Patents

Literature

67results about How to "High degree of greening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

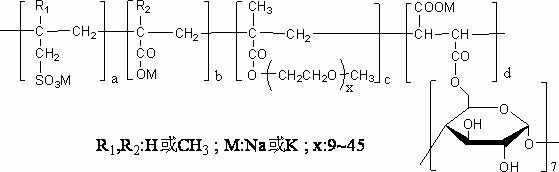

Preparation method of slow-setting polycarboxylic acid water reducing agent

The invention relates to a preparation method of a slow-setting polycarboxylic acid water reducing agent, which is implemented by carrying out free radical copolymerization reaction on allylsulfonate monomers, acrylic monomers, polyethylene glycol nono-methyl ether methacrylate macromonomers and maleic anhydride grafted beta-cyclodextrin macromonomers. The invention is characterized in that a beta-cyclodextrin side chain is introduced into a polycarboxylic acid main chain, so that the polycarboxylate water reducing agent has favorable slow setting property, micro air-entraining property and better fluidity. The obtained polycarboxylic acid water reducing agent has the advantages of stable product performance, strong adaptability to cement and favorable compatibility; and the cement paste fluidity is up to higher than 290mm (W / C=0.29), the water reducing rate of concrete is up to 30-40%, and the slump protection time is 3-5 hours. The preparation method provided by the invention has the characteristics of unique technique, excellent product performance and the like.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

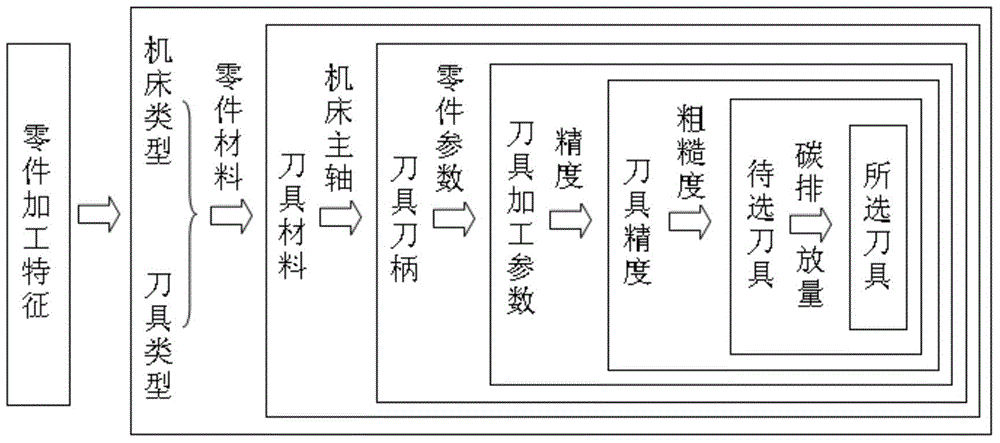

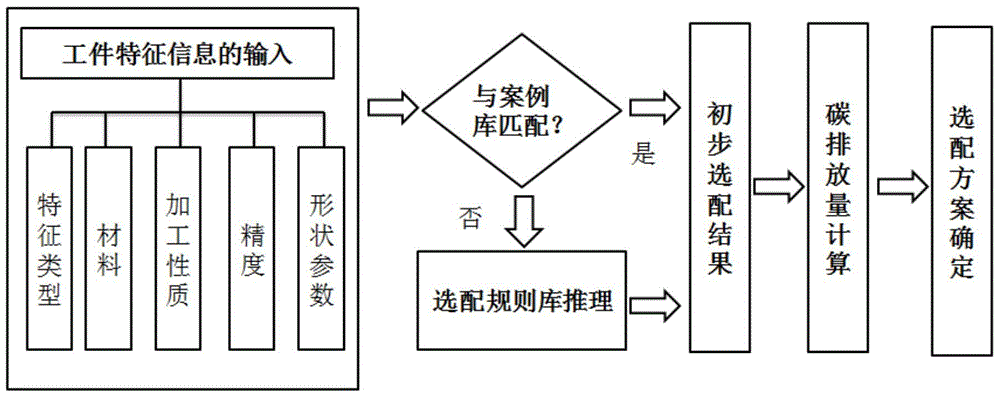

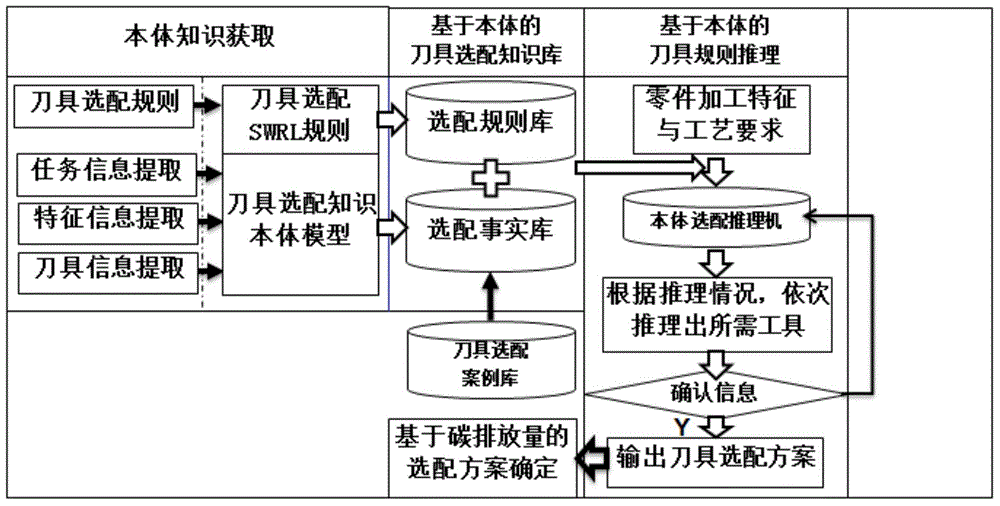

Cutter matching method for machining process

ActiveCN104400527AReduce complexityImprove efficiencyPositioning apparatusMetal-working holdersMatching methodsMachining process

The invention provides a cutter matching method for a machining process. A selective range of cutters to be matched is gradually decreased according to different characteristics of parts to be machined to obtain multiple cutters to be selected satisfying part processing requirements; and then, a final cutter is selected through calculating a carbon emission. The matching method is clear in steps and definite in levels, can reduce the cutter matching complexity, and can improve the reasoning efficiency and the accuracy of cutter matching. As the carbon emission in the machining process is introduced into a cutter matching scheme evaluation as a final selecting standard of the cutters to be matched, on the one hand, the finally matched cutter scheme is closer to actual production requirements to guarantee the matching result practicability, and on the other hand, the control of energy consumption of a workshop production system and the control of the carbon emission in the machining process are realized to a certain extent to improve the green degree of the whole system and to provide the reference for the realization of efficient cutter selection, energy conservation and emission reduction in the machining process.

Owner:XI AN JIAOTONG UNIV

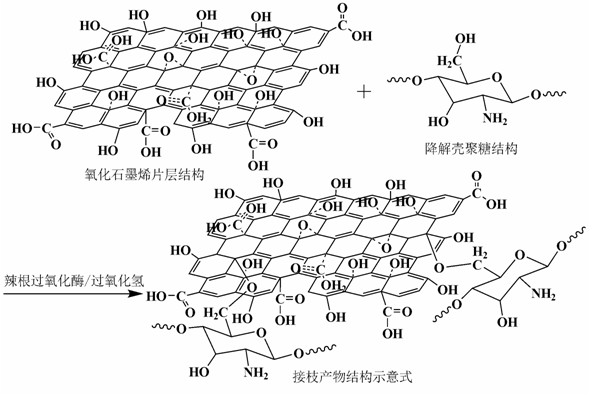

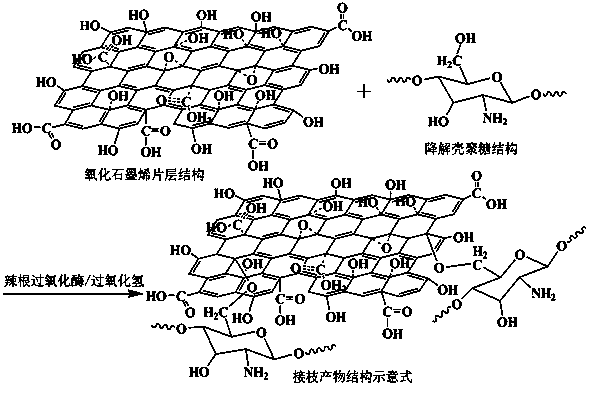

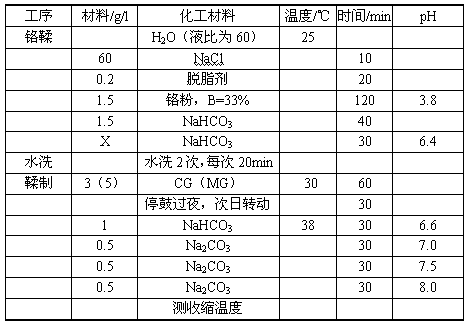

Preparation method of chitosan modified graphite oxide functional leather tanning agent

The invention relates to a preparation method of a chitosan modified graphite oxide functional leather tanning agent. Currently, the common leather tanning agents are chroming tanning agent, aluminum tanning agent, vegetable tanning agent, aldehyde tanning agent and synthetic tanning agent and the like, but the leather tanning agents can generate pollution problems hard to treat. The preparation method provided by the invention has the following steps of: mixing crystalline flake graphite powder, sodium nitrate and concentrated sulfuric acid and stirring uniformly, slowly adding potassium permanganate for oxygenation, and preparing a suspending liquid through washing, pH adjustment and ultrasonic treatment; and degrading chitosan with high-temperature alpha-amylase so as to obtain a degraded chitosan solution, modifying graphite oxide with the degraded chitosan under a horseradish peroxidase-hydrogen peroxide catalysis system, thus obtaining the chitosan modified graphite oxide functional leather tanning agent. The preparation method provided by the invention has the advantages of unique synthetizing preparation process and good tanning property, is suitable for main tanning and retanning; and the leather has excellent intensity and flexibility after main tanning.

Owner:JIANGSU BESCON PHARMA

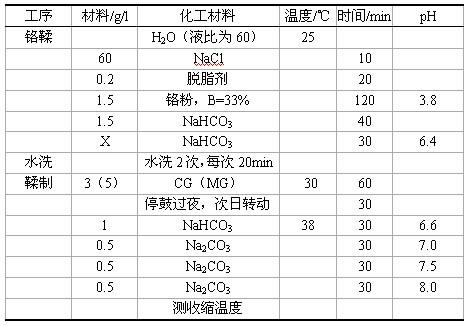

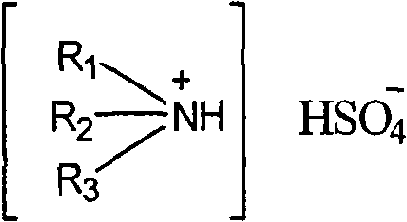

Process for continuously generating methyl acetate by reactive distillation taking ionic liquid as catalyst

ActiveCN101560151AGuaranteed purityReduce loadOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIonChemistry

A process for continuously generating methyl acetate by reactive distillation taking ionic liquid as a catalyst is as follows: raw materials are preheated, acetic acid is input from the upper segment of a reactive distillation tower, ionic liquid is input from the central segment of the tower and methanol is input from the lower segment of the tower simultaneously, the central segment of the reactive distillation tower is a reaction zone, the product of methyl acetate is extracted from the top of the tower, the catalyst of ionic liquid is extracted from the bottom of the tower and enters a flash drum for flash evaporation, the liquid extracted from the bottom of the flash drum is the catalyst of ionic liquid which returns to the reactive distillation tower, gas phase evaporated from the flash drum is mixed vapour of water and methanol, which is input to a methanol recovery tower, raw material of methanol is extracted from the top of the methanol recovery tower after being separated, and returns to the reactive distillation tower to be raw material, water is extracted from the bottom of the methanol recovery tower and is discharged. The process of the invention discharges no waste acid water, the material of devices of the required towers is only 316L stainless steel and can reduce the corrosion for the devices and one-time investment remarkably, energy consumption decreases by more than 15% simultaneously, therefore the production cost of final product reduces by more than 30%.

