Puncture type terminal, electric connector and technique for producing the same

A piercing terminal and electrical connector technology, which is applied in the direction of conductive connection, connection, line/collector parts, etc., can solve the problems of unstable electrical contact, low electrical impedance, and high electrical impedance, and achieve contact Stability, low electrical impedance, and performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

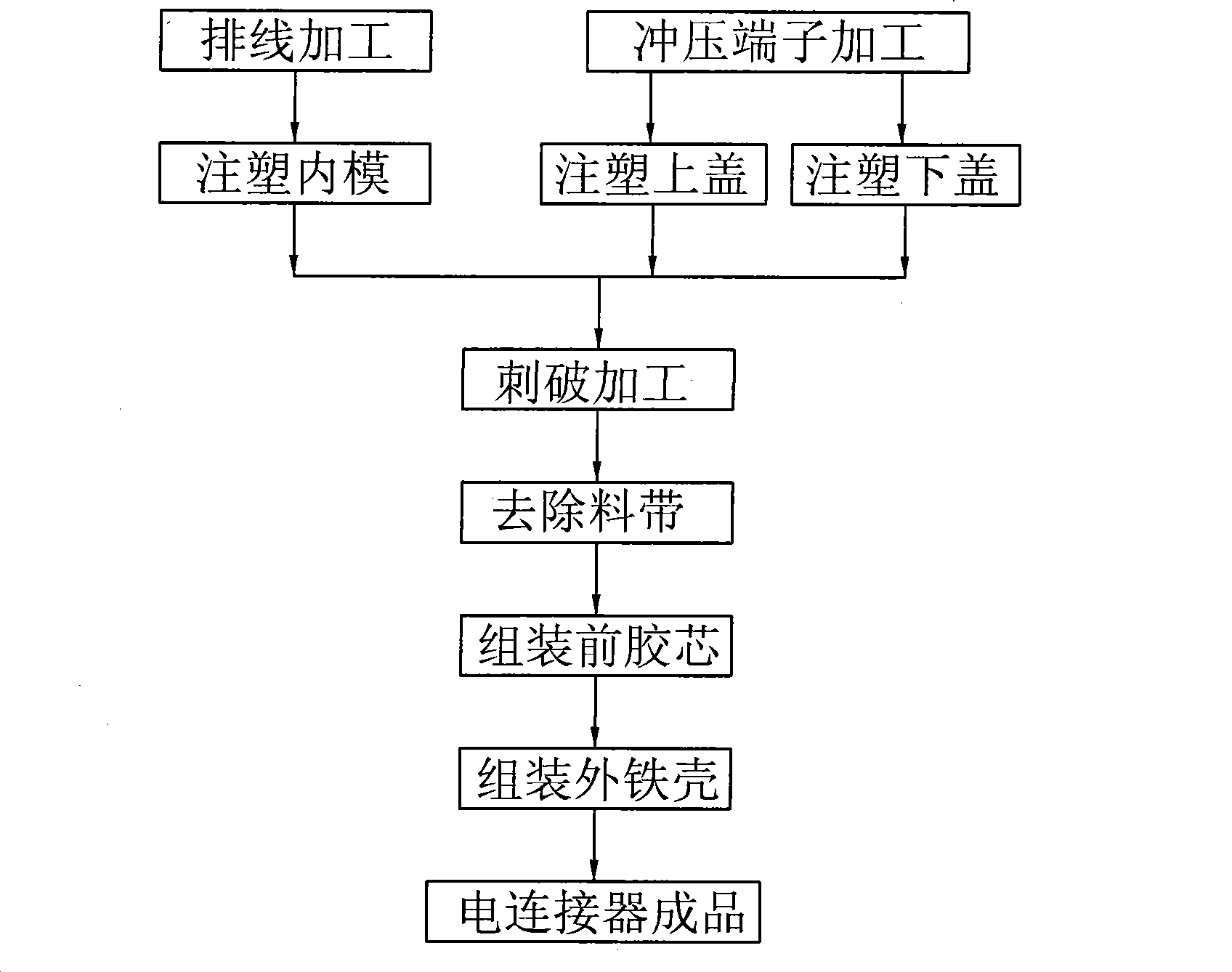

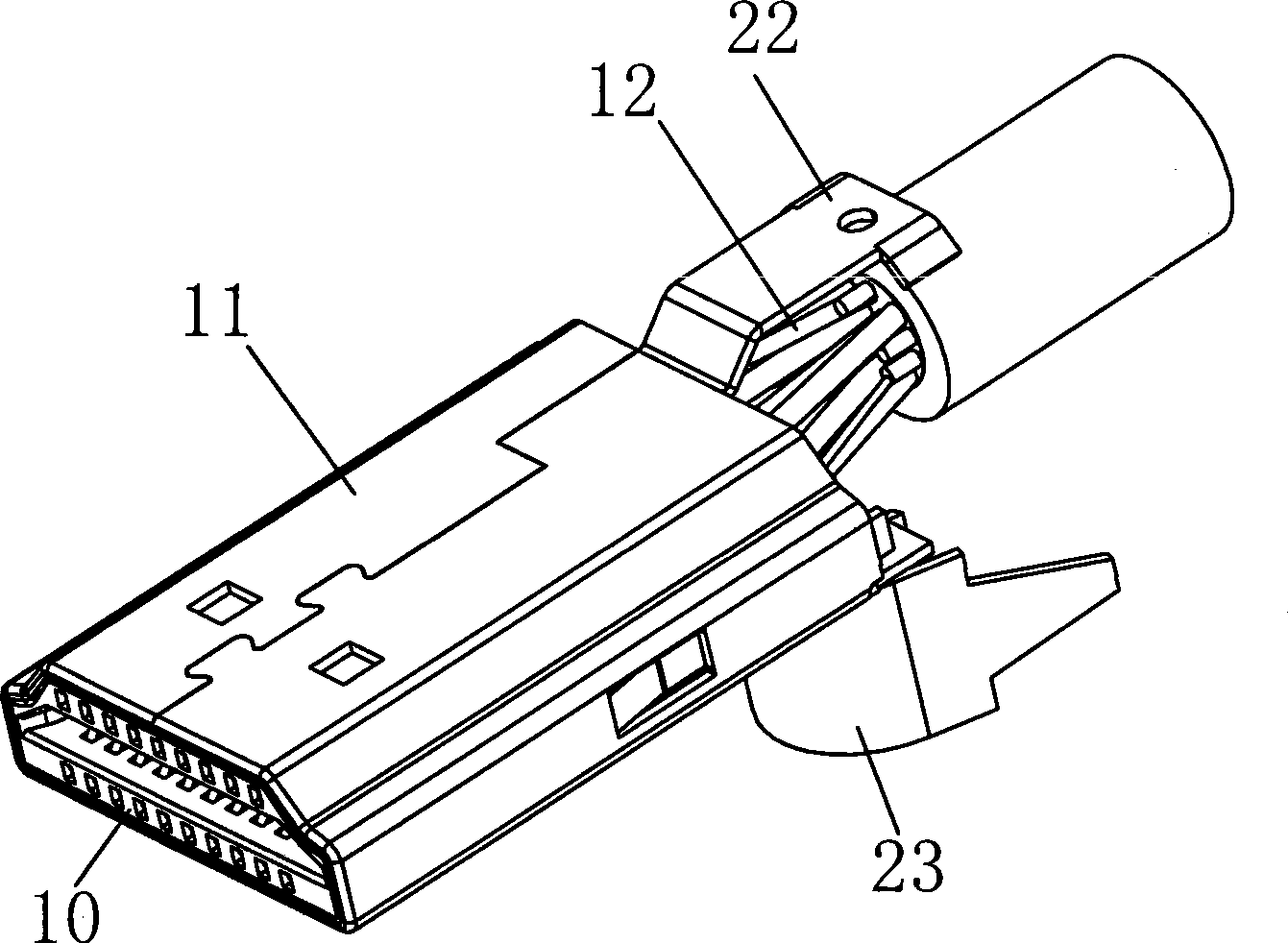

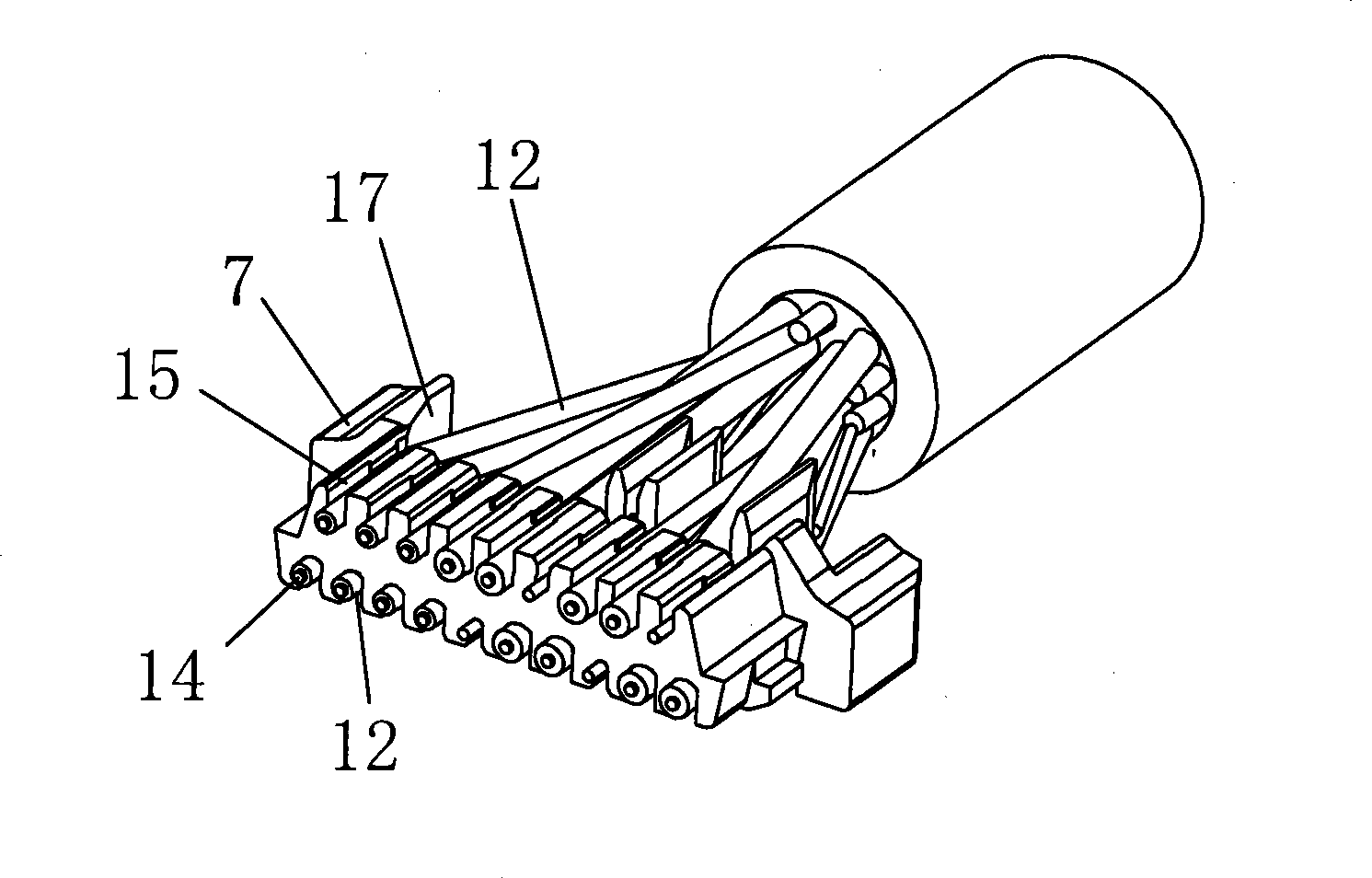

[0070] For the processing technology of piercing HDMI electrical connector, see the attached figure 1 , which includes the following steps:

[0071] Stamping terminal processing, stamping and forming terminal 13, see attached Figures 19 to 23 , the front end of the terminal 13 is the electrical contact part 1, the middle part of the terminal 13 is the shaft 2, and the rear end of the terminal 13 is the electrical connection part 3, and the electrical connection part 3 is formed with three fangs 4 with staggered tips, and the fangs 4 are arranged on the terminal On the electrical connection part 3 of 13, the