Air bearing spindle with speed measurement function

An electric spindle and functional technology, applied in the direction of manufacturing tools, measuring/indicating equipment, large fixed members, etc., can solve the problem that the performance of the air-floating shaft core is difficult to meet the high standard requirements, the measurement of the electric spindle is even more difficult, and the power cannot meet the requirements and other problems, to achieve the effect of reasonable air flotation air circuit design, good heat dissipation effect and high rotation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

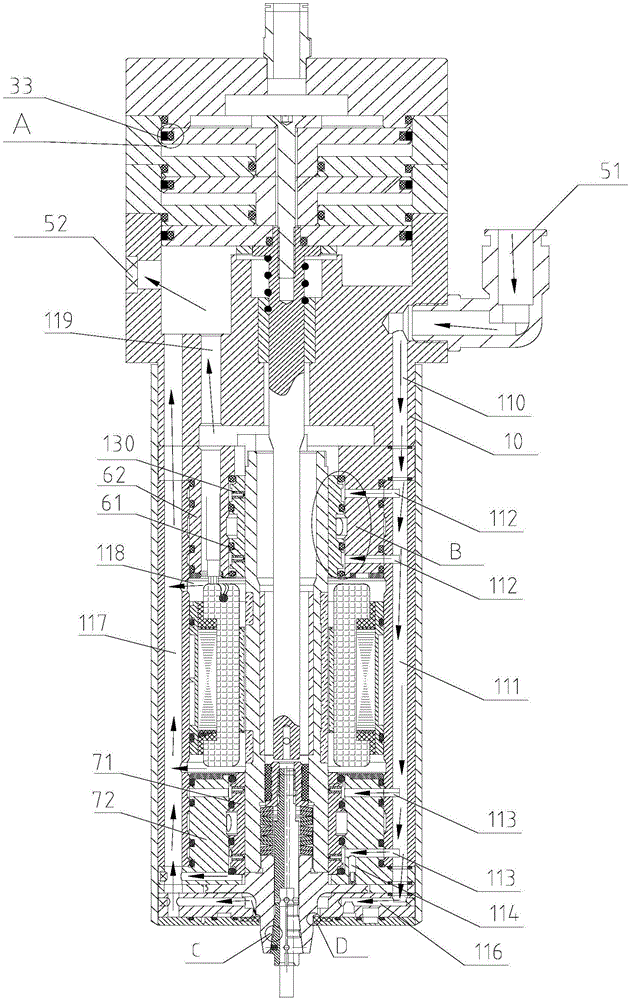

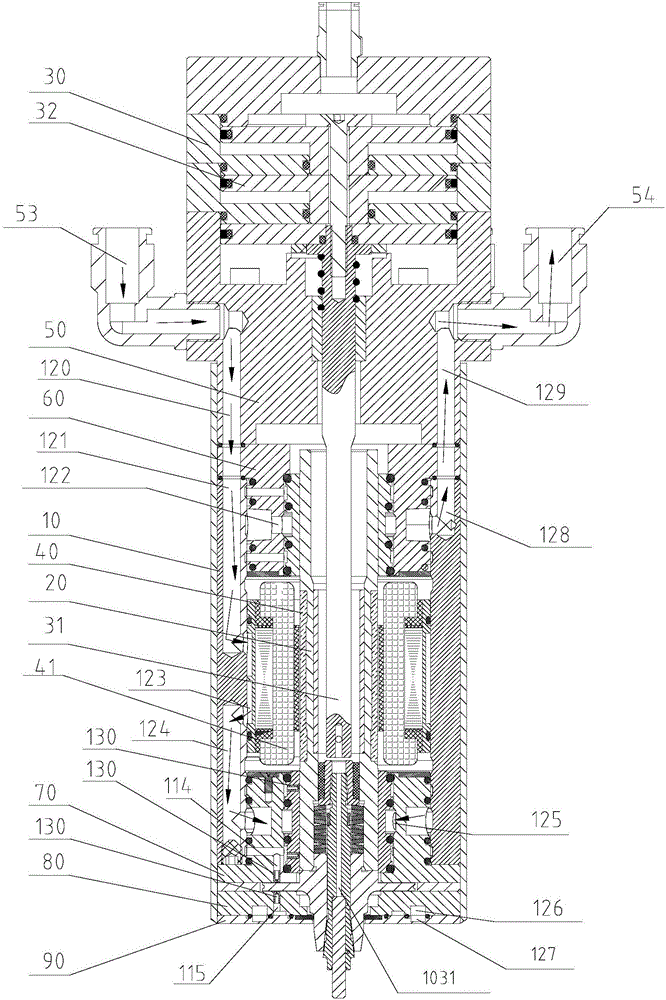

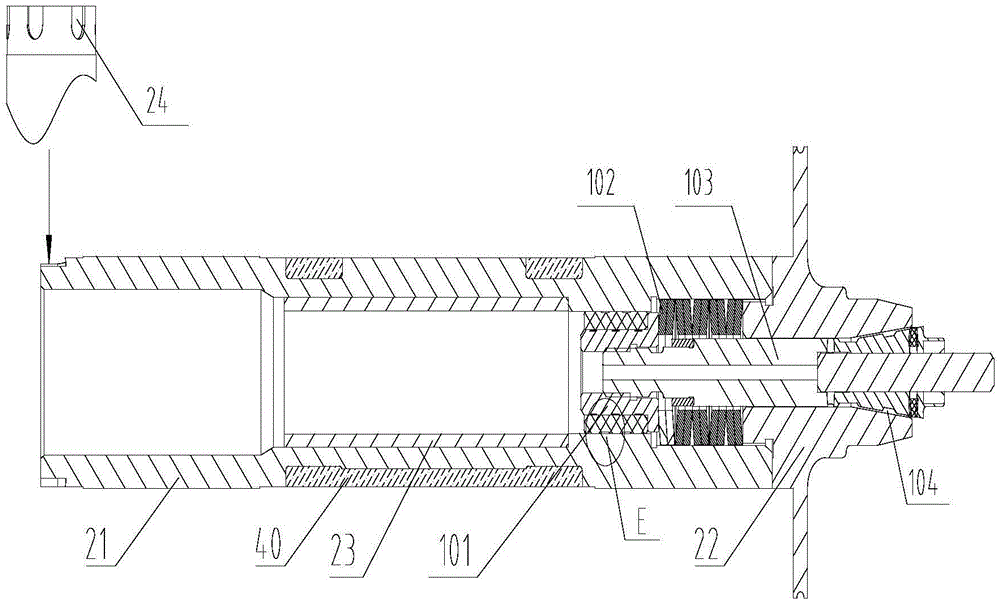

[0044] Such as Figure 1-11 As shown, an air-floating electric spindle with speed measuring function includes a body 10, a shaft core assembly 20, a power assembly, an aluminum water jacket 50, a cylinder 30, an upper bearing assembly 60, a lower bearing assembly 70, a thrust bearing assembly 80 and a cover The plate assembly 90; the body 10 is a cavity structure, and the main air inlet passage 111 and the return air passage 117 are respectively arranged in the wall surface of the body 10 along the axial direction; the shaft core assembly 20 is arranged in the body 10, which includes a chuck section 22 and shaft section 21; (see image 3) The chuck section 22 and the rotating shaft section 21 are both hollow structures; the chuck section 22 is provided with a shaft shoulder; the upper part of the rotating shaft section 21 is provided with a number of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com