Owner:NANJING UNIV

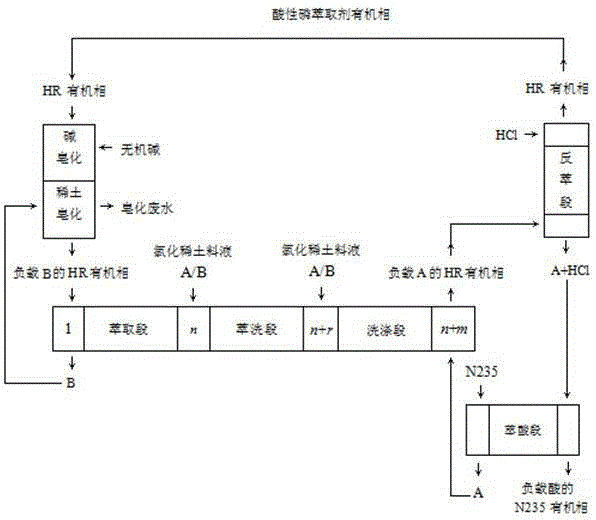

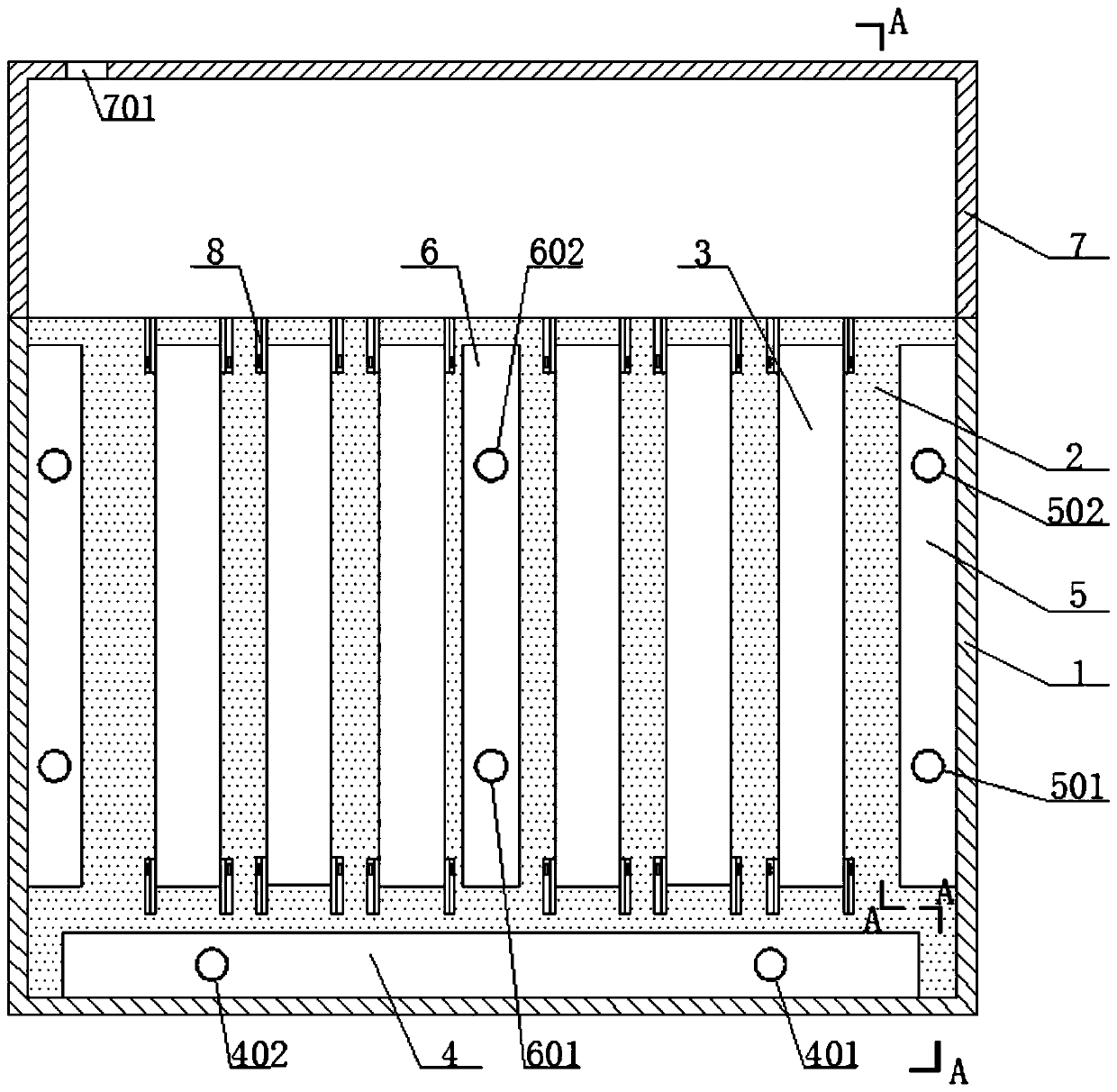

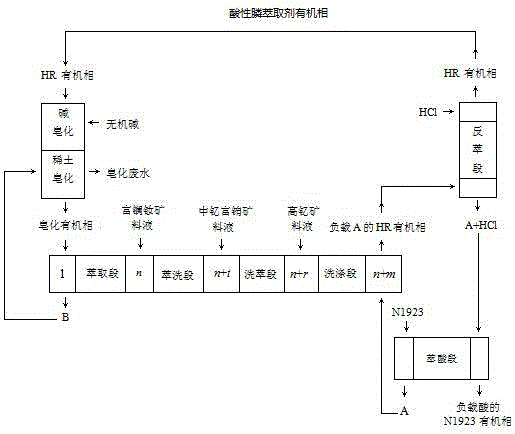

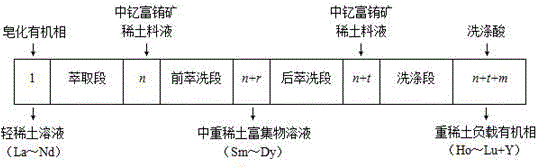

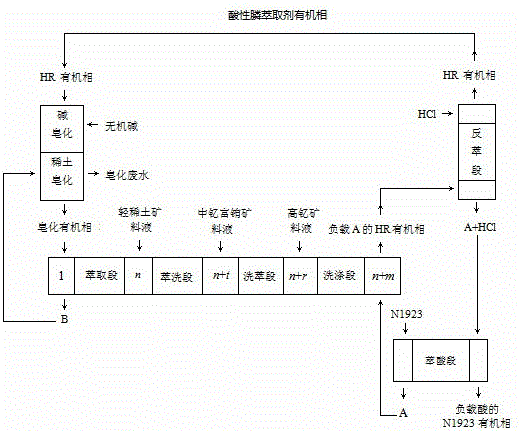

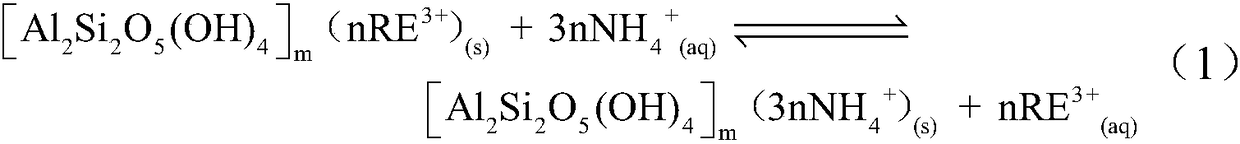

Two-feeding-opening fully-loaded rare earth fractional extraction separation process method

InactiveCN104561546AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementSide effectTotal investment

The invention discloses a two-feeding-opening fully-loaded rare earth fractional extraction separation process method. According to the method, P507 serves as a rare earth extracting agent; in a two-feeding-opening fractional extraction separation process, an acid extraction section which takes N235 as an acid extracting agent and takes trioctyl phosphate as an N235 organic phase demulsifying agent is arranged, and the side effect of hydrogen ions can be eliminated through the acid extracting effect of the N235, so that not only is the rare earth separation coefficient not reduced, but also the extracting amount of rare earth in a two-feeding-opening fractional extraction system is not lower than the saponification amount of the rare earth. Compared with the existing two-feeding-opening fractional extraction process, the consumption of acid and alkali in a rare earth separation process can be greatly reduced, wherein the consumption amount of an alkaline reagent is reduced by 39 to 51 percent, and the consumption amount of hydrochloric acid can be reduced by 17 to 26 percent; the waste water discharging amount in the rare earth extraction separation process is greatly reduced; the green degree of rare earth separation is greatly improved; the stage number of extracting tanks can be reduced by 32 to 38 percent; the total investment of the rare earth extraction separation process is reduced. Therefore, the separation cost is remarkably reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

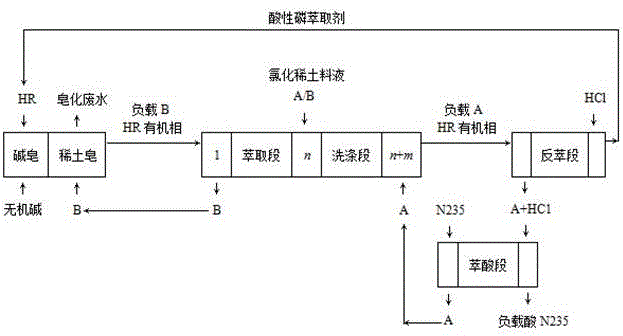

Technological method of full load fractional extracting and separating rare earths

InactiveCN104532022AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementSeparation factorWater discharge

The invention relates to a technological method of full load fractional extracting and separating rare earths. According to the technological method disclosed by the invention, P507 or P204 serves as a rare earth extractant; in a fractional extraction separation technology, N235 serves as an acid extraction agent, and a mixed alcohol serves as an acid extraction segment of an N235 organic phase regulator; an easily-extracted rare earth component solution with a pH value to be 1-4 serves as a washing solution; by virtue of the acid extraction action of the N235 in the acid extraction segment, the side effects of hydrogen ion washing are eliminated, so that the separation factor of the rare earths is ensured not to be lowered, and the extraction quantity of the extractant in a fractional extraction system is also ensured. Compared with the traditional fractional extraction separation technology, the acid and alkali consumption in the process of the rare earth separation technology can be greatly lowered, wherein the consumption of a basic reagent is lowered by 34-62 percent, and the consumption of hydrochloride is lowered by 16-29 percent; the waste water discharge in the process of the rare earth extraction separation technology is greatly reduced, the greening degree of rare earth separation is greatly increased; the grade amount of extraction tank is reduced by 22-46 percent, the total investment of the rare earth extraction separation technology is lowered; the separation cost is greatly lowered.

