Patents

Literature

68results about How to "High braking torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

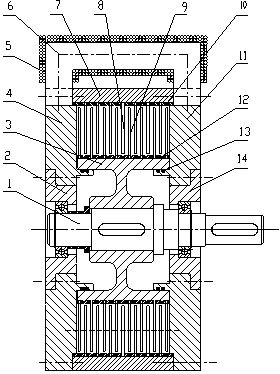

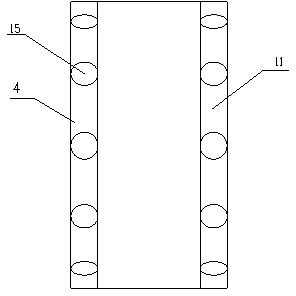

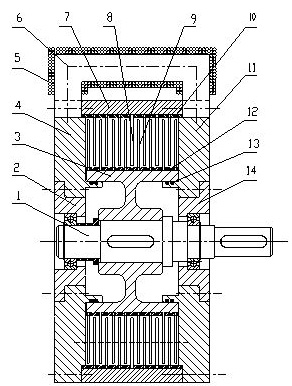

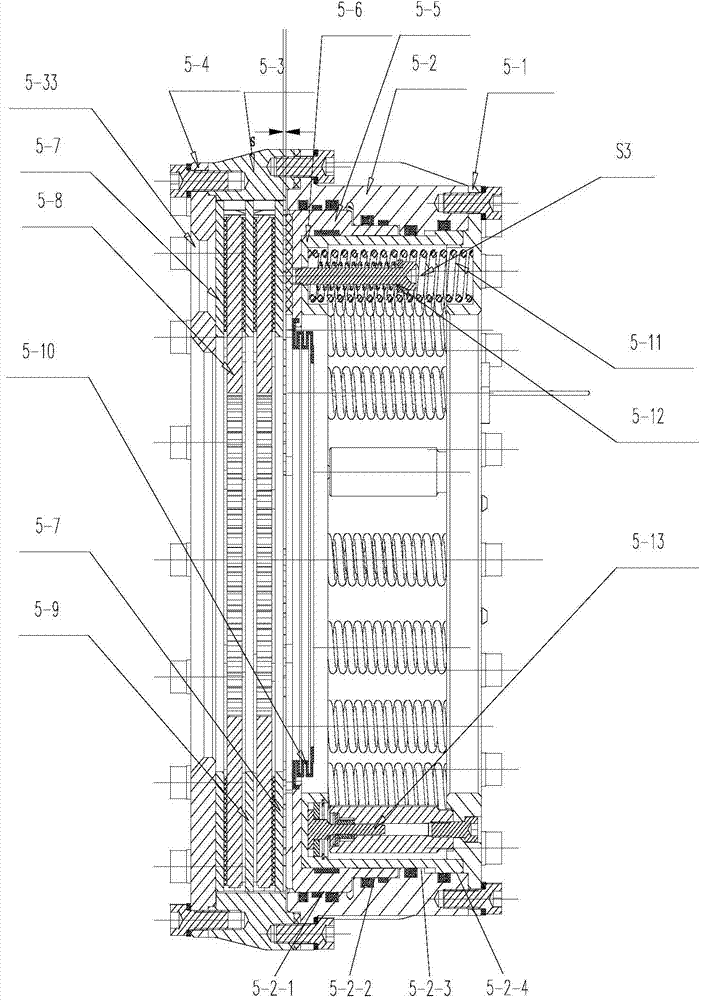

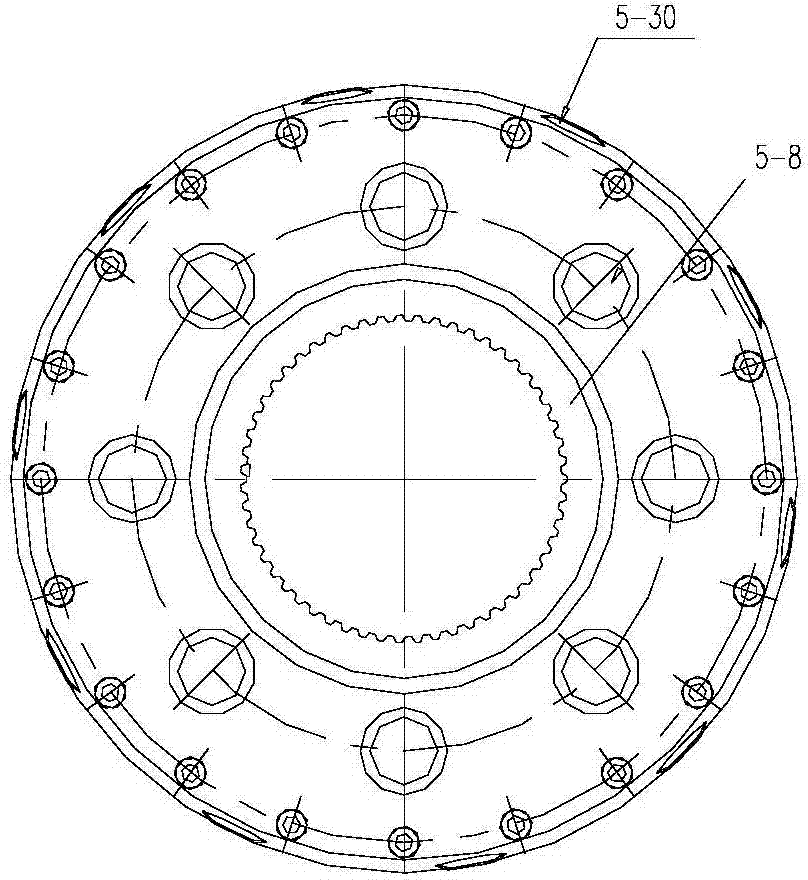

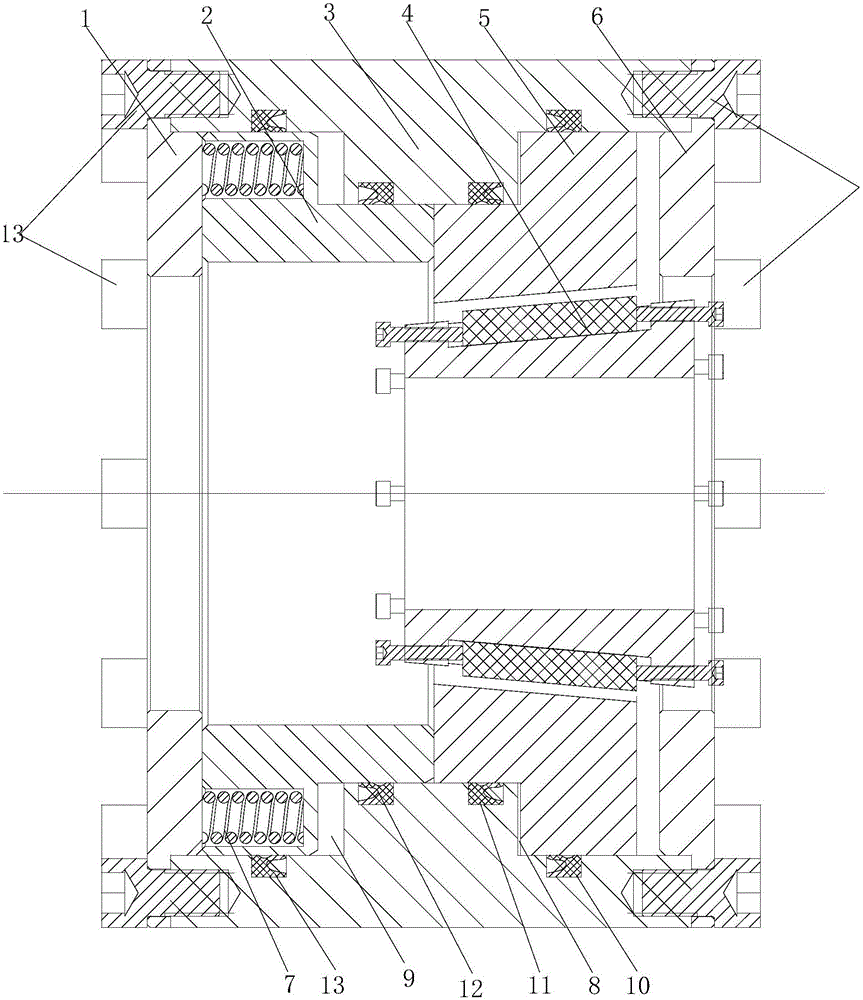

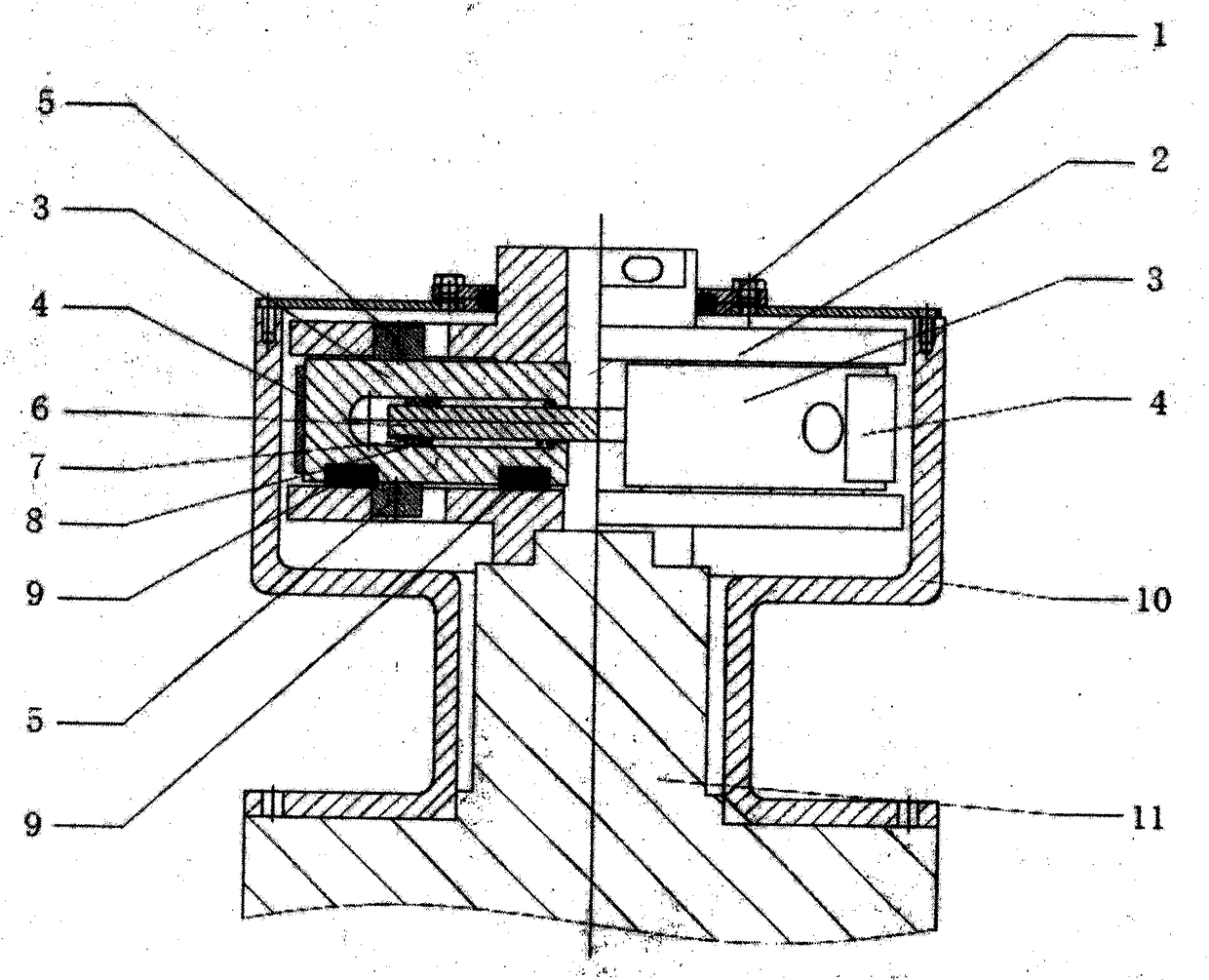

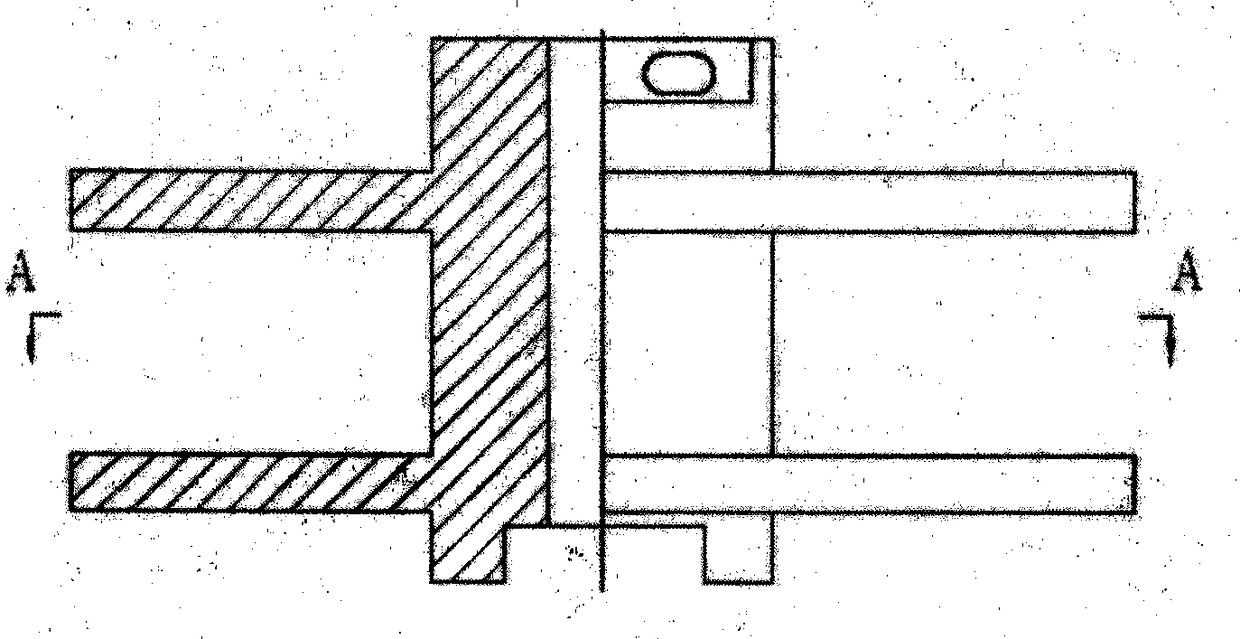

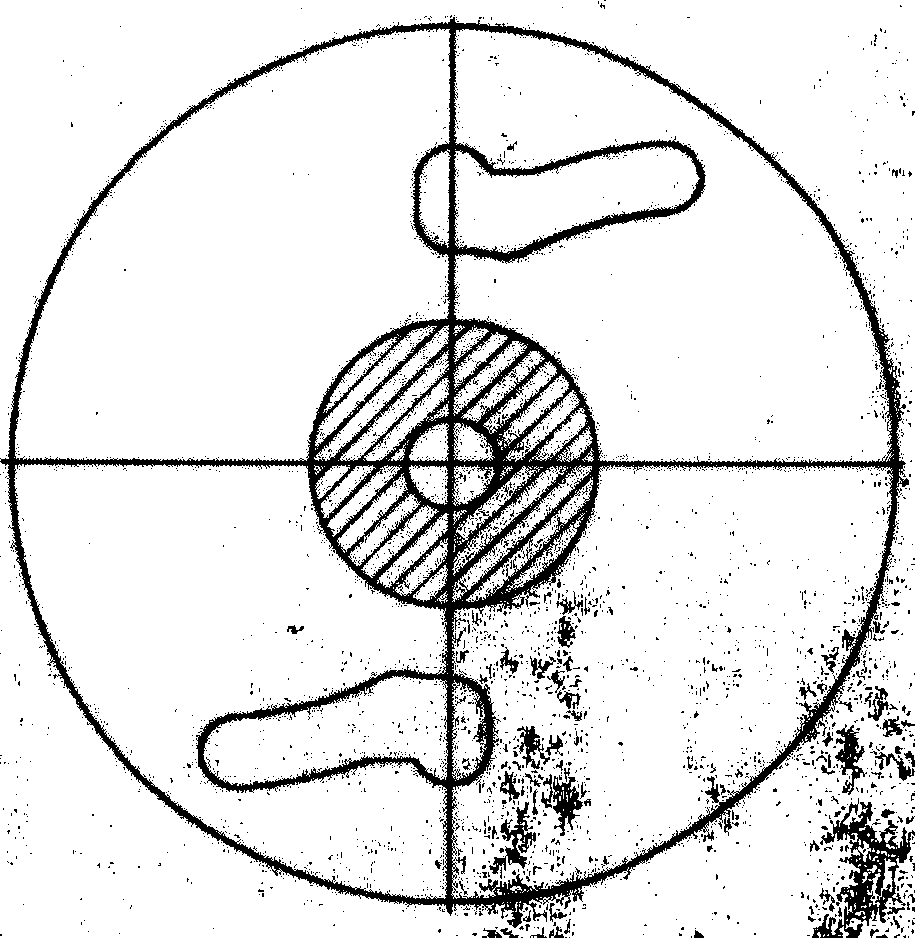

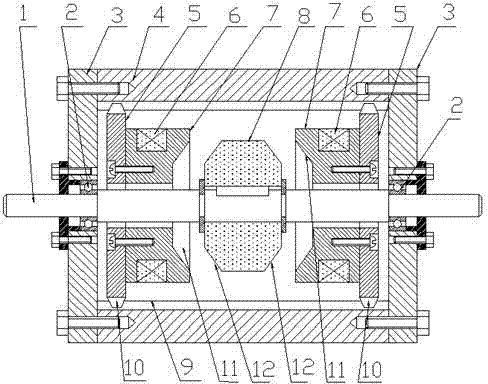

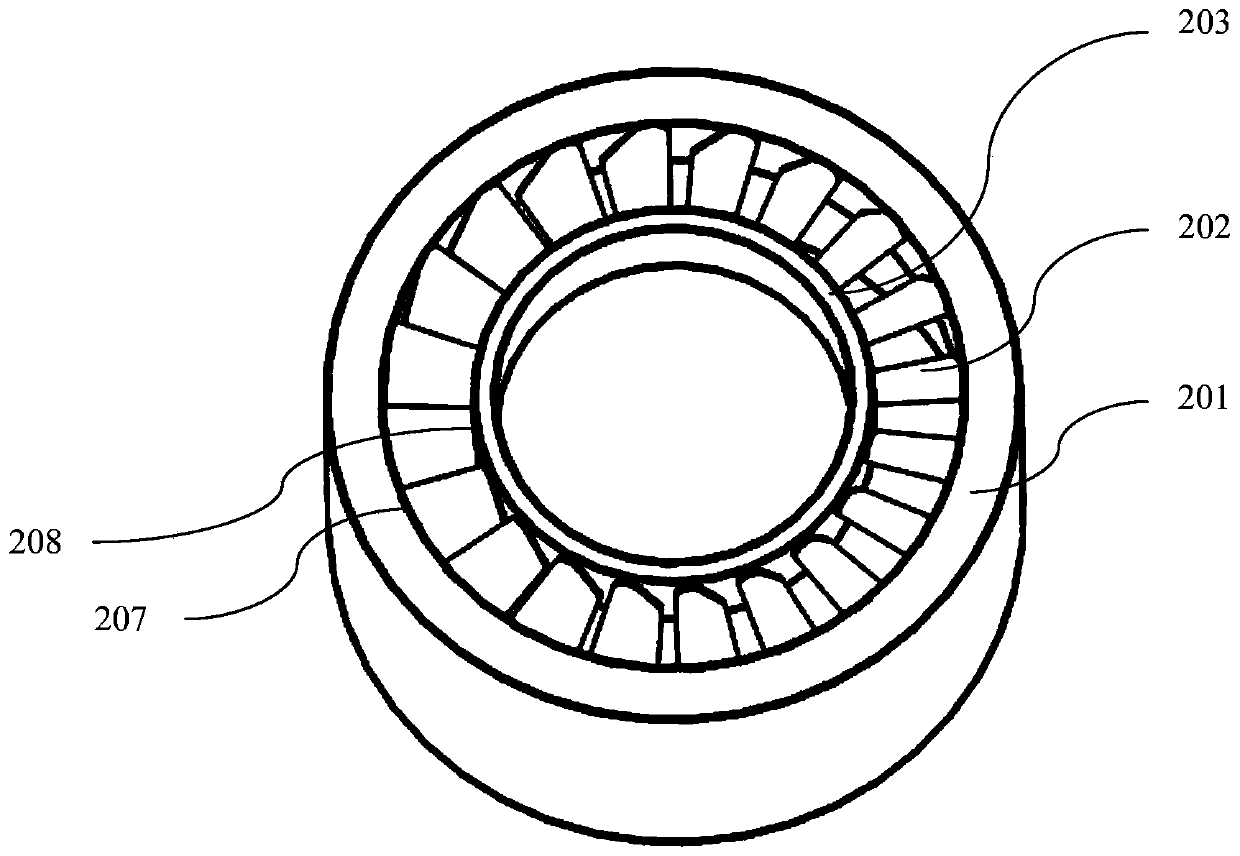

Multiple-disc type magnetorheological brake

InactiveCN102146968AGood heat dissipationImprove cooling effectLiquid resistance brakesMagnetic currentBrake torque

The invention relates to a multiple-disc type magnetorheological brake which mainly comprises a transmission shaft, a wheel hub, a drive friction plate group, a driven friction plate group, inner and outer magnetic isolation rings, an exciting coil with a U-shaped iron core, magnetic-conducting side plates and a magnetic isolation casing. A sealing ring is used for sealing magnetorheological fluid between the drive friction plate group and the driven friction plate group; the drive friction plate group and the driven friction plate group are respectively sleeved on the magnetic isolation rings and the wheel hub through splines; the drive friction plate group is separated from the driven friction plate group by the inner magnetic isolation ring and the outer magnetic isolation ring; the exciting coil with the U-shaped iron core is directly spliced in iron core jacks of the magnetic conducting side plates; and the braking torque can be changed through changing the current intensity of the coil. When the braking torque is not enough, the quantity of friction plates can be increased or the quantity of the exciting coil with the U-shaped iron core can be increased to adapt to the big torque braking. The multiple-disc type magnetorheological brake has the advantages that the structure is compact, the braking torque is big, the assembly and the disassembly are convenient, the coil is easily used for radiating the heat, and the number of turns wounded by the coil is more.

