Constant tension numerical control multi-thread square cutting machine without pressure sensor

A technology of pressure sensor and constant tension, which is applied in the field of constant tension control CNC multi-wire square cutting machine, can solve the problems of unstable tension control, reduced cutting efficiency, and high separation cost, and achieve fast loading and unloading, stable cutting speed, and high tension The effect of small fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

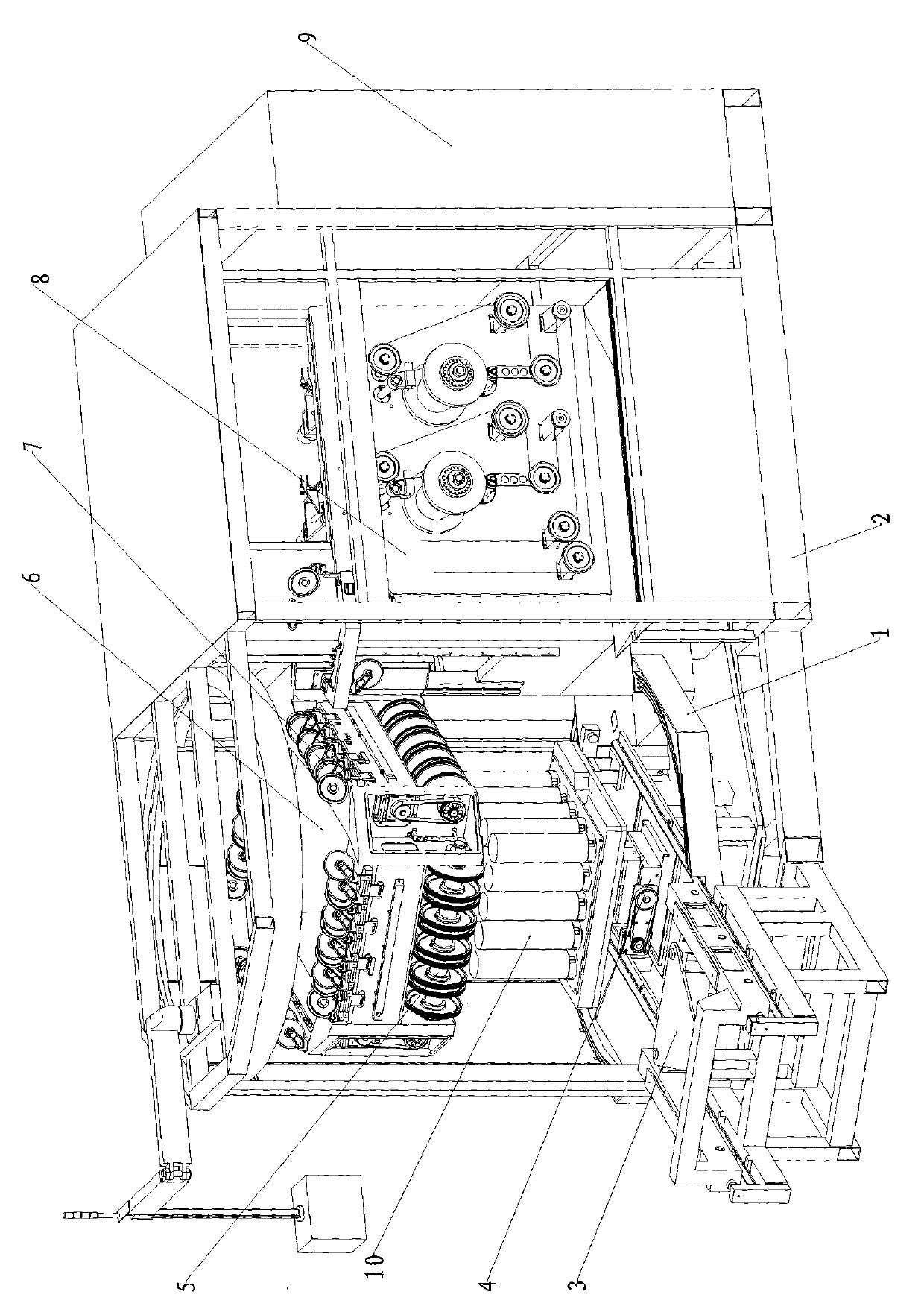

[0071] A constant tension control CNC multi-wire square cutting machine without a pressure sensor, including a chassis 1, a frame 2, a trolley 3, a workbench 4, a cutting roller 5, a cutting head frame 6, a guide wheel 7, and wire winding Department 8, electrical cabinet 9, such as figure 1 As shown, the specific structure is: there are two slide rails on the chassis 1, the trolley 3 is placed on the slide rails, the workbench 4 is fixed between the slide rails, the frame 2 is fixed behind the chassis 1, and the cutting head is above the workbench 4 Frame 6, the cutting head frame 6 is fixed on the crossbeam of the frame 2, the cutting roller 5 is fixed under the cutting head frame 6, the servo motor is installed in the cutting head frame 6, and the cutting spindle and the tangent wheel are driven to rotate through the V-ribbed belt transmission, cutting The wire is introduced by the wire winding part 8 through the importing wire wheel, and is exported to the wire winding part...

Embodiment 2

[0131] A constant tension control numerically controlled multi-wire square cutting machine without a pressure sensor. The cutting roller 5 is engraved with ten V-shaped grooves, and the cutting wires are embedded in the V-shaped grooves. The other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com