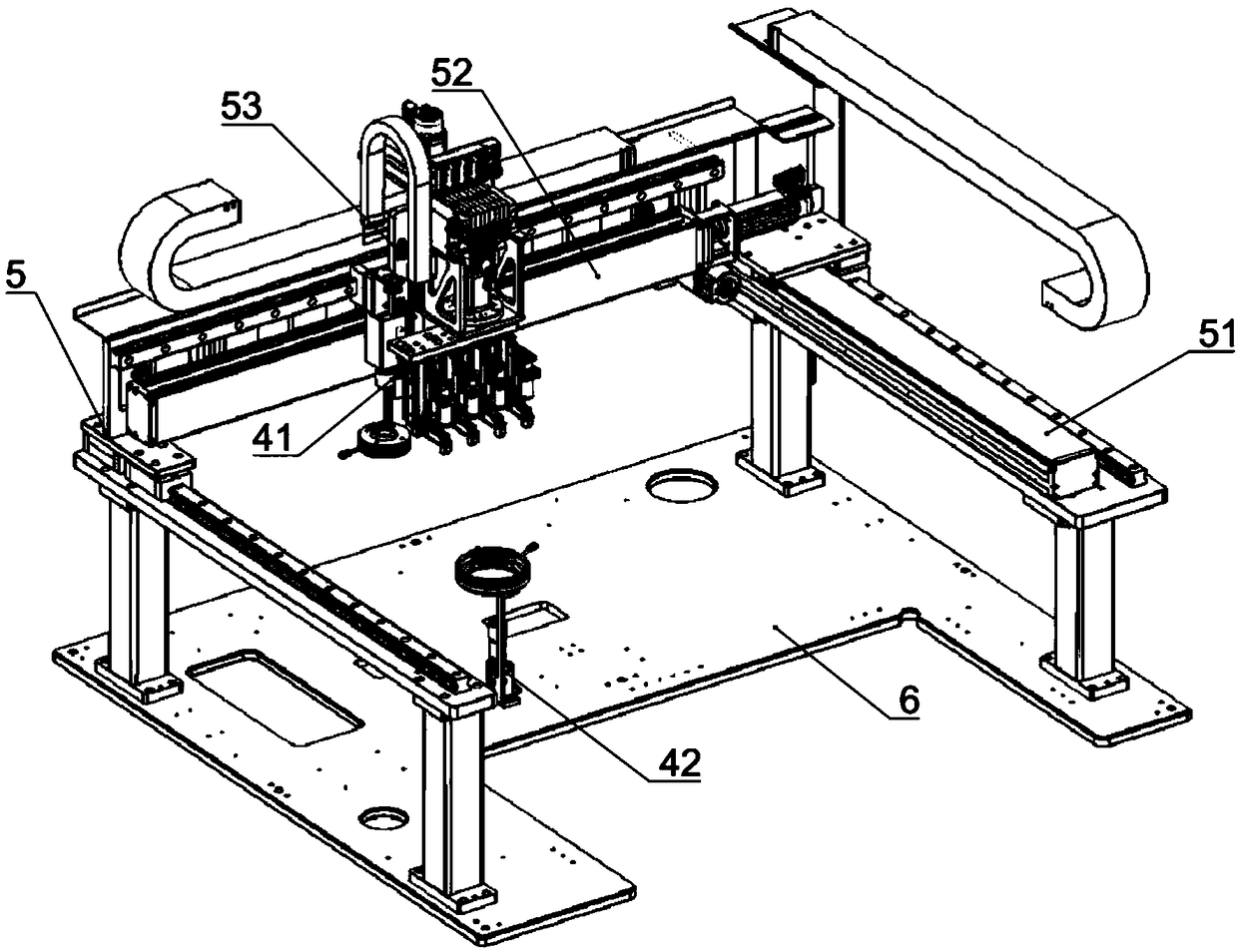

ActiveCN106623609AReasonable distributionHigh degree of automationMetal-working feeding devicesMetal working apparatusPunchingEngineering

