Patents

Literature

35results about How to "Large boost ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

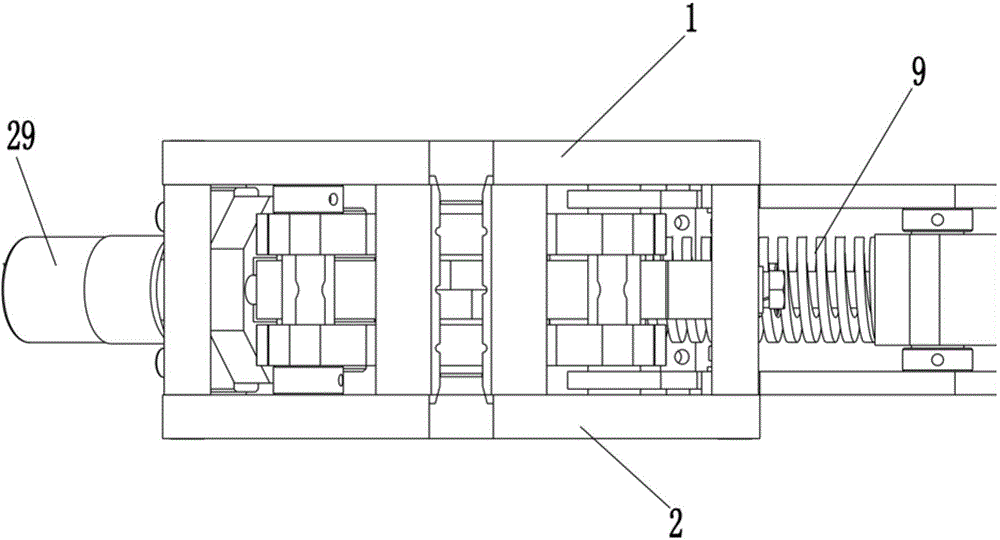

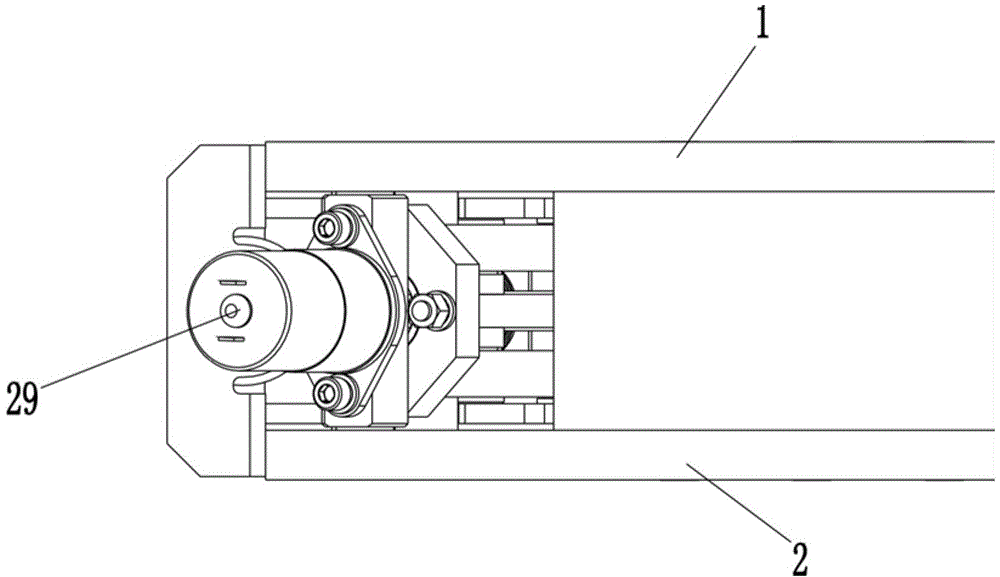

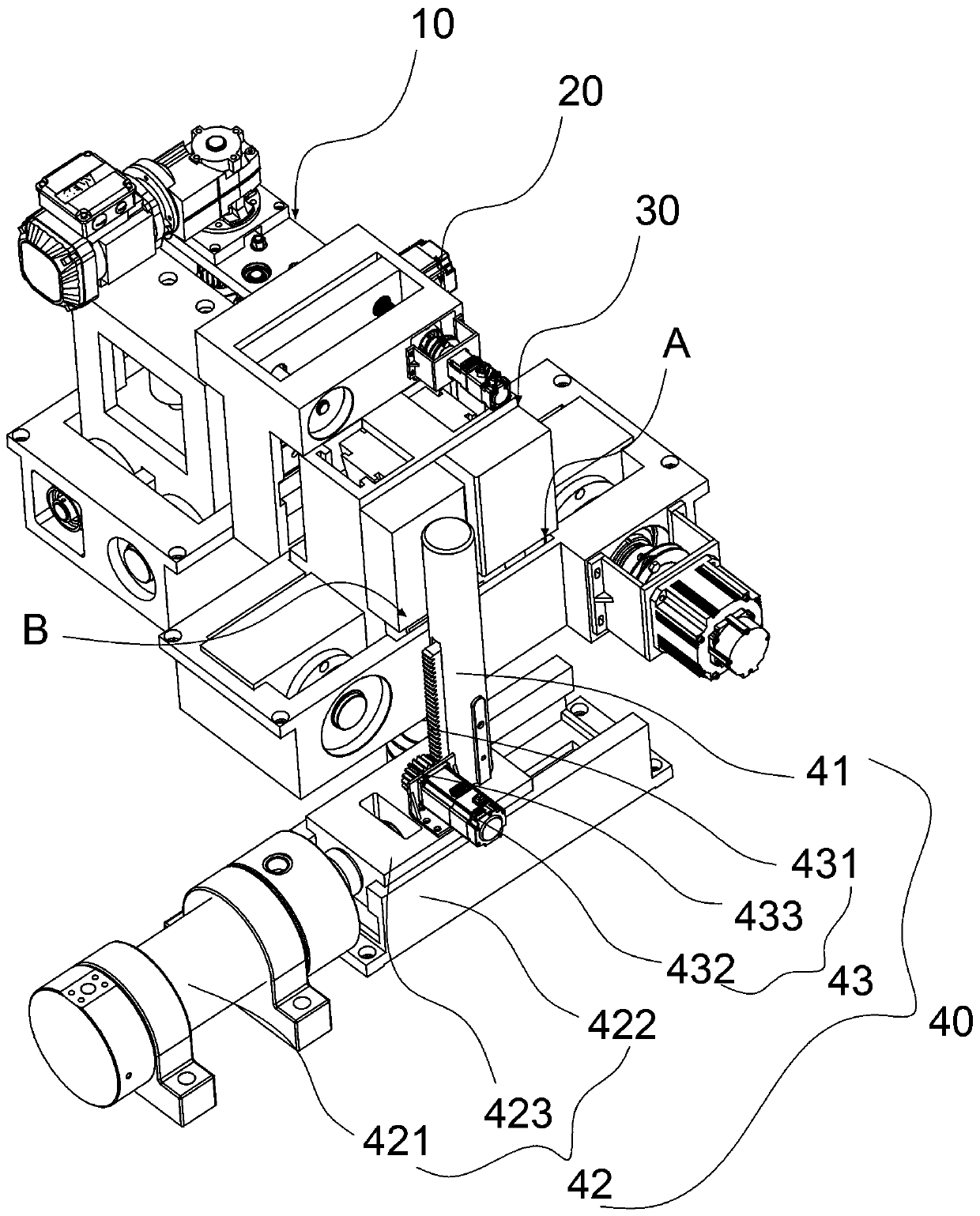

On-orbit repeated locking and releasing mechanism for space

InactiveCN106608373ARestricted degrees of freedomNon-affecting gestureCosmonautic component separationLocking mechanismEngineering