Owner:CHINA UNIV OF MINING & TECH

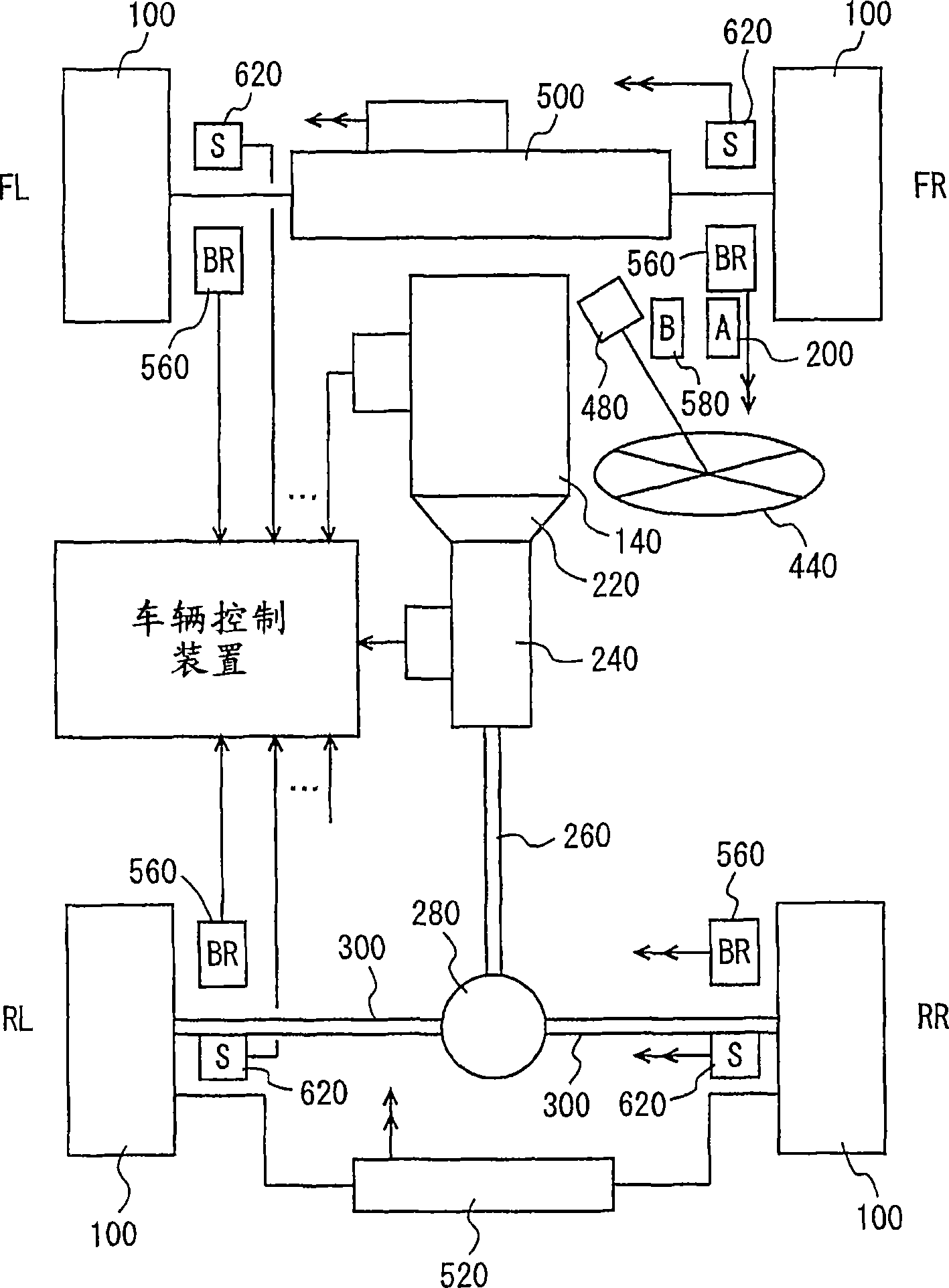

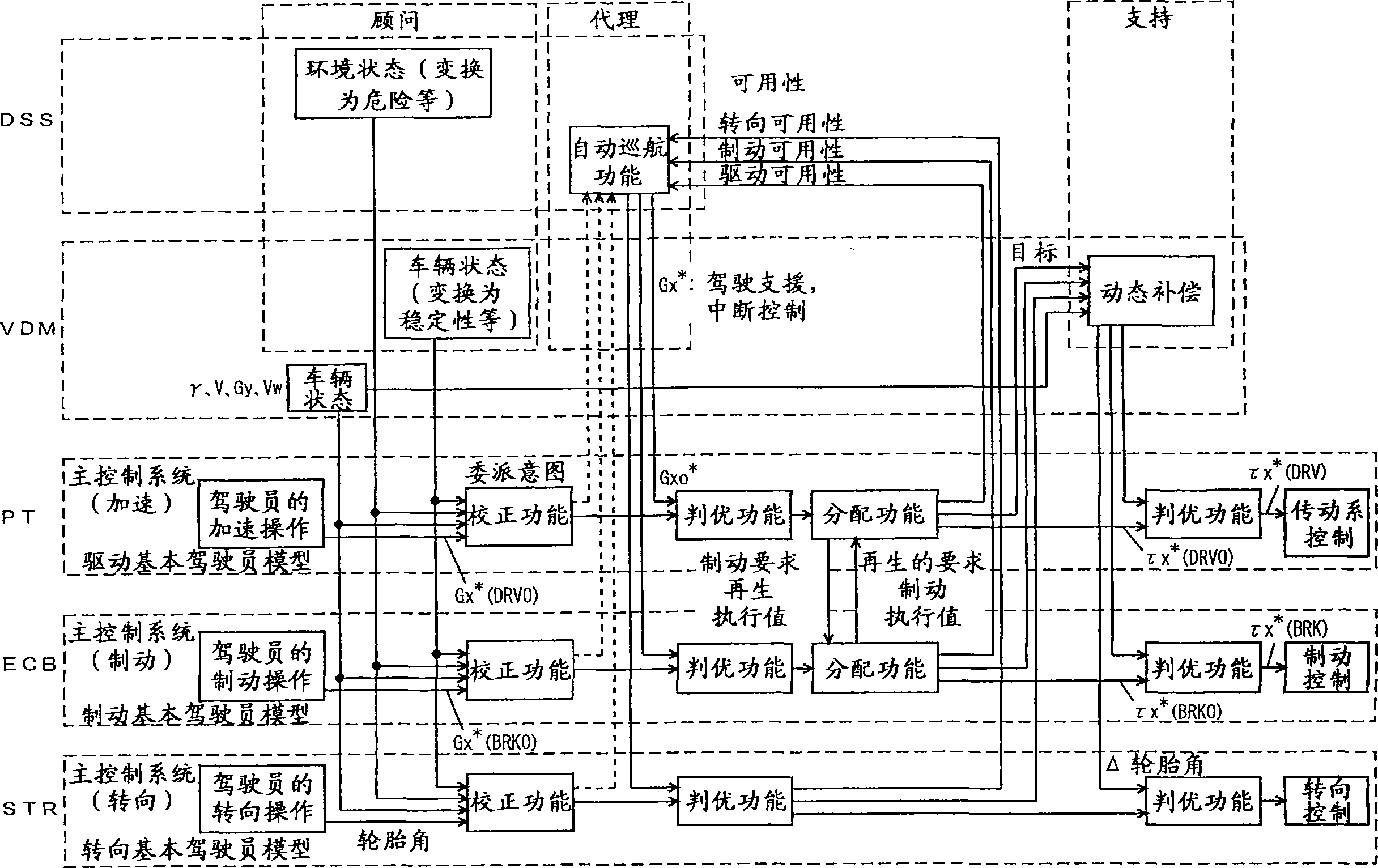

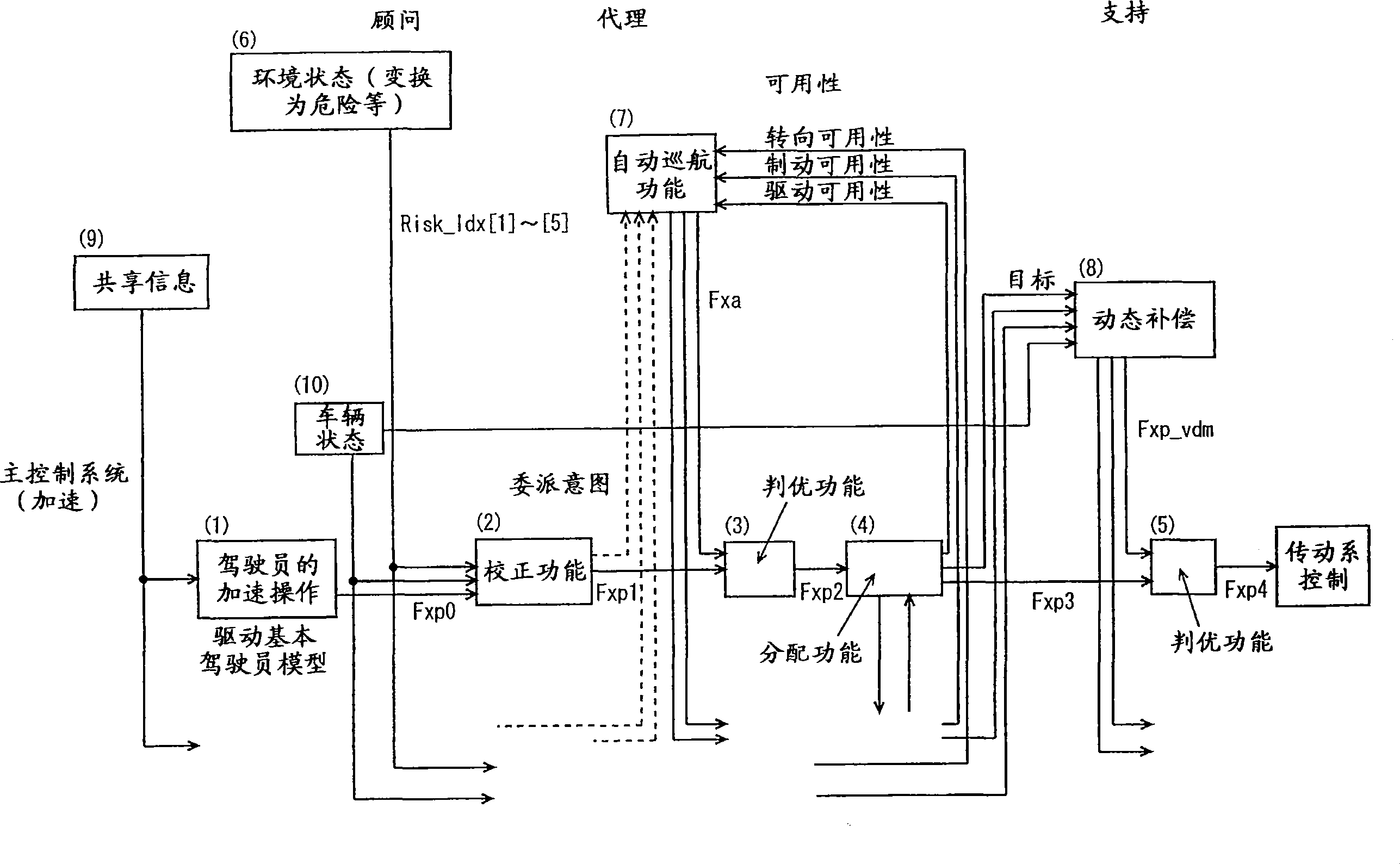

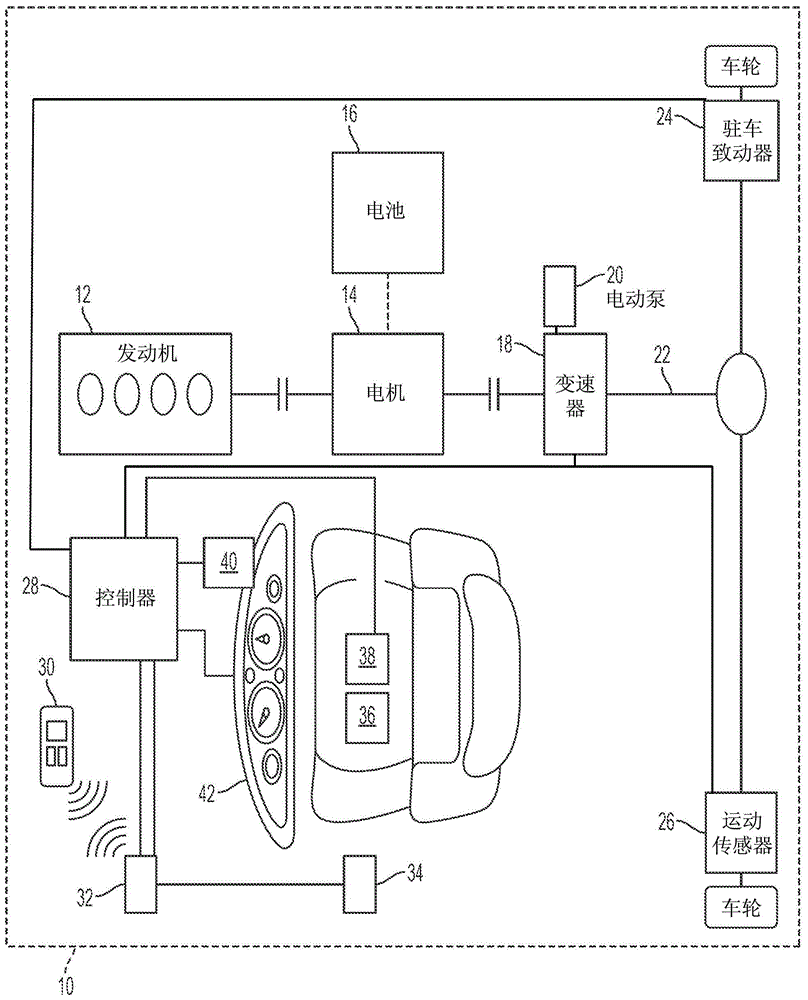

Vehicle integrated control system

InactiveCN1898115ASmall braking forceHigh torqueAnti-collision systemsEngine controllersControl systemBraking system

An integrated control system includes a main control system (accelerator) controlling a driving system, a main control system (brake) controlling a brake system, and a main control system (steering) controlling a steering system, based on manipulation by a driver, as well as an adviser unit generating and providing information to be used at each main control system based on environmental information around a vehicle or information related to a driver. The advisor unit executes a program including the steps of: sensing a vehicle state, driver's manipulation, and environmental information (S 1000, S 1100 and S 1200); operating an expected value by the driver with regard to a driving force (S 1300); performing distribution processing of a braking / driving torque (S 1500); and operating a distribution ratio (S 1600) so as to carry out distribution (S 1700).

Owner:TOYOTA JIDOSHA KK

Braking device for vehicle

ActiveCN104728313AAchieve separation releaseDrive freelyAxially engaging brakesBrake actuating mechanismsEngineeringChange positions

The invention relates to a braking device for a vehicle and belongs to the technical field of vehicles. A braking disk is arranged between every two adjacent friction sheets of the brake so that a friction pair can be formed; an oil cylinder block is provided with an axial oil cylinder hole, a hollow driving piston with a step outer circle is installed in the large-diameter segment and the diameter-shrinkage segment of the oil cylinder hole, and the driving piston and an annular cavity formed at the diameter changing position between the large-diameter segment and the diameter-shrinkage segment form a driving braking oil cylinder; a parking piston is installed in the isolation segment and the diameter-enlarging segment, and the parking piston and an annular cavity at the diameter changing position between the isolation segment and the diameter-enlarging segment form a parking braking oil cylinder; parking springs are distributed in the parking piston in the circumferential direction in a spaced mode, return springs pressed and held by the pressing and holding end of return bolts are installed in the parking springs, and the ends, far away from the pressing and holding ends, of the return bolts penetrate through the bottom of the parking piston and are fixedly connected with the driving piston. According to the braking device, space is made full use of, the structure is very compact, the thermal load capacity of the friction sheets can be improved easily, service life is remarkably prolonged, and the braking device is very suitable for flexible configuration of various vehicles with narrow design spaces.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

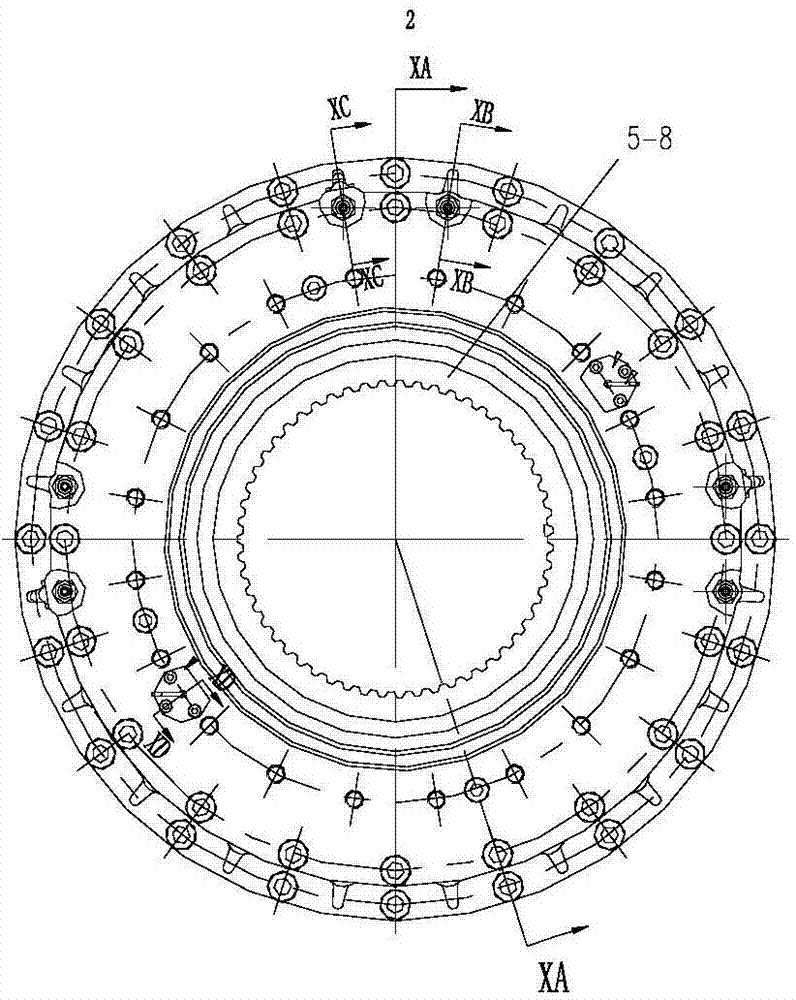

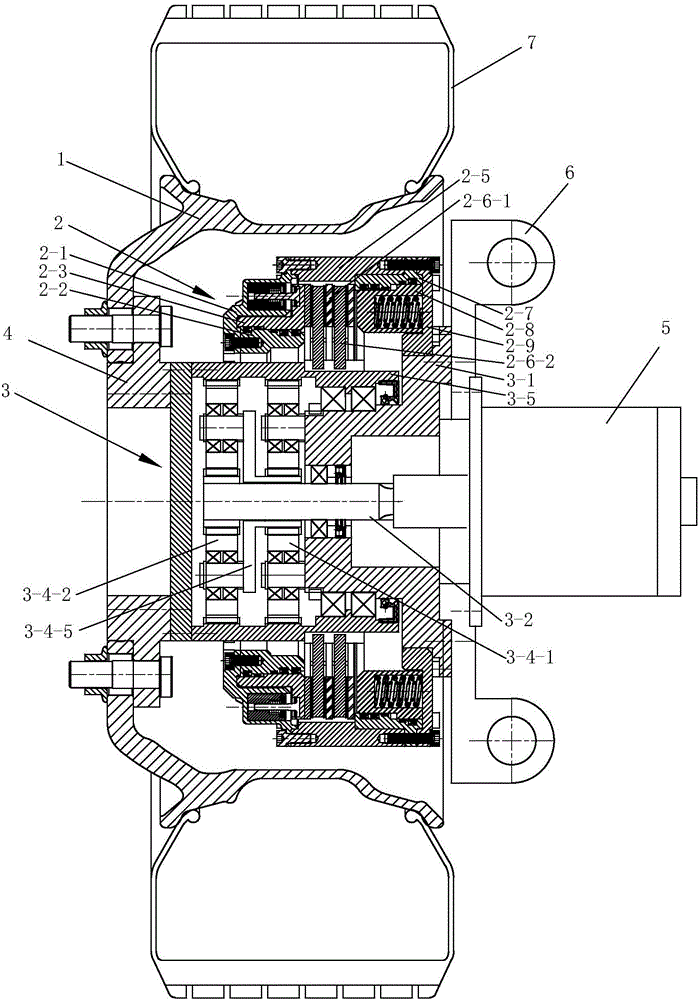

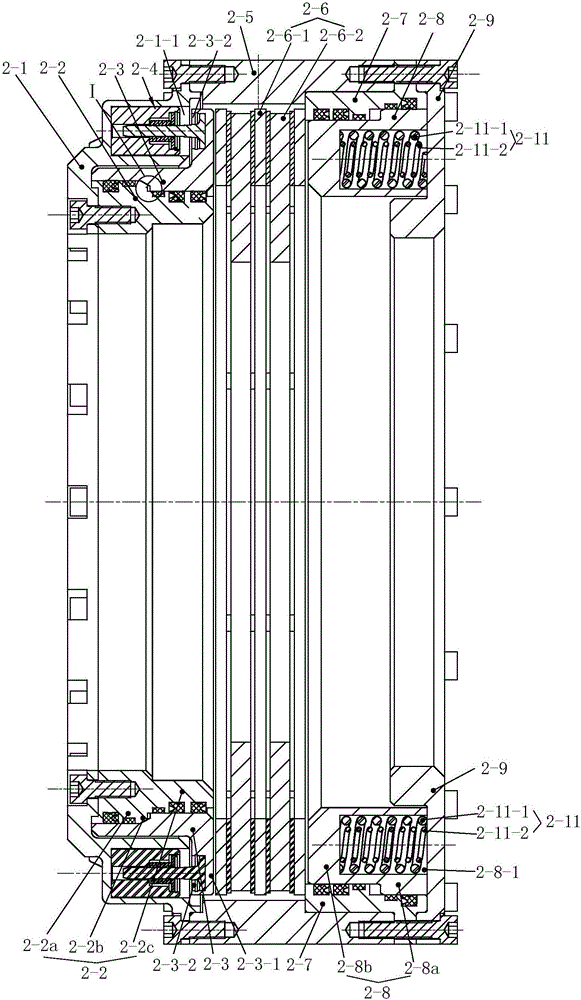

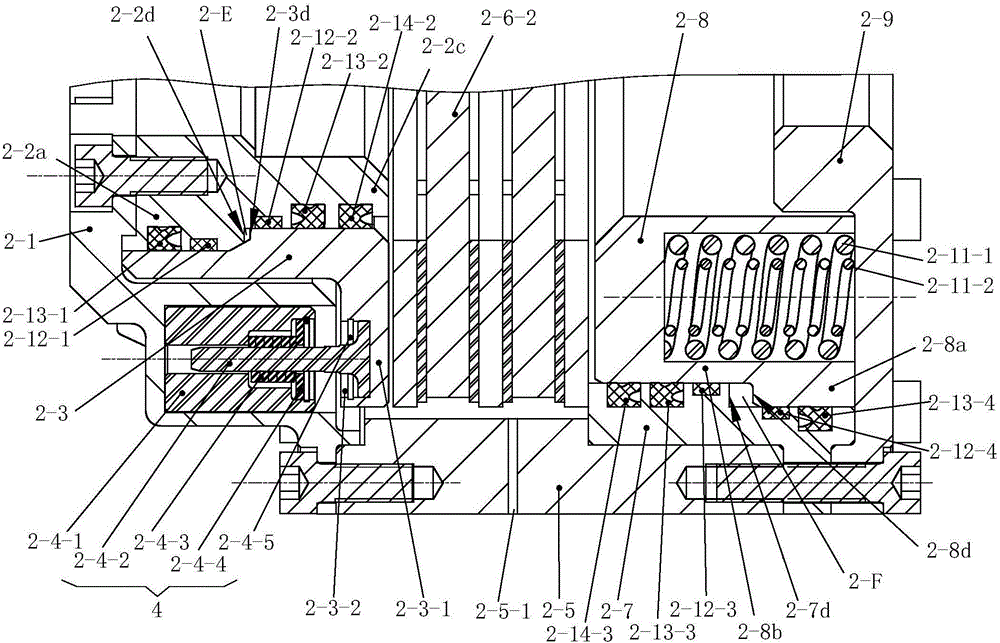

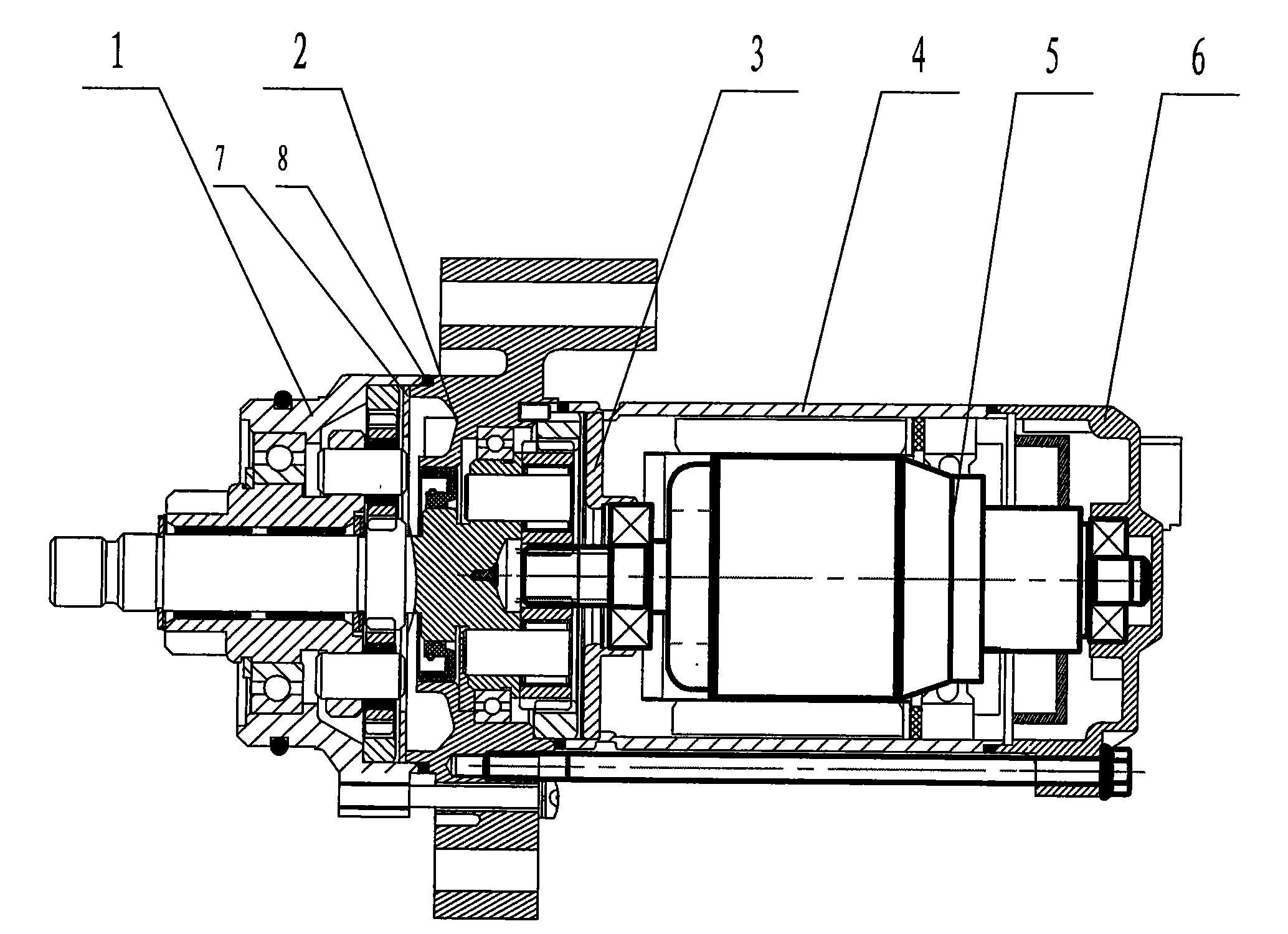

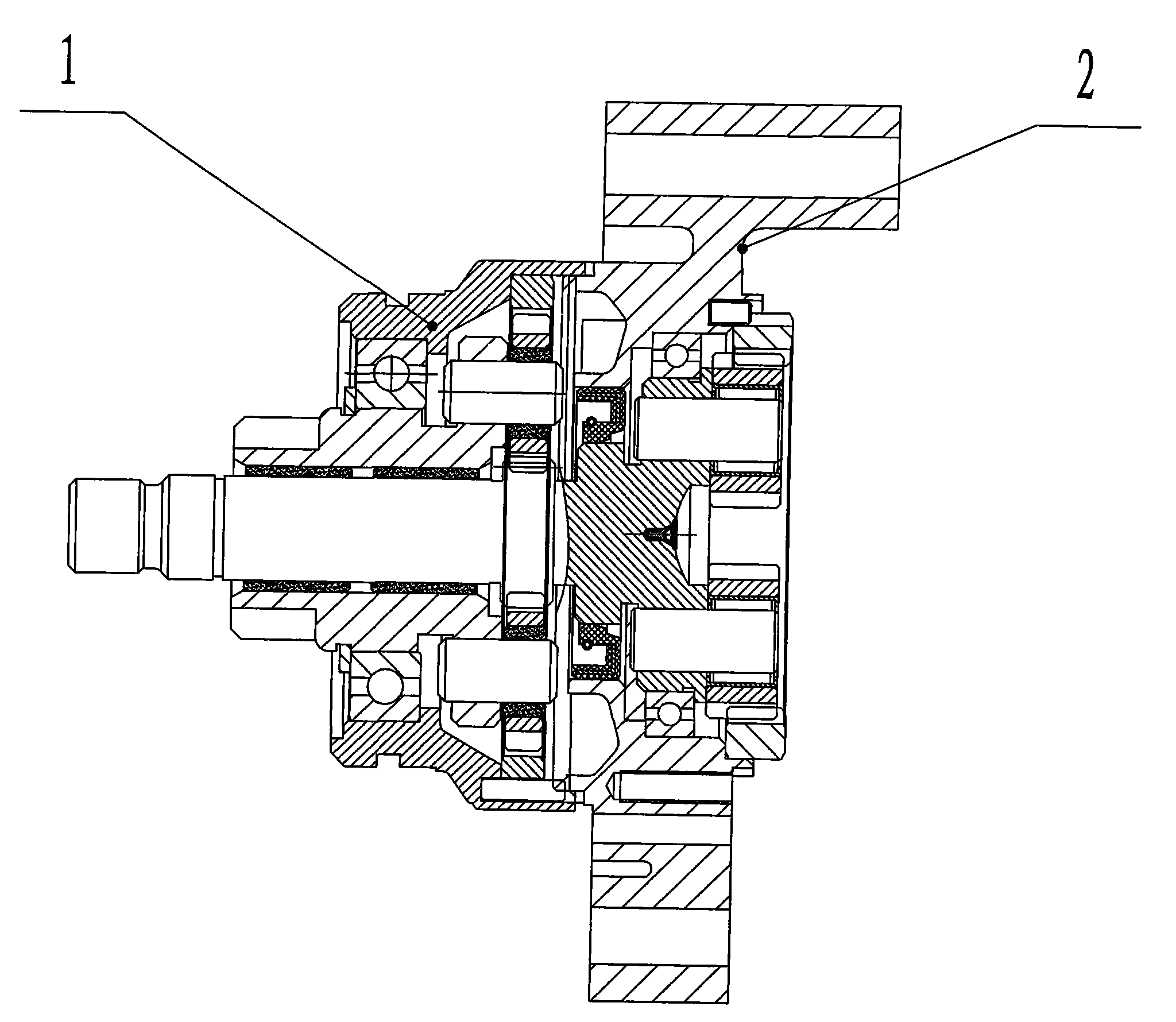

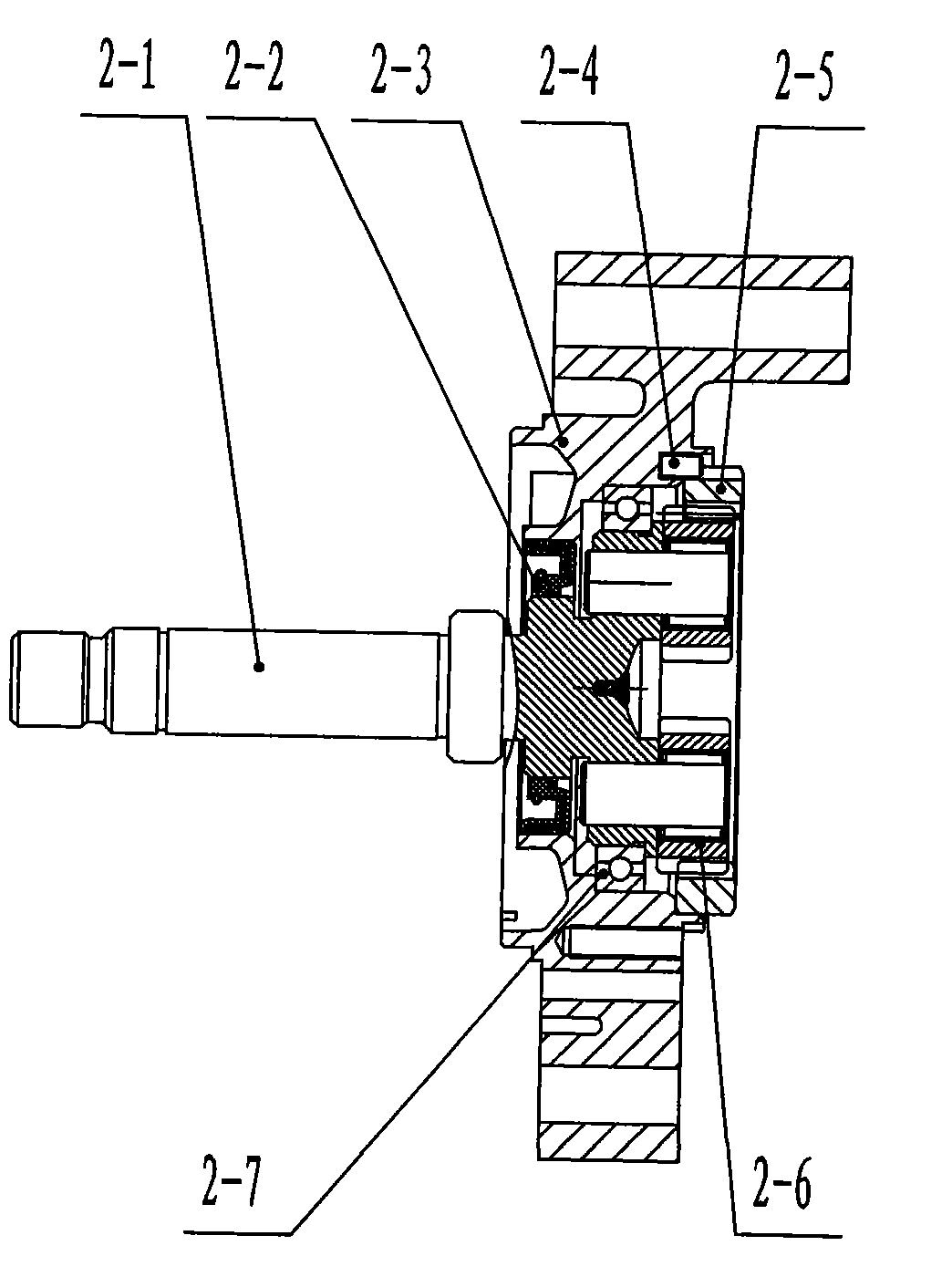

Transmission and braking integrated device for vehicle

ActiveCN106015406ACompact structureReduce volumeToothed gearingsBrake actuating mechanismsVehicle frameReducer

The invention discloses a transmission and braking integrated device for a vehicle. The transmission and braking integrated device comprises a wheel rim, a brake, a speed reducer and a motor. The brake comprises a vehicle end cover, a traveling cylinder body, a traveling piston, a cylindrical intermediate body, a braking friction pair assembly, a parking cylinder body, a parking piston, a parking end cover and a parking spring. The traveling cylinder body is sleeved with the traveling piston in a movable fit manner. An annular gap exists between the traveling piston and the traveling cylinder body, wherein the annular gap is a traveling braking oil cavity. The parking piston is arranged in the parking cylinder body in a movable fit manner. An annular gap exists between the parking cylinder body and the parking piston, wherein the annular gap is a parking braking oil cavity. The traveling piston and the parking piston can abut against the friction pair assembly from the two sides correspondingly. The parking piston is provided with the parking spring abutting against the parking end cover. By means of the transmission and braking integrated device for the vehicle, the motor, the brake and the speed reducer are integrated, the brake is arranged in the wheel rim, the speed reducer is arranged in a cavity of the brake, the structure is compact, the size is small, the space of a vehicle frame is greatly saved, and the transmission and braking integrated device is very suitable for flexible configuration with various vehicles narrow in structure space.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

