Automatic centering and clamping device based on transmission of worm and worm gears and crank connecting rods

A crank connecting rod and automatic centering technology, applied in the mechanical field, can solve the problems of many intermediate links in energy transmission and conversion, affecting the stability and accuracy of motion, hydraulic transmission can not guarantee the transmission ratio, etc., to shorten the time to adjust the fixture , Realize multi-directional clamping and clamping direction conversion, and expand the effect of clamping range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

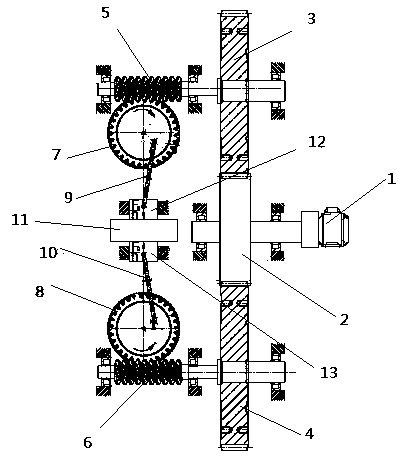

[0021] Such as figure 1 As shown, an automatic centering clamping device based on worm gear and crank connecting rod transmission includes an upper worm gear 7 and a lower worm gear 8 symmetrically arranged above and below the workpiece 11, each of which is hinged with a crank connecting rod, The end of the upper crank connecting rod 9 is connected with an upper pressure head 12, and the end of the lower crank connecting rod 10 is connected with a lower pressure head 13. The upper and lower pressure heads respectively drive the crank connecting rod through the rotation of the upper and lower worm wheels to clamp the pressure head. Workpiece 11. Wherein, the upper worm wheel 7 is driven by an upper worm 5 meshed with it, the lower worm wheel 8 is driven by a lower worm 6 meshed with it, and the upper and lower worms are respectively provided with an upper driven gear 3 and a lower driven gear 4, said Both driven gears are meshed on a driving gear 2, which is driven by a reduct...

Embodiment 2

[0026] The invention also discloses an automatic centering clamping device based on the transmission of worm gears and crank connecting rods, which includes three worm gears, the angles between the three worm gears are 120°, and the shaft center of each worm gear reaches the workpiece Each of the worm wheels is hinged with a crank connecting rod, and the end of the crank connecting rod is fixedly connected with a pressure head, and the pressure head drives the crank connecting rod through the rotation of the worm wheel to make the pressure head clamp the workpiece. Each worm gear is driven by a worm meshed with it, and each worm is provided with a driven gear, and each driven gear is meshed with a driving gear, and the driving gear is driven by a reduction motor, wherein the worm is a single Head worm, and the lead angle is less than 3.5°

[0027] The only difference between this embodiment 2 (not shown) and embodiment 1 is that there are three worm wheels with an angle of 120...

Embodiment 3

[0029] The invention also discloses an automatic centering clamping device based on the transmission of worm gears and crank connecting rods, which includes four worm gears, the angles between the four worm gears are 90°, and the axis center of each worm gear reaches the workpiece Each of the worm wheels is hinged with a crank connecting rod, and the end of the crank connecting rod is fixedly connected with a pressure head, and the pressure head drives the crank connecting rod through the rotation of the worm wheel to make the pressure head clamp the workpiece. Each worm gear is driven by a worm meshed with it, and each worm is provided with a driven gear, and each driven gear is meshed with a driving gear, and the driving gear is driven by a reduction motor, wherein the worm is a single Head worm, and the lead angle is less than 3.5°

[0030] The only difference between Embodiment 3 (not shown) and Embodiment 1 and Embodiment 2 is that it has four worm wheels at an angle of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com