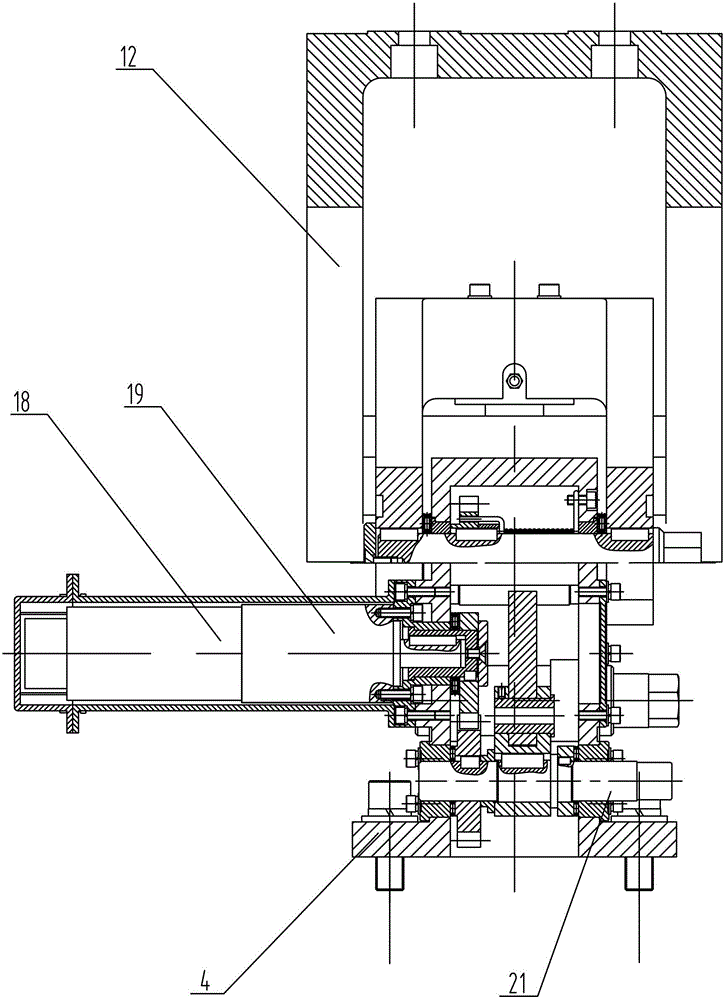

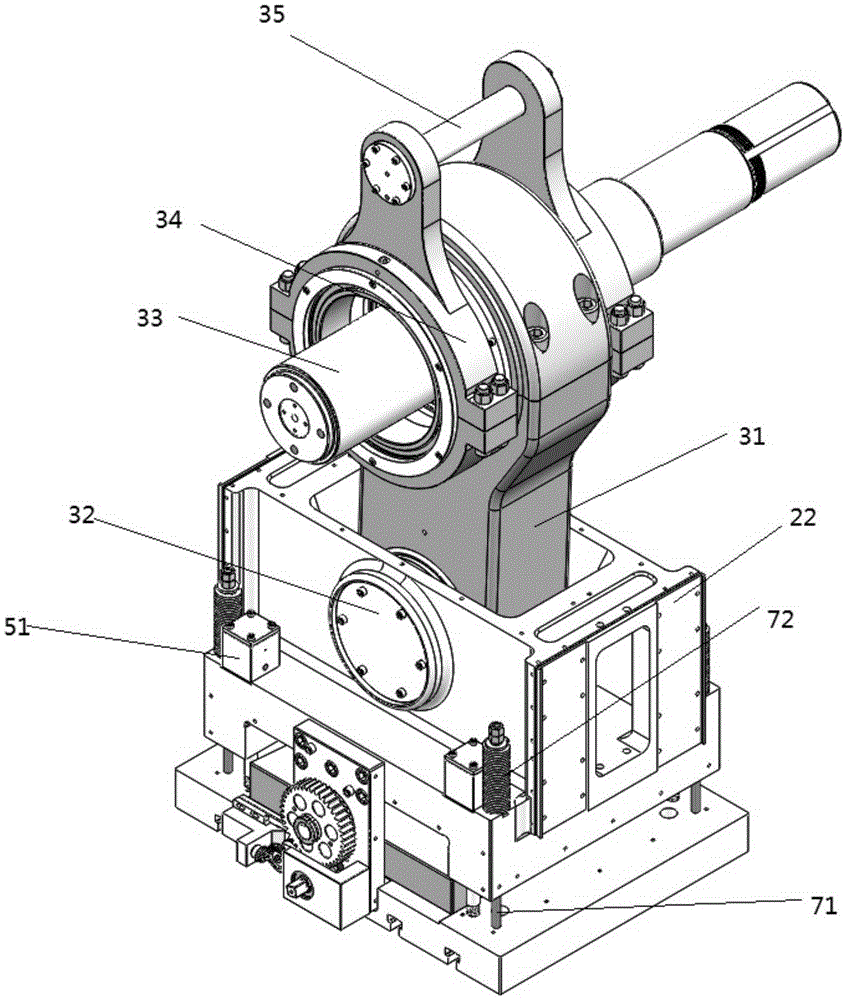

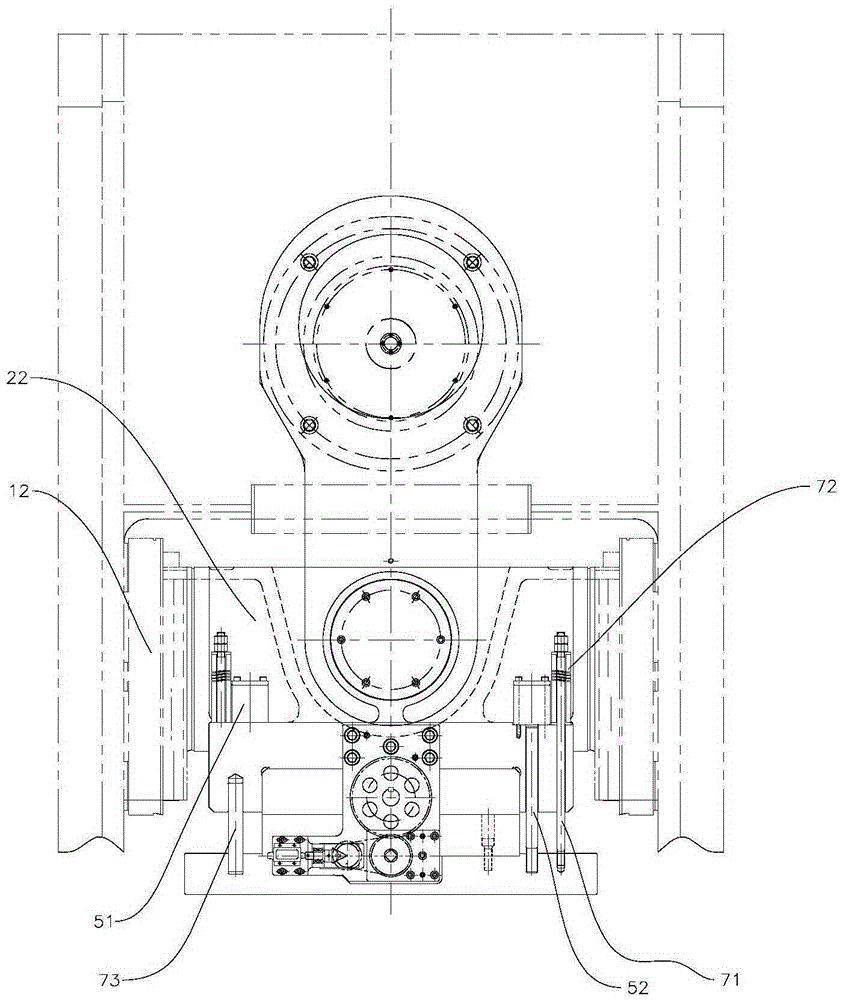

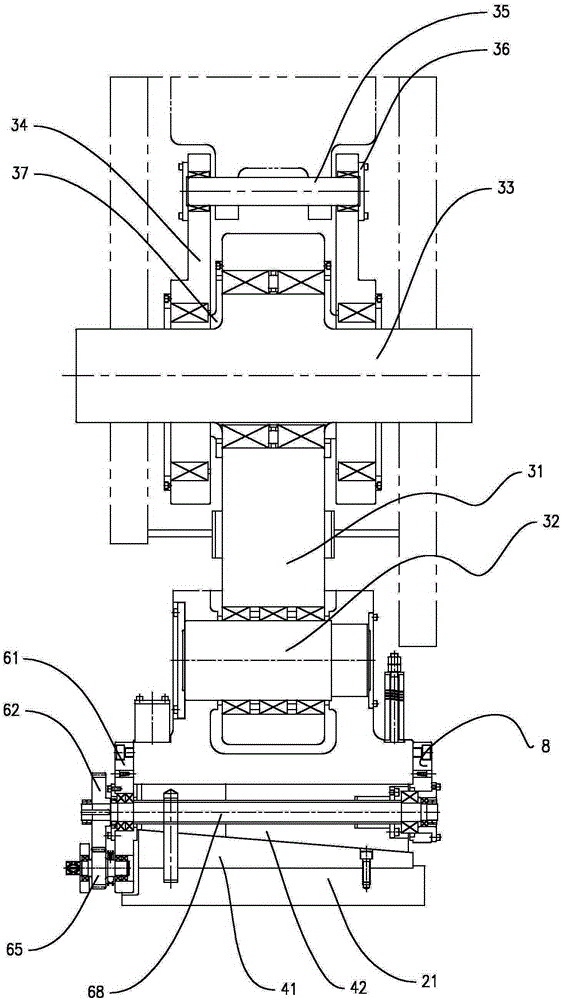

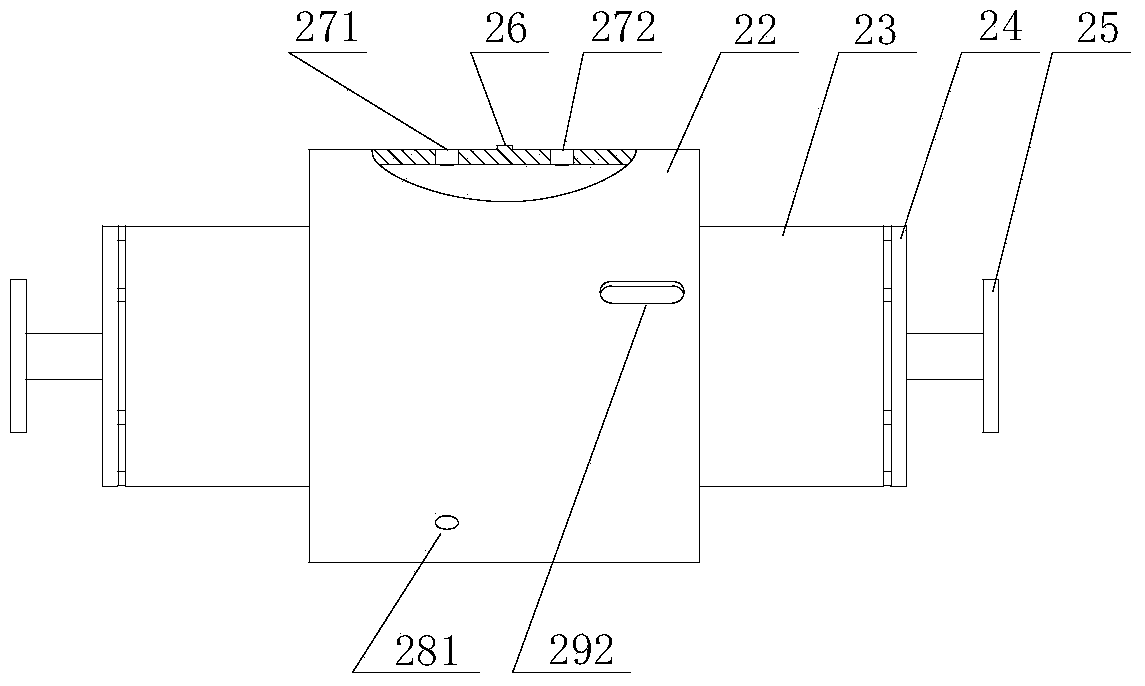

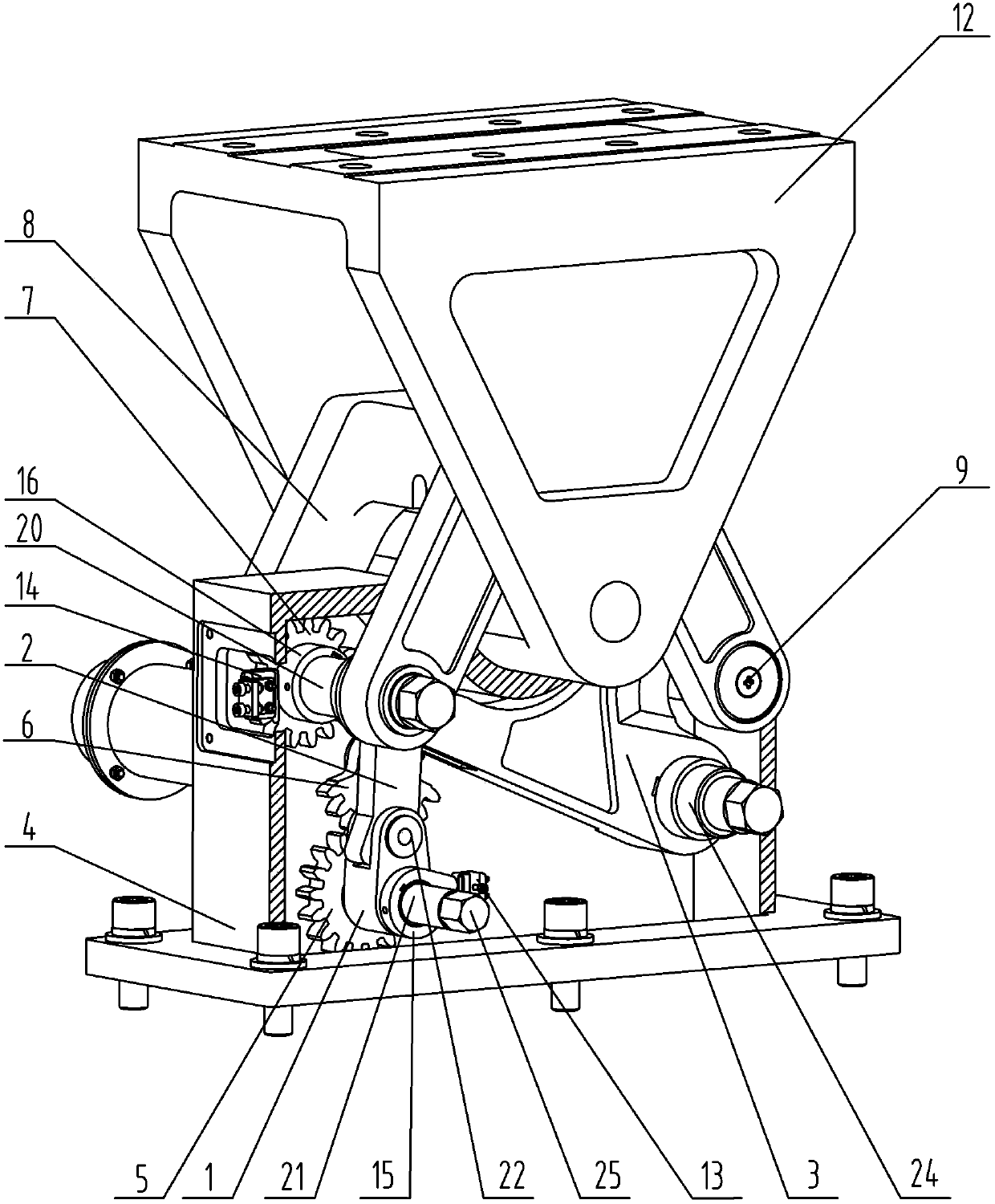

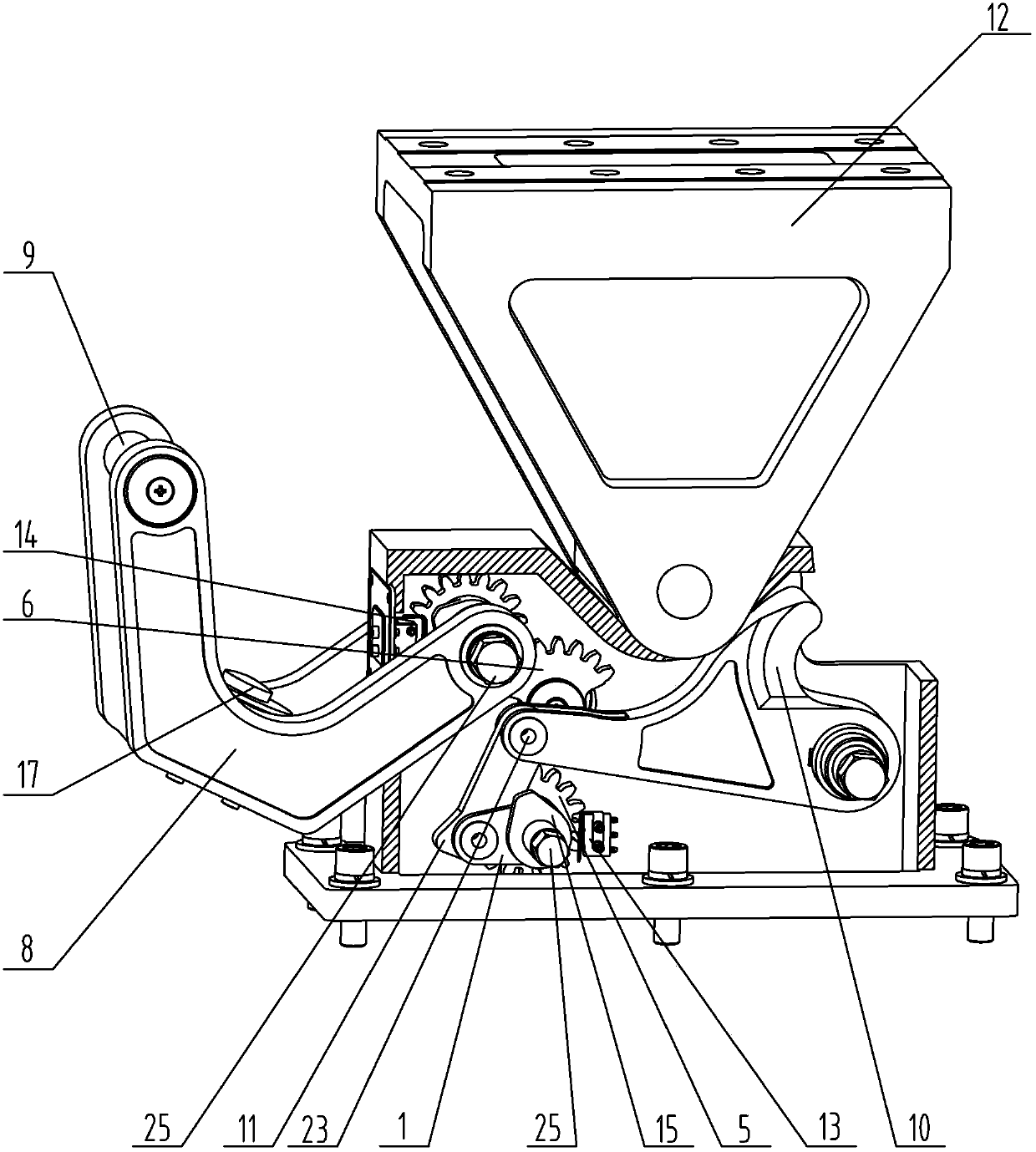

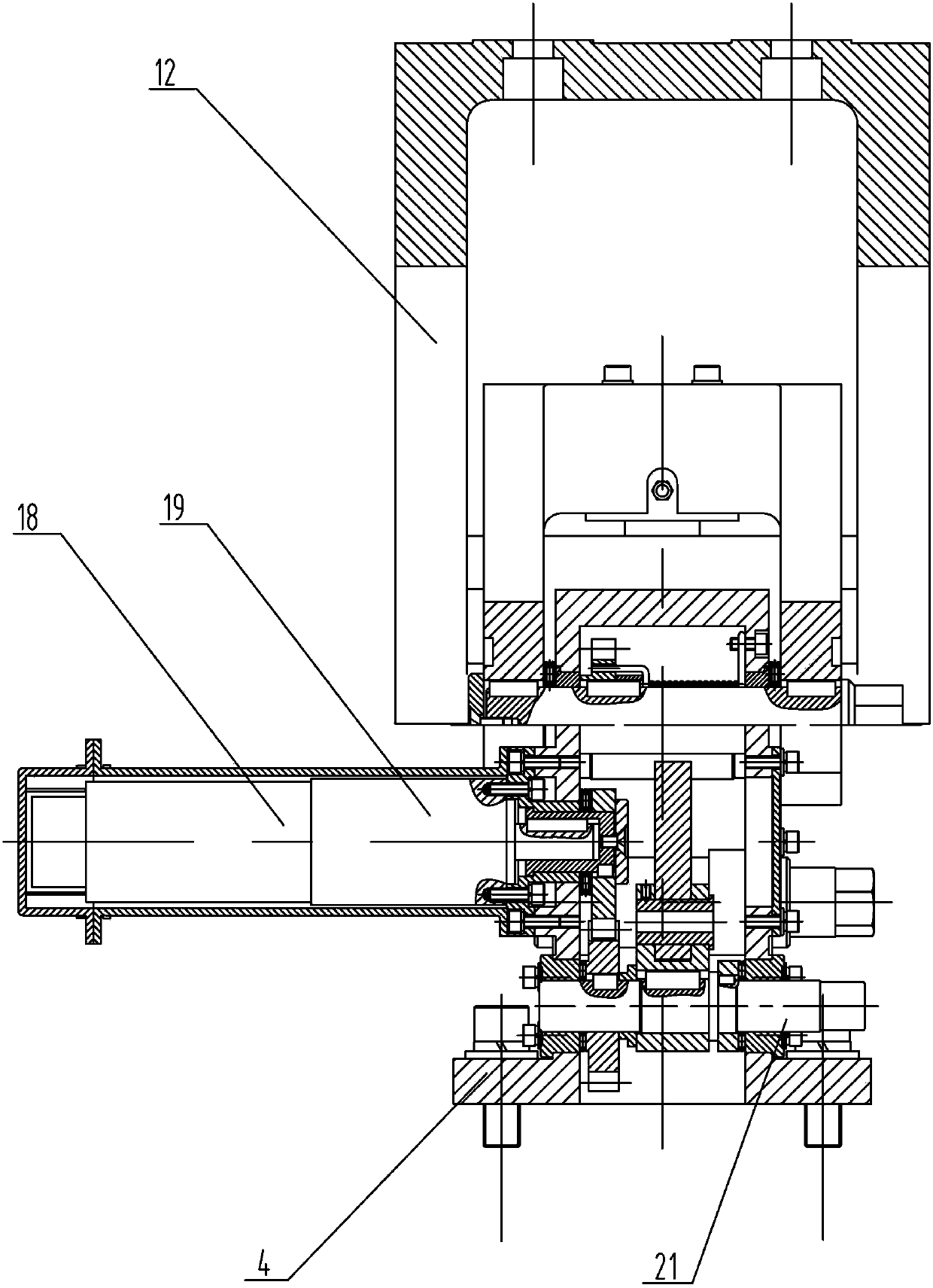

The invention relates to a repeated locking and releasing mechanism, in particular to an on-orbit repeated locking and releasing mechanism for space, and aims to solve the problem of repeated on-orbit locking and releasing of a large-scale actual load in a spacecraft. The on-orbit repeated locking and releasing mechanism comprises a trunnion locking mechanism, a lock hook compacting mechanism, a base locking mechanism, a crank and rocker mechanism and a driving gear mechanism, wherein the trunnion locking mechanism is arranged at the upper end of the base locking mechanism; and the driving gear mechanism is connected with the lock hook compacting mechanism and the crank and rocker mechanism. According to the on-orbit repeated locking and releasing mechanism disclosed by the invention, the trunnion locking mechanism, the lock hook compacting mechanism, the base locking mechanism, the crank and rocker mechanism and the driving gear mechanism are arranged in a crossed manner, so that the on-orbit repeated locking and releasing mechanism is simple and compact in structure; all the freedom degrees of a fixed object can be completely limited, and repeated locking can be realized; the maneuverability is good, so that the using requirement of on-orbit locking-releasing-relocking can be met. The on-orbit repeated locking and releasing mechanism disclosed by the invention is suitable for the technical field of aerospace and the technical field of electromechanical integration.

Owner:赵士野

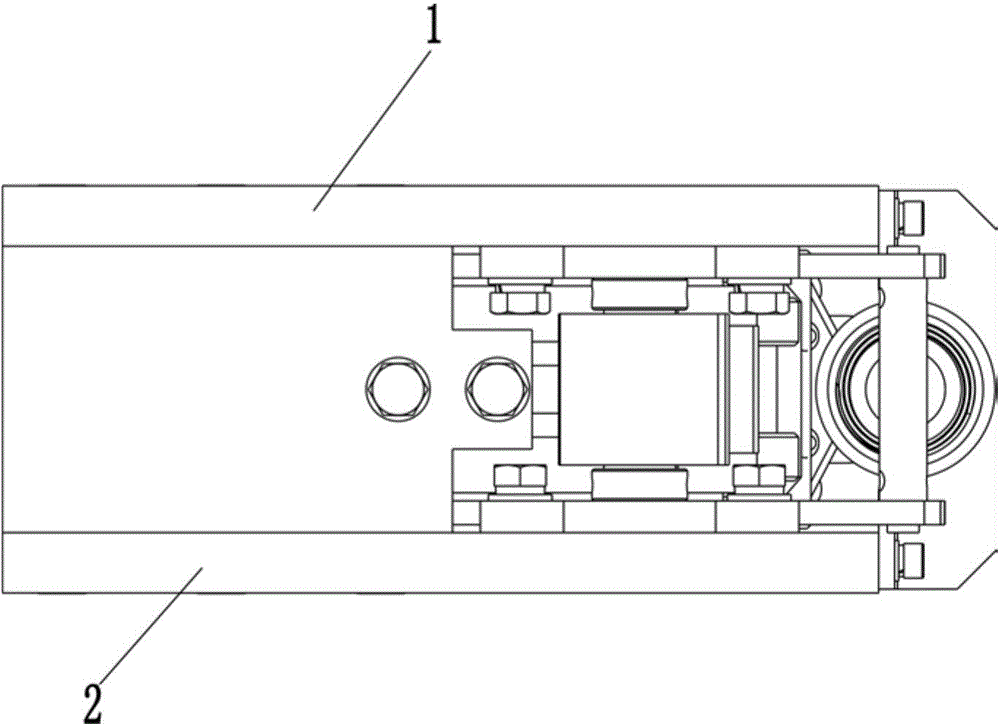

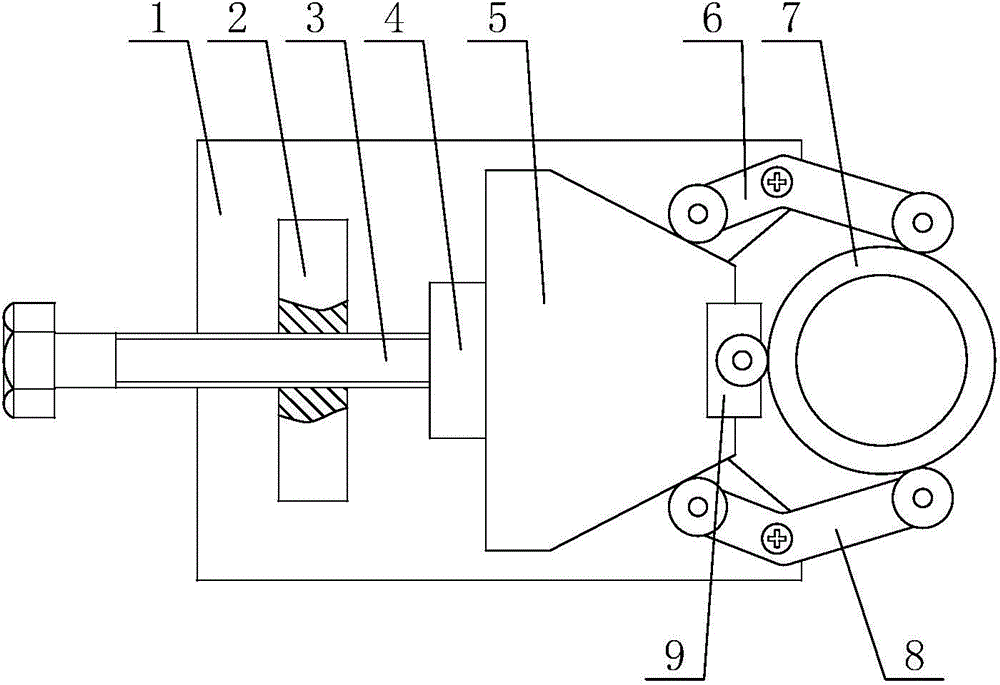

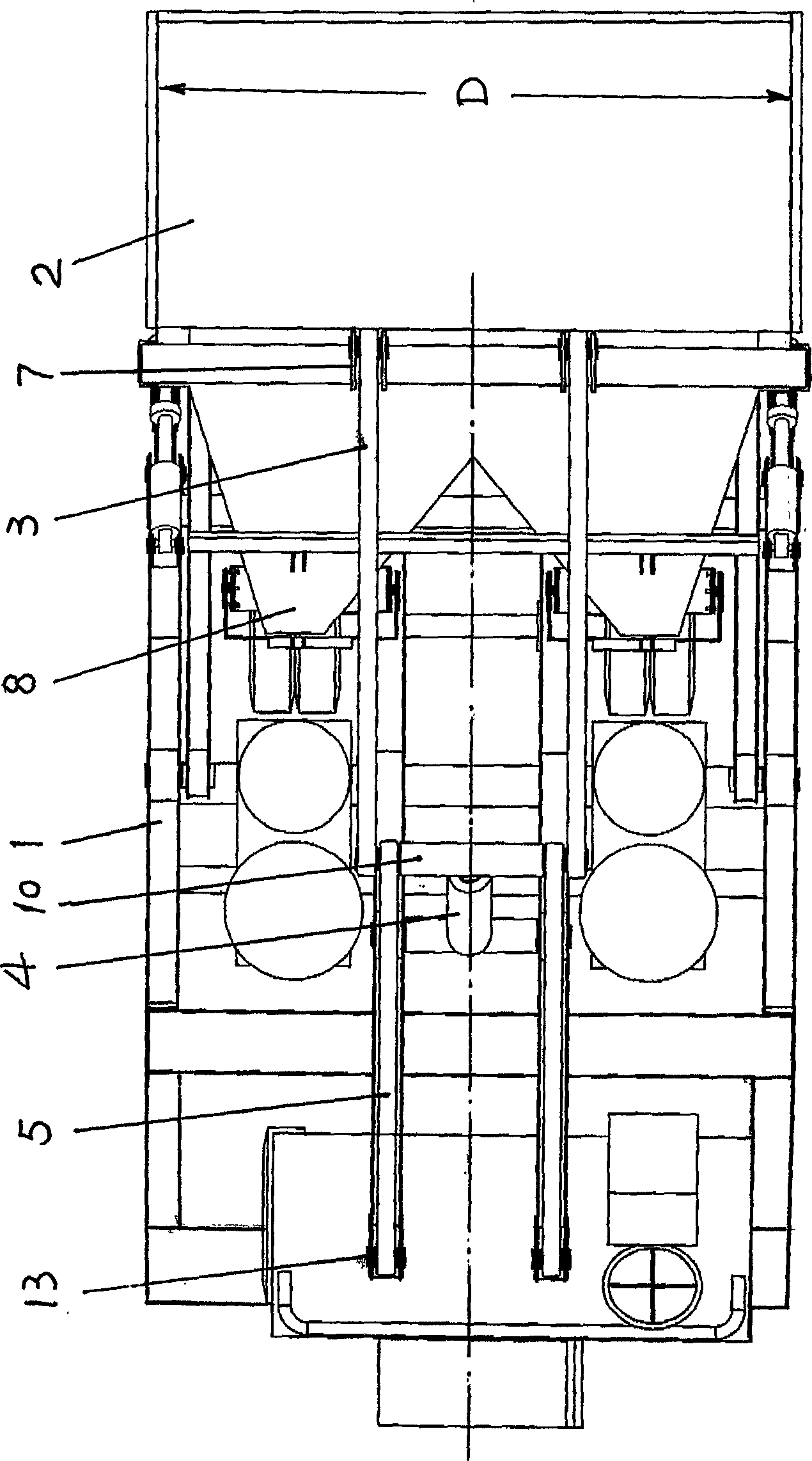

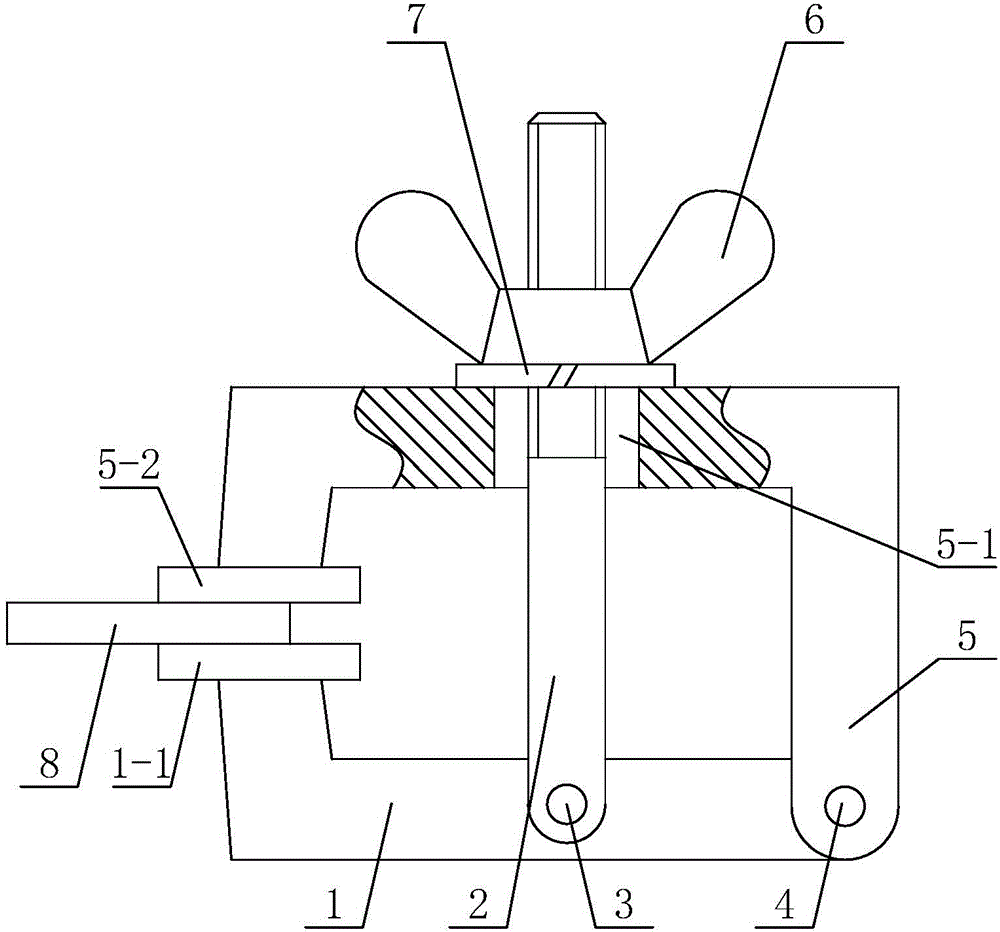

Combined elevator rail clamping device

The invention discloses a combined elevator rail clamping device which comprises two mounting plates. The two mounting plates are vertically and parallelly laid to form corresponding notches, a translational brake block is arranged between the mounting plates on two sides of each notch, clamping surfaces of the two brake blocks are opposite, a distance is reserved between the clamping surfaces of the two brake blocks, a trigger mechanism and a reset mechanism are arranged between the two mounting plates, the trigger mechanism is an electromagnet, the reset mechanism is a motor, a force-amplifying mechanism is arranged between the two mounting plates, the trigger mechanism triggers the brake blocks to clamp rails towards the opposite side through the force-amplifying mechanism, and the force-amplifying mechanism after rail clamping action is reset by the reset mechanism. By the aid of the combined elevator rail clamping device, excessive speed is controlled by the aid of the trigger mechanism, the reset mechanism and the force-amplifying mechanism, and the elevator rail clamping device is stable in operation and reliable to control. By means of secondary force amplifying, force-amplifying ratio is large, and performances are reliable.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

Threaded self-locking type automatic centering work fixture used for annular workpiece

InactiveCN105729147AReasonable designCompact structureWork holdersPositioning apparatusSelf lockingEngineering