Owner:NANCHANG HANGKONG UNIVERSITY

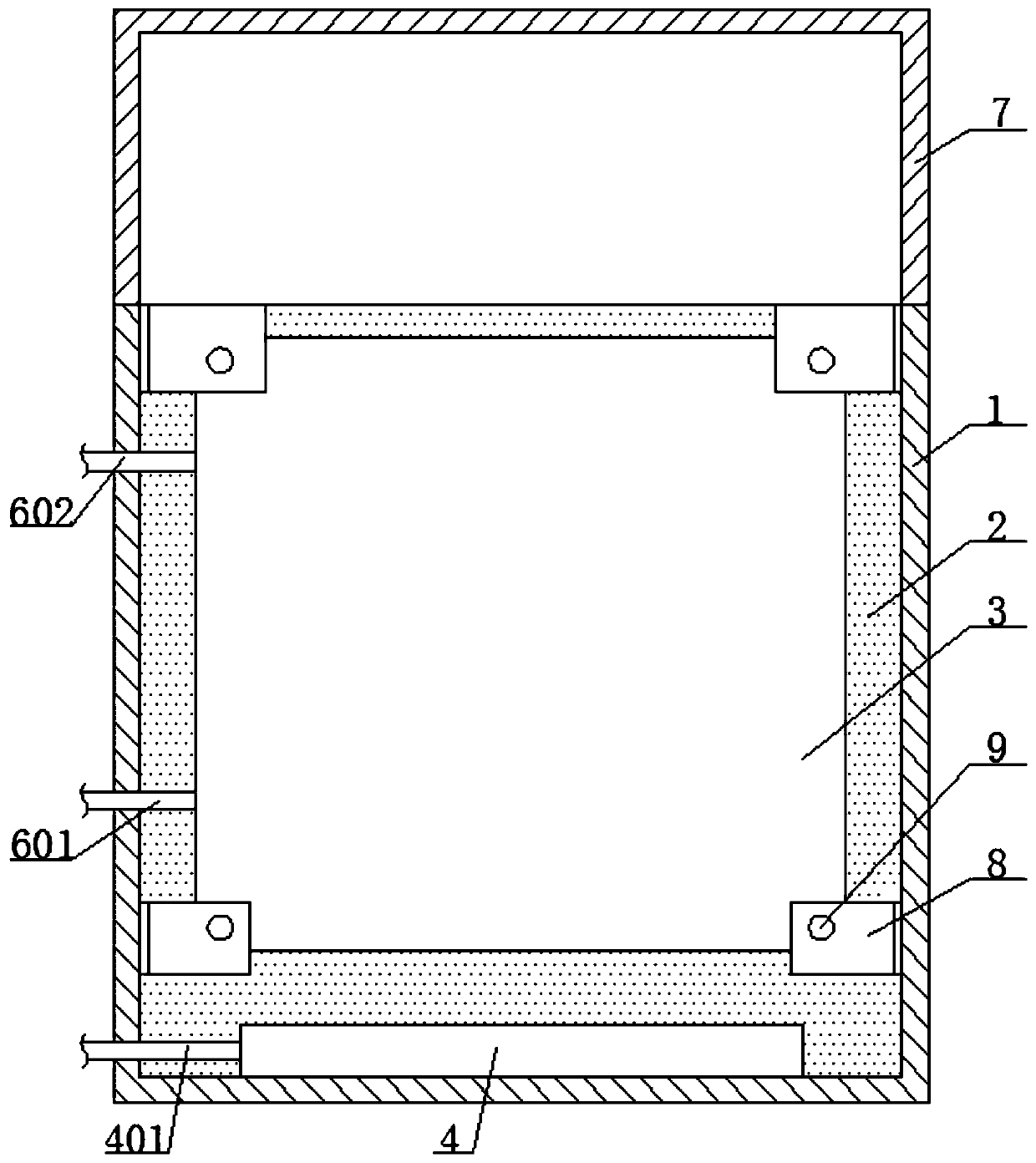

Data center liquid cooling system

PendingCN109952003ALow viscosityNo lossCooling/ventilation/heating modificationsData centerLiquid cooling system

The invention discloses a data center liquid cooling system and relates to the technical field of data center heat dissipation devices. The system comprises a box body, a server, a cold plate, a cooling device, a liquid storage tank and a refrigerant pump. The box body is filled with a single-phase refrigerant, the server is immersed in the single-phase refrigerant, the server is connected to thebox body, the cold plate is arranged in the box body and is connected to the box body, and the cold plate is sequentially connected to the cooling device, the liquid storage tank and the refrigerant pump to form a circulation loop. The invention realizes the combination of indirect contact liquid cooling, single-phase direct immersion liquid cooling and natural cooling, so that the single-phase refrigerant does not need to be circulated under the driving of a pump but is circulated by the change of temperature and density, although the refrigerant is circulated under the driving of the refrigerant pump, the refrigerant has a smaller viscosity than that of the single-phase refrigerant and is easy to flow, the loss of the refrigerant pump is not increased, so the pump loss caused by the single-phase refrigerant is reduced, the PUE of a data center is lowered, and the greenness of the data center is improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Method for fractionation and extraction separation of mischmetal through three feeding openings

InactiveCN106498191AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementChemistryYttrium

The invention discloses a method for fractionation and extraction separation of mischmetal through three feeding openings. According to the method for fractionation and extraction separation of mischmetal through the three feeding openings, P507 is used as a rare extraction agent, primary amine N1923 is used as an acid extraction agent, and TOP is used as an organic phase modifier; the three feeding openings are arranged in a fractionation and extraction system, Gd / Tb grouped separation is conducted to treat three kinds of rare earth chloride feed liquid of lanthanum-neodymium-rich ore, yttrium-intermediate europium-rich ore and high-yttrium ore at the same time, and then a light and middle rare earth product and a heavy rare earth product are obtained; the lanthanum-neodymium-rich ore feed liquid enters the fractionation and extraction system from the first feeding opening; the yttrium-intermediate europium-rich ore feed liquid enters the fractionation and extraction system from the second feeding opening; and the high-yttrium ore feed liquid enters the fractionation and extraction system from the third opening. The light and middle rare earth product with the purity being 5N is obtained from the water phase of an outlet of a first-level extraction tank of the fractionation and extraction system; and the heavy rare earth product with the purity being 5N is obtained from the extraction raffinate water phase of an acid extraction section. Compared with an existing traditional fractionation and extraction technology, the consumption amount of organic-phase saponification alkaline is lowered by 39%-52%, the consumption amount of pickling acid is lowered by 66%-80%, and the total number of levels of extraction tanks is reduced by 30%-60%.

Owner:NANCHANG HANGKONG UNIVERSITY

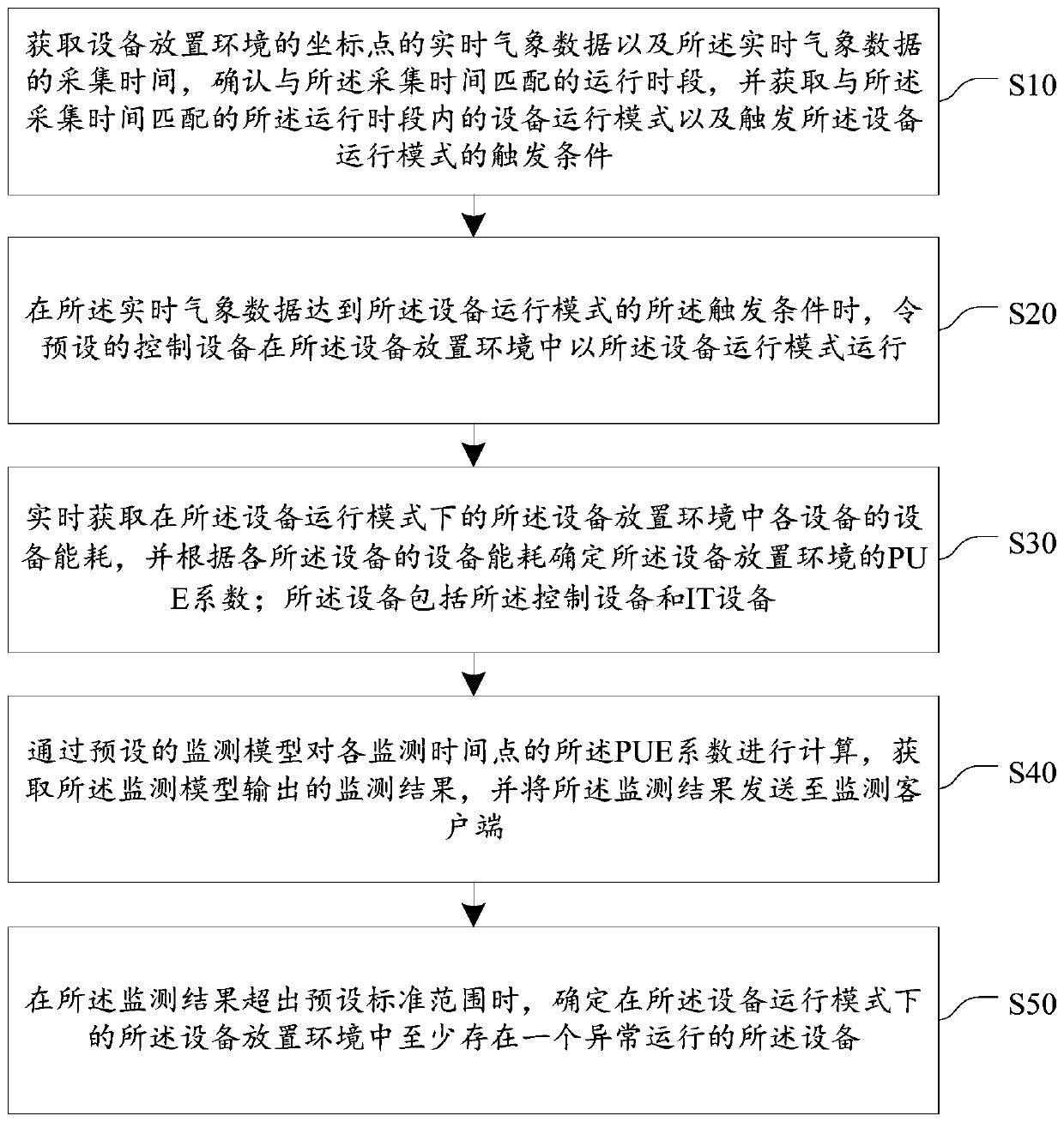

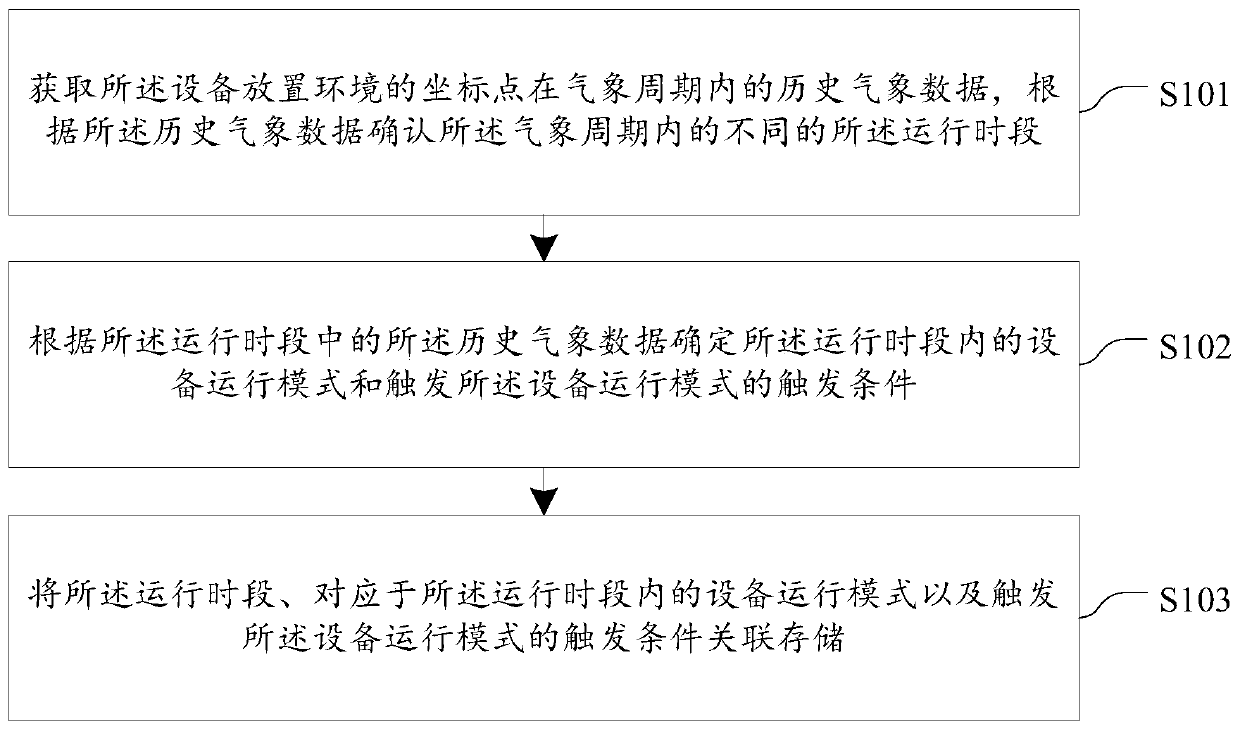

Equipment operation and monitoring method, device, equipment and medium

ActiveCN110442170AImprove operational efficiencyHigh degree of greeningIndication of weather conditions using multiple variablesSimultaneous control of multiple variablesAcquisition timeOperation mode

