Manipulator internal-grab device based on worm-gear and crank-link transmission

A crank connecting rod and grabbing device technology, which is applied in the field of machinery, can solve problems such as not being able to meet the needs of economic development, and achieve the effects of reducing energy consumption, improving labor intensity of workers, and improving labor productivity and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

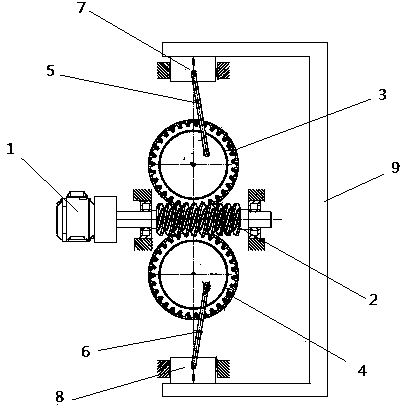

[0021] like figure 1 As shown, an inner gripping device of a manipulator based on the transmission of a worm gear and a crank connecting rod comprises an upper worm gear 3 and a lower worm gear 4, and the upper and lower crank connecting rods 5 and the lower crank connecting rod 6 are respectively hinged on the upper and lower worm gears, The end of the upper crank connecting rod 5 is fixedly connected with an upper grabbing head 7, and the end of the lower crank connecting rod 6 is fixedly connected with a lower grabbing head 8, and the upper and lower worm gears are driven by the same worm 2 that meshes with it, The two grabbing heads drive the crank connecting rod through the rotation of the upper and lower worm gears, so that the grabbing heads hold the workpiece tightly, and the worm 2 is driven by the deceleration motor 1 .

[0022] After the reduction motor 1 is driven, the output torque drives the worm 2 to rotate, the upper part of the worm 2 meshes with the upper wor...

Embodiment 2

[0025] The invention also discloses an inner gripping device of a manipulator based on the transmission of a worm worm gear and a crank connecting rod, which comprises three worm gears, a crank connecting rod is hinged on each worm gear, and the end of each crank connecting rod is fixedly connected with a gripping rod. The indenter, the three worm gears form an included angle of 120° with each other and are arranged along the peripheral surface of the worm, and the worm is driven by the worm, and the worm is driven by a deceleration motor.

[0026] The only difference between the second embodiment (not shown) and the first embodiment is that there are three worm gears arranged along the peripheral surface of the worm at an included angle of 120°, which facilitates the realization of three-point support for the cylindrical workpiece and the realization of fixation. , thereby expanding the scope of use of the inner grabbing device, the principle is the same as that of Embodiment ...

Embodiment 3

[0028] The invention also discloses an inner grasping device of a manipulator based on the transmission of a worm worm gear and a crank connecting rod. The indenter, the four worm gears form an included angle of 90° with each other and are arranged along the peripheral surface of the worm, and the worm is driven by the worm, and the worm is driven by a deceleration motor.

[0029] The only difference between this embodiment 3 (not shown) and the first embodiment is that there are four worm gears arranged along the peripheral surface of the worm with an included angle of 90° to each other, which is convenient to realize four-point support and fixation for larger workpieces. Thus, the scope of use and the fixing effect of the inner grabbing device are expanded, and the principle is the same as that of Embodiment 1, and will not be repeated here.

[0030] To sum up, the present invention provides an inner grasping device of a manipulator based on the transmission of a worm worm g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com