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

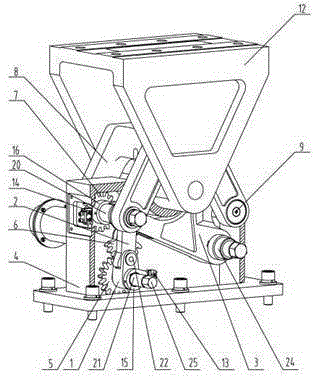

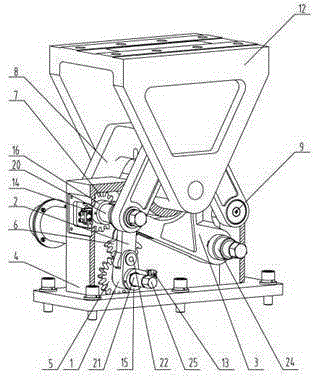

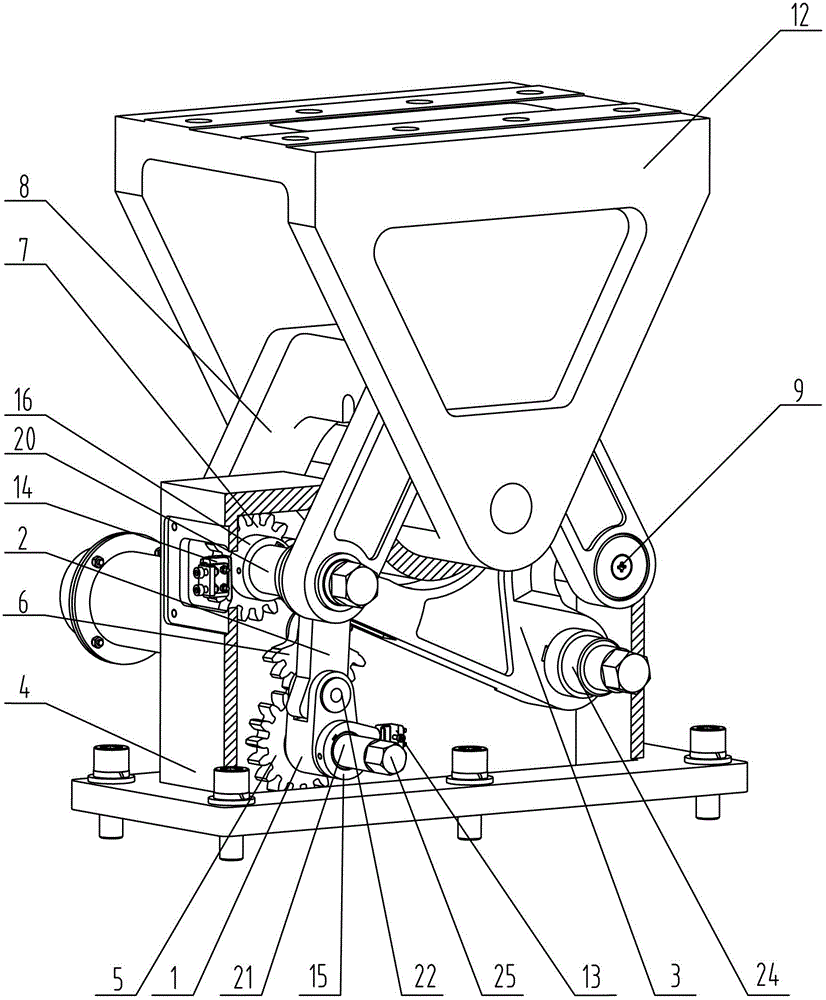

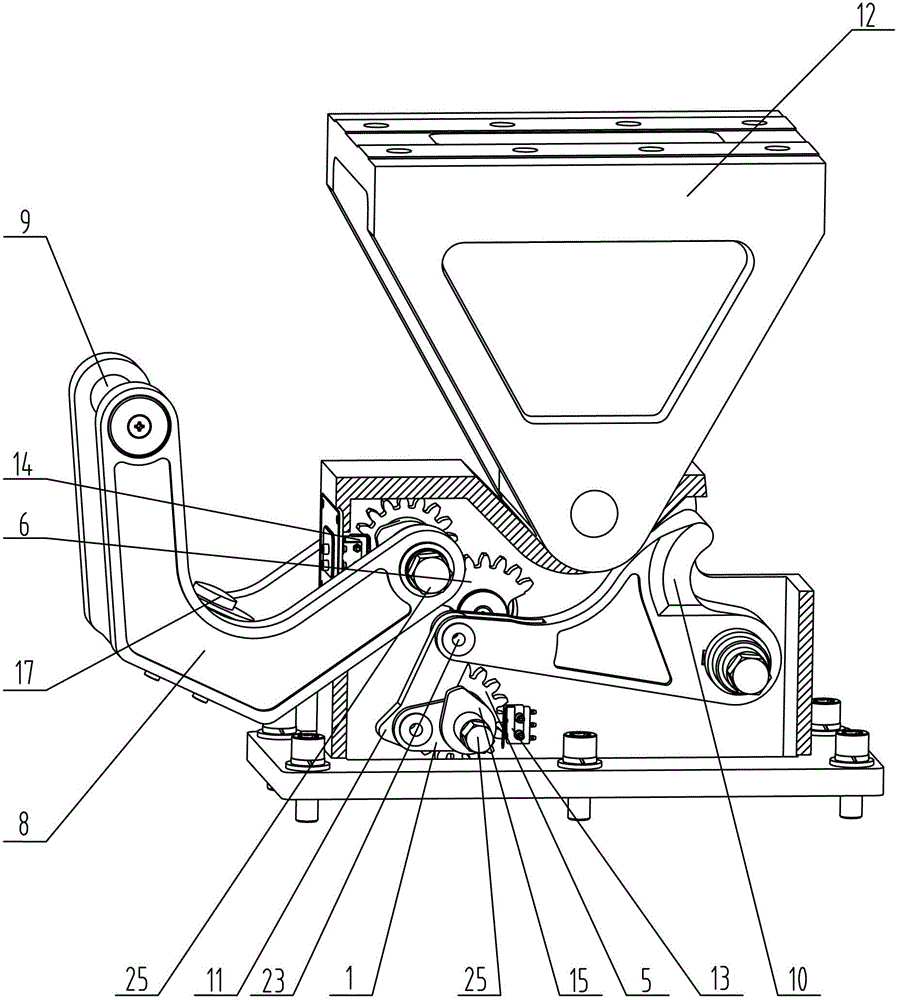

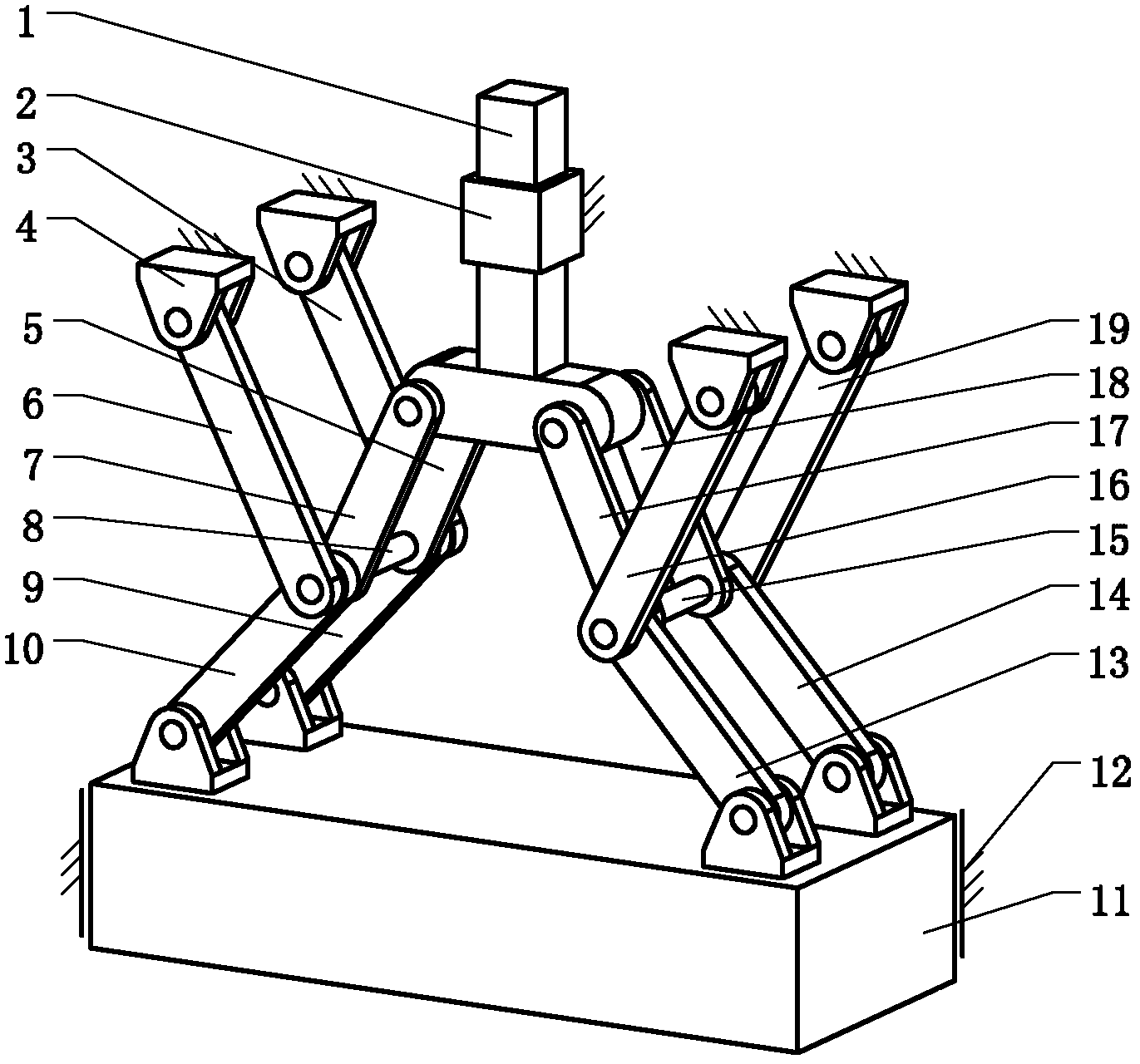

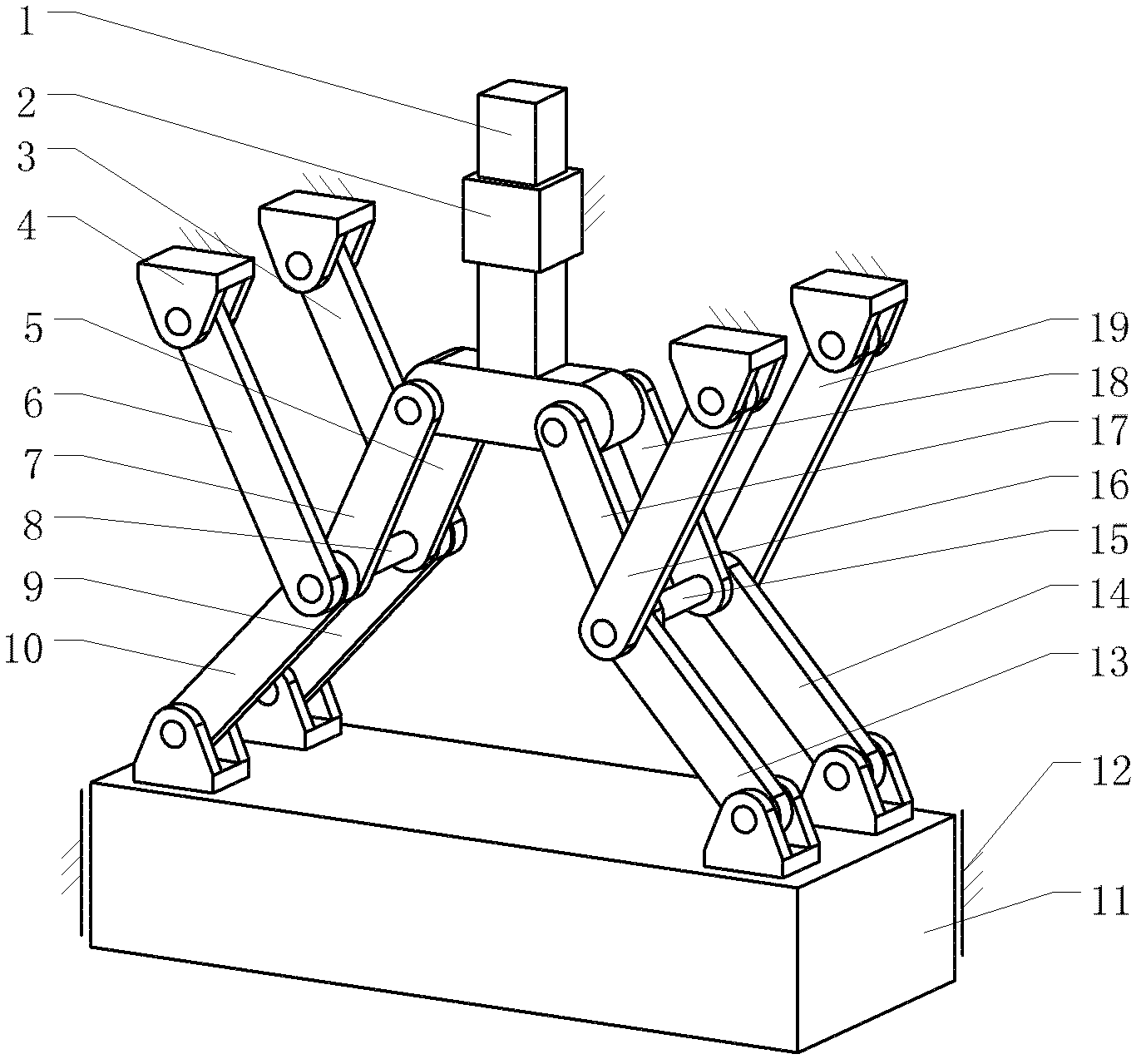

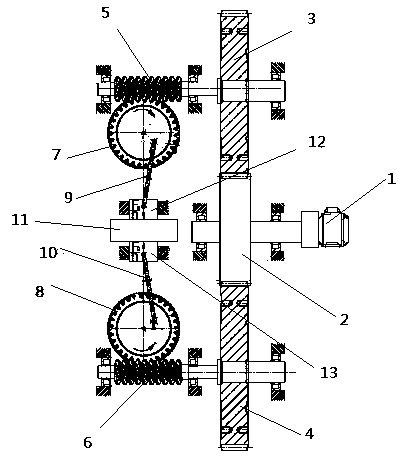

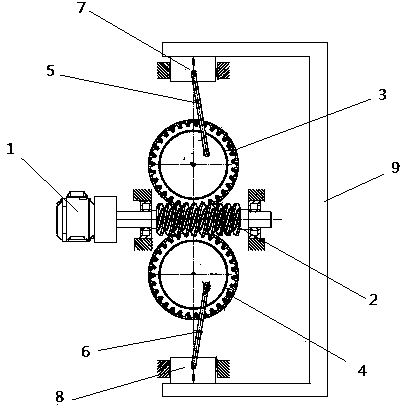

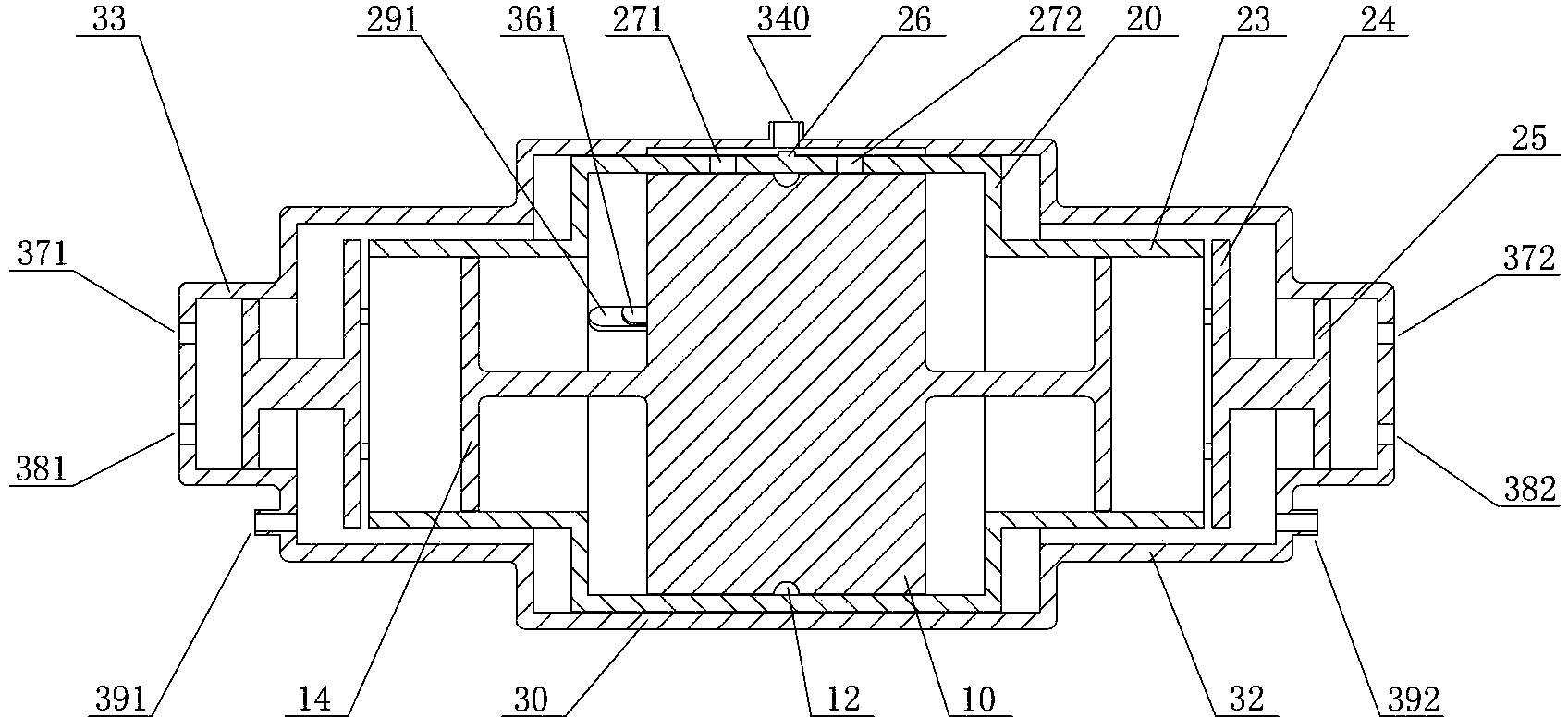

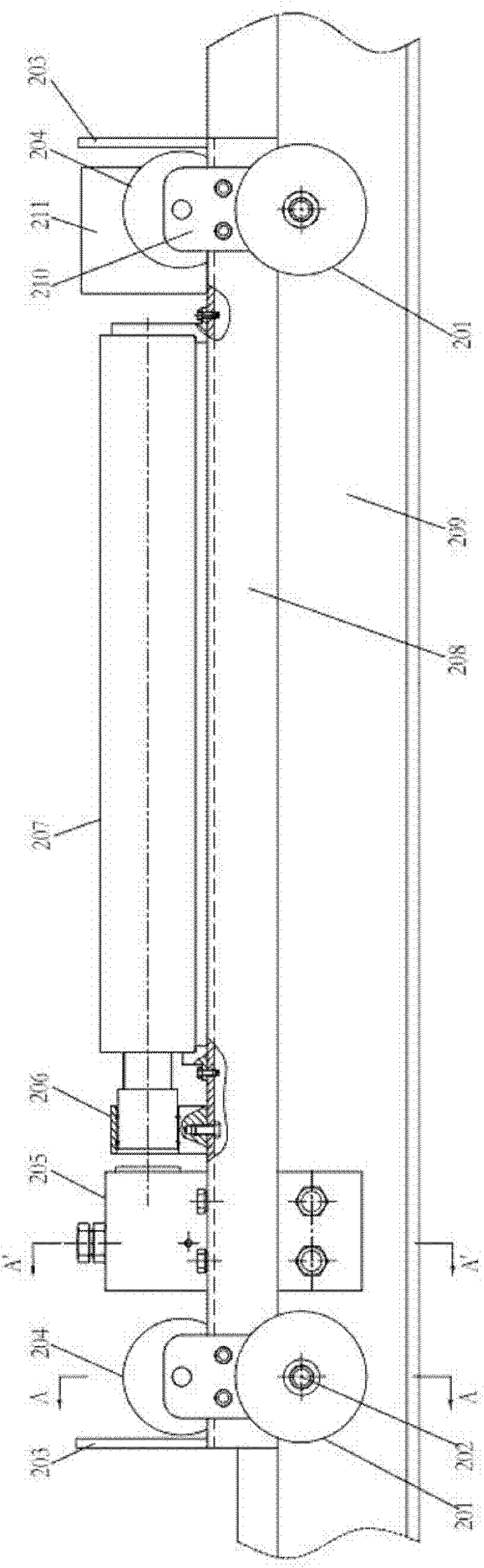

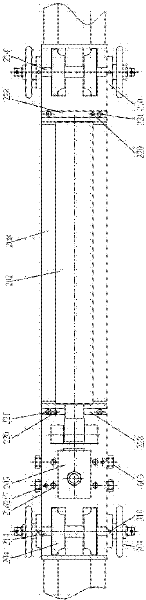

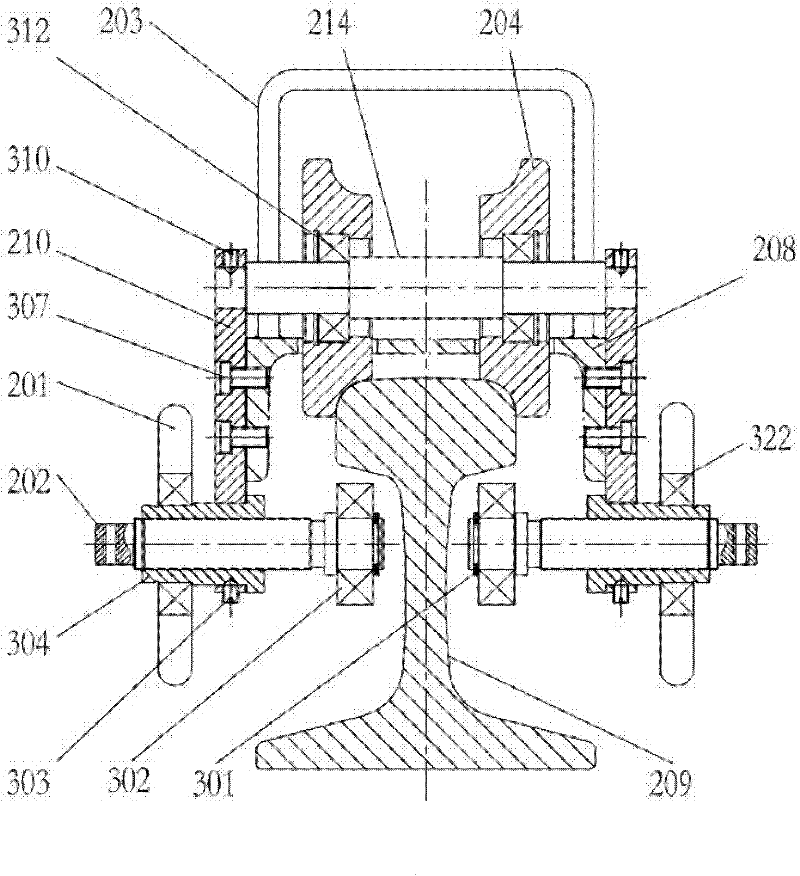

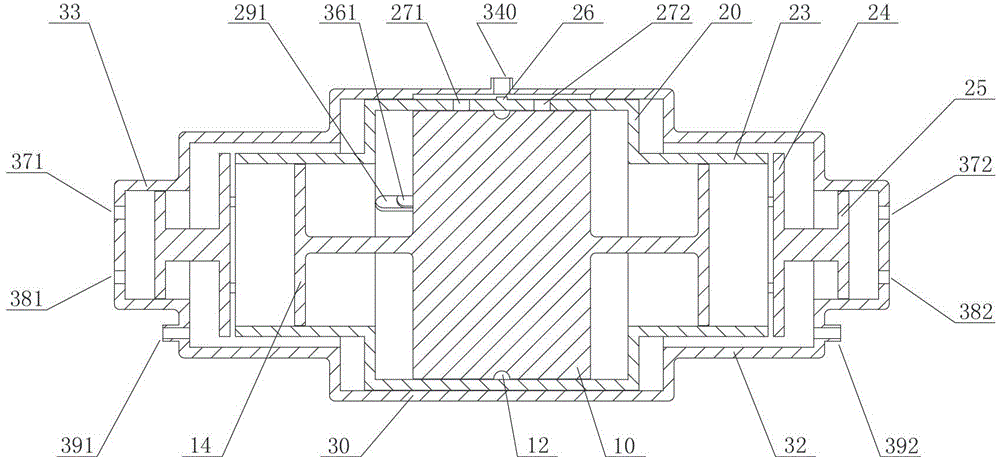

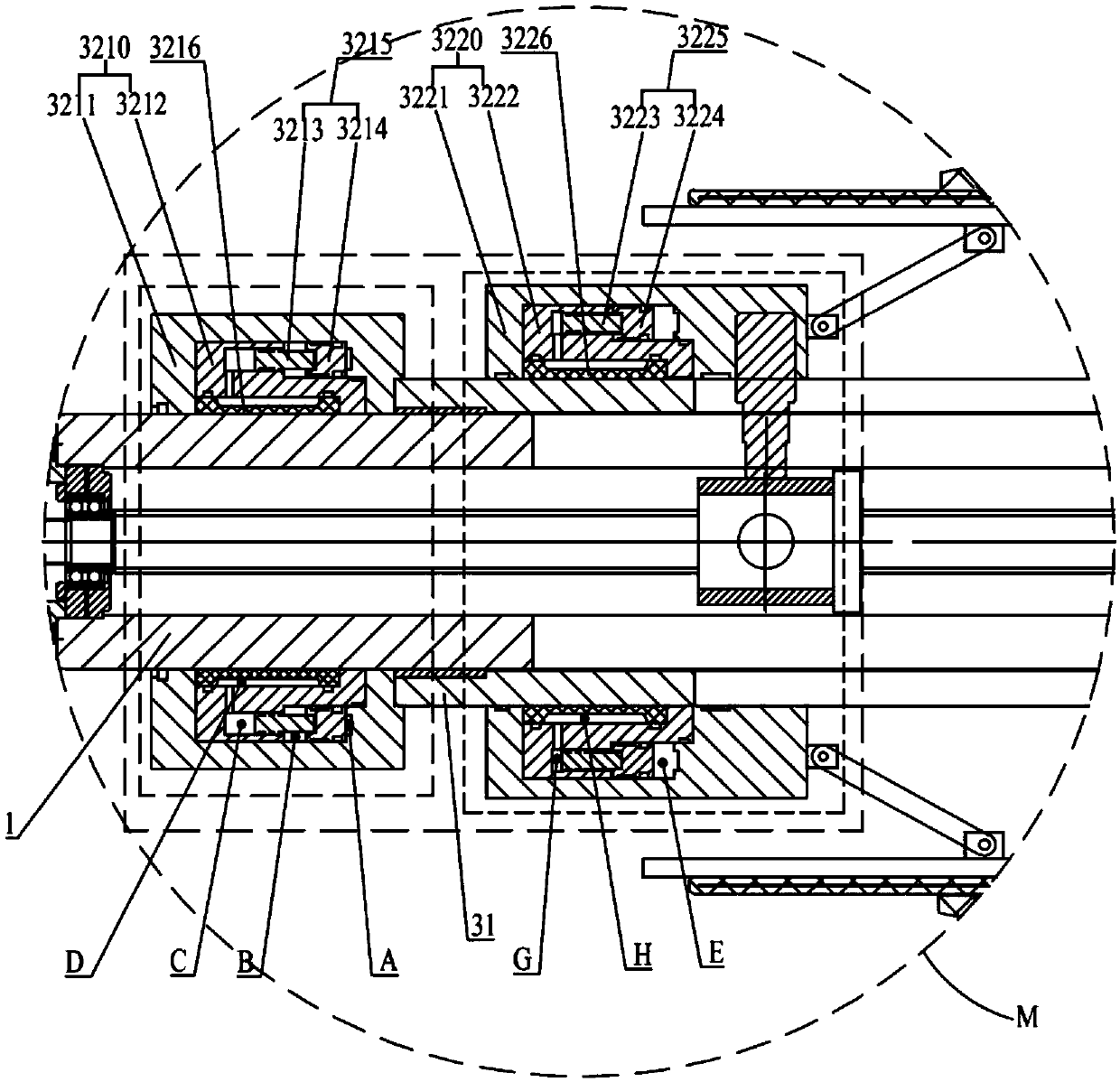

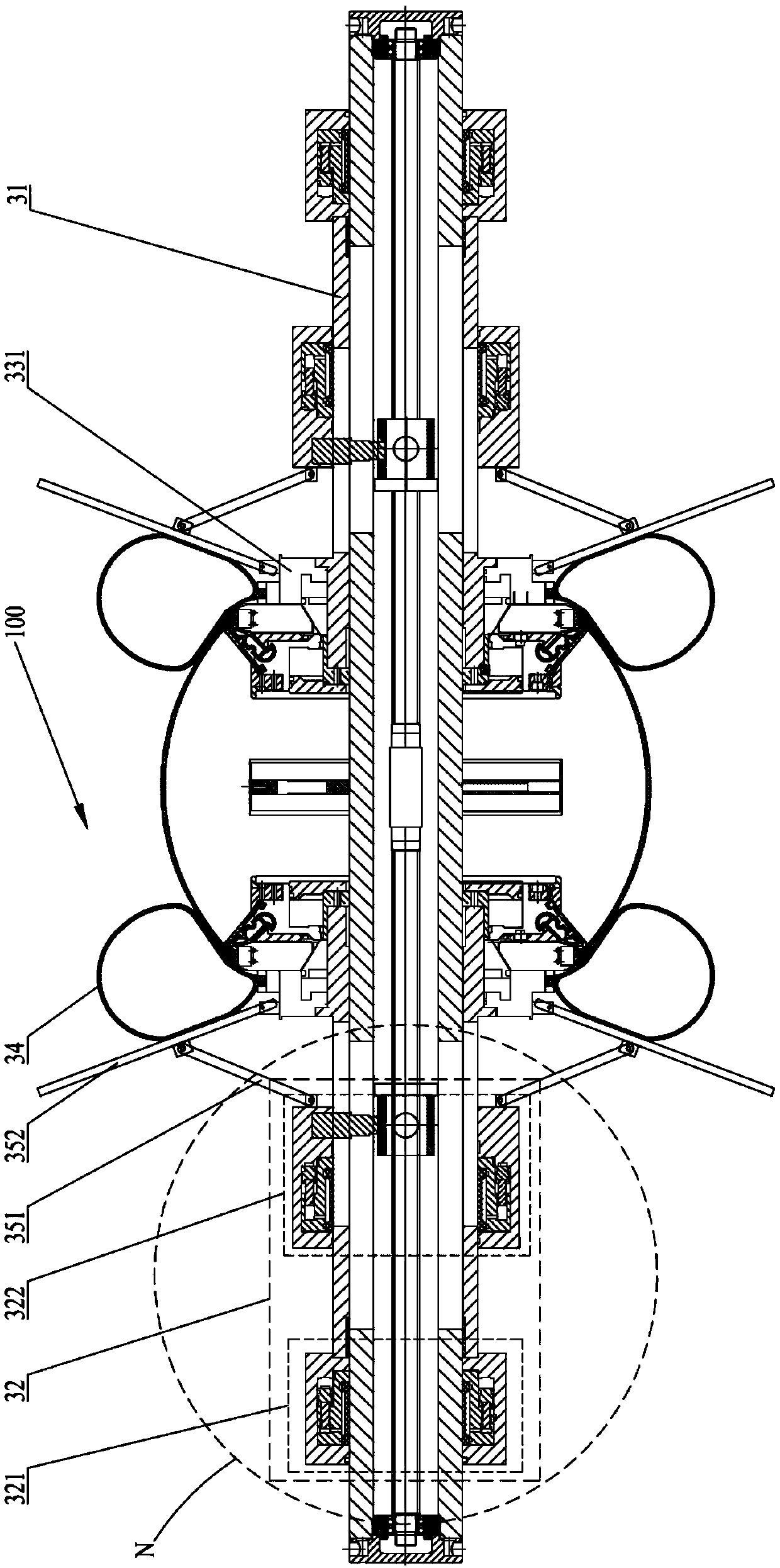

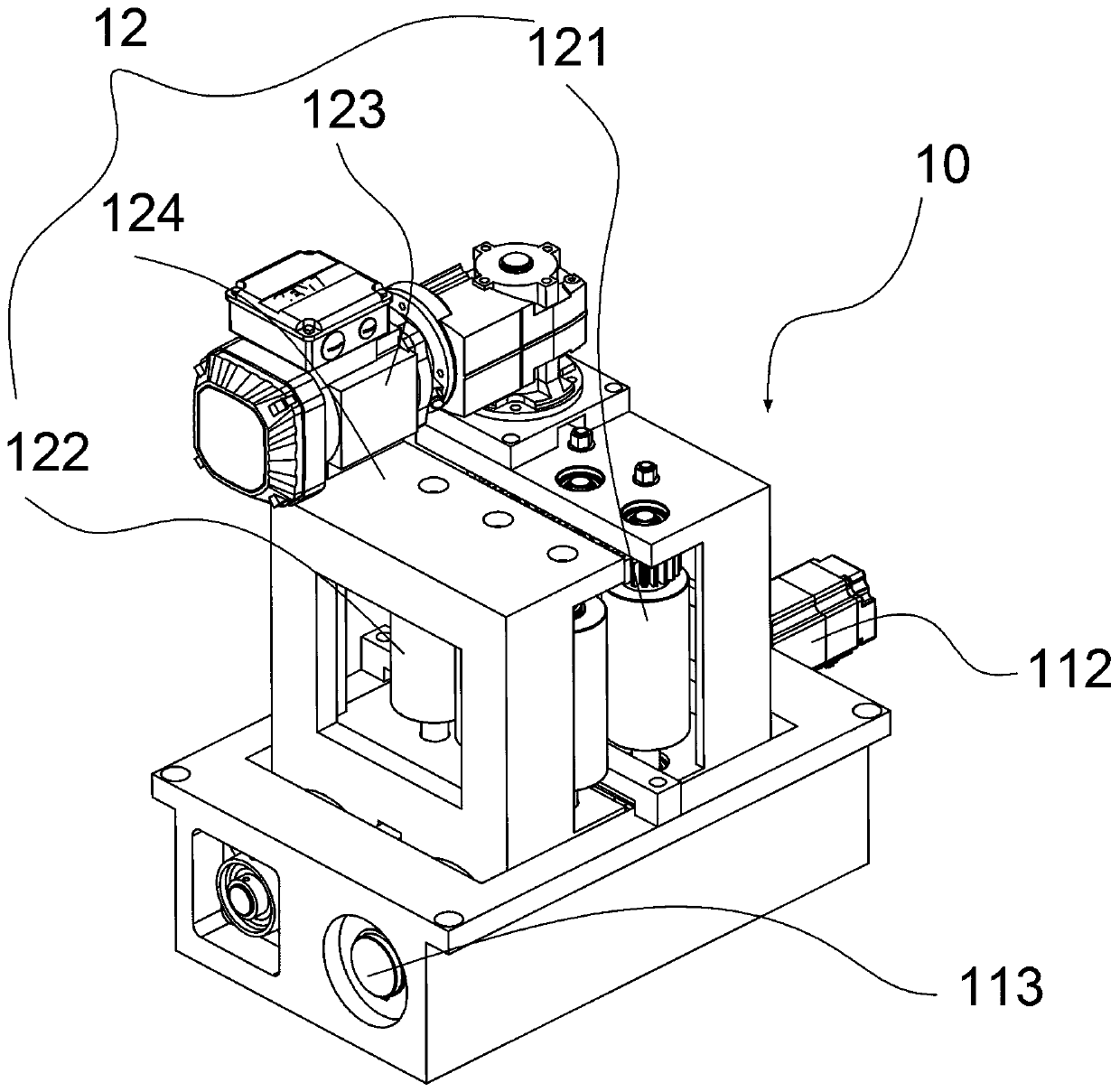

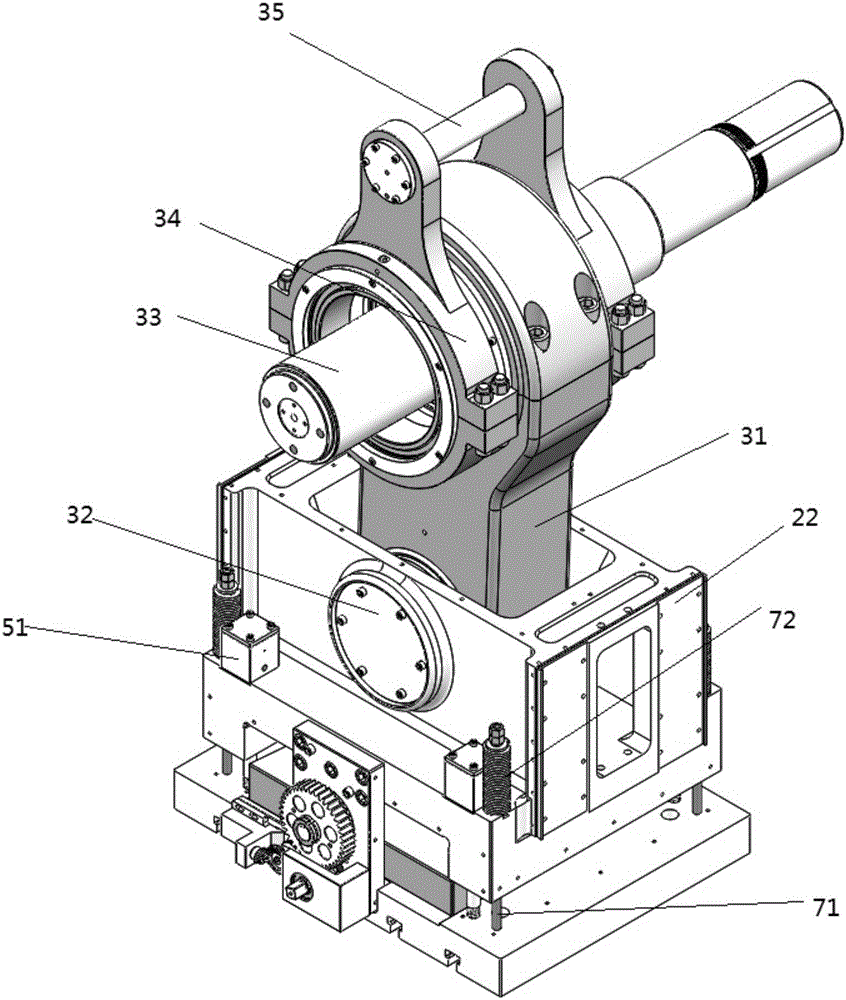

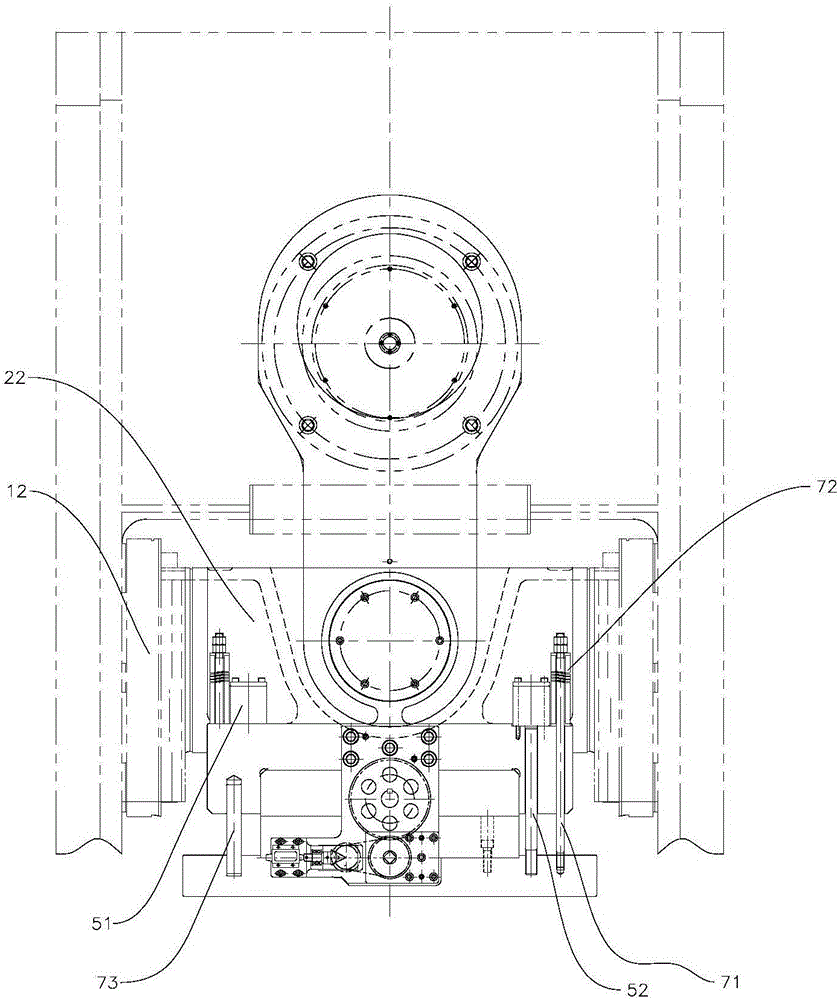

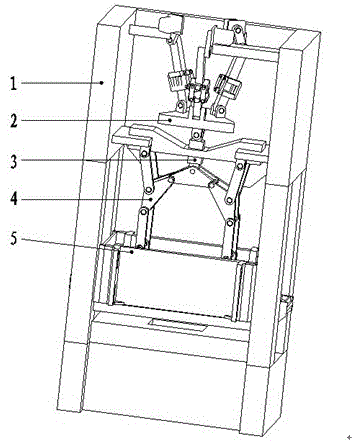

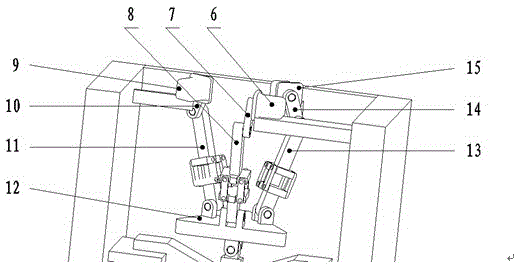

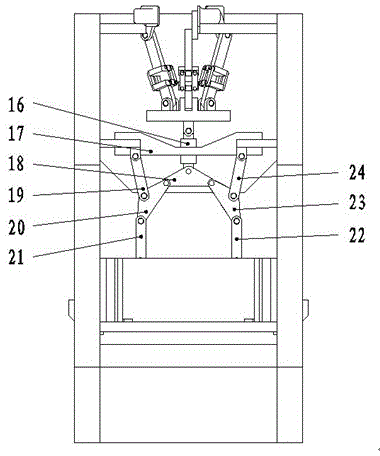

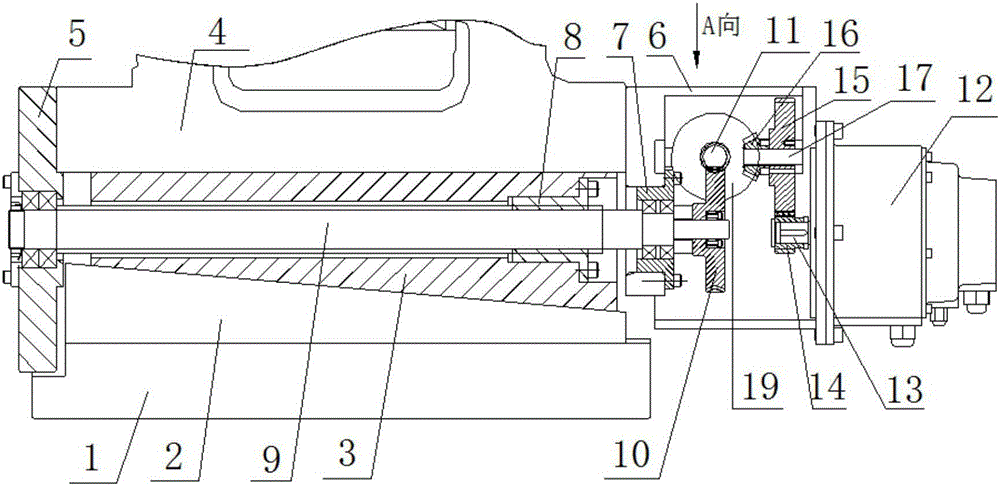

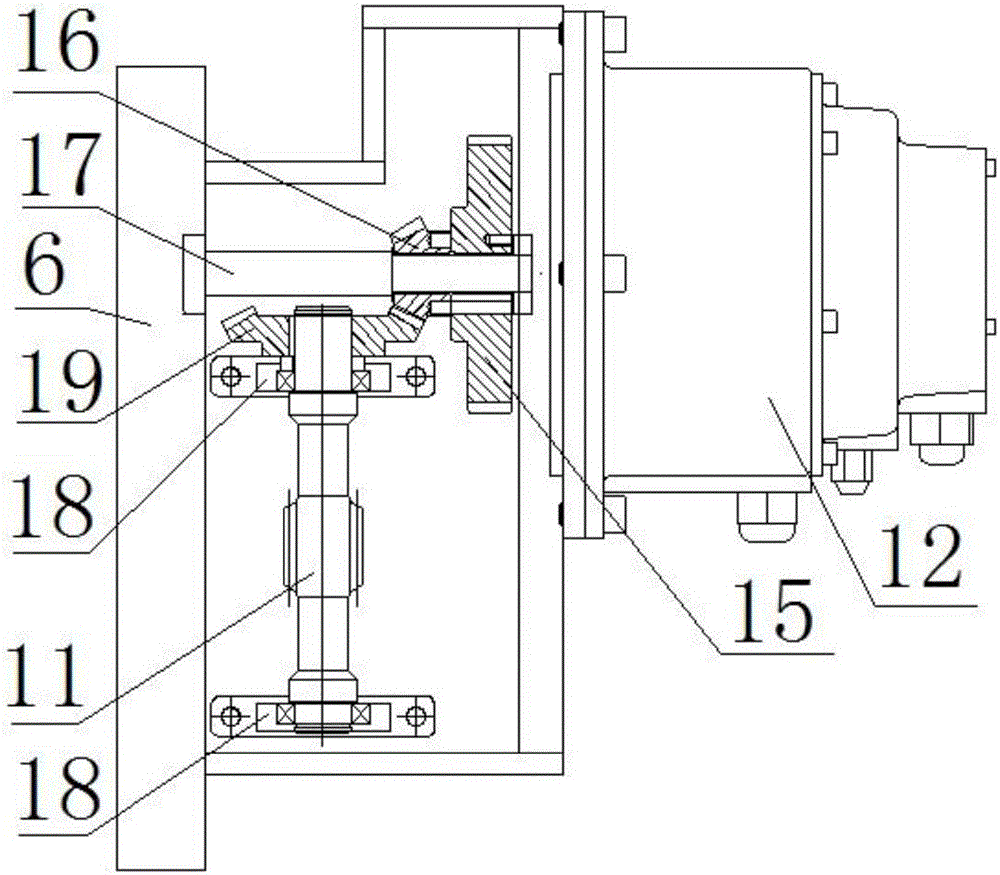

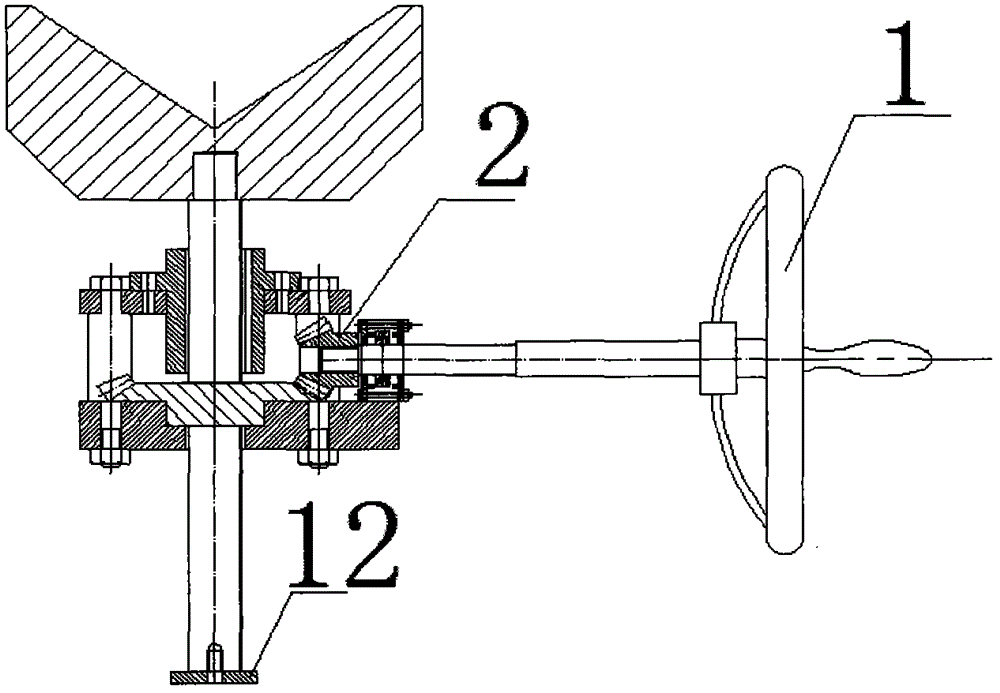

Space on-track repeated locking and releasing mechanism

ActiveCN102720733ARestricted degrees of freedomSimple structureSecuring devicesDegrees of freedomEngineering

The invention discloses a space on-track repeated locking and releasing mechanism, relating to a repeated locking and releasing mechanism. The invention aims to solve the problem in on-track repeated locking and releasing of large payload on spacecraft. The mechanism comprises a locking trunnion mechanism, a compaction lock hook mechanism, a locking base mechanism, a crank-rocker mechanism and a drive gear mechanism, wherein the locking trunnion mechanism is arranged at the upper end of the locking base mechanism; and the drive gear mechanism is connected with the compaction lock hook mechanism and the crank-rocker mechanism respectively. In the invention, the locking trunnion mechanism, the compaction lock hook mechanism, the locking base mechanism, the crank-rocker mechanism and the drive gear mechanism are crossed, the structure is simple and compact, all degrees of freedom of the fixed object can be completely limited, the repeated locking can be realized, the operability is good, and the using requirement of on-track locking-releasing-locking can be met. The mechanism disclosed by the invention is applicable to the technical field of aerospace and mechatronics.

Owner:HARBIN INST OF TECH

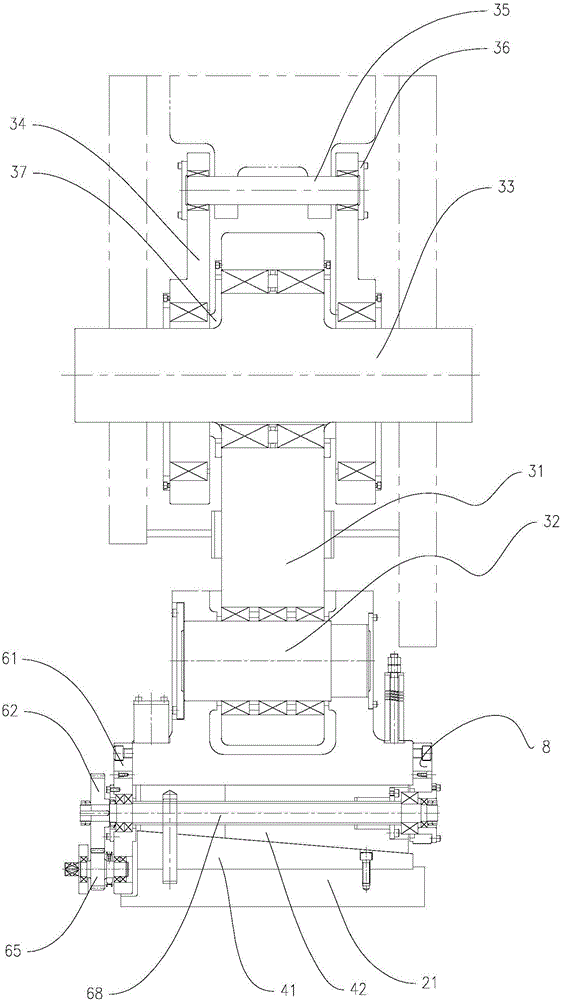

Manual adjustment tapered wedge type closed die height adjusting device