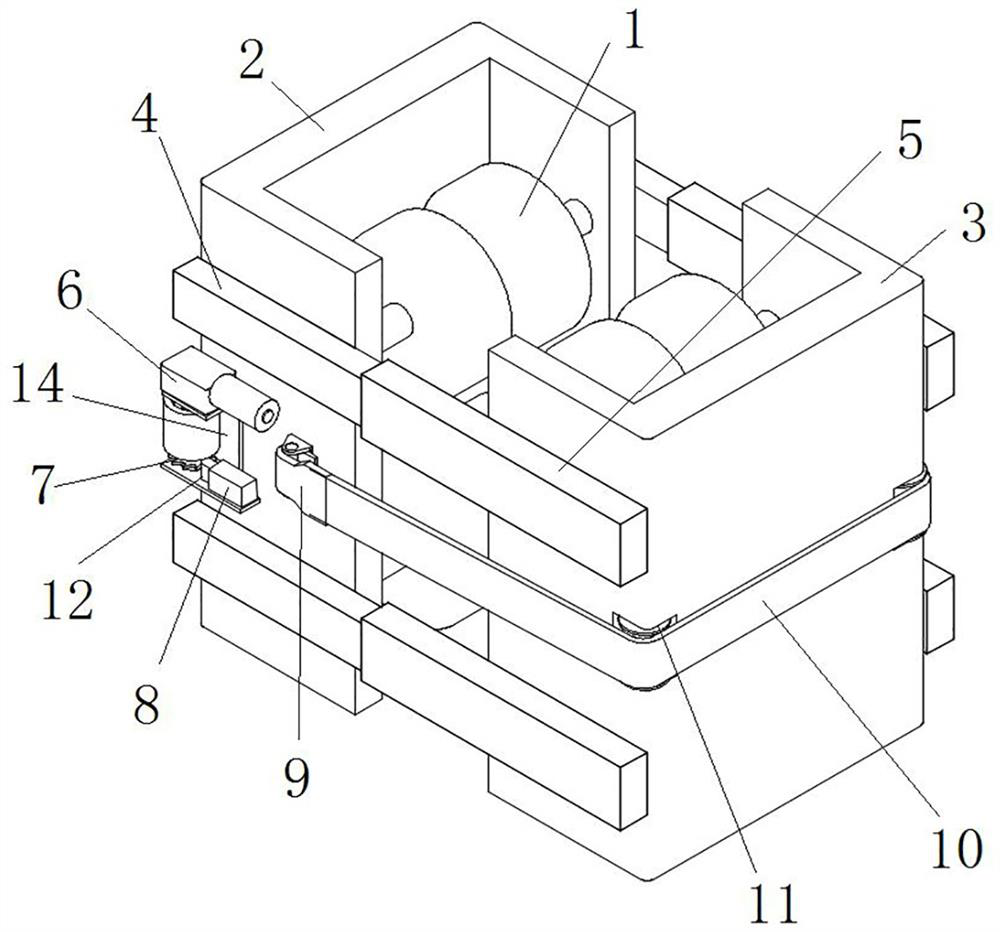

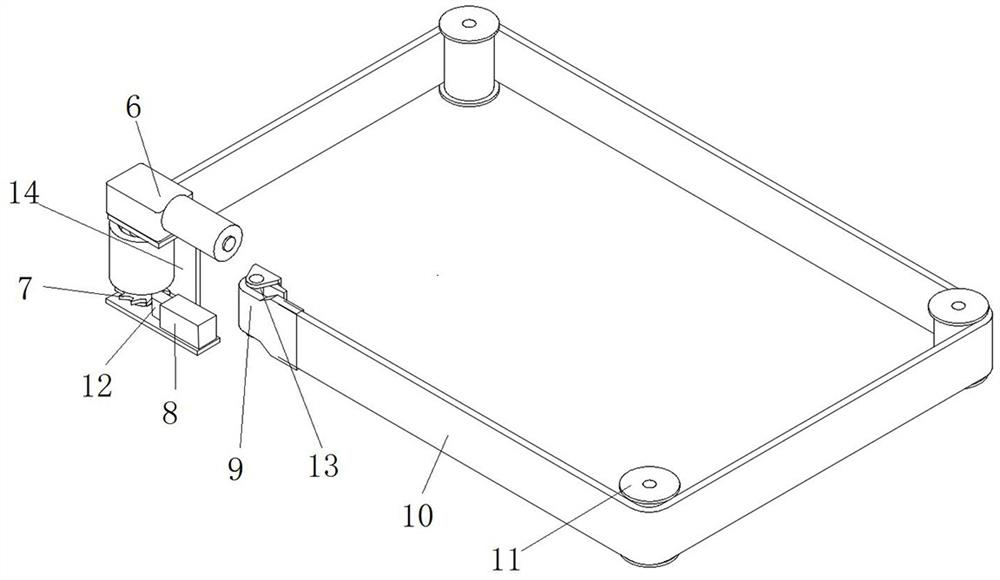

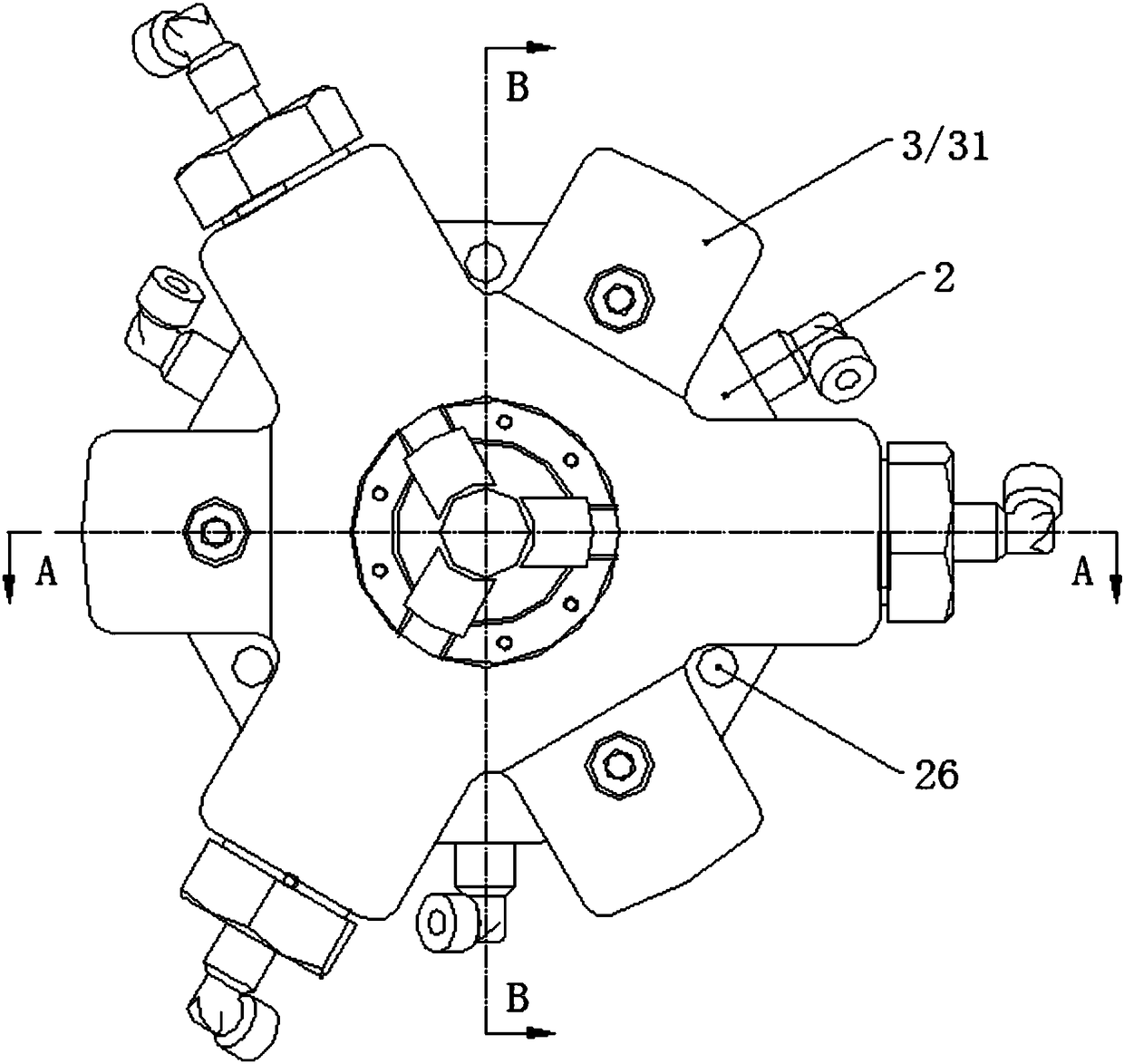

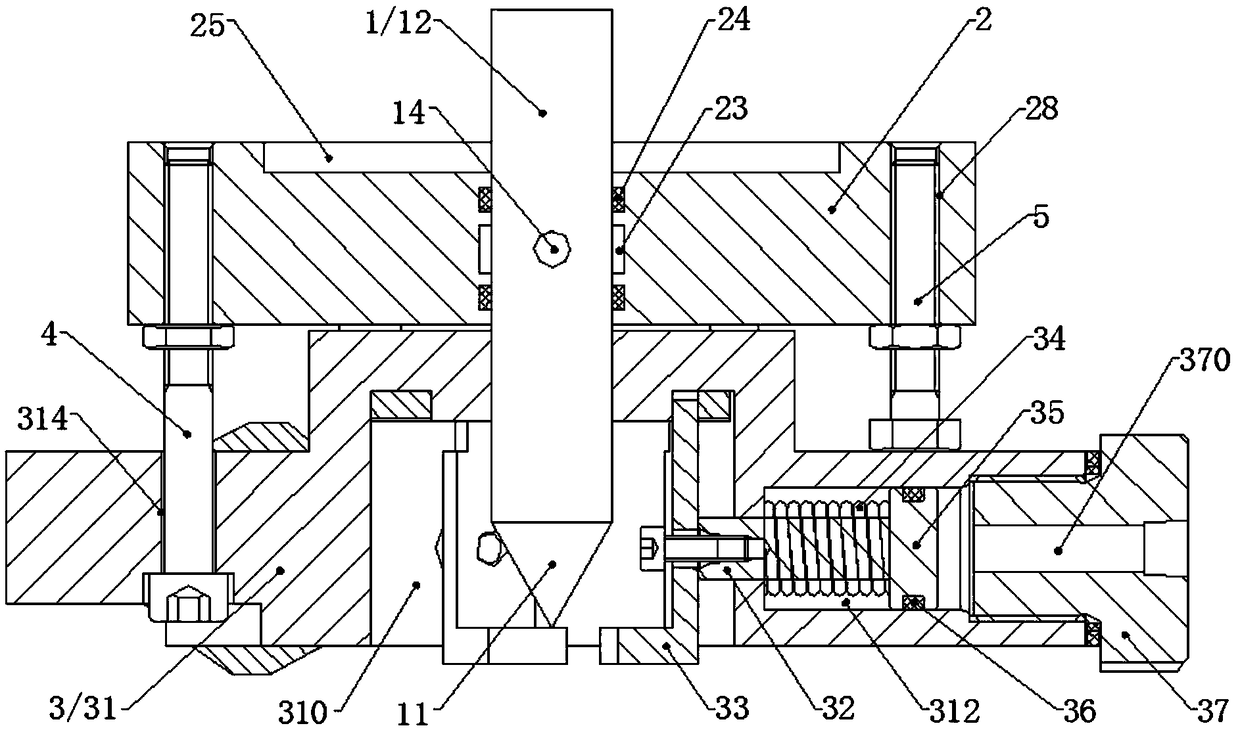

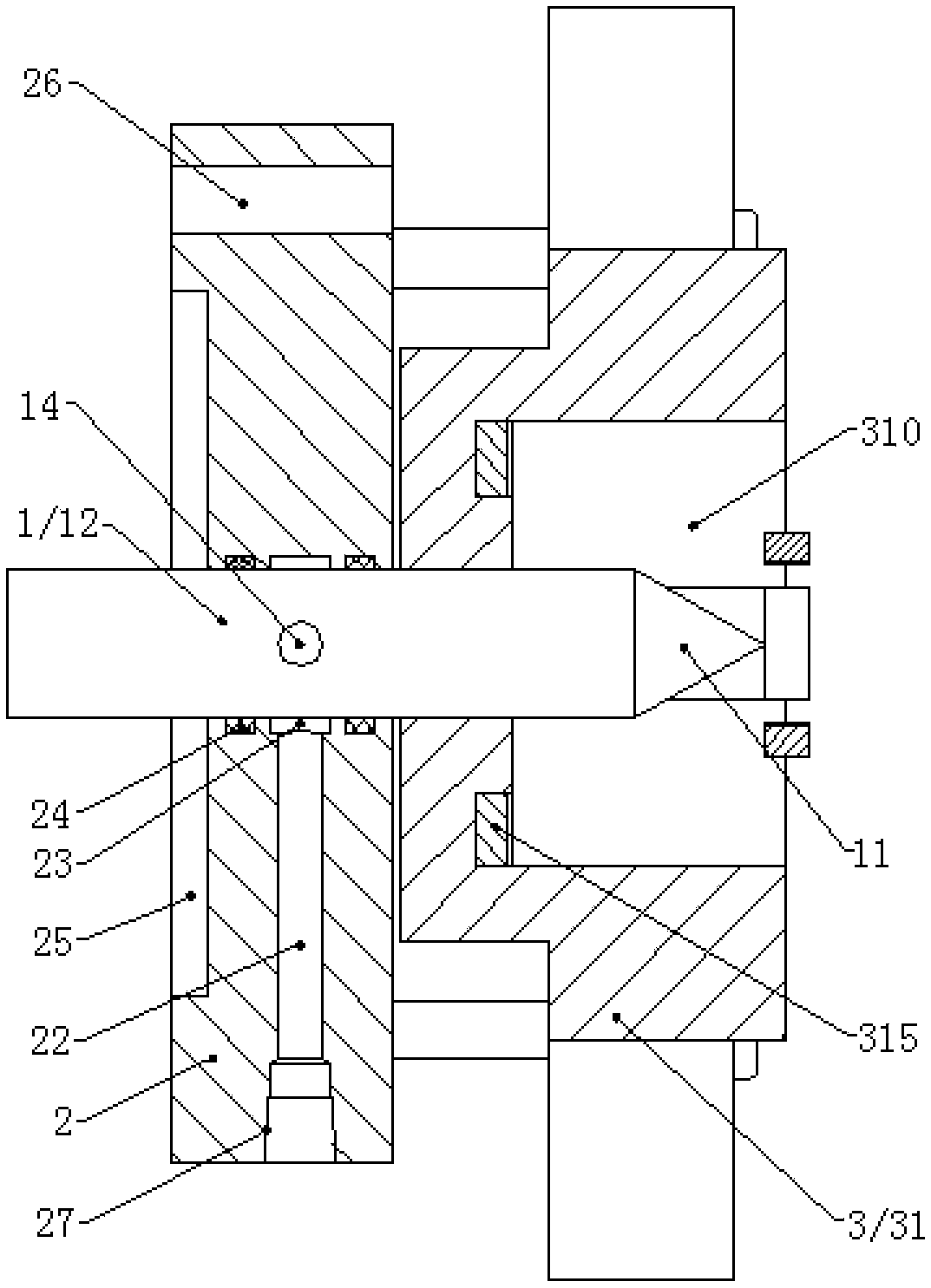

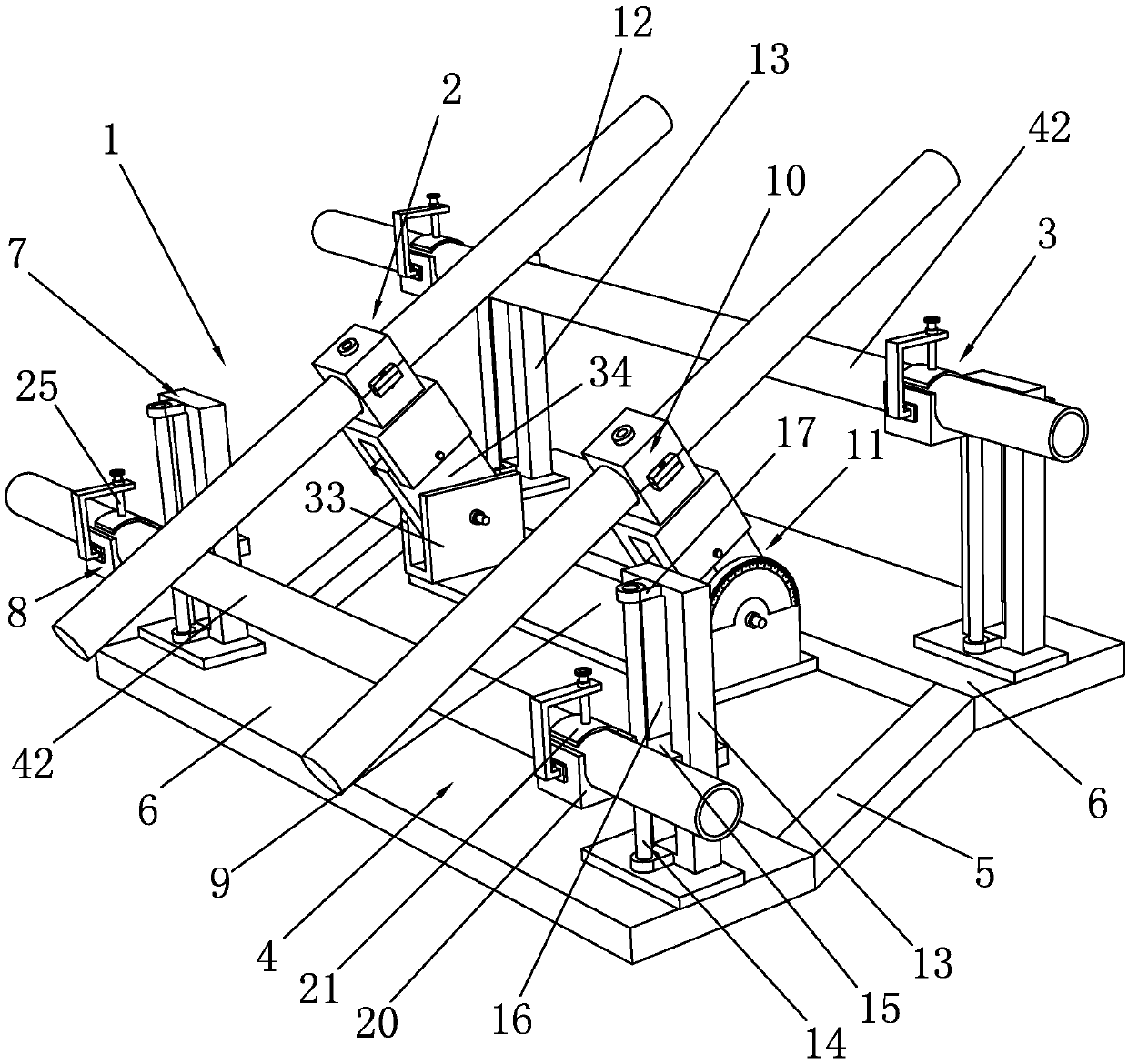

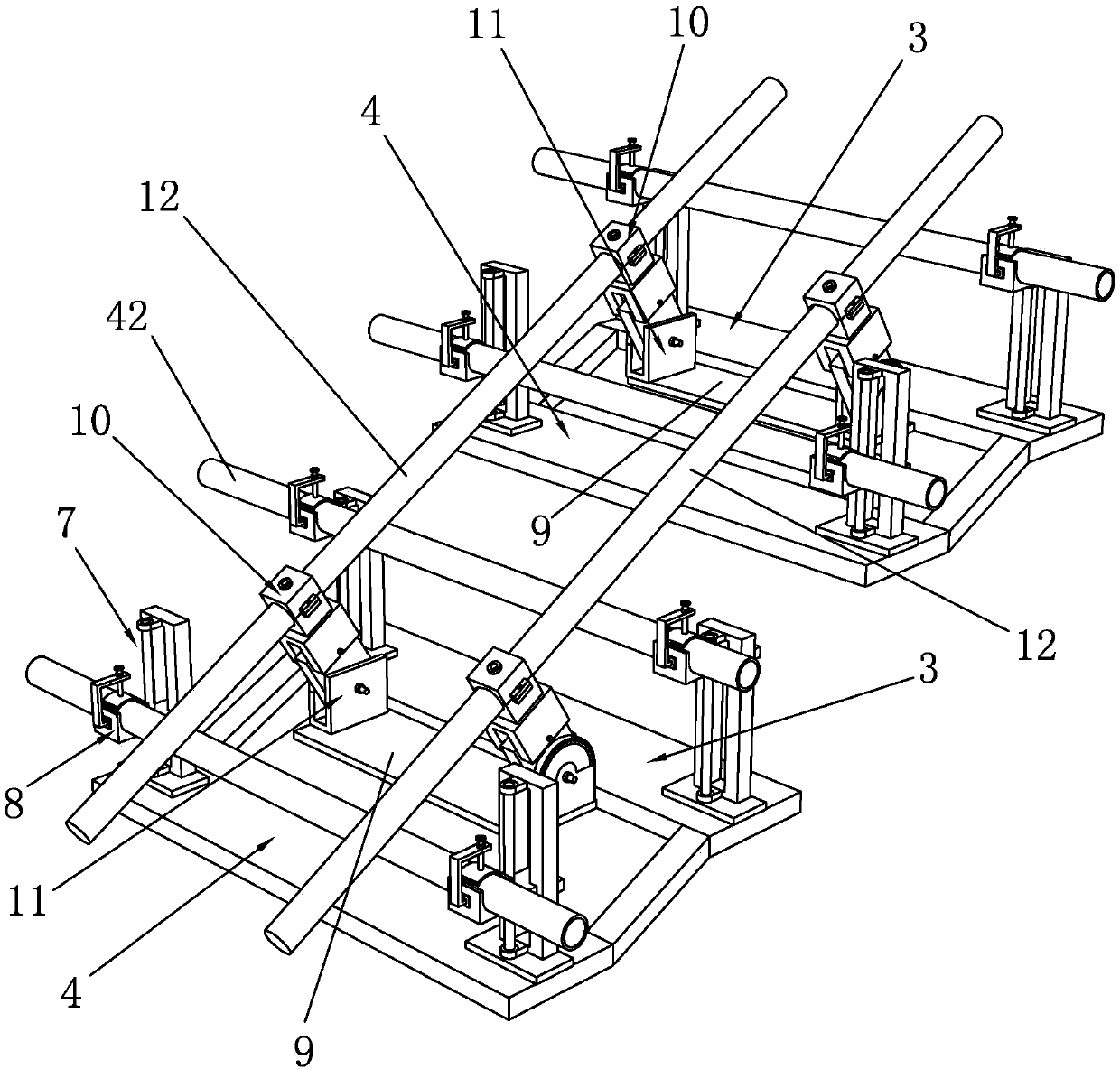

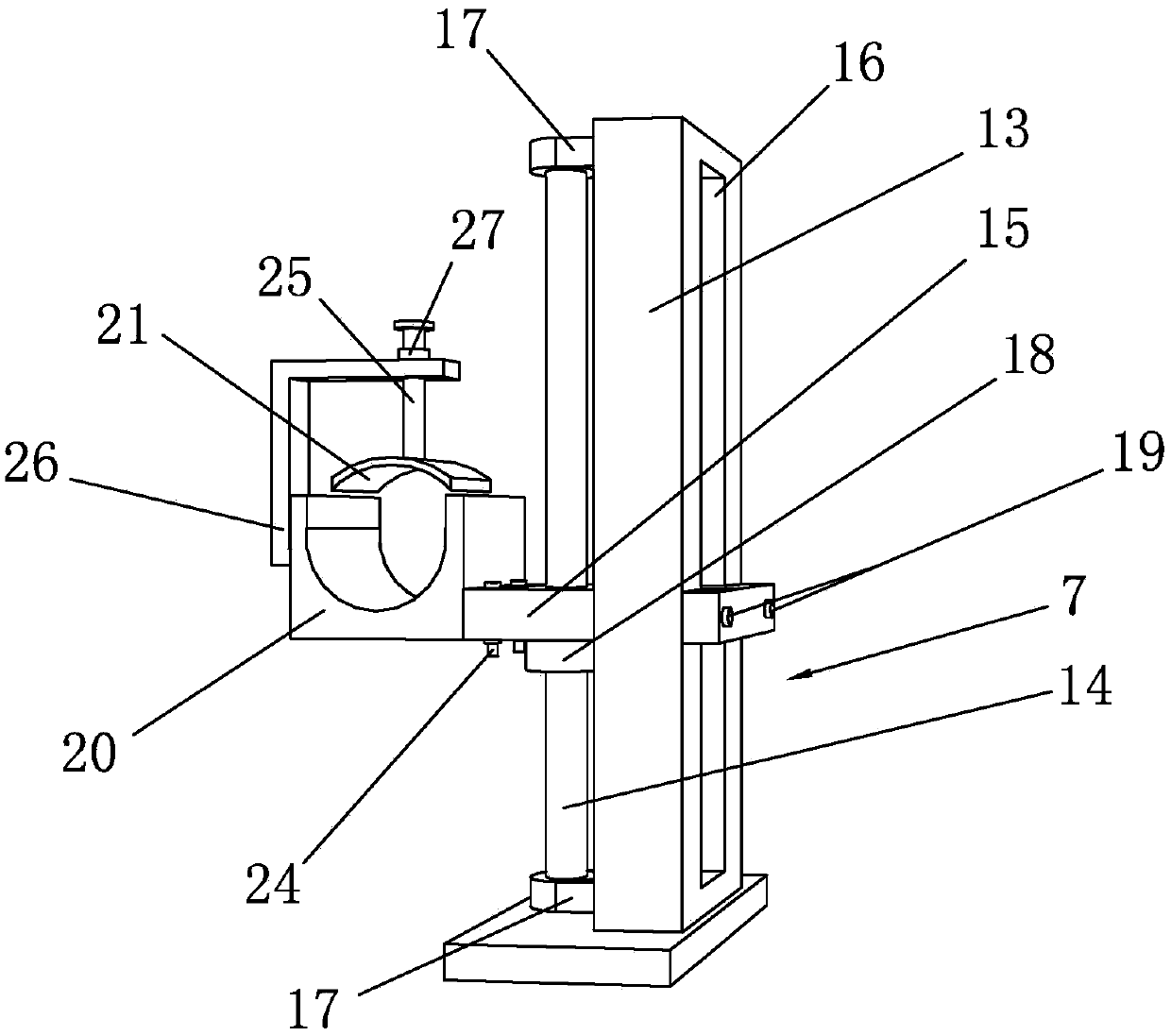

The invention discloses umbrella handle rod automatic continuous stamping equipment. The umbrella handle rod automatic continuous stamping equipment comprises an automatic material distribution and feeding module used for automatically discharging umbrella handle rods to be machined one by one, a discharging module used for receiving finished umbrella handle rods to be machined, an X-direction reciprocating feeding module for supporting and clamping the umbrella handle rods to be machined and sending the umbrella handle rods to be machined from the automatic material distribution and feeding module to the discharging module, a symmetric clamping and circumferential positioning module used for clamping the umbrella handle rods to be machined and determining the zero position, a Y-direction feeding and machining module for conducting Y-direction feeding and punching on the umbrella handle rods to be machined passing the Y-direction feeding and machining module, a digital control module and a machine tool bed used for fixing the devices. According to the umbrella handle rod automatic continuous stamping equipment, the seven-position series connection layout is adopted, distribution is reasonable, and the automation degree is high; all the positions move synchronously, the machining efficiency is greatly improved, and the production quality is improved; moreover, on the premise of guaranteeing the production efficiency, convenient conditions are provided for fault self-diagnosis of the equipment, machining quality detection of products in each position, statistics of the rate of finished products and the like.

Owner:杭州萧山进化镇徐峰五金机械厂

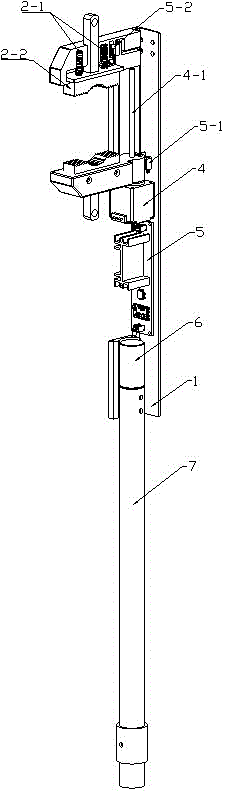

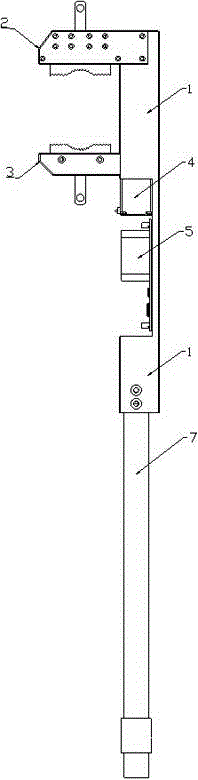

Pole-climbing robot

The invention relates to a pole-climbing robot. The pole-climbing robot comprises at least two climbing blocks, a flexible hooping piece and a tightening driving device, wherein the at least two climbing blocks are used for being distributed in the circumferential direction of a pole piece to be clamped, climbing wheels are arranged on the sides, which face the pole piece, of the climbing blocks,at least one climbing wheel is a