The invention discloses an equipment operation and monitoring method, a device, equipment and a medium. The method includes the following steps of: acquiring real-time meteorological data and an acquisition time thereof, confirming an operation period matched with the acquisition time, and acquiring a corresponding equipment operation mode and a trigger condition thereof; when the real-time meteorological data reaches a trigger condition, instructing control equipment to operate in an equipment operation mode in an equipment placement environment; obtaining the energy consumption of each pieceof equipment in the equipment placement environment in the equipment operation mode, and determining the PUE of the equipment placement environment; calculating the PUE of each monitoring time pointthrough a monitoring model, and obtaining a monitoring result; and when the monitoring result exceeds the preset standard range, determining that at least one piece of equipment in an abnormal operation state exists. According to the scheme of the invention, the intelligent operation of the equipment is realized; and meanwhile, abnormalities can be found and processed in time according to the PUEof the equipment placement environment during the operation of the intelligent monitoring equipment, the energy consumption ratio of the equipment placement environment is reduced, and thus the greening degree of the equipment placement environment is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

Method for two-in and three-out fractional extraction and group separation of europium-rich middle yttrium ore

InactiveCN104531994AReduce volumeHigh degree of greeningProcess efficiency improvementRare-earth elementChemistry

The invention discloses a method for two-in and three-out fractional extraction and group separation of europium-rich middle yttrium ore. Two rare-earth feed liquid feeding holes and three rare-earth product solution outlets are formed in a fractional extraction system; chlorinated rare-earth feed liquid of the europium-rich middle yttrium ore is divided into two parts, and is fed to the fractional extraction system from different feeding holes; a third outlet is formed in a water phase of an extraction eluting section, so as to obtain three products; P507 is used as an extracting agent; light rare-earth elements 'La-Nd' products, heavy rare-earth elements 'Ho-Lu+Y' products and medium rare-earth 'Sm-Dy' enriched products are obtained by adopting the method for two-in and three-out fractional extraction and group separation of europium-rich middle yttrium ore Nd / Sm-Dy / Ho. Compared with an existing process for group separation of Nd / Sm-Dy / Ho at three water outlets in the water phase of the P507 extraction eluting section, the method has the advantages that the saponification alkali consumption is reduced by 28%-36%; the acid consumption of the washing acid is reduced by 34%-42%; the separation cost is low; and the green degree is high.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of permeable reinforced raw silk processing agent

The invention relates to a preparation method of a permeable reinforced raw silk processing agent. Processing agents sold in the present market generally have the disadvantages of small raw silk breaking strength, bad cohesion, bad fabric breathability, difficult wastewater processing the like. The preparation method of the invention comprises the following steps: adding graphite powder, sodium nitrate and concentrated sulfuric acid to potassium permanganate in an ice bath environment; reacting above substances in a 35DEG C water bath, heating, washing, applying ultrasonic processing, carrying out centrifugal filtration and vacuum drying, carrying out ultrasonic processing on the resulting substance with N,N-dimethyl formamide, ethylene diamine and dicyclohexylcarbodiimide, adding waterless ethanol, allowing the resulting solution to stand overnight, and carrying out vacuum drying to obtain amino modified graphene oxide; and stir-reacting the amino modified graphene oxide, oxidized polyethlene wax, lanolin, oxidized rapeseed oil, oxidized lard, an emulsifier OS-15h and an emulsifier 1631 to obtain the permeable reinforced raw silk processing agent. The strength, the surface lustereffect, the smooth and soft performances, the antistatic performance, the flame retardation and the like of raw silk processed with the permeable reinforced raw silk processing agent of the inventionare greatly improved.

Owner:苏州盛泽科技创业园发展有限公司

High-temperature-wear-resistant anticorrosive paint as well as preparation method and application thereof

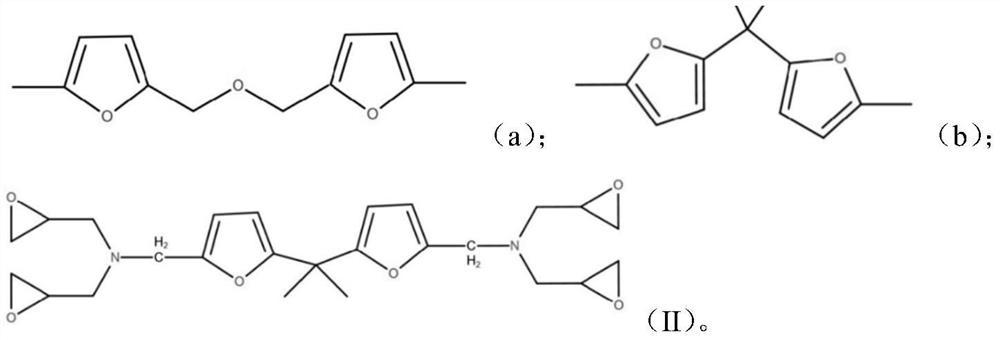

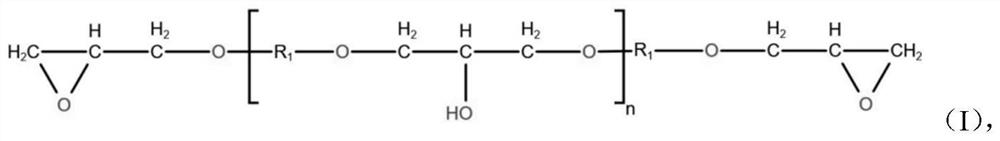

ActiveCN113248959AGood dispersionCompact appearanceFireproof paintsLiquid surface applicatorsEpoxyFuran

The invention relates to a high-temperature-wear-resistant anticorrosive paint and a preparation method and an application thereof, a combination of furan modified epoxy resin with a specific structure is selected as a film forming substance, the high temperature resistance, corrosion resistance and other properties of the epoxy resin and furan resin are utilized, and functionalized graphene is selected as a heat-conducting and anticorrosive component, epoxy polyether-polysiloxane is used as a dispersion functional component, good dispersion of graphene, the filler and other components is realized, the coating with good and compact appearance is prepared, the coating has excellent high temperature resistance, wear resistance, corrosion resistance and the like, can meet the high-temperature corrosion resistance requirements of the surfaces of the four tubes of the boiler, and meanwhile, the method has the advantages of simple process, simple operation, mild curing conditions, short time required for complete curing, low energy consumption ratio of the curing process, and high greenization degree of the process.

Owner:深圳优易材料科技有限公司

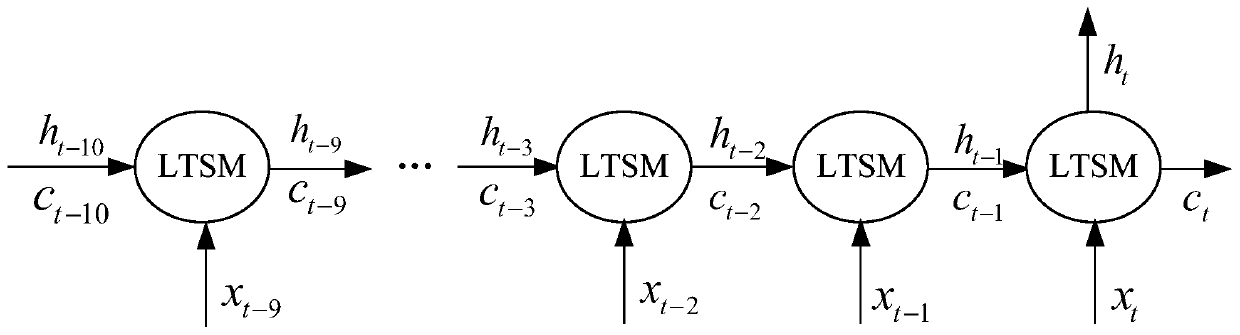

Prediction method and device for energy utilization efficiency, storage medium and terminal equipment