The invention discloses a manual adjustment tapered wedge type closed die height adjusting device. The manual adjustment tapered wedge type closed die height adjusting device comprises a rack assembly, a sliding block assembly, a connecting rod assembly, a tapered wedge assembly, an oil cylinder assembly, a transmission adjusting assembly and an auxiliary guide assembly. The sliding block assembly is mounted on the rack assembly through the connecting rod assembly, and the tapered wedge assembly is connected with the sliding block assembly through the oil cylinder assembly and the auxiliary guide assembly; the oil cylinder assembly, the auxiliary guide assembly and the transmission adjusting assembly are all connected to the sliding assembly; power drives the connecting rod assembly to move, and the connecting rod assembly further drives the sliding block assembly to do reciprocating operation along the assembling position of the rack assembly; and when the transmission adjusting assembly is affected by external force, the tapered wedge assembly is adjusted, and therefore the sliding block assembly, the oil cylinder assembly and the auxiliary guide assembly are adjusted, and finally, fine adjustment of die filling height can be achieved. Through cooperative use of an upper tapered wedge, a lower tapered wedge and a sliding block, the adjustment precision, stability and portability of the closed die height can be improved, and accurate die adjusting of different materials can be achieved.

Owner:江苏兴锻智能装备科技有限公司

Booster for servo press

The invention discloses a booster for a servo press, which comprises a frame, four moving branched chains of the same structure, a sliding platform, a guide rod and two links. The four same moving branched chains are symmetrically arranged, wherein two branched chains are jointly connected to one link to form a left mechanism of a symmetric mechanism, the other two branched chains are jointly connected to the other link to form a right mechanism of the symmetric mechanism, each branched chain comprises three connecting rods, one connecting rod is connected to the guide rod, one connecting rod is connected to the sliding platform, and the rest connecting rod is connected to the frame. Four-point output of the four branched chains on the sliding platform can be obtained by means of input of the guide rod. Besides, the booster has a great boosting effect at some positions of the sliding platform, namely a great output force can be obtained at the position of the sliding platform by applying a small input force to the guide rod. The booster is simple in structure, low in manufacturing cost and capable of effectively solving the problem that an existing servo press cannot realize four-point output through single-point input.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

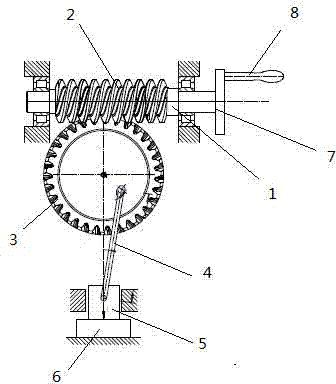

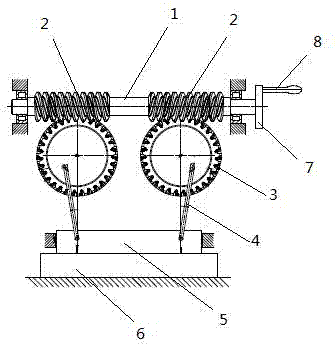

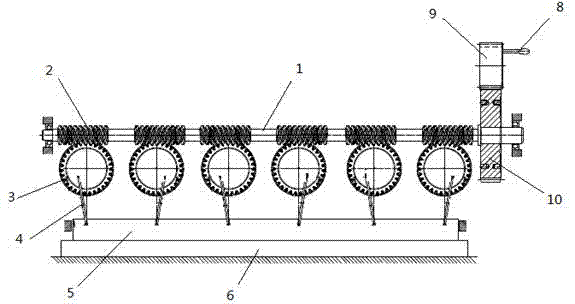

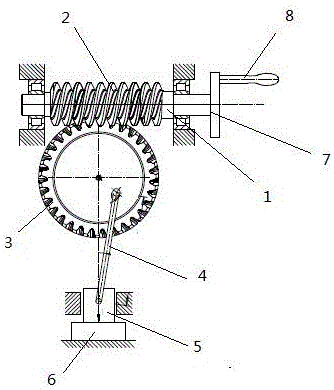

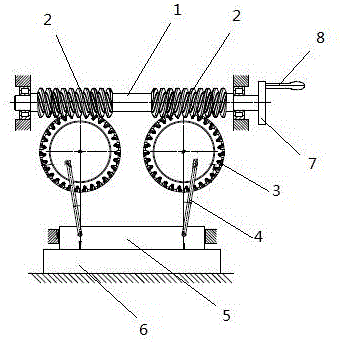

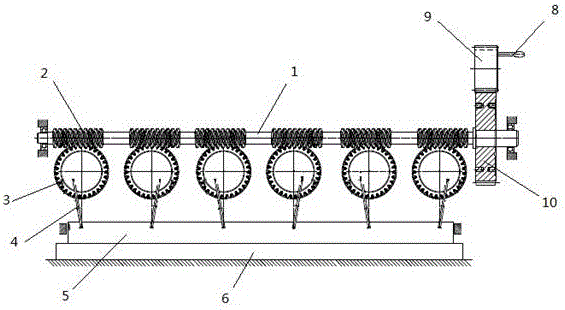

Manual pressing device based on worms, worm wheels and crank connecting rod transmissions