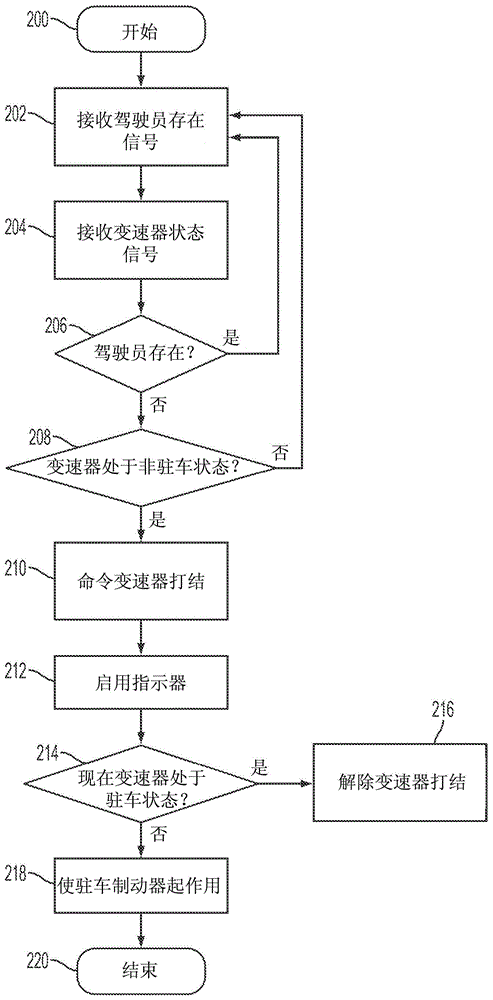

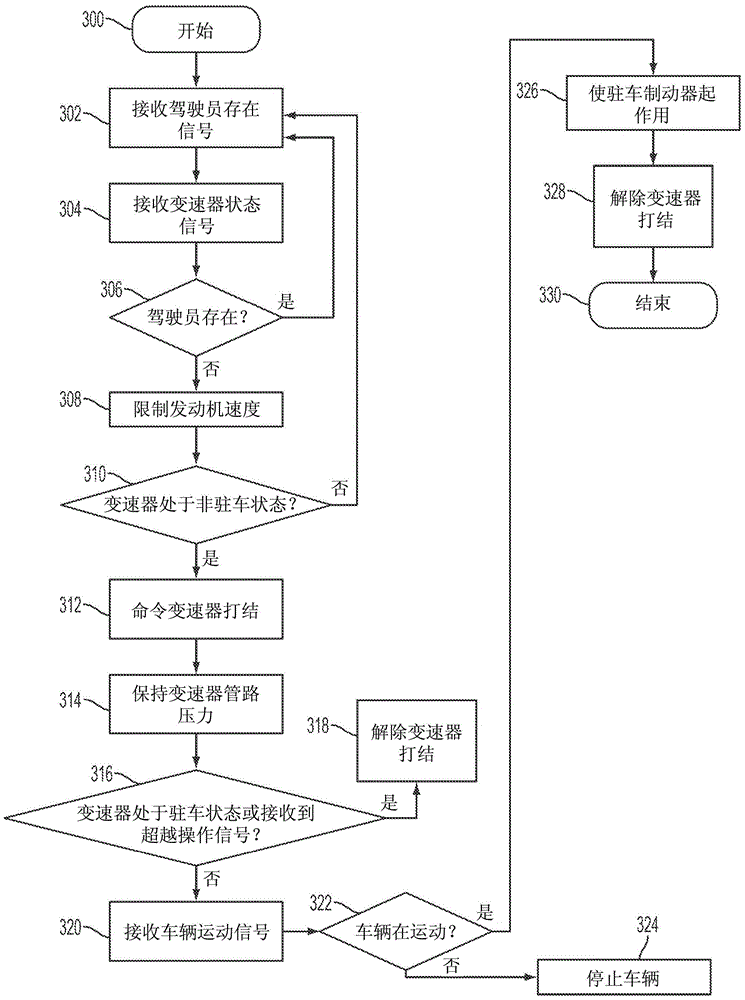

Vehicle immobilizer method and system

ActiveCN104044579ARestricted movementAvoid overall overheatingAnti-theft devicesLimiting/preventing/returning movement of partsEmbedded systemVIT signals

A system and method of immobilizing a vehicle include receiving a driver presence signal and a transmission state signal and commanding a transmission tie-up in response to the driver presence signal and the transmission state signal. In one embodiment, controlling a transmission element to tie-up a transmission includes braking approximately simultaneously a combination of transmission elements to inhibit rotation of a transmission output and maintaining transmission line pressure to maintain the transmission tie-up when an engine is off.

Owner:FORD GLOBAL TECH LLC

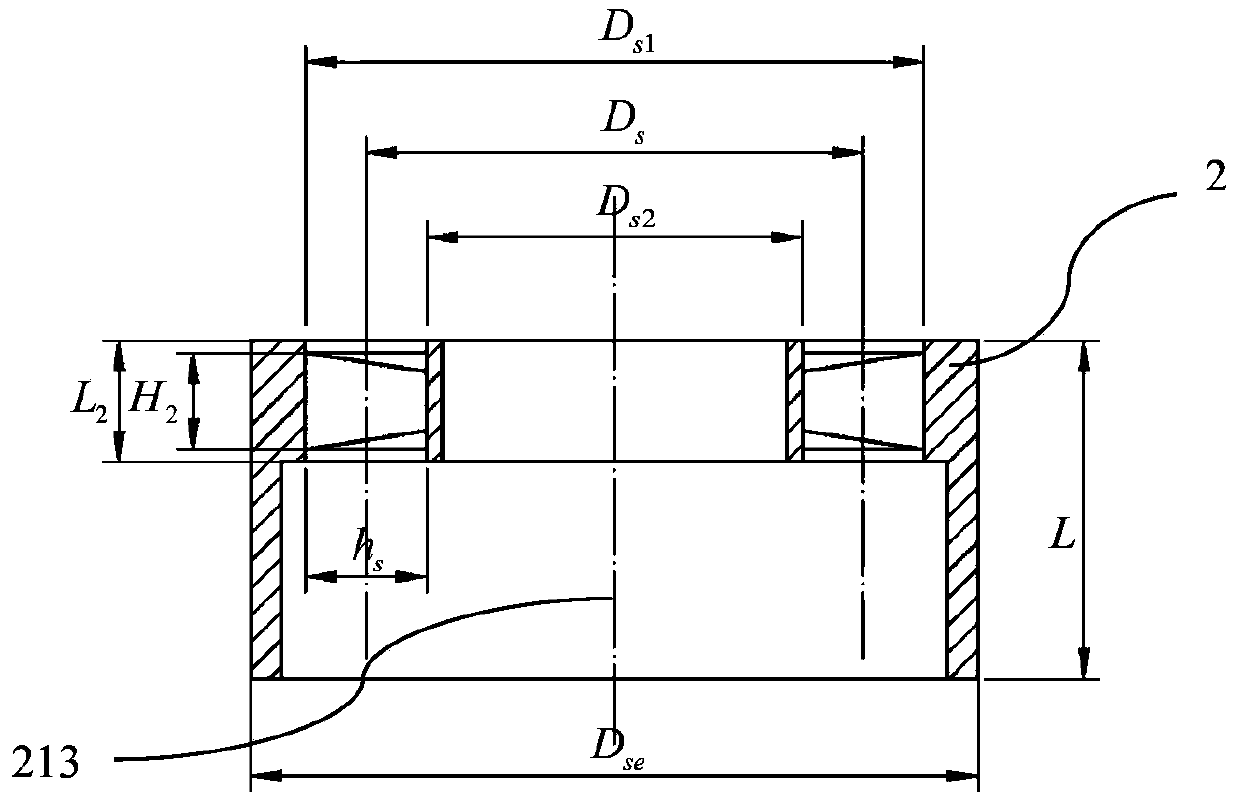

Vehicle gap adjustable conical brake device

ActiveCN106523550AAchieve separation releaseTravel piston stationaryFluid actuated brakesBrake actuating mechanismsBrake torqueVehicle frame

The invention relates to a vehicle gap adjustable conical brake device. The vehicle gap adjustable conical brake device comprises a barrel. The barrel is provided with a first end port and a second end port. A parking end cover is arranged in the first end port. A running end cover is arranged in the second end port. The parking end cover, the running end cover and the barrel define a cavity. A parking piston and a running piston are arranged in the cavity. One end of the parking piston can abut against the parking end cover, and the other end of the parking piston can abut against the running piston. The running piston can abut against the running end cover. A set of spring positioning grooves extending axially are evenly distributed in the parking piston. Parking springs are arranged in the spring positioning grooves and tightly abut against the parking end cover. The running piston is hollow, and a transmission shaft which is in sliding fit with the running piston is arranged in the hollow interior of the running piston. The vehicle gap adjustable conical brake device has the advantages that large brake torque can be achieved in a small mounting space, the brake effect is better, by adopting the nesting integral design of running and parking brakes, a parking brake does not need to be arranged independently, a vehicle frame space is saved, and great convenience is provided for overall vehicle arrangement.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Oil pump dual-motor drive device with electric-hydraulic power steering function

InactiveCN103625544ARealize integrated designHigh braking torqueFluid steeringElectrical steeringLow speedEngineering

The invention provides an oil pump dual-motor drive device with an electric-hydraulic power steering function. A main drive motor (brushless DC motor) directly drives an oil pump to rotate, and a secondary drive motor (brush DC motor) works in due time. The rotation speed, torque and other working states of the double motors can be adjusted in the manner that an electronic control unit collects steering wheel rotation speed signals, car speed signals, current signals of the double motors and the like, and dynamic coupling of the main drive motor and the secondary drive motor can be achieved through a synchronous belt and a belt wheel by means of a one-way clutch. The double motors, a power transmission and coupling mechanism, the steering oil pump and a steering controller are of an integrated structure, and the integrated design of the dual-motor electric oil pump can be achieved. According to the oil pump dual-motor drive device, a dual-motor distributed type control scheme is adopted, the degree of freedom of system control is improved; low-speed steering is convenient, and high-speed road feel is good; the motors work at high speed only when power assistance is needed, and rotate at low speed on the condition of no steering, and the energy consumption of a system is low; when one motor breaks down, the other motor can still provide a certain steering power, so safety of the system is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

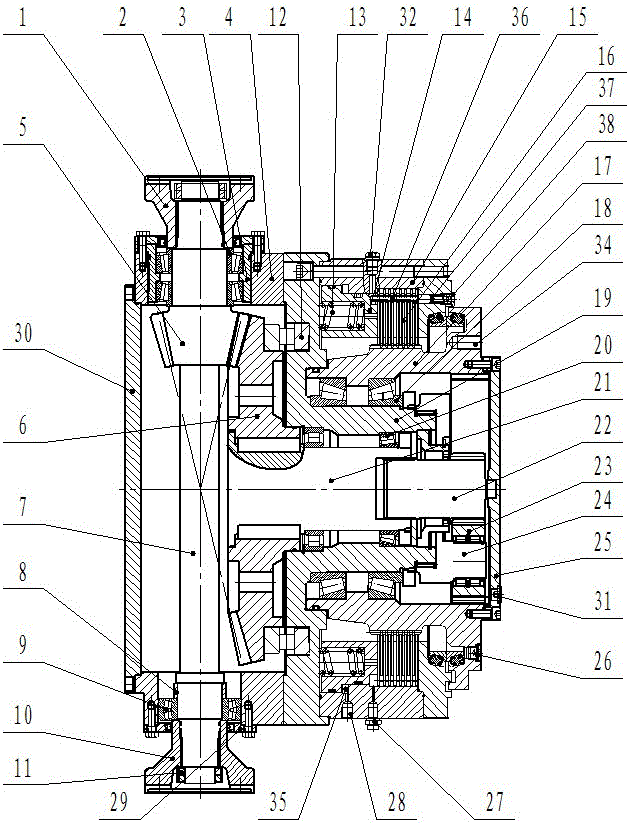

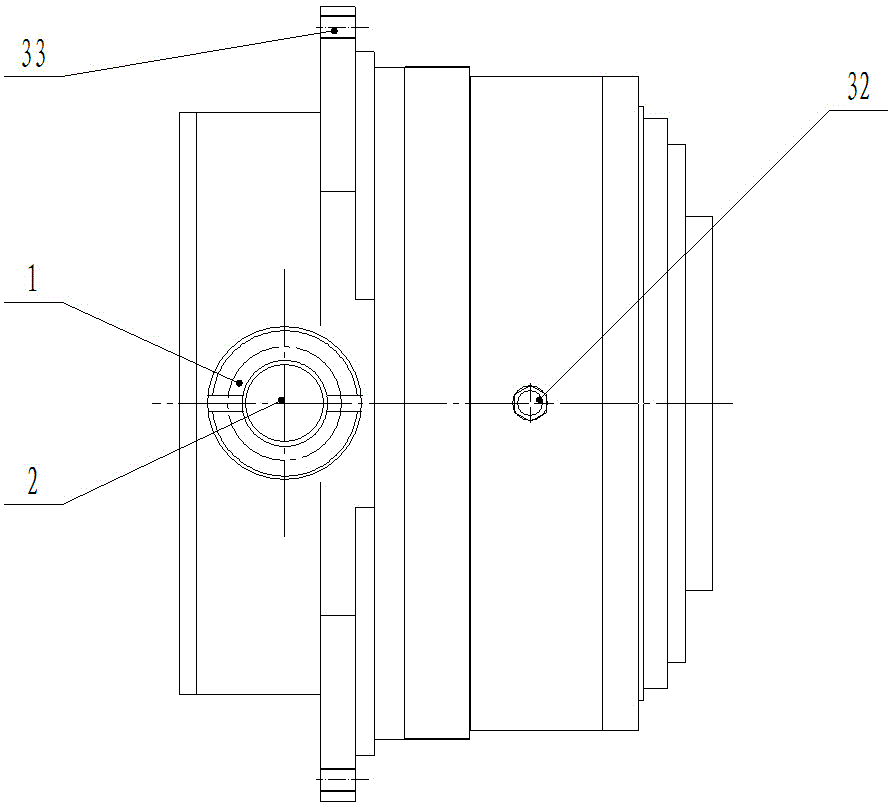

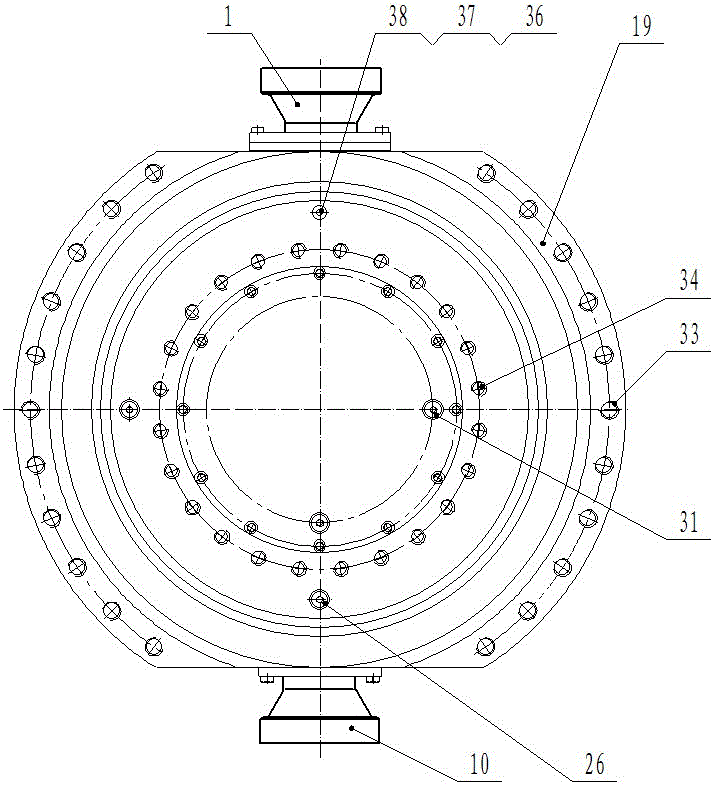

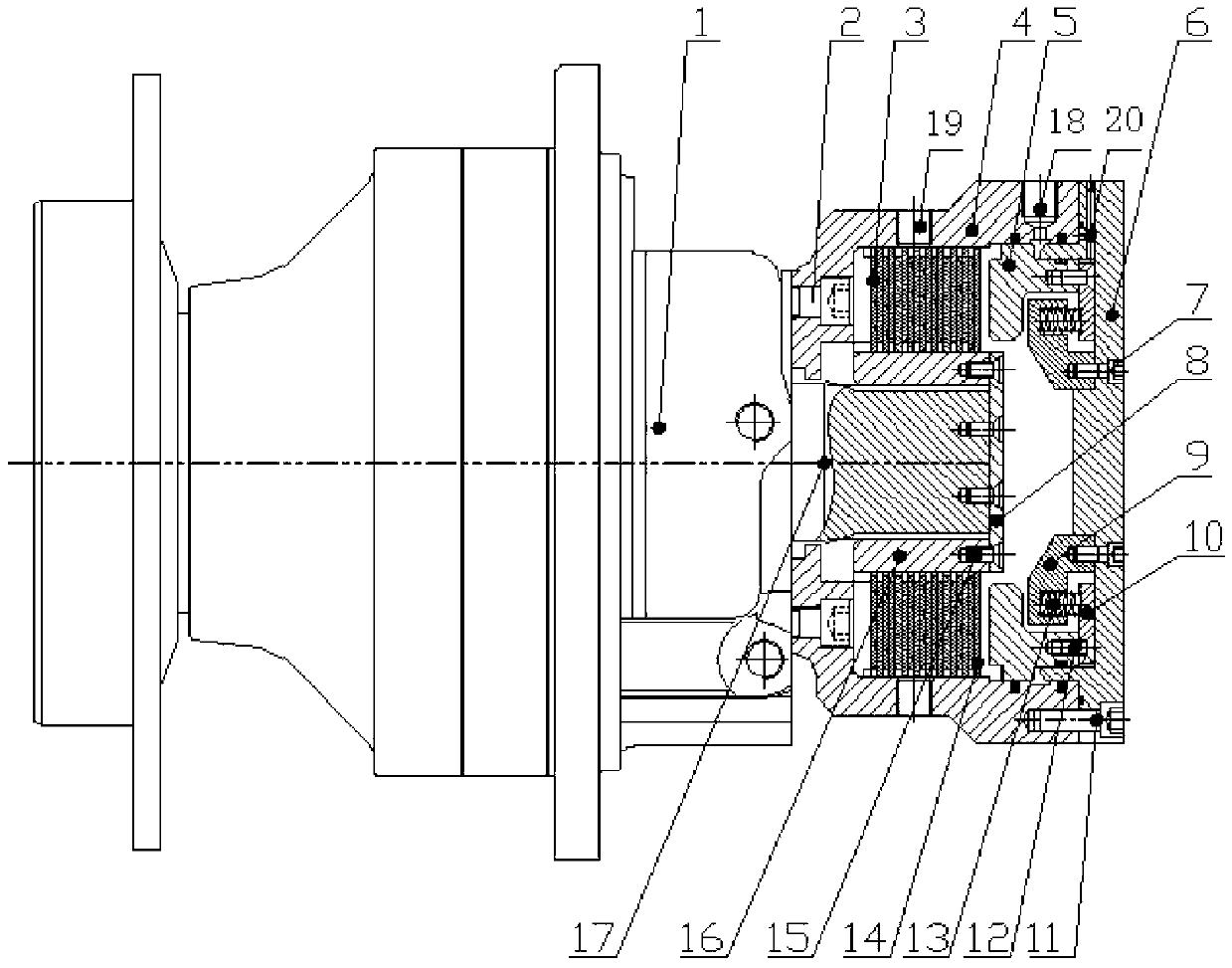

Shell turn type inner-curve radial plunger hydraulic motor

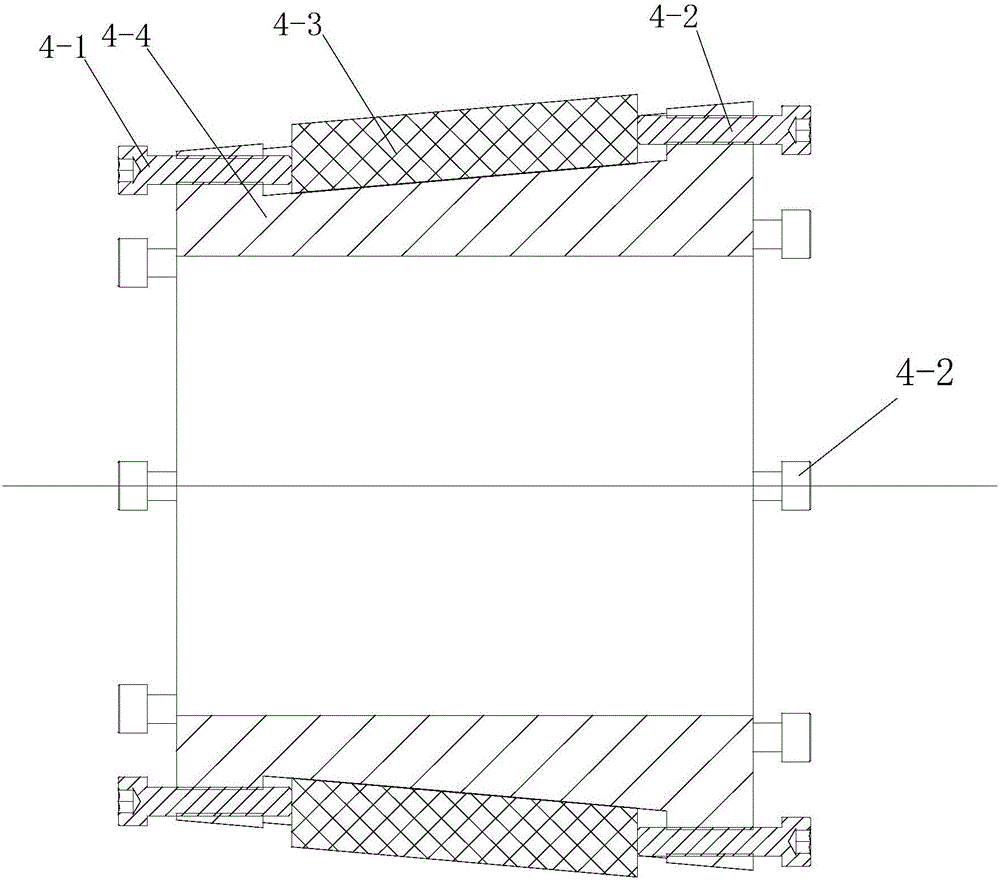

ActiveCN102493913AIncrease the number ofLarge output torqueAxially engaging brakesBrake actuating mechanismsHydraulic motorStatic friction

The invention relates to a shell turn type inner-curve radial plunger hydraulic motor, which comprises a machine casing composed of a front cover, a stator and a rear cover. The machine casing is provided with an oil through shaft, a rotor and an oil distribution disc. The shell turn type inner-curve radial plunger hydraulic motor is characterized in that the oil distribution disc is sleeved on the oil through shaft and fixed with an inner scapula of the rear cover, a fixed brake seat is fixed on the periphery of the oil through shaft, the machine casing can rotate around the axis relative to the oil through shaft, and a plurality of dynamic friction sheets and a plurality of static friction sheets which are arranged at mutual intervals and in an overlaying mode are sleeved on the periphery of the fixed brake seat. A plunger is further arranged in the rear cover and sleeved on the fixed brake seat and can glide in the axial direction, a spring enabling the plunger to keep the mutual tight compression between the dynamic friction sheets and the static friction sheets is further arranged in the rear cover, a sealed oil cavity is formed between the plunger and fixed brake seat, and the fixed brake seat is provided with an oil hole communicated with the oil. The shell turn type inner-curve radial plunger hydraulic motor is provided with a brake structure organically combined with the hydraulic motor, thereby being compact and reasonable in structure.

