Solid electrolyte for inhibiting lithium dendrites growth in full-solid-state battery, and preparation method thereof

A solid-state electrolyte and all-solid-state battery technology, applied in secondary batteries, electrochemical generators, circuits, etc., can solve the problems of different thermodynamic properties, chemical stability and electrochemical stability between solid-state electrolytes and electrode materials, and improve the interface Effects of ion conductivity, reduction of grain boundary migration resistance, and reduction of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a solid-state electrolyte for inhibiting the growth of lithium dendrites in an all-solid-state battery, using the following steps:

[0040] Step 1: Weigh lithium carbonate, lanthanum oxide, and zirconium oxide according to the stoichiometric ratio, and grind them evenly by dry grinding method, so that the mixture is fully mixed, and then placed in an alumina crucible with a cover;

[0041] The second step: put the mixture in the first step in an alumina crucible with a cover, sinter in a muffle furnace at 900°C for 3 to 6 hours, the heating and cooling rate is 5°C / min, and cool to room temperature;

[0042] The third step: transfer the reactant in the second step to an agate mortar for grinding, mix well, and record it as mother powder A;

[0043] Step 4: Grind the reactants in the second step in an agate mortar, add 0.1-10 wt% of the second phase with a low melting point, mix well, and record it as mother powder B;

[0044] Step 5: Add 0.3g of t...