The invention discloses a manual pressing device based on worms, worm wheels and crank connecting rod transmissions. The manual pressing device comprises a rotary shaft, wherein at least two worms are fixedly arranged on the rotary shaft, the worm wheels meshed with the worms are arranged under the corresponding worms, the crank connecting rod transmissions are arranged on the worm wheels, and the tail ends of the crank connecting rod transmissions are connected to the same press block. The symmetrical synchronous multi-point driving is achieved, the manual pressing device is compact in structure, simple and convenient to use and rapid in positioning and pressing, the synchronous multi-point or multi-station pressing can be achieved according to the demands of workpieces, and accordingly labor productivity and product quality are improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Automatic centering and clamping device based on transmission of worm and worm gears and crank connecting rods

InactiveCN104209781AReduce labor intensityNo pollutionPositioning apparatusMetal-working holdersMechanical engineering

The invention discloses an automatic centering and clamping device based on transmission of worm-worm gears and crank connecting rods. The automatic centering and clamping device comprises at least two worm gears, wherein each worm gear is hinged to a crank connecting rod; the tail ends of the crank connecting rods are fixedly connected with pressure heads; the pressure heads are used for driving the crank connecting rods through rotation of the worm gears to drive the pressure heads to clamp a workpiece; each worm gear is driven by a worm which is meshed with the worm gear respectively; each worm is provided with a driven gear; each driven gear is meshed on the same driving gear. According to the automatic centering and clamping device, the worm-worm gears and the crank connecting rod mechanisms are arranged symmetrically, and the output force generated by the pressure heads is equal in magnitude and reverse in directions, so that automatic centering and alignment are realized, the fixture adjusting time can be shortened, the workpiece machining efficiency is increased, and the effects of saving labor force, saving time and increasing efficiency are achieved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

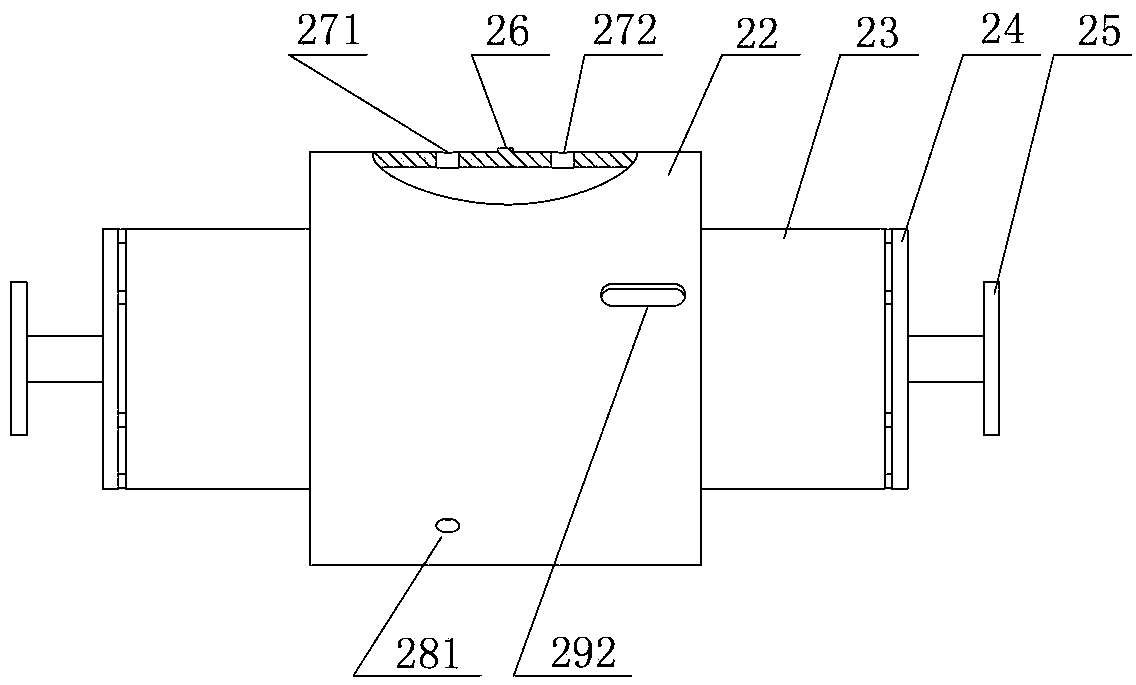

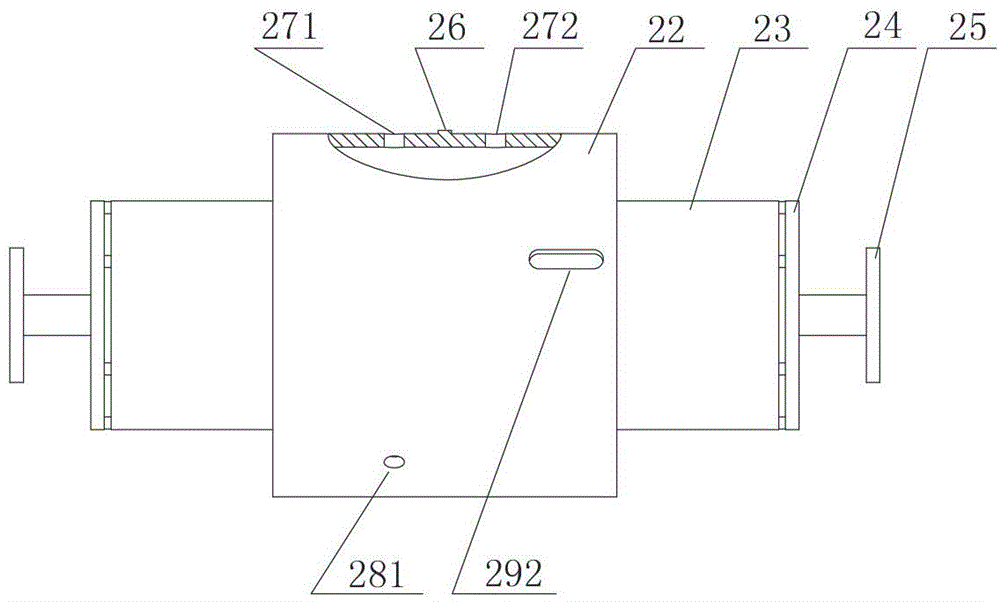

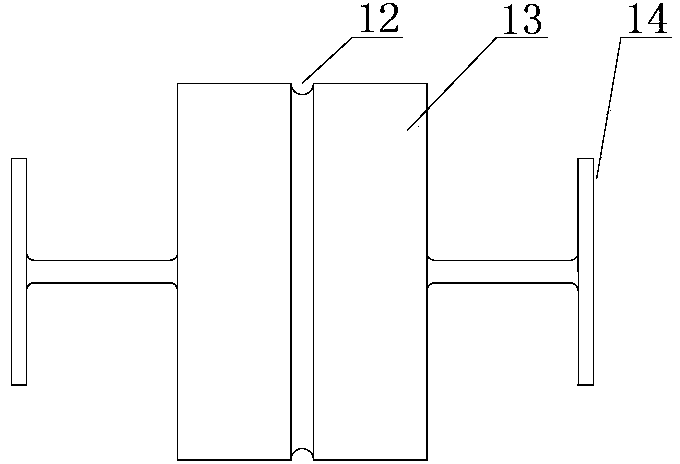

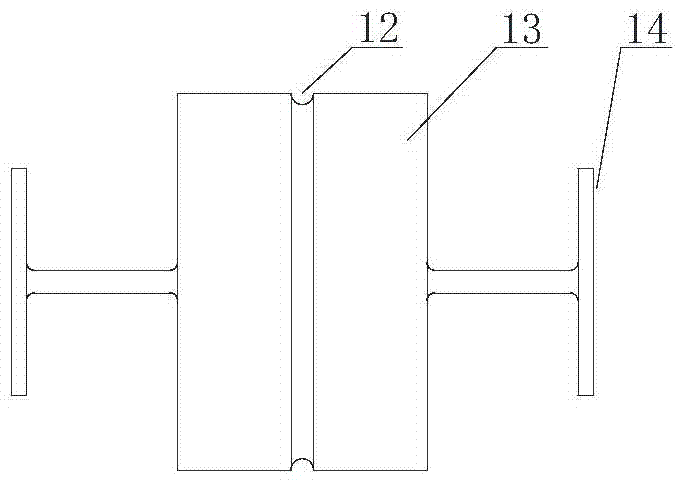

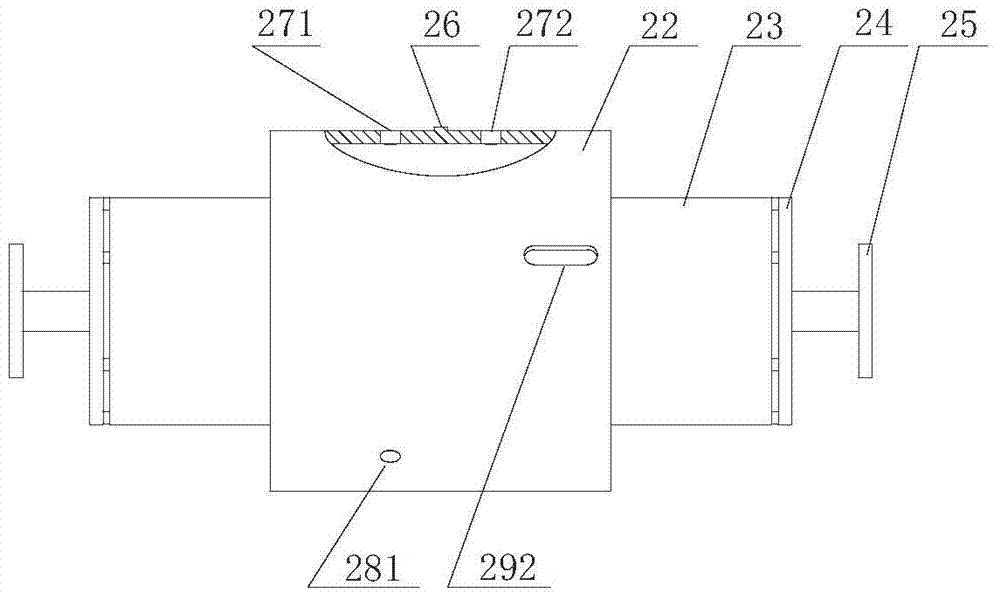

Integrated valve block

ActiveCN103452940AReduce volumeRadial volume is smallServomotor componentsElectric controlReversing valve

The invention discloses an integrated valve block and belongs to the field of hydraulic technology. The integrated valve block comprises a valve body (200) provided with an inner cavity (201). Through holes are formed at two ends of the inner cavity (201) of the valve body (200). Five annular through holes are radially formed between the outer wall face of the valve body (200) and the inner cavity. A valve element (220) is nested into the inner cavity (201). Four coaxial cylinders with the same cross section are disposed at intervals in the axial direction of the valve element (220). The four cylinders of the valve element (220) are matched with the inner cavity (201) to form a zero-openness two-position four-way reversing valve. Compared with the prior art, the integrated valve block is free of an electric control system and simple in system.

Owner:SHANDONG UNIV OF SCI & TECH

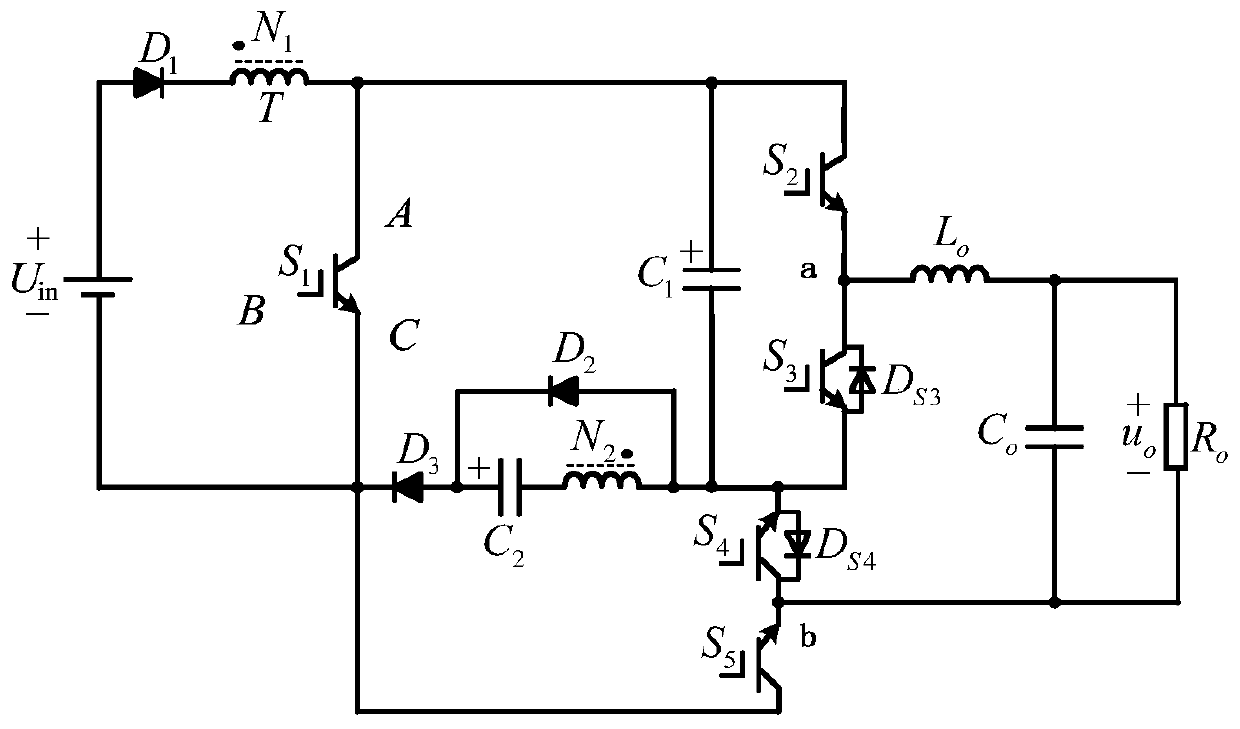

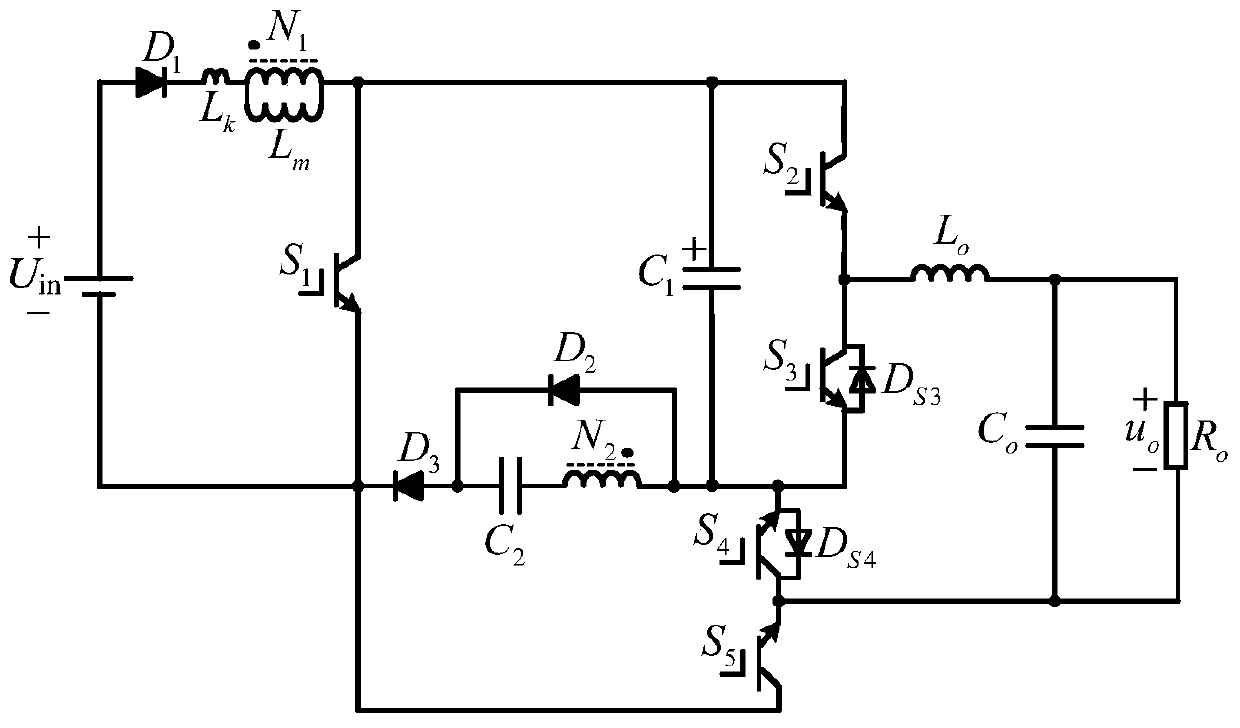

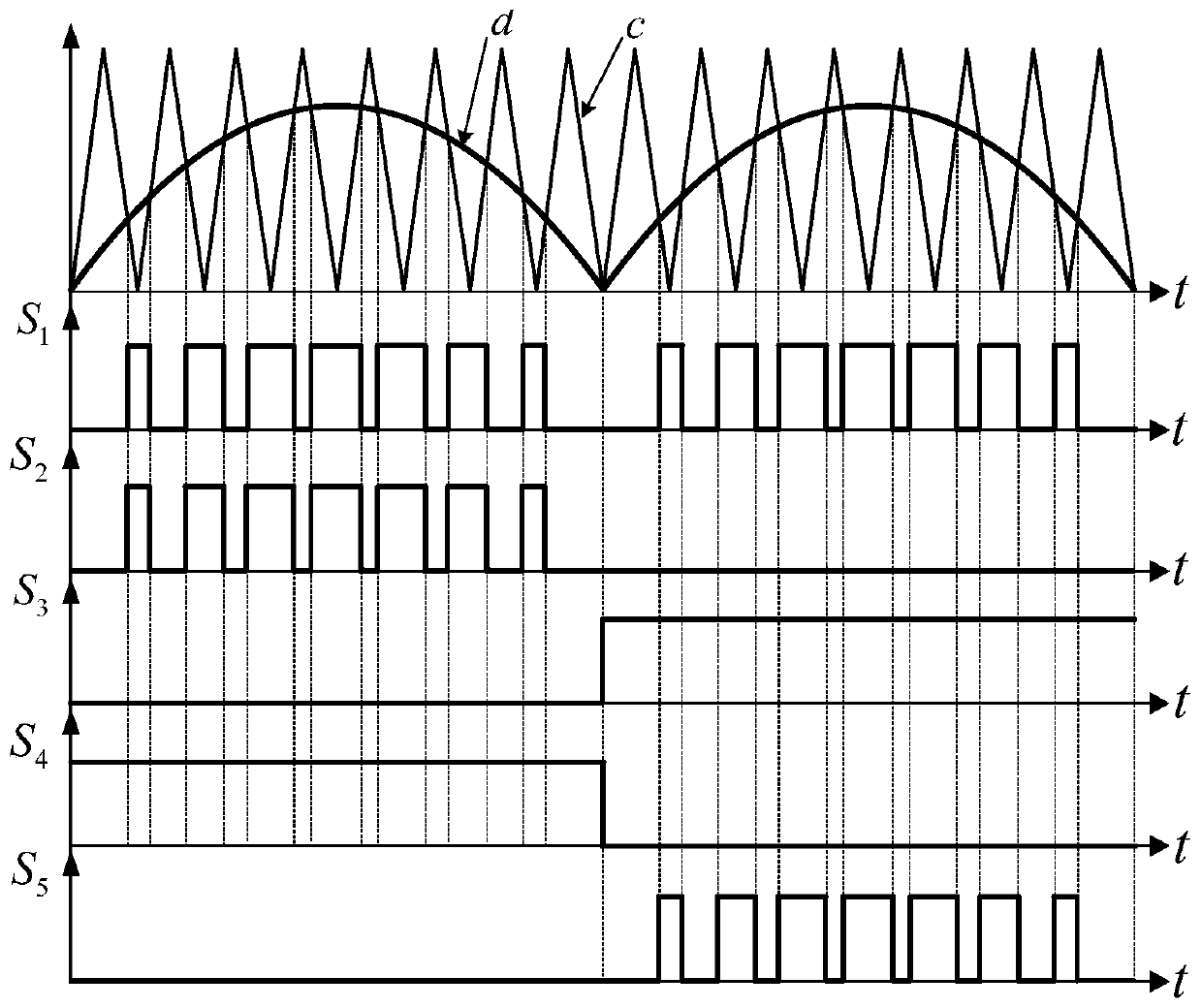

Coupling inductor employed boosting inverter and control method thereof

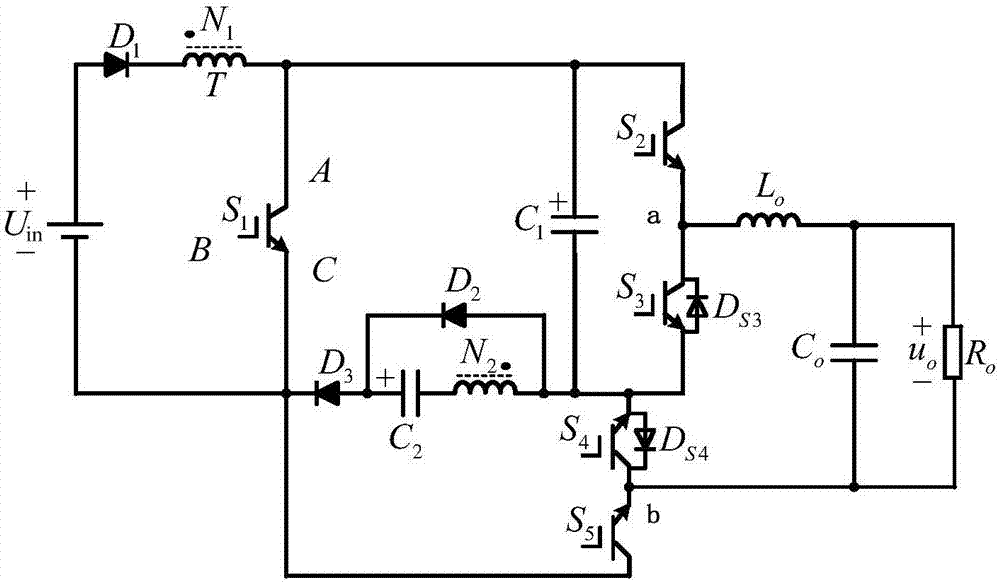

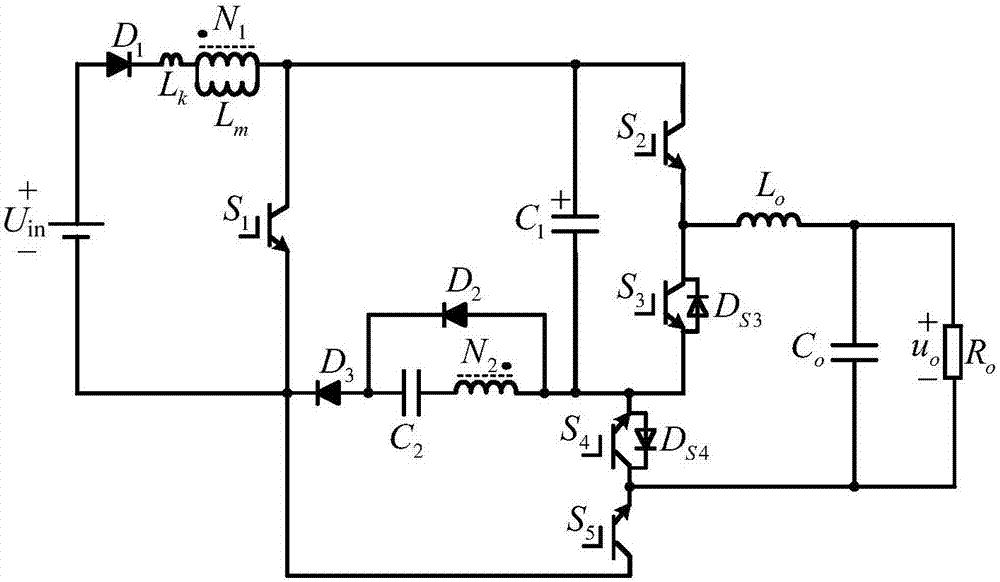

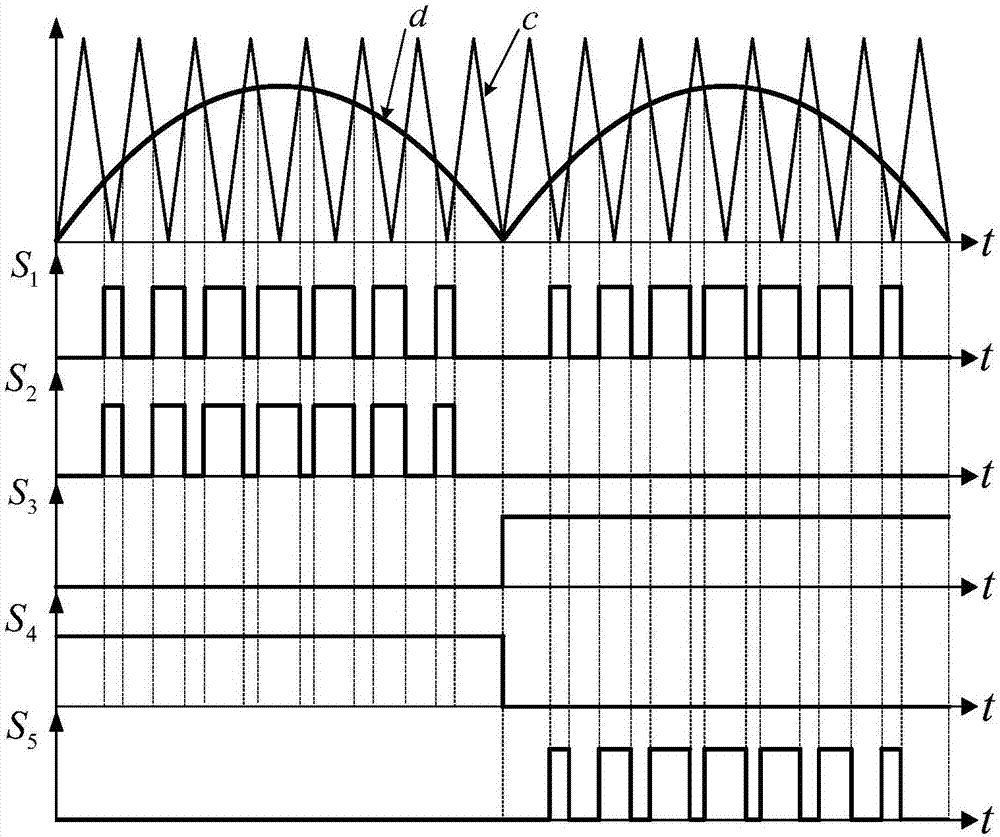

InactiveCN107959429AReduce in quantityReduce volumeEfficient power electronics conversionAc-dc conversionCapacitanceCoupling inductor

The invention discloses a coupling inductor employed boosting inverter and a control method thereof and belongs to the technical field of power electronic converters. The inverter includes a diode D1,a diode D2, a diode DS3 and a diode DS4, a switch tube S1, a switch tube S2, a switch tube S3, a switch tube S4, a switch tube S5, a primary winding N1 and an auxiliary winding N2 of a coupling inductor T and a capacitor C1. The anode of the diode D1 is connected with one end of an input power source Uin. A cathode of the diode D1 is connected with a dotted terminal of a primary winding N1 of thecoupling inductor T. A non-dotted terminal of the primary winding N1 of the coupling inductor T is connected with an A terminal of the switch tube S1, an A terminal of the switch tube S2 and one endof the capacitor C1. A C terminal of the switch tube S1, the cathode of a diode D3, an A terminal of the switch tube S5 are connected with the other end of the input power source Uin. The anode of thediode D3 and the cathode of the diode D2 are connected with one end of the capacitor C2. Aiming at a problem of low boosting ratio of a boosting inverter in the prior art, the inverter provided by the invention is high integration level, high in boosting ratio and flexible in boosting ratio adjustment.

