Oil pump dual-motor drive device with electric-hydraulic power steering function

A hydraulic power steering, dual motor drive technology, applied in electric steering mechanism, fluid steering mechanism, etc., can solve the problems of inability to obtain flow characteristics, handling stability, consumption of electric vehicle power, hydraulic power steering failure, etc., and achieve good speed regulation. Features, improve safety, work smoothly and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

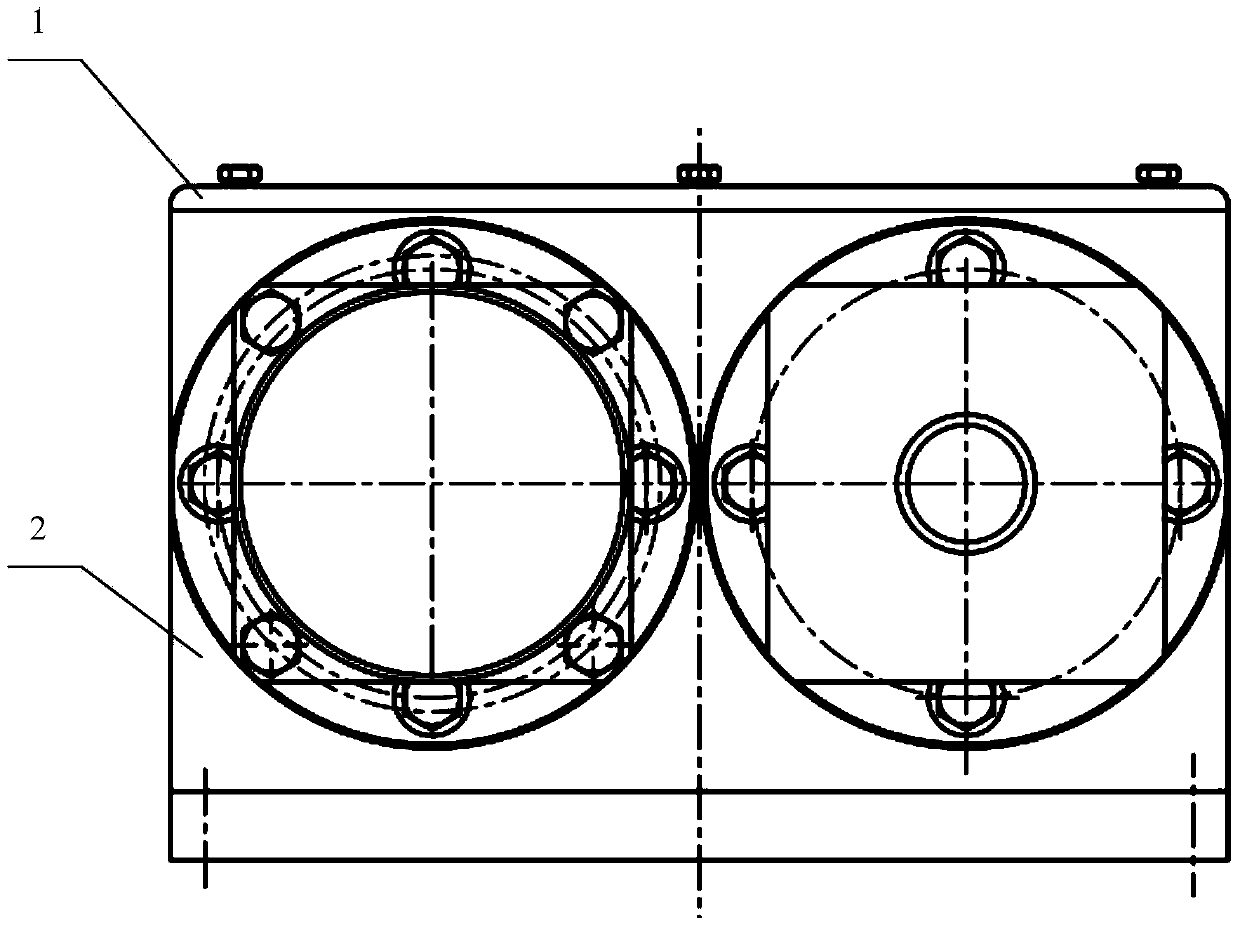