driving wheel, and the driving wheel is in transmission connection with a wheel driving mechanism; a guiding telescopic structure is arranged between any two adjacentclimbing blocks and used for guiding the two corresponding climbing blocks to get close to each other in the opposite direction to press the pole piece and guiding the two corresponding climbing blocks to get away from each other in the opposite direction to release the pole piece; the flexible hooping piece extends in the distribution circumferential direction of all the climbing blocks, the flexible hooping piece is hooped on all the climbing blocks during tensioning, the tensioned flexible hooping piece applies hooping acting force to all the climbing blocks to drive all the climbing blocksto get close to each other, and then the climbing wheels of all the climbing blocks are pressed on the pole piece; and the tightening driving device is arranged on the corresponding climbing blocks and is in transmission connection with the flexible hooping piece so as to be used for tensioning the flexible hooping piece.

Owner:临颍县爬杆机器人有限公司

High-altitude wiring device for mutual inductor detection equipment

InactiveCN105319399AAvoid damageGuaranteed damageMeasurement instrument housingElectricityEngineering

The invention relates to a high-altitude wiring device for mutual inductor detection equipment, and belongs to the technical field of power equipment. The device comprises an operating connecting rod and a wiring clamp disposed at the top of the operating connecting rod. The wiring clamp comprises a movable jaw and a fixed jaw, which are vertically arranged in an opposite manner. A side surface of the movable jaw is provided with a threaded hole, and a screw rod passes through the threaded hole. One end of the screw rod is fixed on an insulating support through a bearing. The insulating support is fixedly connected with the operating connecting rod. The fixed jaw is connected to an installation seat which is located on the insulating support and extends outwards. One end of the screw rod is connected to a motor output shaft fixed on the insulating support. The movable jaw and the fixed jaw are provided with wiring ends. The device provided by the invention employs a stepping motor to drive the movable jaw to gradually clamp a high-altitude wire. The fixe jaw is installed through the spring, so as to protect the wire from being damaged. Afterwards, the movable and fixed jaws are used for taking and leading out electricity for testing.