Owner:NINGBO DECHEN HYDRAULIC TECH

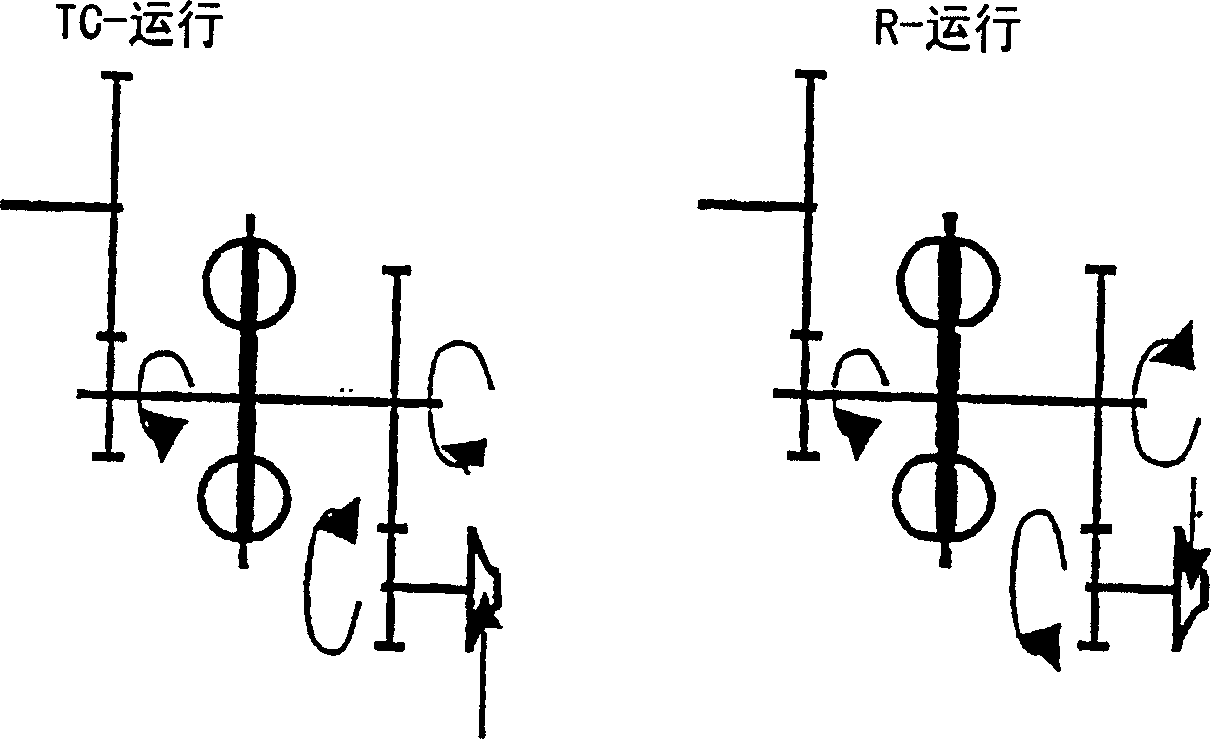

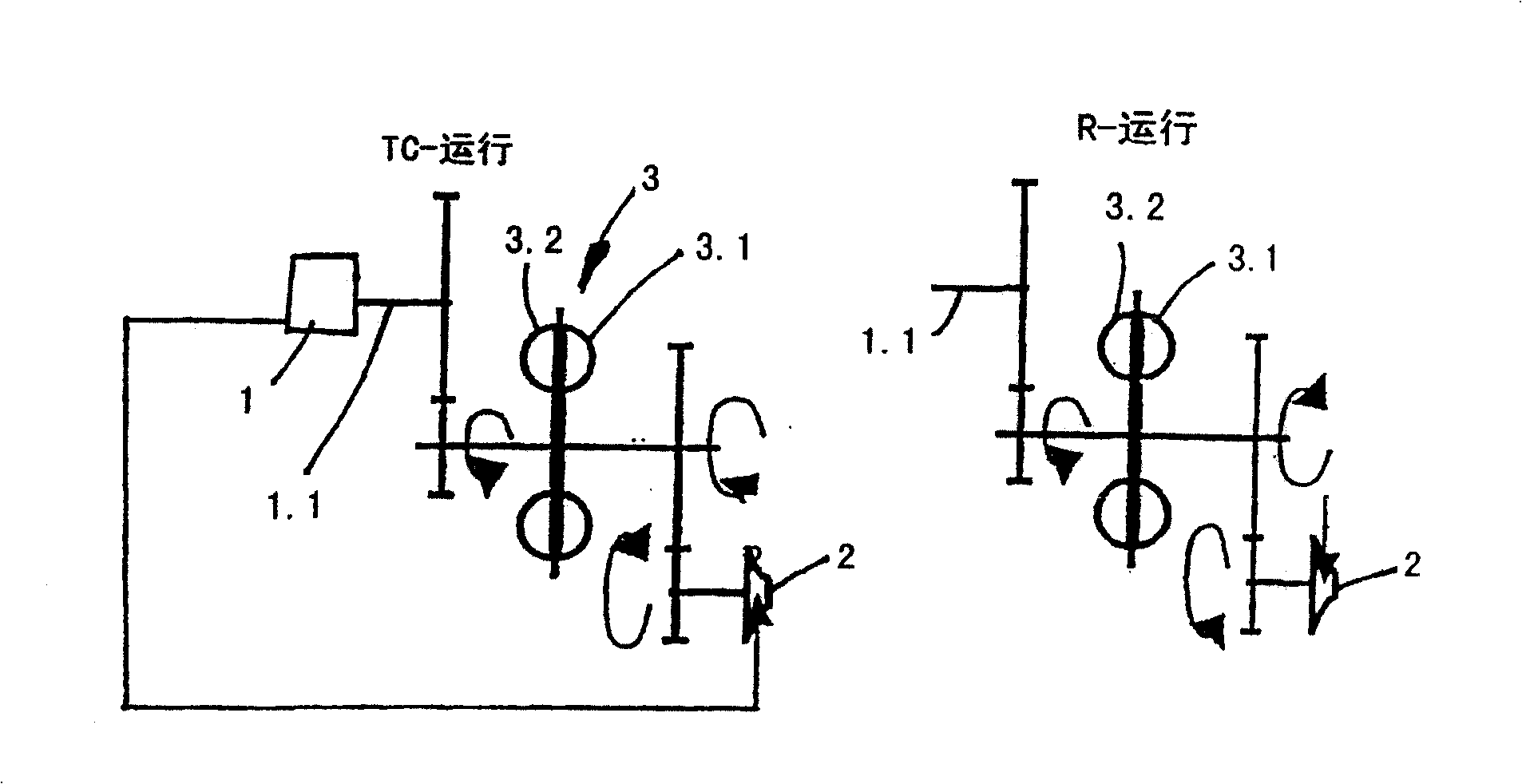

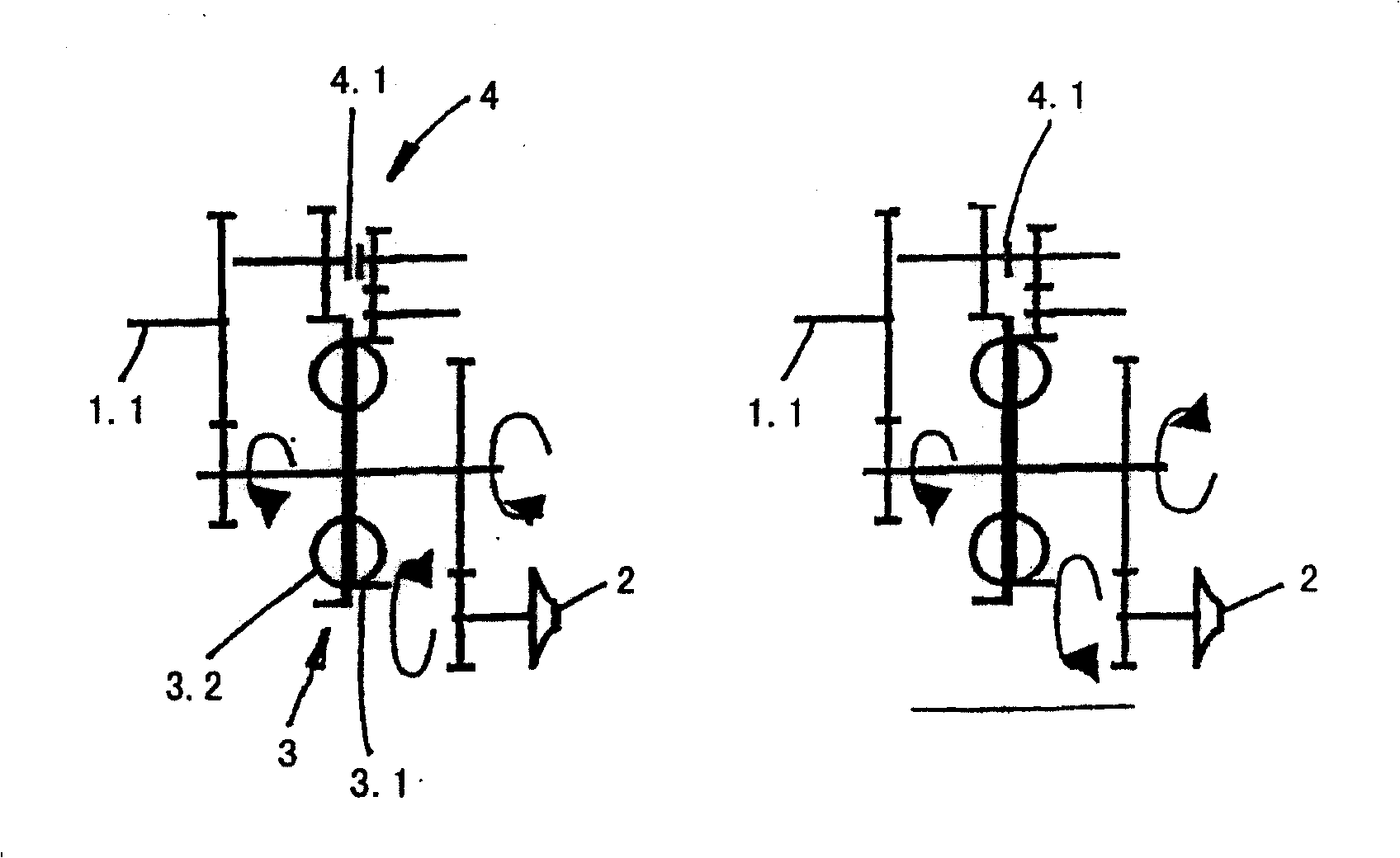

Turbo-compound system

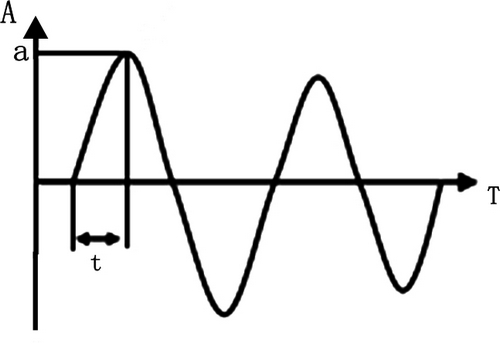

InactiveCN1910354AHigh braking torqueUniform braking torque curveLiquid resistance brakesInternal combustion piston enginesFluid couplingInternal combustion engine

The invention relates to a turbine compound system, with a crankshaft, driven by an internal combustion engine, an exhaust-driven turbine, arranged in the exhaust flow from the internal combustion engine, a hydrodynamic coupling, comprising a first rotor and a second rotor, together forming a working chamber which may be or is filled with a working medium, arranged with a drive connection between the crankshaft and the exhaust-driven turbine, such that, with the working chamber of the hydrodynamic coupling filled, drive power is transmitted from the exhaust-driven turbine to the crankshaft. Said turbine compound system is characterised in that a switching means is provided for inverting the direction of rotation of the primary rotor or the secondary rotor of the hydrodynamic coupling.

Owner:VOITH TURBO GMBH & CO KG

Tension control and torsion spring steel coil brake device for spindle of braiding machine

ActiveCN103173928AShort tension fluctuation rangeSmall tension fluctuation rangeBraidBrakeTorsion spring

A tension control and torsion spring steel coil brake device for a spindle of a braiding machine comprises a steel coil torsion spring, an elastic sleeve, a drill axis, a base and a central shaft, wherein a torque arm above the steel coil torsion spring is inserted in a notch on the elastic sleeve, and a torque arm below the steel coil torsion spring is inserted in a notch of the central shaft; under a free state, the inner wall of the steel coil torsion spring wraps up the outer walls of the drill axis and the central shaft, and a gap is reserved between the elastic sleeve and the steel coil torsion spring, so that the elastic sleeve and the steel coil torsion spring can rotate relatively; a rolling wheel is arranged on a bulge at the upper end of the elastic sleeve, and the circumferential profile of the rolling wheel is closely attached on a wedge of a draw bar; and when the machine is stopped, the tension of braiding wires disappears instantly, the draw bar drops on the base under the action of the spring, during descending, the wedge pushing the rolling wheel is loosen, the elastic sleeve restores rotationally, the steel coil torsion spring returns back to be in a free state, the inner diameter of the helix also wraps up the outer walls of the central shaft and the drill axis, and a lug on the drill axis clamps the spindle to enable the spindle to stop rotating instantly. The tension control and torsion spring steel coil brake device adopts a band-type brake to brake, so that the braking operation is flexible and reliable.

Owner:浙江本发科技有限公司

Screw pump reverse rotation preventing braking method

InactiveCN108331748AWork lessSynchronous operationMachines/enginesPump controlCentrifugal forceScrew pump

Owner:DAQING SENENPU MACHINERY MFG

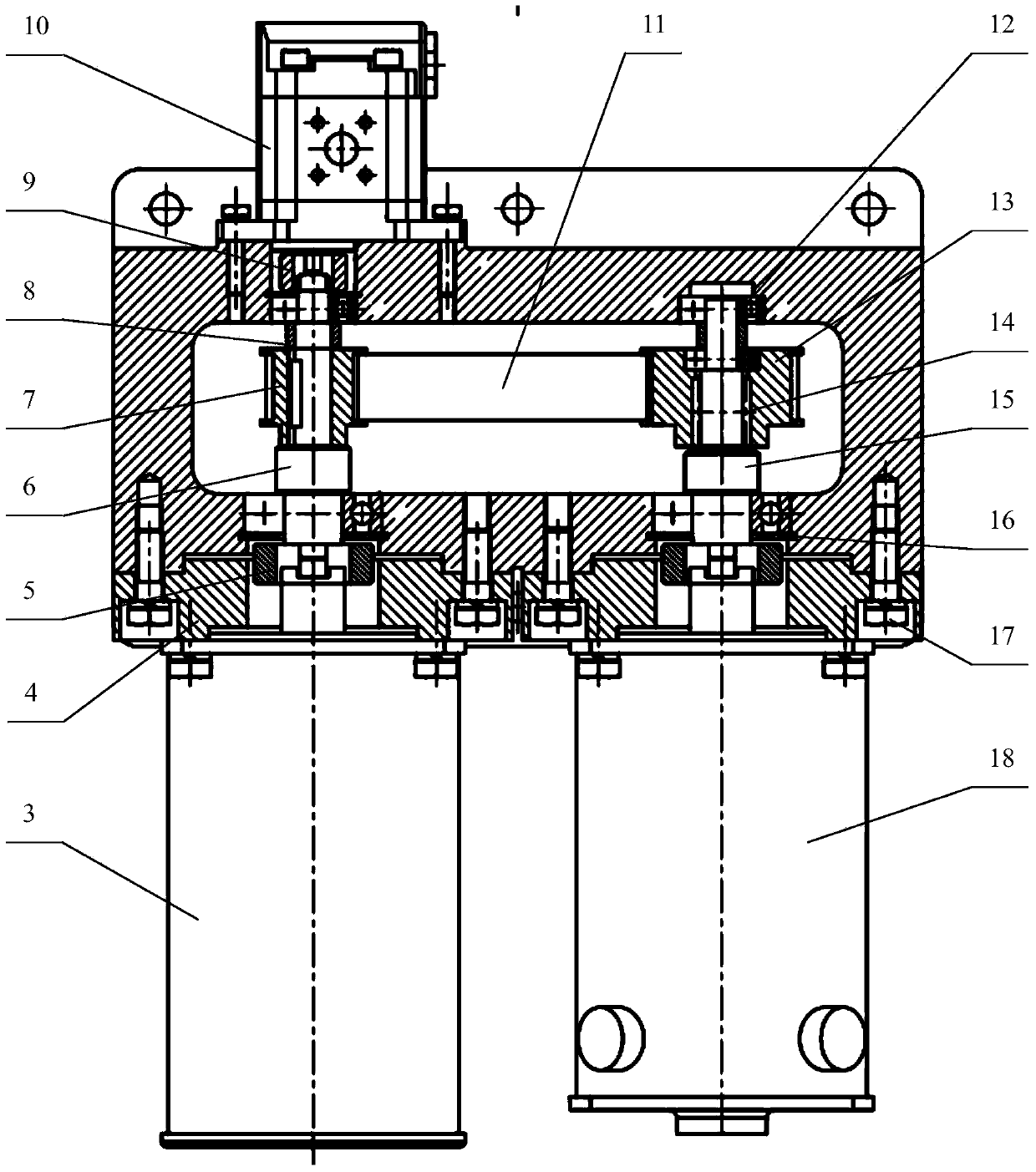

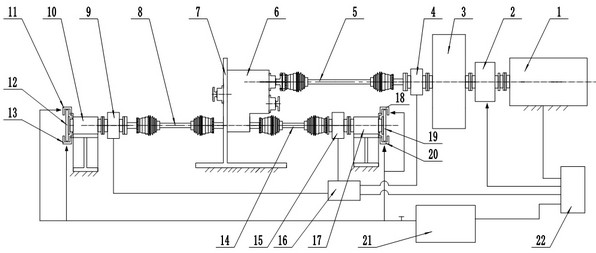

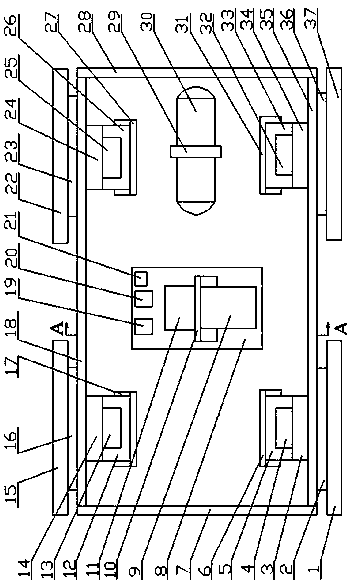

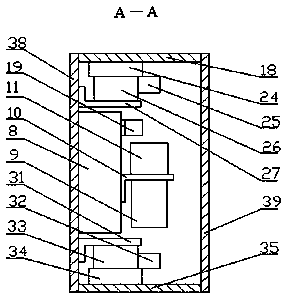

Passenger vehicle gearbox impact test device and test method thereof

ActiveCN112393869AScientific and meet the requirements of real vehicle conditionsHigh braking torqueHybrid vehiclesMachine part testingElectromagnetic clutchDrive shaft

The invention relates to a passenger vehicle gearbox impact test device and a test method thereof. The passenger vehicle gearbox impact test device comprises a supporting device for fixing a passengervehicle gearbox to be detected, a driving mechanism directly connected with one input end of the passenger vehicle gearbox to be detected, a brake mechanism connected with two output ends of the passenger vehicle gearbox to be detected, and a hydraulic loading device connected with the brake mechanism. The driving mechanism comprises a driving motor, an electromagnetic clutch, an inertia flywheelbox and an input transmission shaft which are connected in sequence. An input end torque rotating speed sensor is installed on an output shaft of the inertia flywheel box. The brake mechanism comprises an output transmission shaft, an output end torque rotating speed sensor, a middle support and a brake device which are connected in sequence. According to the invention, the instantaneous impact condition of the gearbox under the working condition of the whole vehicle can be scientifically simulated, an impact test process can be completed in a very short time, and the impact torque, the impact simulation inertia and the impact test rotating speed are adjustable.

Owner:XIANGYANG DAAN AUTOMOBILE TEST CENT

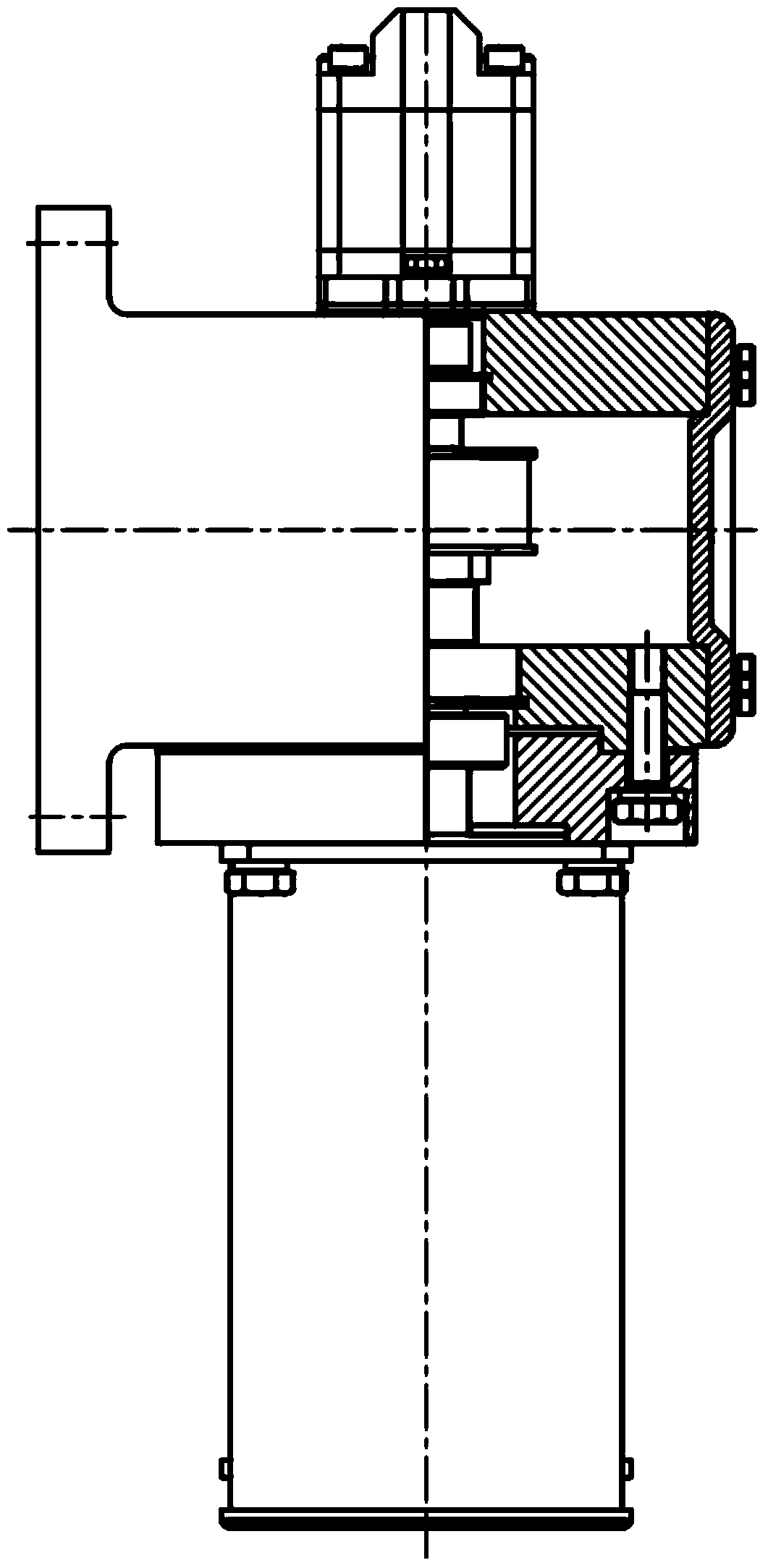

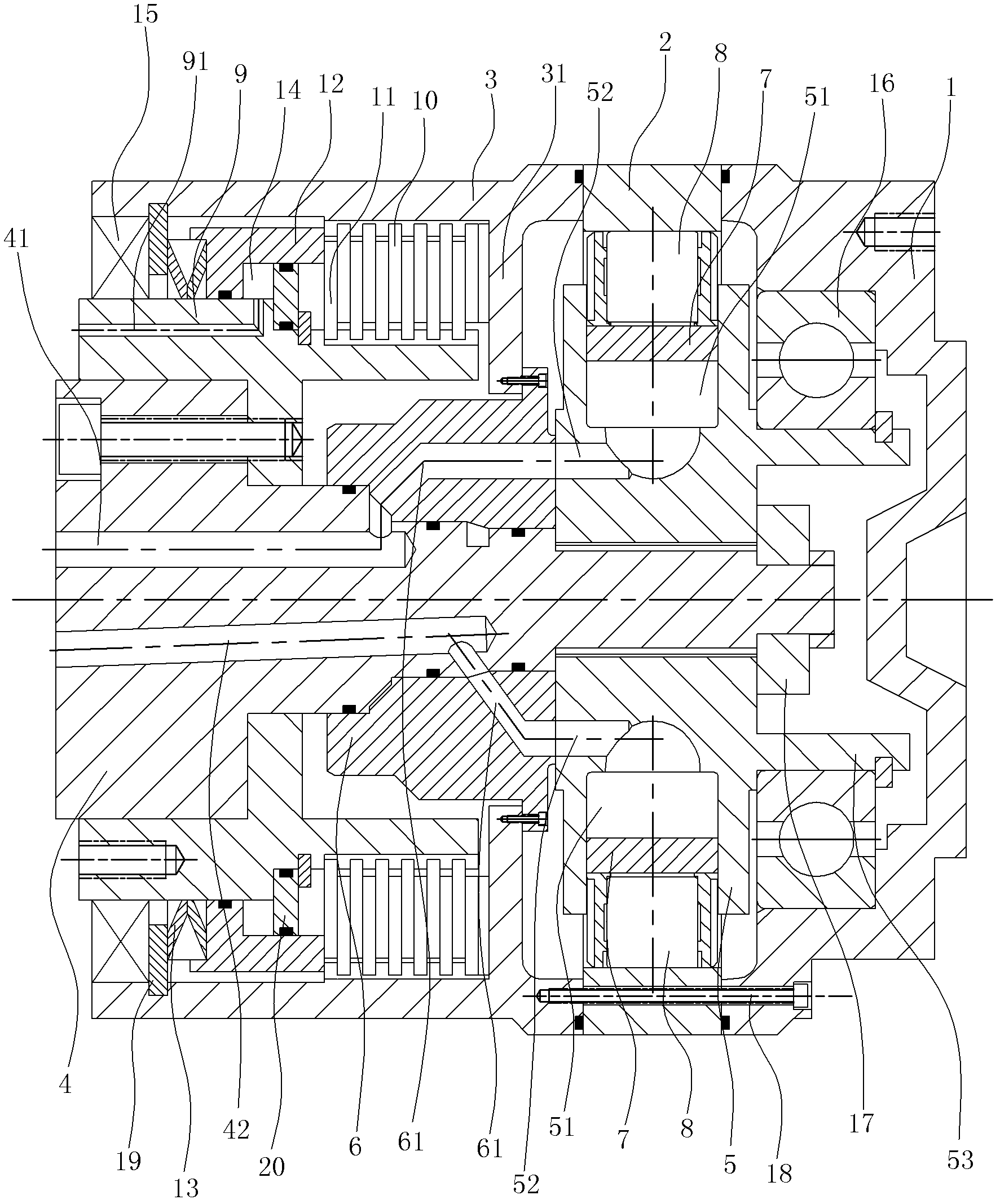

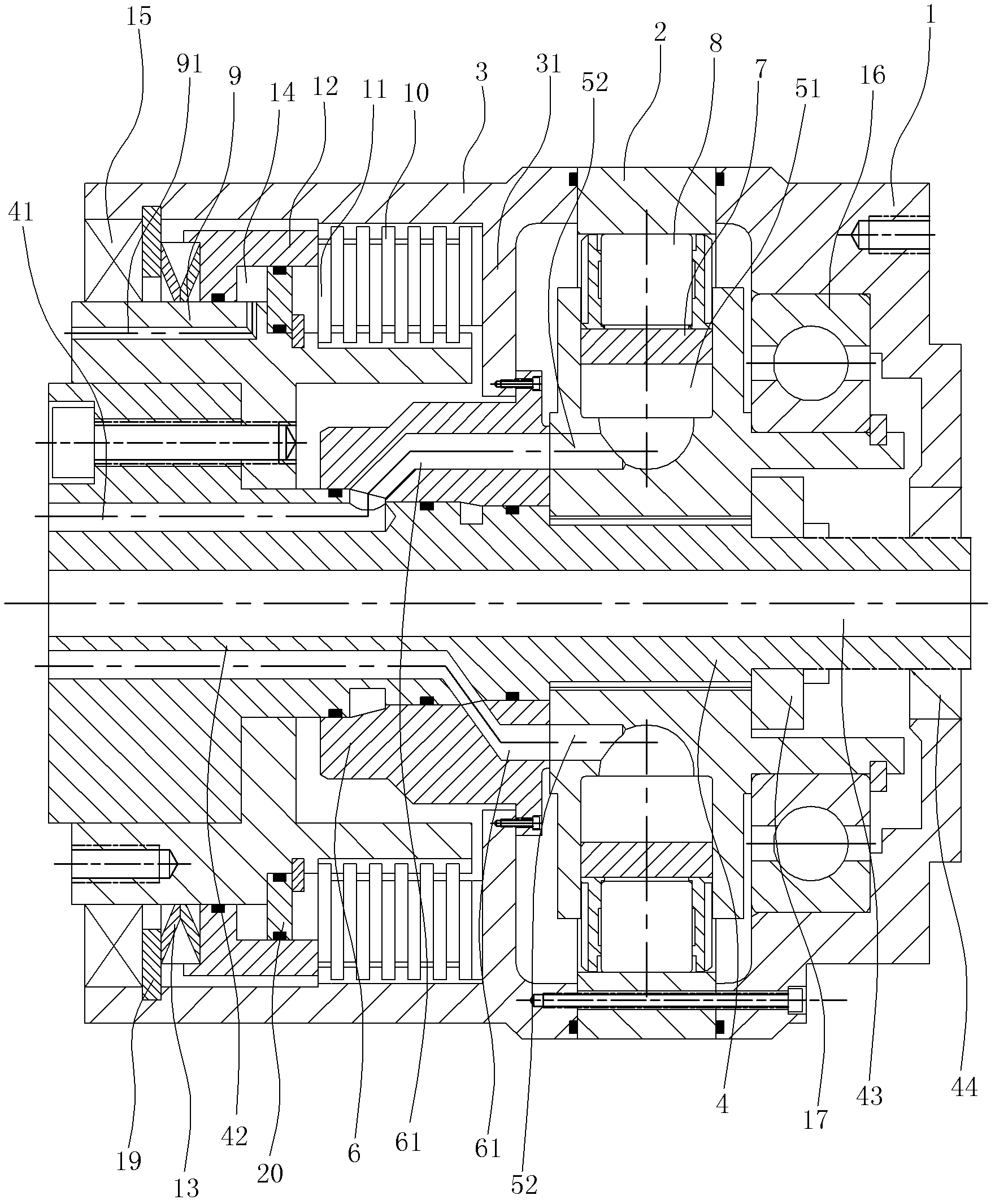

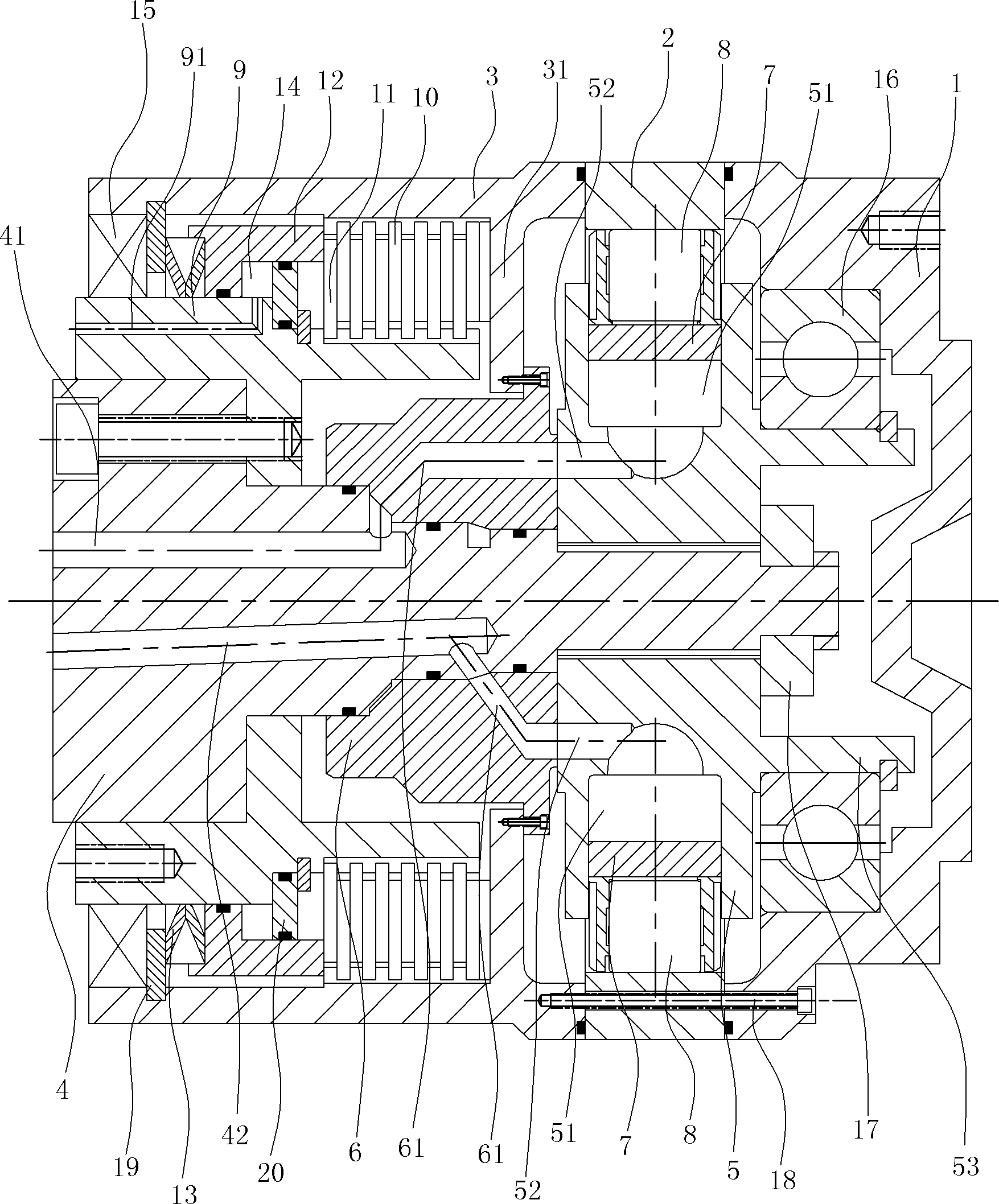

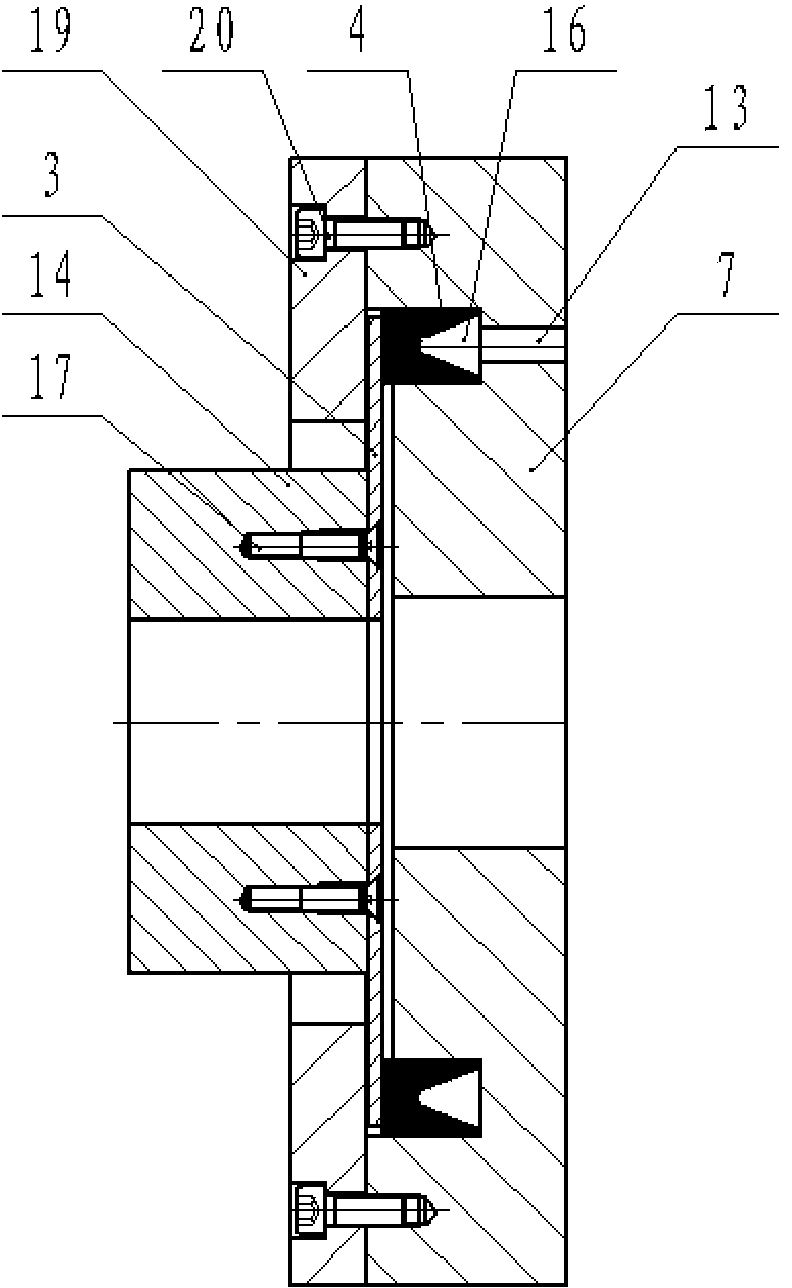

Through shaft tapered-tooth planet wheel side reducer with brake

PendingCN106704554AReduce width sizeReduce axial sizeBrake typesGearing detailsInjection portReduction drive