Owner:HOHAI UNIV WENTIAN COLLEGE

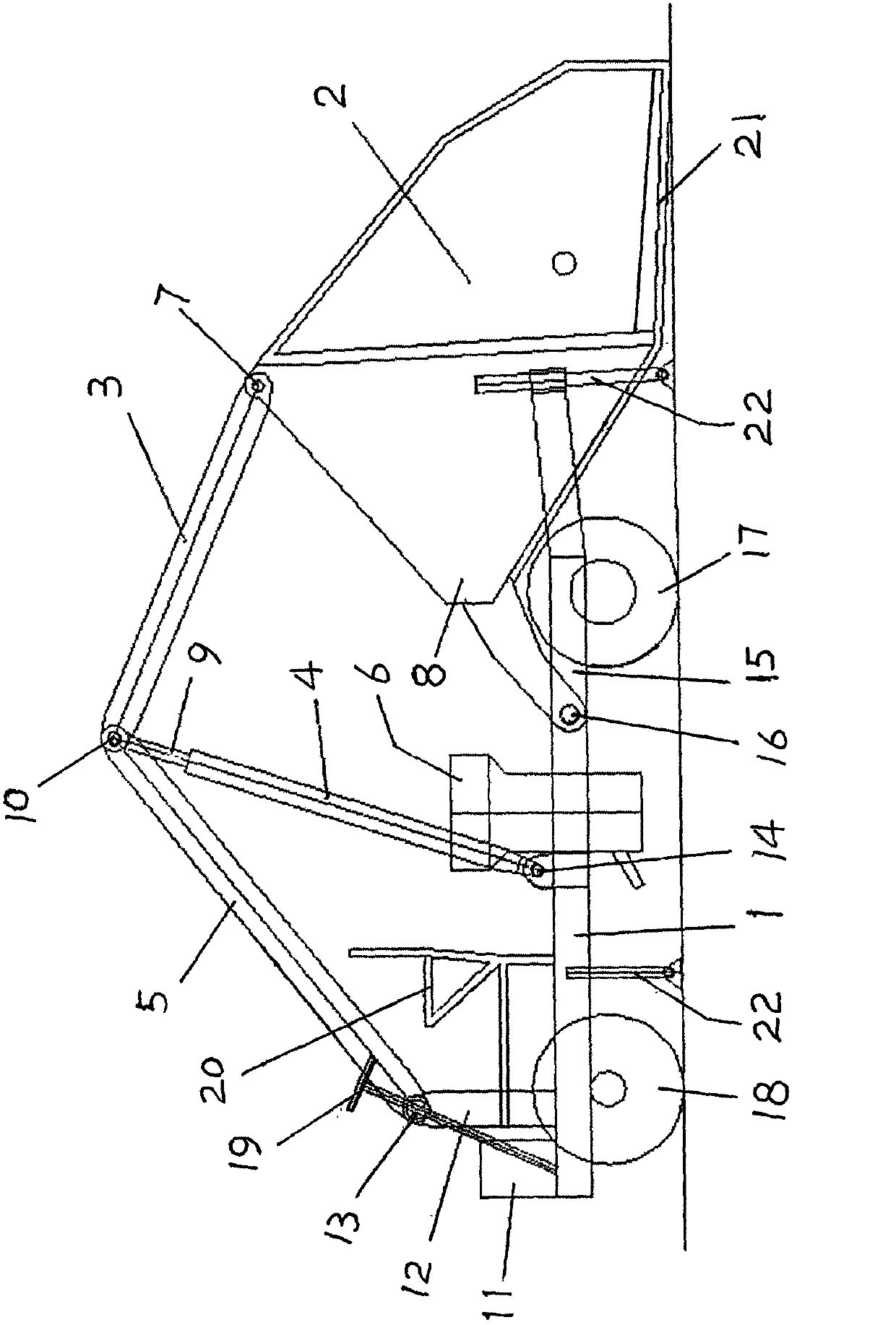

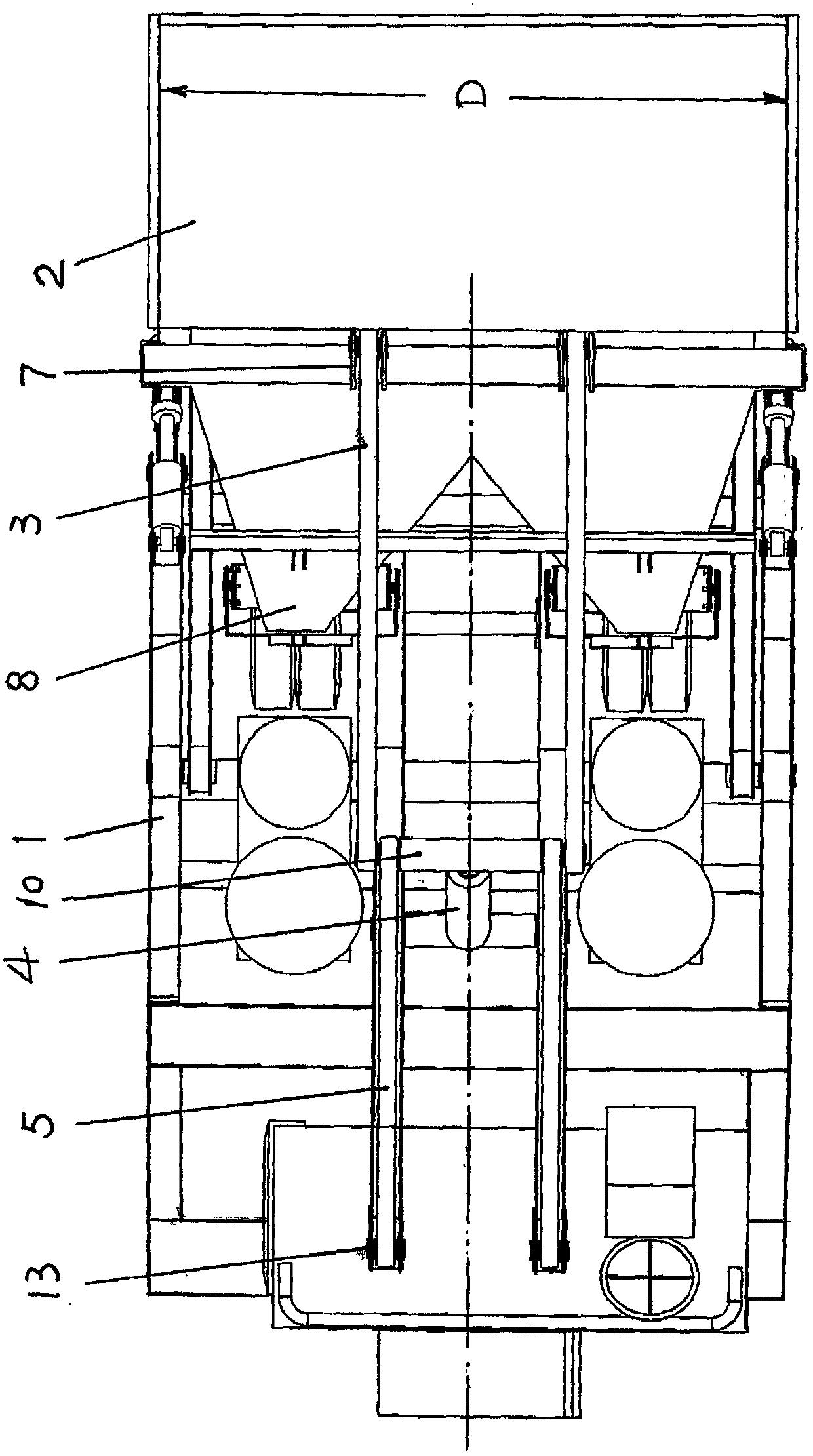

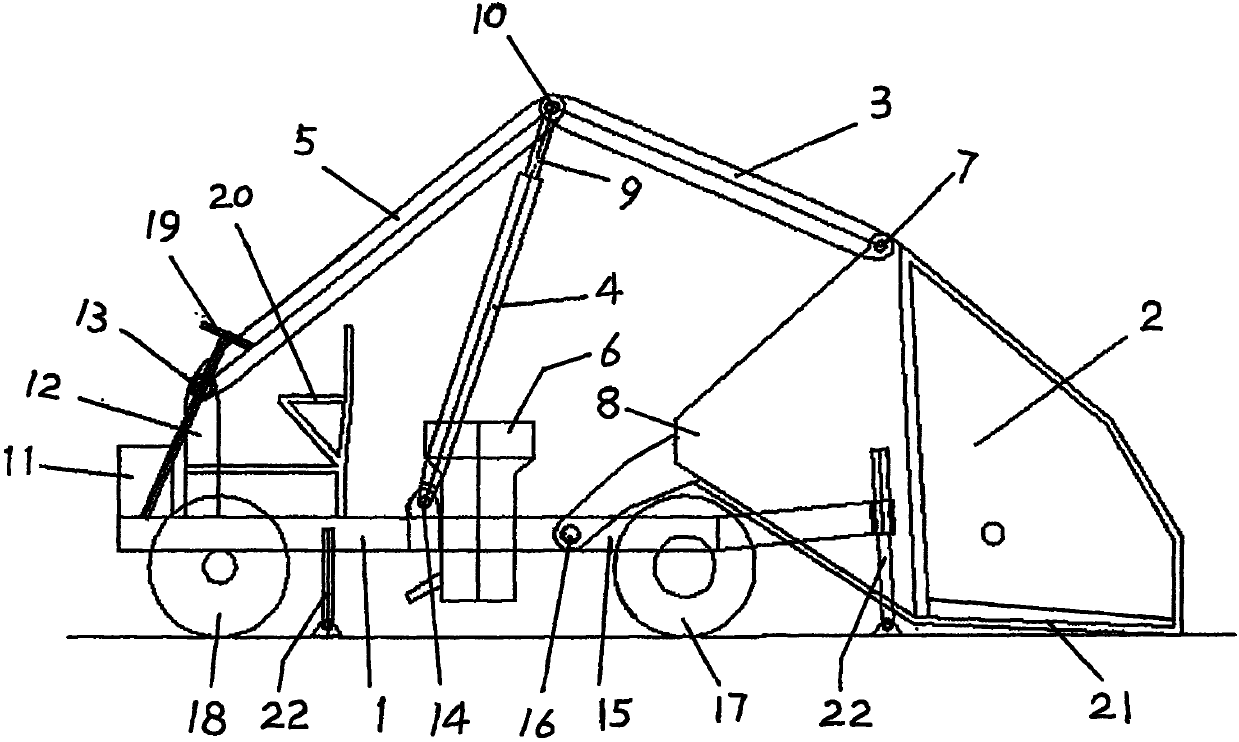

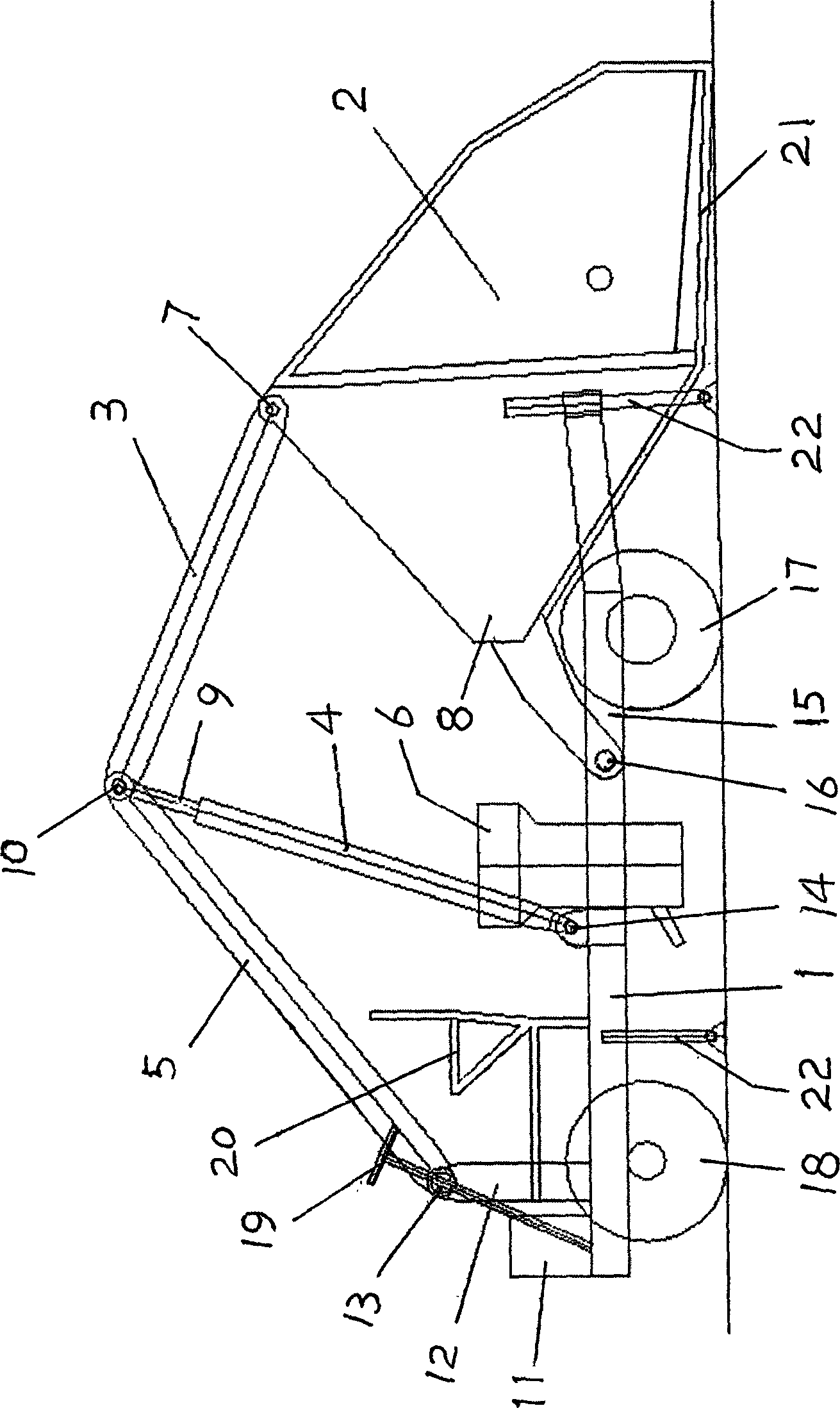

Traveling type automatic material loading patching machine device

InactiveCN102677904AShort tripSolve the contradiction between thrust and strokeBuilding material handlingHinge jointHydraulic pressure

The invention relates to a traveling type automatic material loading patching machine device. The device comprises a device body rack, a charging hopper, a patching machine and a hydraulic pressure oil cylinder used for loading material. The device is characterized in that the charging hopper is in a hinged connection with a hinged joint point which is close to device body rear portion, the upper portion of the charging hopper is in a hinged connection with a hinged joint point which is close to the head portion of the device body sequentially through a pair of pull rods and a pair of connecting rods which are in the hinged connection, the hydraulic pressure oil cylinder is installed at the front of the charging hopper, a cylinder body of the hydraulic pressure oil cylinder is in a hinged connection with a hinged joint point which is close to the middle of the device body, a push rod of the hydraulic pressure oil cylinder is in a hinged connection with a hinged joint point of the pull rods and the connecting rods, and therefore a five-connecting rod charging mechanism composed of the device body rack, connecting rods, the hydraulic pressure oil cylinder, the push rod and the charging hopper is formed to load materials. According to the traveling type automatic material loading patching machine device, the complete device is beneficial to widening the charging hopper and substantially increasing the hopper capacity, and the hopper capacity can be increased by about 100%, lifting and turning performances are stable, the charging operation is convenient, the structure is simple, the device is energy-saving and environment-friendly, and the cost is low.

Owner:FUJIAN FANGZHENG MACHINERY CO LTD

Manipulator internal-grab device based on worm-gear and crank-link transmission

The invention discloses a manipulator internal-grab device based on worm-gear and crank-link transmission. The manipulator internal-grab device is characterized by comprising at least two gears; each gear is hinged with a crank link, a grab press head is fixedly connected to the tail end of each crank link and drives the same under rotation of the corresponding gear so as to support a workpiece tightly, and each gear is driven by one worm meshing with the same. Through second series-connection boosting of the worm-gear and crank-link transmission, high boost ratio is acquired, boosting effect is obvious, labor productivity and product quality can be improved and labor intensity of workers can be reduced. According to the nonlinear characteristic between the output force and the output displacement of a crank-link mechanism, the grab press heads are fed rapidly on the condition of large pressure angle, and the grab force is increased rapidly on the condition of small pressure angle.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