Owner:STATE GRID CORP OF CHINA +1

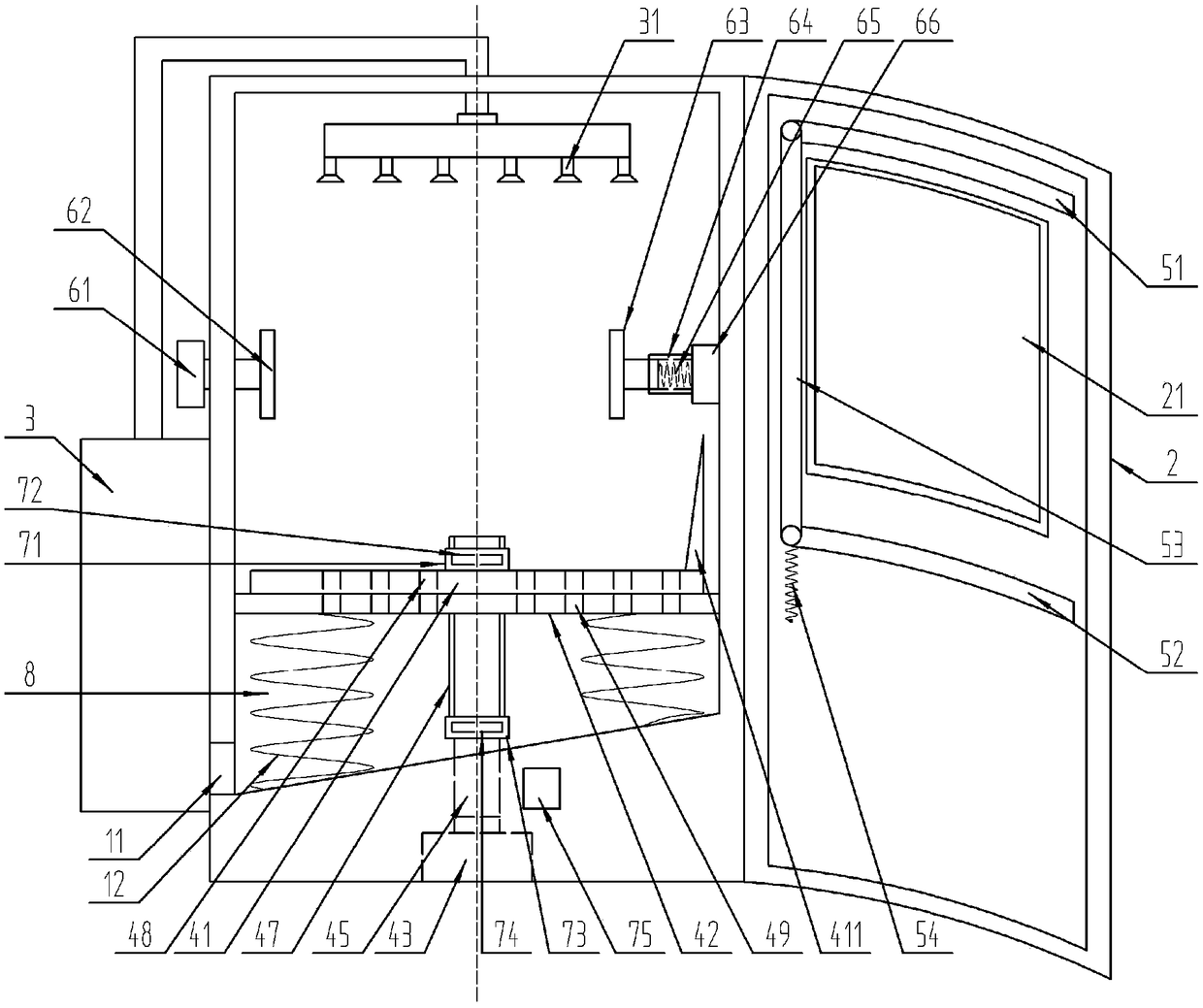

Gloss oil spraying device for spare parts of automobiles

The invention belongs to the technical field of machining equipment for spare parts of automobiles and particularly discloses a gloss oil spraying device for the spare parts of the automobiles. The gloss oil spraying device comprises a box body and a paint mechanism; an opening and closing door is arranged on the side wall of the box body; an observation window is embedded in the opening and closing door; a recovering opening is formed in the bottom of the box body; a rotating clamping mechanism is arranged at the middle-upper part of the box body; a first scraping piece is arranged inside thebox body and comprises a first rotating plate, a second rotating plate, a first motor, a driving piece and a vertical rotating shaft; a first rotating hole is formed in the eccentric position of thefirst rotating plate; a second rotating hole is formed in the center of the second rotating plate; a bulge is arranged on the vertical rotating shaft; first leakage holes are formed in the first rotating plate; and second leakage holes are formed in the second rotating plate. By the aid of the spraying device, a lot of gloss oil which adheres to the side wall of the box body after being scatteredin all directions can be recycled.

Owner:临朐县大地汽车零部件有限公司

Mechanical arm device

The embodiment of the invention provides a mechanical arm device. The mechanical arm device includes an installation base, a drive mechanism a support and two clamping mechanisms; the drive mechanism is arranged on the installation base; the support is connected to the drive mechanism; the two clamping mechanisms are symmetrically arranged two sides of the support; the drive mechanism includes a motor, an over-current protector and an output shaft, wherein the over-current protector is electrically connected to the motor and is used for turning off power of the motor when the motor is overloaded, a surface of the output shaft is provided with threads; a threaded hole is formed in the center of the support, the output shaft passes through the threaded hole, and the threaded hole can be in fit connection with the threads of the output shaft; the motor is connected to the output shaft and is used for driving the output shaft to rotate around the axis of the output shaft to drive the support to do straight reciprocating motion and then drive the two clamping mechanisms to rotate relative to the installation base to hold articles. According to the mechanical arm device, the motor is turned off when articles are clamped, and then burnout due to locked rotor can be avoided; the clamping force can be kept during power off, and the clamped articles cannot fall down; and the mechanical arm device is simple in structure and is easy to control.

Owner:SHENZHEN MAKER WORKS TECH CO LTD

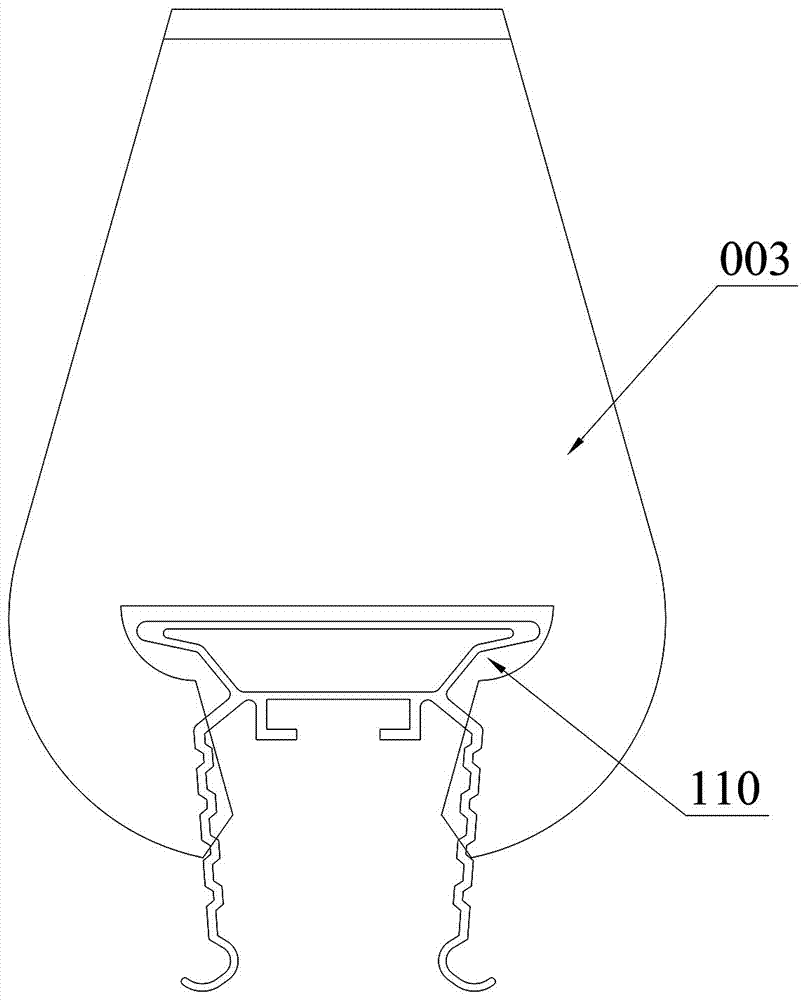

Outdoor illumination equipment convenient to clean and install

InactiveCN111336480AImprove stabilityAvoid random movementLighting applicationsMechanical apparatusLight equipmentEngineering

Owner:长沙如洋环保科技有限公司

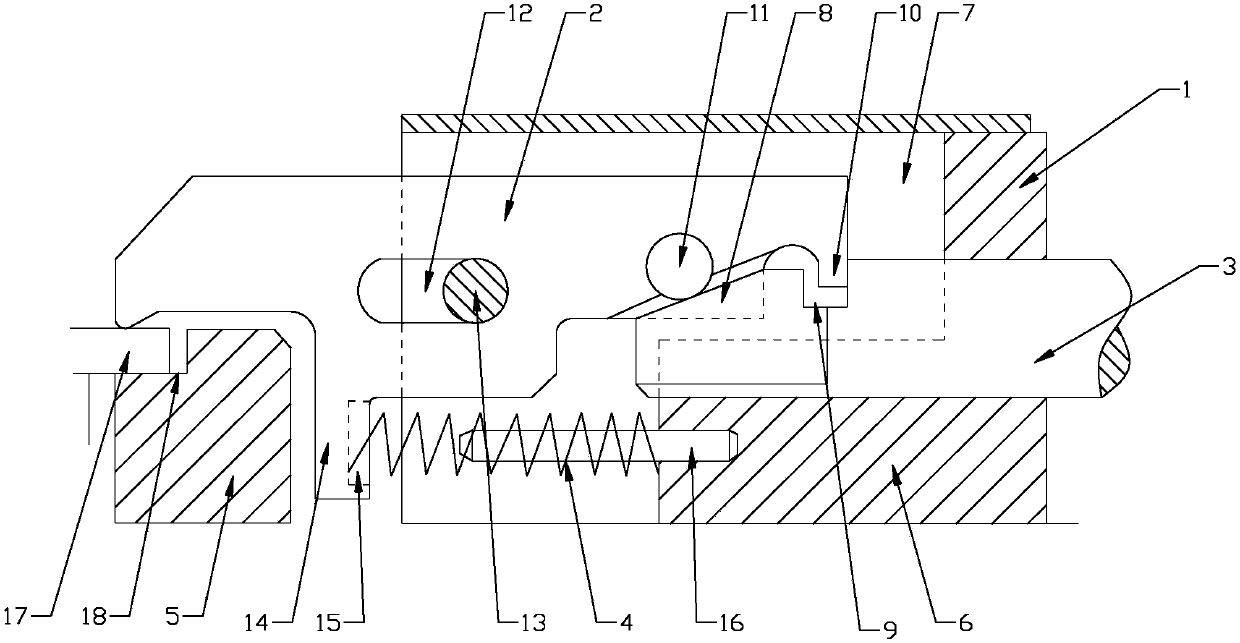

Pneumatic clamping tool

InactiveCN103639734AReduce machining accuracyGuaranteed clamping forcePositioning apparatusMetal-working holdersMilling cutterEngineering

The invention relates to a pneumatic clamping tool. The pneumatic clamping tool is characterized in that a base is provided with a guide rail and an air cylinder in a matched mode, and the guide rail is parallel with the air cylinder; the guide rail is provided with a sliding clamping block and a fixed clamping block, a clamping groove is formed between the sliding clamping block and the fixed clamping block, the fixed clamping block is arranged at the tail end of the guide rail, and the sliding clamping block is arranged on the guide rail in a sliding mode; a supporting rod is arranged between the guide rail and the air cylinder, an output shaft of the air cylinder is fixedly connected with one end of the supporting rod, and the other end of the supporting rod is matched with a limiting shaft arranged on the guide rail in a sliding mode through a hinge pin; the guide rail is provided with a push rod, one end of the push rod is fixedly connected with the supporting rod, and the other end of the push rod penetrates through a guiding hole in the guide rail and is fixedly connected with the sliding clamping block. According to the pneumatic clamping tool, the sliding clamping block is pushed through air pressure to clamp a workpiece, not only can clamping strength be guaranteed, but also operation personnel keep away from turning tools or milling cutters or drill bits, operation safety is guaranteed, and meanwhile control over machining precision of the workpiece is facilitated.

