Electromagnetic coil with velocity measurement function

An electromagnetic coil and function technology, which is applied in the measurement device, engine cooling, linear/angular velocity measurement, etc., can solve the problems of single function of electromagnetic coil and no speed measurement function, and achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

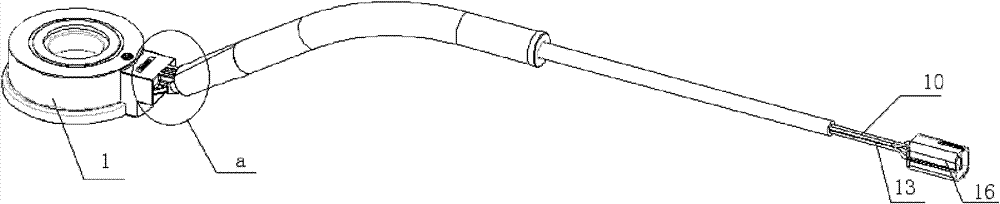

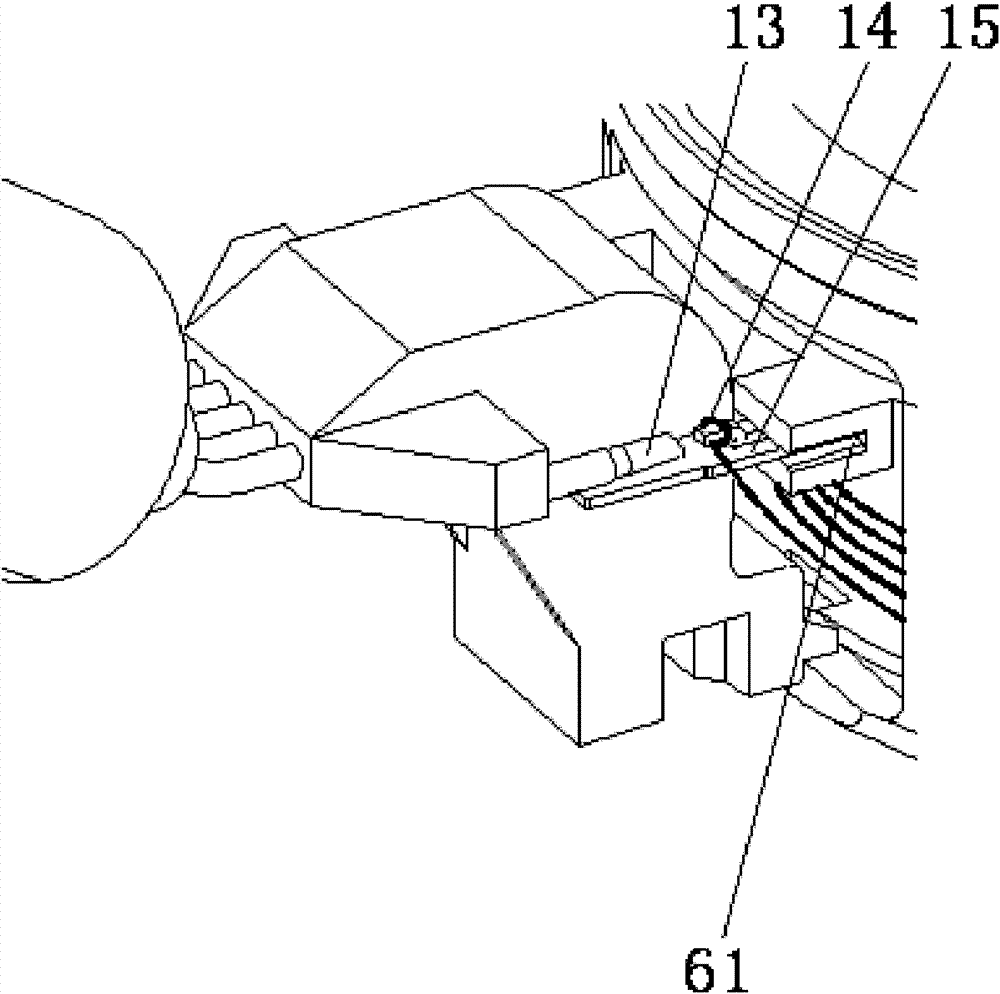

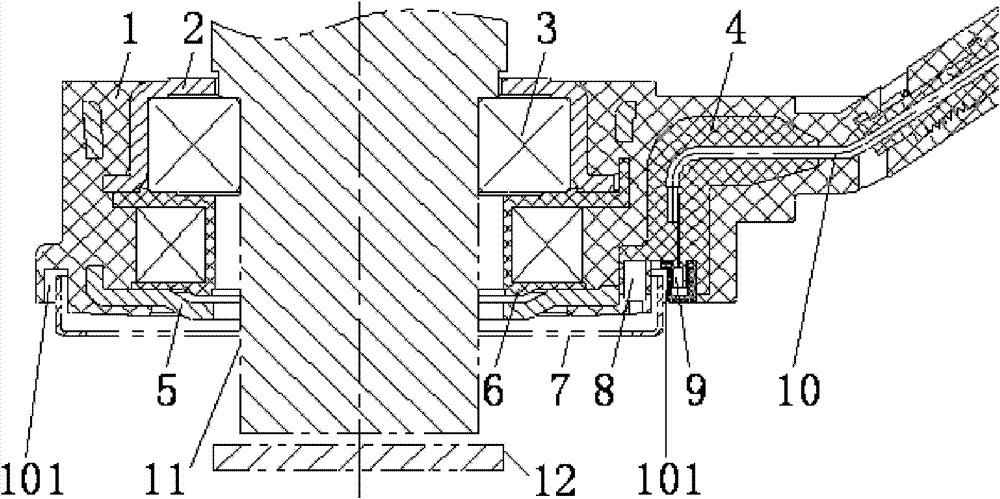

[0019] see figure 1 , figure 2 and image 3 , the present invention comprises a magnet 8, a hall sensor 9, a five-pin plug 16 connected to an automobile ECU, an outer shell 1 and a bearing base 2 installed in the outer shell 1, a bearing 3 interference-fitted in the bearing base 2, The coil 6 and the coil base 5 for installing the coil 6; and the bearing base 2, the bearing 3, the coil 6 and the coil base 5 are coaxially installed in the outer shell 1, and the coaxial installation will reduce the difficulty of subsequent installation of other parts.

[0020] Copper enameled wire 14 and two symmetrical coil grooves 61 are wound on the coil 6 .

[0021] The three pins of the Hall sensor 9 are respectively connected to the five-pin plug 16 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com