Multi-connecting-rod mechanical press driven by three parallel servo motor inputs

A technology of mechanical presses and servo motors, applied in the field of forging machinery, can solve the problems of increasing the forming pressure of presses, increasing the difficulty of control strategies, and deteriorating control stability, so as to reduce loads, improve the ability to resist partial loads, The effect of increasing the input power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

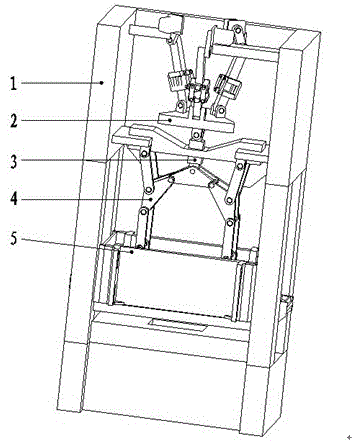

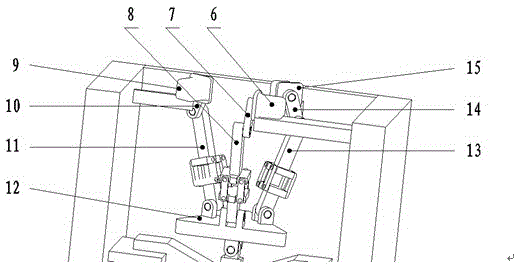

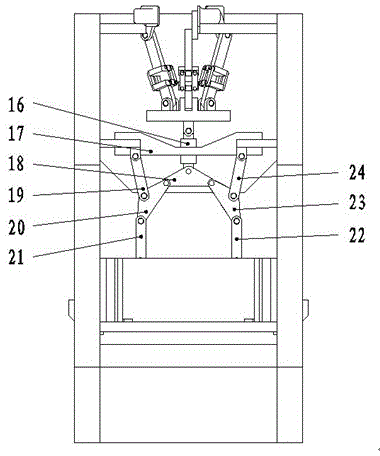

[0021] Such as figure 1 As shown, this embodiment includes: a frame 1 , three motors and a three-degree-of-freedom parallel mechanism 2 , a connecting mechanism 3 , a toggle mechanism 4 and a stamping slider 5 . Among them: the output end of the three-motor and three-degree-of-freedom parallel mechanism 2 is connected with the input end of the connecting mechanism 3 through a hinge, the output end of the connecting mechanism 3 is connected with the input end of the toggle mechanism 4 through a hinge, and the stamping slider 5 is used as a toggle The output of mechanism 4. The frame 1 is socketed on the outside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com