Owner:新昌县永强空调配件有限公司

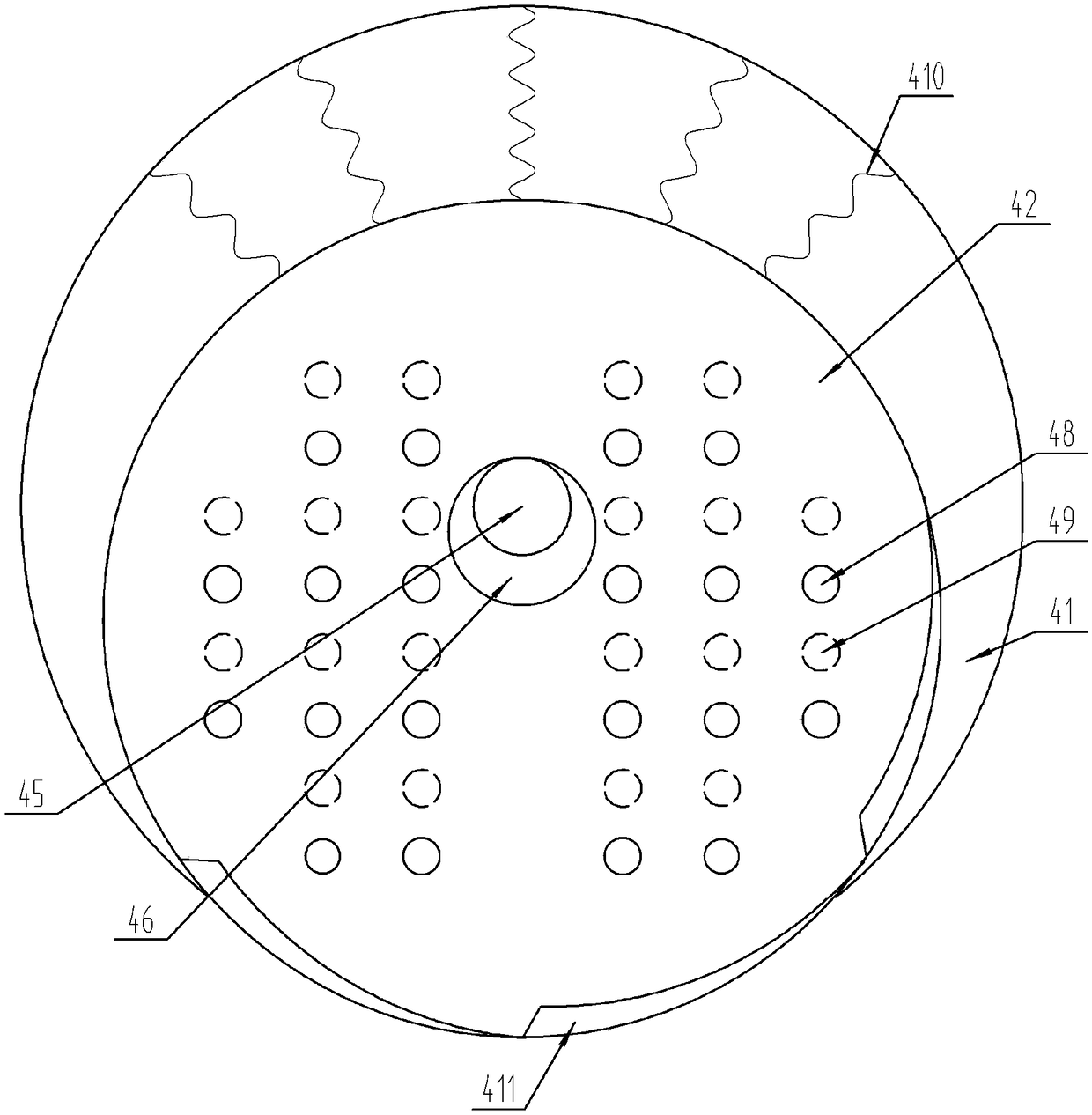

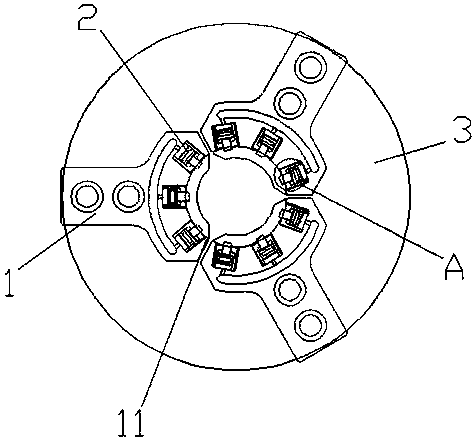

Multi-point equal clamping device

The invention discloses a multi-point equal clamping device applied to the field of mechanical tools. The multi-point equal clamping device is characterized by structurally comprising a plurality of claw fingers and a claw finger drive device, wherein each claw finger comprises a clamping part, and the position, towards a clamped object, of each clamping part is uniformly equipped with a pluralityof hydraulic cylinders; each hydraulic cylinder comprises an oil cylinder piston and a pressure cavity; the pressure cavity on the same claw finger is in communication; and each oil cylinder piston comprises a clamping end which extends to the outside of the corresponding clamping part. The clamping ends of the hydraulic cylinders are utilized to perform clamping operation; pressure cavities of the hydraulic cylinders communicate with one another, so that the position of hydraulic oil also can be transferred according to different pressure, and therefore, the occurrence of a condition that acting force between the clamping ends and workpieces is too high is avoided. Circulating action of the hydraulic oil guarantees stress uniformity of the surface of the clamped object, so that a workpiece damage rate is effectively reduced, and the take-up effect of the clamped object is guaranteed. Meanwhile, weakening, caused by stress deformation, of clamping force can be eliminated during claw clamping by uniform stress, so that guarantee is provided for clamping force, on the clamped objects, of the claw fingers.

Owner:苏州磐岩精密机械有限公司

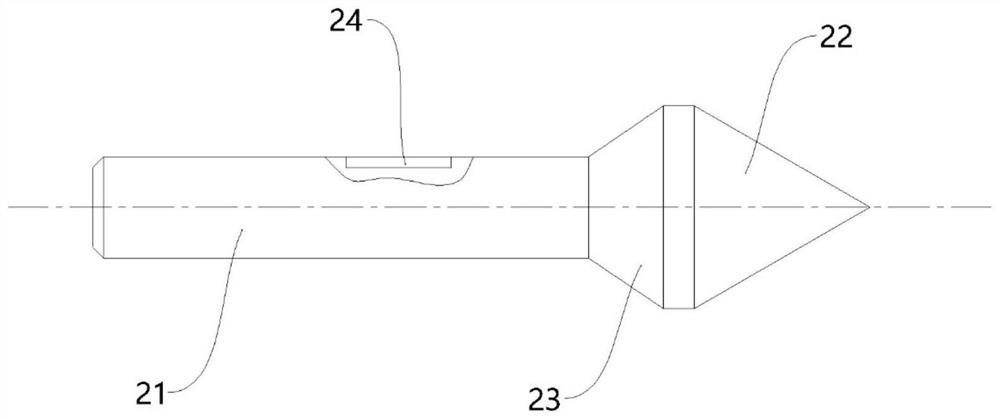

Numerical control grinding machine pneumatic clamp for gear grinding

PendingCN108406010AGuaranteed axial stabilityGuaranteed sizeGear-cutting machinesGear teethNumerical controlGear grinding

The invention discloses a numerical control grinding machine pneumatic clamp for gear grinding. The numerical control grinding machine pneumatic clamp comprises a centre. The clamp further comprises abase plate and an air cylinder. One end of the base plate is fixedly arranged on a lathe bed base, and the air cylinder is fixedly arranged at the other end of the base plate and comprises a clampingcavity. The centre penetrates the base plate. One end of the centre is fixedly connected with the lathe bed base, and a tip at the other end of the centre is located in the clamping cavity of the aircylinder. The numerical control grinding machine pneumatic clamp for gear grinding can achieve automatic workpiece clamping, and automatic mechanical arm clamping is achieved; the workpiece machiningefficiency is effectively improved, and economic benefits are good; the safety coefficient in the workpiece machining process is improved, and protection to an operator is effectively guaranteed; thegear machining stability and precision are guaranteed, and the gear workpiece fly-out accident and the gear workpiece loosening situation are avoided; and the structure is simple, and the appearanceis exquisite.

Owner:HEFEI CHANGYUAN HYDRAULICS

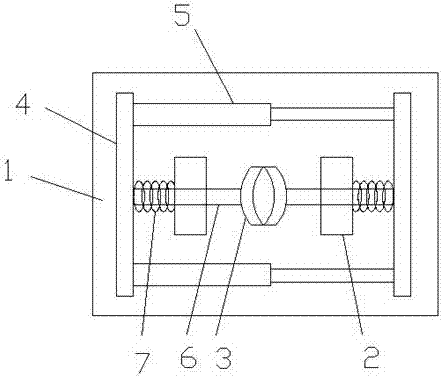

Device for stamping with adjustable distance between the rolls

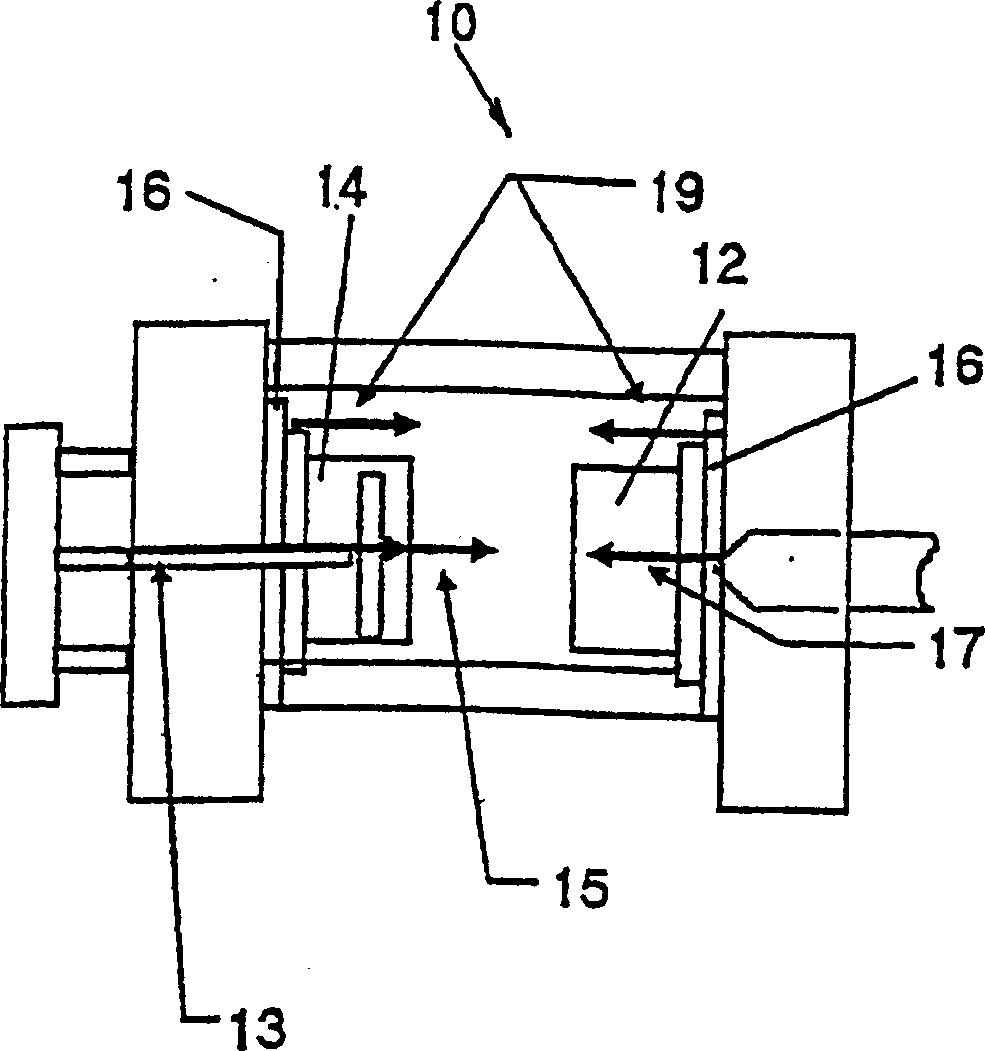

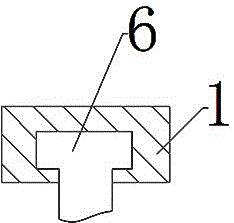

InactiveCN102896888ASimple structureIncrease punching forcePaper/cardboard articlesMetal working apparatusRotational axisPunching