The invention belongs to the technical field of underground coal mine auxiliary conveying device spare parts and specifically relates to a through shaft tapered-tooth planet wheel side reducer with a brake. According to the shaft tapered-tooth planet wheel side reducer with the brake, the problem that the width of an overall support conveying vehicle is large due to the fact that the occupied space of a motor directly inserting wheel side reducer is large is solved. The shaft tapered-tooth planet wheel side reducer with the brake comprises an input fork frame I, a first rolling bearing, an inner supporting frame, an input shell, a small bevel gear, a large bevel gear, a through shaft, a shaft sleeve, a radial bearing, an output fork frame II, a locking nut, a brake spring, a brake block, a brake fixed sleeve, a friction plate set, an inner gear frame, a second rolling bearing, a bearing shaft sleeve, a third rolling bearing, a main transmission shaft, a sun wheel shaft, a planet wheel, a planet carrier, a right end cap, a vent plug, a high-pressure oil injection port, a small end cap, a left end cap, a rack installing hole, wheel installing screw holes and a high-pressure oil cavity. According to the shaft tapered-tooth planet wheel side reducer with the brake, the through shaft tapered-tooth planet combined reducer is adopted, power of an engine or a motor can be input through the transmission shaft, and the axial size of the reducer is reduced.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

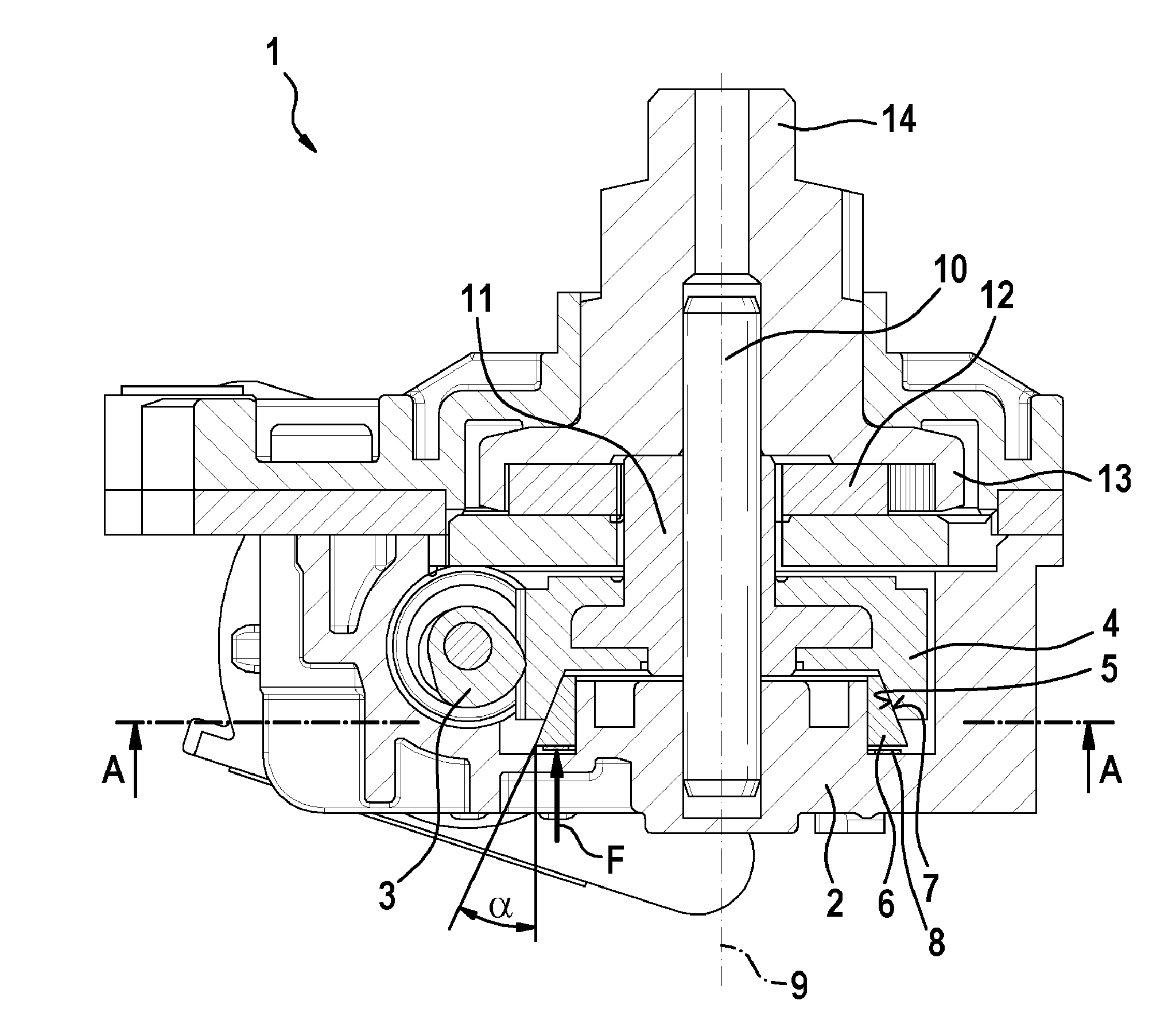

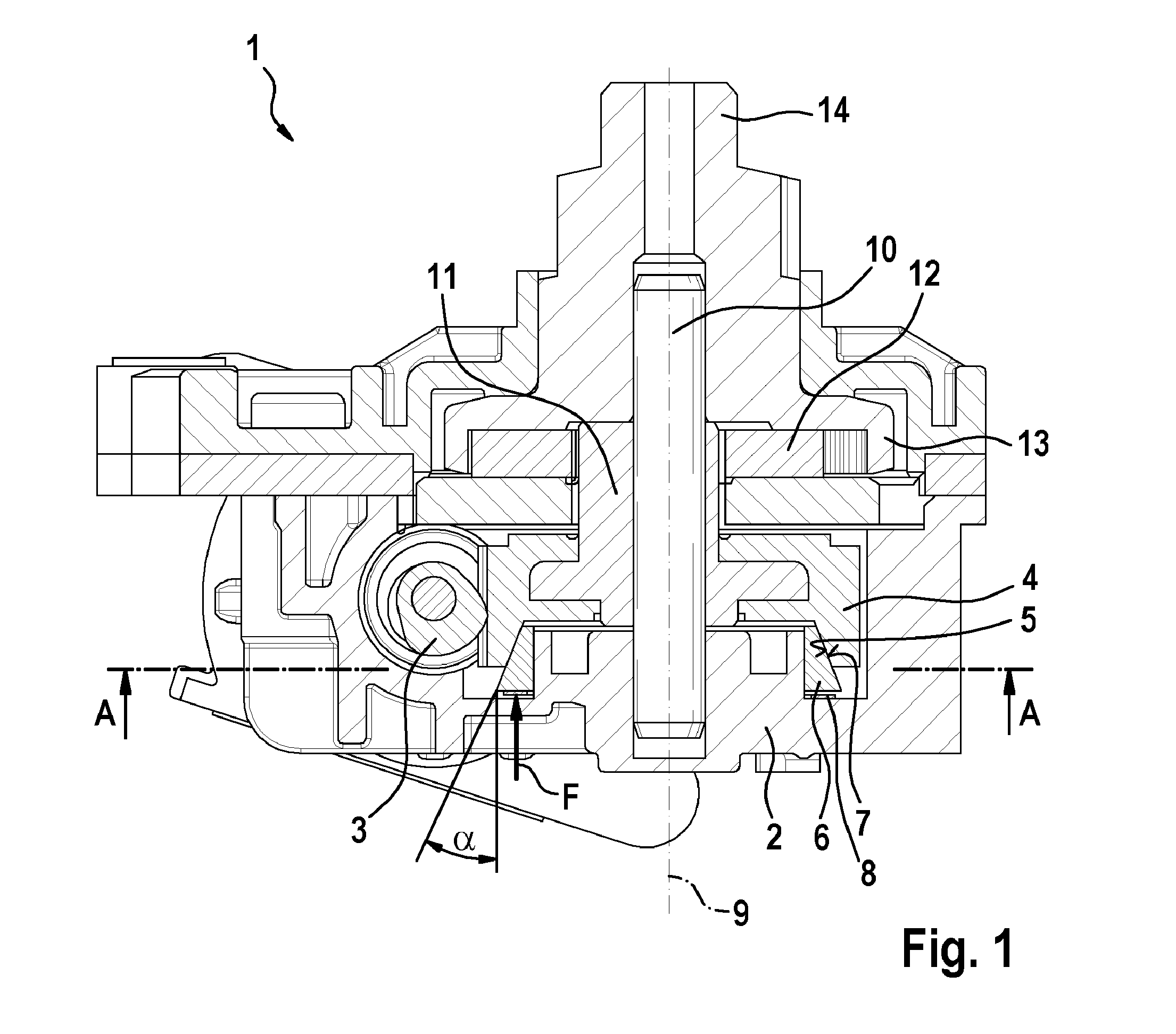

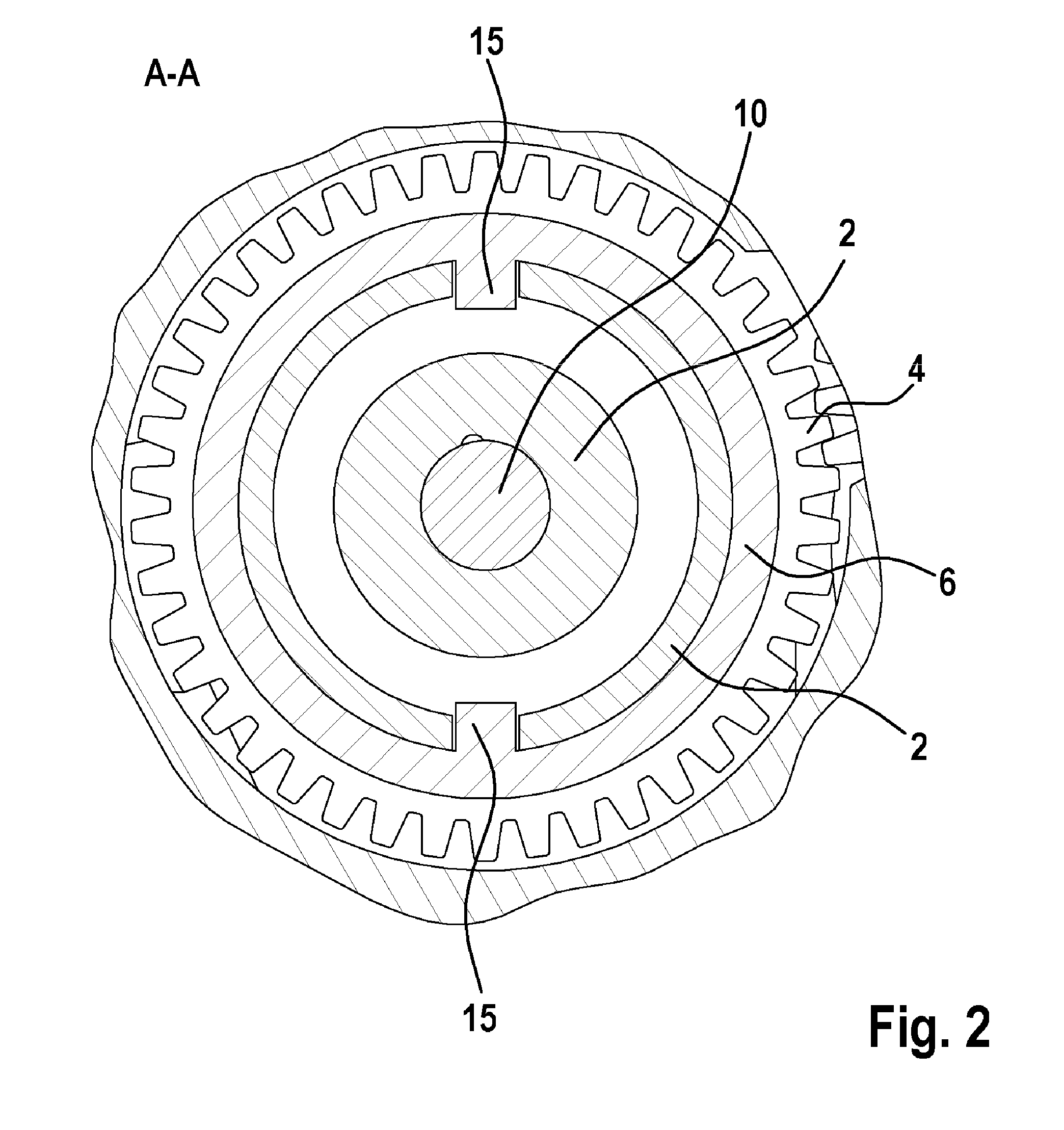

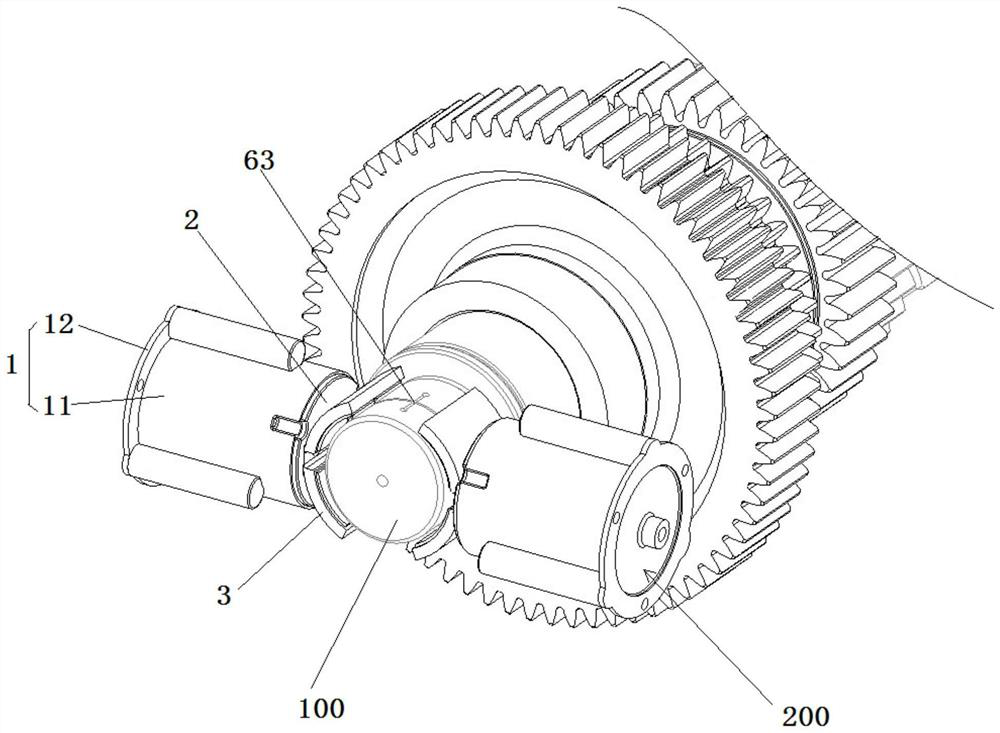

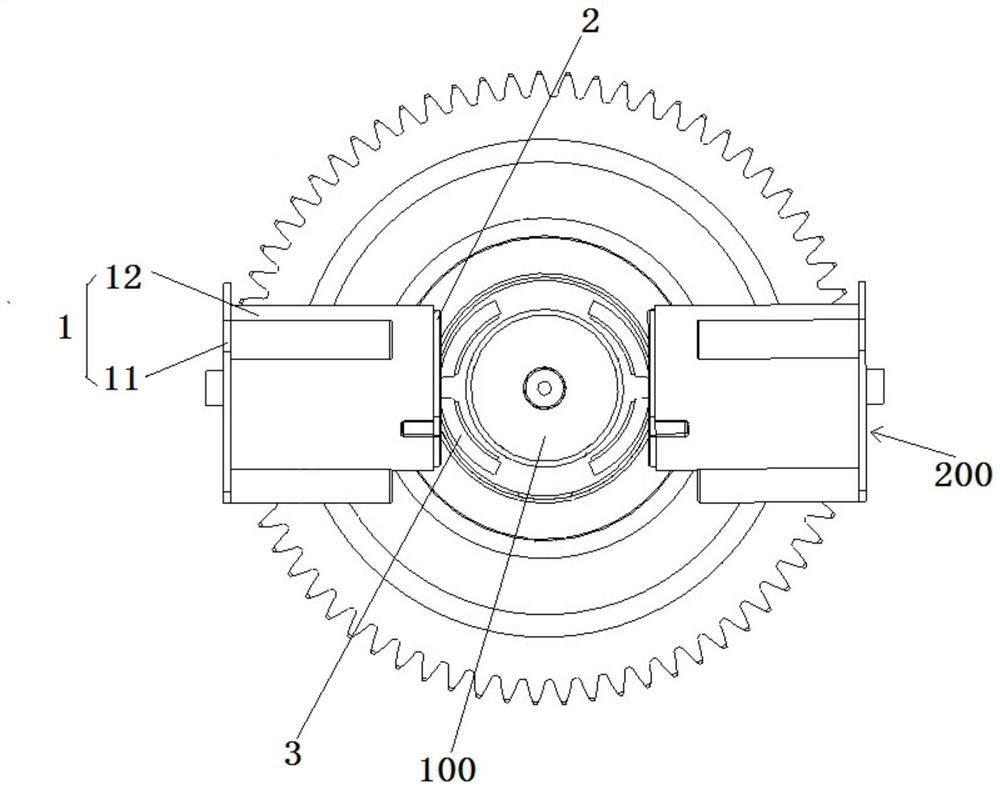

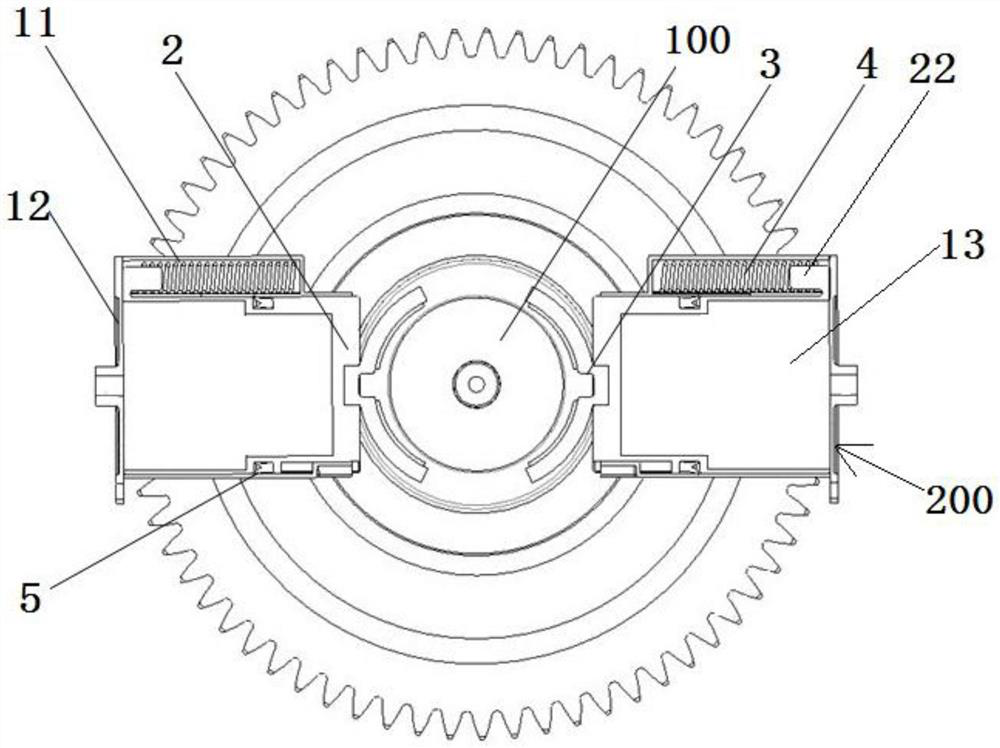

Transmission, in particular for an adjustment drive

ActiveUS20150000444A1Prevents chatter vibrationHigh braking torqueVehicle seatsGear vibration/noise dampingEngineeringMechanical engineering

The present invention relates to a transmission (1), in particular for an adjustment drive, comprising a housing (2), a worm shaft (3) which is rotatably mounted in the housing (2) and which can be driven, a worm wheel (4) which is rotatably mounted in the housing (2) and which meshes with the worm shaft (3), an encircling first wedge surface (5) which is formed on the worm wheel (4) or fixedly connected to the worm wheel (4), a brake element (6) which is arranged so as to be rotationally conjoint with respect to the worm wheel (4) and which has a second wedge surface (7), wherein the first wedge surface (5) bears areally against the second wedge surface (7).

Owner:ROBERT BOSCH GMBH

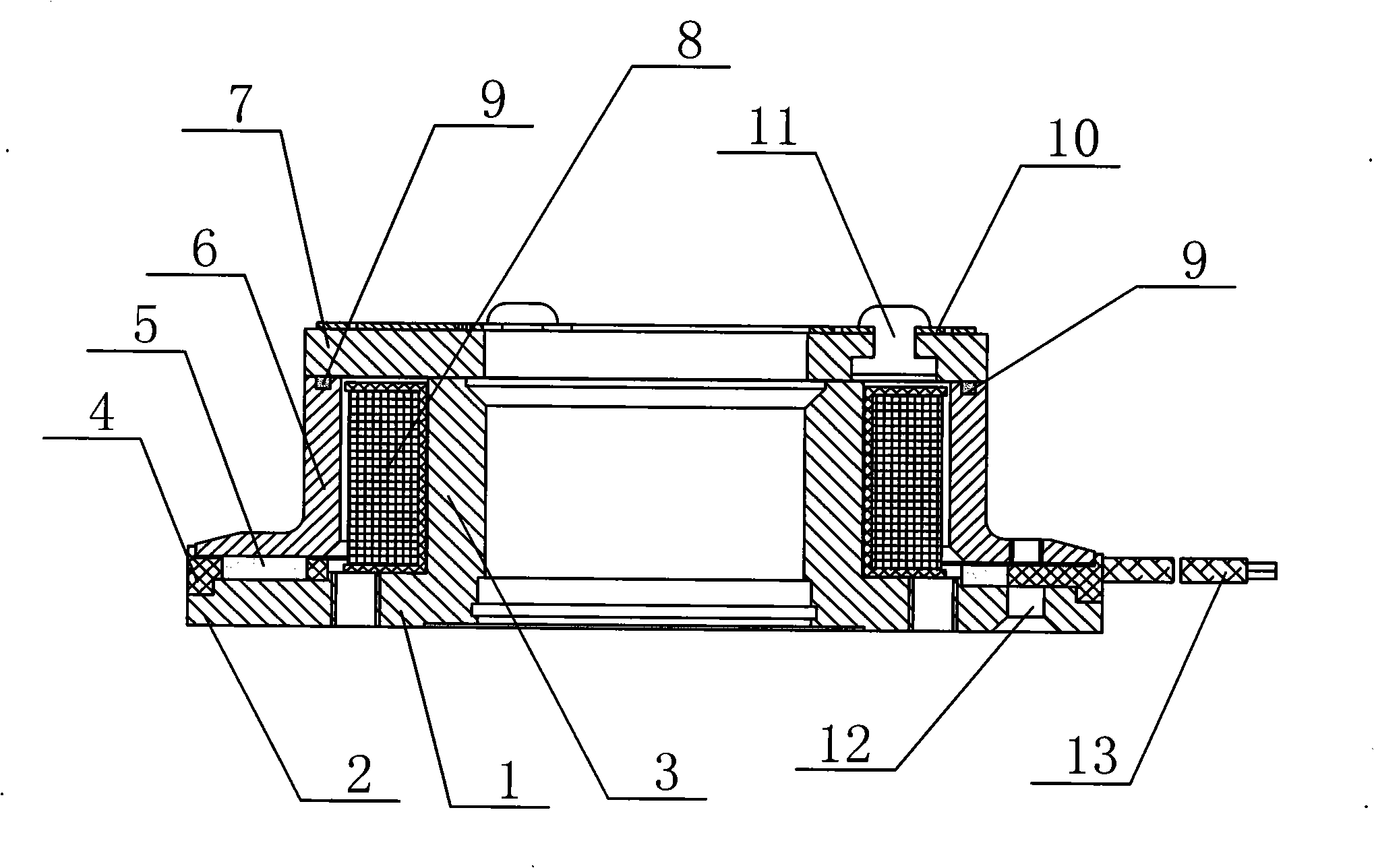

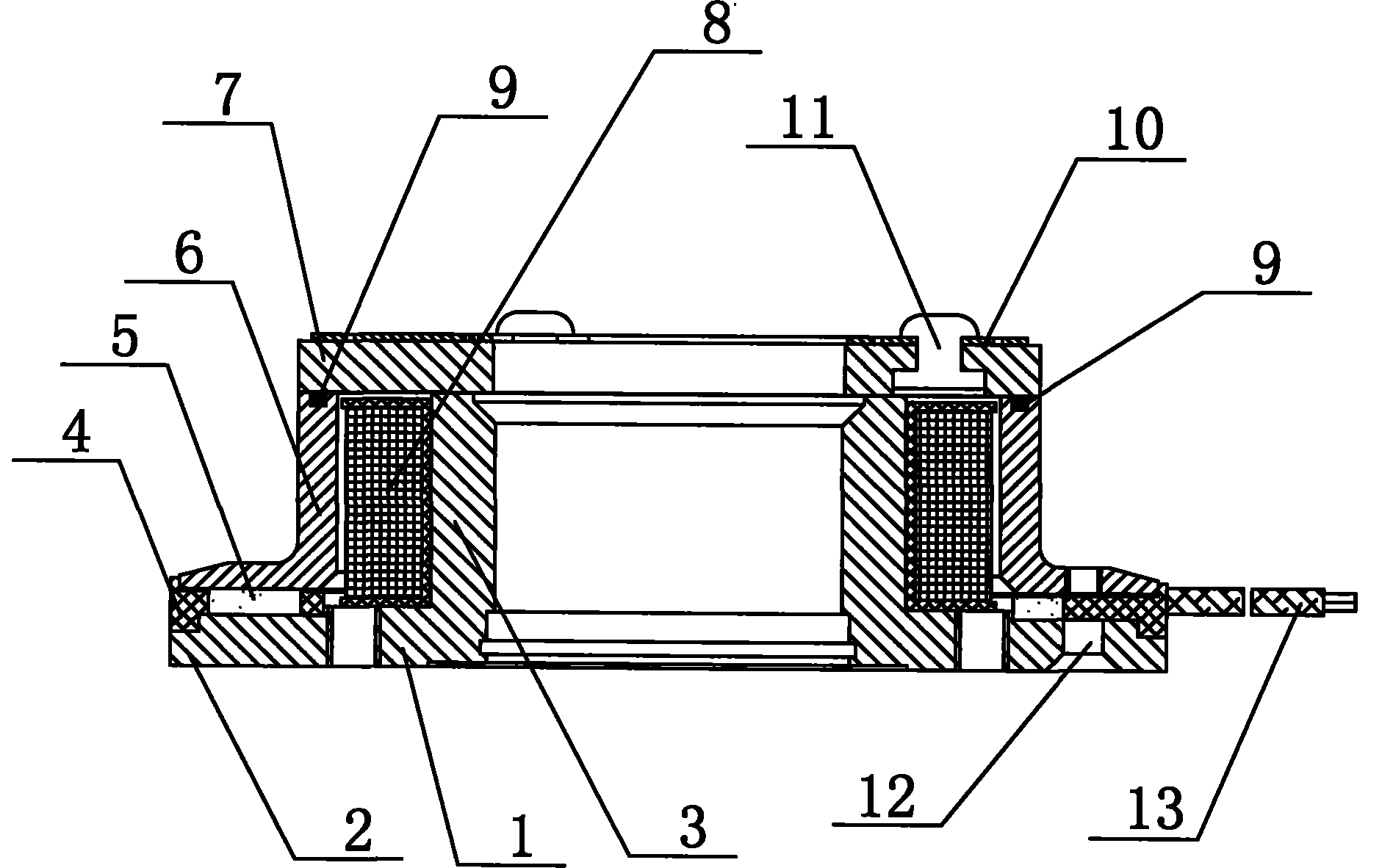

Electromagnetic brake

InactiveCN102562872ASimple structureHigh braking torqueAxially engaging brakesActuatorsEngineeringMechanical engineering

An electromagnetic brake is characterized in that two end caps are respectively mounted at two end ports of a brake body, a brake shaft is fixedly mounted with the two end caps on the left and the right through bearings, a brake wheel is mounted in the middle of the brake shaft, two guide rings are respectively arranged in inner holes, on two sides of the brake wheel, of the brake body, an electromagnetic iron core is fixedly mounted on the inner side of each guide ring, and electromagnetic coils with the same parameters are respectively embedded in the two corresponding electromagnetic iron cores. The two electromagnetic coils mounted oppositely attract or repel mutually so that inner cones and outer cones among the electromagnetic iron cores and the brake wheel can be matched with each other or separated from each other to realize braking or releasing. The electromagnetic brake has the advantages of simple structure, safety and reliability and high braking torque, can meet requirements of sites needing higher braking torque, and accordingly can reduce equipment cost.