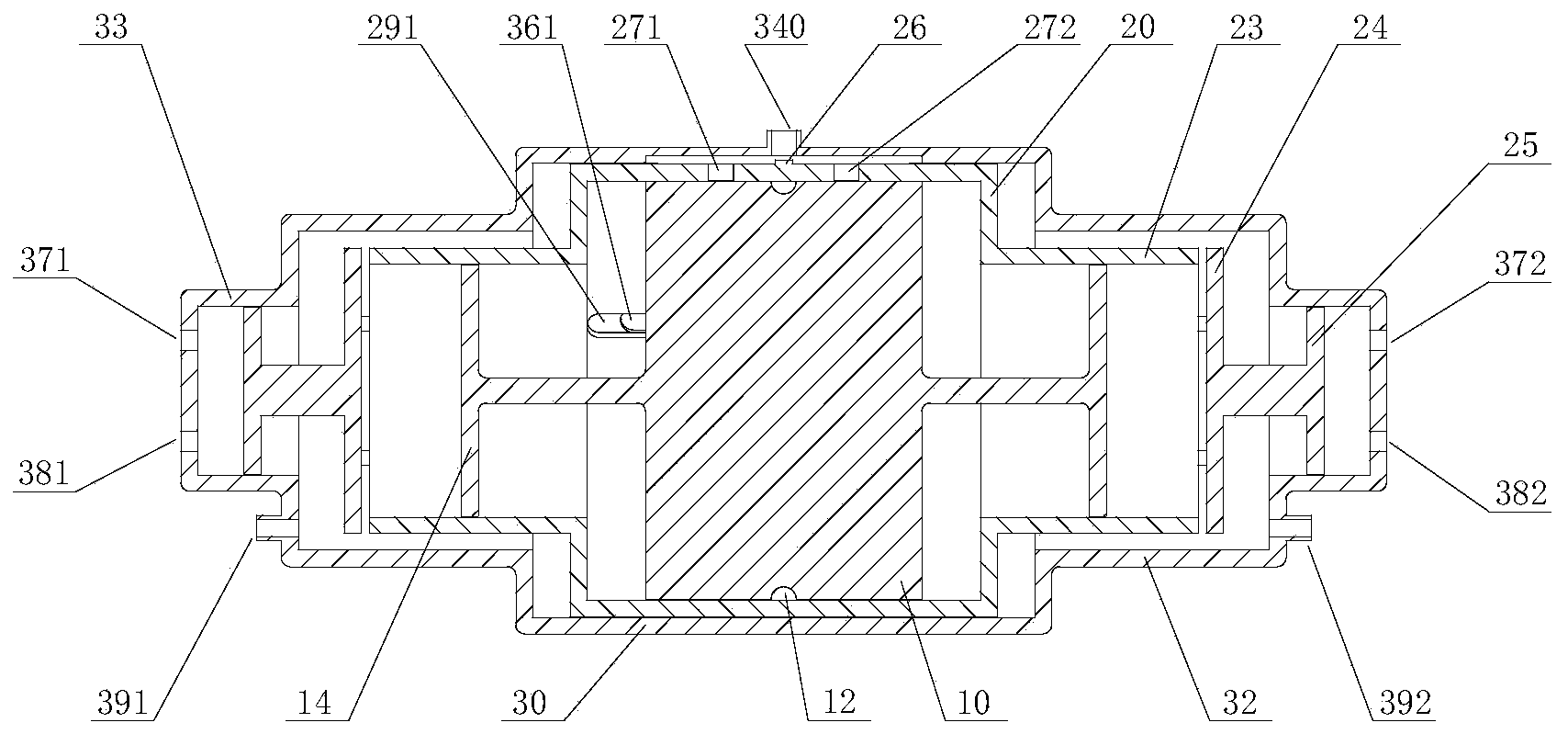

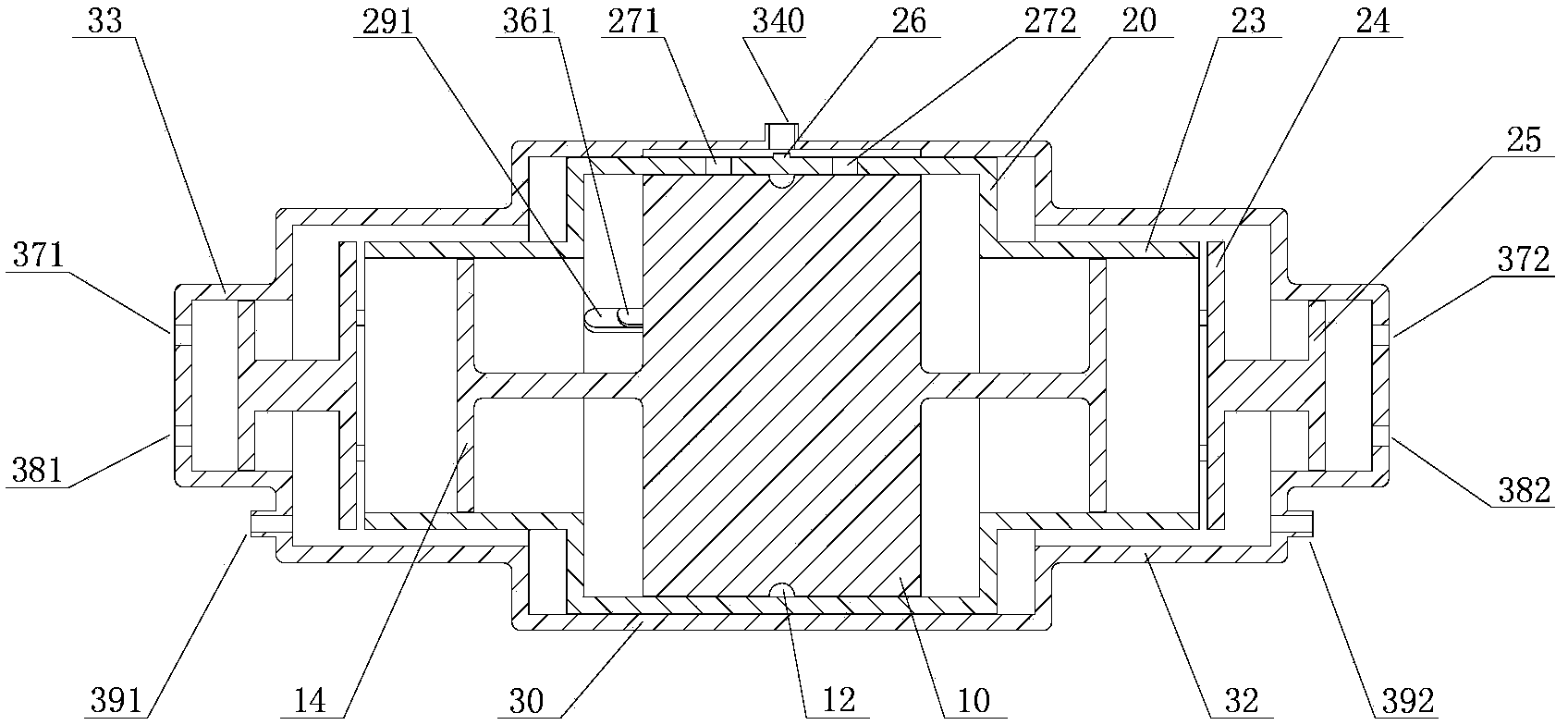

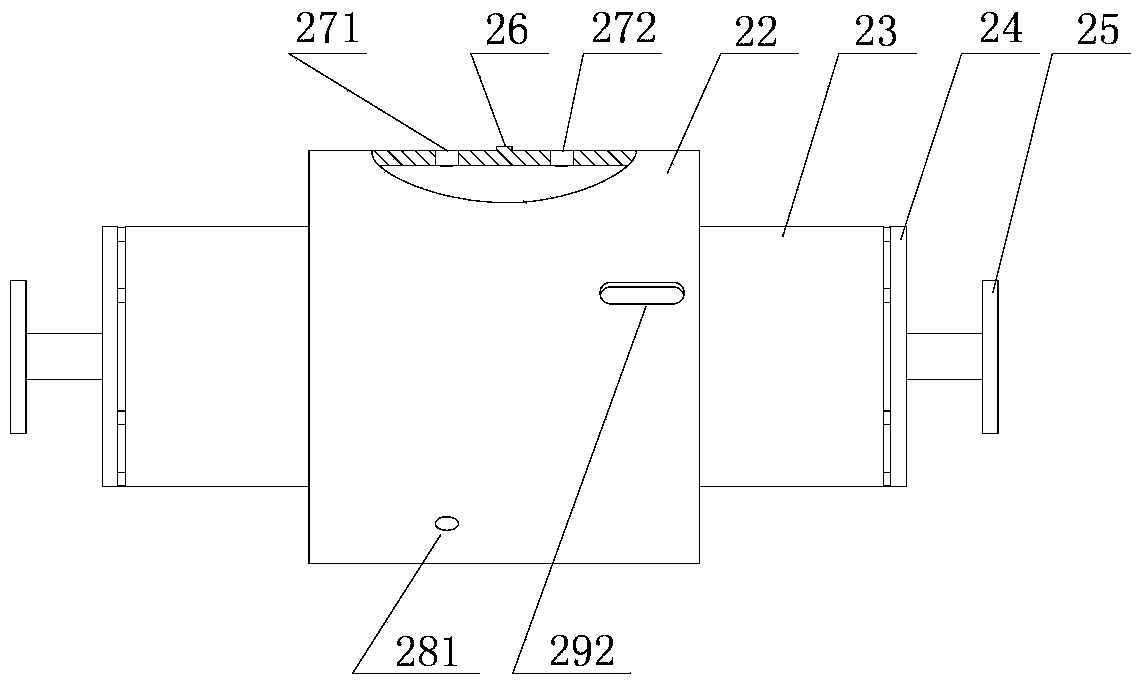

Pressurizing device

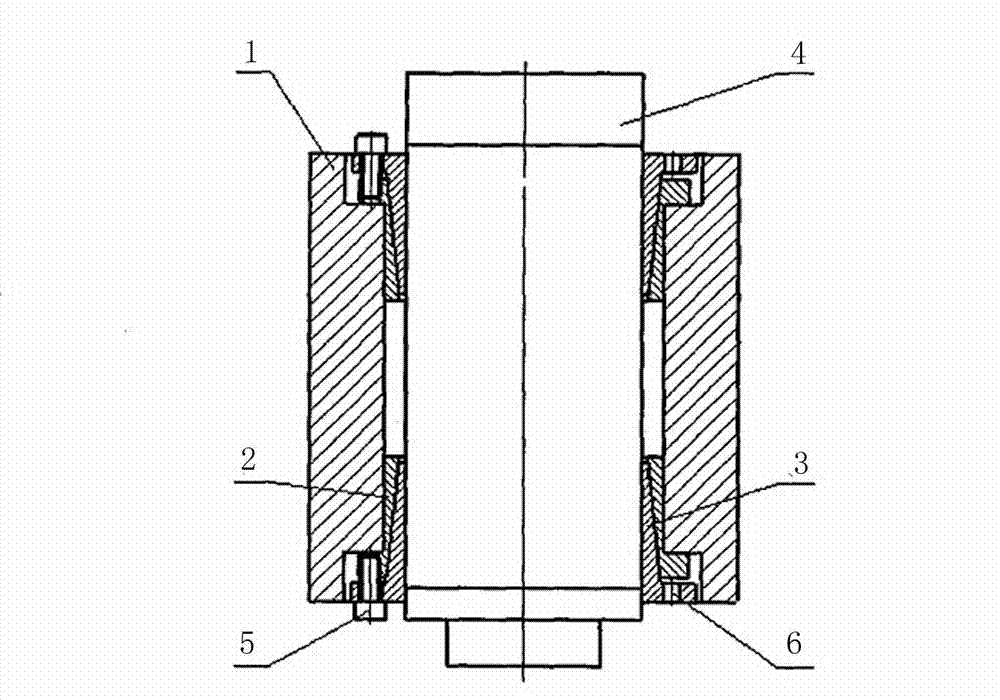

ActiveCN103470550AReduce volumeRadial volume is smallFluid-pressure convertersFluid-pressure actuatorsEngineeringElectric control

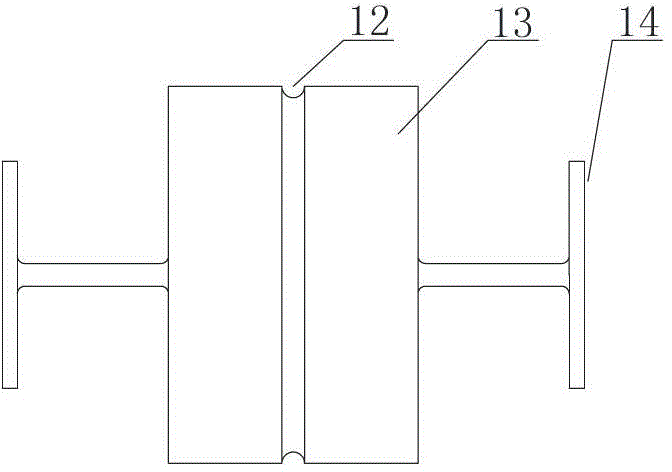

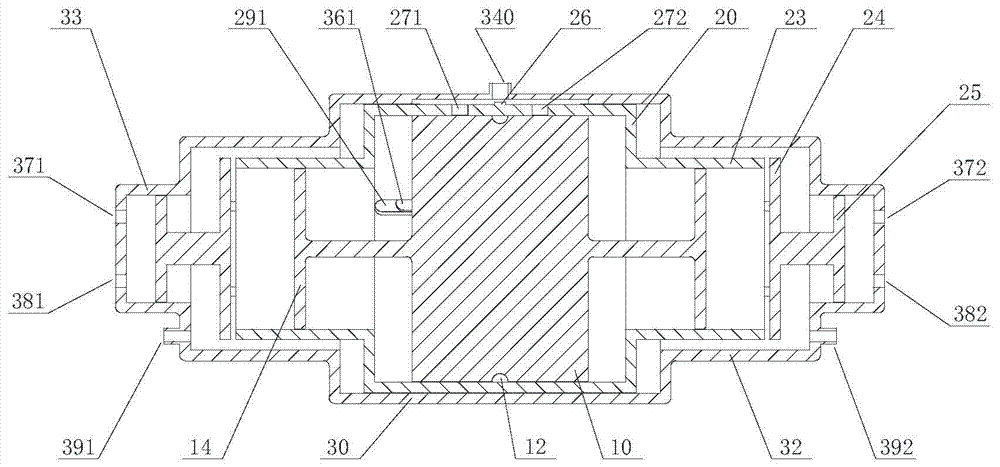

The invention provides a pressurizing device. The pressurizing device comprises a pressurizing cylinder and an integrated valve block, wherein the pressurizing cylinder comprises a primary piston (10), a secondary piston (20) and a cylinder tube (30), the primary piston (10) is sleeved in an inner cavity of the secondary piston (20), and the secondary piston (20) is sleeved in an inner cavity of the cylinder tube (30); the integrated valve block comprises a valve body (200), the valve body (200) is provided with an inner cavity (201), the valve body (200) is respectively provided with a through hole at two ends of the inner cavity (201), five annular through holes are radially arranged between the wall surface of the outer wall and the inner cavity (201) of the valve body (200), the inner cavity (201) is internally sleeved with a valve core (220), and a zero-opening two-position four-way reversing valve is formed in a way that the valve core (220) is matched with the inner cavity (201). Compared with a pressurizing device in the prior art, the pressurizing device provided by the invention is small in size, has no participation of an electric control system and is simple in system.

Owner:SHANDONG UNIV OF SCI & TECH

Traveling type automatic material loading patching machine device

InactiveCN102677904BIncrease widthWidth does not affectBuilding material handlingEngineeringHydraulic pressure

The invention relates to a traveling type automatic material loading patching machine device. The device comprises a device body rack, a charging hopper, a patching machine and a hydraulic pressure oil cylinder used for loading material. The device is characterized in that the charging hopper is in a hinged connection with a hinged joint point which is close to device body rear portion, the upper portion of the charging hopper is in a hinged connection with a hinged joint point which is close to the head portion of the device body sequentially through a pair of pull rods and a pair of connecting rods which are in the hinged connection, the hydraulic pressure oil cylinder is installed at the front of the charging hopper, a cylinder body of the hydraulic pressure oil cylinder is in a hinged connection with a hinged joint point which is close to the middle of the device body, a push rod of the hydraulic pressure oil cylinder is in a hinged connection with a hinged joint point of the pull rods and the connecting rods, and therefore a five-connecting rod charging mechanism composed of the device body rack, connecting rods, the hydraulic pressure oil cylinder, the push rod and the charging hopper is formed to load materials. According to the traveling type automatic material loading patching machine device, the complete device is beneficial to widening the charging hopper and substantially increasing the hopper capacity, and the hopper capacity can be increased by about 100%, lifting and turning performances are stable, the charging operation is convenient, the structure is simple, the device is energy-saving and environment-friendly, and the cost is low.

Owner:FUJIAN FANGZHENG MACHINERY CO LTD

Stress-relieving device for seamless rails by using excitation method, and the relieving method

InactiveCN102226326BEasy to carryBalance overturning momentRailway track constructionElectricityStress relieving

The invention discloses a stress-relieving device for seamless rails by using a vibration method and a stress-relieving method, and is implemented by carrying out field detection on the stress-relieving effect of rails mainly by using a device for realizing the stress homogenization of rails in a periodic-vibration gas-liquid pressurized mode and supplementarily by using a stress sensor, and then carrying out stress-relieving operation in a machine-liquid-electricity integrated automatic mode. The whole stress-relieving device disclosed by the invention is light in weight, and provided with an anti-overturn device for ensuring a trolley is not overturned to the side during the operation of the trolley, thereby reducing the labor intensity and improving the operating efficiency and quality.

Owner:HUBEI UNIV OF TECH

Pressurizing device

ActiveCN103470550BReduce volumeRadial volume is smallFluid-pressure convertersFluid-pressure actuatorsEngineeringElectric control

The invention provides a pressurizing device. The pressurizing device comprises a pressurizing cylinder and an integrated valve block, wherein the pressurizing cylinder comprises a primary piston (10), a secondary piston (20) and a cylinder tube (30), the primary piston (10) is sleeved in an inner cavity of the secondary piston (20), and the secondary piston (20) is sleeved in an inner cavity of the cylinder tube (30); the integrated valve block comprises a valve body (200), the valve body (200) is provided with an inner cavity (201), the valve body (200) is respectively provided with a through hole at two ends of the inner cavity (201), five annular through holes are radially arranged between the wall surface of the outer wall and the inner cavity (201) of the valve body (200), the inner cavity (201) is internally sleeved with a valve core (220), and a zero-opening two-position four-way reversing valve is formed in a way that the valve core (220) is matched with the inner cavity (201). Compared with a pressurizing device in the prior art, the pressurizing device provided by the invention is small in size, has no participation of an electric control system and is simple in system.

Owner:SHANDONG UNIV OF SCI & TECH

Tyre forming drum and tyre forming machine provided with same

PendingCN110549659AAnti-package is highly consistentIncrease productivityTyresLocking mechanismEngineering

The invention provides a tyre forming drum and a tyre forming machine provided with the same. The tyre forming drum comprises a main shaft and two half-drum devices which sleeve the main shaft, wherein each half-drum device comprises an outer shaft which sleeves the main shaft, an interlocking mechanism, an anti-package capsule and an anti-package boosting mechanism, the interlocking mechanism comprises a first locking mechanism and a second locking mechanism which are in alternative type locking, the first locking mechanism sleeves the main shaft and is fixedly connected to the outer shaft, the second locking mechanism sleeves the outer shaft; the anti-package boosting mechanism comprises a plurality of boosting plates which are uniformly distributed along the periphery and a plurality ofboosting connecting rods; when the first locking mechanism locks the main shaft and the second locking mechanism loosens the outer shaft, the second locking mechanism can axially move along the outershaft to push the boosting plates to turn over towards the radial outer sides of the half-drum devices, so that boosting force is provided for the anti-package capsule. The forming drum provided by the invention has the advantages of being consistent in anti-package height, good in anti-package periphery continuity, uniform in stress, high in production efficiency and the like, and also can meetthe requirements of light weight, simplification and small size.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

Thread self-locking type manual clamping fixture

The invention discloses a thread self-locking type manual clamping fixture which comprises an L-shaped supporting plate, a n-shaped pressing plate, a threaded rod and a compression nut. The middle portion of the L-shaped supporting plate is rotatably connected with the lower end of the threaded rod through a first hinge pin. One end of the L-shaped supporting plate is rotatably connected with one end of the n-shaped pressing plate through a second hinge pin. The upper end of the threaded rod penetrates through an unthreaded hole in the middle of the n-shaped pressing plate and then is provided with the compression nut. An anti-skid gasket is arranged between the compression nut and the n-shaped pressing plate. A first pressure foot is fixedly arranged at the open end of the L-shaped supporting plate. A second pressure foot matched with the first pressure foot is fixedly arranged at the open end of the n-shaped pressing plate. The thread self-locking type manual clamping fixture has the following characteristics of being reasonable in design, simple in structure, convenient to operate, small in size, low in weight, convenient to mount and dismount, reliable in clamping, large in force increasing ratio, good in self-locking performance, low in production cost and convenient to use and popularize.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

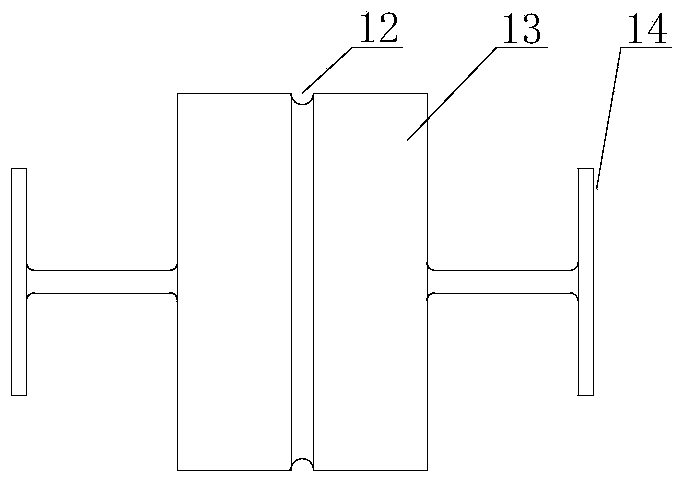

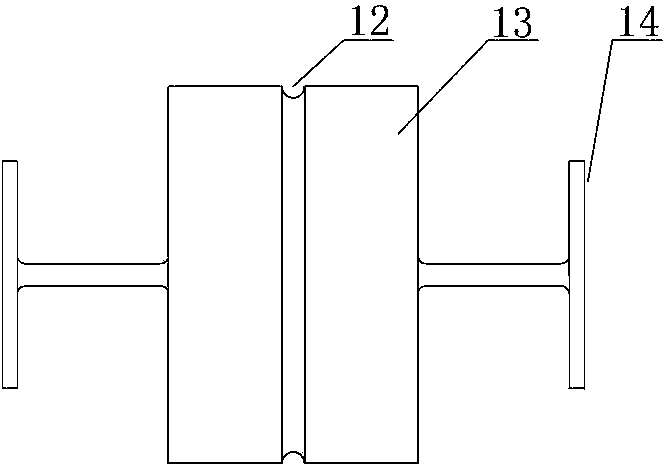

Pressurizing cylinder

ActiveCN103470549AReduce volumeRadial volume is smallFluid-pressure convertersFluid-pressure actuatorsState of artControl theory

The invention provides a pressurizing cylinder, which belongs to the technical field of hydraulic pressure. The pressurizing cylinder comprises three parts, namely a primary piston (10), a secondary piston (20) and a cylinder tube (30), wherein the primary piston (10) is sleeved in an inner cavity of the secondary piston (20), the secondary piston (20) is sleeved in an inner cavity of the cylinder tube (30), and first pressurizing to hydraulic oil is completed due to mutual movement of the primary piston (10) and the secondary piston (20), and second pressurizing to the hydraulic oil is completed due to relative movement of the secondary piston (20) and the cylinder tube (30). Compared with a pressurizing cylinder in the prior art, the pressurizing cylinder provided by the invention has the advantages that the size is small, particularly, the radial size is greatly reduced, and the structure is compact.

Owner:SHANDONG UNIV OF SCI & TECH

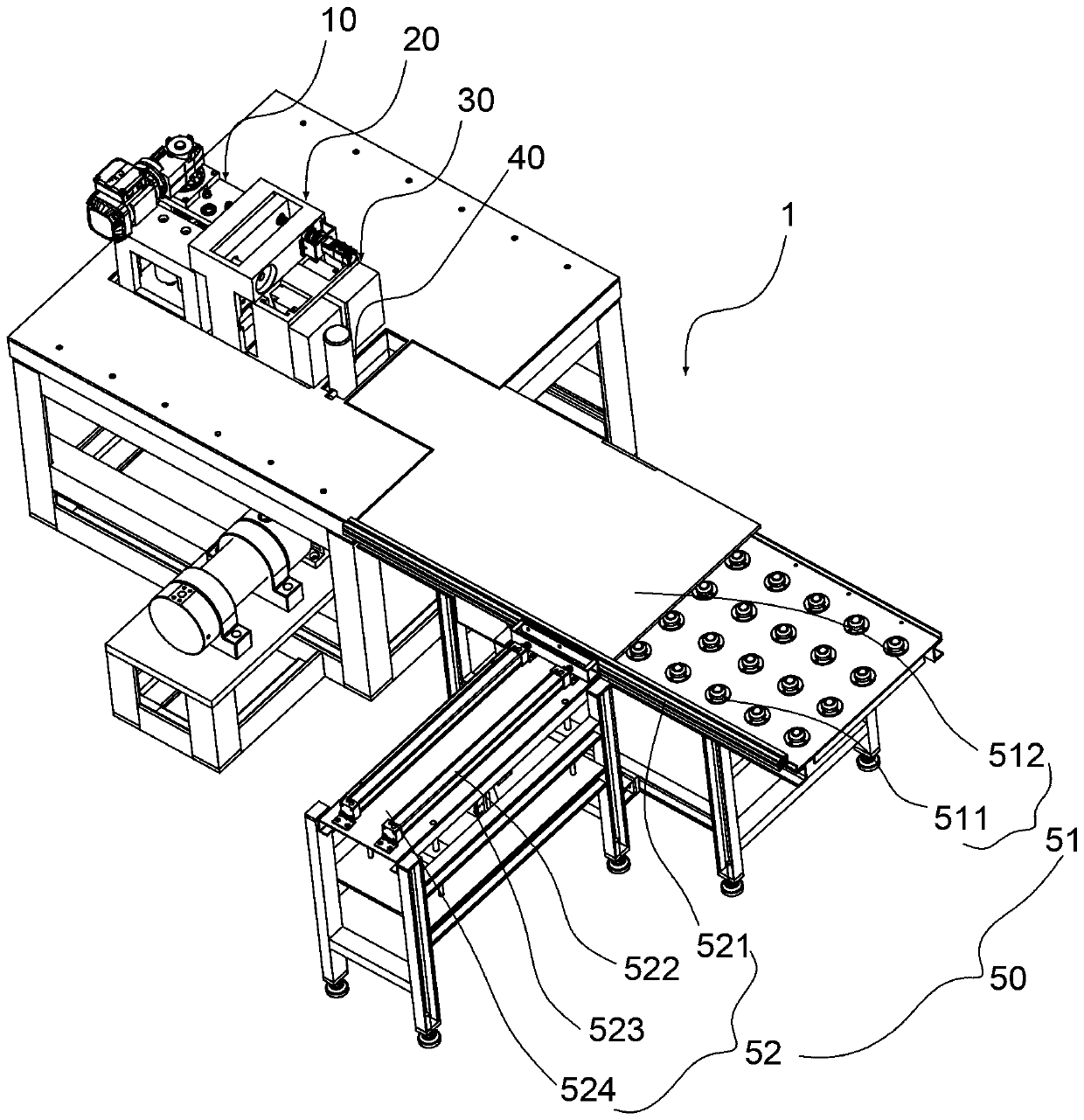

Bending machine

PendingCN109772961ARealize automatic bending operationAutomatic adjustment of feeding positionMetal-working feeding devicesPositioning devicesEngineeringMoving parts

The invention provides a bending machine. The bending machine comprises a feeding device, a transition clamping device, a clamping device and a bending device which are arranged in sequence; the feeding device is provided with a first moving part and two roller shaft sets; the first moving part is connected with the two roller shaft sets for driving the two roller shaft sets to move oppositely; the transition clamping device is provided with a first clamp and a second moving part; the second moving part is connected with the first clamp for driving the first clamp to reciprocate between the feeding device and the clamping device; the clamping device is provided with a second clamp; the second clamp clamps a to-be-bent position of a workpiece, so that the to-be-bent position of the workpiece penetrates out of the second clamp; the bending device comprises a bending die rod and a third moving part for driving the bending die rod to be fed; and the bending die rod is used for being fed tothe workpiece, so that the to-be-bent position of the workpiece is bent by a certain angle relative to the clamped position. Thus, the bending machine is good in flexibility, suitable for bending ofworkpieces of various sizes and capable of achieving automatic bending of workpieces.

Owner:XIAMEN HIPRECISE TECH CO LTD

Tool structure of electric spindle

InactiveCN102764901ASmall clamping stabilityEasy and uniform deformationMetal-working apparatusEngineeringSelf locking

The invention discloses a tool structure of an electric spindle. The tool structure comprises a base, an outer taper sleeve and an inner taper sleeve, the outer taper sleeve and the inner taper sleeve are matched with each other to form a taper ring, the inner taper sleeve is sleeved on the outer side of the electric spindle, the base is sleeved on the outer side of the outer taper sleeve, a locking screw is arranged on the base, and the taper ring is axially locked by the locking screw. The outer taper sleeve and the inner taper sleeve have small taper angles, a taper surface of the taper ring and a threaded surface of the screw are used for double force increase, the force increasing ratio is high, self-locking can be realized, clamping is reliable, a taper ring group with an opening is easy and uniform in deformation, can keep good surface contact with (the electric spindle) internally and externally matched cylindrical surfaces and is low in clamping deformation and high in positioning precision and clamping rigidity, and the taper ring with two grouped ends has double support and fine clamping stability.

Owner:CHANGZHOU TPD PRECISION MACHINERY

A manual adjustment wedge block type closed mold height adjustment device

The invention discloses a manual adjustment tapered wedge type closed die height adjusting device. The manual adjustment tapered wedge type closed die height adjusting device comprises a rack assembly, a sliding block assembly, a connecting rod assembly, a tapered wedge assembly, an oil cylinder assembly, a transmission adjusting assembly and an auxiliary guide assembly. The sliding block assembly is mounted on the rack assembly through the connecting rod assembly, and the tapered wedge assembly is connected with the sliding block assembly through the oil cylinder assembly and the auxiliary guide assembly; the oil cylinder assembly, the auxiliary guide assembly and the transmission adjusting assembly are all connected to the sliding assembly; power drives the connecting rod assembly to move, and the connecting rod assembly further drives the sliding block assembly to do reciprocating operation along the assembling position of the rack assembly; and when the transmission adjusting assembly is affected by external force, the tapered wedge assembly is adjusted, and therefore the sliding block assembly, the oil cylinder assembly and the auxiliary guide assembly are adjusted, and finally, fine adjustment of die filling height can be achieved. Through cooperative use of an upper tapered wedge, a lower tapered wedge and a sliding block, the adjustment precision, stability and portability of the closed die height can be improved, and accurate die adjusting of different materials can be achieved.