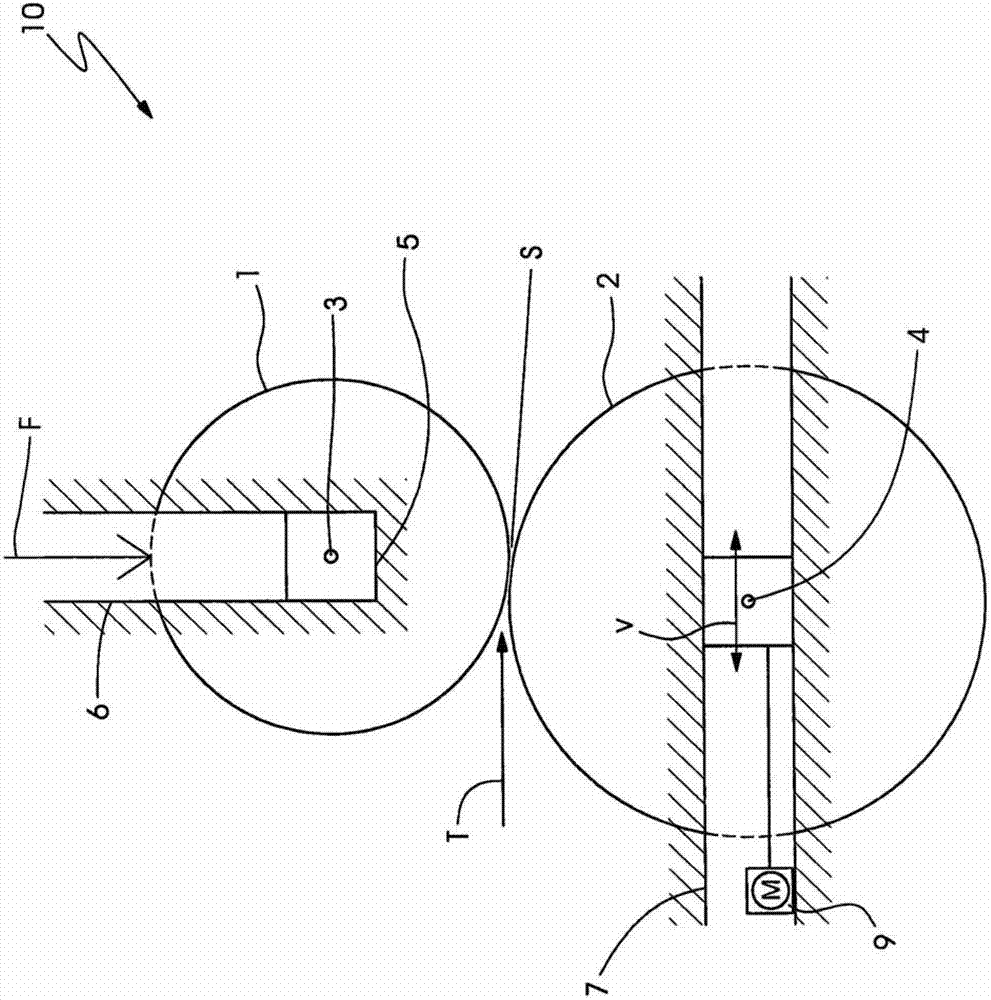

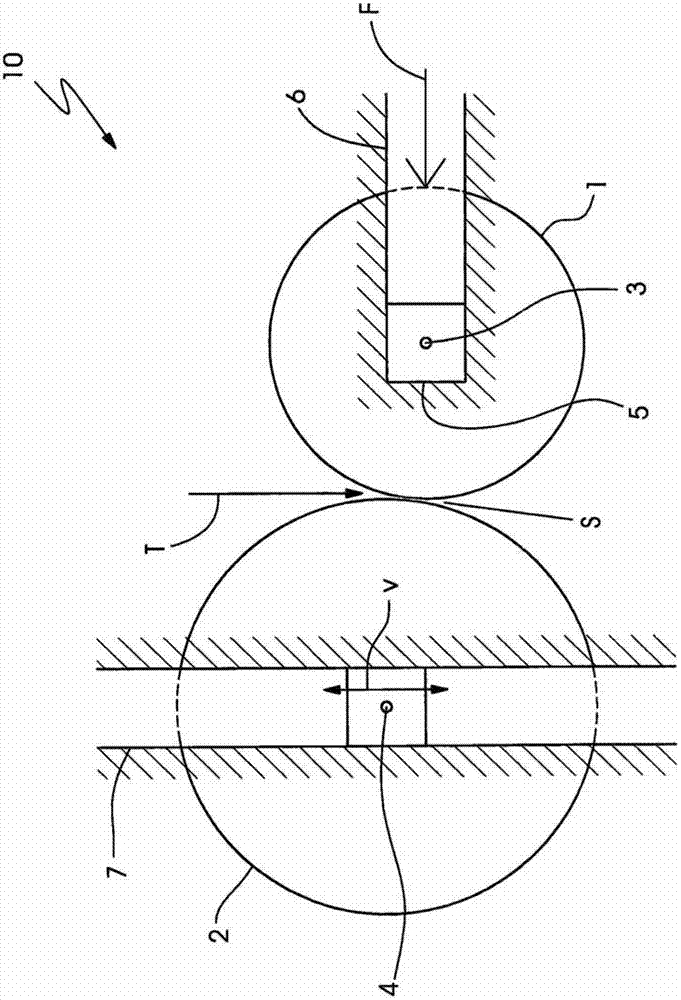

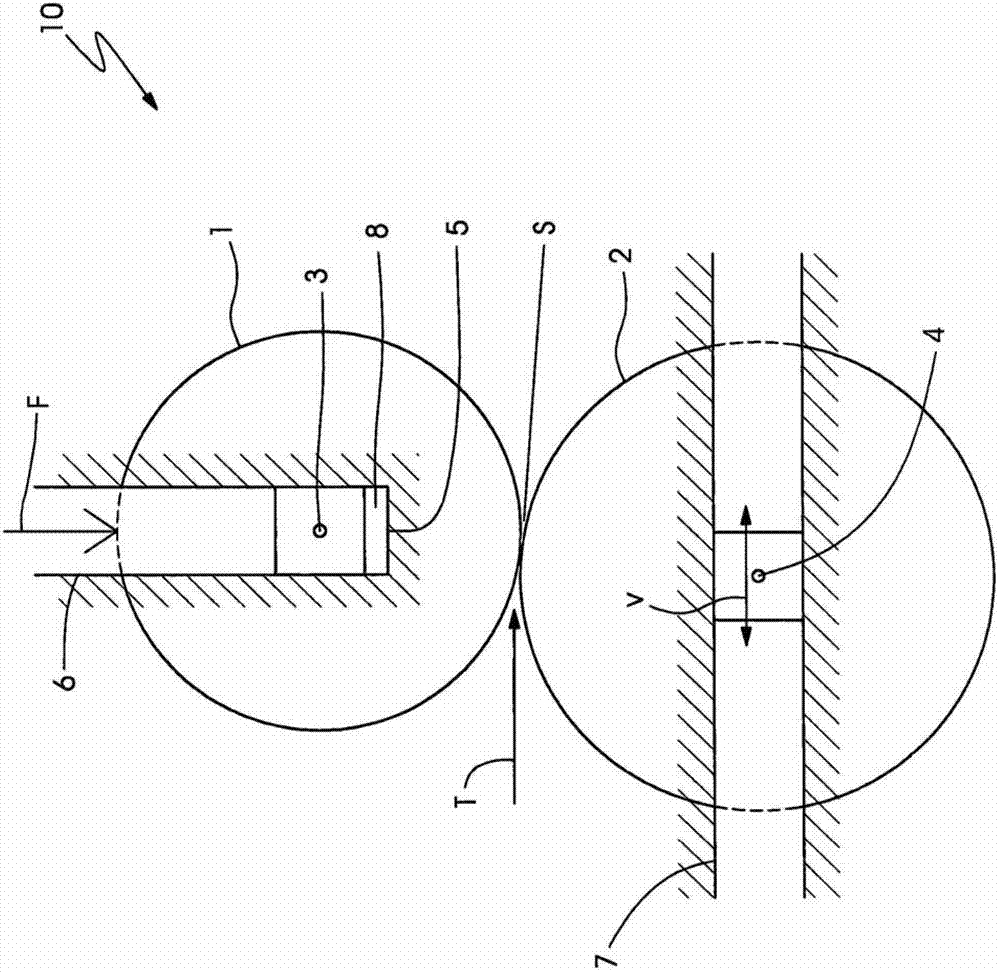

The punching apparatus (10) has a rotatable punching cylinder (1) about a rotational axis (3) and a rotatable cylindrical object (2) parallel to another rotational axis (4) of the punching cylinder, where a distance (S) between the punching cylinder and the cylindrical object is adjustable. The cylindrical object is slidably mounted in a guide (7). The clamping force (F) and the guide are aligned perpendicular to each other. In addition, the invention further relates to a narrow-width printer equipped with the device for stamping.

Owner:GALLUS DRUCKMASCHINEN GMBH

Automatic centering and clamping device based on transmission of worm and worm gears and crank connecting rods

InactiveCN104209781AReduce labor intensityNo pollutionPositioning apparatusMetal-working holdersMechanical engineering

The invention discloses an automatic centering and clamping device based on transmission of worm-worm gears and crank connecting rods. The automatic centering and clamping device comprises at least two worm gears, wherein each worm gear is hinged to a crank connecting rod; the tail ends of the crank connecting rods are fixedly connected with pressure heads; the pressure heads are used for driving the crank connecting rods through rotation of the worm gears to drive the pressure heads to clamp a workpiece; each worm gear is driven by a worm which is meshed with the worm gear respectively; each worm is provided with a driven gear; each driven gear is meshed on the same driving gear. According to the automatic centering and clamping device, the worm-worm gears and the crank connecting rod mechanisms are arranged symmetrically, and the output force generated by the pressure heads is equal in magnitude and reverse in directions, so that automatic centering and alignment are realized, the fixture adjusting time can be shortened, the workpiece machining efficiency is increased, and the effects of saving labor force, saving time and increasing efficiency are achieved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Clamping method of self-clamping type clamp

InactiveCN107470936AGuaranteed clamping forceEasy to useWork holdersPositioning apparatusEngineeringMechanical engineering

Owner:WUXI HOUFA AUTOMATIC EQUIP CO LTD

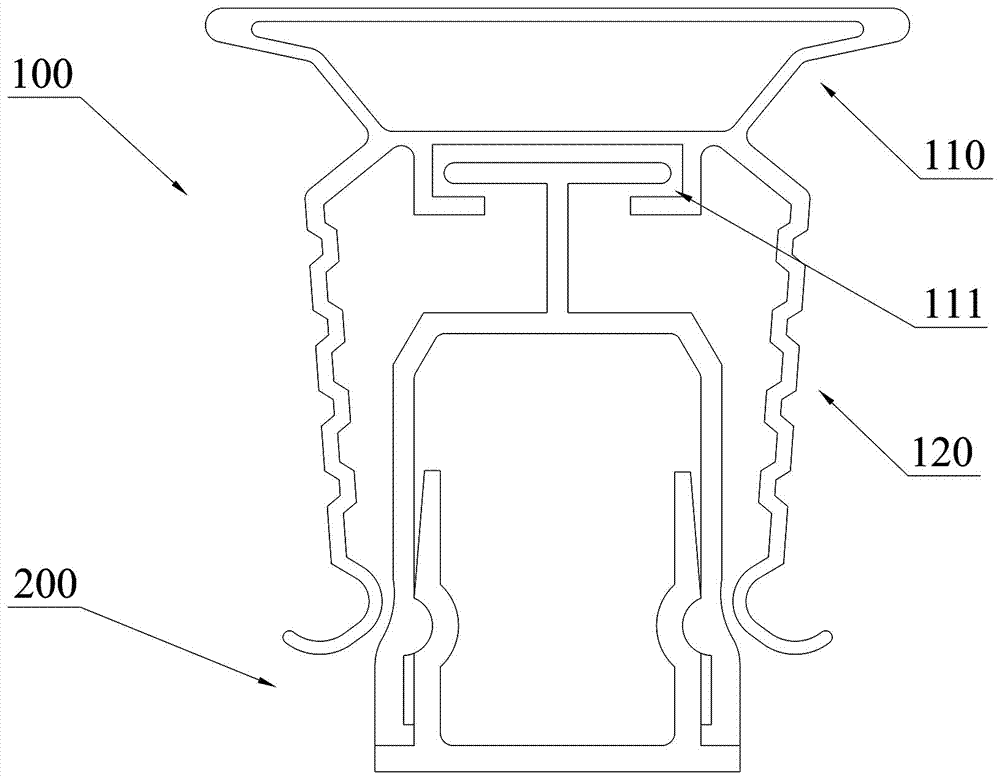

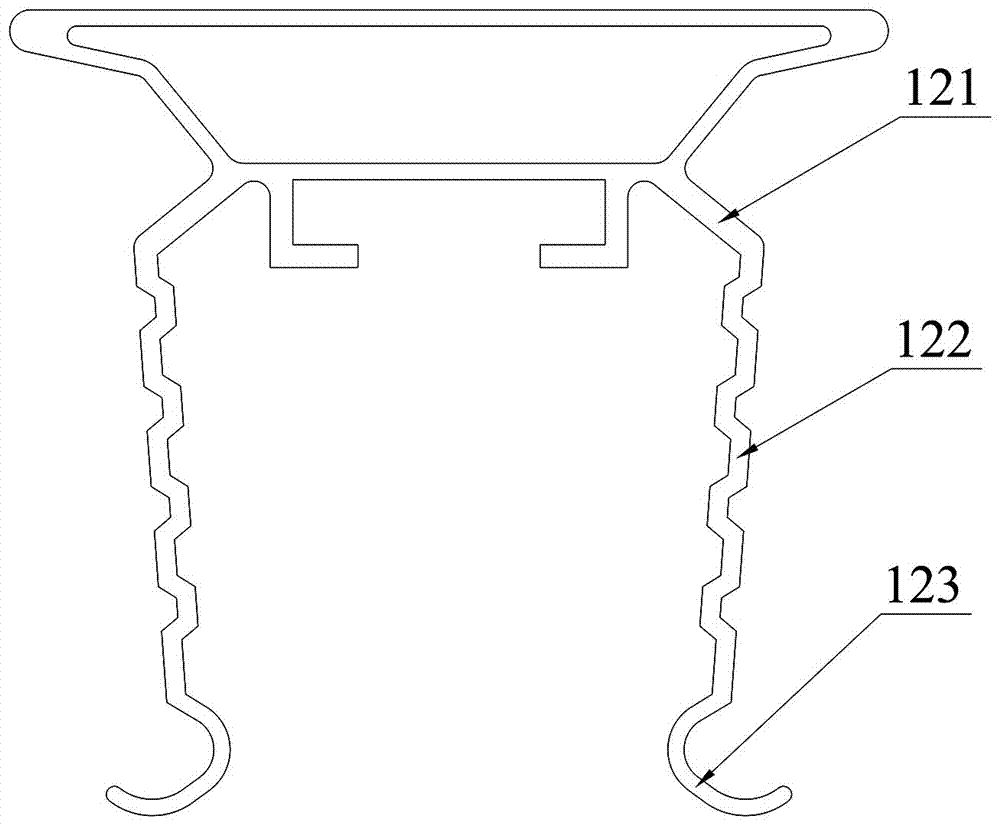

Decorative rib keel

ActiveCN107268867AGuaranteed stabilityGuaranteed reliabilityCeilingsPhotovoltaic energy generationStructural engineeringMechanical engineering