Owner:XUZHOU KAILAN INFORMATION TECH

Permanent magnet safe brake with high friction coefficient

InactiveCN101900174AExtended useful lifeReliable operationAxially engaging brakesBrake actuating mechanismsBrake torqueConductor Coil

The invention discloses a permanent magnet safe brake with high friction coefficient. The brake comprises a base, wherein the base is provided with a magnetic steel framework used for installing permanent magnet steel; the permanent magnet steel has a circular structure; an electrified excitation winding is sleeved on the base; the outsides of the permanent magnet steel and the electrified excitation winding are separately provided with a shell and a friction plate corresponding to the shell; a spring piece is arranged on each friction plate; a plurality of auxiliary balk rings with high friction coefficient are embedded on the contact surface of each shell and the corresponding friction plate; the auxiliary balk rings and the friction surface of the shell are on the same plane; and a plurality of auxiliary balk rings are embedded on the contact surface of the shell of the permanent magnet safe brake with high friction coefficient and the friction plates. The invention has simple structure and is easy to realize; the friction coefficient of the brake is increased, the noise generated in the contact braking process is reduced, the service life of the brake is prolonged, and the brake torque is increased so that the brake can operate more reliably.

Owner:WUXI HUALING MACHINERY SWITCHGEAR

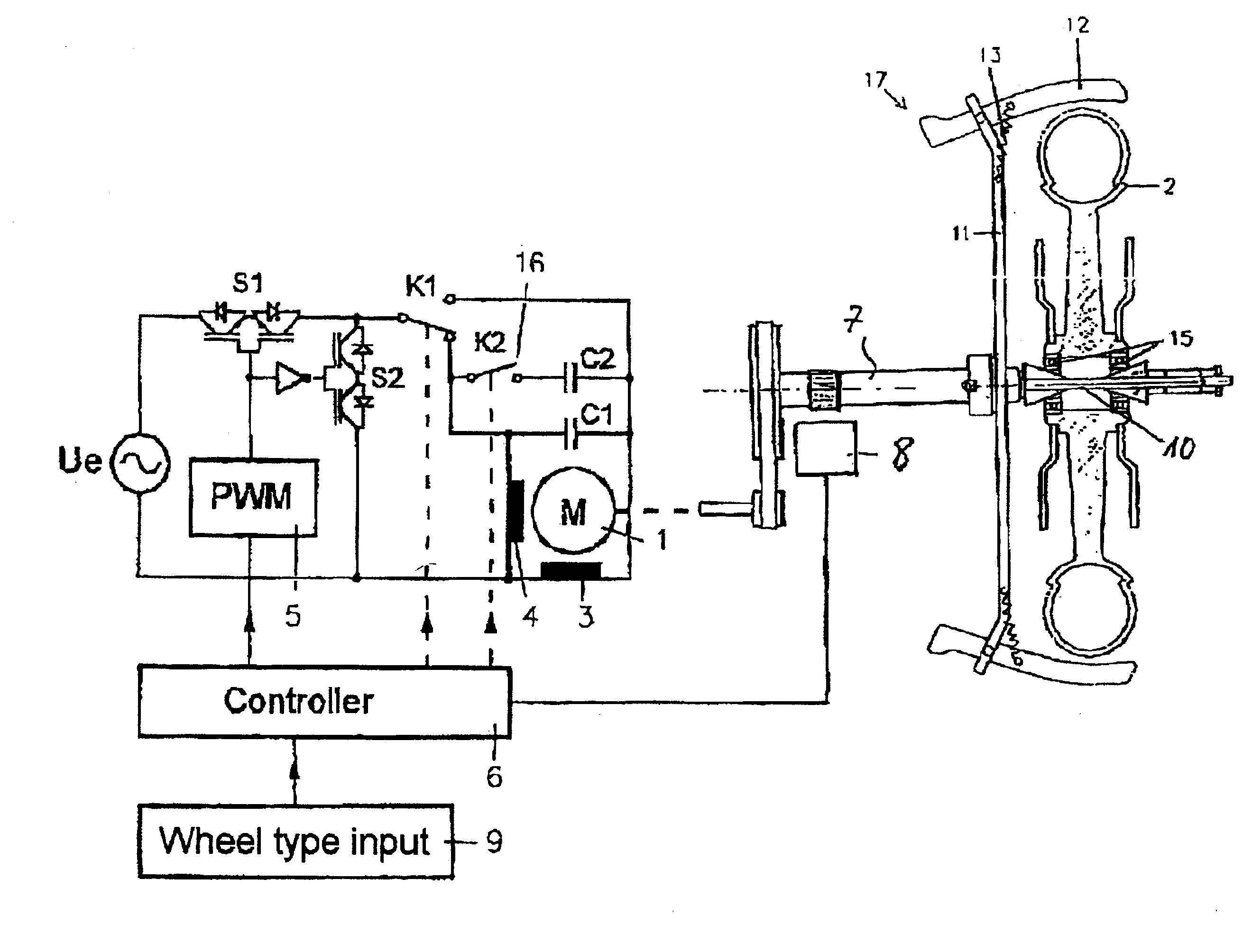

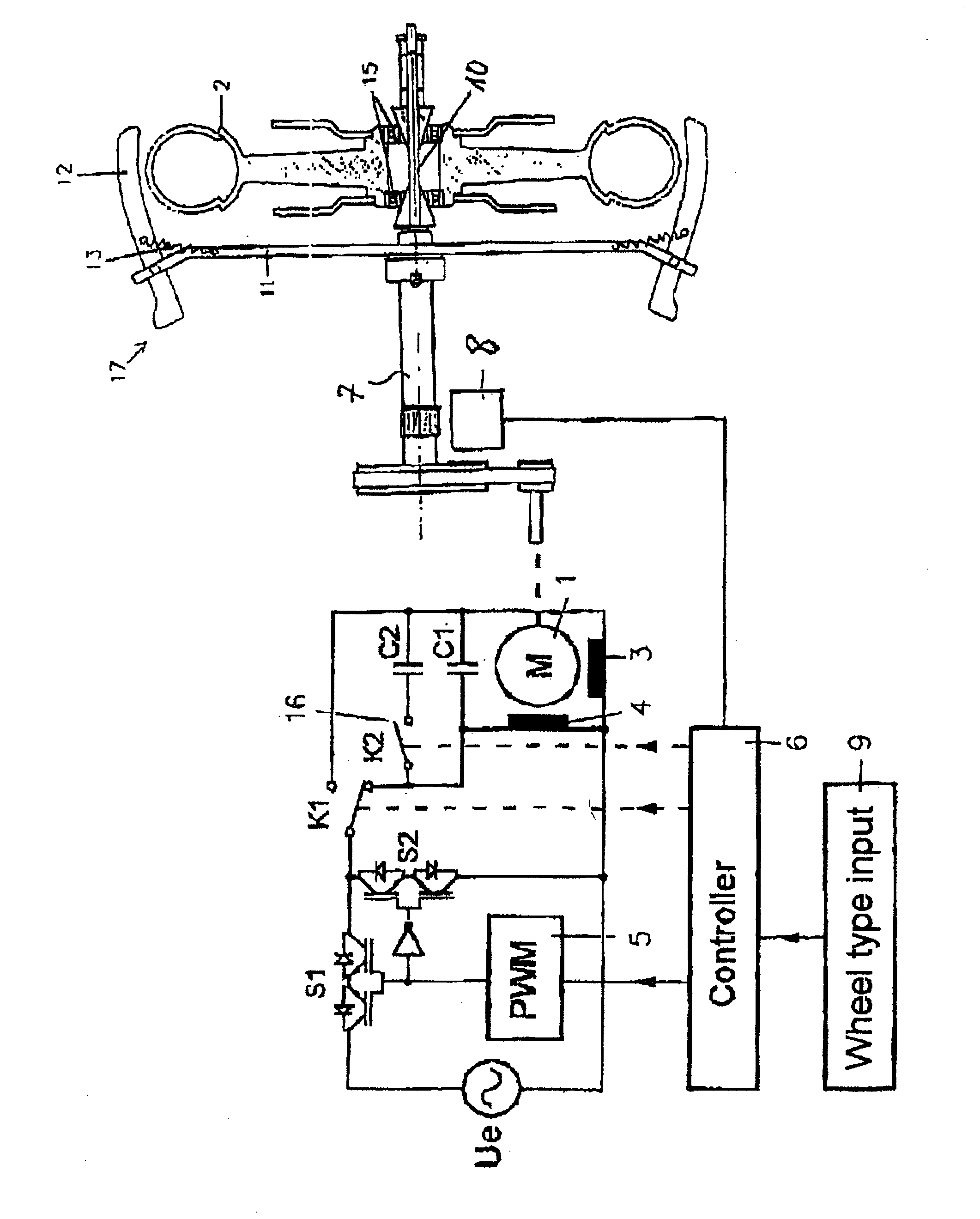

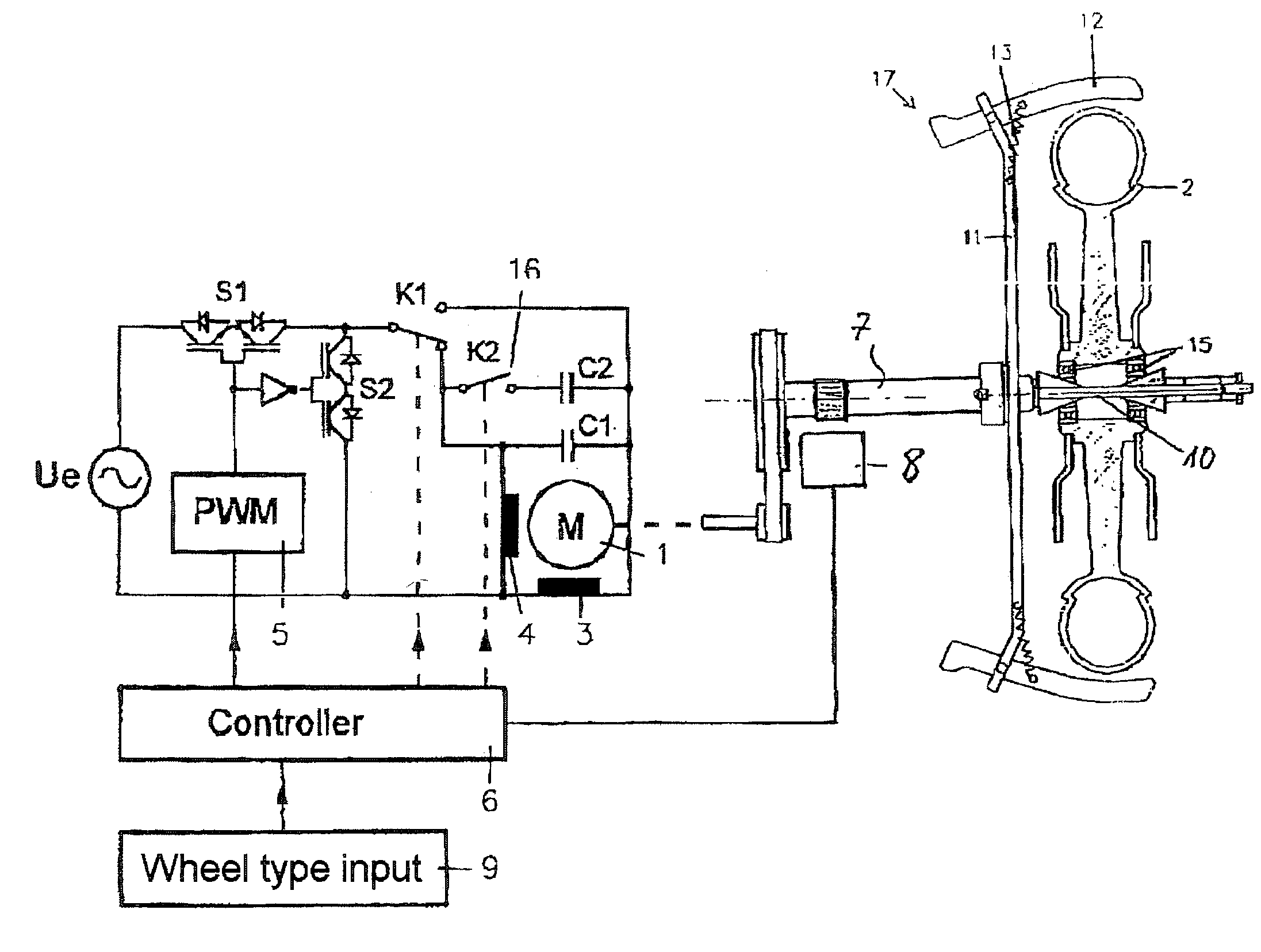

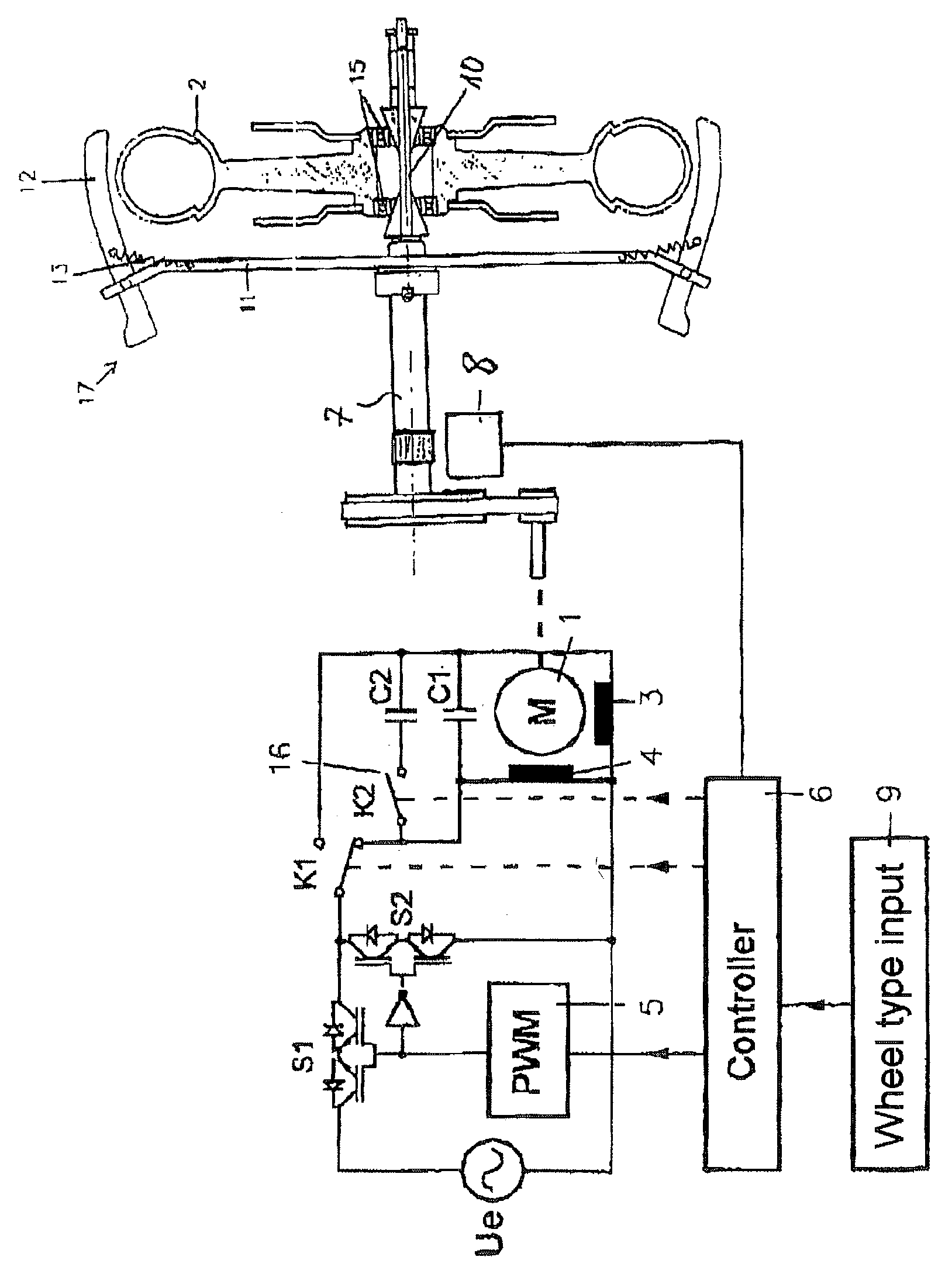

Method and apparatus for balancing a motor vehicle wheel

InactiveUS6752016B2Accurate measurementIncrease torqueStatic/dynamic balance measurementVehicle tyre testingAcceleration UnitAutomotive engineering

Owner:SNAP ON EQUIP

Permanent magnet double-reduction motor

InactiveCN101552513AImprove applicabilityReduce volumeToothed gearingsMechanical energy handlingLow noiseDrive motor

The invention relates to a motor, in particular to a permanent magnet double-reduction motor which belongs to the mechanical field. The permanent magnet double-reduction motor comprises a stator assembly, an armature assembly and a rear cover. The permanent magnet double-reduction motor is characterized in that: the permanent magnet double-reduction motor further comprises a planetary reducer mechanism I and a planetary reducer mechanism II, the armature assembly is connected with the planetary reducer mechanism I through a bearing base, and the planetary reducer mechanism II is arranged on the planetary reducer mechanism I. The reducing mechanisms of the motor are the two-stage planetary reducer mechanisms and can simultaneously output two torques, thereby improving the applicability of the motor; simultaneously, the motor has small motor volume, stable performance, low noise, small no-load current and great braking torque. The motor has the advantages of a permanent magnet direct current motor, simultaneously has the advantages of a reduction motor and a direct-driven motor and can output the different torques to achieve multiple purposes of one machine, thereby overcoming the problem of small torque of the existing direct current permanent magnet direct-driven motor.

Owner:乐山东风汽车电器有限公司

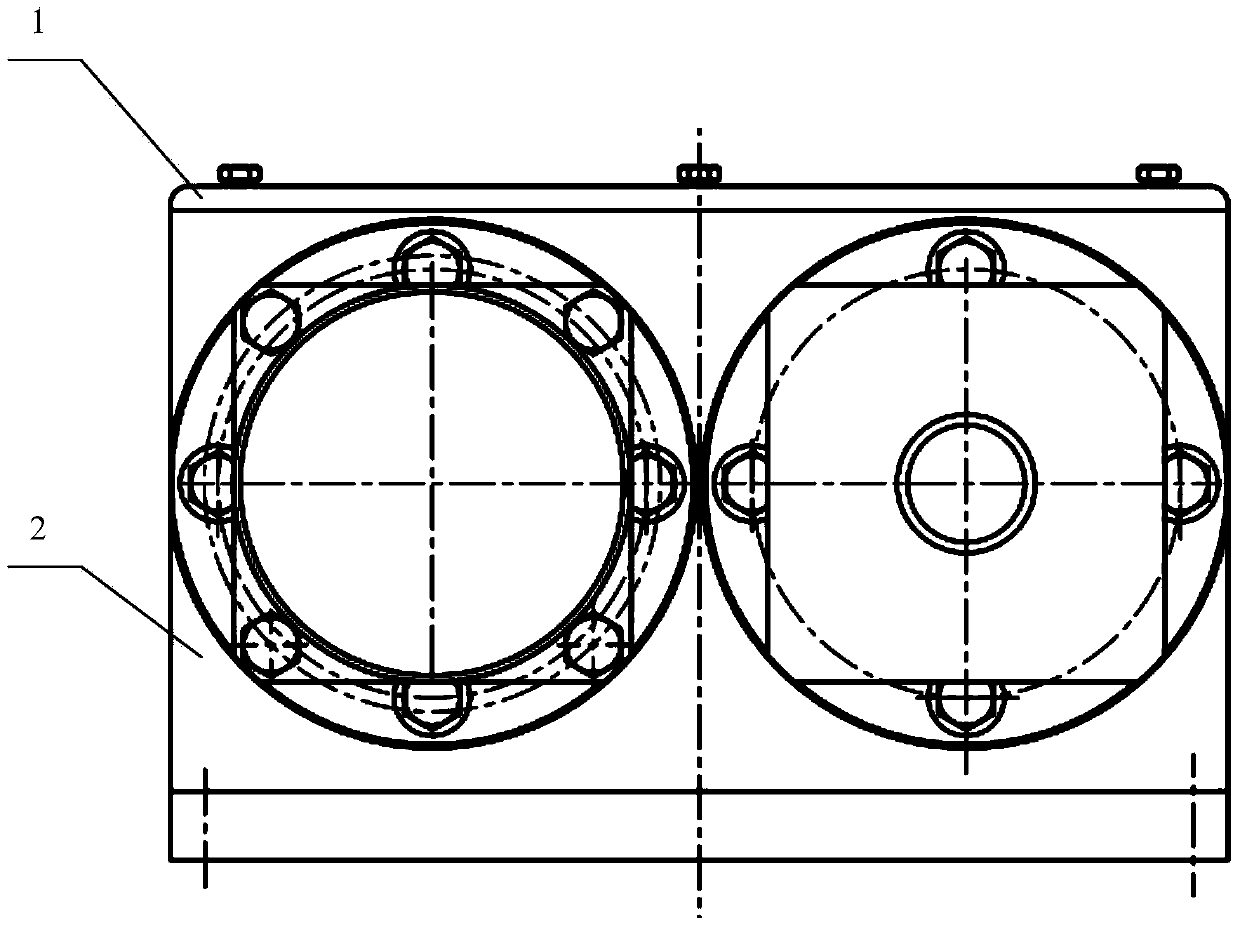

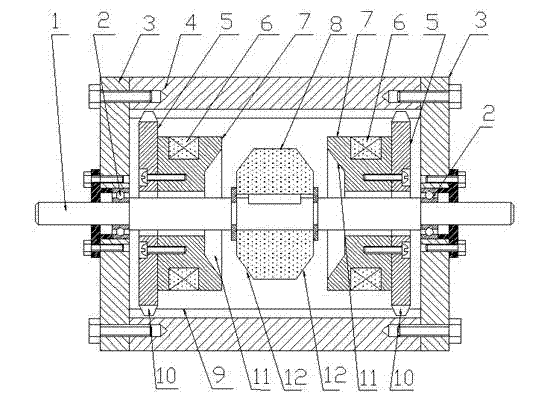

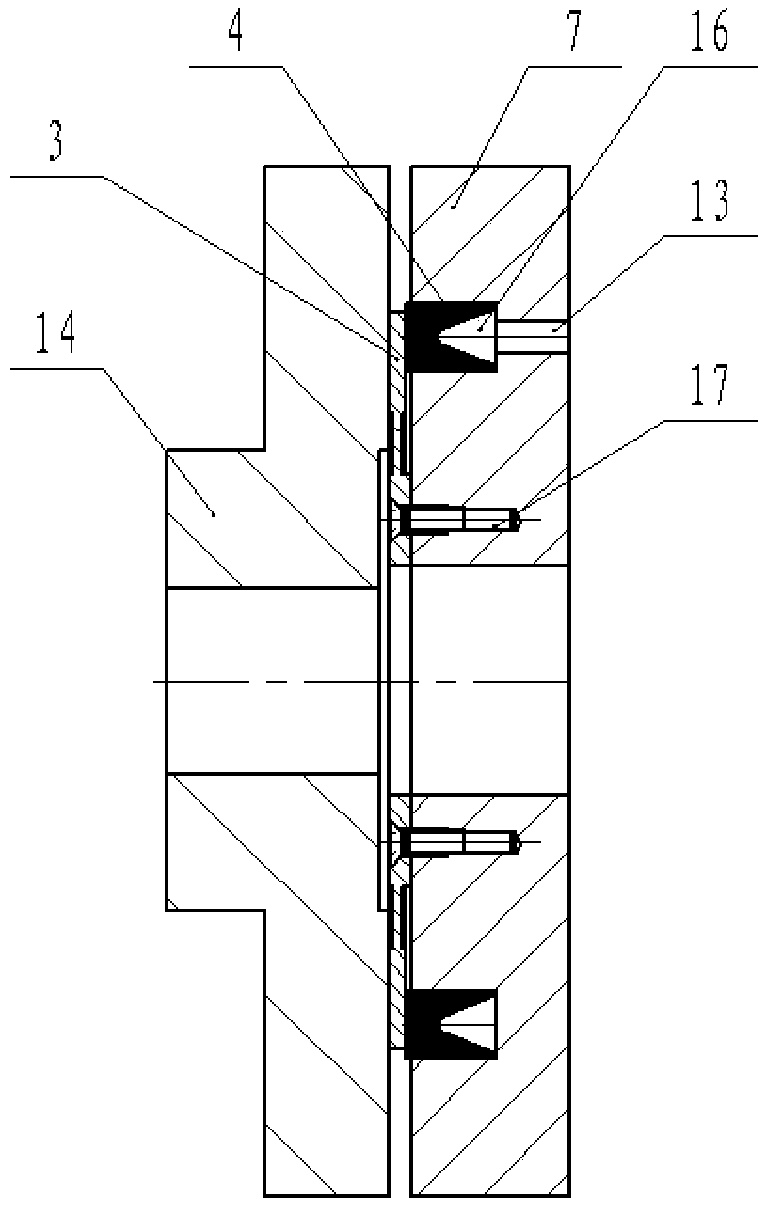

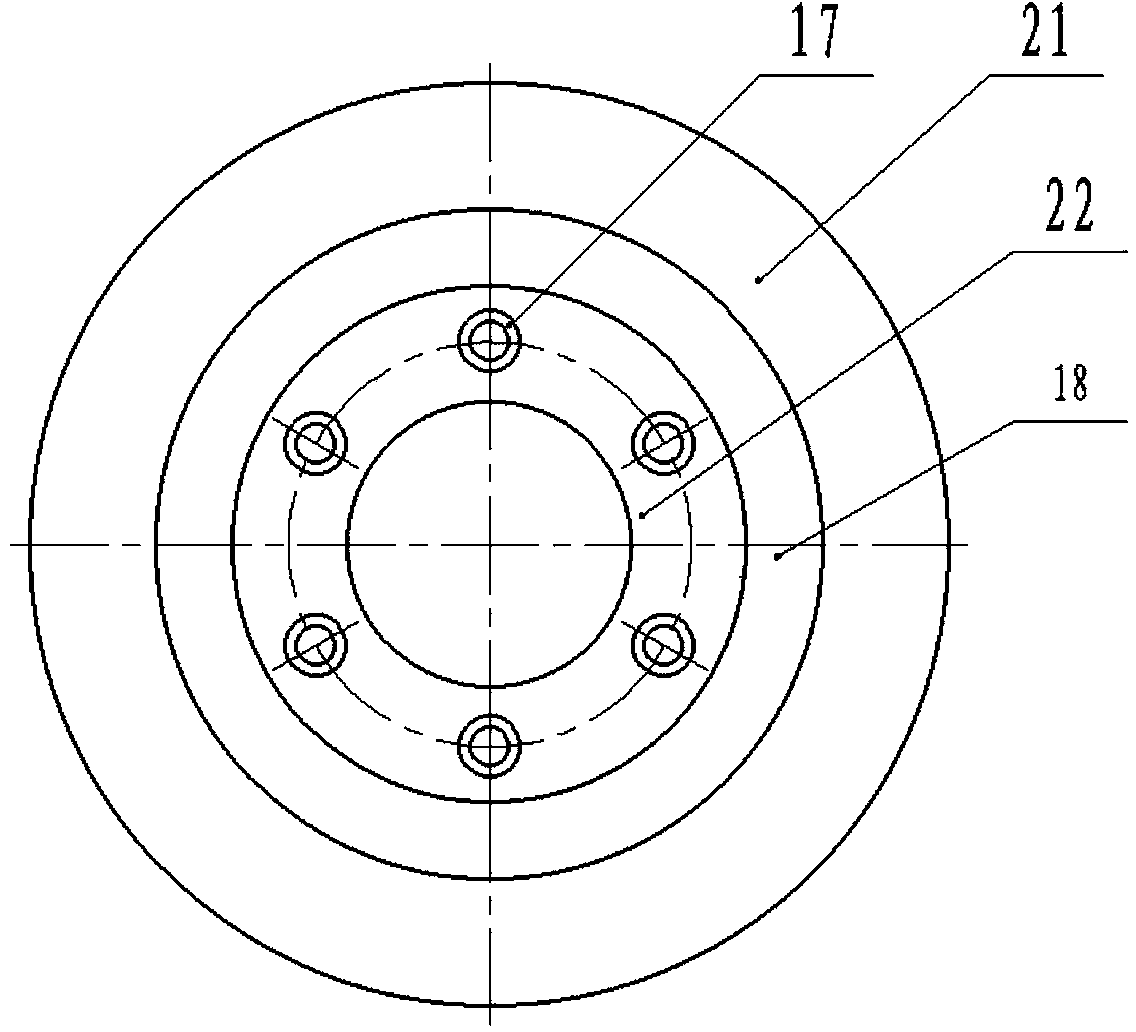

Hydraulic motor integrating wet brake

InactiveCN103277433AWon't enterWill not polluteAxially engaging brakesBrake actuating mechanismsBrake torqueHydraulic motor

The invention discloses a hydraulic motor integrating a wet brake. The hydraulic motor integrating the wet brake comprises a hydraulic motor body and a brake body, wherein the brake body is arranged on the tail portion of the hydraulic motor body, the brake body comprises a brake outer shell, braking pistons, a driving friction plate, a driven friction plate, reset springs, first reset spring bases, second reset spring bases and a transition disk, wherein the braking pistons, the driving friction plate, the driven friction plate, the reset springs, the first reset spring bases, the second reset spring bases and the transition disk are arranged in the brake outer shell. Internal teeth of the transition disk are meshed with external teeth of a transmission shaft of the hydraulic motor body, and the driving friction plate can rotate along with the transmission shaft of the hydraulic motor body when the transmission shaft rotates. When braking is not carried out, the driving friction plate and the driven friction plate are in a separated state. When braking is carried out, the braking pistons overcome force of the reset springs to move left, and braking begins when the reset springs make contact with the driving friction plate and the driven friction plate. Due to the facts that a braking mode of dynamic braking is adopted, and braking torque changes along with braking pressure in a linear mode, the slowly-opened function and the slowly-closed function can be achieved, and due to the fact that a braking cooling oil port is formed, the defect that a motor is poor in heat dissipation capacity can be overcome.