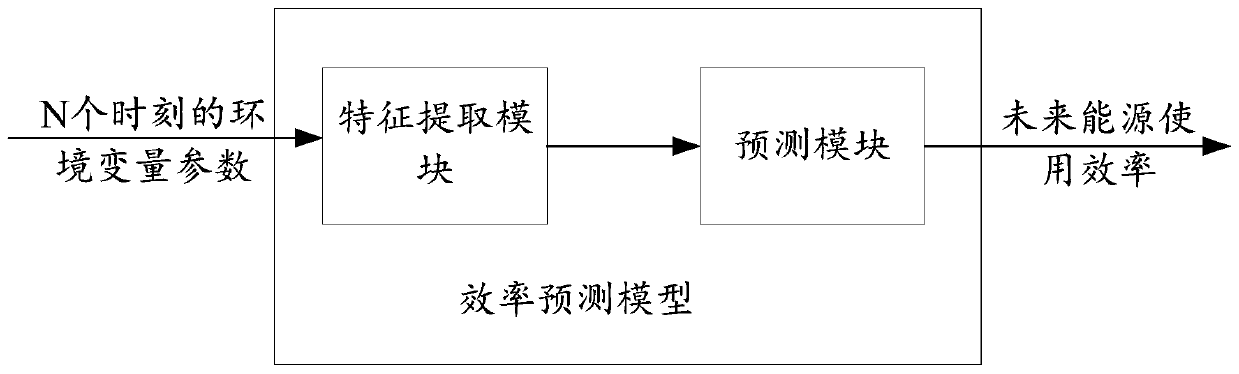

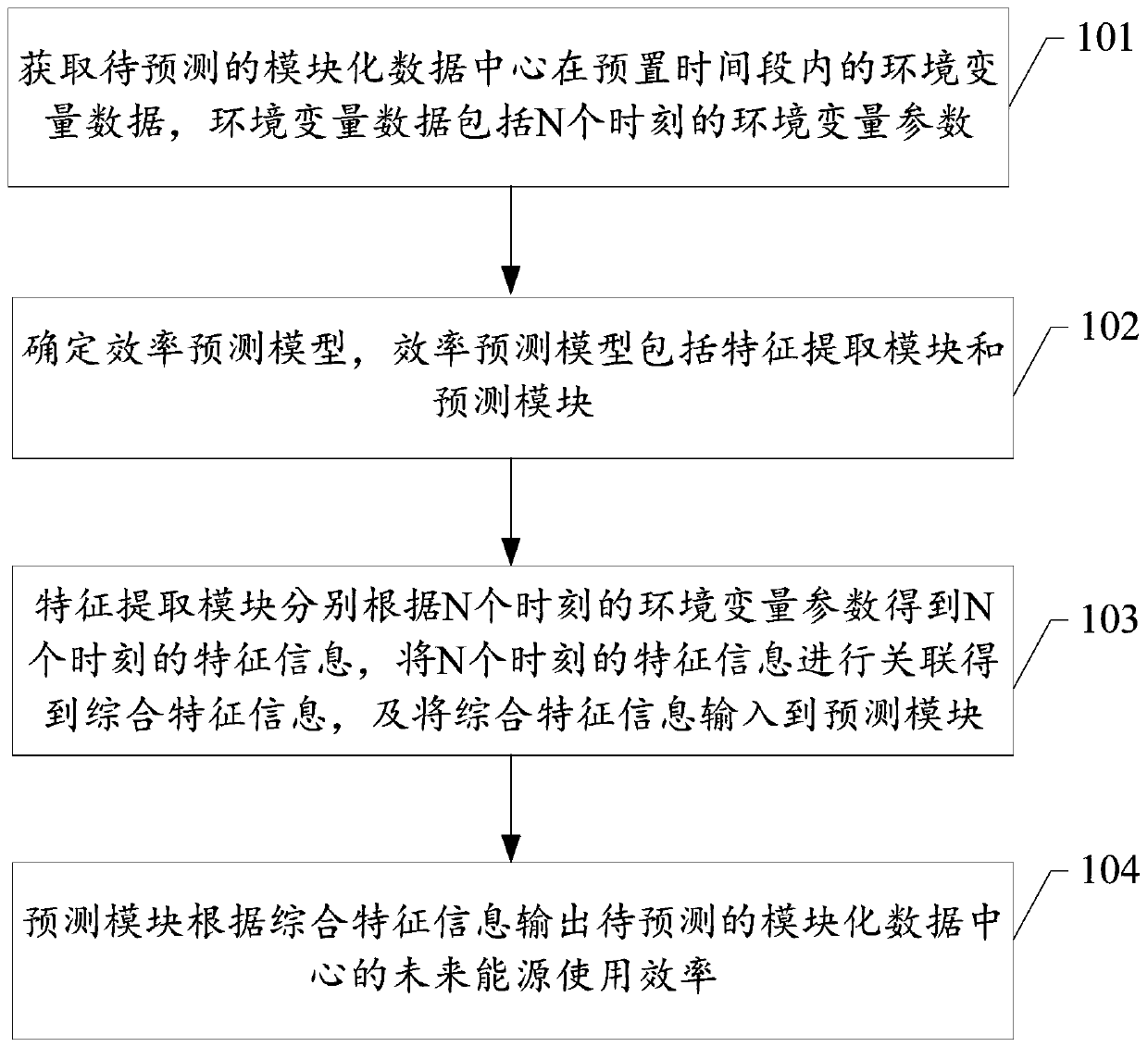

PendingCN110826784AHigh degree of greeningConvenient guidanceForecastingNeural architecturesInformation processingFeature extraction

The embodiment of the invention discloses a prediction method and device for energy use efficiency, a storage medium and terminal equipment, which are applied to the technical field of information processing of artificial intelligence. The prediction device for the energy utilization efficiency can obtain environment variable parameters of the modular data center at N moments in a preset time period, and utilizes a feature extraction module in the efficiency prediction model to extract feature information of the environment variable parameters at N moments, associates the feature information at the N moments to obtain comprehensive feature information, and a prediction module in the efficiency prediction model outputs the future energy use efficiency of the modular data center according tothe comprehensive feature information. The efficiency prediction model is a machine learning model, the machine learning model can be combined with environmental variable parameters collected for multiple times in a period of time to obtain future energy use efficiency, the future energy use efficiency can be accurately predicted, and operation and maintenance personnel can be well guided to create a modular data center with a high degree of greenization.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

Method for directly preparing light-emitting material 8-hydroxyquinoline copper

InactiveCN104744365AIncrease profitHigh purityOrganic chemistryLuminescent compositionsPhysical chemistryQuinoline

The invention discloses a method for directly preparing a light-emitting material 8-hydroxyquinoline copper. According to the invention, tetrahydrate copper formate and 8-hydroxyquinoline are adopted as reaction raw materials, and 8-hydroxyquinoline copper is prepared with a vacuum hot-melt method. The method comprises the following specific steps: the raw materials are added into a mixer according to a molar ratio that tetrahydrate copper formate to 8-hydroxyquinoline is 1:2, and the raw materials are well mixed; the well mixed mixture of the reaction raw materials is transferred into a vacuum reaction kettle; the reaction kettle is pumped until a vacuum degree is reduced to 0.1Pa, and the temperature in the reaction kettle is increased to 80-100 DEG C with a heating speed of 1 DEG C / min; the vacuum degree is maintained at 0.1Pa, and a reaction is carried out for 60-90min under a maintained temperature; and when the reaction is finished, an obtained product is cooled to room temperature and is fetched. With the method, 8-hydroxyquinoline copper with purity of 97-99% is obtained, and the yield is 98-100%. The method provided by the invention has the advantages of simplicity in operation, high raw material utilization rate, short process, high yield, no waste liquid discharge, low production cost, and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

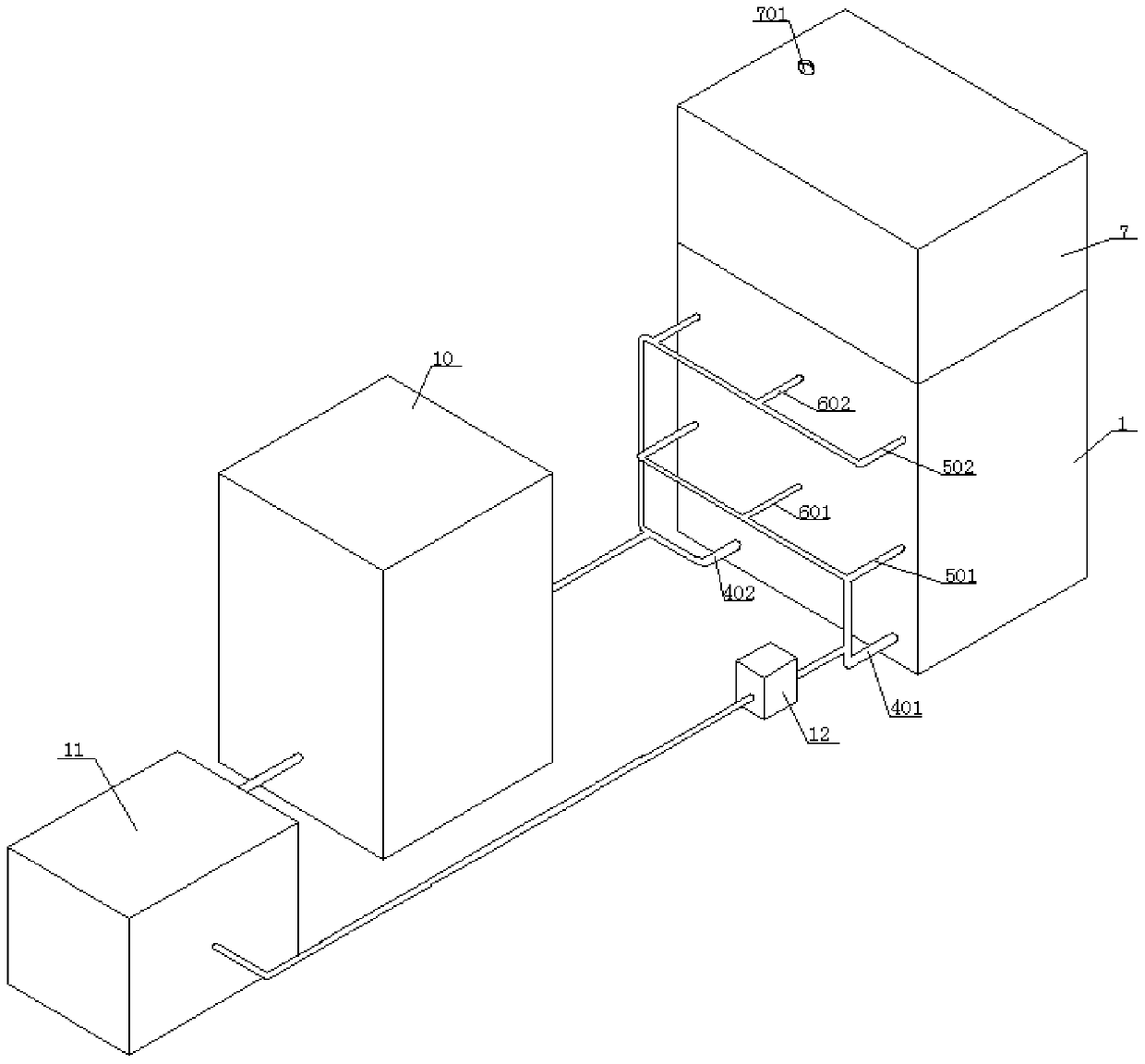

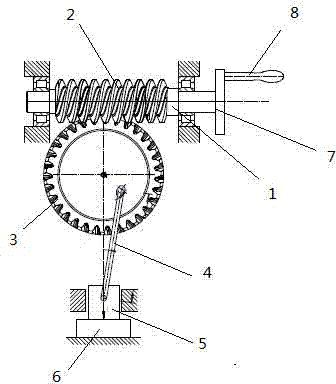

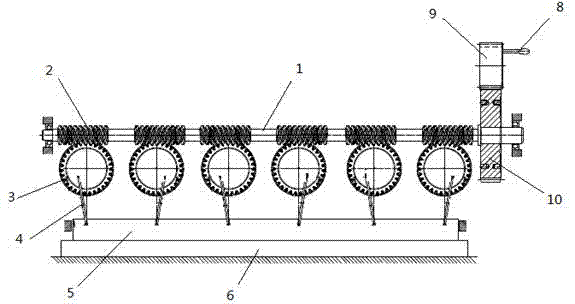

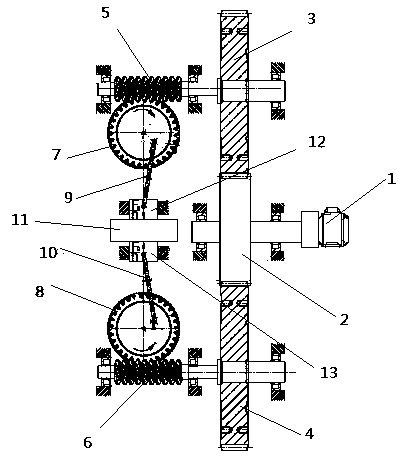

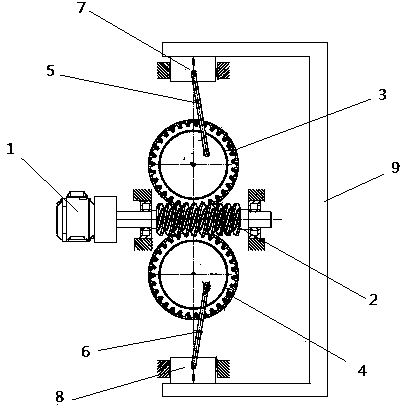

Manual pressing device based on worms, worm wheels and crank connecting rod transmissions

The invention discloses a manual pressing device based on worms, worm wheels and crank connecting rod transmissions. The manual pressing device comprises a rotary shaft, wherein at least two worms are fixedly arranged on the rotary shaft, the worm wheels meshed with the worms are arranged under the corresponding worms, the crank connecting rod transmissions are arranged on the worm wheels, and the tail ends of the crank connecting rod transmissions are connected to the same press block. The symmetrical synchronous multi-point driving is achieved, the manual pressing device is compact in structure, simple and convenient to use and rapid in positioning and pressing, the synchronous multi-point or multi-station pressing can be achieved according to the demands of workpieces, and accordingly labor productivity and product quality are improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Extraction method for group separating three types of rare earth raw materials

InactiveCN106498193AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementRare earthChloride

The invention discloses a fractional extraction method for separating mixed rear earth utilizing three feeding ports. P507 is adopted as a rear earth extraction agent, primary amine N1923 is adopted as an extraction acid agent, and TBP is adopted as an organic phase modifier agent; the three feeding ports are formed in a fractional extraction system, three types of rare earth chloride liquid such as light rare earth ore, middle yttrium europium rich ore, and high yttrium ore are subjected to -Gd / Tb- group separating simultaneously, and two types of rear earth products such as light middle rear earth and heavy rear earth are obtained; the light rear earth ore liquid enters the fractional extraction system from the first feeding port, the middle yttrium europium rich ore liquid enters the fractional extraction system from the second feeding port, and the high yttrium ore liquid enters the fractional extraction system from the third feeding port; and light middle rear earth products with purity of 5N class are obtained from water phase of a first stage extraction trough exit of the fractional extraction system, and heavy rear earth products with 5N class are obtained from waste extraction water phase of an extraction section. According to the extraction method for group separating three types of rare earth raw materials, and compared with a traditional fractional extraction art, consumption of washing acid is reduced by 75%-83%, consumption of organic phase saponification alkali is reduced by 49%-67%, and the number of the whole stages of the extraction troughs is reduced by 30-60%.