Embodiment 2

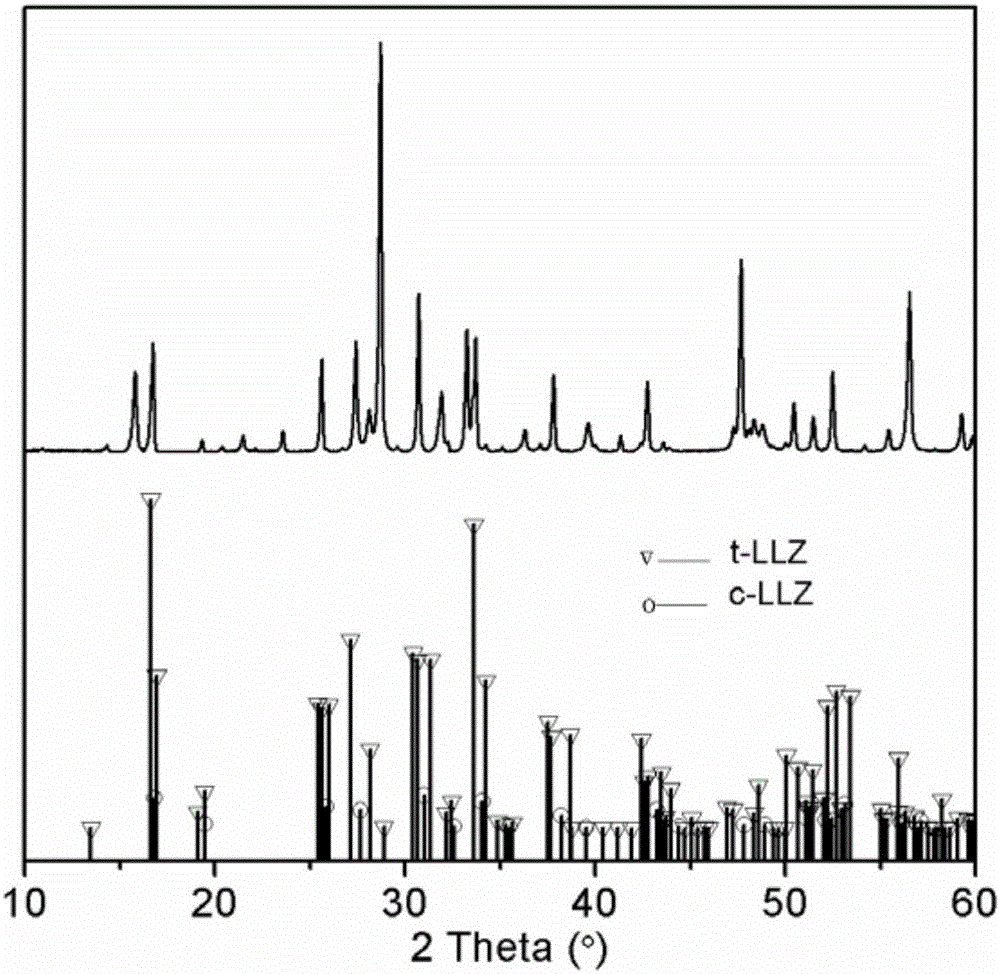

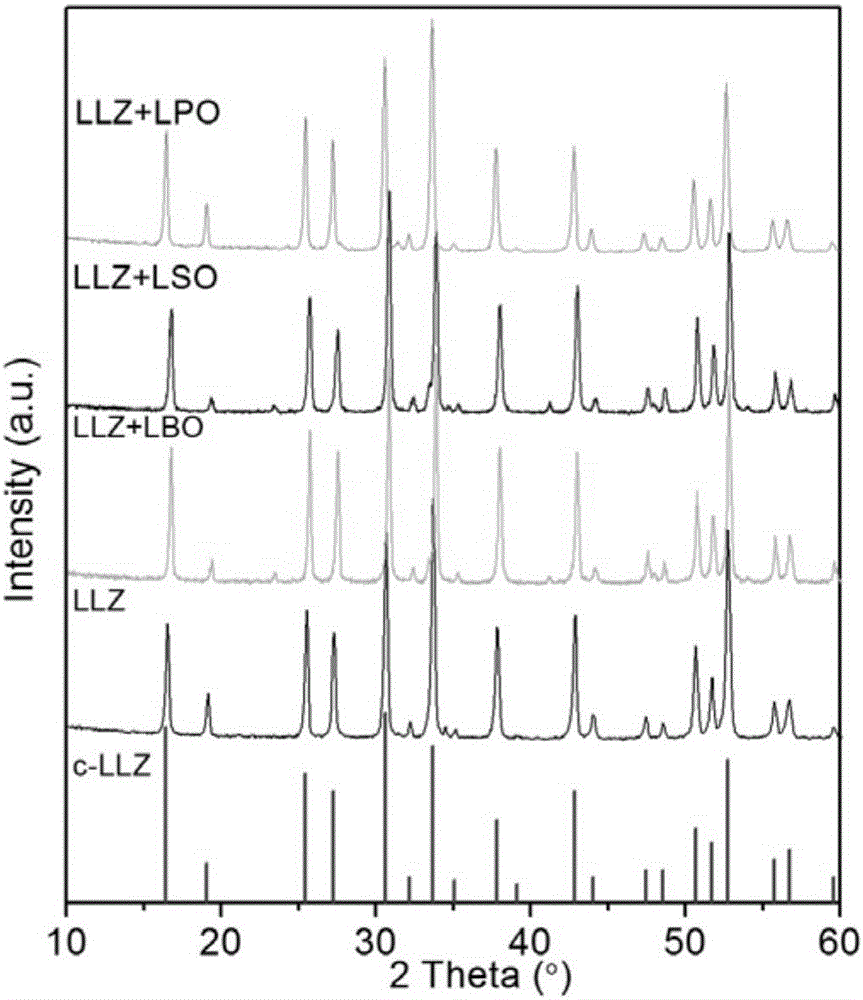

[0050] The preparation method in this example is the same as in Example 1. In step 4 of this example, a low-temperature second-phase sintering aid is used, the lithium-containing garnet with lithium borate is marked as LLZ+LBO, and the lithium-containing garnet with lithium borate is added. Garnet is marked as LLZ+LPO, and lithium-containing garnet with lithium borate is marked as LLZ+LSO. Depend on figure 2 It can be seen that the XRD of the lithium-containing garnet prepared in Example 2 is completely consistent with the standard cubic phase lithium-containing garnet (c-LLZ), and the doping of the low-temperature second-phase sintering aid lithium-containing garnet does not change its crystal structure, good crystallinity, and no second phase additive detected by XRD.

