Woodworking polishing machine

A polishing machine and polishing mechanism technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problems of unstable working state, small single polishing area, inaccurate positioning, etc. Guaranteed operational safety, good self-locking performance, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

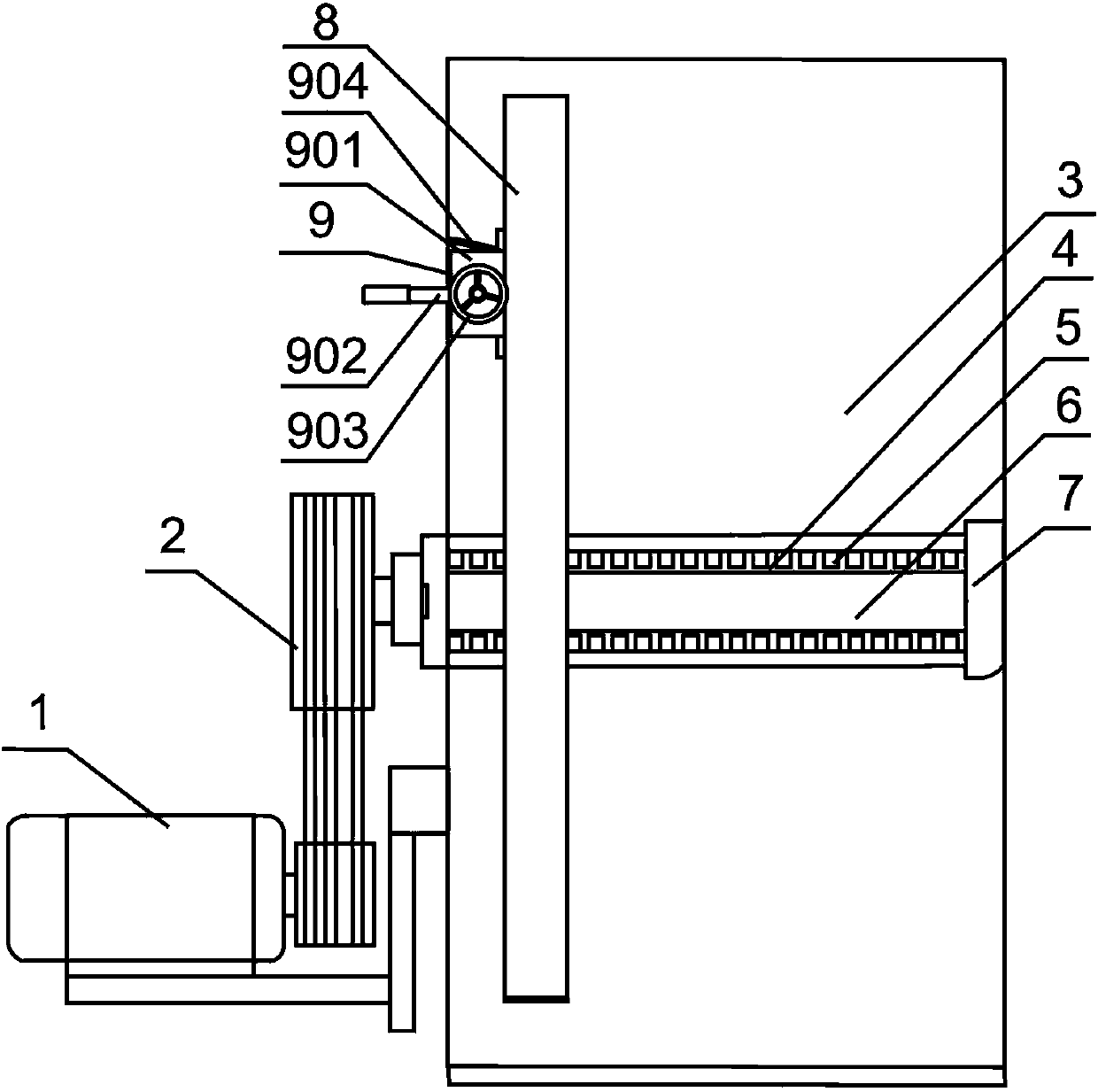

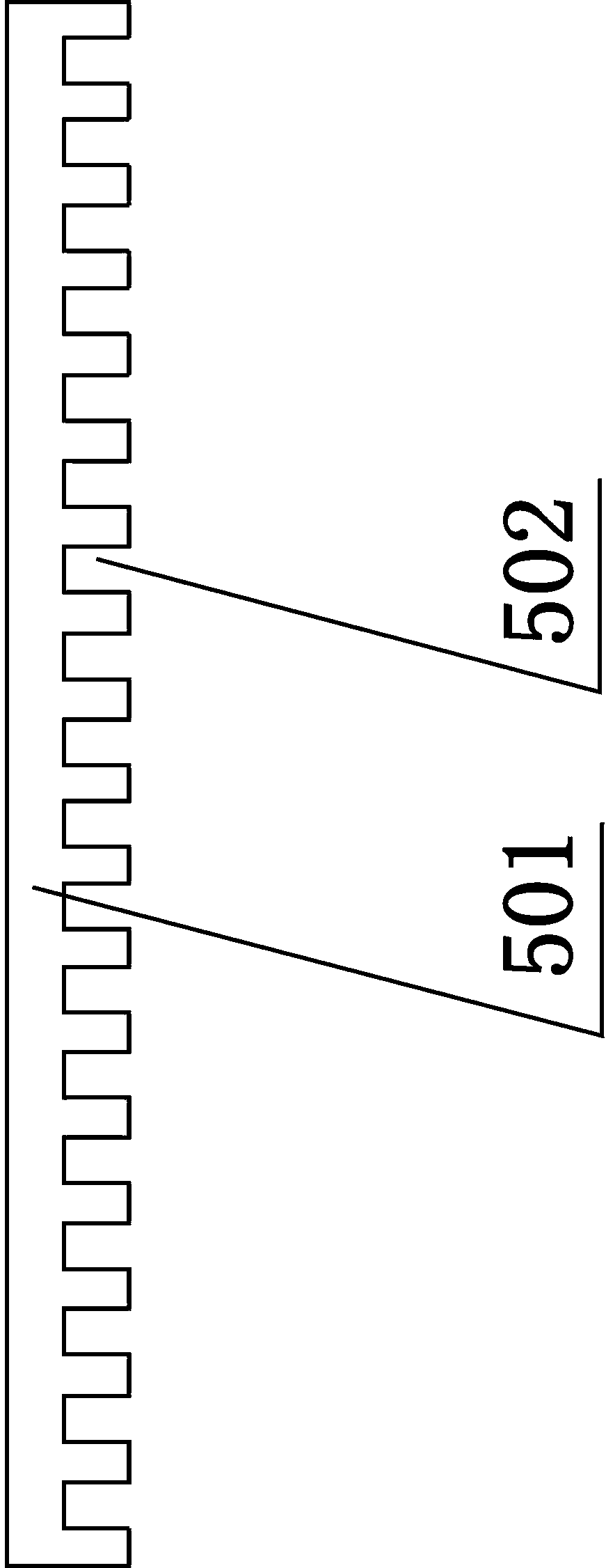

[0038] Such as figure 1As shown, the present invention includes a drive motor 1, a transmission mechanism 2, a polishing mechanism 6, a workbench 3, and also includes a roller groove 4, two edges 5, a block 7, a baffle plate 8, and a mounting mechanism 9. The workbench There is a roller groove 4 in the middle of 3, the polishing mechanism 6 is installed in the roller groove 4, the transmission mechanism 2 is connected to the drive motor 1 and the polishing mechanism 6, and the edge 5 is fixed on the worktable on both sides of the roller groove 4 3, the block 7 is fixed on the table 3 at the end of the roller groove 4 away from the transmission mechanism, and pressed on the edge 5; the baffle 8 includes two baffle mounting pieces 801 and a columnar protrusion 802 , the columnar protrusion 802 is connected below one end of the baffle 8, the baffle mounting piece 801 is connected to the middle part of the baffle 8, and the baffle 8 is installed on the installation mechanism 9 thr...