Owner:佛山市志联永道铝业有限公司

Novel cutting fixture

PendingCN112570741AEasy to disassembleGuaranteed clamping forceTailstocks/centresChucksEngineeringCam

The invention relates to the technical field of machining, and discloses a novel cutting fixture. The fixture comprises a fixture body, a centering centre and a live centre; the centering centre and the live centre are coaxially arranged; the centering centre is axially and movably inserted into the fixture body; an elastic piece for elastically supporting the centering centre is arranged at the tail end of the fixture body; a clamping jaw is further rotationally assembled on the fixture body; the front end of the clamping jaw is defined as a clamping end, and the tail end is defined as a driving end; a cam is formed at the driving end; the centering centre is provided with a jacking slope for jacking the cam during axial movement; the clamping jaw is provided with a clamping position forenabling the jacking inclined surface to jack the cam to enable the clamping end to clamp the workpiece and a releasing position for enabling the jacking inclined surface to be separated from the camto enable the clamping end to release the workpiece in the rotating stroke. When the workpiece is machined, the jacking inclined surface of the centering centre jacks the cam, the clamping end of theclamping jaw clamps the workpiece in the radial direction, the larger the movement amount of the centering centre is, the larger the clamping force of the clamping jaw is, clamping is completed whilethe clamping force is guaranteed, the clamping speed and efficiency are improved, and meanwhile, the clamping precision is guaranteed.

Owner:GUANGZHOU CITY POLYTECHNIC

Integral mounting device for inclined surface pipeline

ActiveCN109578691AIncrease the maximum height differenceExtended range of inclination anglesPipe laying and repairEngineeringBuilding construction

