Tension control and torsion spring steel coil brake device for spindle of braiding machine

A tension control and braking device technology, applied in the field of knitting machines, can solve the problems of unstable braking force, easy wear of friction plates, large braking stroke, etc., and achieve the effect of large braking torque, short braking stroke and sensitive braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

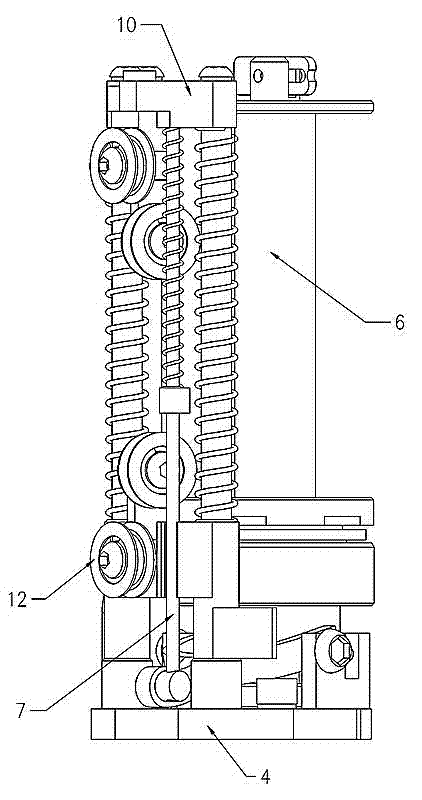

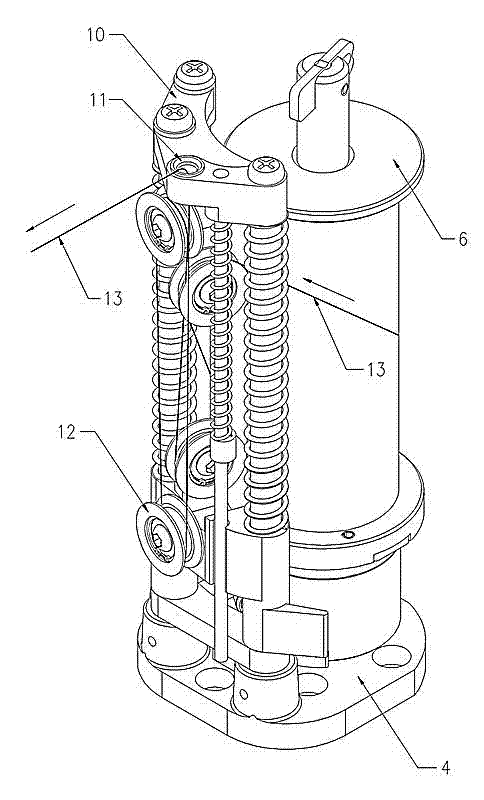

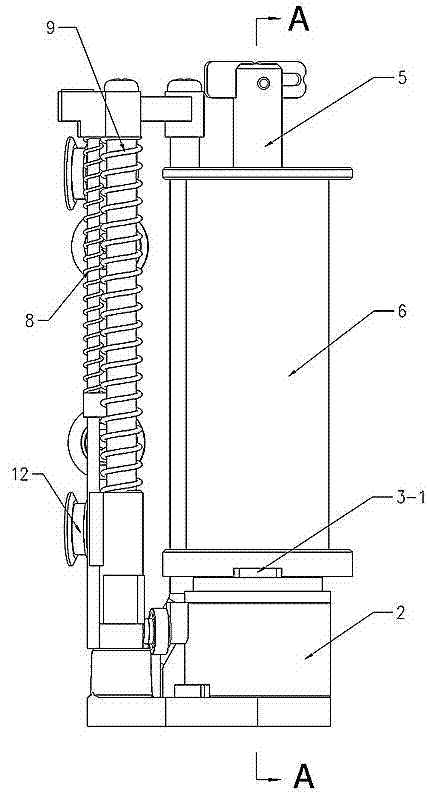

[0029] The structure of the tension control of the spindle of the braiding machine and the braking device of the torsion spring steel coil is as follows: figure 2 - Figure 9 As shown, it includes: steel coil torsion spring 1, elastic sleeve 2, shaft support 3, base 4, central shaft 5, spindle 6, pull rod 7, small spring 8, large spring 9, upper frame 10;

[0030] see Figure 5 - Figure 7 , the upper torsion arm 1-1 of the steel coil torsion spring 1 is in a horizontal direction, inserted into the upper gap 2-1 of the elastic sleeve; the lower torsion arm 1-2 is vertically arranged, and inserted into the step gap of the central axis 5; The helical inner diameter of the torsion spring 1 is the same as the lower end of the shaft 3 and the outer diameter of the step of the central shaft 5. In the free state, the inner wall of the steel coil torsion spring 1 wraps tightly the outer walls of the shaft 3 and the central shaft 5 at the same time, showing a braking state. . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com