Preparation method of chitosan modified graphite oxide functional leather tanning agent

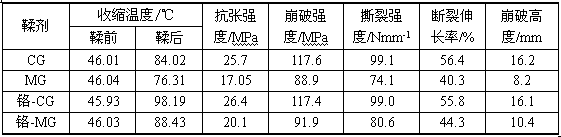

A technology of chitosan modification and oxidized stone, which is applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, tanning treatment, etc. It can solve the problems of poor softness, Aluminum tanning agent can solve problems such as flat and thin leather, water pollution, etc., and achieve good social and economic benefits, excellent strength and flexibility, and good filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

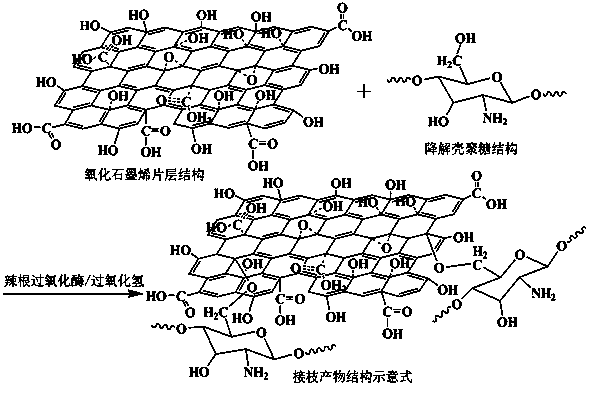

Method used

Image

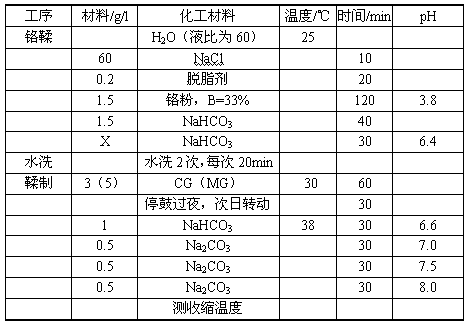

Examples

Embodiment 1

[0031] Mix and stir 10 parts by weight of graphite powder, 2 parts by weight of sodium nitrate and 80 parts by weight of concentrated sulfuric acid and slowly add 19 parts by weight of potassium permanganate. The temperature of this process is 5°C; then heat up to 45°C for water bath reaction 60min, after gradually adding 360 parts by weight of deionized water, the temperature was raised to 58°C to continue the reaction for 4h; then 24 parts by weight of hydrogen peroxide solution with a mass fraction of 30% was added dropwise, washed 5 times to make 1000 parts by weight of Suspension, after ultrasonic treatment for 30min, set aside;

[0032] Step 2: Preparation of degraded chitosan solution:

[0033] Mix 20 parts by weight of chitosan with 100 parts of deionized water and 0.1 part of high-temperature α-amylase in the reactor and heat it to 80°C for degradation, and measure its viscosity at 80°C with NDJ-5S digital rotational viscometer After about 5.5mpa??s, cool down to roo...

Embodiment 2

[0038] Mix and stir 10 parts by weight of graphite powder, 2 parts by weight of sodium nitrate and 80 parts by weight of concentrated sulfuric acid and slowly add 19 parts by weight of potassium permanganate. The temperature of this process is 15°C; then heat up to 45°C for water bath reaction 60min, after gradually adding 360 parts by weight of deionized water, the temperature was raised to 58°C to continue the reaction for 4h; then 24 parts by weight of hydrogen peroxide solution with a mass fraction of 30% was added dropwise, washed 5 times to make 1000 parts by weight of Suspension, after ultrasonic treatment for 30min, set aside;

[0039] Step 2: Preparation of degraded chitosan solution:

[0040] Mix 25 parts by weight of chitosan, 125 parts of deionized water, and 0.3 parts of high-temperature α-amylase in a reactor and heat it to 90°C for degradation, and measure its viscosity with a NDJ-5S digital rotational viscometer at 80°C After about 5.5mpa??s, cool down to room...

Embodiment 3

[0045]Mix and stir 10 parts by weight of graphite powder, 2 parts by weight of sodium nitrate and 80 parts by weight of concentrated sulfuric acid and slowly add 19 parts by weight of potassium permanganate. The temperature of this process is 25°C; then heat up to 45°C for water bath reaction 60min, after gradually adding 360 parts by weight of deionized water, the temperature was raised to 58°C to continue the reaction for 4h; then 24 parts by weight of hydrogen peroxide solution with a mass fraction of 30% was added dropwise, washed 5 times to make 1000 parts by weight of Suspension, after ultrasonic treatment for 30min, set aside;

[0046] Step 2: Preparation of degraded chitosan solution:

[0047] Mix 30 parts by weight of chitosan with 150 parts of deionized water and 0.3 parts of high-temperature α-amylase in a reactor and heat it to 85°C for degradation, and measure its viscosity at 80°C with an NDJ-5S digital rotational viscometer After about 5.5mpa??s, cool down to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com