canines 4 punched out are in the shape of a pyramid, and the inner surface 5 of the canines 4 is formed with an arc surface, and the tips of the three canines 4 are respectively inclined to the outside. The direction of the inner surface 5 of the tooth 4 is the same, and is opposite to the direction of the inner surface 5 of the canine 4 located in the middle. The three c...

Embodiment 2

[0102] The processing technology of the puncture type HDMI electrical connector, this embodiment is to continue processing after completing the various processing steps of the first embodiment, and its various production steps are the same as the first embodiment, and this embodiment also includes the following steps:

[0103] In the plastic shell injection molding step, the outer iron shell 11 and the electrical connector assembly are placed in an injection mold, and a plastic shell is injected outside the outer iron shell 11 .

[0104] Since the puncture-type HDMI electrical connector of the present invention has made a huge breakthrough in thinning and miniaturization, the thickness of the electrical connector is far smaller than the minimum thickness defined by the micro HDMI electrical connector, so it can be electrically connected The outside of the connector is injection-molded with a housing, and the thickness of the electrical connector injected with the housing is sti...

Embodiment 3

[0107] piercing terminal, see attached Figures 19 to 26 The front end of the terminal 13 is an electrical contact part 1, the middle part of the terminal 13 is a shaft 2, and the rear end of the terminal 13 is an electrical connection part 3. At least two fangs 4 with staggered tips are formed on the electrical connection part 3. The fangs 4 are Pyramid shape, the inner surface 5 of the canine 4 is formed with an arc surface.

[0108] Three canines 4 are arranged on the electrical connection portion 3 of a terminal 13, wherein the direction of the inner surface 5 of the canine 4 at the front end and the rear end is the same, and the direction of the inner surface 5 of the canine 4 in the middle is opposite to that of the arc. The surface is formed on the upper end position of the inner side surface 5 of the canine 4 .

[0109] The three fangs 4 form a "V"-shaped or "U"-shaped core wire holder on the vertical projection plane, see attached Figure 23 . The front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com