Embodiment 2

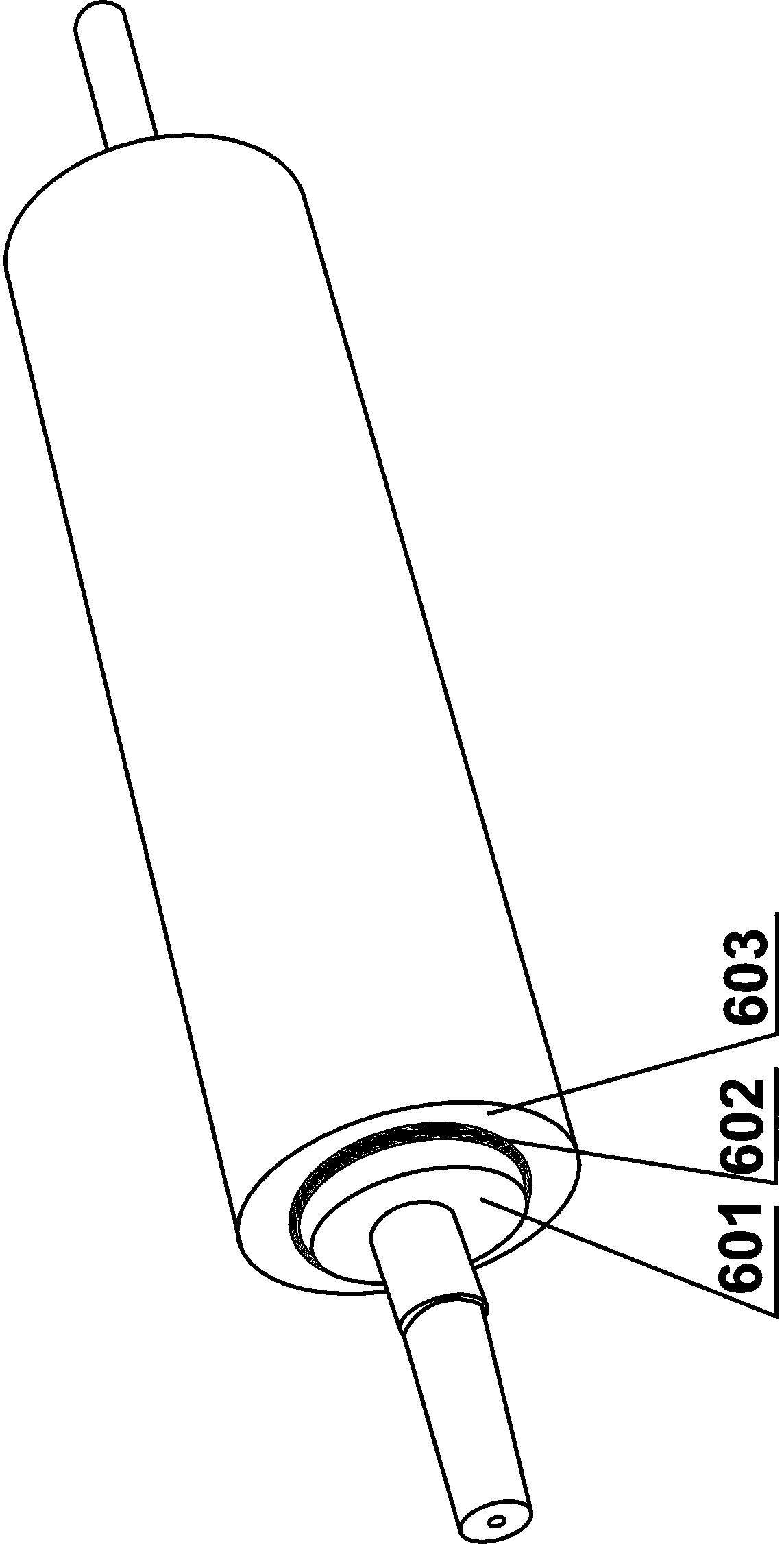

[0042] In order to make the polishing mechanism simple in structure, good in working stability, and easy to maintain, this embodiment is further improved on the basis of any embodiment of Embodiment 1, such as figure 2 As shown, the polishing mechanism 6 of this embodiment includes a roller shaft 601, a graphite cloth 602, and a polishing fabric 603. The graphite cloth 602 is fixed on the roller shaft 601 through a collar, and the polishing fabric 603 is fixed on the roller shaft through a collar. The polishing cloth 603 is above the graphite cloth 602 on the shaft 601 .

Embodiment 3

[0044] In order to make the roller shaft have better strength, toughness and wear resistance, this embodiment is further improved on the basis of embodiment two. The material of the roller shaft 601 in this embodiment is 37SiMn2MoV steel, 38CrMoAlA steel, 20Cr steel, 20CrMnTi steel , 40MnB steel, 40CrNi steel, 40Cr steel, any one of tungsten steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com