Owner:NANCHANG HANGKONG UNIVERSITY

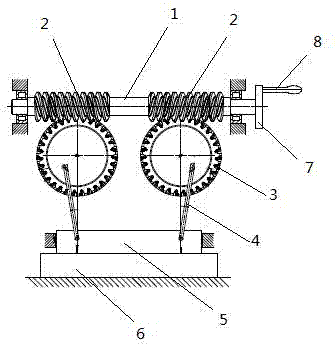

Automatic centering and clamping device based on transmission of worm and worm gears and crank connecting rods

InactiveCN104209781AReduce labor intensityNo pollutionPositioning apparatusMetal-working holdersMechanical engineering

The invention discloses an automatic centering and clamping device based on transmission of worm-worm gears and crank connecting rods. The automatic centering and clamping device comprises at least two worm gears, wherein each worm gear is hinged to a crank connecting rod; the tail ends of the crank connecting rods are fixedly connected with pressure heads; the pressure heads are used for driving the crank connecting rods through rotation of the worm gears to drive the pressure heads to clamp a workpiece; each worm gear is driven by a worm which is meshed with the worm gear respectively; each worm is provided with a driven gear; each driven gear is meshed on the same driving gear. According to the automatic centering and clamping device, the worm-worm gears and the crank connecting rod mechanisms are arranged symmetrically, and the output force generated by the pressure heads is equal in magnitude and reverse in directions, so that automatic centering and alignment are realized, the fixture adjusting time can be shortened, the workpiece machining efficiency is increased, and the effects of saving labor force, saving time and increasing efficiency are achieved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

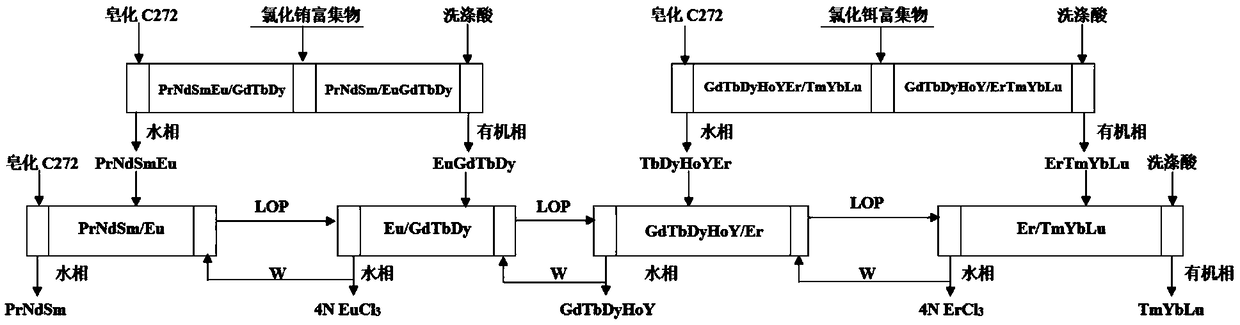

Extraction and separation technology for fractional extraction co-production of pure europium and pure erbium

InactiveCN109055745AImprove stabilityReduce consumptionProcess efficiency improvementSeparation technologyChloride

The invention discloses an extraction and separation technology for fractional extraction co-production of pure europium and pure erbium. According to the extraction and separation technology, C272 serves as an extraction agent, an europium-rich chloride solution serves as a first feed liquid, and an erbium-rich chloride solution serves as a second feed liquid. The extraction and separation technology comprises the six steps of fractional extraction separation of PrNdSmEu and EuGdTbDy, fractional extraction separation of GdTbDyHoYEr / ErTmYbLu, full-loaded fractional extraction separation of PrNdSm / Eu, full-loaded fractional extraction separation of Eu / GdTbDy, full-loaded fractional extraction separation of GdTbDyHoY / Er and fractional extraction separation of Er / TmYbLu. Two high-purity products of 4N-grade europium chloride and 4N-grade erbium chloride are simultaneously obtained through one extraction and separation technology. Through the extraction and separation technology, the consumption of acid and alkali for preparing the 4N-grade europium chloride and the 4N-grade erbium chloride can be lowered, and the product percent of pass of the 4N-grade europium chloride and the 4N-grade erbium chloride can be improved.

Owner:NANCHANG HANGKONG UNIVERSITY

Manipulator internal-grab device based on worm-gear and crank-link transmission

The invention discloses a manipulator internal-grab device based on worm-gear and crank-link transmission. The manipulator internal-grab device is characterized by comprising at least two gears; each gear is hinged with a crank link, a grab press head is fixedly connected to the tail end of each crank link and drives the same under rotation of the corresponding gear so as to support a workpiece tightly, and each gear is driven by one worm meshing with the same. Through second series-connection boosting of the worm-gear and crank-link transmission, high boost ratio is acquired, boosting effect is obvious, labor productivity and product quality can be improved and labor intensity of workers can be reduced. According to the nonlinear characteristic between the output force and the output displacement of a crank-link mechanism, the grab press heads are fed rapidly on the condition of large pressure angle, and the grab force is increased rapidly on the condition of small pressure angle.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

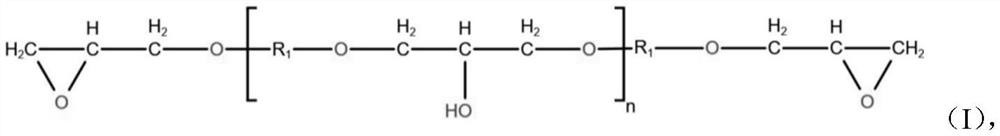

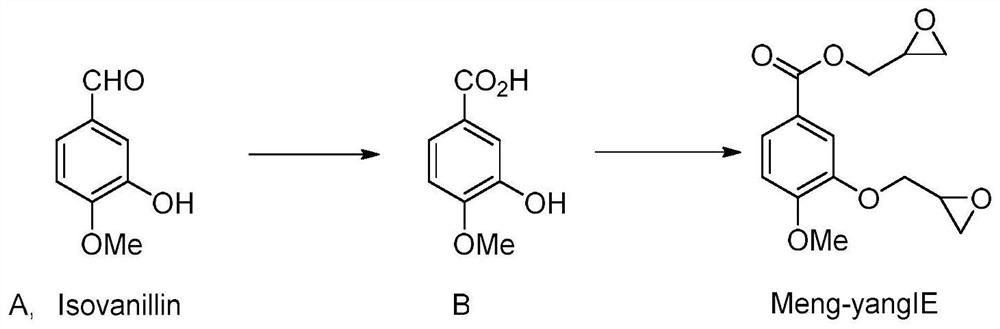

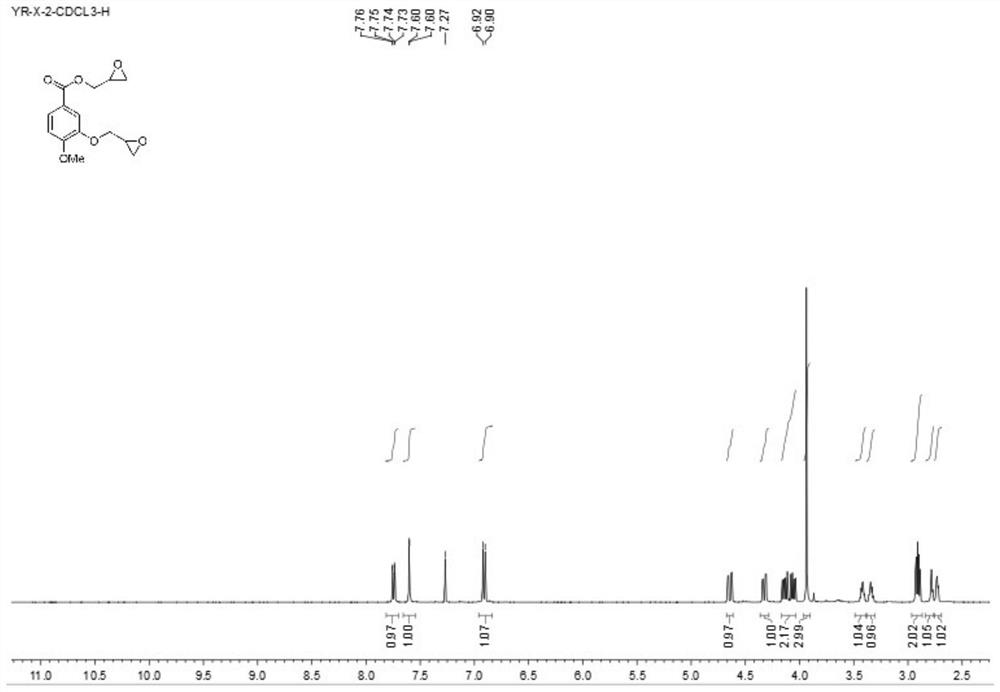

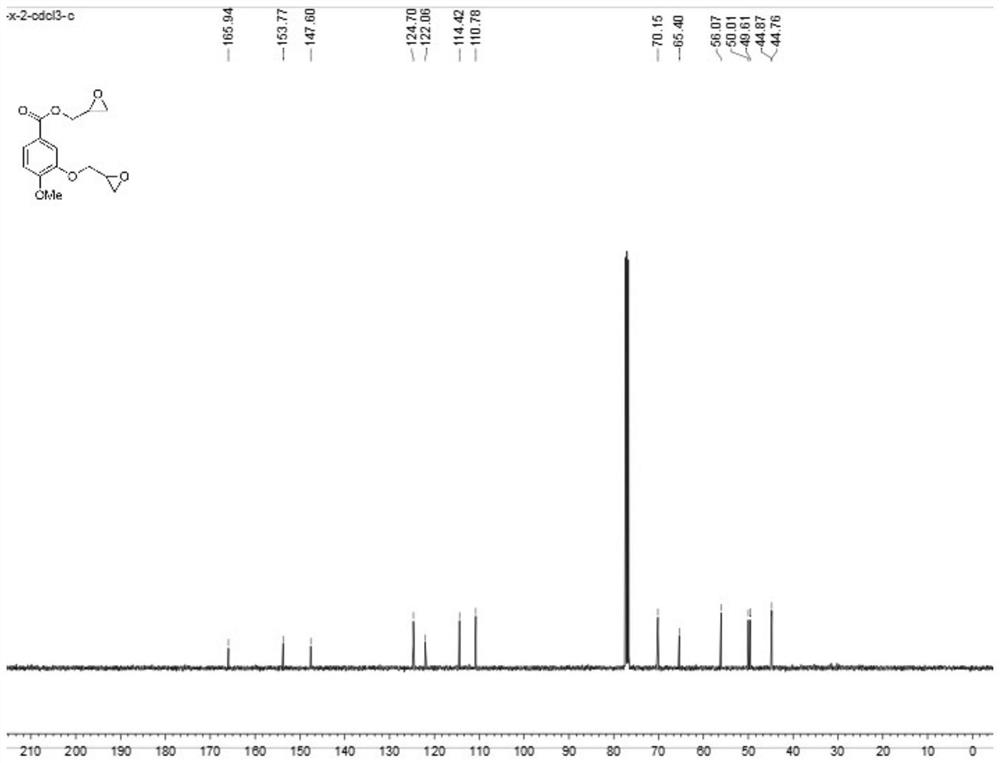

Application of novel isovanillin epoxy resin monomer in preparation of silicon-containing polymer

ActiveCN114456128ANovel structureHigh degree of greeningOrganic chemistryChemical recyclingEpoxyPolymer science

The invention discloses an application of a novel isovanillin epoxy resin monomer in preparation of a silicon-containing polymer, which comprises the following steps: mixing an isovanillin bio-based epoxy resin monomer as shown in a formula Meng-yangIE with an organic silicon polyamine curing agent as shown in a formula D, a formula E or a formula F, melting, and curing to obtain the novel isovanillin epoxy resin monomer. The silicon-containing polymer containing the isovanillin bio-based epoxy resin monomer as shown in the formula Meng-yangIE is obtained. According to the method, the bio-based isovanillin is used as the raw material for preparing the corresponding epoxy resin monomer material for the first time, the synthesis steps of the resin monomer are simple, the conversion rate of the reaction process is high, the source is wide, the greenization degree is high, and the biological safety of the product is high. In addition, the bio-based epoxy resin obtained through polymerization of the isovanillin epoxy resin monomer is novel in structure, and the obtained bio-based epoxy resin polymer material has low curing processing technology temperature and good heat resistance (the initial decomposition temperature ranges from 300.8 DEG C to 300.8 DEG C).