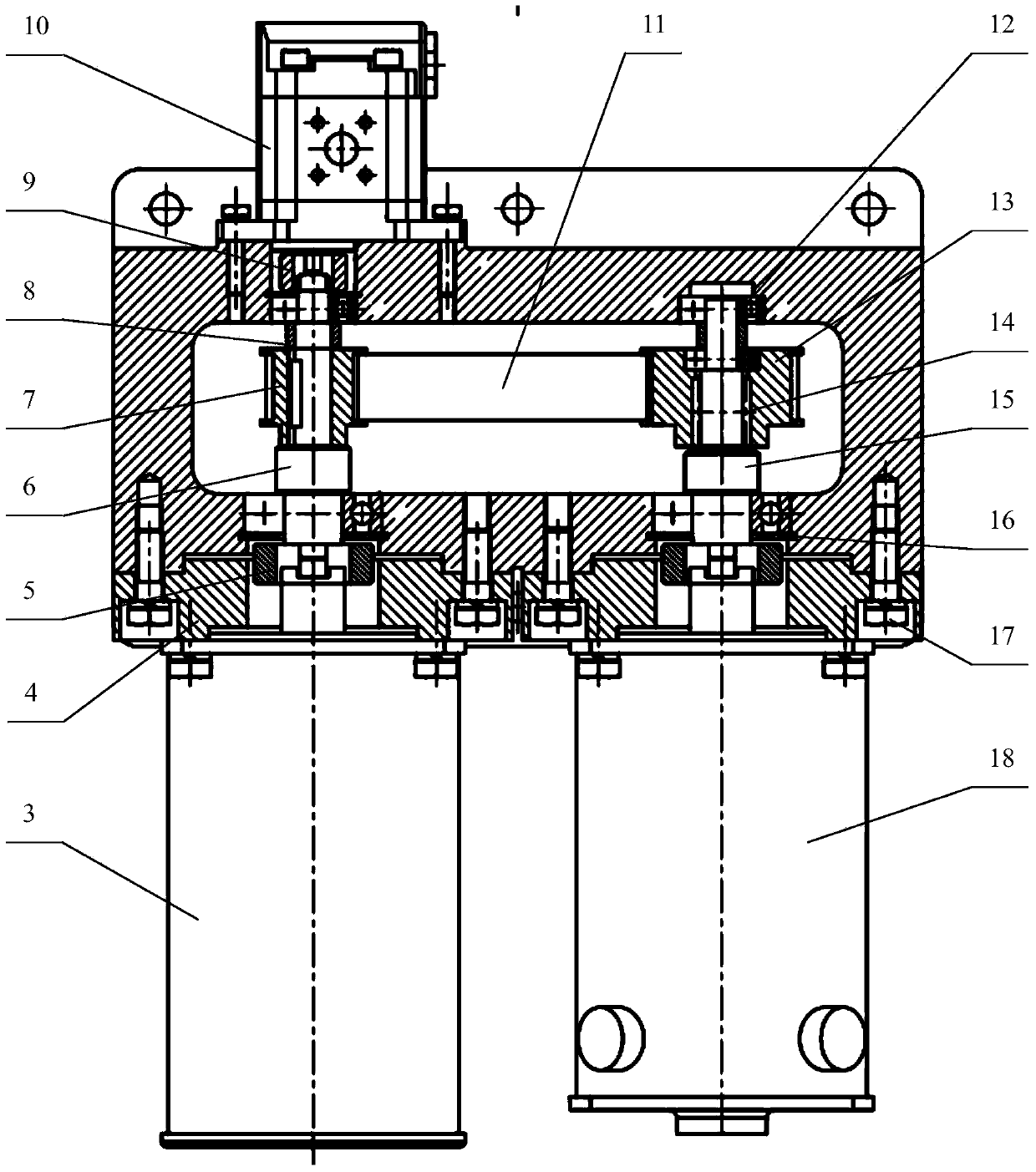

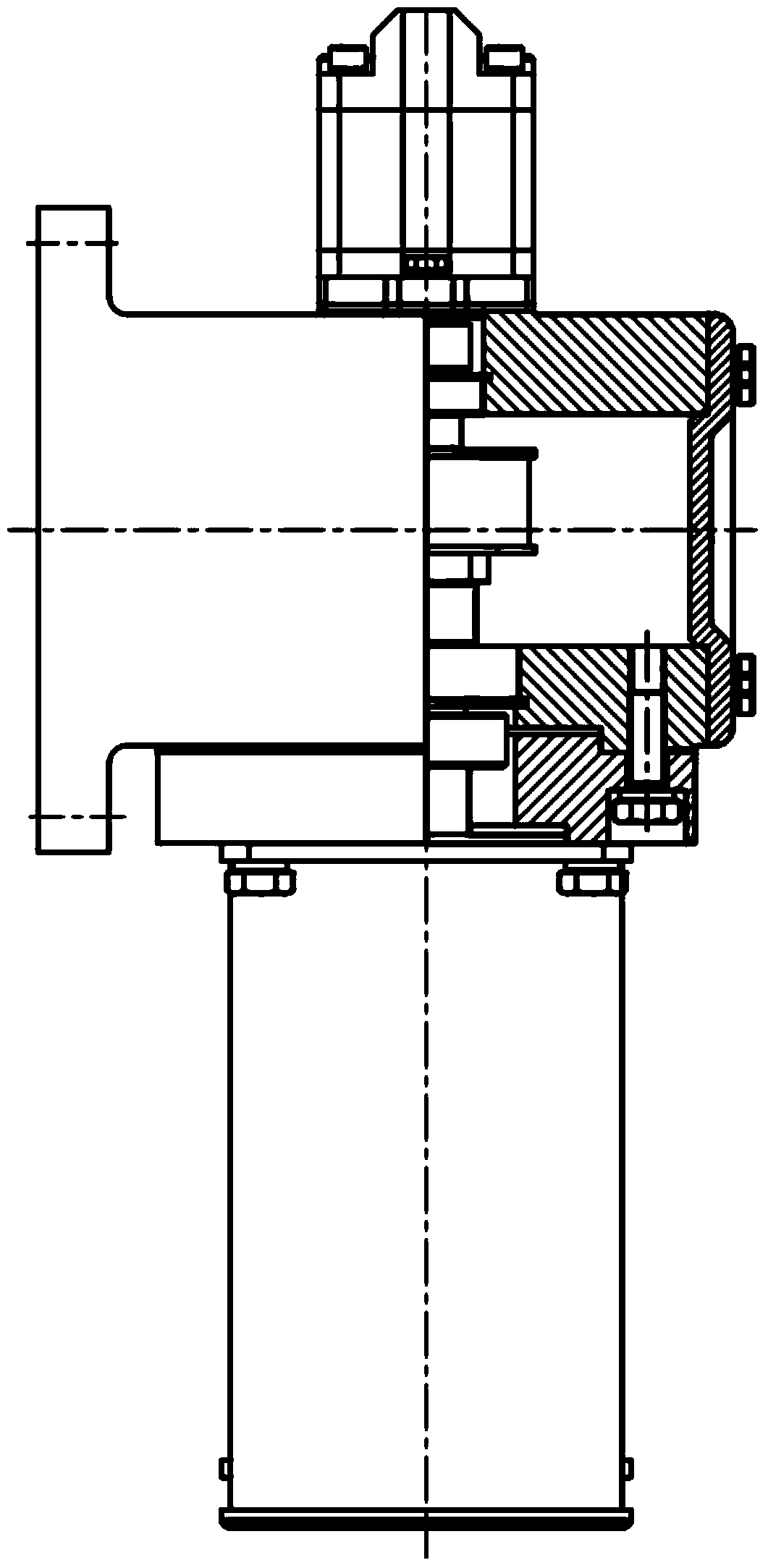

[0035] Such as figure 1 As shown in the figure, the steering oil pump in the new electric oil pump hydraulic power steering system adopts the structure of main and auxiliary motors. The main motor (3) is a DC brushless motor, which has good speed regulation characteristics and high braking performance Torque and overload capacity, high efficiency and long life; the auxiliary motor (1) is a DC brush motor with brush commutation, small speed range, short life and simple control. The main motor (3) and the auxiliary motor (1) are connected by a synchronous pulley meshing with the synchronous belt (4), and the output shaft of the auxiliary motor is connected with the synchronous pulley through a one-way needle clutch (2). The motor transmits speed and torque unidirectionally to the output shaft of the main motor. In this way, when the auxiliary motor (1) does not rotate, the main motor (3) directly drives the steering oil pump (5) to work when it rotates; when the main motor (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com