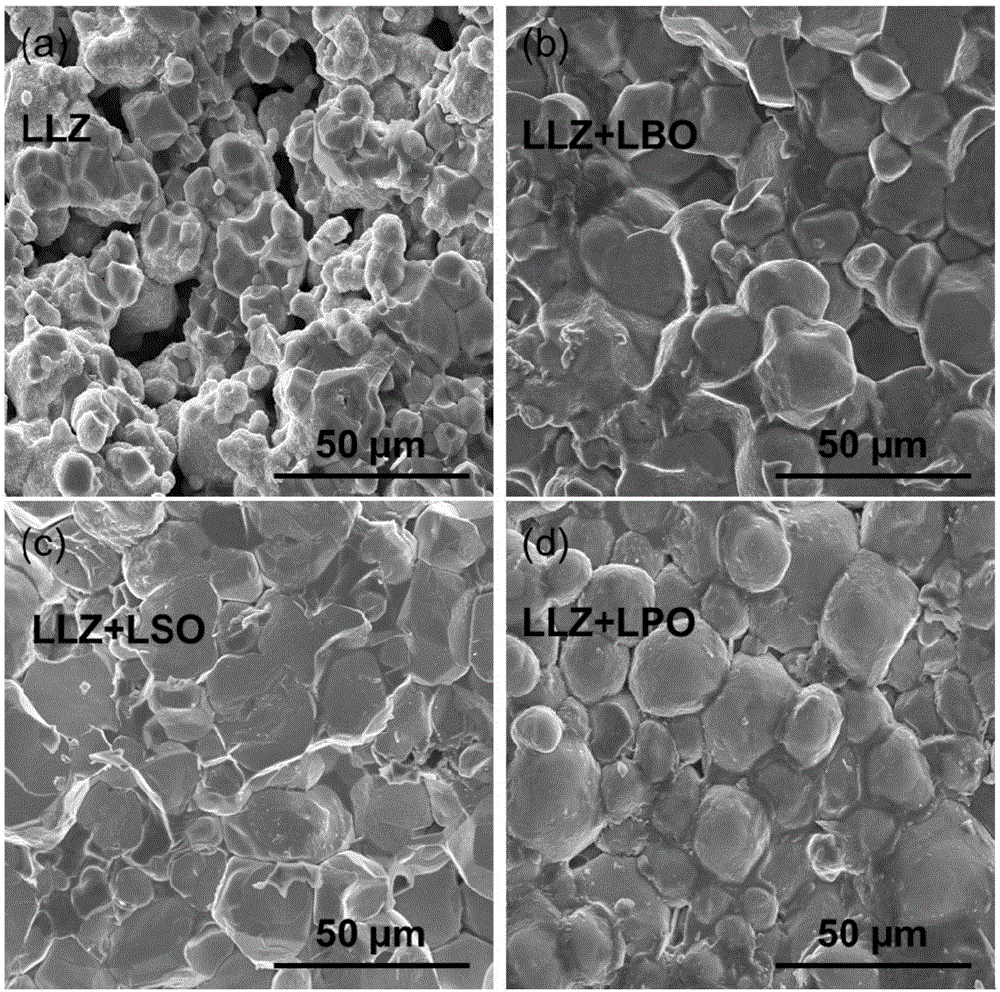

[0051] Depend on image 3 It can be seen that undoped lithium-containing garnet, lithium-containing garnet with lithium borate (LLZ+LBO), lithium-containing garnet with lithium borate (LLZ+LPO), lithium-co...

Embodiment 3

[0055] The preparation method in this example is the same as in Example 1, the only difference is that the mass ratio of lithium carbonate, lanthanum oxide, and zirconia is 20:50:20, the addition of the second phase in the preparation process is different, and the temperature rise and fall speed of the muffle furnace The control is 1° C. / minute, and the auxiliary agent added in Step 4 of this embodiment is lithium borate.

[0056] The phase of the lithium-containing garnet prepared in Example 3 was characterized by X-ray diffraction and other means. X-ray diffraction shows that the lithium-containing garnet obtained in Example 3 at 900° C. for 16 hours is a cubic phase. The lithium borate second phase effectively reduces the sintering temperature of lithium-containing garnet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com