Material picking device and workpiece carrying mechanism

A technology of reclaiming device and workpiece, applied in conveyor control device, conveyor, metal processing, etc., can solve the problem of inability to identify the installation position of the workpiece, and meet the requirements of protection, avoid workpiece damage, and meet the requirements of installation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

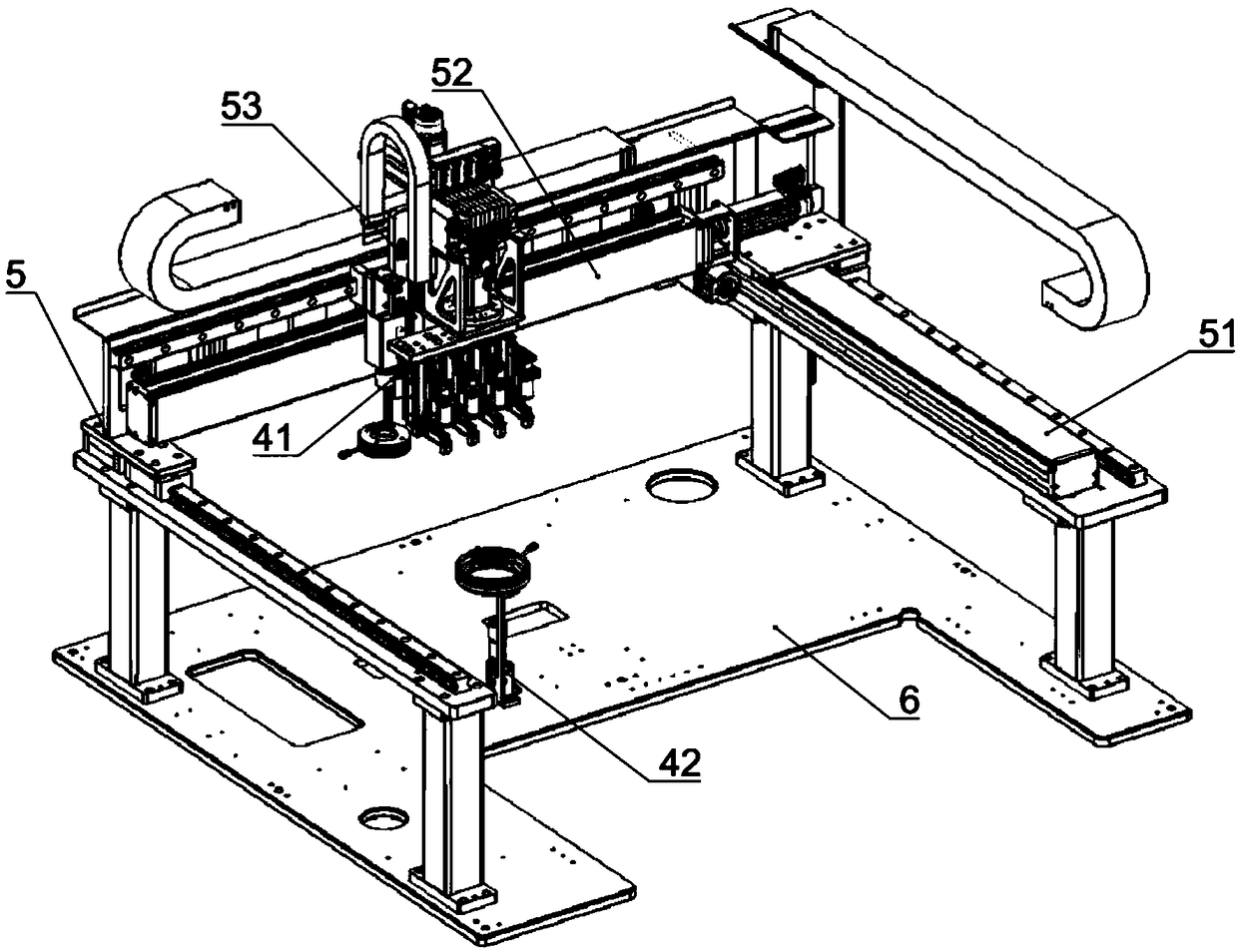

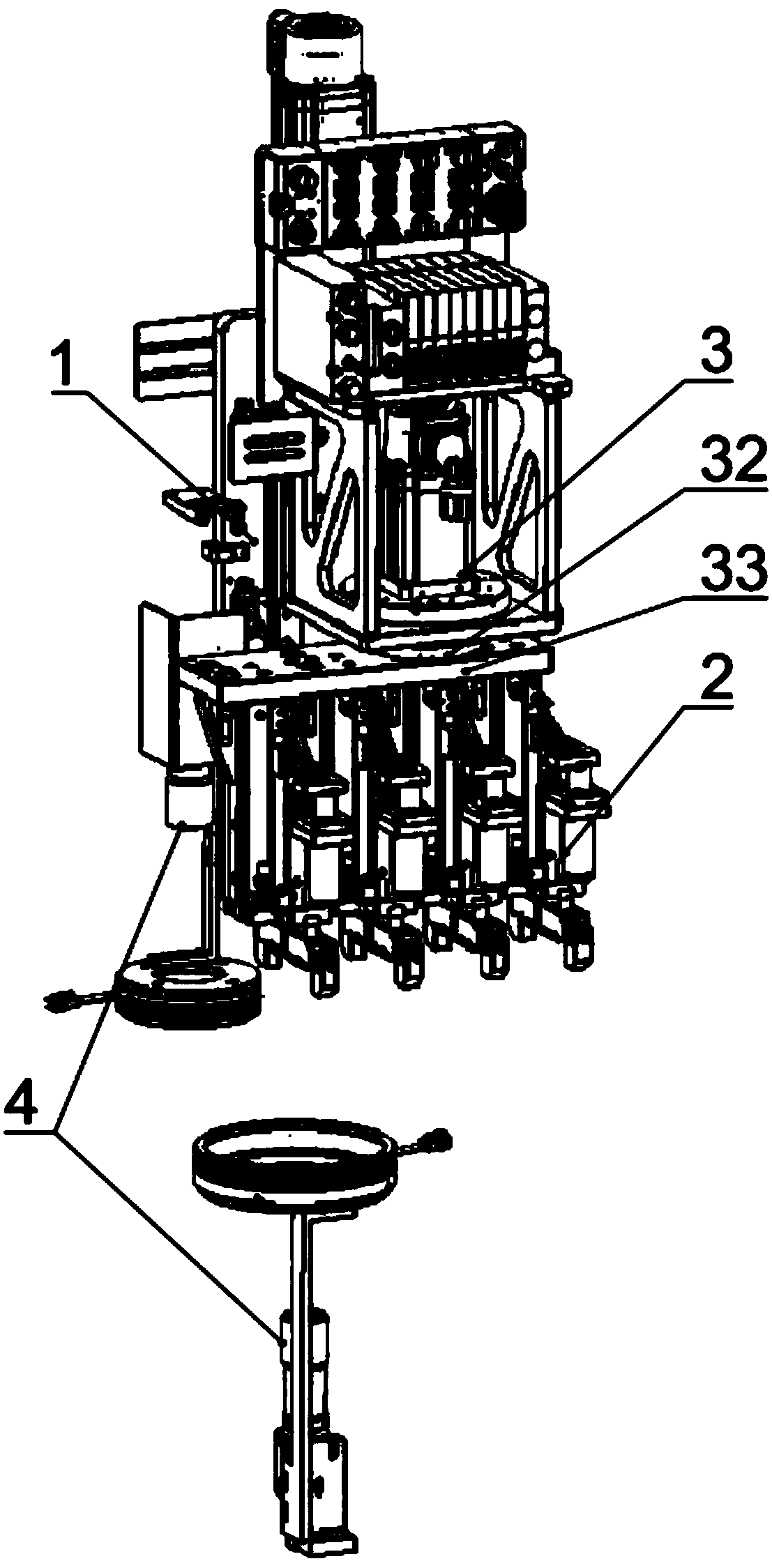