Owner:嵊州市越通非开挖建设有限公司

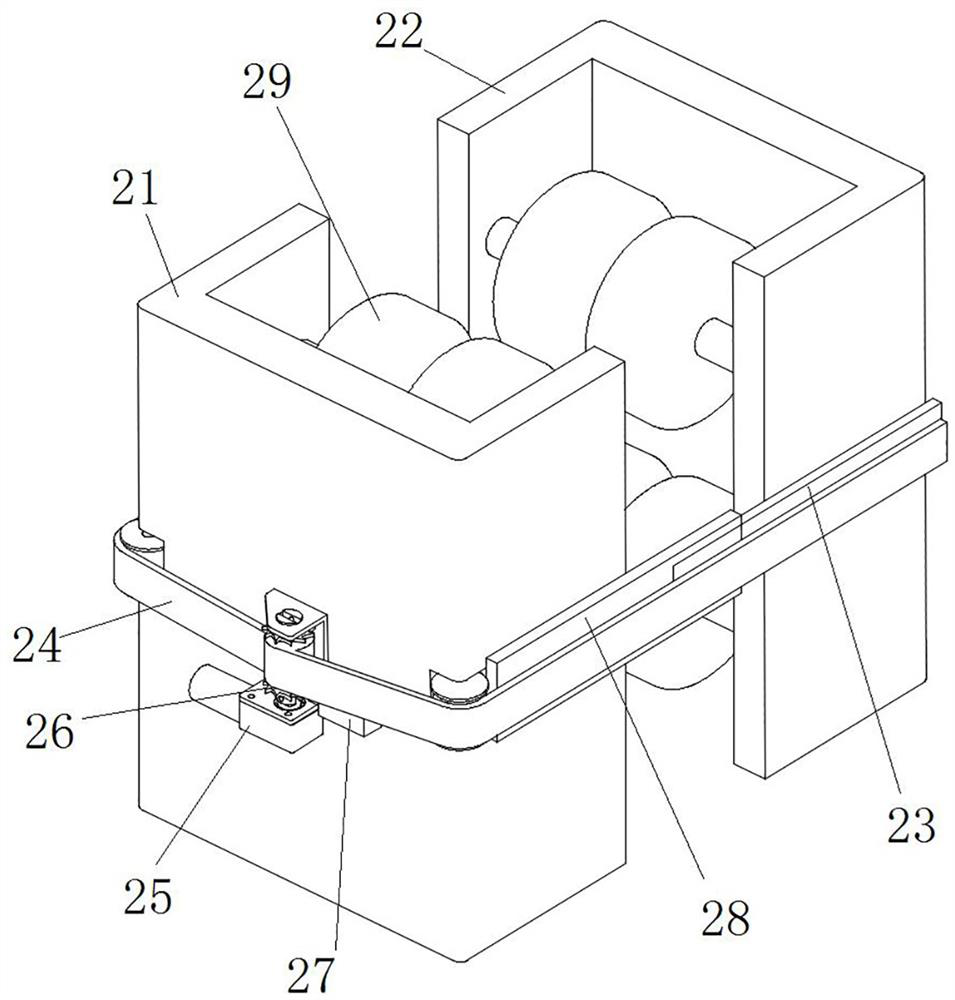

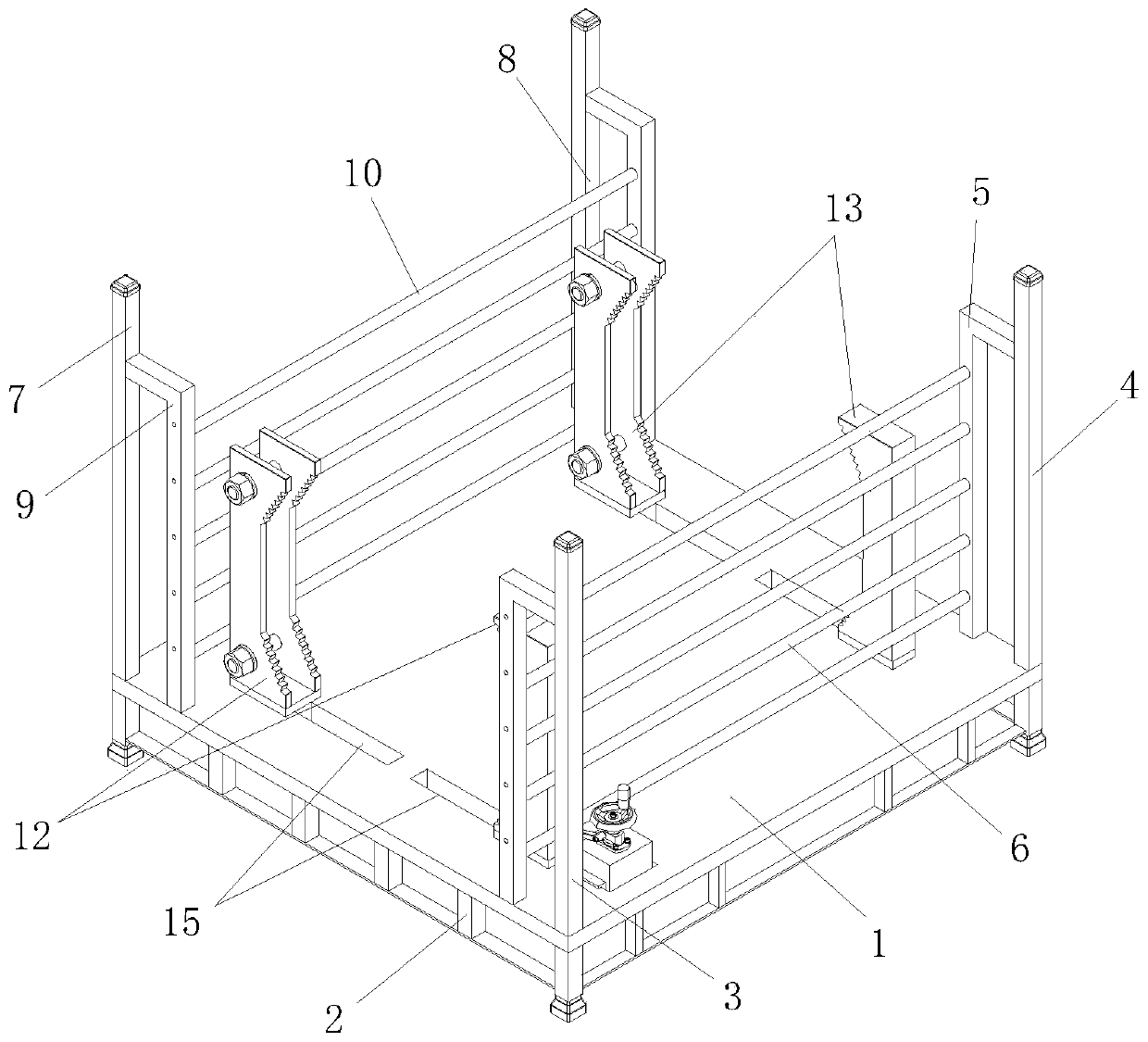

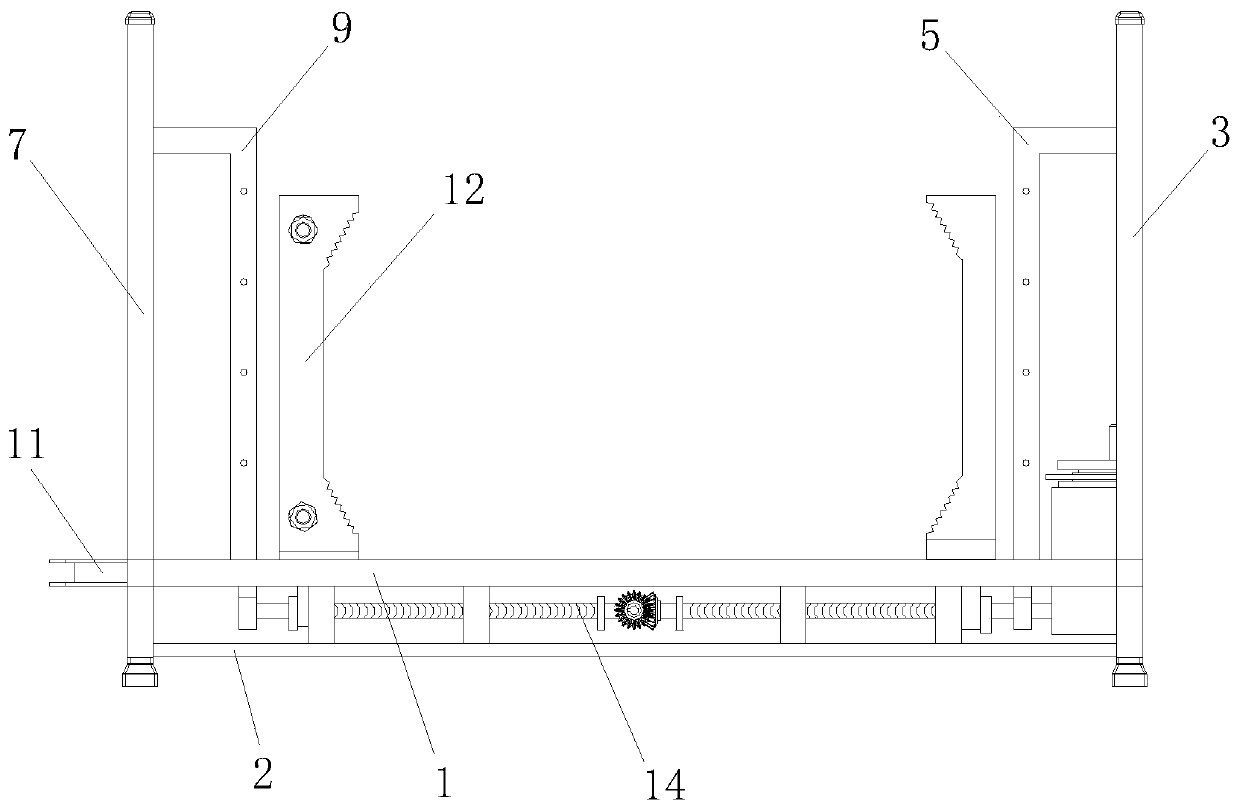

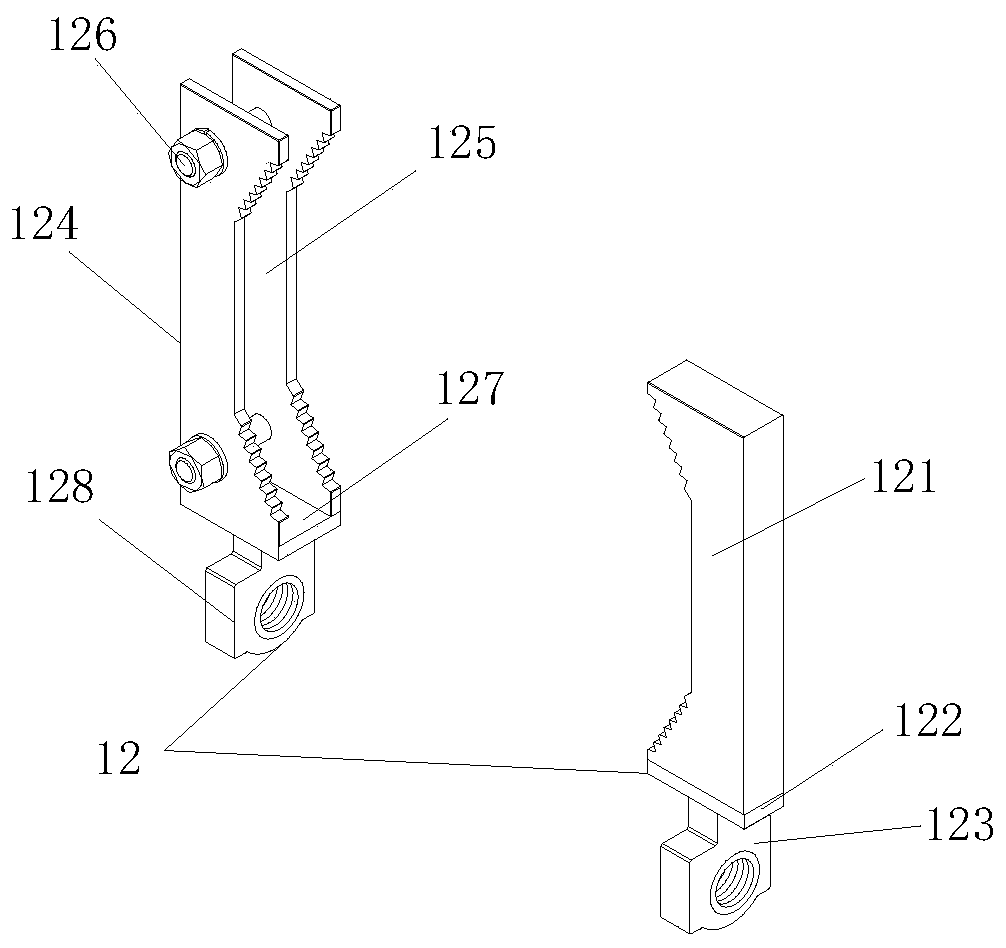

Auxiliary mechanism for electric steel tube rod transportation

The invention discloses an auxiliary mechanism for electric steel tube rod transportation. The auxiliary mechanism comprises a bottom plate, a supporting bottom frame, a first side frame, a second side frame, a first inner frame, a first transverse cross bar, a third side frame, a fourth side frame, a second inner frame, a second cross bar, an outer connecting plate, a first clamping structure, asecond clamping structure, a clamping transmission device and a slide slot. According to the auxiliary mechanism disclosed by the invention, the first clamping structure and the second clamping structure are separately mounted at front and rear sides of the upper end of the bottom plate, the clamping transmission device arranged on the bottom of the bottom plate can transit for synchronously moving the first clamping structure and the second clamping structure, so that two positions of an electric steel tube rod are synchronously clamped, and clamping force and stability is guaranteed; and theelectric steel tube rod is clamped more firmly, so that stability can be guaranteed while the electric steel tube rod is transported, and transportation of the electric steel tube rod is convenient.

Owner:张新兴

Movable type push and pull clamping device

InactiveCN107717528AAchieve clampingAchieve relaxationPositioning apparatusMetal-working holdersPush and pullPush pull

The invention relates to a clamping device, in particular to a mobile push-pull clamping device, comprising a base, a pressure plate, a push rod and a compression spring, the base includes a support table and an installation table, the installation table is provided with an installation cavity, and the push rod It extends horizontally into the installation cavity and is slidably connected to the installation table. The end of the push rod is located in the installation cavity with a wedge block, the upper part of the push rod close to the wedge block is provided with a groove, and the right end of the pressure plate is provided with a collision block and a roller , the striker extends into the groove, the roller slides with the wedge-shaped surface of the wedge-shaped block, the middle of the pressure plate is horizontally provided with a strip-shaped groove, and the strip-shaped groove slides with the pin set on the installation table. The pressure plate also includes a downward extending Mounting block for mounting compression springs. The mobile push-pull clamping device adopting the technical scheme of the present invention has the characteristics of simple structure, convenient assembly and disassembly, and good clamping effect.

Owner:成都中源红科技有限公司

Clamping device

InactiveCN107175522AGuaranteed clamping forceEasy clampingPositioning apparatusMetal-working holdersMechanical engineeringVertical plane

The invention discloses a clamping device, which includes a base body, an upper clamping body, a lower clamping body and a rotating shaft. A cavity A and a cavity B are opened in the base body. The outer end of the cavity A is large and the inner end is small, and the cavity A At the outer end and the end close to the base body, the inner wall of cavity A is provided with tenon-shaped grooves, and the upper and lower clamping bodies are equipped with tenon-shaped heads, and the upper and lower clamping bodies are placed in the cavity. The tenon-shaped head in and on A is adapted to the tenon-shaped groove. The chamber B is located at the inner end of the chamber A and is connected. The rotating shaft is hinged on the inner wall of the chamber B along the vertical plane. One end of the rotating shaft is located at The other end is in cavity B and the other end is located in cavity A. A pressure plate is connected to the inner surface of the upper clamping body and the lower clamping body through spring A, and the pressure plate is in contact with the end of the rotating shaft; The contacting ejector rod is connected with the output shaft of the motor through threads, and the motor is fixed on the base body. The beneficial effects of the invention are: convenient clamping, fastening and reliable clamping.

Owner:四川利丰航空科技有限公司

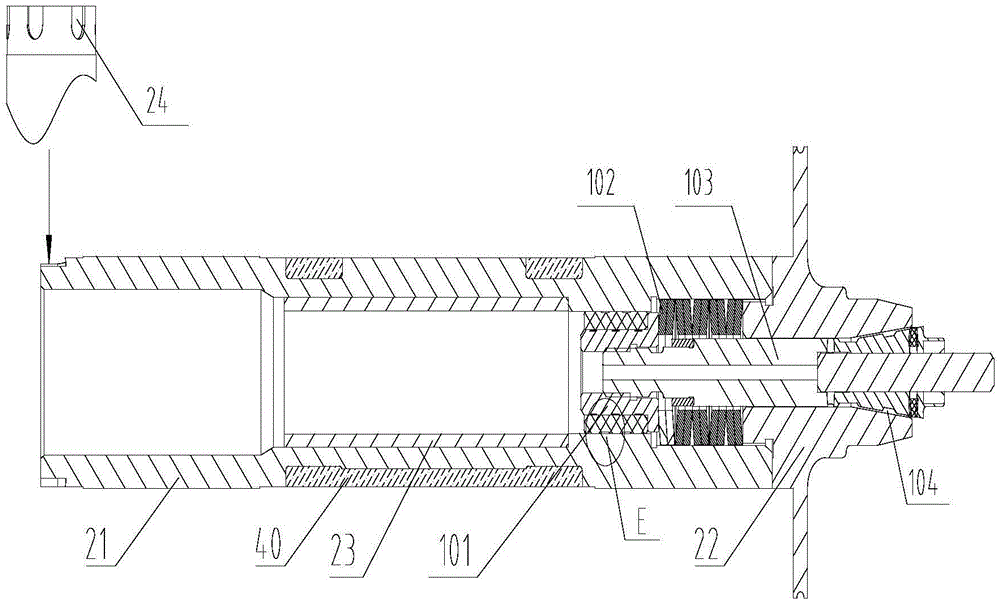

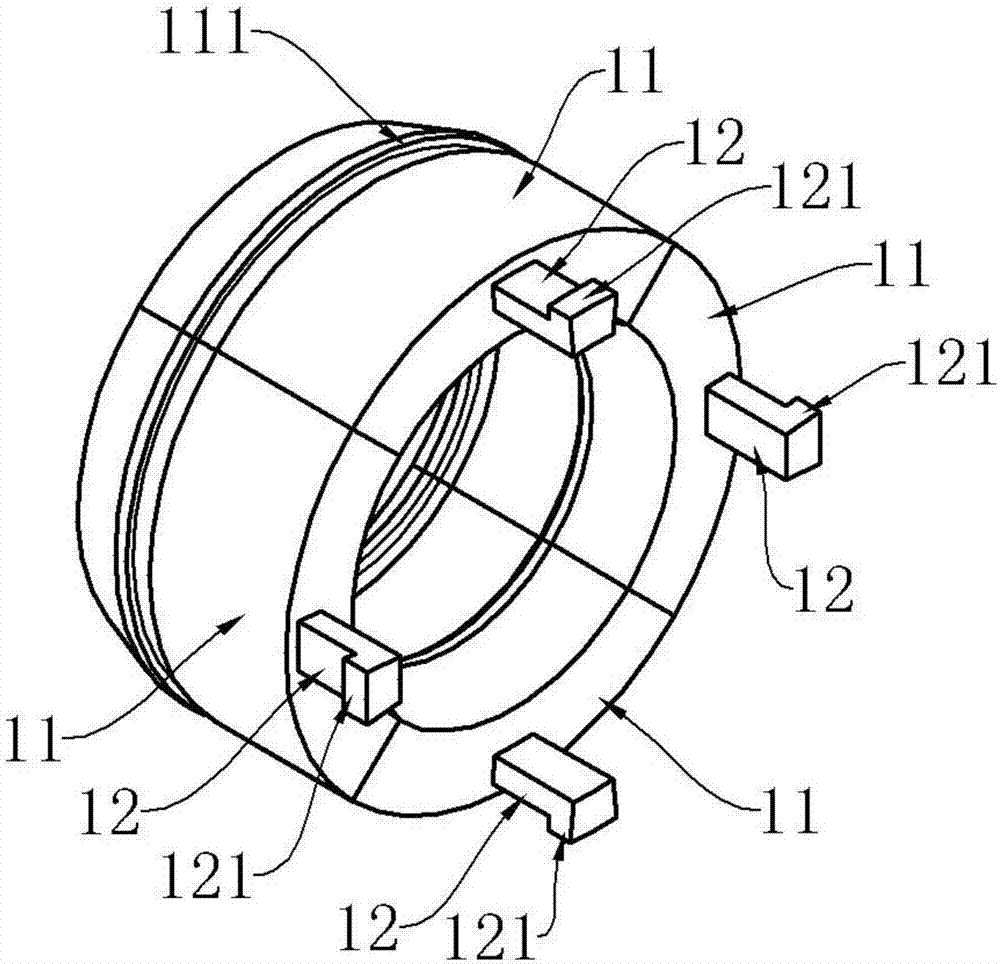

Cable clamp structure for radio frequency coaxial cable connector

ActiveCN107331984AGuaranteed clamping forcePrevent tamperingConcentric cablesClamped/spring connectionsInterference fitCoaxial cable

The invention provides a cable clamp structure for a radio frequency coaxial cable connector. The cable clamp structure can solve the problems that an existing cable clamp is inconvenient to install and is easy to deform or break due to external force, and besides, since the existing cable clamp cannot clamp cables tightly, the whole system is not stable. The cable clamp structure comprises a cable clamp body. The cable clamp body is formed by four arc-shaped clamp blocks, which are enclosed and spliced together. The four arc-shaped clamp blocks are mounted on a cable clamp base after being enclosed and spliced together, and the peripheries of the four arc-shaped clamp blocks are radially fastened through an O-shaped ring; and the cable clamp base is arranged to a rear housing in an interference fit manner.

Owner:JIANGSU HENGXIN TECH CO LTD

Clamping device of surgical operating instrument

InactiveCN107662167AAvoid uneven forceGuaranteed clamping forceWork holdersBiochemical engineeringScrew thread

Owner:QILU CHILDRENS HOSPITAL OF SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com