Shell turn type inner-curve radial plunger hydraulic motor

A technology of hydraulic motor and inner curve, applied in the field of shell-turn inner curve radial piston hydraulic motor, can solve the problems of high cost, inconvenient installation and operation, etc., and achieves large installation space, reasonable design, and increased braking torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

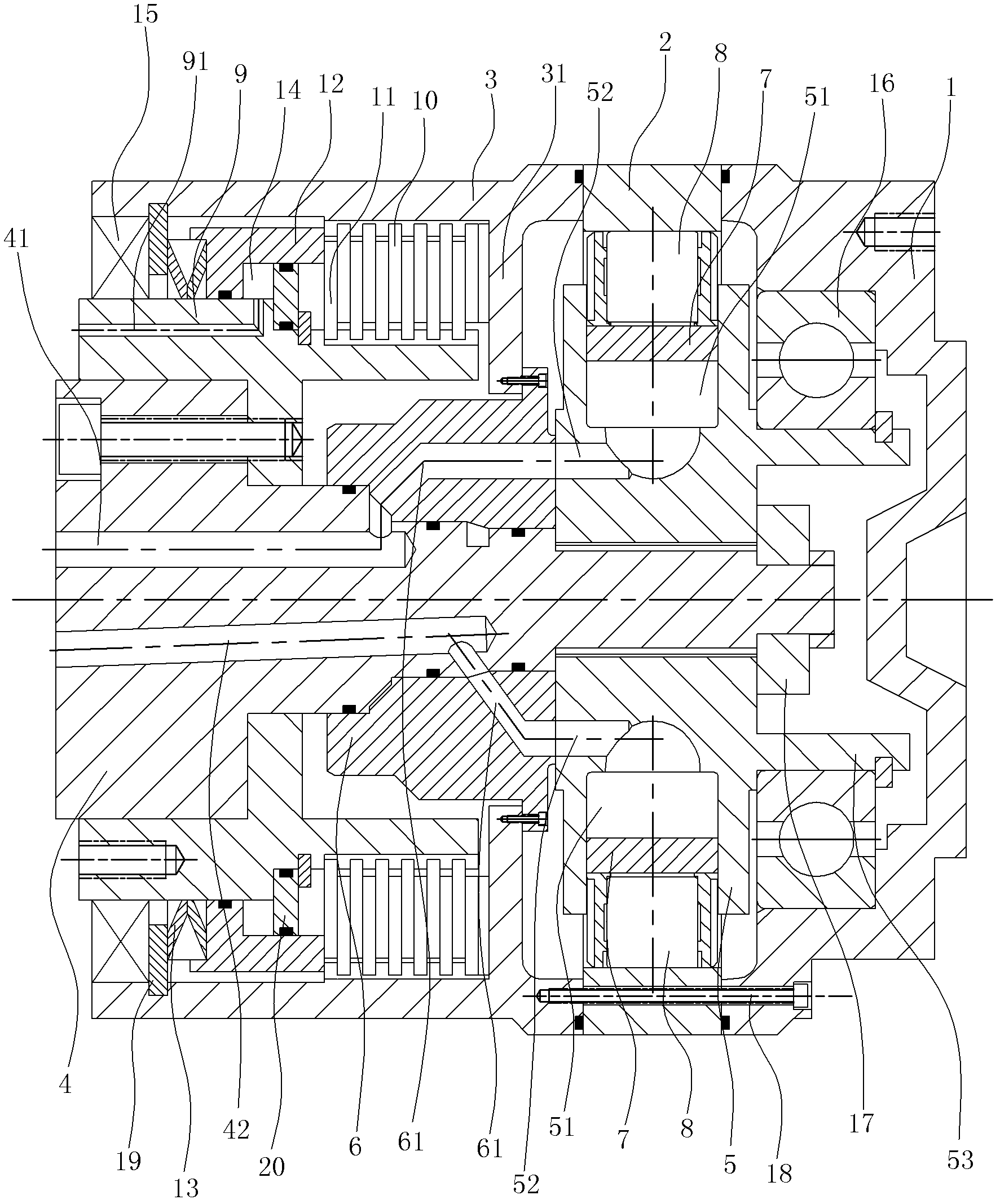

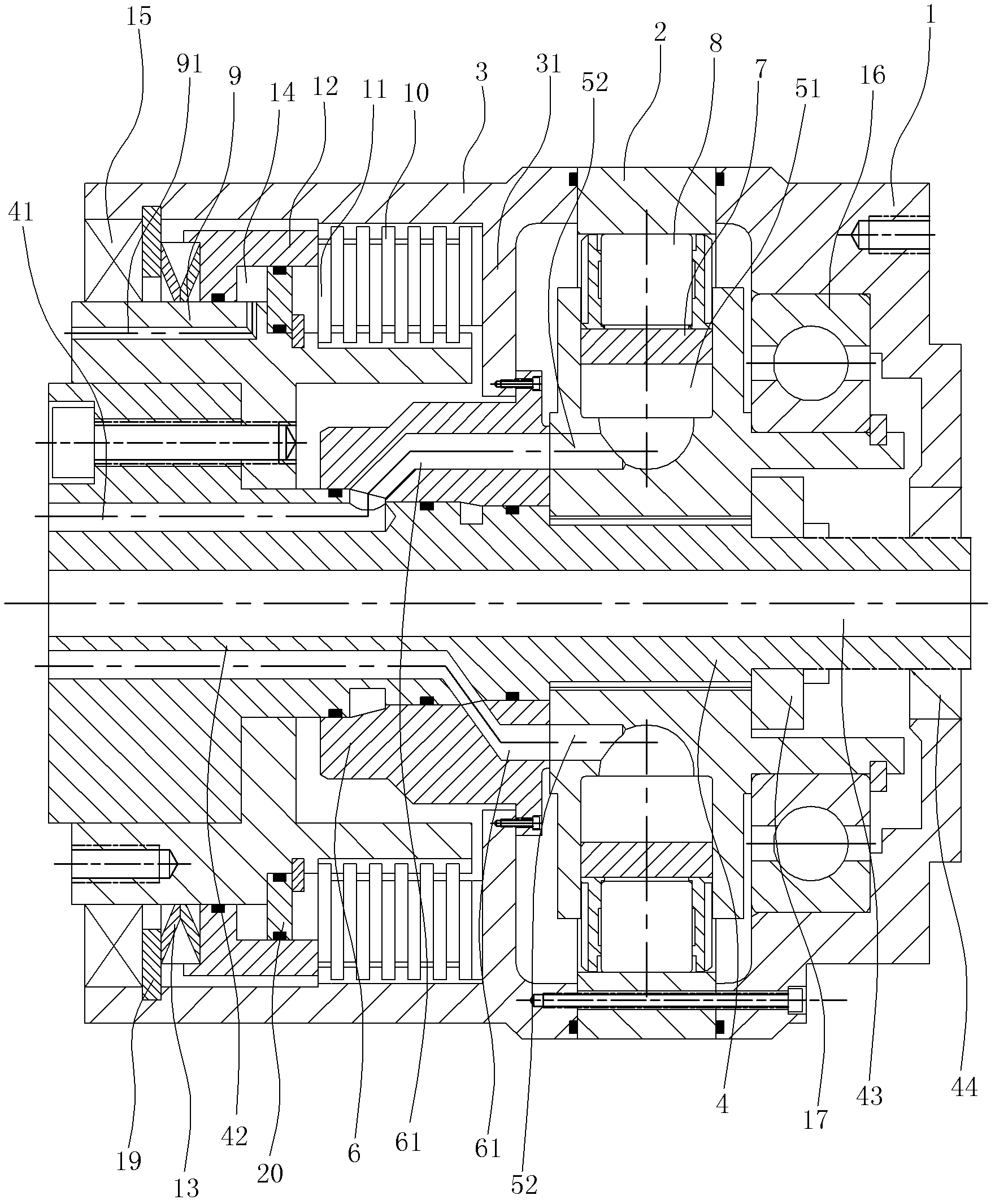