Owner:ZHEJIANG UNIV

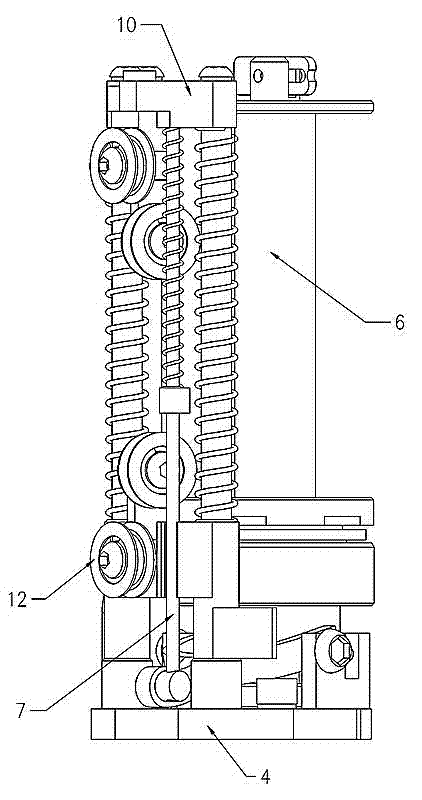

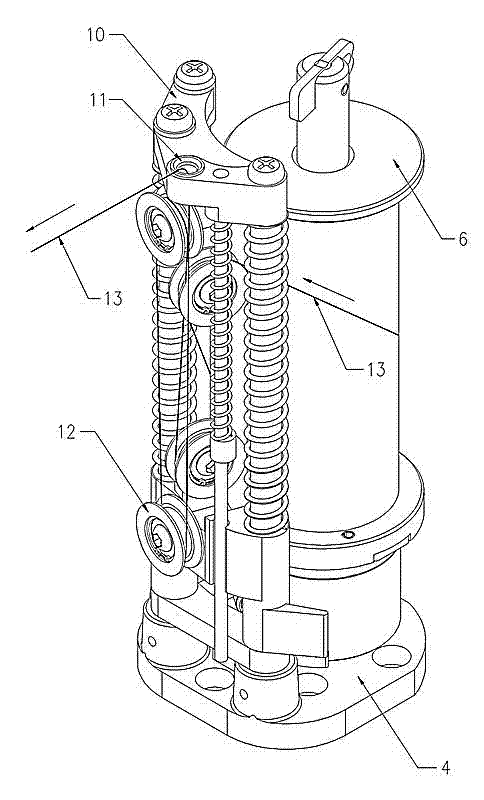

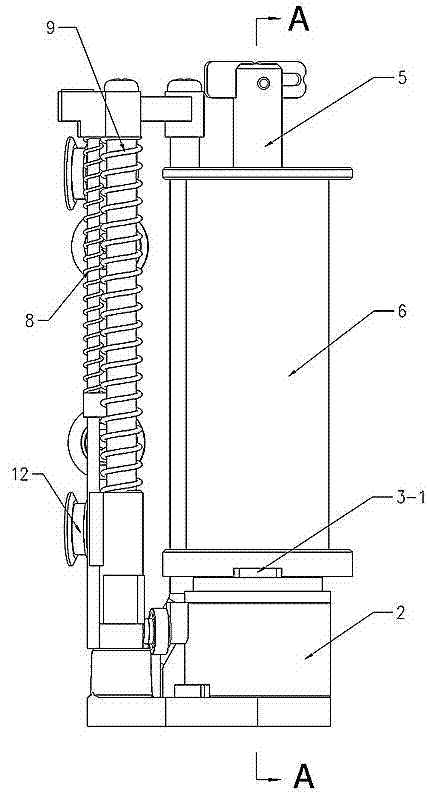

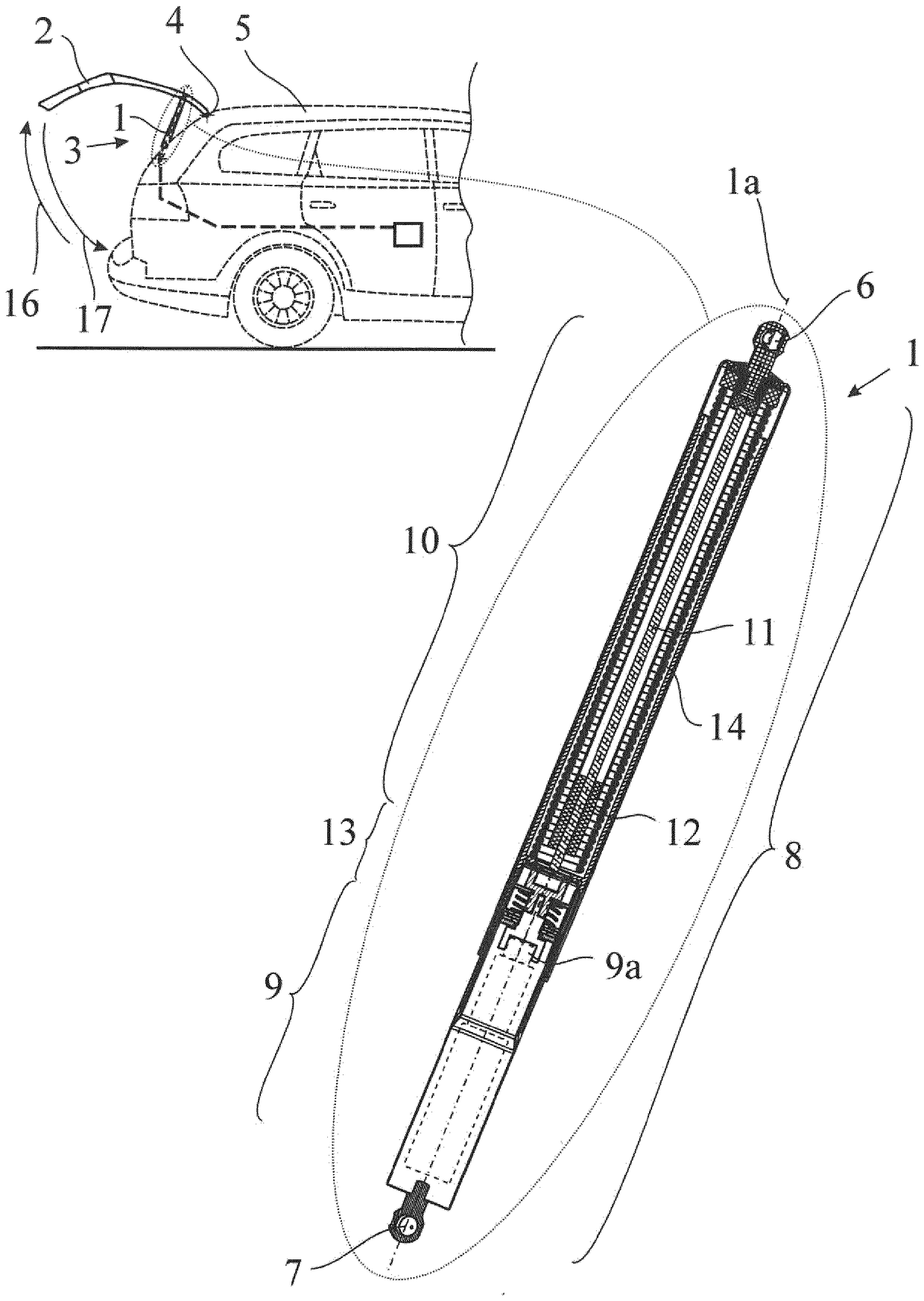

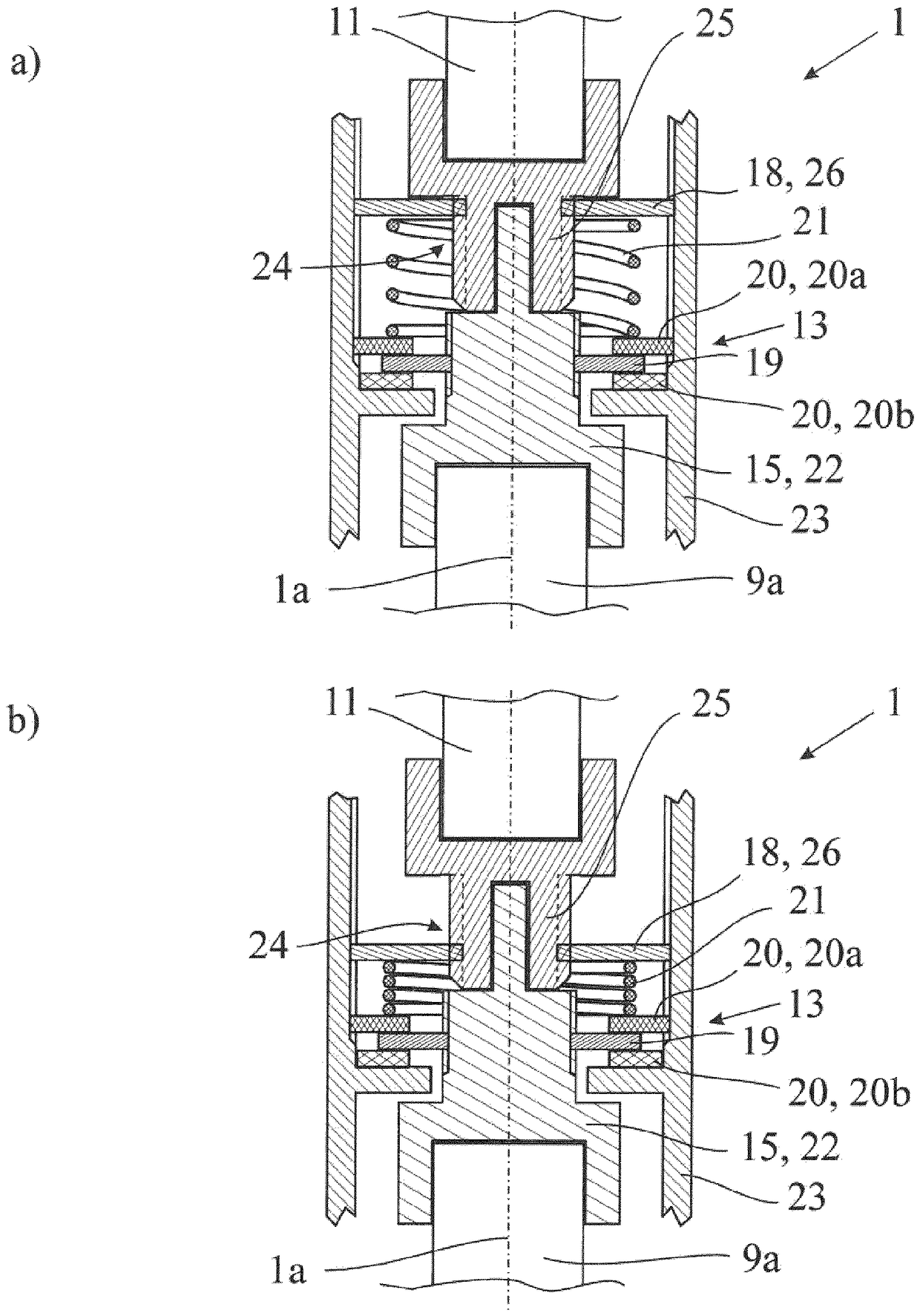

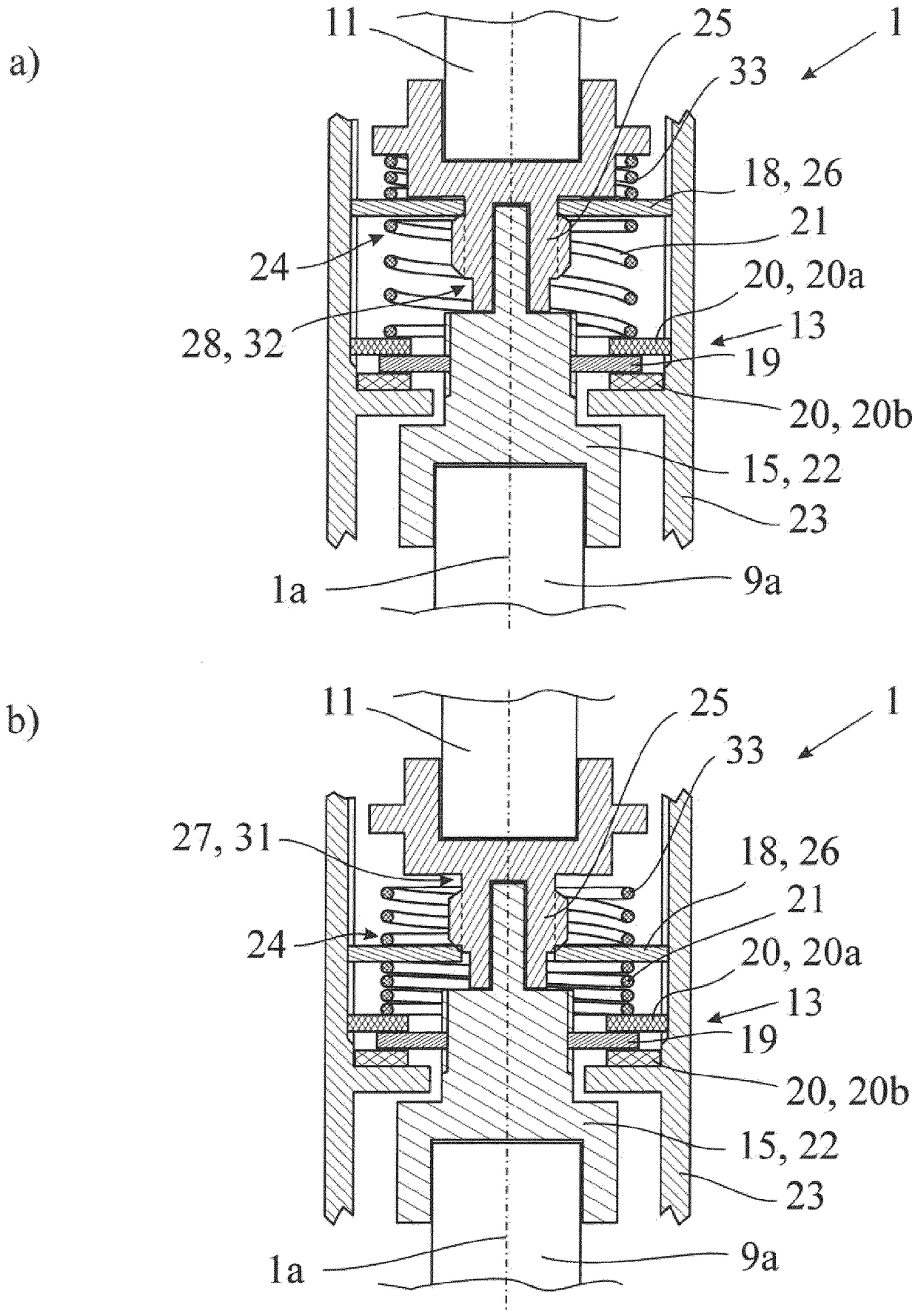

Spindle drive

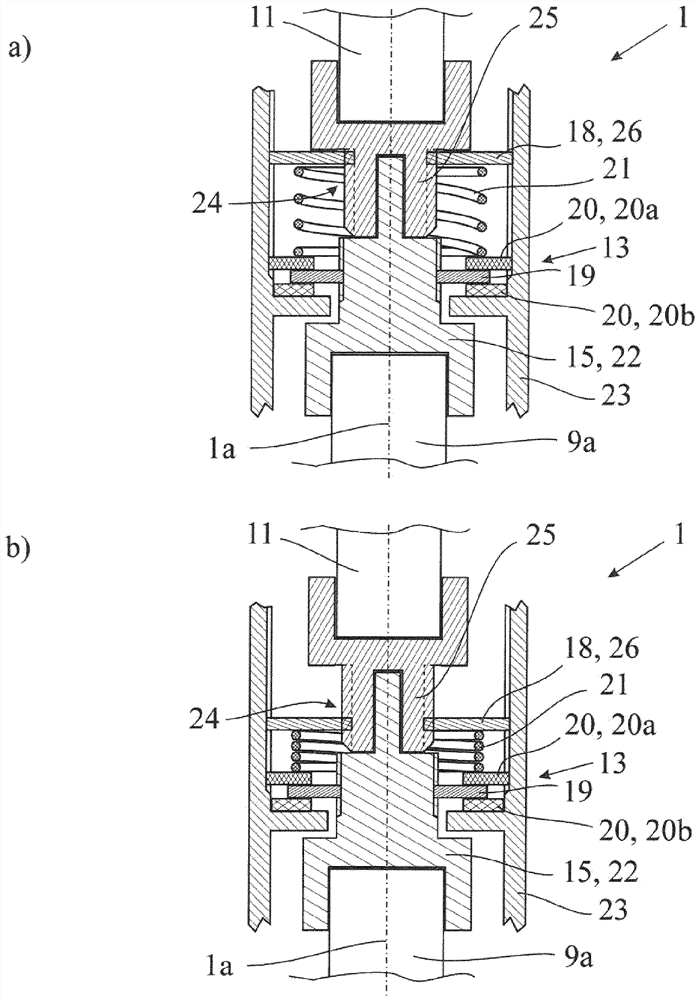

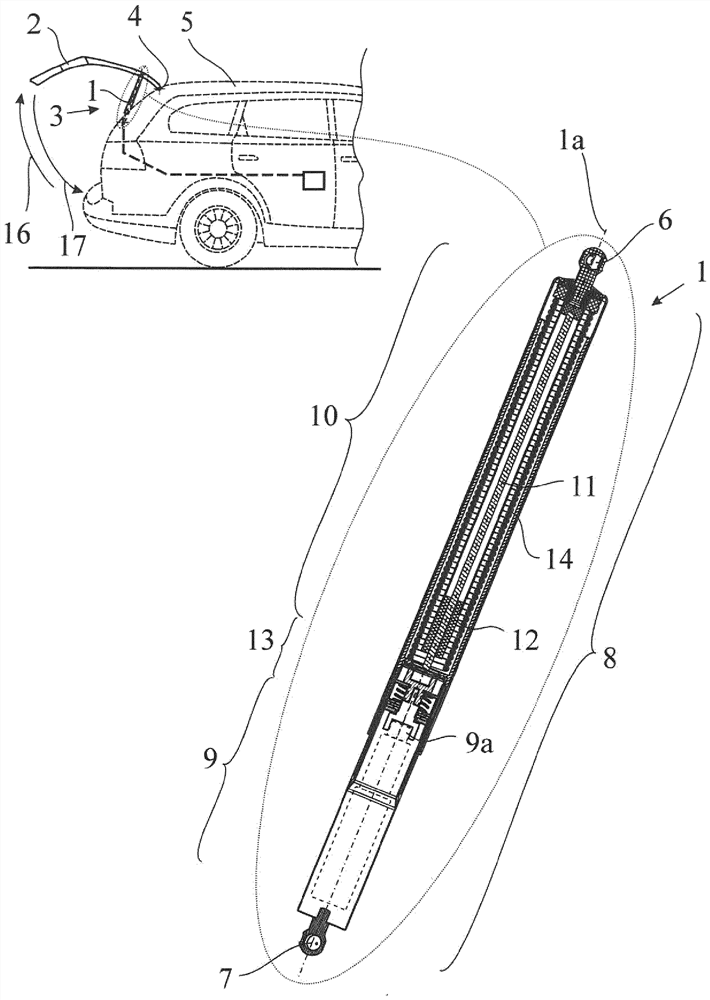

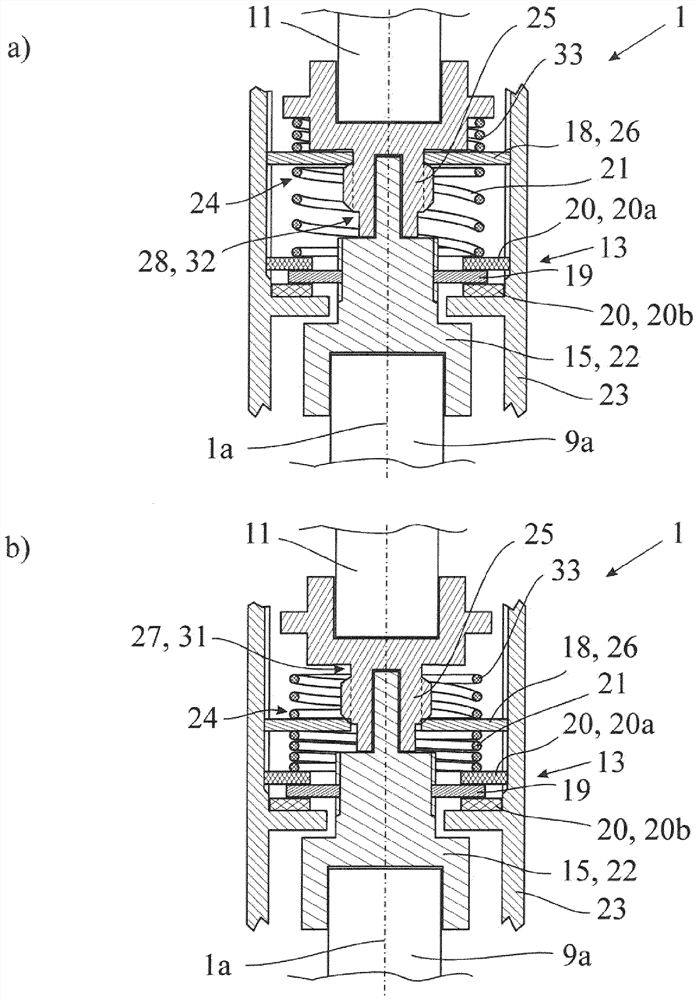

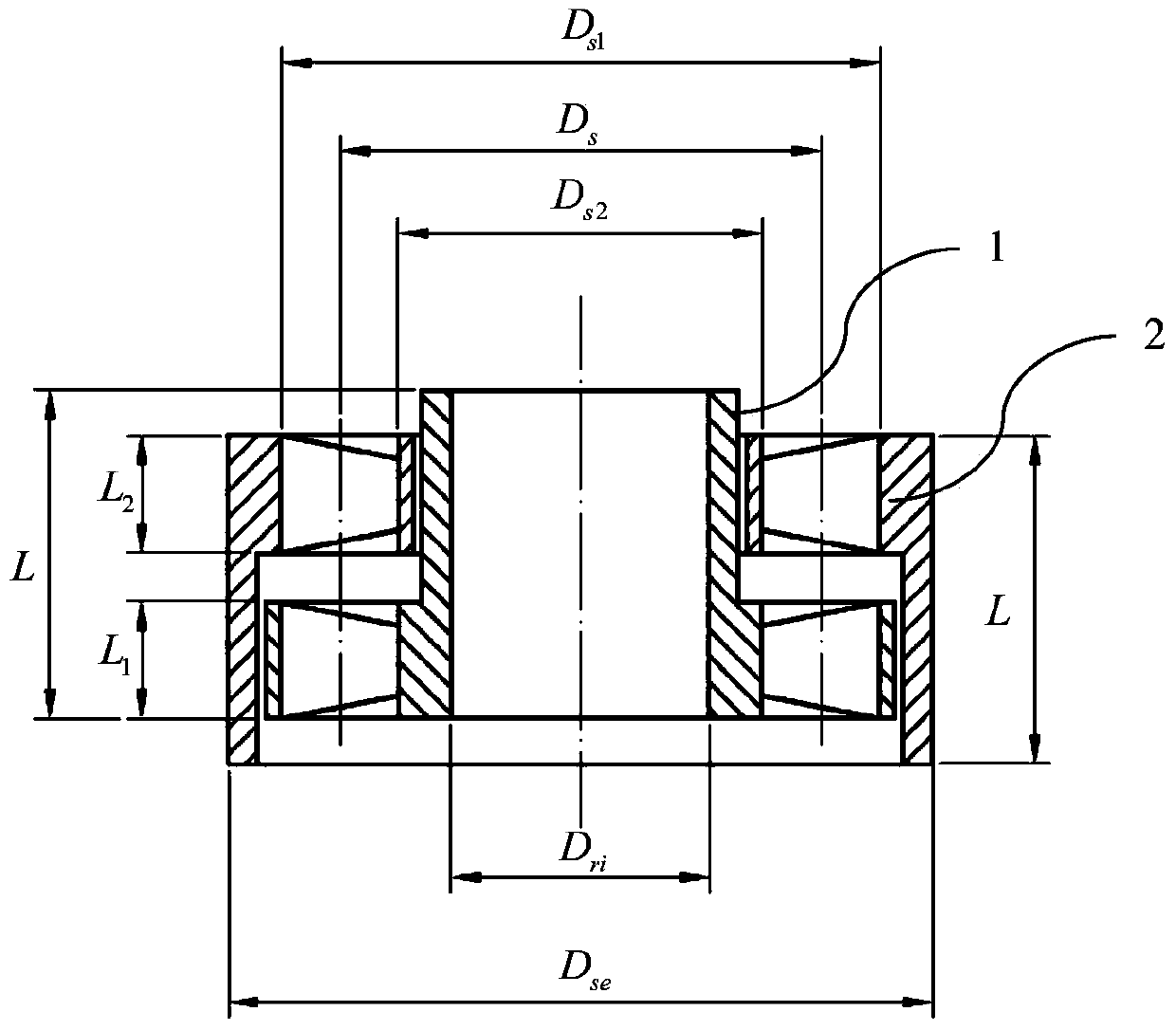

ActiveCN108368724AAvoid discontinuitiesFunction without interferenceBuilding braking devicesPower-operated mechanismEngineeringMechanical engineering

The invention relates to a spindle drive for a flap (2) of a motor vehicle, which spindle drive can be moved between two drive end positions, in particular between a retracted position and an extendedposition, wherein two drive connections (6,7) for channelling drive movements and a drive train (8) between the drive connections (6,7) are provided, wherein the drive train (8) has a motor unit (9)and a drive screw mechanism (10) arranged downstream of the motor unit (9) in terms of drive, wherein the drive screw mechanism (10) has a spindle (11) with a spindle external thread and a spindle nut(12) with a spindle nut internal thread which is in screwed engagement with the spindle external thread, wherein a braking arrangement (13) for braking at least part of the drive train (8) of the spindle drive (1) is provided. It is proposed that the braking arrangement (13) can be adjusted in terms of its braking action (B) and that, for its adjustment, the braking arrangement (13) is coupled toa component (15) of the drive train (8).