Owner:NANJING UNIV OF TECH

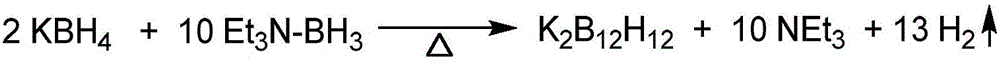

Method for preparing K2B12H12

The invention provides a KBH 4 with Et 3 N·BH 3 The product after thermal reaction in an aprotic medium can be directly prepared into pure K by solvent treatment without any chemical transformation. 2 B 12 h 12 Methods. This preparation method avoids the use of highly toxic B 2 h 6 , B 5 h 9 or B 10 h 14 or its derivatives, to avoid the separation step of converting the reaction product into insoluble salts such as triethylamine salt, tetraalkylammonium salt or chitin salt or cesium salt, without passing H + Ion-column exchange, eliminating the need for KOH or K 2 CO 3 Neutralization step. The method involves few chemical species, simple procedure, routine operation, and convenient handling, and is the ideal method for preparing K 2 B 12 h 12 A method with a higher degree of greening.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

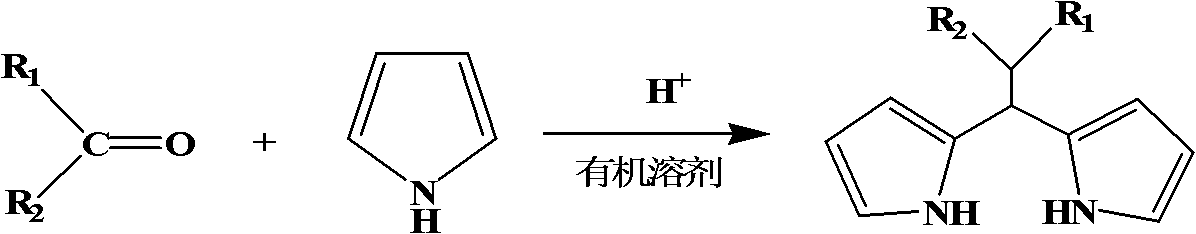

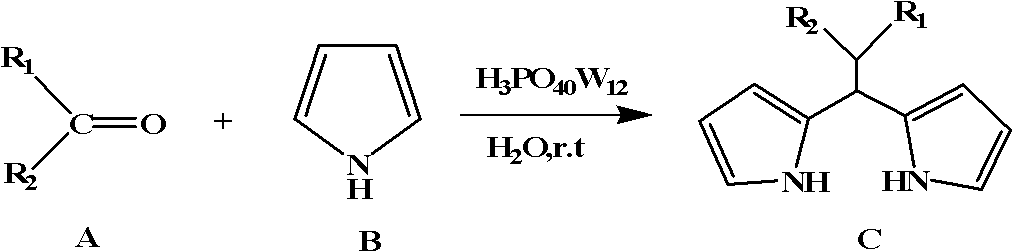

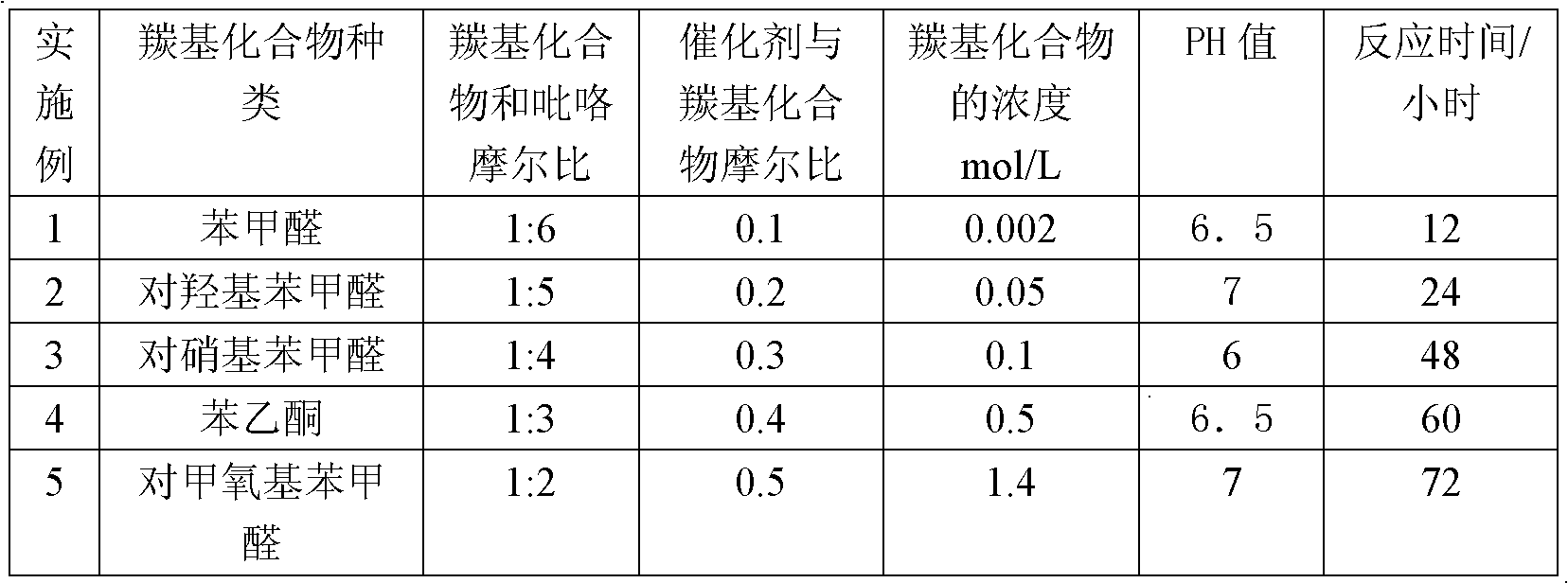

Dipyrromethene compound synthetic method

InactiveCN102850251ASimple post-processingHigh degree of greeningOrganic chemistryOrganic solventRoom temperature

A dipyrromethene compound green synthetic method, especially a synthetic method for pyrrolo Beta-position non-substituted dipyrromethane using pyrrole and aromatic aldehydes and ketones, includes using water as solvent, using pyrrole and aromatic aldehydes and ketones as raw material and phosphotungstic acid as catalyst, and synthesizing dipyrromethane at room temperature in one-step. The dipyrromethane has yield of 44%-95% and purity greater than 99%, and the inventive method avoids the use of organic solvent of greater toxicity and the yield increased by 14%-28%, and it significantly reduces the cost and is batch synthesis process.

Owner:CHANGCHUN UNIV OF TECH

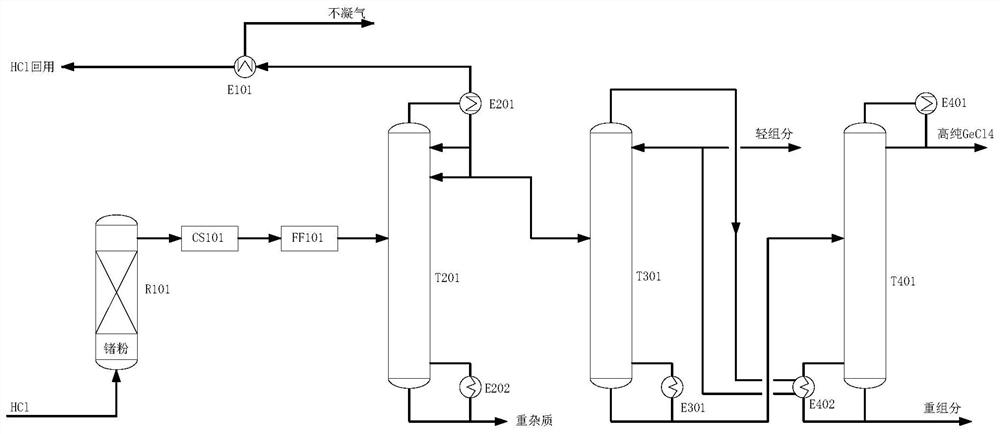

Method and device for synthesizing and refining optical fiber grade germanium tetrachloride

PendingCN111957064AAvoid introducingReduce generationGermanium halidesFractional distillationPhysical chemistryHydrogen chloride

The invention relates to a method and a device for synthesizing and refining optical fiber grade germanium tetrachloride. The method comprises the steps: making hydrogen chloride and germanium powderreact under the conditions where the pressure is 0.1-1 MPa and the temperature is 200-400 DEG C, wherein the effective conversion rate of germanium is 60-90%, and obtaining germanium tetrachloride crude gas through reaction; removing dust from the germanium tetrachloride crude product and then carrying out heavy component removal treatment, wherein the heavy component removal operation pressure is0.1-0.3 MPa, and the operation temperature is 82-123 DEG C; recovering hydrogen chloride from non-condensable gas generated in the heavy component removal process under the operating condition of -130--80 DEG C, and then discharging the gas; and refining the de-heavy material under the conditions where the pressure is 0.2-0.5 MPa and the temperature is 103-143 DEG C to obtain a 8N optical fiber grade germanium tetrachloride product. Germanium powder and hydrogen chloride are adopted for direct reaction, so that introduction of sulfuric acid and hydrochloric acid is avoided, generation of waste acid and waste salt is reduced, and the greenization degree of the production process is improved. The effective conversion rate of germanium is 80-95%, and compared with a traditional process, energy is saved by more than or equal to 40%.

Owner:TIANJIN ZHONGKE TUOXIN TECH CO LTD

Preparation method of chitosan modified graphite oxide functional leather tanning agent

ActiveCN102634613BHigh strengthGood flexibilityTanning treatmentHorseradish peroxidaseSodium nitrate

The invention relates to a preparation method of a chitosan-modified graphene oxide functional leather tanning agent. At present, commonly used leather tanning agents include chrome tanning agents, aluminum tanning agents, vegetable tanning agents, aldehyde tanning agents and synthetic tanning agents, etc., but they will produce pollution problems that are difficult to control. In the present invention, flake graphite powder, sodium nitrate and concentrated sulfuric acid are mixed and stirred uniformly, potassium permanganate is slowly added for oxidation, and a suspension is prepared after washing, pH adjustment and ultrasonic treatment; Degraded chitosan solution is obtained by degrading; then the graphene oxide is modified with the degraded chitosan under the catalytic system of horseradish peroxidase and hydrogen peroxide to obtain chitosan-modified graphene oxide functional leather tanning agent. The preparation method of the invention has a unique synthetic preparation process, good tanning performance, is suitable for main tanning and retanning, and the leather after main tanning has excellent strength and flexibility.