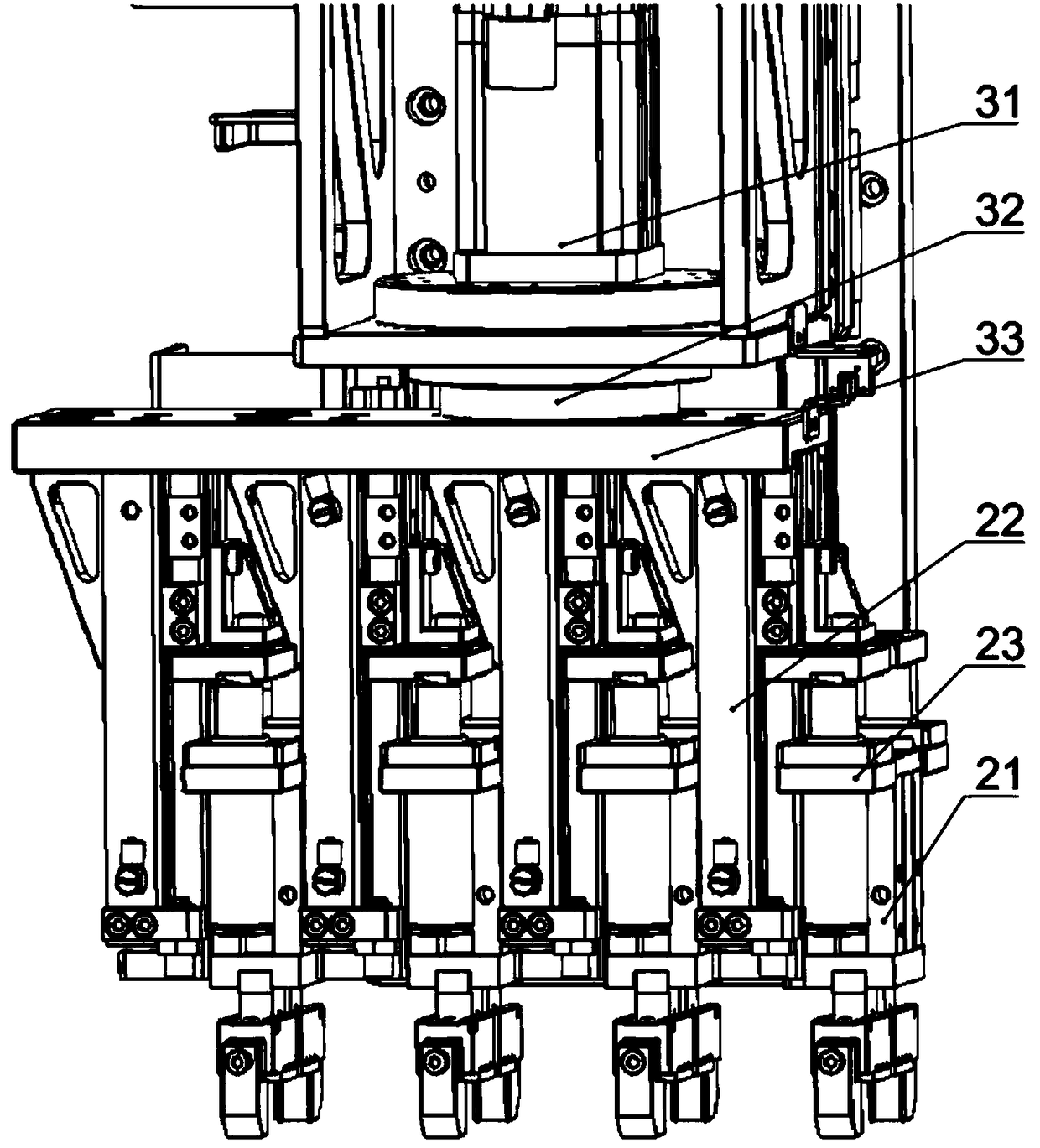

[0052] This embodiment provides a workpiece handling mechanism, the structure of which is as follows: figure 1 As shown, it includes a pick-up device and a moving device 5 arranged on a workbench 6 . The movement of the reclaiming device in the horizontal plane is driven by the horizontal movement structure of the mobile device 5, which includes a Y-axis linear module 51 arranged on the worktable 6 and an X-axis linear module 52 slidably connected thereto. Both the Y-axis linear module 51 and the X-axis linear module 52 include a private motor, a linear screw, and a parallel guide rail. The private motor is electrically connected to the control mechanism. An adjustment command is issued so that the horizontal moving structure can move the reclaimer to the pre-installation position to complete the accurate placement of the workpiece.

[0053] Such as figure 1 As shown, the moving device 5 in this embodiment also includes a vertical moving structure, including a Z-axis lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com