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

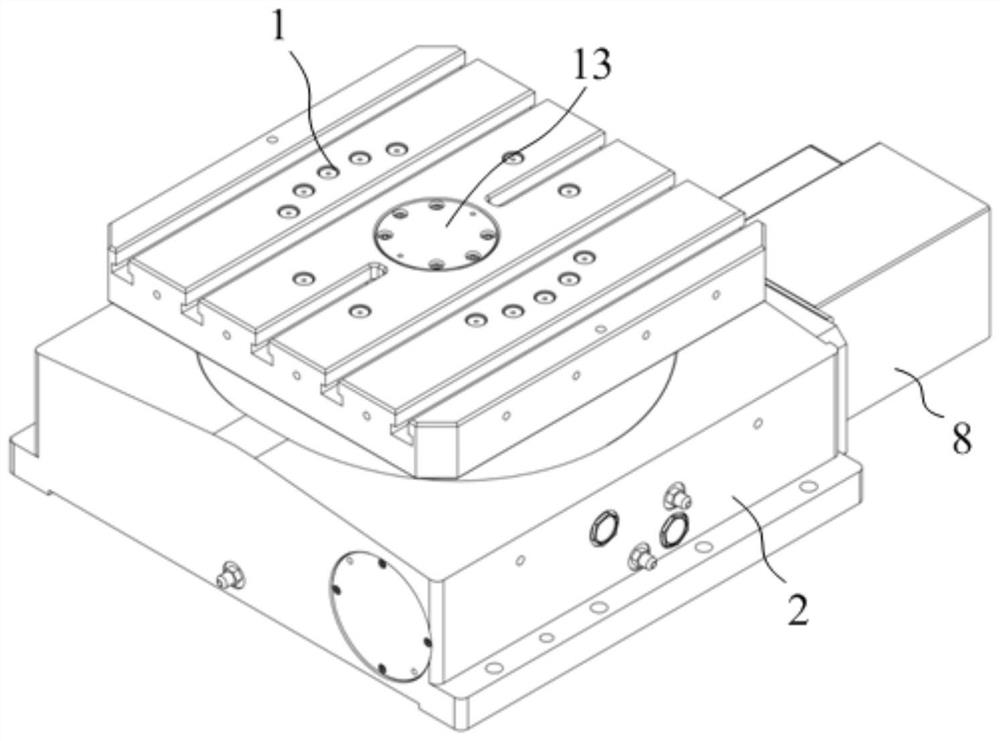

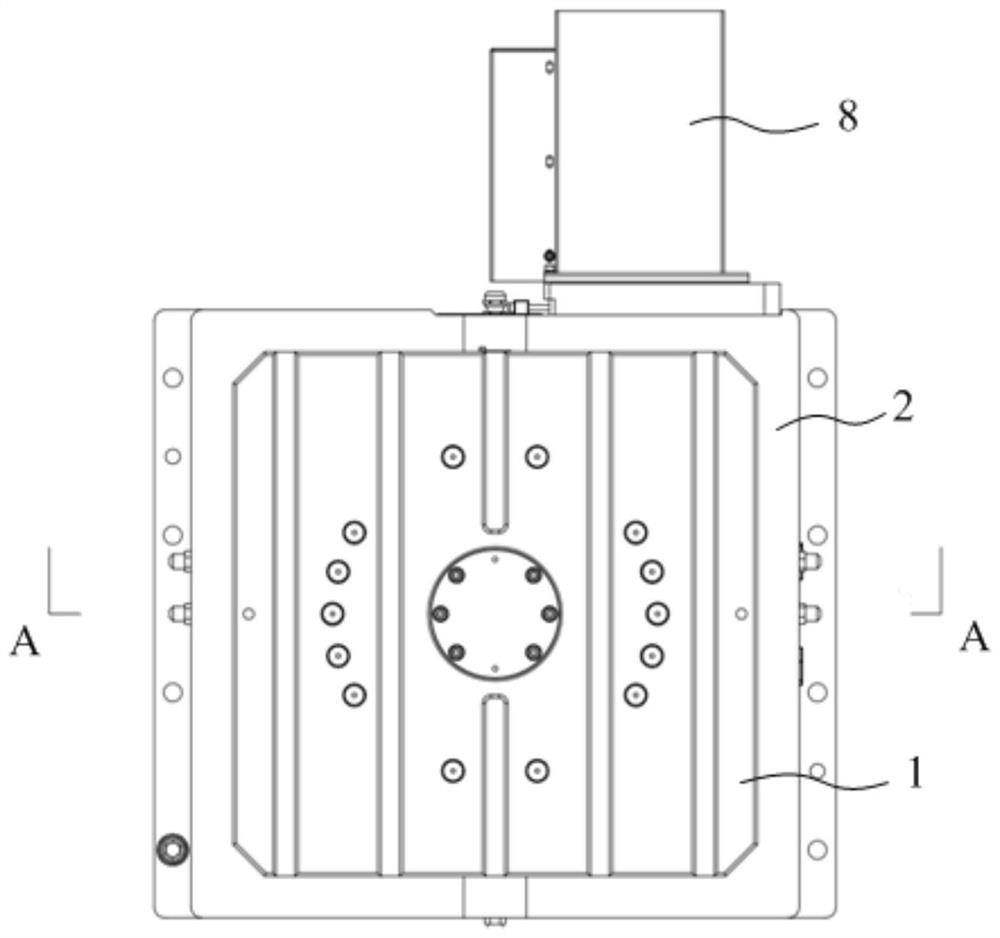

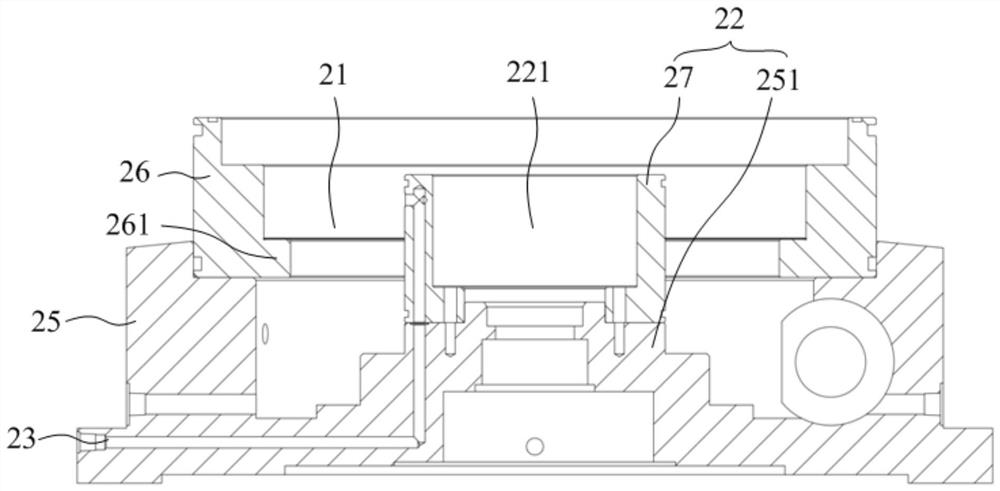

High-precision rotary table with hydraulic brake structure

PendingCN114439866ABraking achievedEasy to processBraking membersStands/trestlesEngineeringMechanical engineering

The high-precision rotary table with the hydraulic brake structure comprises a rotary table body, a mounting seat, an expansion sleeve, an enclasping sleeve and a rotary driving mechanism, a first mounting cavity is formed in the top of the mounting seat, a mounting column is arranged at the position, in the center of the first mounting cavity, of the mounting seat, and the expansion sleeve, the enclasping sleeve and the rotary driving mechanism are sequentially arranged in the first mounting cavity from inside to outside; the expansion sleeve surrounds the mounting column, an annular sealing oil cavity is formed by the expansion sleeve and the outer wall of the mounting column, and an oil way communicating with the sealing oil cavity is formed in the mounting base. The elastic modulus of the enclasping sleeve is larger than that of the expansion sleeve, the enclasping sleeve is arranged outside the expansion sleeve in a sleeving mode, and when oil does not pass through the sealing oil cavity, the enclasping sleeve is in clearance fit with the rotary driving mechanism; the rotary table body is arranged above the mounting column and covers the first mounting cavity, and the rotary driving mechanism is connected with the rotary table body and used for driving the rotary table body to rotate. The brake energy loss is small, machining is convenient, and positioning is accurate.

Owner:FOSHAN PRATIC CNC SCI & TECH

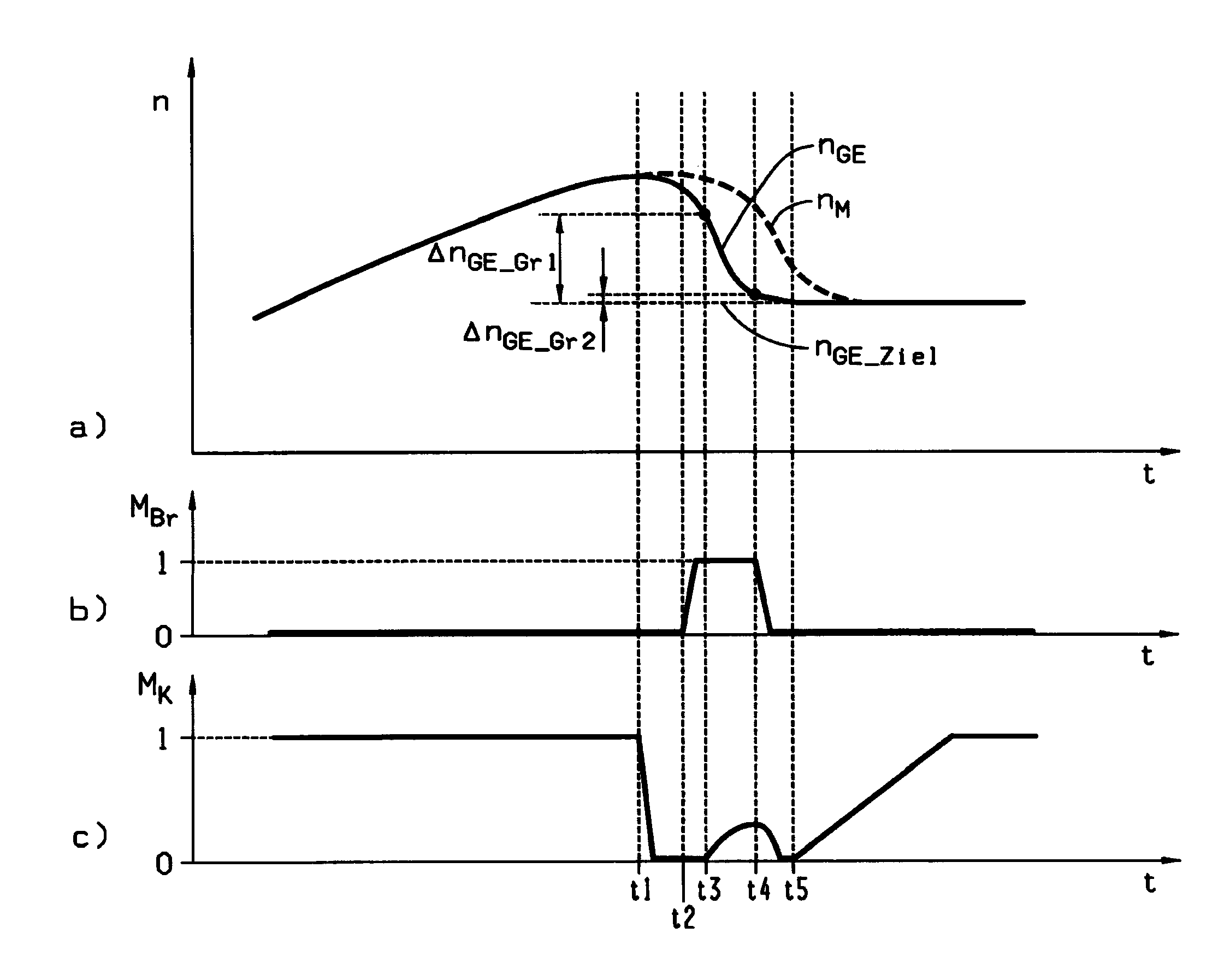

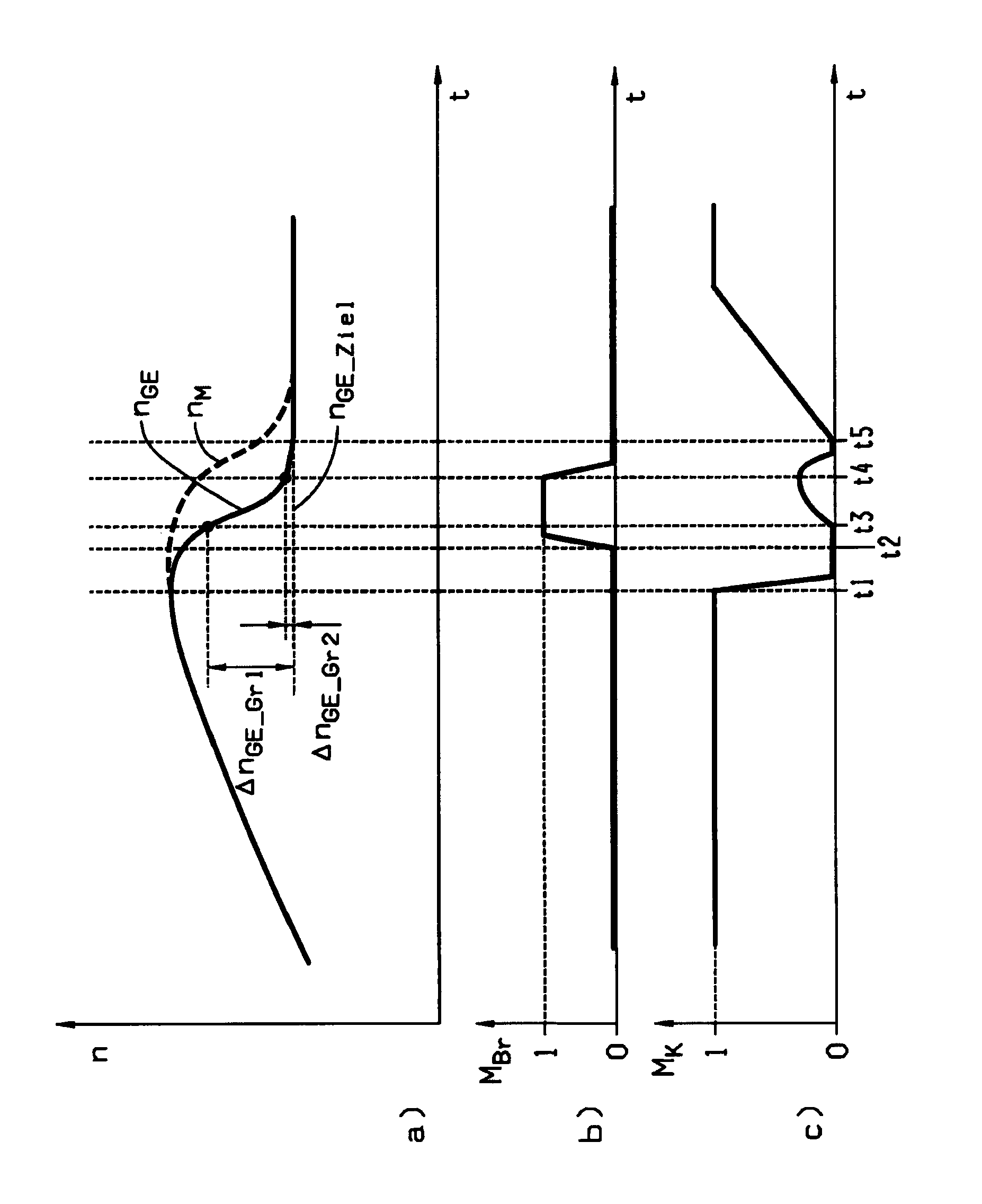

Shift control method in an automated manual transmission

A shift control method for an automated gearshift transmission arranged in a drivetrain of a motor vehicle, between a drive motor and an axle drive, which is provided with unsynchronized gear clutches and whose input shaft can be connected to the driveshaft of the drive motor by an automatically controllable separator clutch such that, for an upshift, the synchronization of the target gear takes place with the separator clutch disengaged by setting a substantially constant braking torque at a transmission brake in driving connection with the input shaft. In order to speed up the shift sequence, without additional design measures, as the input speed of the gear clutch of the target gear approaches its output speed, to complete the synchronization, the separator clutch is partially engaged and then disengaged again substantially simultaneously as the transmission brake is released.

Owner:ZF FRIEDRICHSHAFEN AG

Turbo-compound system

InactiveCN100447386CHigh braking torqueUniform braking torque curveLiquid resistance brakesInternal combustion piston enginesFluid couplingExhaust fumes

Owner:VOITH TURBO GMBH & CO KG

Method and apparatus for balancing a motor vehicle wheel

InactiveUS20030167840A1Increase torqueQuickly reachStatic/dynamic balance measurementVehicle tyre testingAcceleration UnitAutomotive engineering

Owner:SNAP ON EQUIP

Intermediate shaft brake

ActiveCN114370464AAvoid residual brakingNo drag lossGear lubrication/coolingFluid actuated drum brakesControl theoryHigh pressure gas

The invention relates to the technical field of vehicles, in particular to an intermediate shaft brake which comprises an intermediate shaft and two dual friction assemblies, and the two dual friction assemblies are oppositely arranged on the two sides of the radial direction of the intermediate shaft in a spaced mode. The dual friction assembly comprises an air cylinder shell, a piston, a dual friction block and a return spring. The dual friction block is connected to the piston, the piston can slide relative to the air cylinder shell and is provided with a braking position and a non-braking position, when the piston is located at the braking position, the dual friction block is attached to the intermediate shaft, and when the piston is located at the non-braking position, the dual friction block is separated from the intermediate shaft and cannot be affected by an oil film, residual braking is avoided, and the service life of the piston is prolonged. And high-pressure gas input into the piston cavity from the high-pressure gas source can drive the piston to move to the braking position from the non-braking position, and the return spring can drive the piston to move to the non-braking position from the braking position.

Owner:FAW JIEFANG AUTOMOTIVE CO

spindle drive

ActiveCN108368724BAvoid discontinuitiesFunction without interferenceBuilding braking devicesPower-operated mechanismControl theoryScrew thread

The invention relates to a spindle drive for a door cover (2) of a motor vehicle, which can be adjusted between two drive end positions, in particular between a retracted position and an extended position, wherein , two drive interfaces (6, 7) are provided for deriving the drive movement and a drive train (8) is arranged between the drive interfaces (6, 7), wherein the drive train (8) has a motor unit ( 9) and the drive-screw drive (10) connected technically behind the motor unit, wherein the drive-screw drive (10) has a spindle (11) and a spindle nut (12), the spindle has a spindle-external thread, the spindle nut has a spindle nut-internal thread, the spindle nut-internal thread engages with the spindle-external thread, wherein the device for braking the spindle drive (1) is provided A brake assembly (13) for at least a portion of the drive train (8). It is proposed that the brake assembly (13) is adjustable with respect to its braking action (B), and that the brake assembly (13) is coupled to a component (15) of the drive train (8) for to adjust it.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

Point-projection wedge-shaped blade brake-stage stator and rotor assembly

InactiveCN104047795AReduce hydraulic lossHigh braking torqueHydro energy generationBorehole drivesBrake torquePoint projection

The invention provides a point-projection wedge-shaped blade brake-stage stator and rotor assembly. Stator blades and rotor blades are in a wedge shape with the width gradually increasing from top to bottom and from blade bottom to blade top. The multiple stator blades are circumferentially arranged between the outer wall of a stator leaf crown and the inner wall of a stator body in an inclined mode. The multiple rotor blades are circumferentially arranged between the outer wall of a rotor body and the inner wall of a rotor leaf crown in an inclined mode. The stator blades and the rotor blades are the same in inclining angle and inclining direction. Both the stator blades and the rotor blades are formed through point projection. The point-projection wedge-shaped blade brake-stage stator and rotor assembly is small in hydraulic loss and large in braking torque; after a certain number of point-projection wedge-shaped blade brake-stage stators and rotors and a certain number of turbine-stage stators and rotors are assembled together, working time of a turbine drill can be obviously prolonged, overload capacity of the turbine drill can be obviously improved, stability can be obviously improved when the turbine drill works at a low rotating speed, and the footage during turbine drilling can be obviously increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Independent drive and independent turning robot secondary adjusting hydraulic moving platform

InactiveCN110816659ALoad largeFlexible steeringBraking element arrangementsElectrodynamic brake systemsReduction driveHydraulic pump

An independent drive and independent turning robot secondary adjusting hydraulic moving platform mainly comprises wheels, a platform body, an electromagnetic brake, a secondary adjusting hydraulic drive device and the like. Through adjustment of the displacement of secondary elements on the left side or the right side of the platform, the rotation speed and the rotation angle of the wheels on theleft side or the right side of the platform are adjusted, and platform turning is achieved. The four secondary elements drive the four wheels through speed reducers correspondingly, the secondary elements are adjusted to be in a hydraulic motor or hydraulic pump work condition, and the platform is driven to move or the braking kinetic energy and ramp gravity energy of the platform are recycled andstored in an energy accumulator for starting, accelerating and climbing motions of the moving platform. The independent drive and independent turning robot secondary adjusting hydraulic moving platform is suitable for working in the open air, high-speed and large-load work conditions, and the moving platform is high in bearing and high in traction capability; and energy recycling and reutilizingcan be achieved, and the installed power of the moving platform is greatly reduced.

Owner:SHANDONG JIAOTONG UNIV

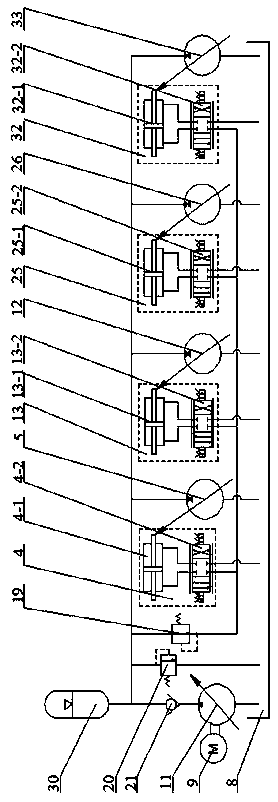

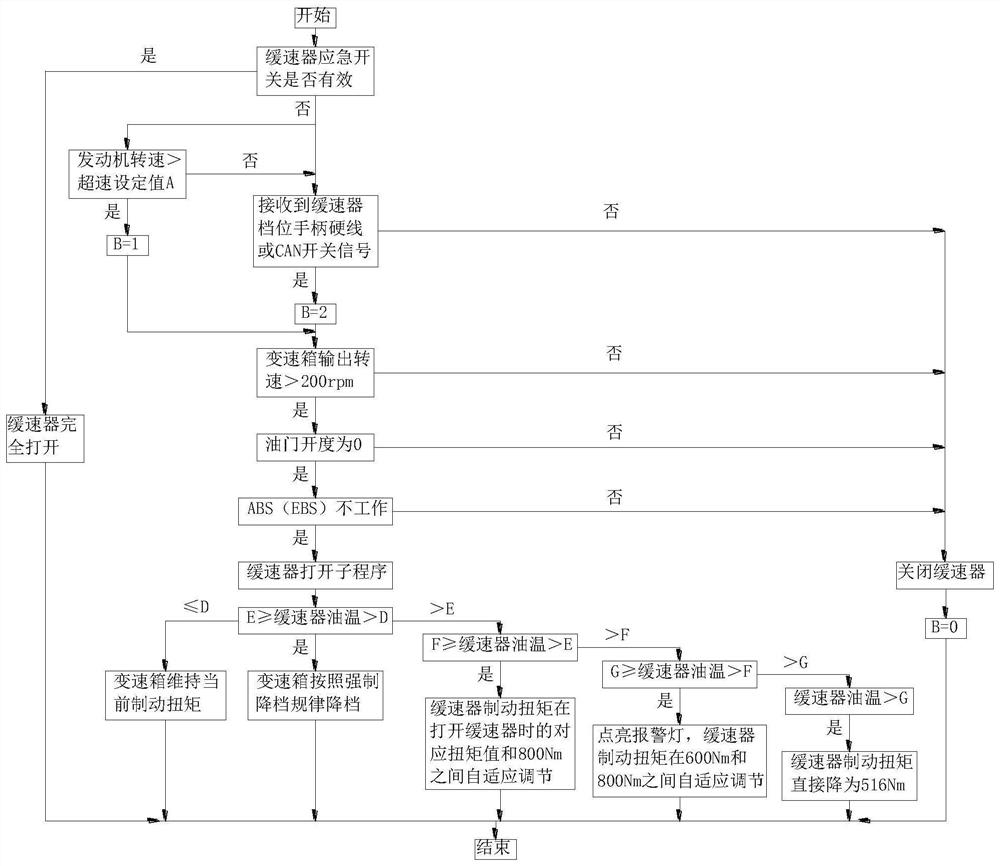

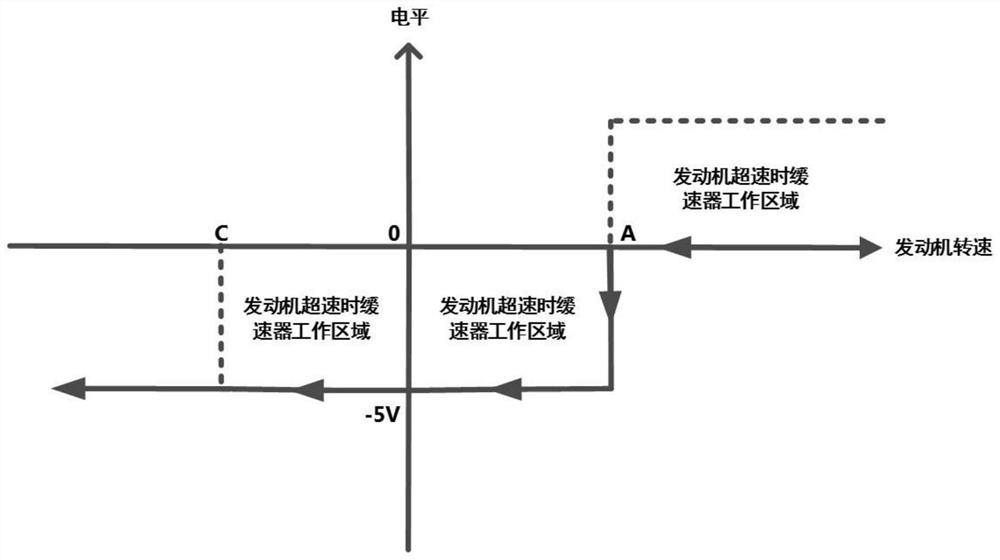

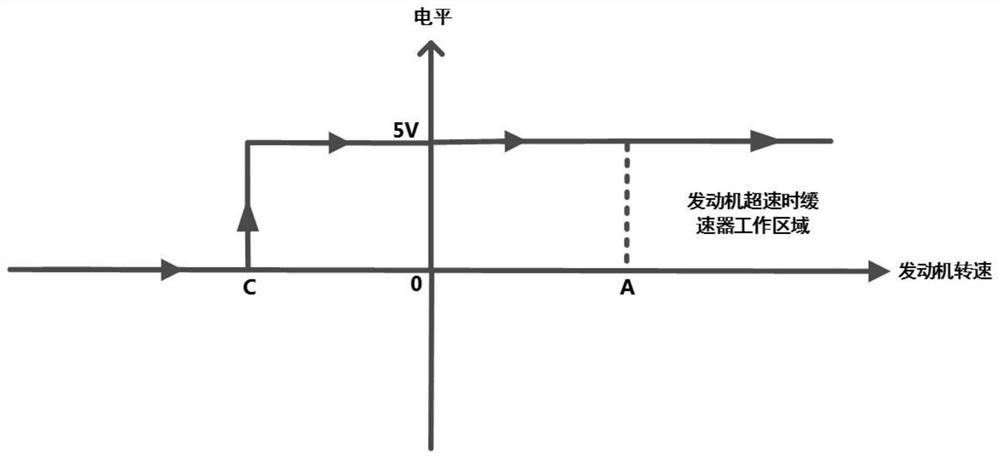

A Control Method of High Power Hydraulic Retarder

ActiveCN112503117BMaximum Braking TorqueHigh braking torqueLiquid resistance brakesGearing controlBrake torqueSolenoid valve

Owner:贵州凯星液力传动机械有限公司

Compact type annular axial high accuracy positioning and clamping mechanism, and using and manufacturing method thereof

ActiveCN104209600AAchieve angular positioning clampingCompact structureAutomatic control devicesFeeding apparatusFriction torqueCompact toroid

The invention discloses a compact type annular axial high accuracy positioning and clamping mechanism, and a using and manufacturing method thereof. The clamping mechanism comprises a base, a sealing ring, an annular clamping plate and a revolved body, wherein the annular clamping plate is fixed on the revolved body or the base through sunk screws; when the revolved body is located to be stopped at any position, liquid and gas can be pressed in an annular sealing cavity, a sealed piston device can generate a certain displacement in the axial direction, the axial force is uniformly acted on the annular face of the annular clamping plate, and the annular clamping plate is pressed to be deformed, so that friction torque is generated to carry out angle positioning and clamping on the revolved body; the revolved body cannot be axially displaced or twisted when the positioning and the clamping occur, so that high accuracy positioning and clamping can be realized; when the liquid pressure and the gas pressure are completely unloaded, the annular clamping plate is immediately rebounded to be at the initial situation, and the revolved body can be released and revolved at will.

Owner:秦川机床工具集团股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com