Owner:JIANGSU BESCON PHARMA

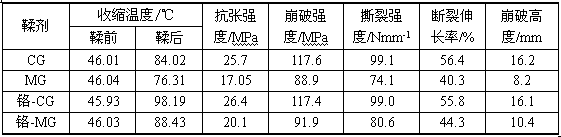

The process of extracting rare earth from southern rare earth ore by p204 extraction

ActiveCN106916949BReduce consumptionReduce concentrationProcess efficiency improvementKeroseneFractionation

Owner:张文欣

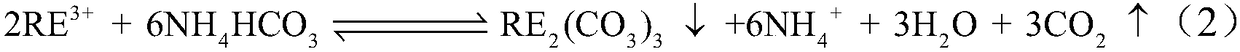

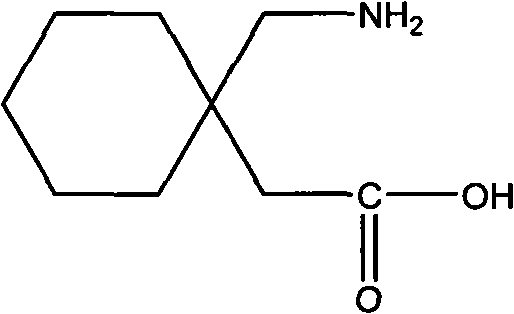

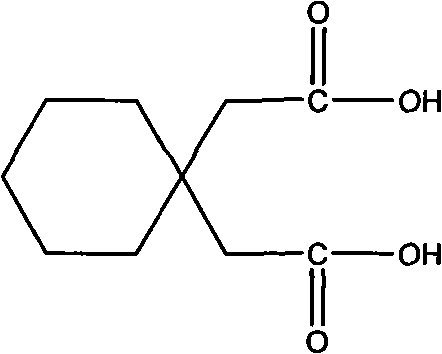

Method for utilizing dilute sulphuric acid to catalyze and hydrolyze alpha,alpha'-dicyano-1,1-cyclohexanediacetamide to prepare 1,1-cyclohexanediacetic acid

InactiveCN101717330AReduce usageReduce pollutionPreparation from nitrilesHydrolytic ProcessHigh pressure

The invention discloses a method for utilizing dilute sulphuric acid to catalyze and hydrolyze alpha,alpha'-dicyano-1,1-cyclohexanediacetamide to prepare 1,1-cyclohexanediacetic acid, comprising the steps of 1) adding dilute sulphuric acid aqueous solution with the mass concentration being between 2% and 20% and alpha,alpha'-dicyano-1,1-cyclohexanediacetamide into a high-pressure reactor, wherein the weight ratio between dilute sulphuric acid aqueous solution and alpha,alpha'-dicyano-1,1-cyclohexanediacetamide is 4:1 to 20:1; stirring and heating up to boiling under atmospheric pressure, then exhausting for 2 to 5 minutes; 2) heating up the reacting solution to 150-250 DEG C, then hydrolyzing for 10 to 120 minutes; 3) filtering to obtain filter cake after the cooling and standing of the reacting solution; 4) dissolving the filter cake hot ethanol aqueous solution and filtering while hot; and 5) crystallizing after cooling of the filtrate, filtering, washing and vacuum drying to obtain the product 1,1-cyclohexanediacetic acid. The method utilizes dilute sulphuric acid to hydrolyze in the hydrolytic process, thus reducing environment pollution, and greatly reducing the dosage of sulphuric acid and corrosion degree to apparatus; and the invention is characterized by simple reacting process, high products yield and purity, and highly improved greening degree in the production process.

Owner:ZHEJIANG UNIV

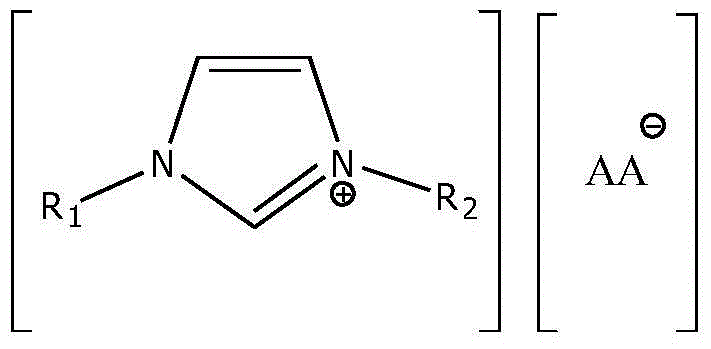

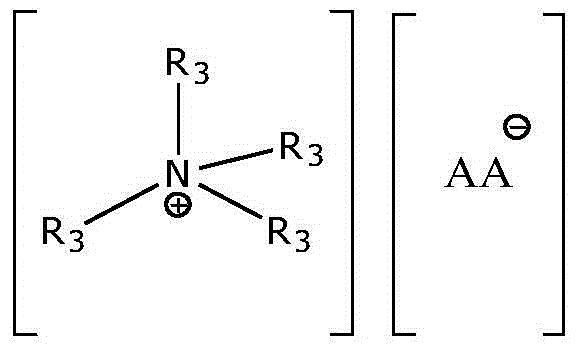

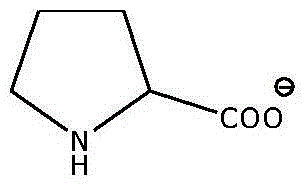

A kind of preparation method of proline ionic liquid catalytic synthesis dibutyl carbonate

ActiveCN103709032BImprove the efficiency of the exchange reactionHigh yieldOxygen-containing compound preparationOrganic compound preparationSolventN-Butyl Alcohol

The invention discloses a preparation method of dibutyl carbonate through catalyzed synthesis of a proline ionic liquid. The method comprises the following steps of preparing dibutyl carbonate through ester interexchange reaction of dibutyl carbonate and n-butyl alcohol by taking a proline ionic liquid as a catalyst, wherein a conversion ratio of the dibutyl carbonate under a set catalytic reaction condition is as high as 99%, and selectivity of the dibutyl carbonate can reach over 90%. Compared with the prior art, a green solvent ionic liquid is taken as a catalyst, and therefore, the preparation method disclosed by the invention has a plurality of advantages of being gentle in reaction condition, environment-friendly, high in reaction selectivity, high in product yield, convenient for recycling of the catalyst, and the like, and is an efficient green novel method of synthesizing the dibutyl carbonate.

Owner:JIANGXI NORMAL UNIV

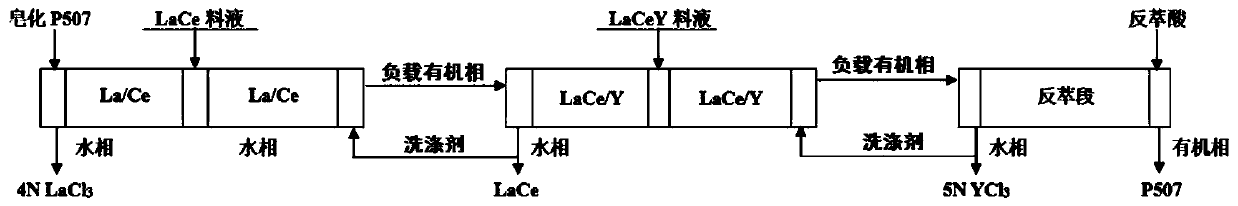

A simple method for co-production of pure lanthanum, rich cerium and pure yttrium

InactiveCN109133143BImprove stabilityReduce consumptionRare earth metal oxides/hydroxidesRare earth metal chloridesLanthanum(III) chlorideAqueous solution

The invention discloses a simple method for co-producing pure lanthanum, rich cerium and pure yttrium. The present invention uses P507 as extraction agent, TBP as modifier, lanthanum cerium chloride solution as the first feed liquid, and lanthanum cerium yttrium chloride solution as the second feed liquid; Fractional distillation extraction separation LaCe / Y and Y stripping section consists of three steps. An extraction and separation process flow of the present invention simultaneously obtains three products of 4N grade lanthanum chloride aqueous solution, 4N grade yttrium chloride aqueous solution and cerium-rich chloride aqueous solution. The invention can not only reduce the consumption of acid and alkali for preparing 4N-grade lanthanum and 4N-grade yttrium, but also improve the qualified rate of 4N-grade lanthanum and 4N-grade yttrium to a certain extent.

Owner:NANCHANG HANGKONG UNIVERSITY

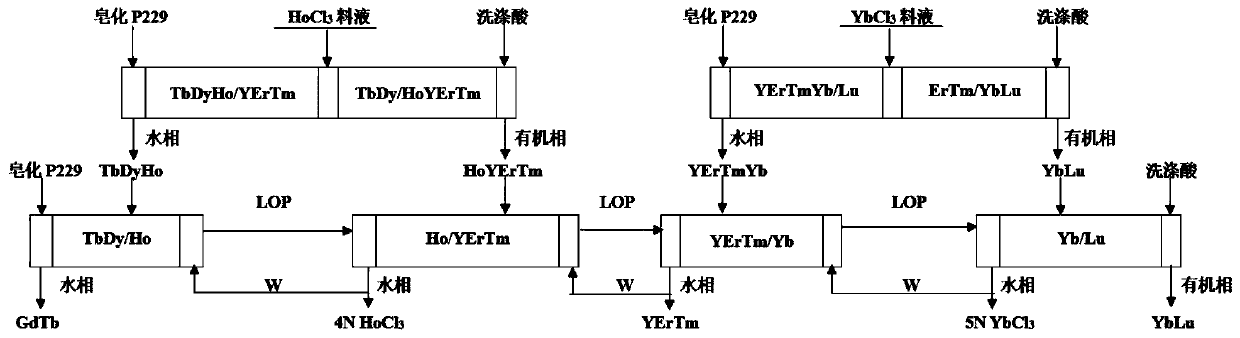

A kind of extraction and separation method of co-producing 4n holmium and 5n ytterbium

The invention discloses an extraction and separation method for the co-production of 4N holmium and 5N ytterbium. The extraction and separation method uses P229 as the extraction agent, 2N grade holmium chloride solution as the first material liquid, and 2N grade ytterbium chloride as the second material. Liquid; separation of TbDyHo / HoYErTm by fractional distillation extraction, separation of YErTmYb / YbLu by fractional distillation extraction, separation of TbDy / Ho by full-load fractionation extraction, separation of Ho / YErTm by full-load fractionation extraction, separation of YErTm / Yb by full-load fractionation extraction and separation of Yb / Lu by fractionation extraction composition. The invention can reduce the acid-base consumption for preparing 4N-grade holmium chloride and 5N-grade ytterbium chloride, and can improve the qualified rate of 4N-grade holmium chloride products.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for quasi-fractionation extraction and separation of sodium and potassium in lithium sulfate

InactiveCN106916947BHigh purityEasy to separateProcess efficiency improvementAlkaline earth metalKerosene

The invention discloses a method for extracting and separating sodium and potassium in lithium sulfate by quasi-fractionation, belonging to the technical field of solvent extraction. The 2N grade lithium sulfate solution after the alkaline earth metal impurities have been separated and removed is used as the feed liquid, t-BAMBP is used as the extractant, sulfonated kerosene is used as the diluent, lithium saponification t-BAMBP is used as the extraction organic phase, and the lithium sulfate feed solution is used for apparent washing Reagent, quasi-fractional extraction method to separate alkali metal impurities sodium and potassium in lithium sulfate. The lithium saponification organic phase enters the quasi-fractionation extraction system from the first stage, the lithium sulfate feed liquid enters the quasi-fractionation extraction system from the junction of the extraction section and the extraction section, and the apparent washing liquid enters from the last stage. Obtain the target product lithium sulfate solution from the first-stage outlet water phase, wherein the concentration of lithium is 1.0M~2.0M, the concentration of sodium is 2.5×10-7M~2.6×10-6M, and the concentration of potassium is 1.1×10-6M 8M~1.0×10‑7M. Concentrate and crystallize the obtained lithium sulfate solution to obtain hydrated lithium sulfate with a purity of 5N-6N. Compared with raw materials, the removal rate of sodium in the separated product is 99.978%-99.9969%, and the removal rate of potassium is 99.9983%-99.99957%.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com