Owner:江苏兴锻智能装备科技有限公司

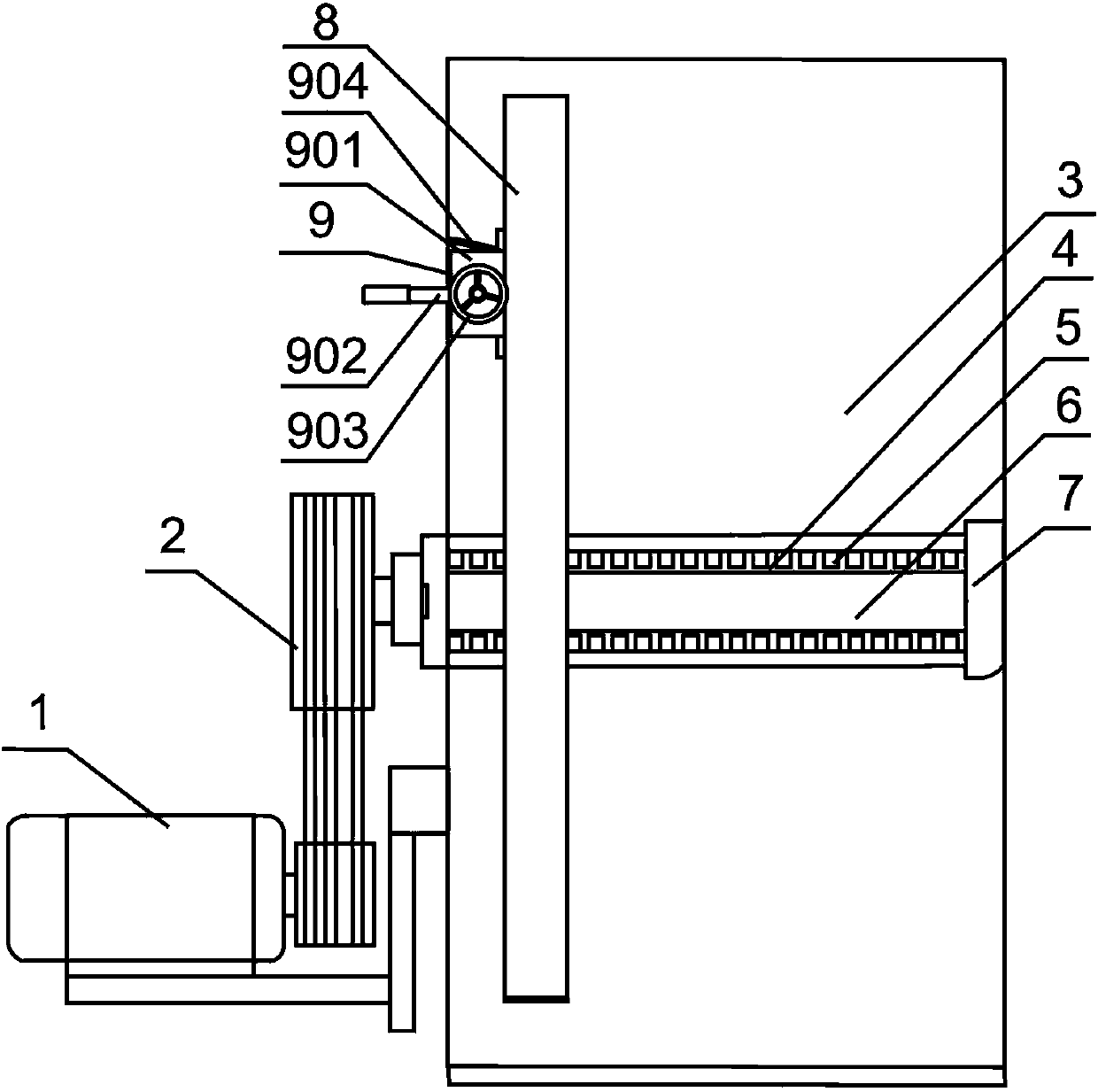

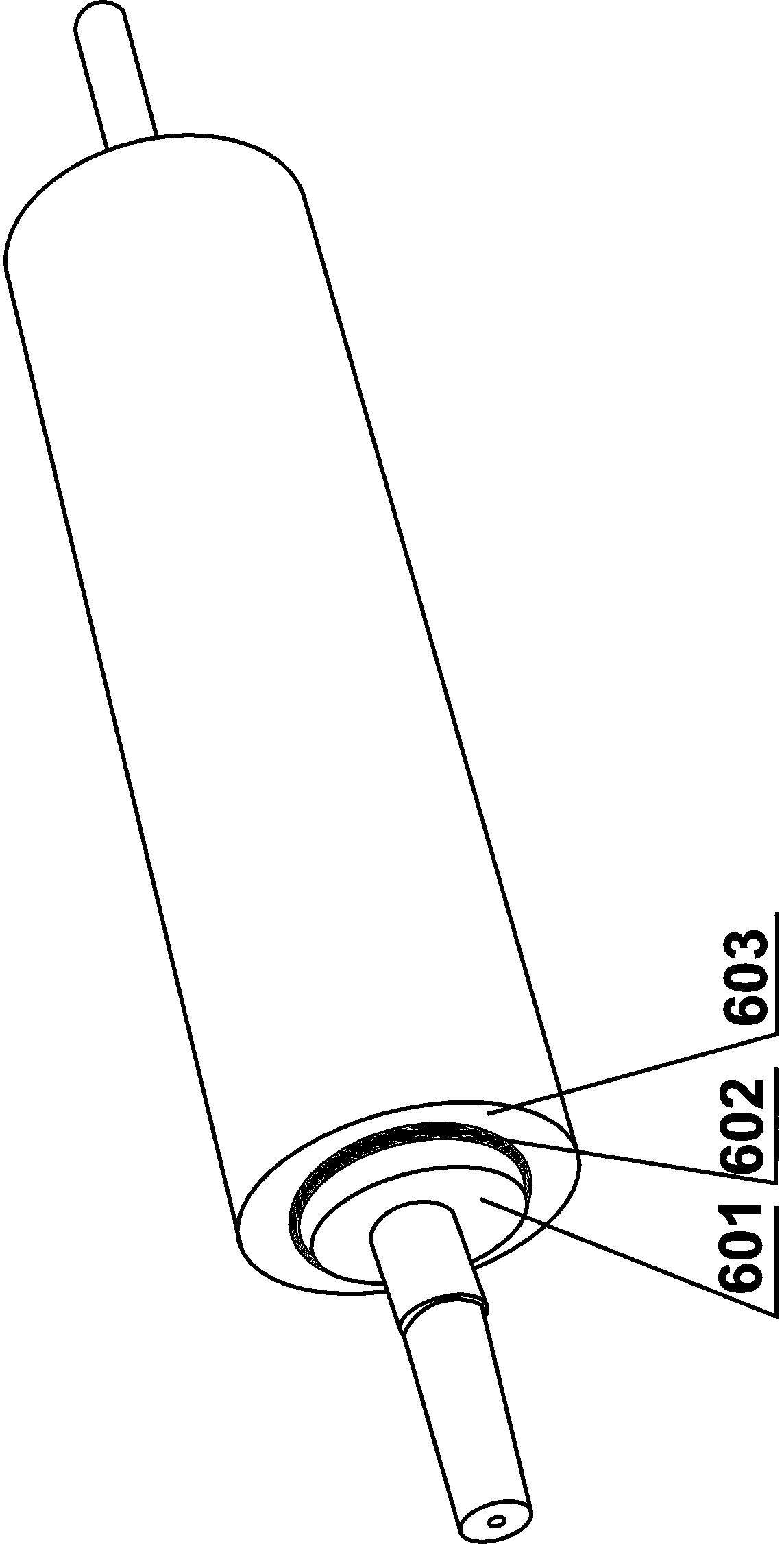

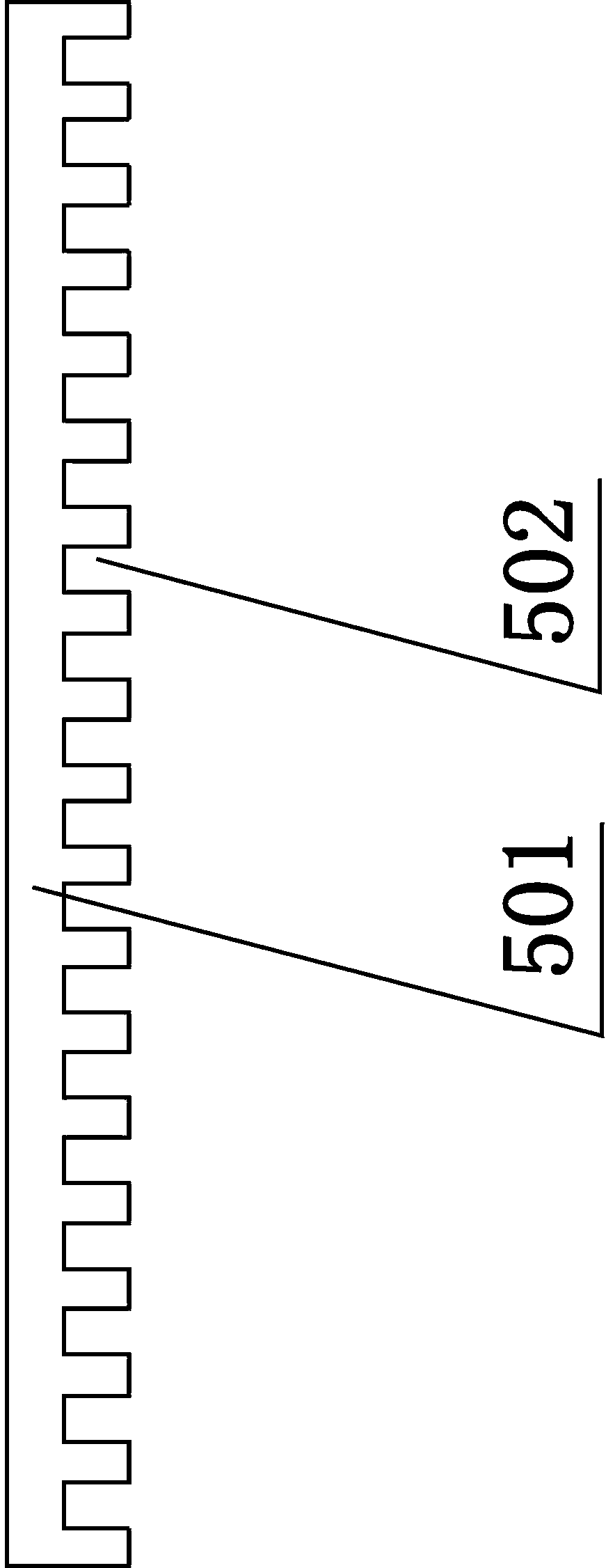

Woodworking polishing machine

InactiveCN104209845AContact stabilityHigh positioning accuracyGrinding carriagesPolishing machinesEngineeringDrive motor

The invention discloses a woodworking polishing machine. The woodworking polishing machine comprises a driving motor (1), a transmission mechanism (2), a polishing mechanism (6) and a workbench (3) and further comprises a roller groove (4), two edges (5), a check block (7), a baffle (8) and a mounting mechanism (9). The roller groove (4) is formed in the middle of the workbench (3), the polishing mechanism (6) is installed in the roller groove (4), the transmission mechanism (2) is in transmission connection with the driving motor (1) and the polishing mechanism (6), the edges (5) are fixed to the portions, on the two sides of the roller groove (4), of the workbench (3), the check block (7) is fixed to the portion, where the end, away from the transmission mechanism, of the roller groove (4) is located, of the workbench (3) and pressed on the edges (5), the baffle (8) is installed on the mounting mechanism (9), and the mounting mechanism (9) is fixed to the workbench (3). The woodworking polishing machine has the advantages of being simple in structure, easy and convenient to operate, stable in working state, good in polishing quality and the like.

Owner:CHENGDU NONDO FURNITURE

Space on-track repeated locking and releasing mechanism

The invention discloses a space on-track repeated locking and releasing mechanism, relating to a repeated locking and releasing mechanism. The invention aims to solve the problem in on-track repeated locking and releasing of large payload on spacecraft. The mechanism comprises a locking trunnion mechanism, a compaction lock hook mechanism, a locking base mechanism, a crank-rocker mechanism and a drive gear mechanism, wherein the locking trunnion mechanism is arranged at the upper end of the locking base mechanism; and the drive gear mechanism is connected with the compaction lock hook mechanism and the crank-rocker mechanism respectively. In the invention, the locking trunnion mechanism, the compaction lock hook mechanism, the locking base mechanism, the crank-rocker mechanism and the drive gear mechanism are crossed, the structure is simple and compact, all degrees of freedom of the fixed object can be completely limited, the repeated locking can be realized, the operability is good, and the using requirement of on-track locking-releasing-locking can be met. The mechanism disclosed by the invention is applicable to the technical field of aerospace and mechatronics.

Owner:HARBIN INST OF TECH

Integrated valve block

ActiveCN103452940BReduce volumeRadial volume is smallServomotor componentsEngineeringElectric control

The invention discloses an integrated valve block and belongs to the field of hydraulic technology. The integrated valve block comprises a valve body (200) provided with an inner cavity (201). Through holes are formed at two ends of the inner cavity (201) of the valve body (200). Five annular through holes are radially formed between the outer wall face of the valve body (200) and the inner cavity. A valve element (220) is nested into the inner cavity (201). Four coaxial cylinders with the same cross section are disposed at intervals in the axial direction of the valve element (220). The four cylinders of the valve element (220) are matched with the inner cavity (201) to form a zero-openness two-position four-way reversing valve. Compared with the prior art, the integrated valve block is free of an electric control system and simple in system.

Owner:SHANDONG UNIV OF SCI & TECH

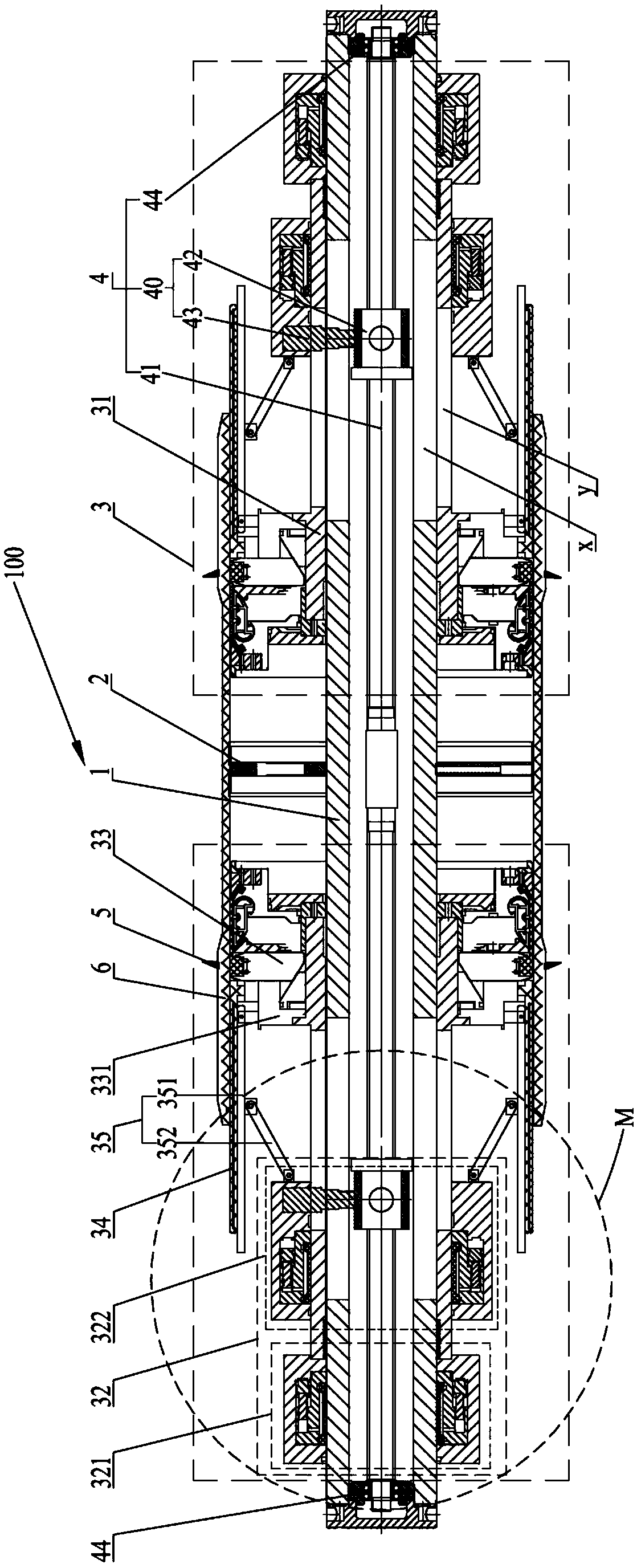

Multi-connecting-rod mechanical press driven by three parallel servo motor inputs

ActiveCN102328448BRealize forging processing actionIncrease input powerPress ramThree degrees of freedomMechanical press

The invention provides a multi-connecting-rod mechanical press driven by three parallel servo motor inputs, which is characterized in that the press comprises a rack, a three-motor and three-degree-of-freedom parallel mechanism, a connecting mechanism, a toggle rod mechanism and a pressing sliding block, wherein the output end of the three-motor and three-degree-of-freedom parallel mechanism is movably connected with the input end of the connecting mechanism, the output end of the connecting mechanism is movably connected with the input end of the toggle rod mechanism, the pressing sliding block is the output end of the toggle rod mechanism, and the rack is sheathed on the external sides of the three-motor and three-degree-of-freedom parallel mechanism, the connecting mechanism, the toggle rod mechanism and the pressing sliding block. The press has the advantages of simple structure, easiness in control and low manufacturing cost and can well solve the problem that a large-tonnage servo press cannot be constructed because the output torque and the power of the existing servo motor are small.

Owner:SHANGHAI JIAOTONG UNIV

A coupled inductor boost inverter and its control method

InactiveCN107959429BReduce in quantityReduce volumeEfficient power electronics conversionAc-dc conversionCapacitanceSoftware engineering

The invention discloses a coupled inductance step-up inverter and a control method thereof, belonging to the technical field of power electronic converters. It includes diode D 1 、D 2 、D S3 and D S4 , switch tube S 1 , S 2 , S 3 , S 4 and S 5 ; The primary winding N of the coupled inductor T 1 and the secondary winding N 2 ; Capacitance C 1 ; Diode D 1 The anode is connected to the input power supply U in One end, the diode D 1 The cathode is connected to the primary winding N of the coupled inductor T 1 Terminal of the same name; primary winding N of coupled inductor T 1 Non-identical end and switch tube S 1 Terminal A, switch tube S 2 A terminal and capacitor C 1 Connected at one end; switch tube S 1 C terminal, diode D 3 Cathode, switch tube S 5 A terminal and input power U in The other end is connected; diode D 3 anode, diode D 2 Cathode and Capacitor C 2 connected at one end. Aiming at the problem of low boost ratio in the prior art boost inverter, it has high integration, high boost ratio and more flexible regulation of boost ratio.

Owner:HOHAI UNIV WENTIAN COLLEGE

Automatic adjusting inclined wedge block type die closing height adjusting device

The invention relates to the technical field of automation of punching machines, and specifically relates to an automatic adjusting inclined wedge block type die closing height adjusting device. The device comprises a bottom plate, a lower inclined wedge block, an upper inclined wedge block and a punching machine slide block, wherein the lower inclined wedge block is fixedly connected to the upper end of the bottom plate; the upper inclined wedge block is movably mounted at the upper end of the lower inclined wedge block; the punching machine slide block is arranged at the upper end of the upper inclined wedge block; a front mounting seat is fixedly connected to the left end of the punching machine slide block, and a rear mounting box is fixedly connected to the right end of the punching machine slide block; a lead screw fixing seat is fixedly mounted on one sidewall of an inner chamber of the rear mounting box; a nut is fixedly connected to one end of the upper inclined wedge block; a lead screw is connected into the nut through threads; the left end of the lead screw is movably connected to the front mounting seat while the right end of the lead screw is movably mounted on a lead screw fixing seat; a worm gear is fixedly connected to one end of the lead screw; a worm which is movably connected to a supporting seat is arranged above the worm gear. The device is convenient to use, can automatically adjust the die closing height of a press machine of the punching machine, and is suitable for popularization and use.

Owner:江苏兴锻智能装备科技有限公司

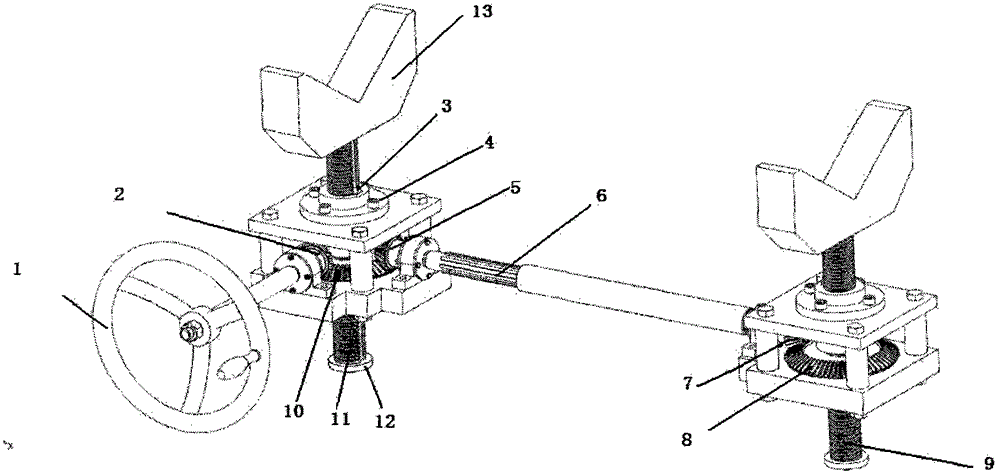

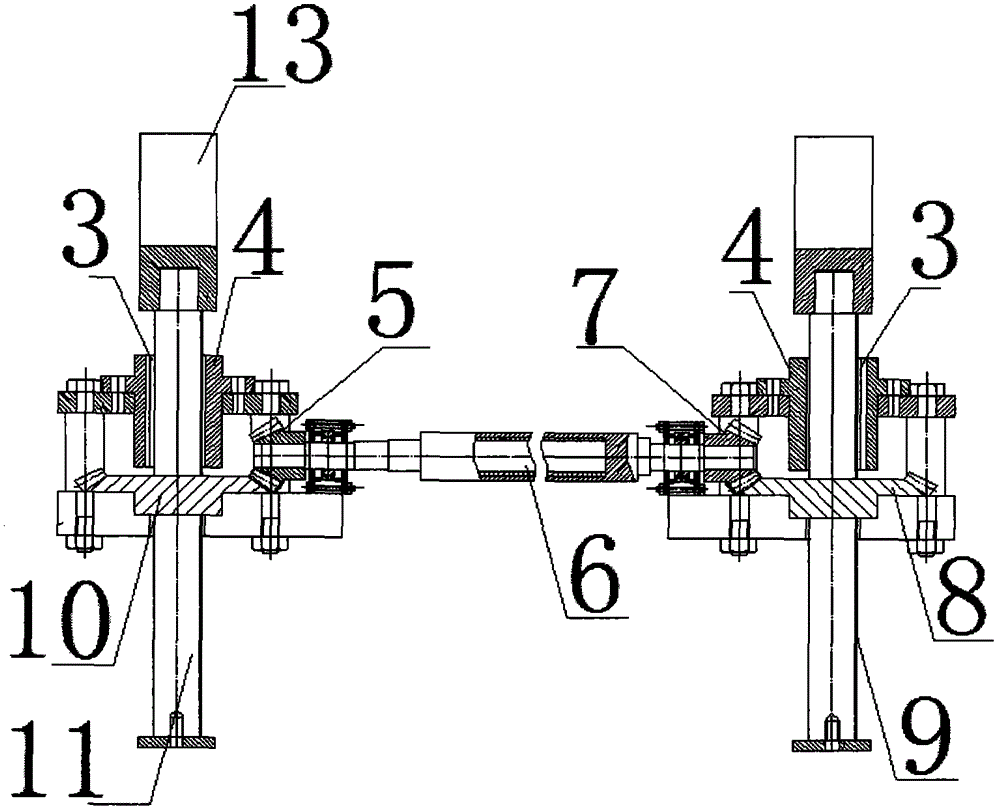

A double v-shaped block parallel synchronous lifting mechanism

InactiveCN103769944BEasy to useLarge boost ratioAutomatic control devicesFeeding apparatusDrive shaftEngineering

The invention discloses a double-V-shaped-block parallel synchronization lifting mechanism which comprises a hand wheel, bevel gears, a right rotating lead screw, a left rotating lead screw, a lead screw guiding sleeve, a lead screw guiding rotating stopping flat key and the like. A first bevel gear is fixedly arranged at the end of a hand wheel rotating shaft and is meshed with a second bevel gear arranged on a supporting plate. One end of a spline telescopic joint sleeve transmission shaft is fixedly provided with a third bevel gear which is meshed with the second bevel gear, and the other end of the spline telescopic joint sleeve transmission shaft is fixedly provided with a fourth bevel gear which is meshed with a fifth bevel gear. The two lead screws which are the same in lead and opposite in rotating direction are screwed on the second bevel gear and the fifth bevel gear through lead screw nuts which are placed at the circular centers of the second bevel gear and the fifth bevel gear and are integrally machined with the two bevel gears respectively. The upper ends of the two lead screws are respectively provided with a V-shaped block. According to the double-V-shaped-block parallel synchronization lifting mechanism, the bevel gears are driven by rotating the hand wheel, then the lead screws drive the two V-shaped blocks to move up and down synchronously, fine adjustment effect is good, accumulative errors are avoided, the force increasing ratio of the whole mechanism is large, and the hand wheel is convenient to use.

Owner:HENAN POLYTECHNIC UNIV

A manual pressing device based on worm gear and crank connecting rod transmission

The invention discloses a manual pressing device based on worms, worm wheels and crank connecting rod transmissions. The manual pressing device comprises a rotary shaft, wherein at least two worms are fixedly arranged on the rotary shaft, the worm wheels meshed with the worms are arranged under the corresponding worms, the crank connecting rod transmissions are arranged on the worm wheels, and the tail ends of the crank connecting rod transmissions are connected to the same press block. The symmetrical synchronous multi-point driving is achieved, the manual pressing device is compact in structure, simple and convenient to use and rapid in positioning and pressing, the synchronous multi-point or multi-station pressing can be achieved according to the demands of workpieces, and accordingly labor productivity and product quality are improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com