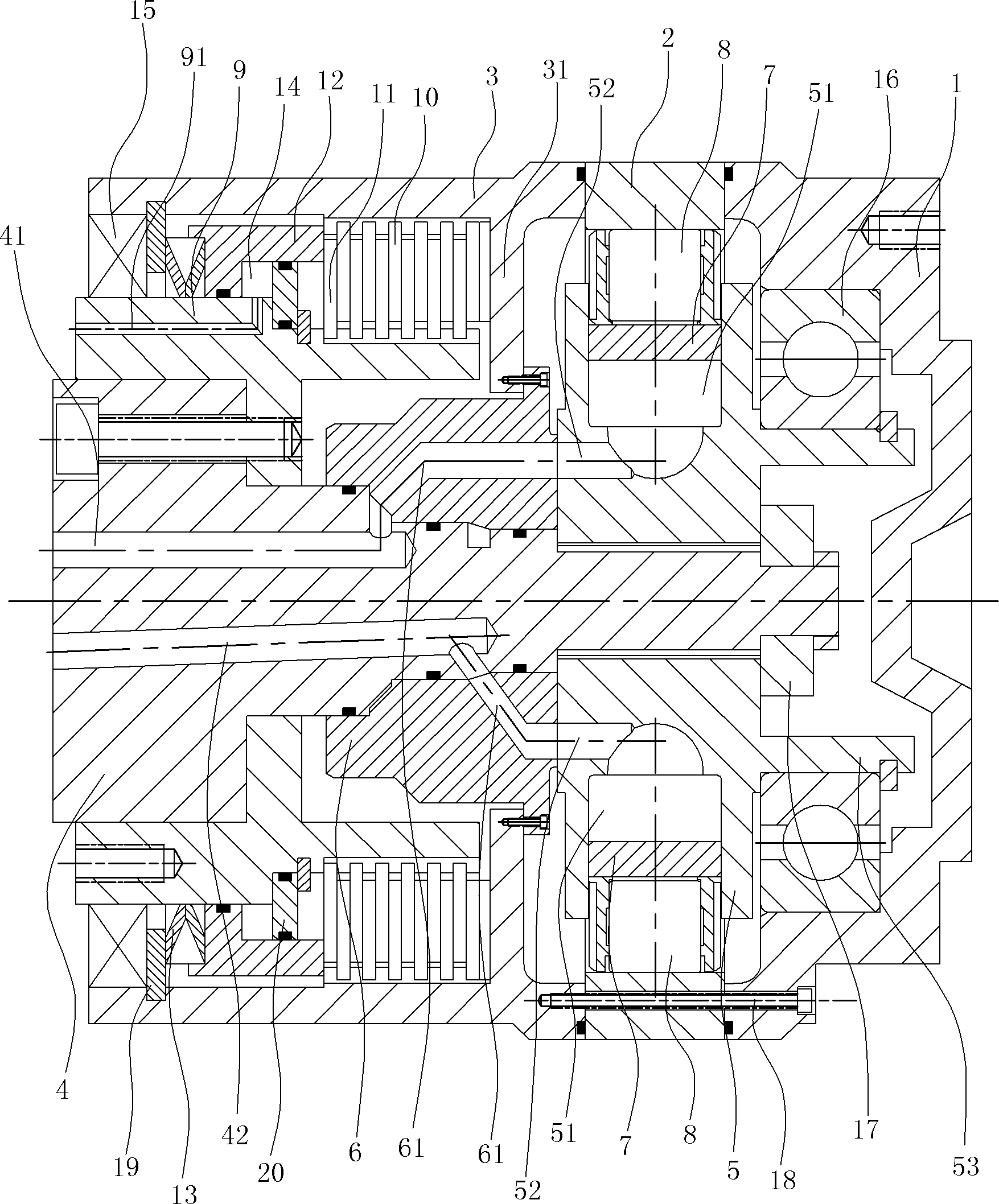

[0020] like figure 1 shown, is the first embodiment of the present invention.

[0021] A shell-rotating inner-curve radial piston hydraulic motor, comprising a casing composed of a front cover 1, a stator 2 and a rear cover 3, the front cover 1 and the rear cover 3 are fixed on the front and rear ends of the stator 2, and the front cover 1. The stator 2 and the rear cover 3 are fixed together by a plurality of screws 18.

[0022] The casing is installed with an oil passage shaft 4, a rotor 5 and an oil distribution plate 6, the rotor 5 is fixed on the oil passage shaft 4, the inner hole of the rotor 5 is connected to the oil passage shaft 4 through splines, and the front end of the oil passage shaft 4 is set. There is a lock nut 17 for axially limiting the rotor 5 . A plurality of radially arranged plunger holes 51 are arranged on the peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com